Patents

Literature

92results about How to "Not easy to foul" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

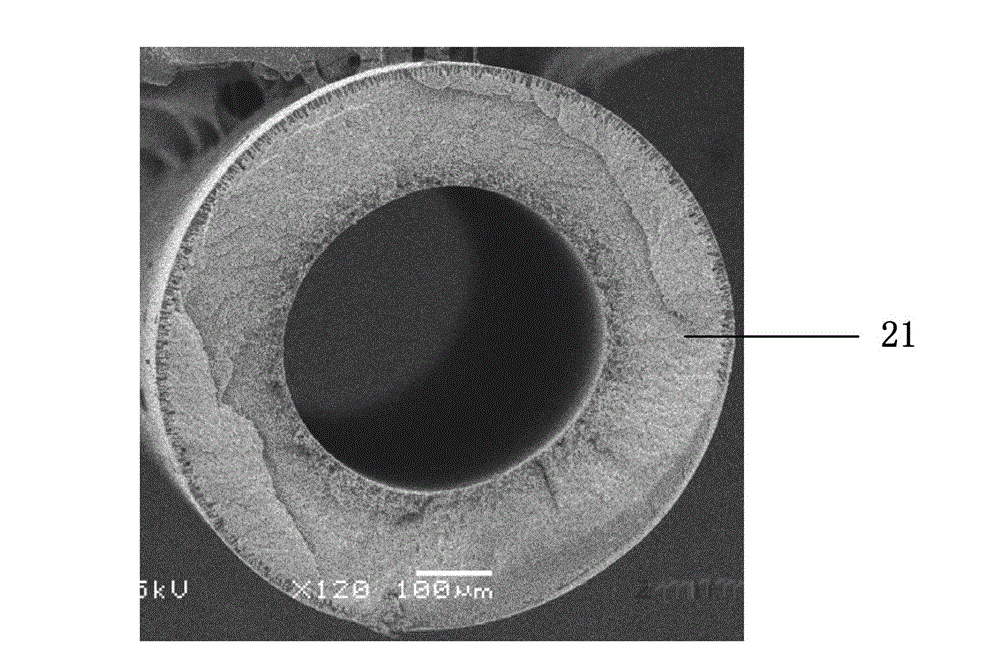

Polypropylene hollow fiber microporous membrane and preparation method thereof

ActiveCN101862601AHigh strengthUniform pore size distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a polypropylene hollow fiber microporous membrane and a preparation method thereof. The hollow fiber microporous membrane comprises the following components in percentage by weight: 15-45% of polypropylene, 50-80% of thinner and 0.1-5% of additive. The preparation method of the hollow fiber microporous membrane is realized on the basis of a thermotropic phase separation process. The preparation method of the polypropylene hollow fiber microporous membrane is simple and easy to industrialize, and has low requirements on equipment, the prepared hollow fiber microporous membrane has the advantages of high strength, uniform pore diameter distribution, high porosity and the like, the pore diameter of the hollow fiber microporous membrane can be controlled between 0.1 and 0.45mu m, and the porosity is 60-85%, so the hollow fiber microporous membrane has large water flux, is not easy to block in use, can be widely used for feeding water treatment, and is particularly suitable for the membrane bioreactor technology and other water treatment fields.

