Novel upflow anaerobic reactor

An up-flow anaerobic reactor technology, which is applied in the directions of gas production bioreactors, bioreactor/fermenter combinations, and specific-purpose bioreactors/fermenters, etc. Freezing and clogging, etc., to achieve the effect of not easy to crust, low investment and operating costs, and high processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

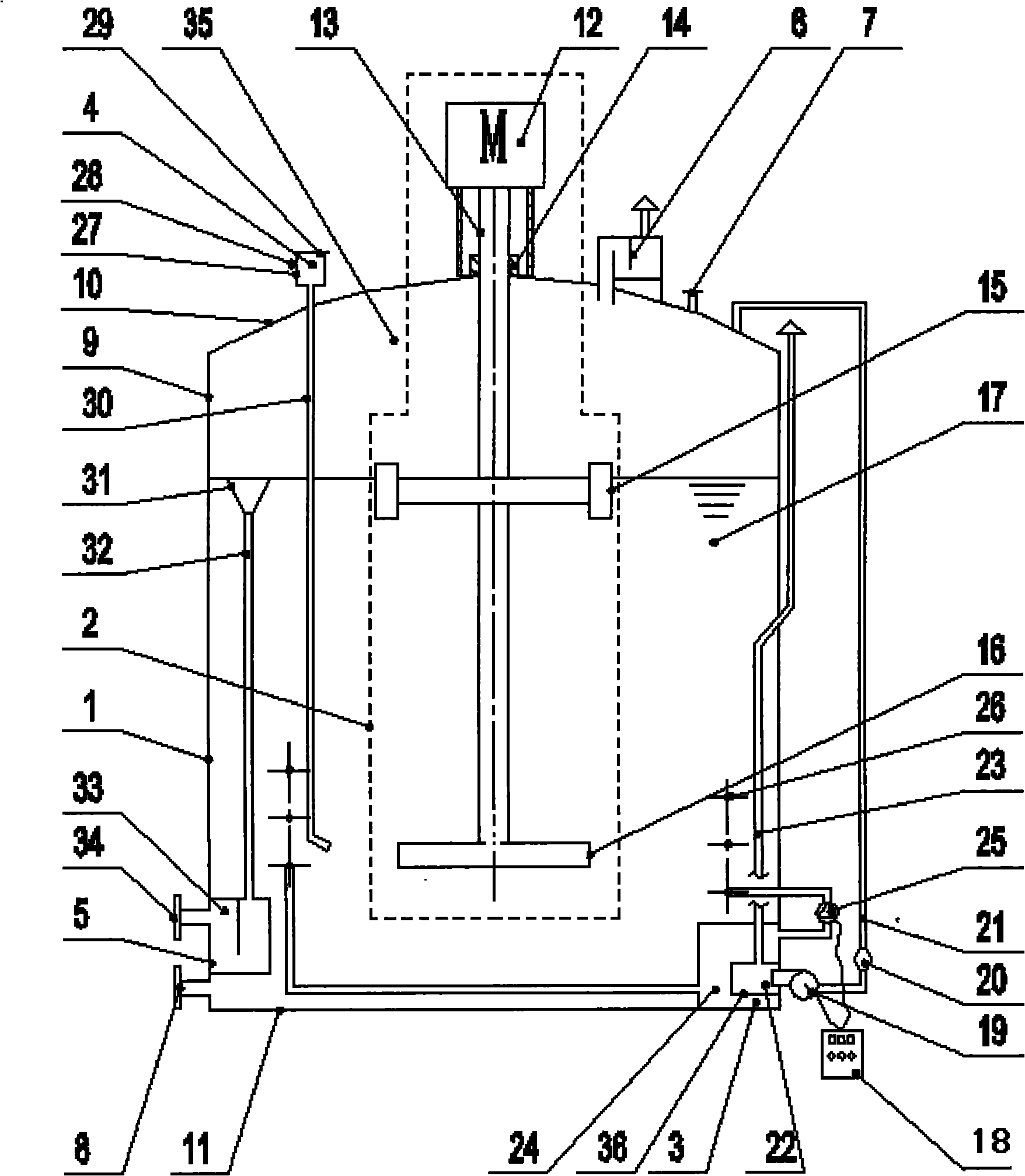

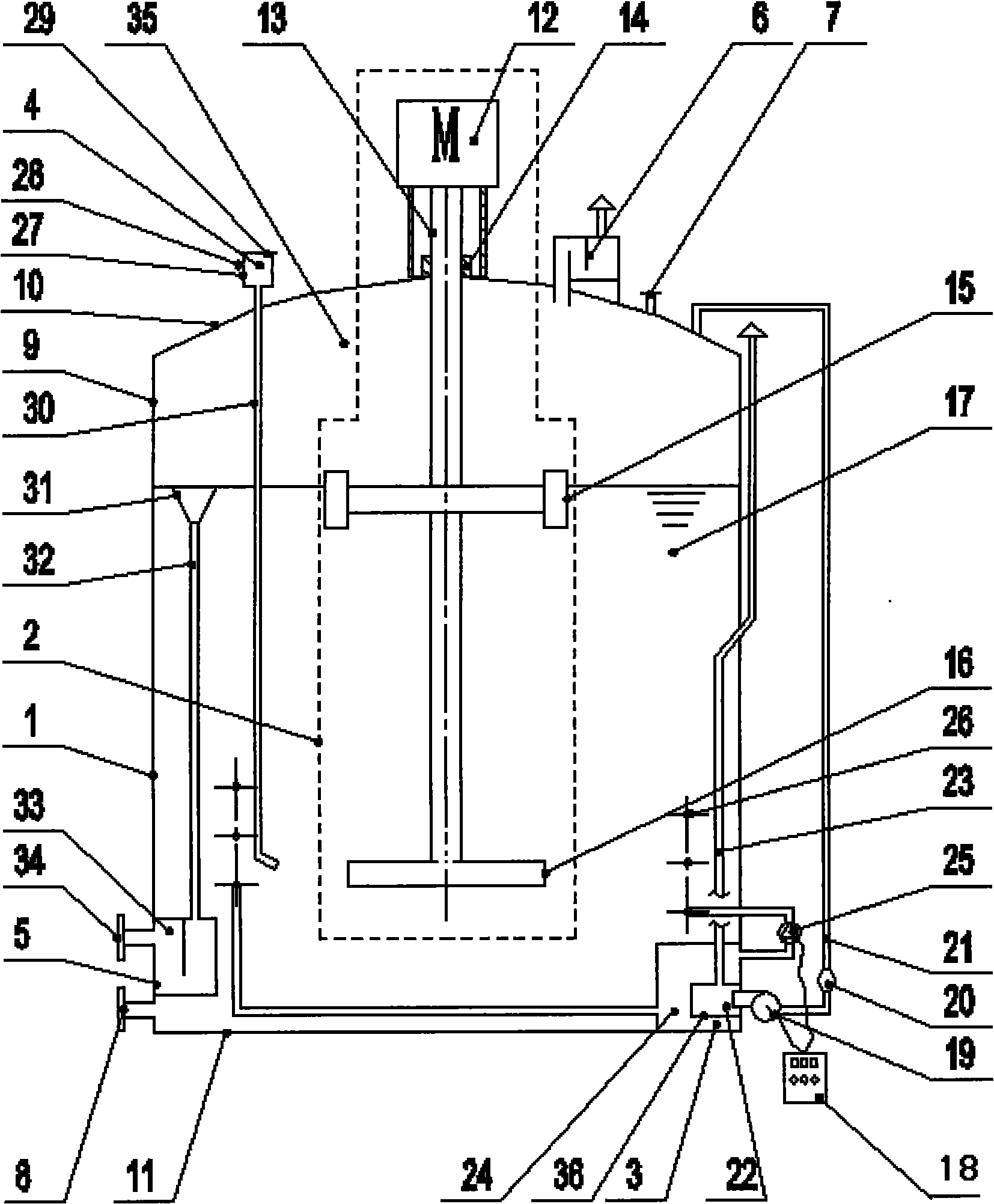

[0012] Such as figure 1 As shown, the present invention includes a tank body 1, a stirring shell breaking assembly 2, a built-in thermal energy conversion unit 3, a feeder 4, a discharger 5, a pressure protector 6, a gas outlet pipe 7, and a slag discharge outlet pipe 8; the tank body 1. It is composed of a cylinder body 9, a tank top 10 and a tank bottom 11; the tank top 10 is in the shape of a flat cover, and can also be in the shape of a flat cover, a semi-ellipse, a semi-dish or a hemispherical shape; the stirring shell breaking assembly 2 Coinciding with the central axis of the tank body 1, the stirring shell breaking assembly 2 is composed of a power mechanism 12, a transmission shaft 13, a seal 14, a shell breaking slag pusher 15, and an impeller 16; the power mechanism 12 is located outside the tank top 10, and is connected to the tank top 10; the transmission shaft 13 is connected to the power mechanism 12; the seal 14 is located at the position where the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com