Spiral rotating bed

A rotating bed, spiral technology, applied in chemical/physical/physical-chemical fixed reactors, dissolution, chemical methods of reacting liquids and gaseous media, etc., can solve the problem of increased energy consumption, no suction, and large resistance and other problems, to achieve the effect of small footprint, not easy to crust, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

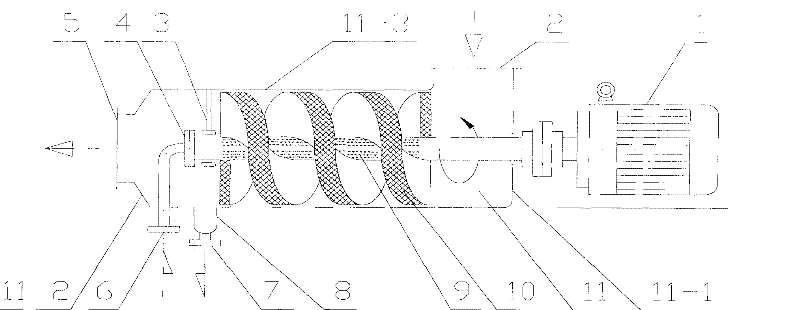

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , 2 , 3, the spiral rotating bed of the present invention consists of a spiral bed 10, a liquid phase distribution pipe 9, a shell 11, a support assembly 3, a gas phase inlet 2, a gas phase outlet 5, a liquid inlet 6, a rotary joint 4, a collection Liquid tank 8, liquid phase outlet 7 and motor 1 constitute.

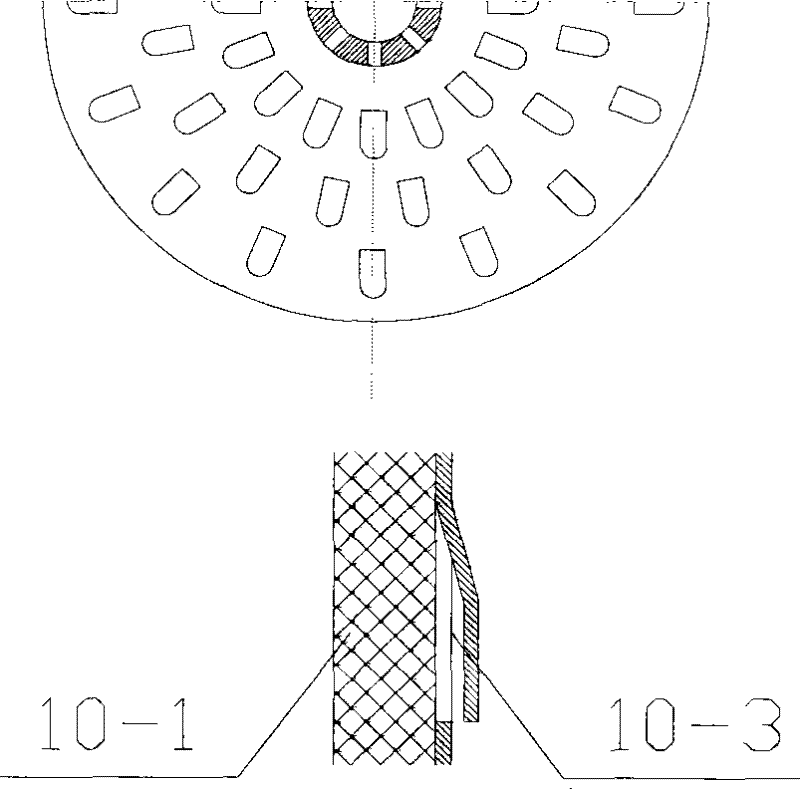

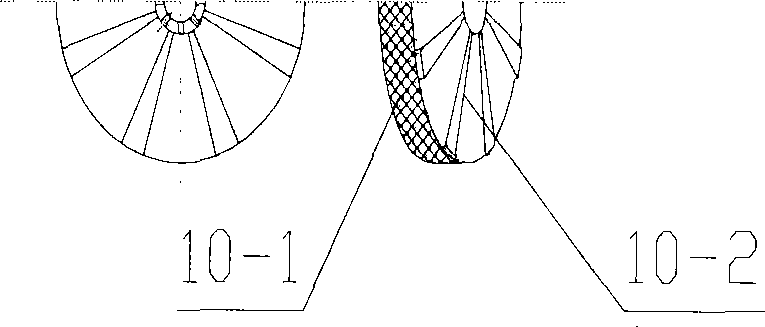

[0014] The spiral bed 10 is made of porous materials such as several layers of screens 10-1; a thin plate 10-3 is attached to the windward side of the rotating bed, or several evenly distributed strip plates 10-2 are attached; the method of attaching thin plates is adopted At the same time, the board is provided with several tongue-shaped slots or I-shaped slots, and the slots are distributed in the shape of fish scales; the slots are stamped, the tongue-shaped plate is raised, the height of the protrusion is 1-2mm, and the opening rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com