Owner:三泰(青岛)膜科技有限公司

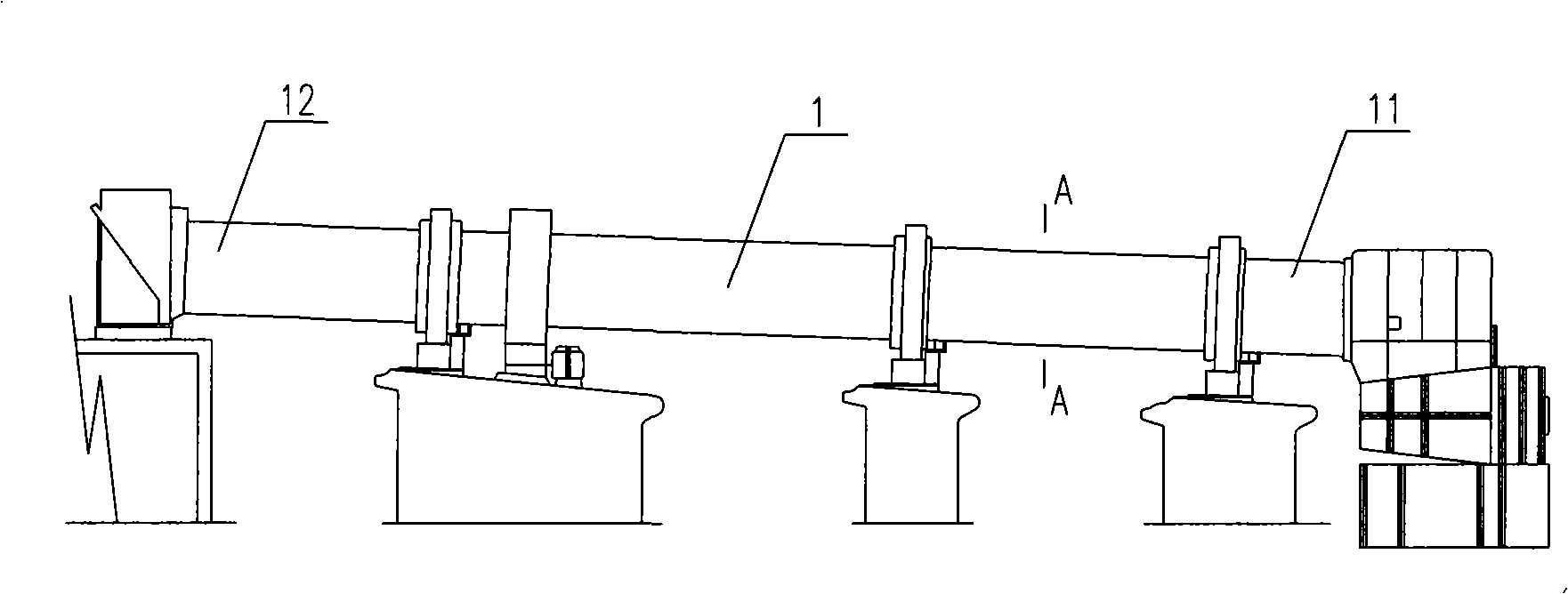

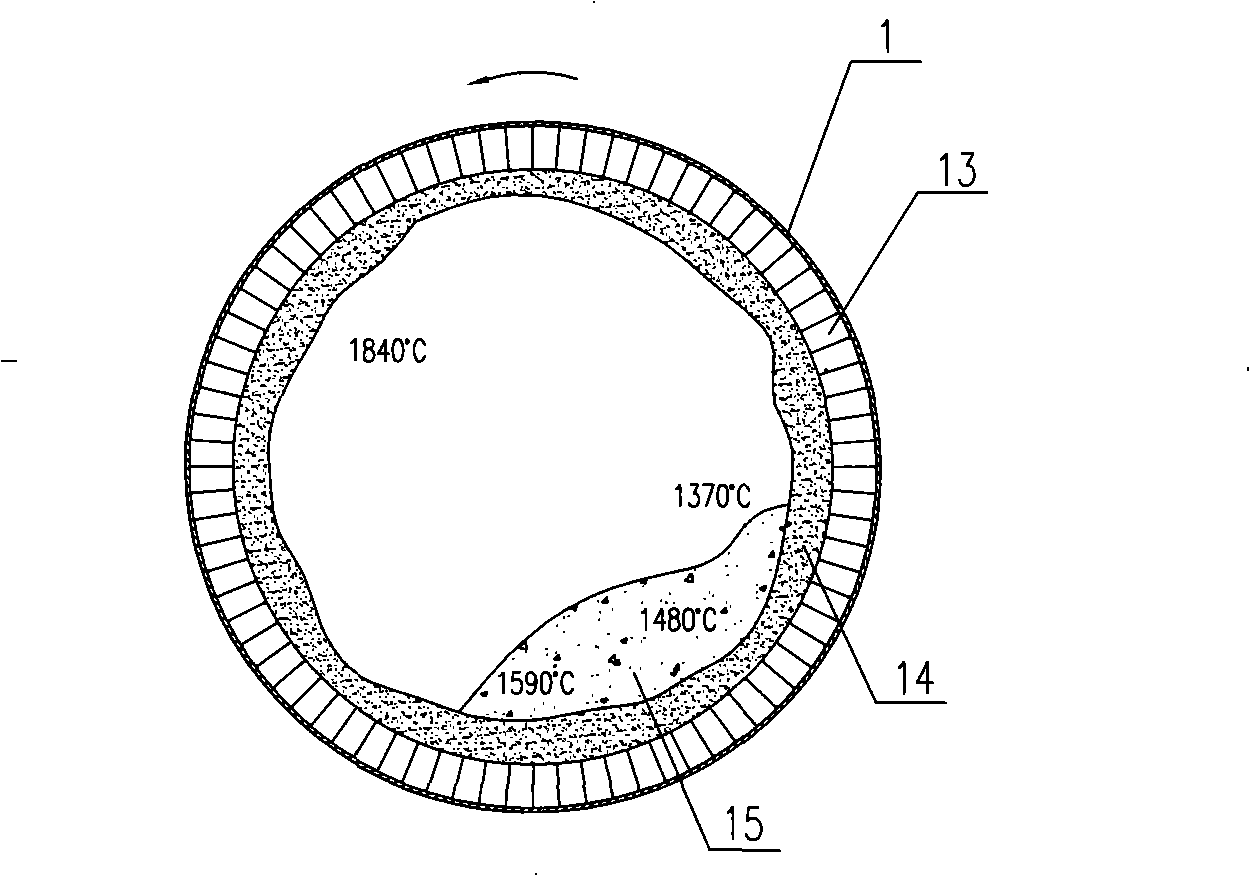

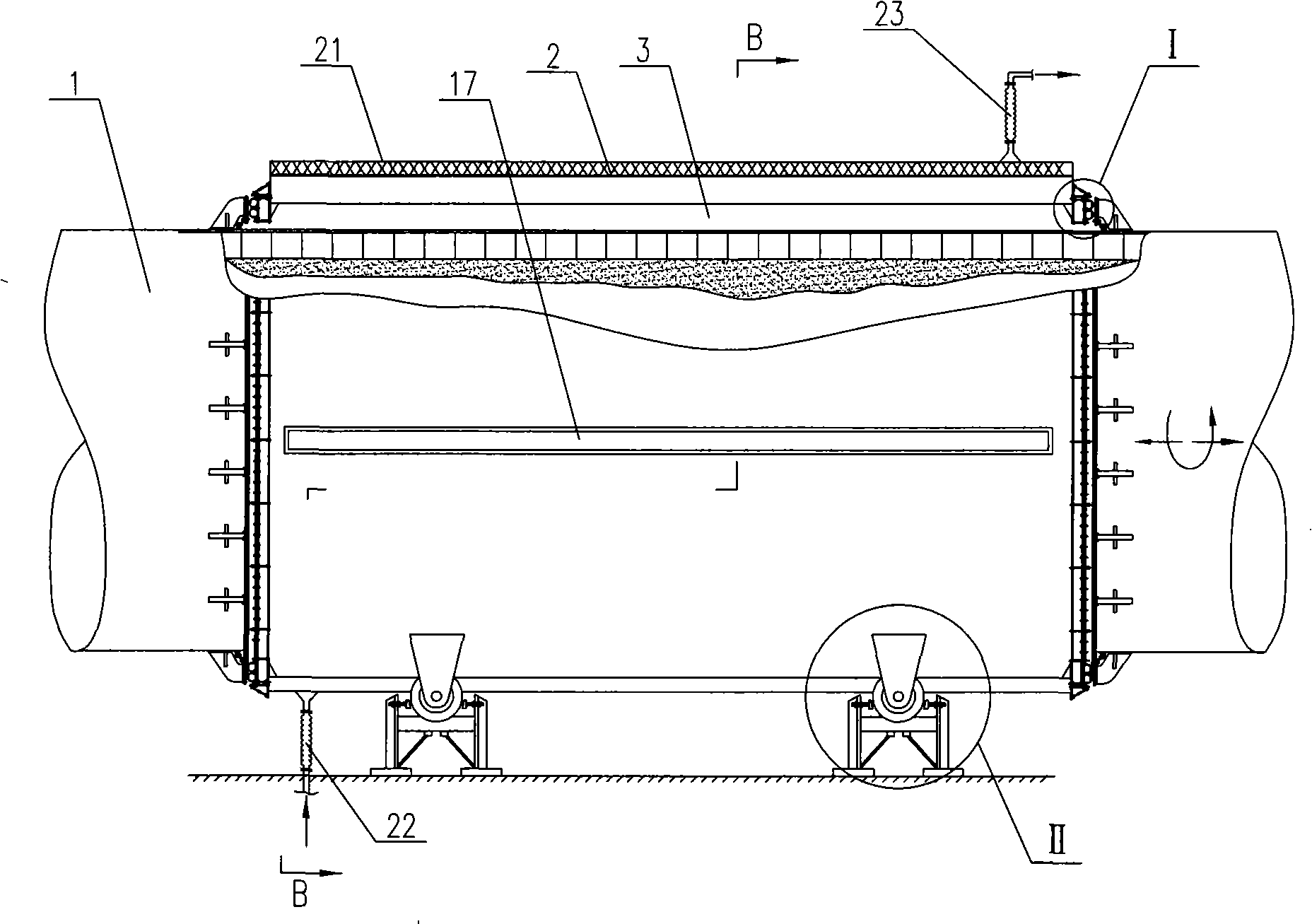

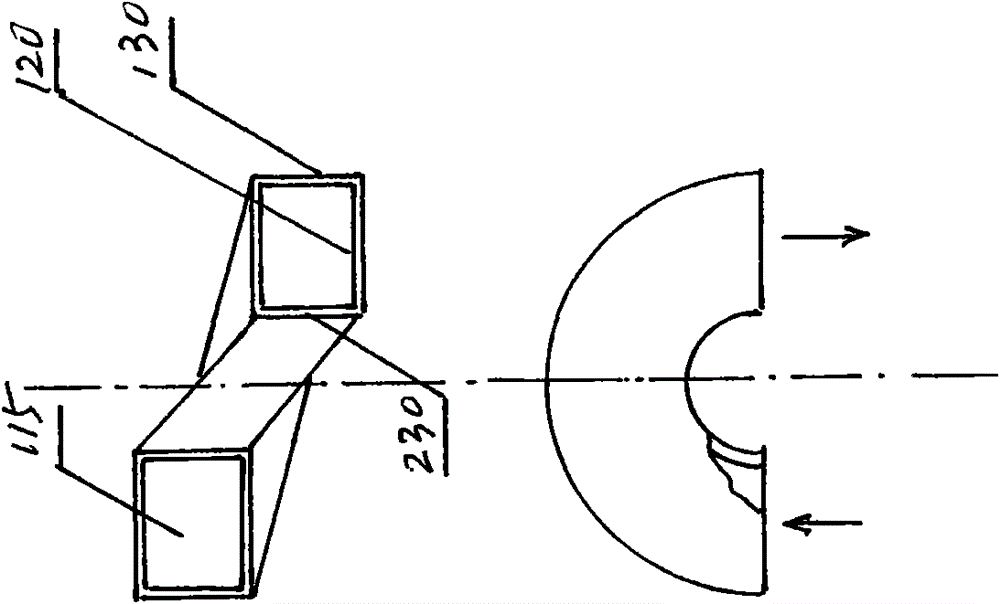

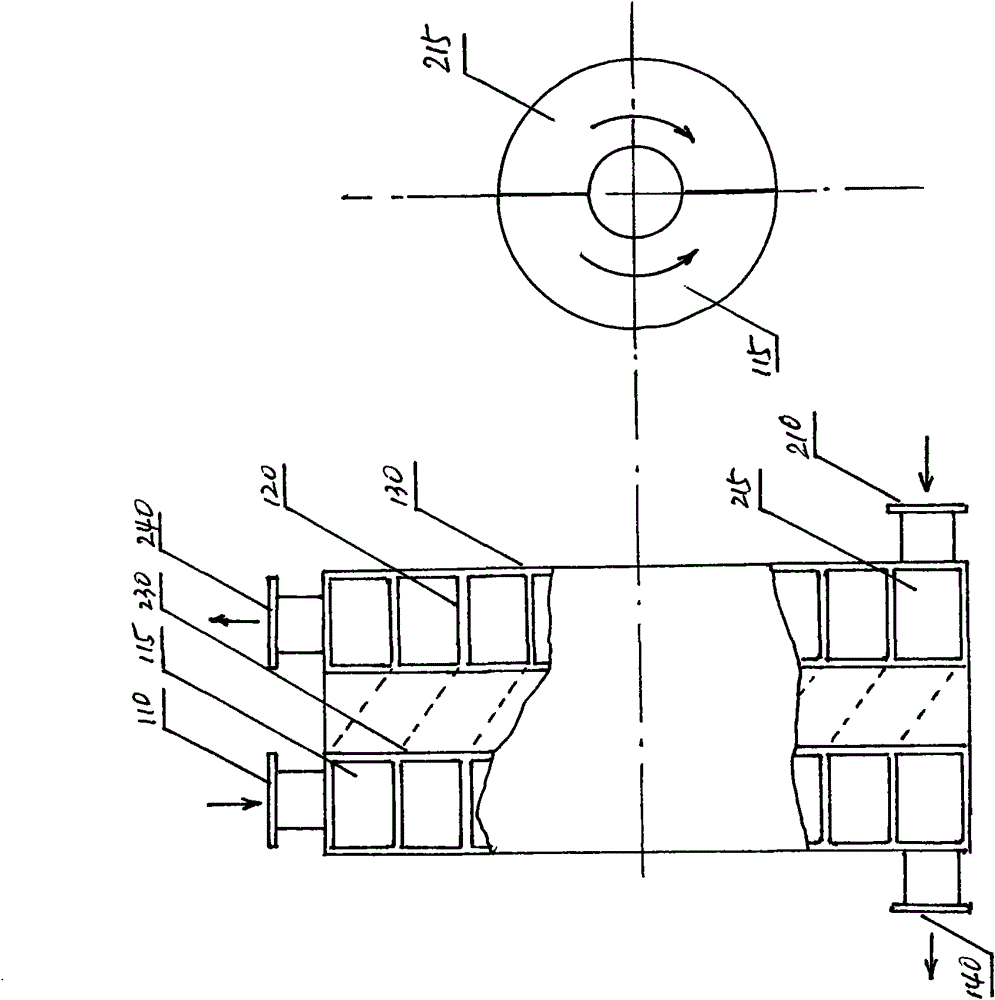

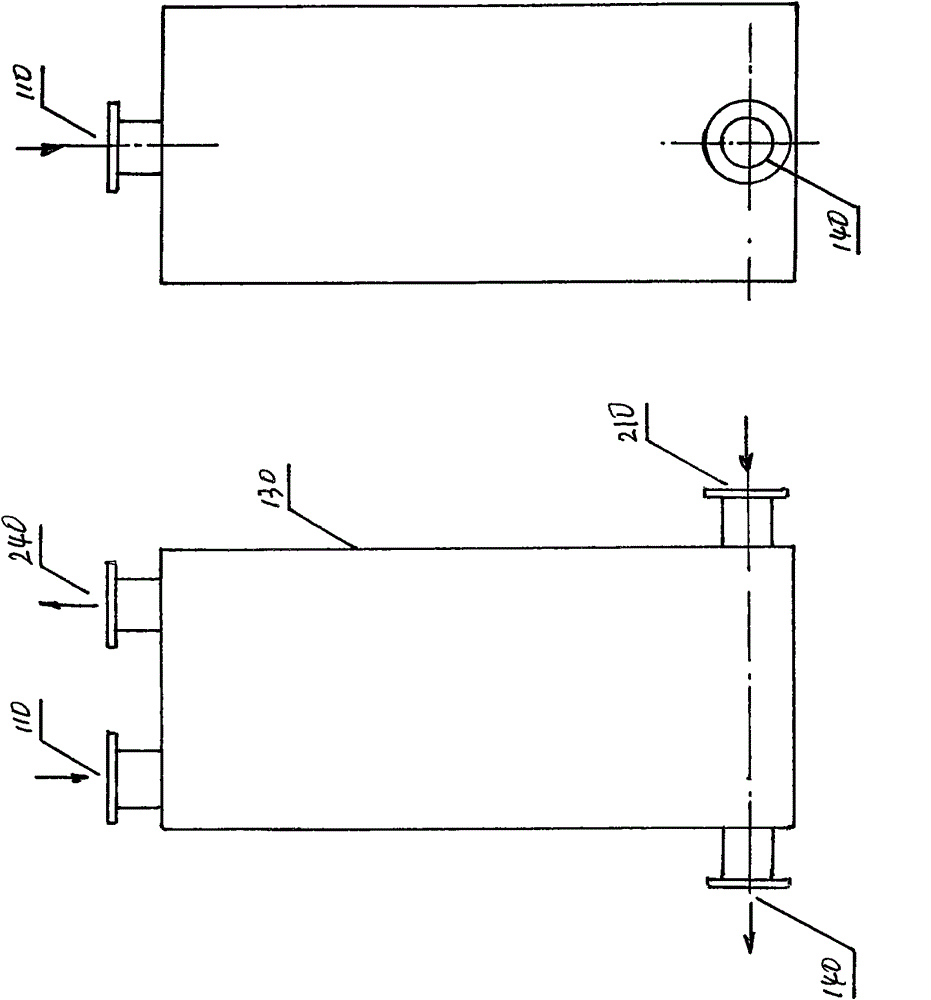

Cement rotary kiln barrel radiation, reclaiming and utilizing device

ActiveCN101290190APracticalSignificant energy saving and economic benefitsRotary drum furnacesIncreasing energy efficiencyCement kilnEngineering

The invention discloses a device for recycling heat radiated from a rotary cement kiln shell body, comprising a plurality of heat transfer covers arranged on the upper section of the rotary cement kiln shell body. Each of the external surfaces of the heat transfer covers is provided with an insulating layer, sealing equipment is arranged between the two ends of the heat transfer covers and the rotary cement kiln shell body, a sealing heat transfer cavity is formed by the inner surfaces of the heat transfer covers and the external surface of the rotary kiln shell body via the sealing equipment, the bottom of the heat transfer covers is provided with an inlet which is communicated with the heat transfer cavity, the top of the heat transfer covers is provided with an outlet which is communicated with the heat transfer cavity, the bottom of the heat transfer covers is connected to a slip fitting so as to realize the axial displacement. The sealing equipment comprises a permanent seat on the external surface of the rotary cement kiln shell body, and one side of the permanent seat is provided with a dynamic sealing ring; the bottom of the dynamic seal ring is hermetically connected to the rotary cement kiln shell body by a temperature resistant rubber I, and a self-propelling stationary seal ring is arranged between the dynamic seal ring and the head face of the heat transfer cover; the top of the self-propelling stationary seal ring is hermetically connected to the head face of the heat transfer cover by a temperature resistant rubber II, the self-propelling stationary seal ring is connected to an elastic stationary seal ring, and a sealing gland is arranged between the elastic stationary seal ring and the dynamic seal ring.

Owner:天津健威泽节能环保科技股份有限公司

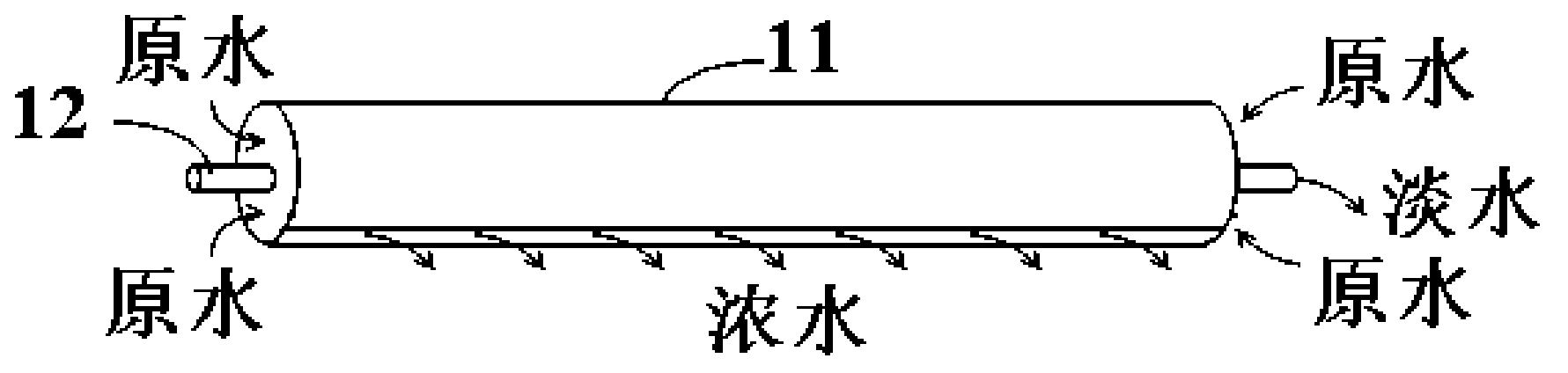

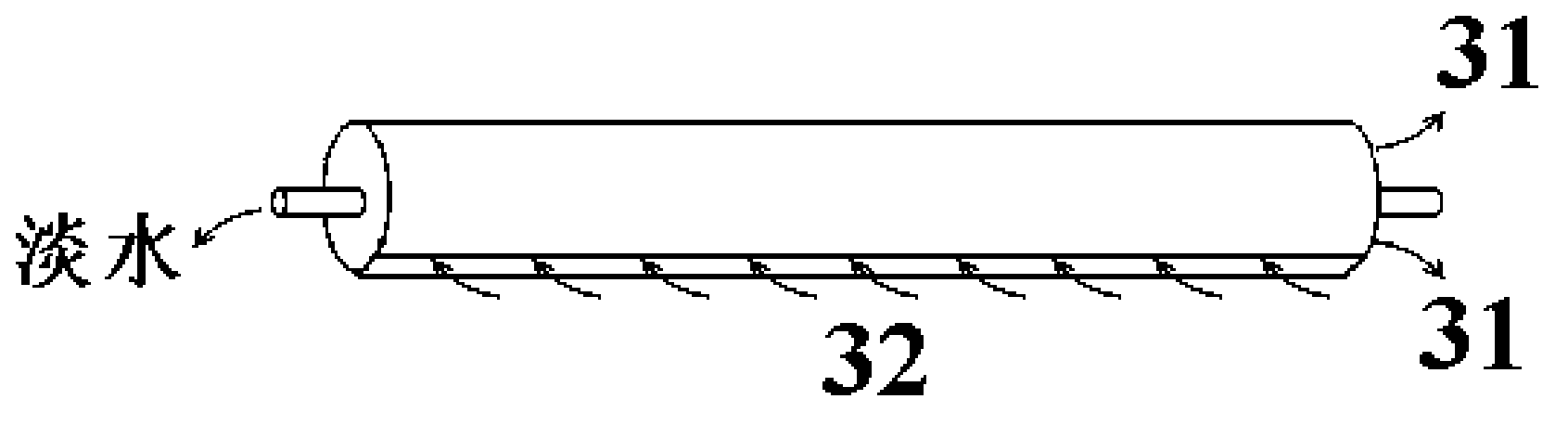

Sidestream reverse osmosis membrane element

ActiveCN102976447AExtend your lifeSimple waterwayWater/sewage treatment bu osmosis/dialysisReverse osmosisMembrane surfaceReverse osmosis

The invention provides a sidestream reverse osmosis membrane element which has a simple water way. A side surface of the sidestream reverse osmosis membrane element is a water outlet and one end of the sidestream reverse osmosis membrane element is a water inlet, or the side surface is the water inlet and the end is the water outlet. According to a technical scheme provided by the invention, the reverse osmosis membrane element only has one water inlet, so the water way is simple, convenient installation is realized, and advantages of the sidestream reverse osmosis membrane element are reserved, e.g., easy rolling and a great flow velocity on a membrane surface.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD

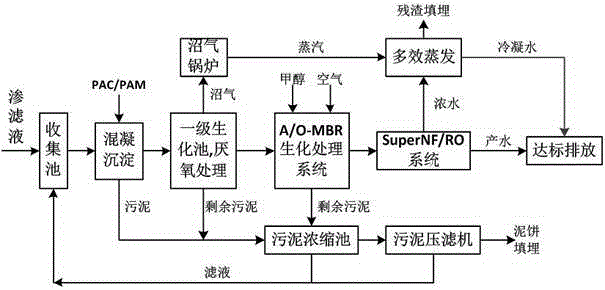

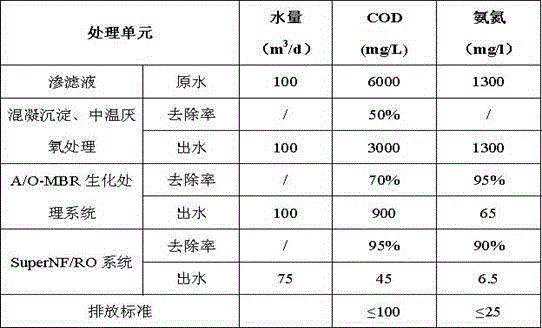

Special film based treatment process for waste incineration plant leachate

InactiveCN105217883ASimple processCost is easy to controlSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSupply energySystem stability

The invention discloses a special film based treatment process for waste incineration plant leachate. The process comprises: centralizing landfill leachate through a collecting pond; firstly carrying out coagulating sedimentation pre-treatment on the landfill leachate; carrying out preliminary treatment on the landfill leachate throng anaerobic microbes; then carrying out bio-treatment on the landfill leachate to remove almost organic pollutants and COD, thereby guaranteeing the inflow water quality for a SuperNF / RO system; and finally, discharging the effluent with a standard through the SuperNF / RO system, and evaporating and separating a concentrated solution. According to the invention, the problem that concentrated water is back-ejected to incinerate is avoided; the equipment is protected; the process is relatively simple; the cost is easy to control; and a film system is hardly polluted and blocked, is stronger in pollution resistance and good in system stability; so that the influence on biochemical treatment effect is effectively avoided to a certain extent; the service life of the film system is greatly prolonged; and meanwhile, biogas generated by anaerobic treatment provides energy supply to evaporation and separation of concentrated water for a biogas boiler, therefore the resource waste is avoided; the wastes are use; and the process is environmental-friendly and energy-saving.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

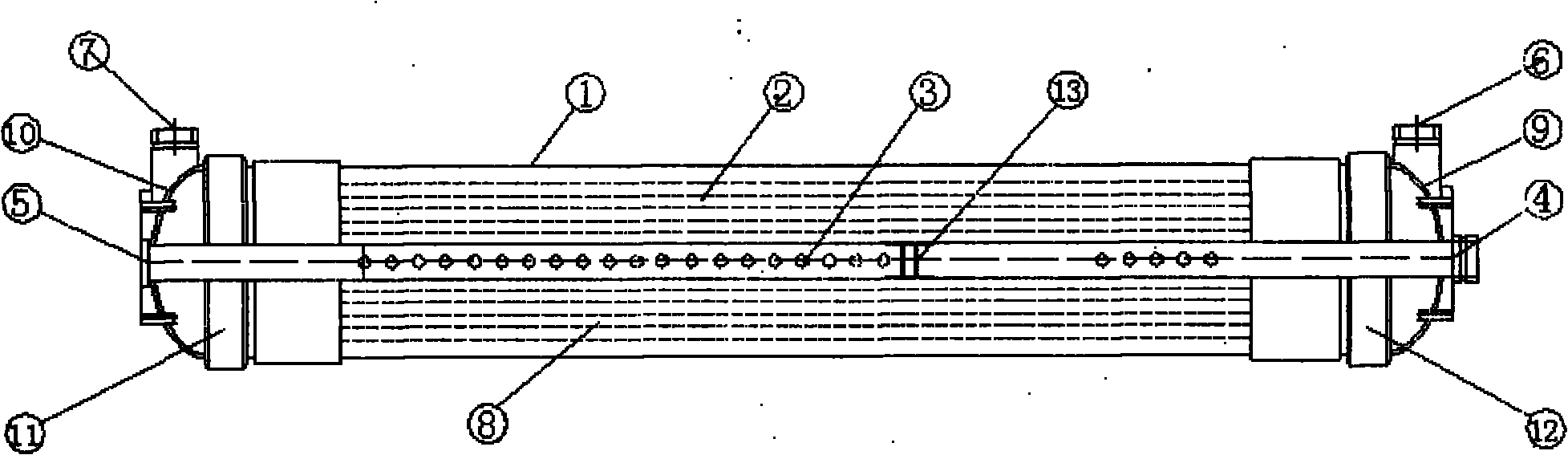

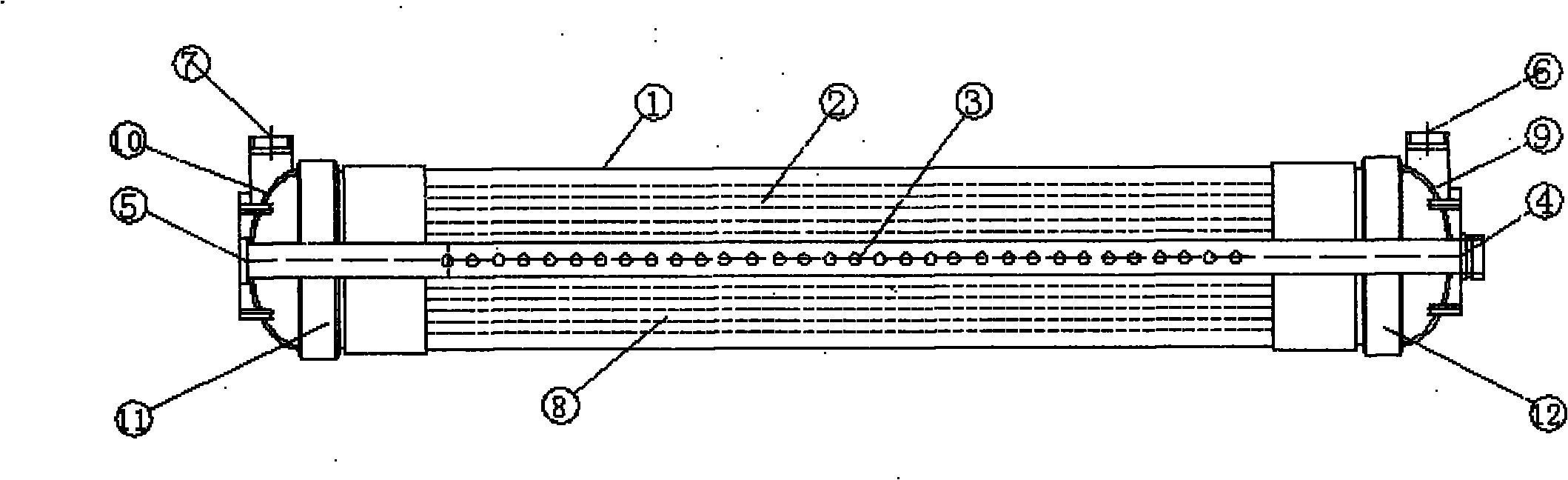

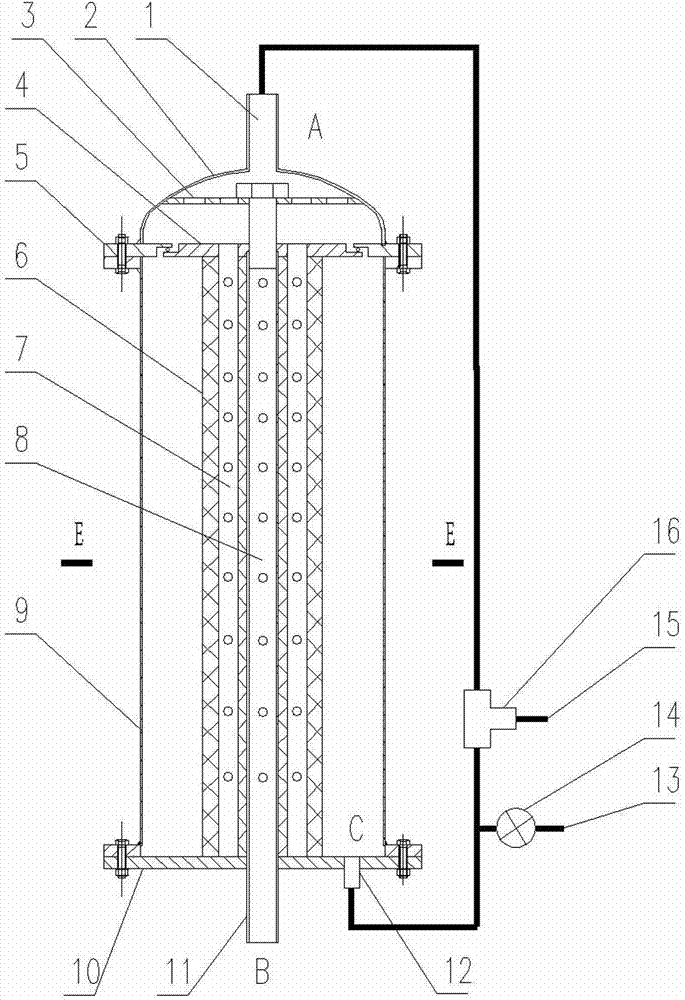

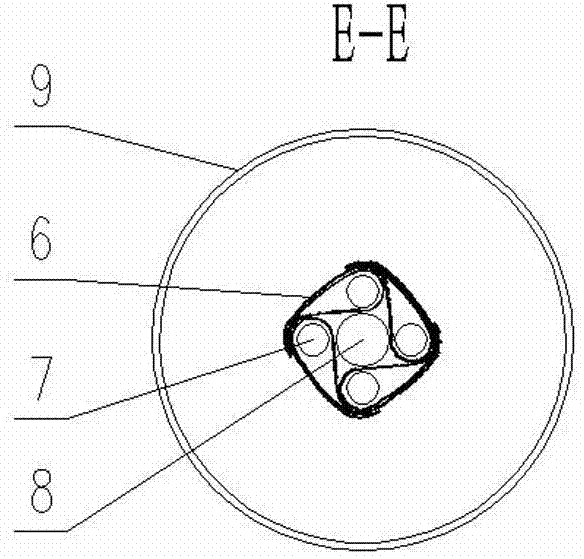

Ultrafiltration and microfiltration membrane assembly for tubular composite membrane

ActiveCN101785973ASolve the filtration accuracyEnhanced mechanical strength recoil availableUltrafiltrationPolyvinyl chlorideEngineering

The invention relates to an ultrafiltration and microfiltration membrane assembly for a tubular composite membrane, relating to the filtering element for water treatment. The ultrafiltration and microfiltration membrane assembly for the tubular composite membrane comprises a tubular machine shell with the ellipse heads which are symmetrically arranged at both ends and fastened by a strap. The centers of the two ellipse heads penetrate through a perforated central tube. A drain plug is arranged in the middle section of the perforated central tube and the ellipse heads are provided with a concentrated water outlet, an original water inlet and a purified water outlet, respectively. Multilayer membranous tubes with different inner and outer diameters are arranged areally on the circumference of the perforated central tube. The shell material of the tubular membrane assembly is polyvinyl chloride (PVC) or glass steel and the inner diameter of the membranous tubes is 5-20mm while the outer diameter thereof is 10-30mm. The membranous tubes consist of a basic membrane and a surface membrane, wherein the basic membrane material is sintered by using ultrahigh molecular weight polyethylene (UHMW-PE), and the material of the surface membrane filtering layer is polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN) and polyvinyl acetate (PVA). The ultrafiltration and microfiltration membrane assembly can be matched with other pipelines, valves, instruments to form an ultrafiltration and microfiltration set for membrane engineering and has the characteristics of high strength, pollution resistance, fouling resisting property, short process flow, rapid online backwash-regeneration, long service life and the like.

Owner:金振忠 +1

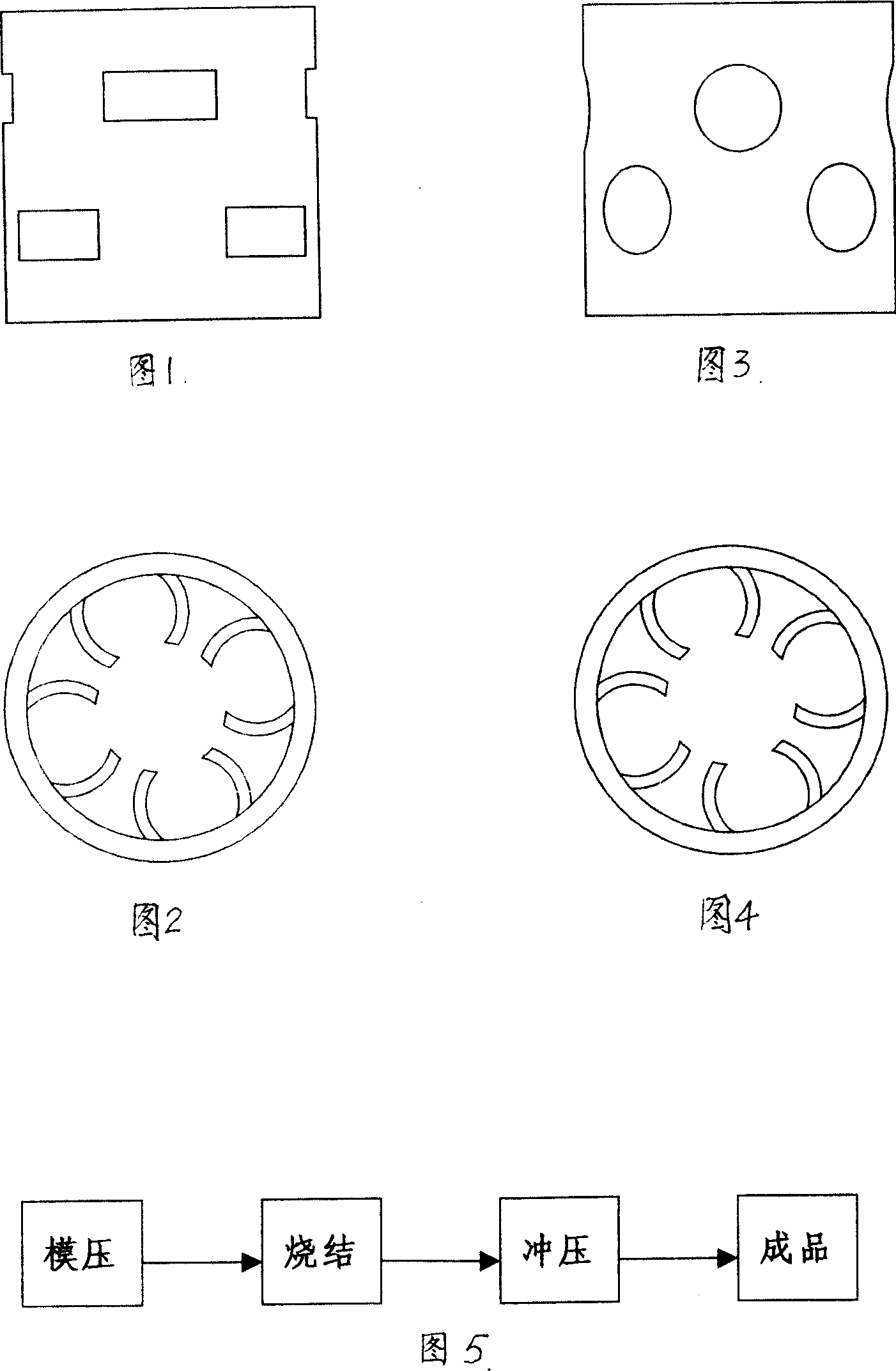

Process for manufacturing tap body

The invention discloses a manufacturing method for water faucet bodies, which comprises: step1, stainless steel pipes and / or stainless steel sheets are used respectively for processing and forming pin components and effluent components of the faucet body; step2, the processed and formed pin components and the effluent components are welded one by one in sequence to form the complete water faucet body in an assembly way; step3, the polishing and the electroplating treatment are carried out on the welded water faucet body. The invention avoids problems of bad quality, low material utilization, energy consumption, environment pollution, and the like produced by the traditional casting and hot forging, simplifies the manufacturing technique, and leads the processing and manufacturing processes to be controllable, thus improving the production efficiency and the yield significantly. As no expensive expenditure on forming dies is needed, the manufacturing method for the water faucet bodies saves the materials and reduces the production cost obviously; meanwhile, the method produces less negative influence to the surrounding environment, meets the requirements of energy-saving and environmental protection, and is very suitable for the wide substitution and application within the industry.

Owner:林铨鸿

Hinge filtering component and filtering system

InactiveCN102389661AExtended service lifePrevent dead film phenomenonSemi-permeable membranesStationary filtering element filtersWater sourceFilter system

The invention discloses a hinge filtering component and a filtering system. The hinge filtering component comprises an outer cylinder, an inner cylinder and a filtering layer, wherein a filtering material is folded into a corrugated layer encircling the exterior of the inner cylinder, thereby forming the filtering layer; the filtering material is composed of two layers of soft filtering net frames and a filtering film or filtering cloth clamped between the two layers of the soft filtering net frames; and all waved hinges of the filtering material are tightly wound on the inner cylinder along a same direction. The filtering system comprises the hinge filtering component. Two filtering modes of positive filtering and negative filtering can be realized by the hinge filtering component provided by the invention. The two filtering modes are alternatively used, so that a stressed direction of the filtering layer is variable. The positive filtering and the negative filtering are realized, so that a film-blocked phenomenon or an irrecoverable film deformation problem caused by long-term filtering along a same direction is avoided. In the filtering system provided by the invention, a process of halting and connecting an external water source is unnecessary and a backwash operation is simple.

Owner:孙世博 +1

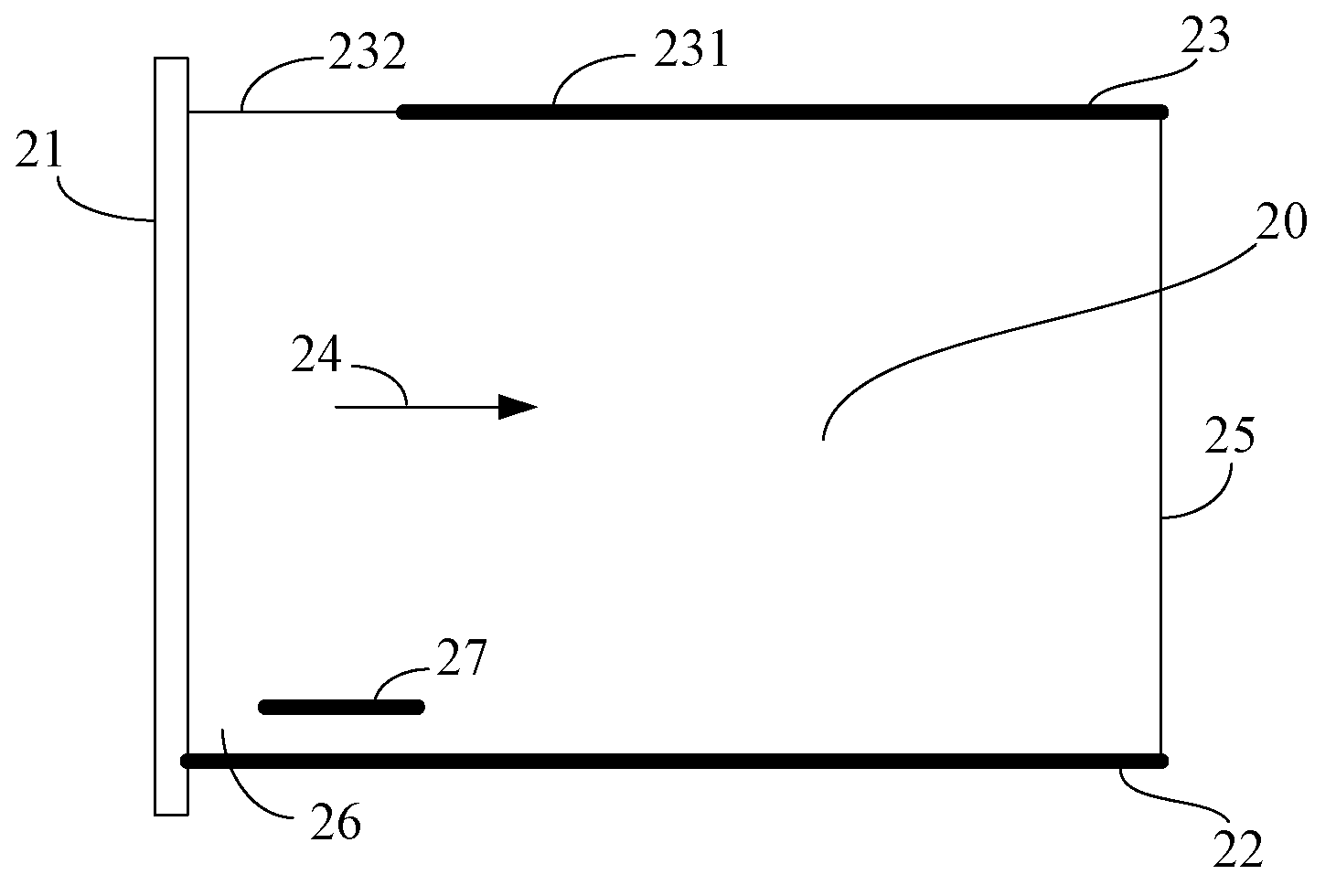

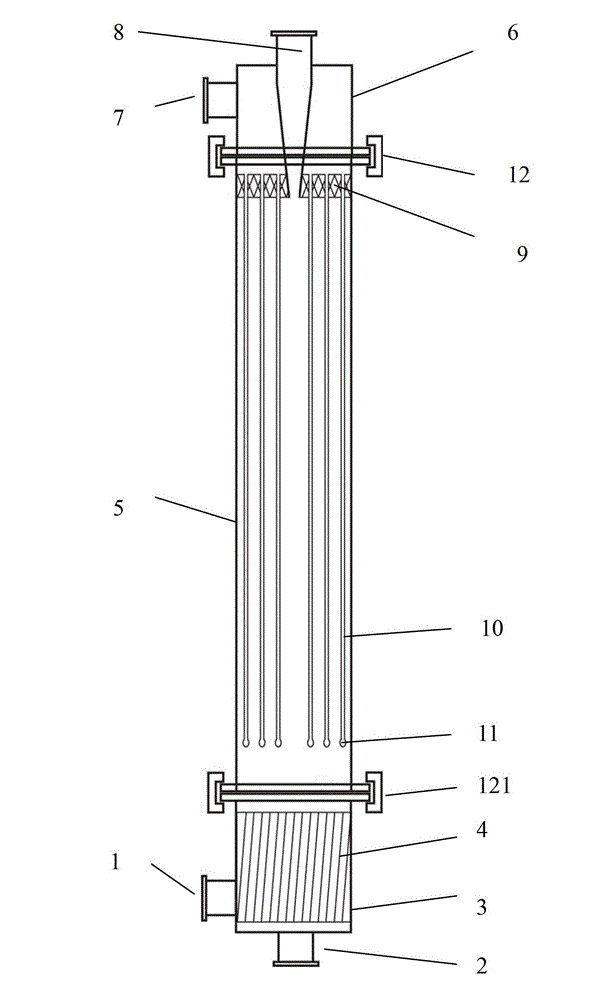

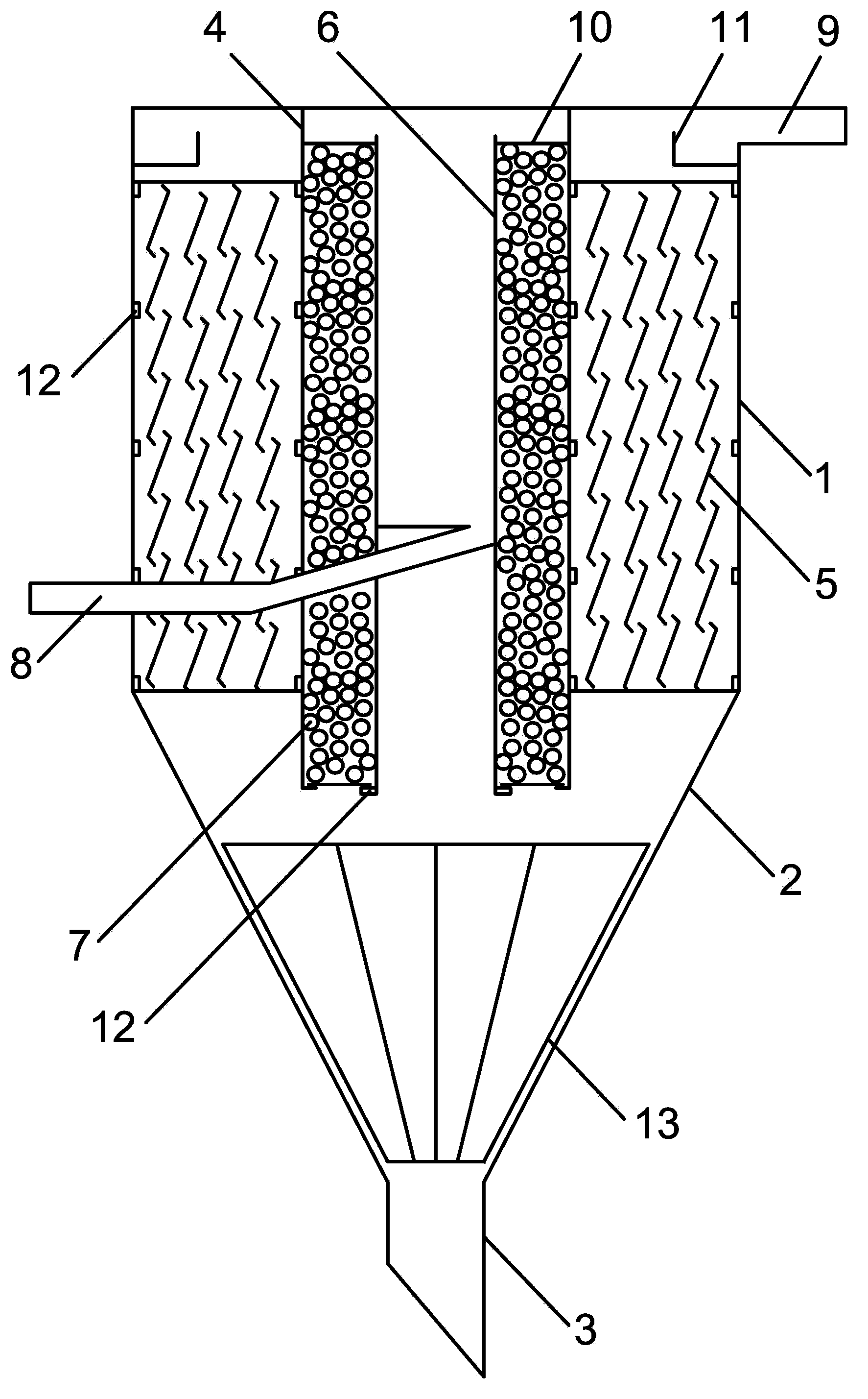

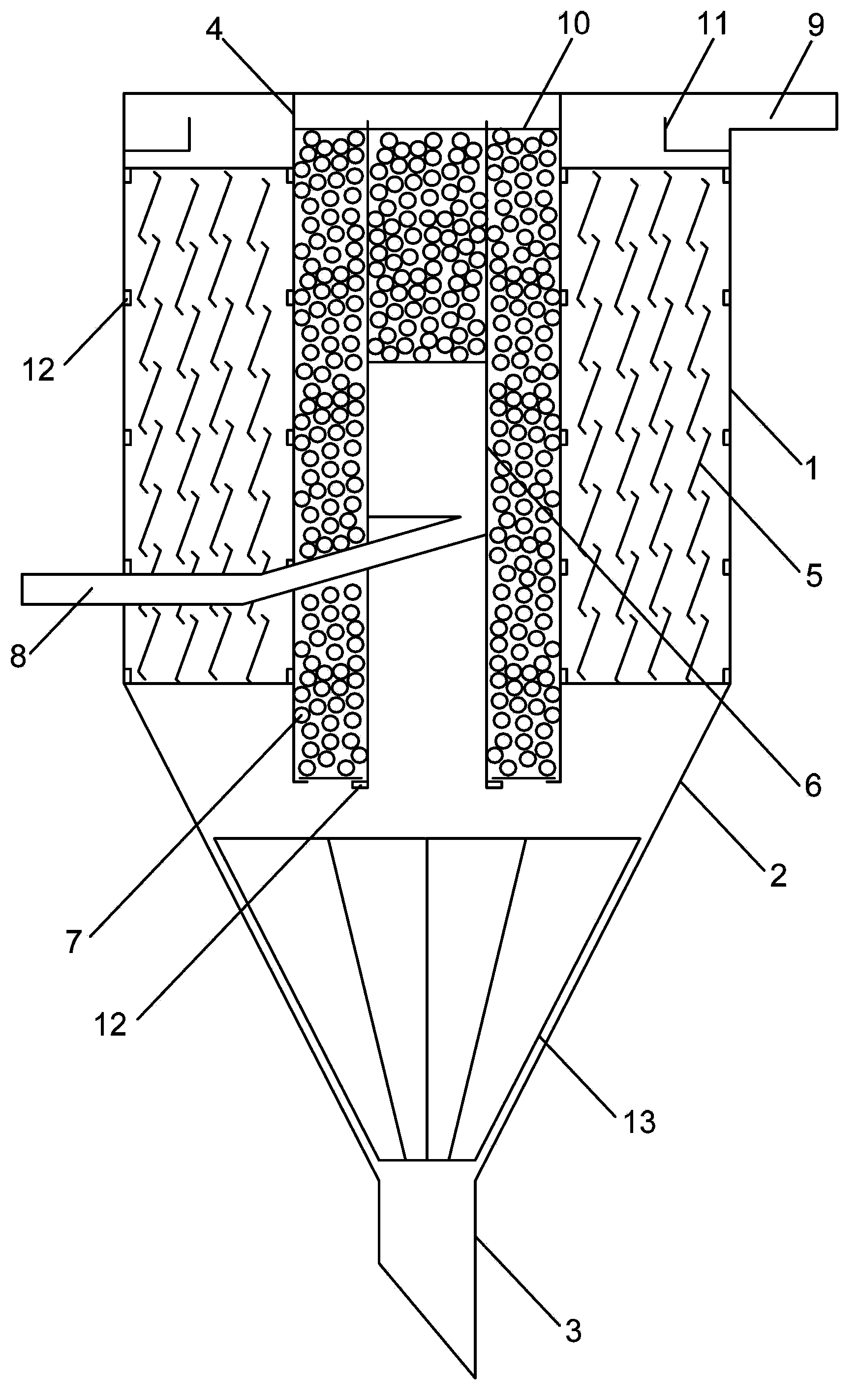

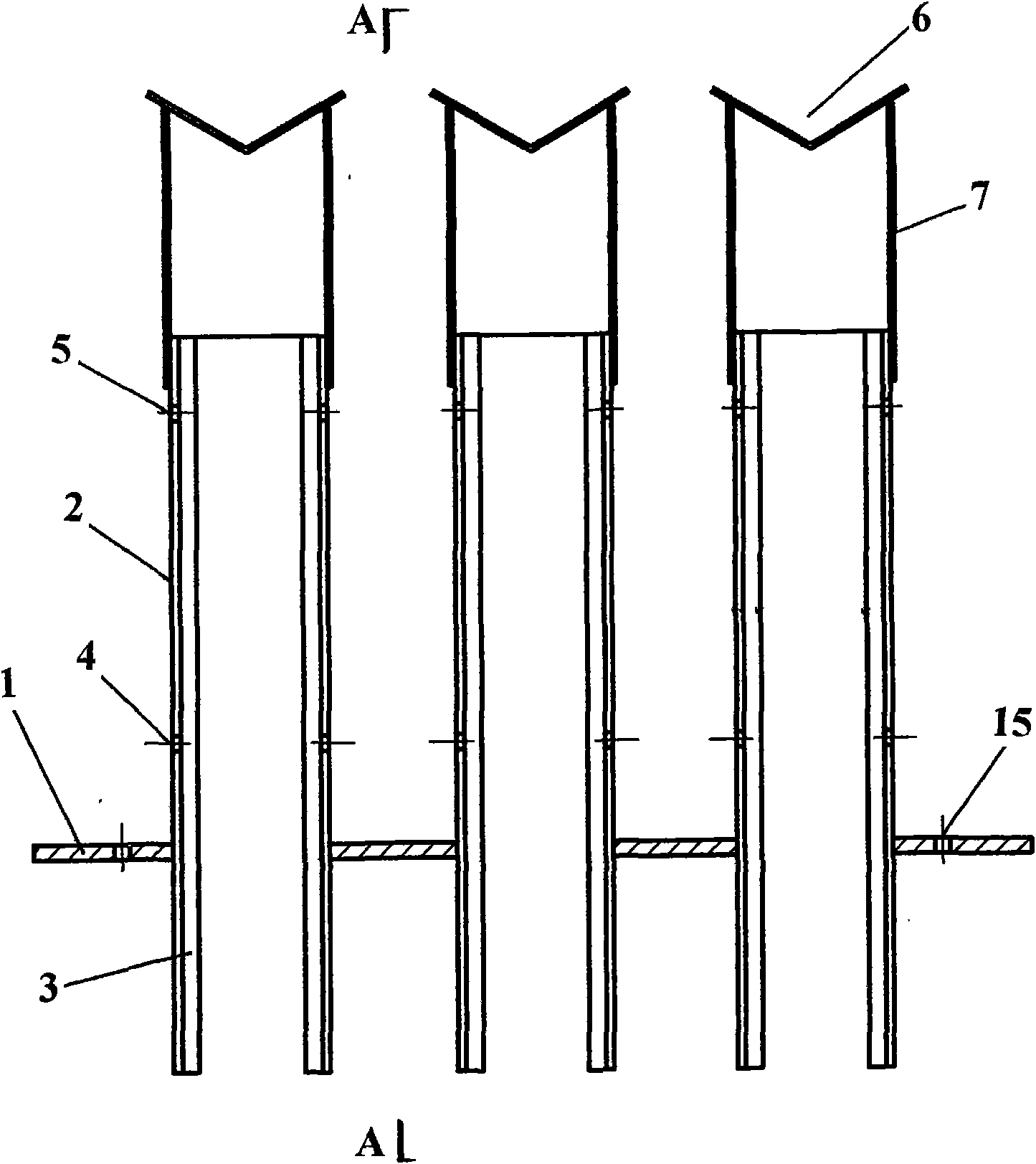

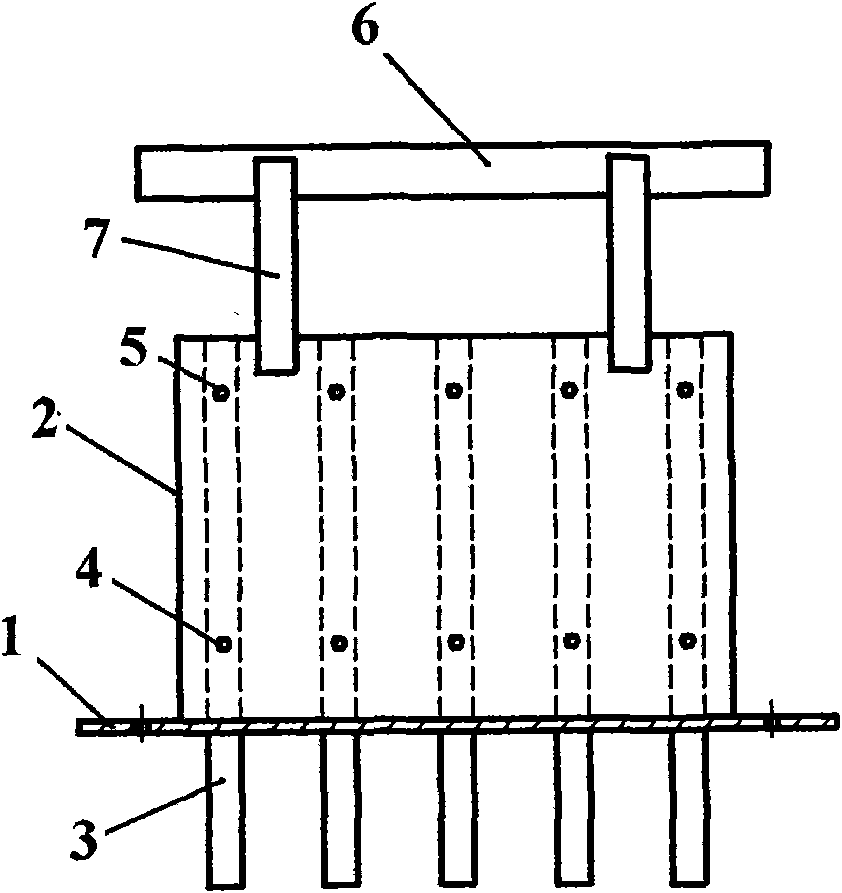

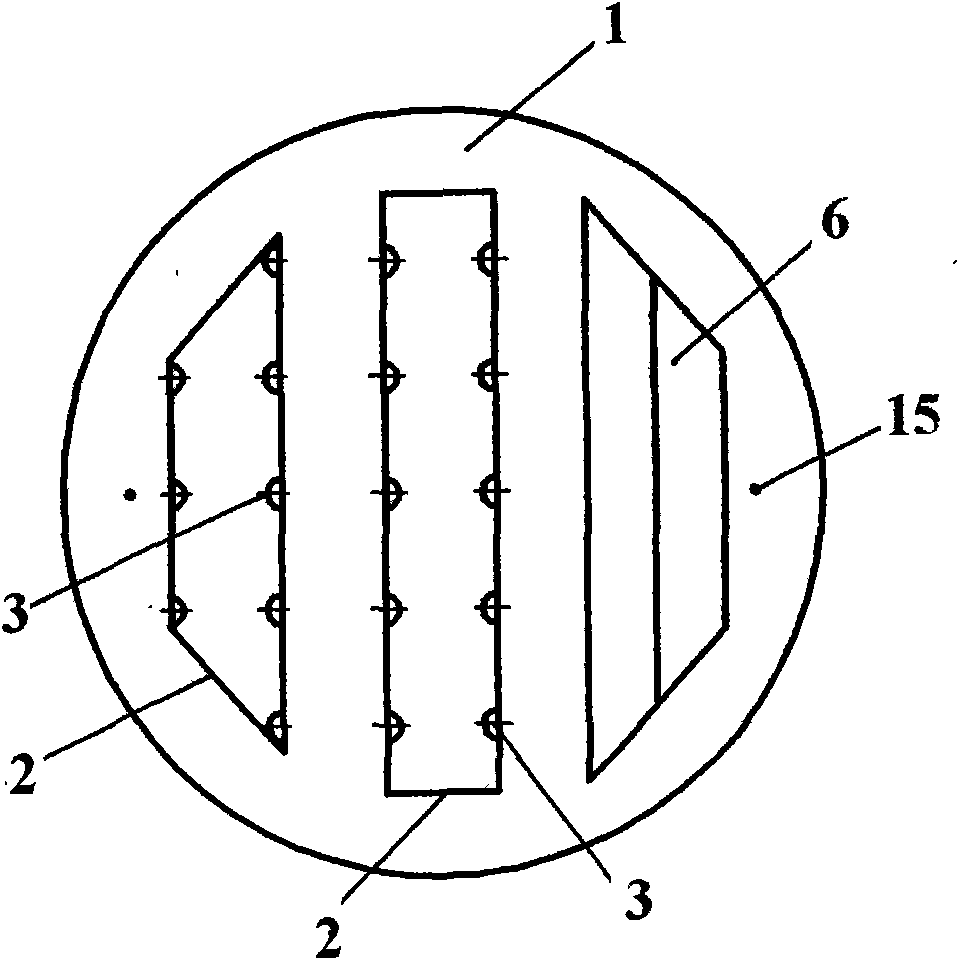

Membrane module for novel efficient membrane bioreactor

InactiveCN102942250AImprove processing efficiencyReduce operating energy consumptionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberActivated sludge

The invention relates to the technical field of membrane separation, and particularly relates to a membrane module for a novel efficient membrane bioreactor. The membrane module comprises an upper end cover (6), a membrane module housing (5), a lower end cover (3), a soft pouring material (9) and hollow fibre membrane silks (10), wherein the upper ends of the plurality of hollow fibre membrane silks (10) are hermetically bonded at an upper port in the membrane module housing (5), and the lower ends of the hollow fibre membrane silks (10) freely drop inside the membrane module housing (5) to form an overhanging structure; and plugging heads (11) are arranged at the bottom ends of the hollow fibre membrane silks (10). The membrane module disclosed by the invention has the advantages that due to the design of the overhanging membrane silks, the membrane module is not easily plugged by dirt and is easy to wash and maintain; due to a positive-pressure operation, the membrane module is large in membrane flux and water treatment amount and small in occupied area is small; external-pressure type membrane silks resist pollution; and the membrane module is suitable for a higher activated sludge concentration and higher in treatment efficiency, low in running energy consumption, long in service life, and low in price, thus saving investment.

Owner:上海膜源环保科技有限公司

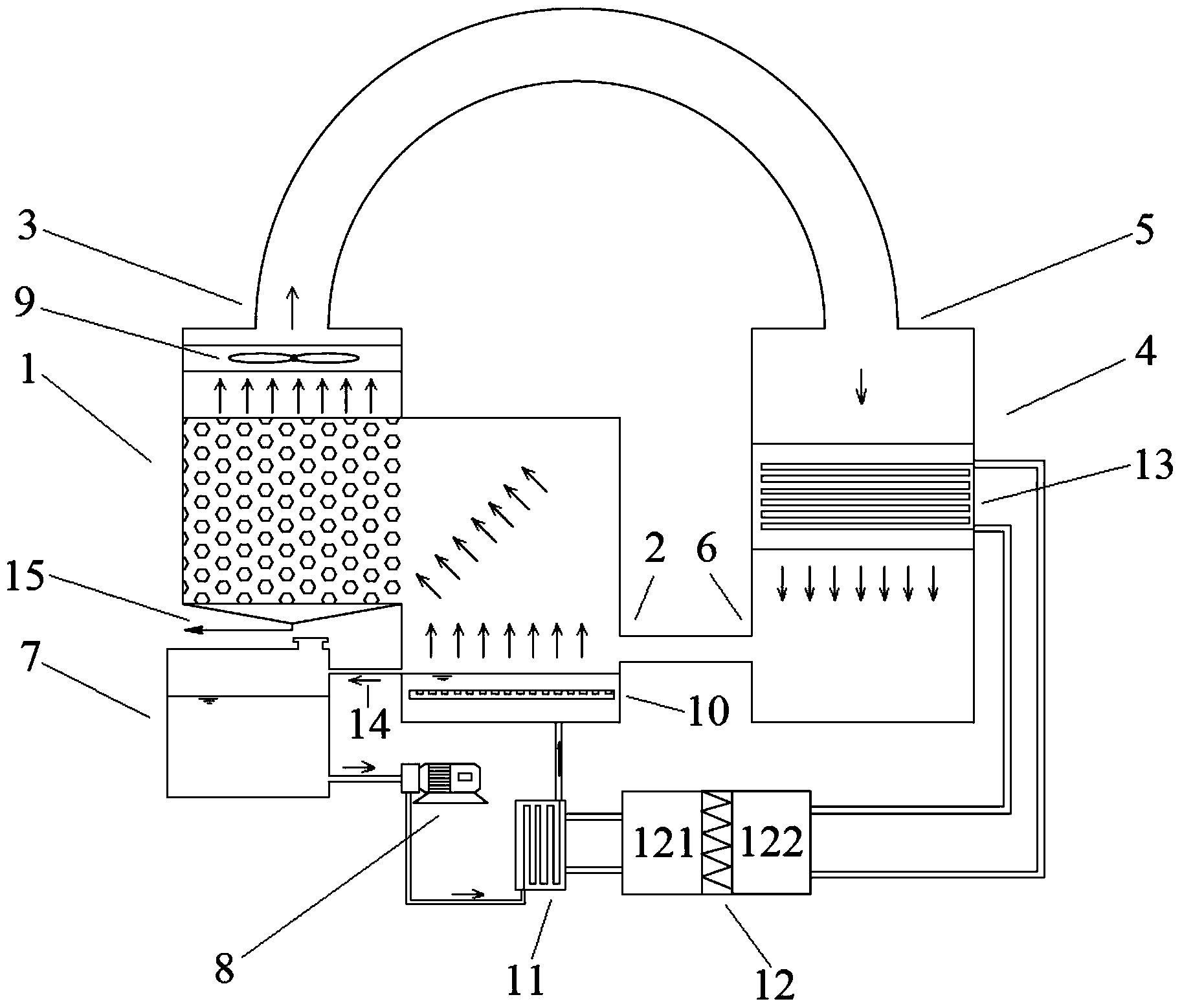

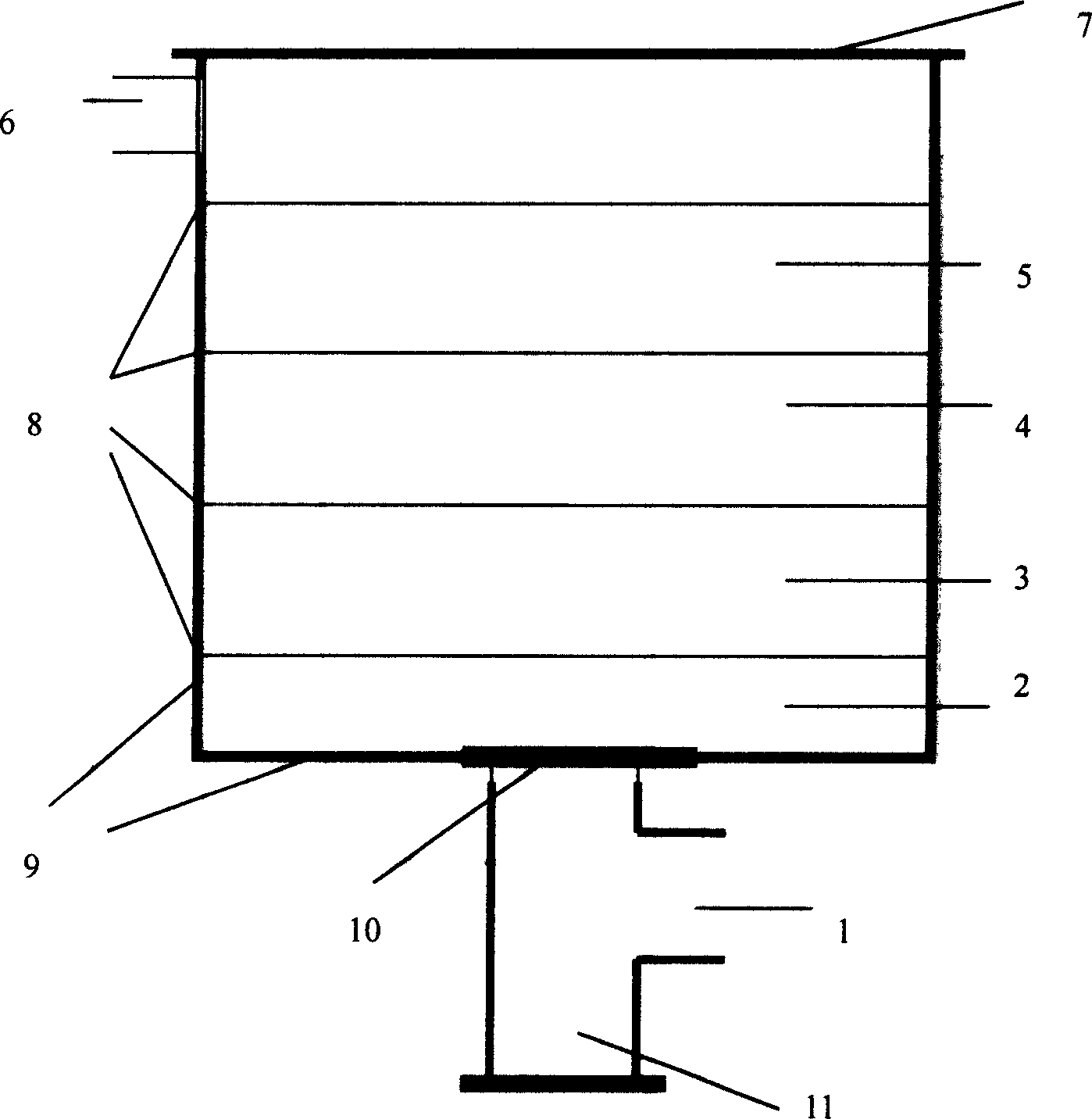

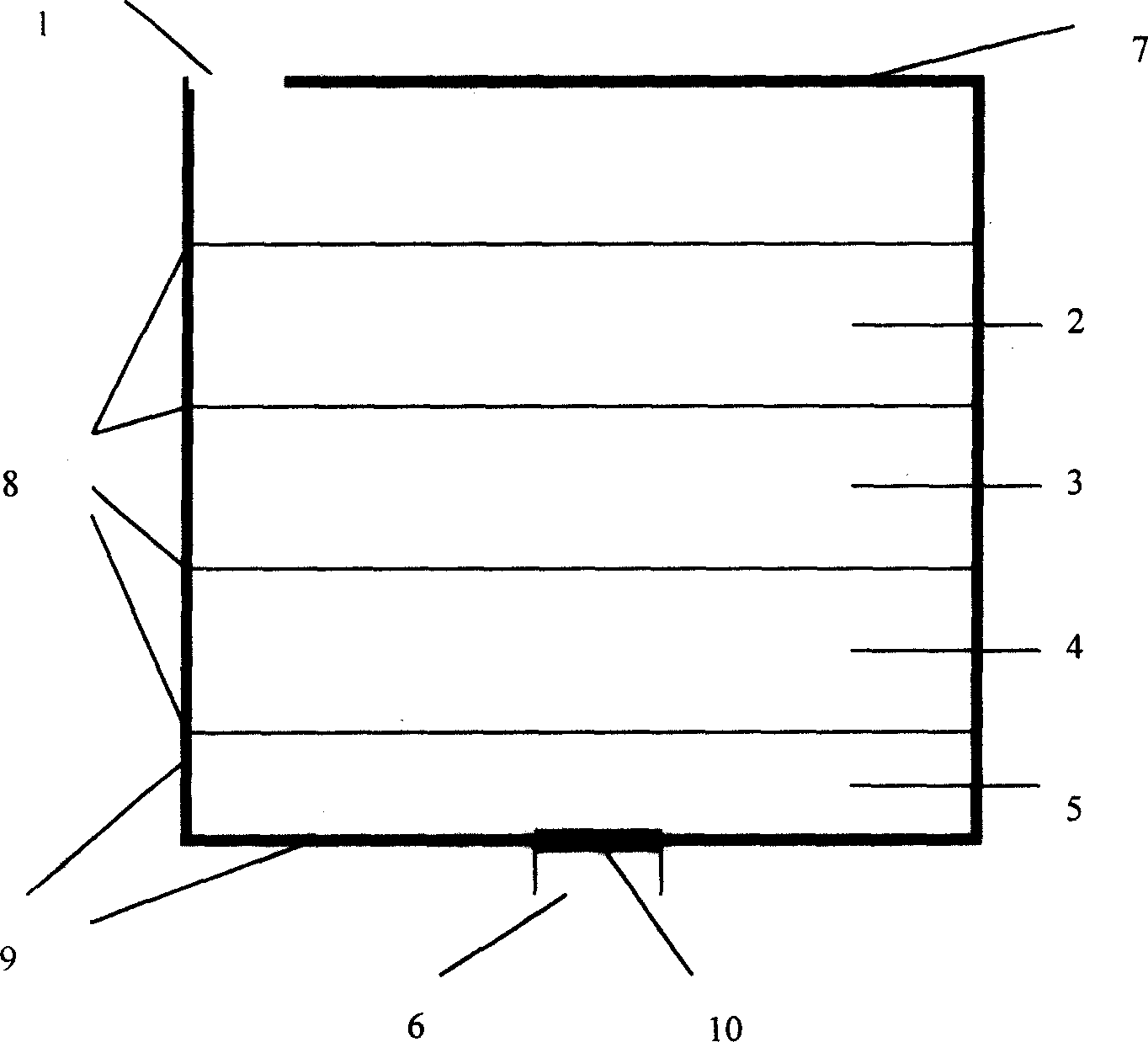

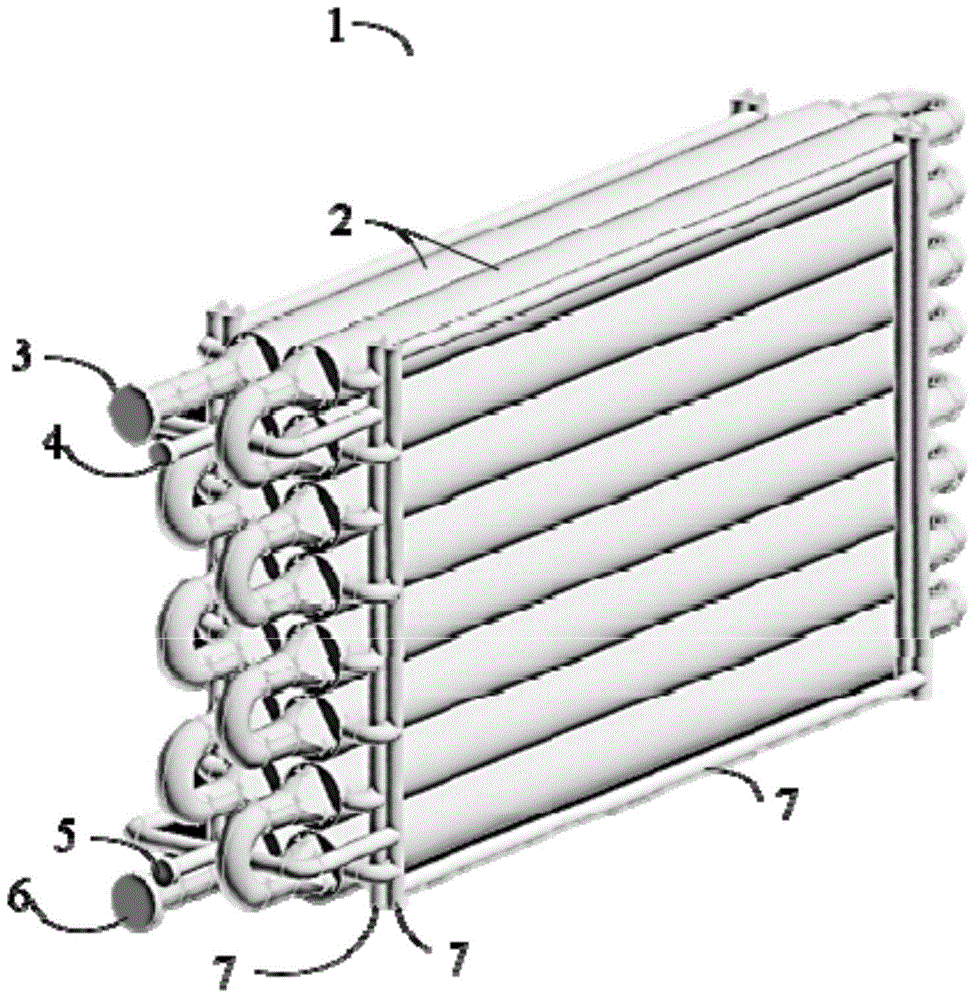

Strong brine evaporation and crystallization system

ActiveCN104163460AImprove evaporation effectImprove evaporation and crystallization efficiencyWater/sewage treatment with mechanical oscillationsWater/sewage treatment by heatingEvaporation chamberCrystallization

The invention provides a strong brine evaporation and crystallization system including an evaporation chamber (1) having a first inlet (2) and a first outlet (3), a condensation chamber (4) having a second inlet (5) and a second outlet (6), and a strong brine tank (7) communicated with the evaporation chamber (1) through a pump (8), wherein the first inlet (2) is communicated with the second outlet (6), the first outlet (3) is communicated with the second inlet (5), the first outlet (3) is provided with a fan (9) for guiding water steam in the evaporation chamber (1) to flow to the condensation chamber (4), and the evaporation chamber (1) is provided with an ultrasonic atomizer (10) for atomizing strong brine in the evaporation chamber (1). The invention aims to provide the efficient and reliable strong brine evaporation and crystallization system which can effectively prevent generation of scaling during the treatment process.

Owner:BEIJING WANBANGDA ENVIRONMENTAL PROTECTION TECH

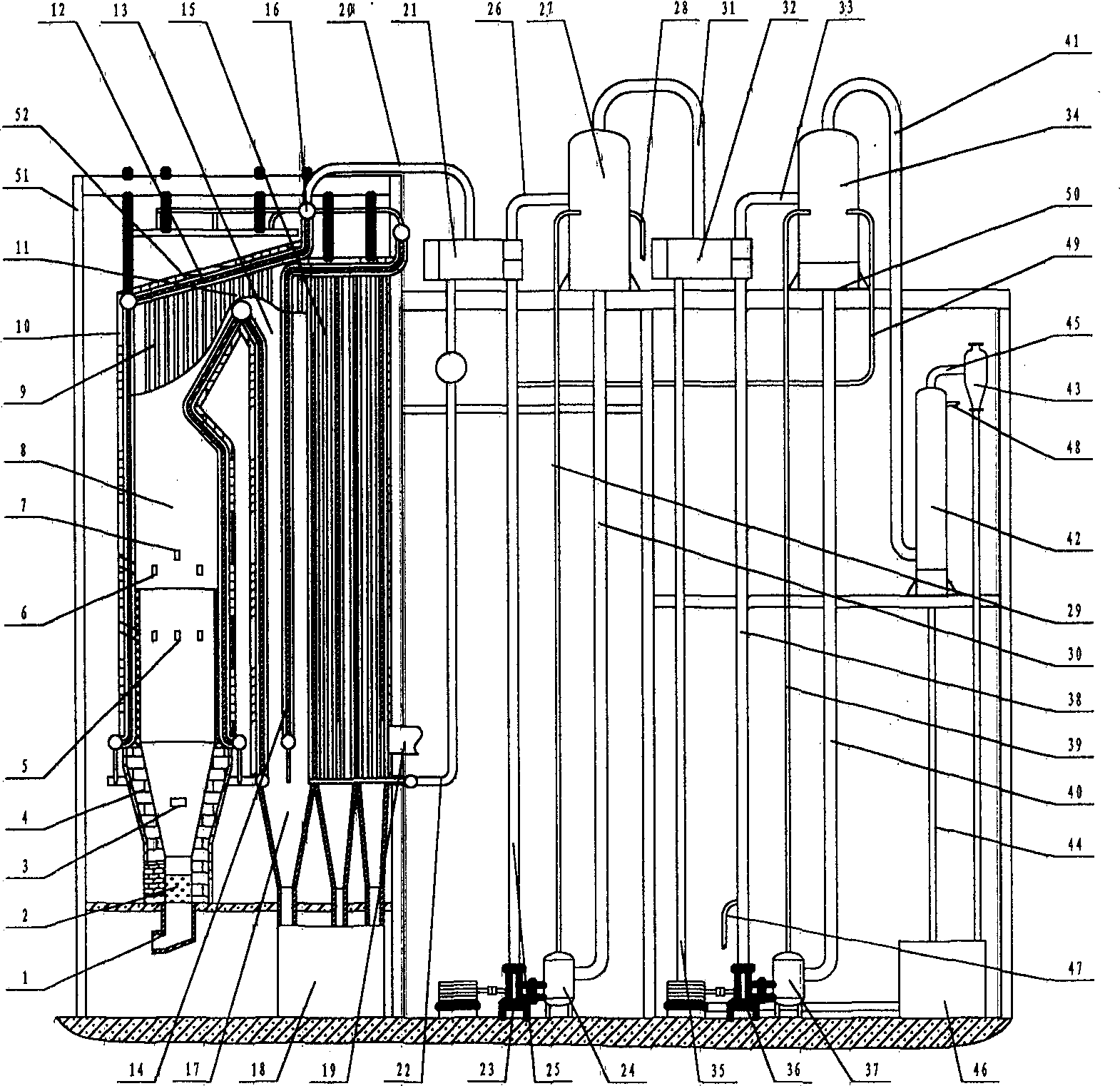

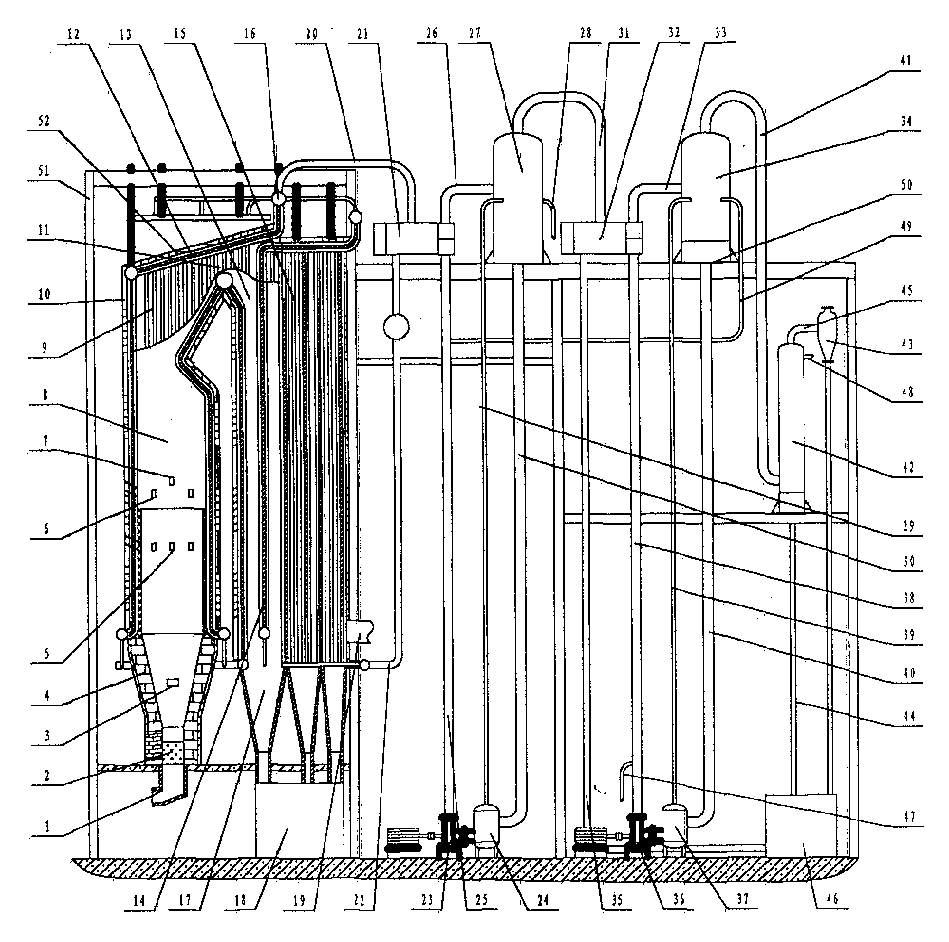

Hot-pipe type organic waste liquor treatment system

InactiveCN1367344AReduce processing costsGood controlIncinerator apparatusLiquid wasteCombustion chamber

The heat pipe organic waste liquor treatment equipment is characterized by that the combustion furnace and concentration device are integrated into one body, in which the cold water part of combustion chamber of combustion furnace, internal top wall and four side-walls of U-shaped fly ash settling chamber and heated face of water-cooling partition wall adopt heat-pipe water-cooling structure. Itsconcentration device is divided into two circulating loops respectively formed from heater, separator, circulating pump and balance box, the heat-pipe to end of heat-pipe water-cooling structure is communicated with heater, and the bottom end of heat pipe is communicated with return pipe of heater.

Owner:广西绿洲热能设备有限公司

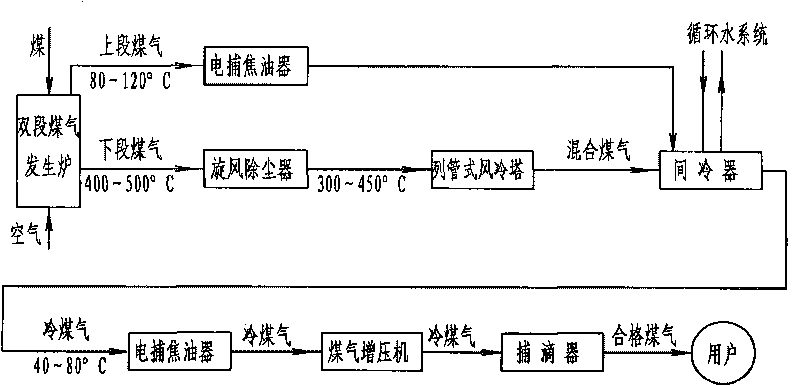

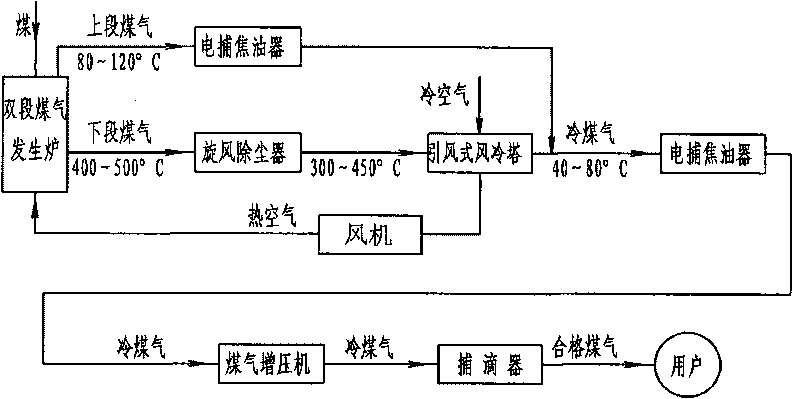

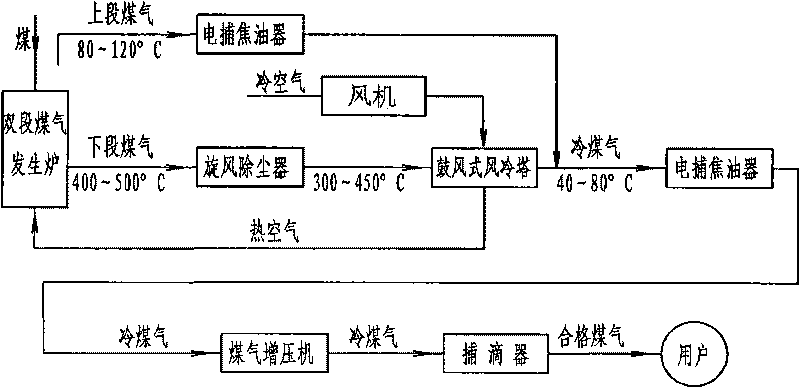

Gas purifying and cooling process and equipment of two-section furnace

InactiveCN101696362AIncrease productionEnhanced gasification processEnergy inputCombustible gas productionProcess systemsCooling tower

The invention relates to gas purifying and cooling process and equipment, in particular to gas purifying and cooling process and equipment of a two-section furnace. The gas is cooled by an induced air or blast type air cooling tower instead of a tube air cooling tower and an intercooler in the traditional gas cooling and purifying process, and the preheated air enters a gas furnace. Because the intercooler and a softened water supplying, returning and cooling system thereof are eliminated, the equipment manufacture cost and the maintenance cost of the whole process system are greatly reduced; the preheated air enters the gas furnace, thereby strengthening the gasification process of coal, improving the output of the coal and reducing energy loss; the induced air or blast type air cooling tower has a large heat transfer coefficient, reinforced convection heat transfer and good cooling effect; meanwhile, the volume and the weight of the induced air or blast type air cooling tower are reduced, and the equipment investment is lowered.

Owner:祁举 +1

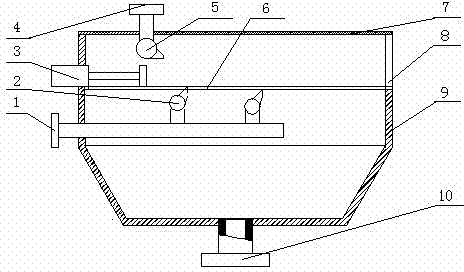

Self-cleaning and automatic deslagging filter

The invention discloses a self-cleaning and automatic deslagging filter used for deslagging cane juice in a cane sugar factory. The self-cleaning and automatic deslagging filter comprises an air inlet pipe, a sweeping screen sprayer, a piston slag pushing device, a cane juice inlet pipe, a cane juice distributor, a wedge-shaped screen, a cover plate, a solid waste slag discharging hole, a shell and a cane juice outlet pipe. The self-cleaning and automatic deslagging filter is characterized in that the rectangular wedge-shaped screen is arranged in the shell, the cane juice distributor is arranged at one end of the wedge-shaped screen, and is connected with the cane juice inlet pipe, the piston slag pushing device is arranged on the surface of the wedge-shaped screen, solid waste slag is discharged from the solid waste slag discharging hole in the other end of the wedge-shaped screen, the sweeping screen sprayer is arranged on the bottom surface of the wedge-shaped screen and is connected with the air inlet pipe, the cover plate is arranged above the shell to prevent the solid waste slag from being sprayed, and the cane juice outlet pipe is arranged below the shell, and is connected with a cane juice tank below the cane juice outlet pipe. The self-cleaning and automatic deslagging filter has the advantages of good filtering effect, low energy consumption, small noise, simple structure, reliable work and the like; self-cleaning and automatic deslagging are easily realized.

Owner:GUANGXI DETIAN CHEM CYCLE CO LTD

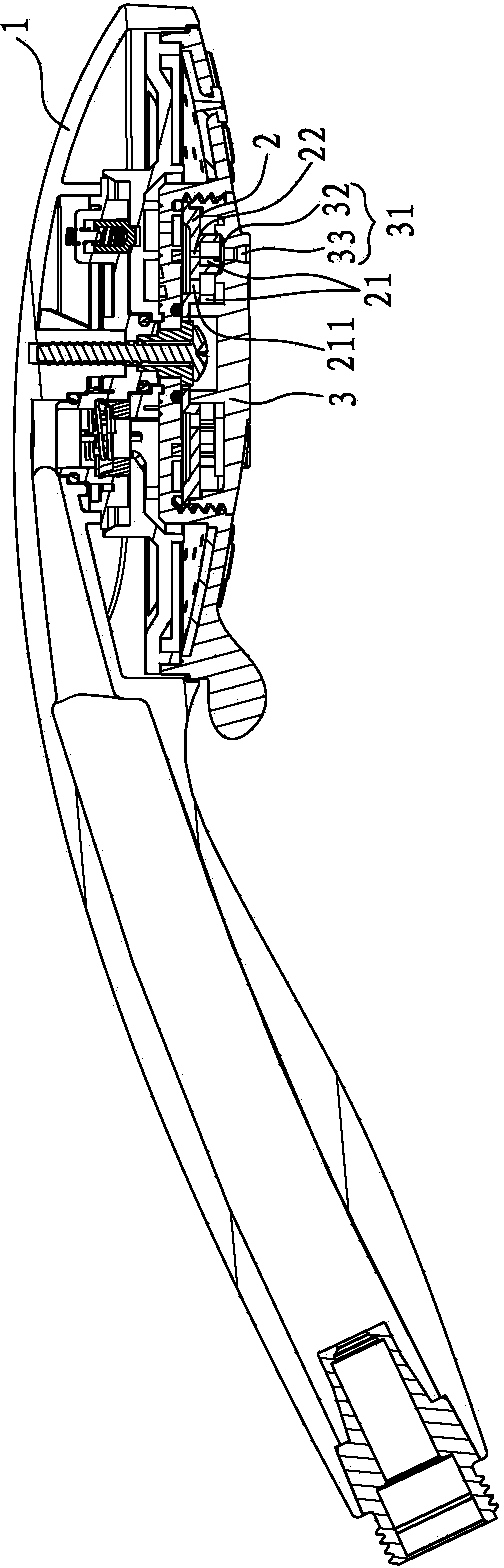

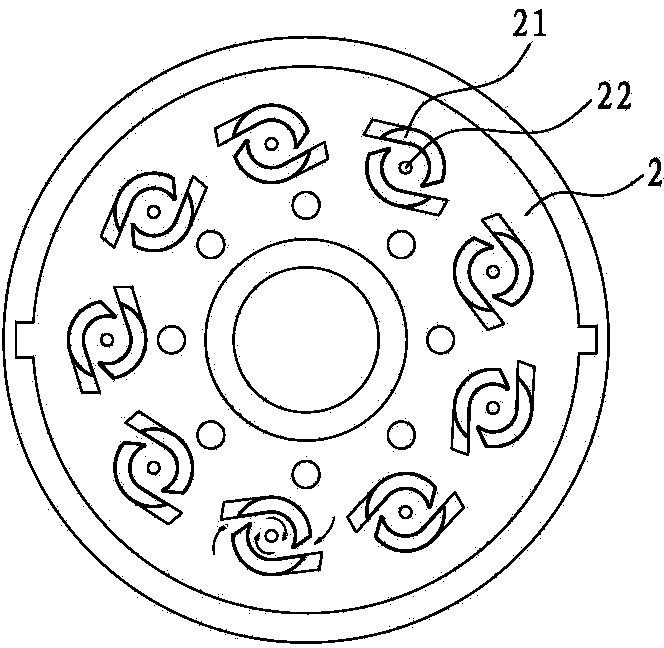

Micro-vortex high-efficiency clarification reactor and operation method for same

ActiveCN103880131ASimple structureLow running costWater/sewage treatment by flocculation/precipitationSettling basinEngineering

The invention discloses a micro-vortex high-efficiency clarification reactor and an operation method for the same. The reactor is used for solving the problem that devices are in the prior art is difficult to install, liable to obstruct, low in work efficiency, poor in using effect and short in service life. The micro-vortex high-efficiency clarification reactor includes: a clarification basin; a sludge settling basin which is disposed under the clarification basin and is communicated with the bottom of the clarification basin; a sludge discharge pipeline which is communicated with the bottom of the sludge settling basin; a flocculating reaction basin which is disposed in the clarification basin with the bottom of the flocculating reaction basin being communicated with the clarification basin and the sludge settling basin; an inclined plate settlement layer which is disposed between the clarification basin and the flocculating reaction basin and includes a plurality of inclined plates; a central basin which is disposed in the flocculating reaction basin with the top of the central basin being communicated with the upper part of the flocculating reaction basin; micro-vortex filling material which is arranged between the flocculating reaction basin and the central basin; a water inlet pipe which is tangentially connected to the lower part of the central basin; and a water outlet pipe which is communicated with the upper part of the clarification basin. The beneficial effects of the reactor are that the reactor is convenient to install and operate and is high in efficiency, excellent in processing effect, small in agent usage amount and long in service life. With the reactor, a mixing, a flocculating and a separating operation can be achieved synchronously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

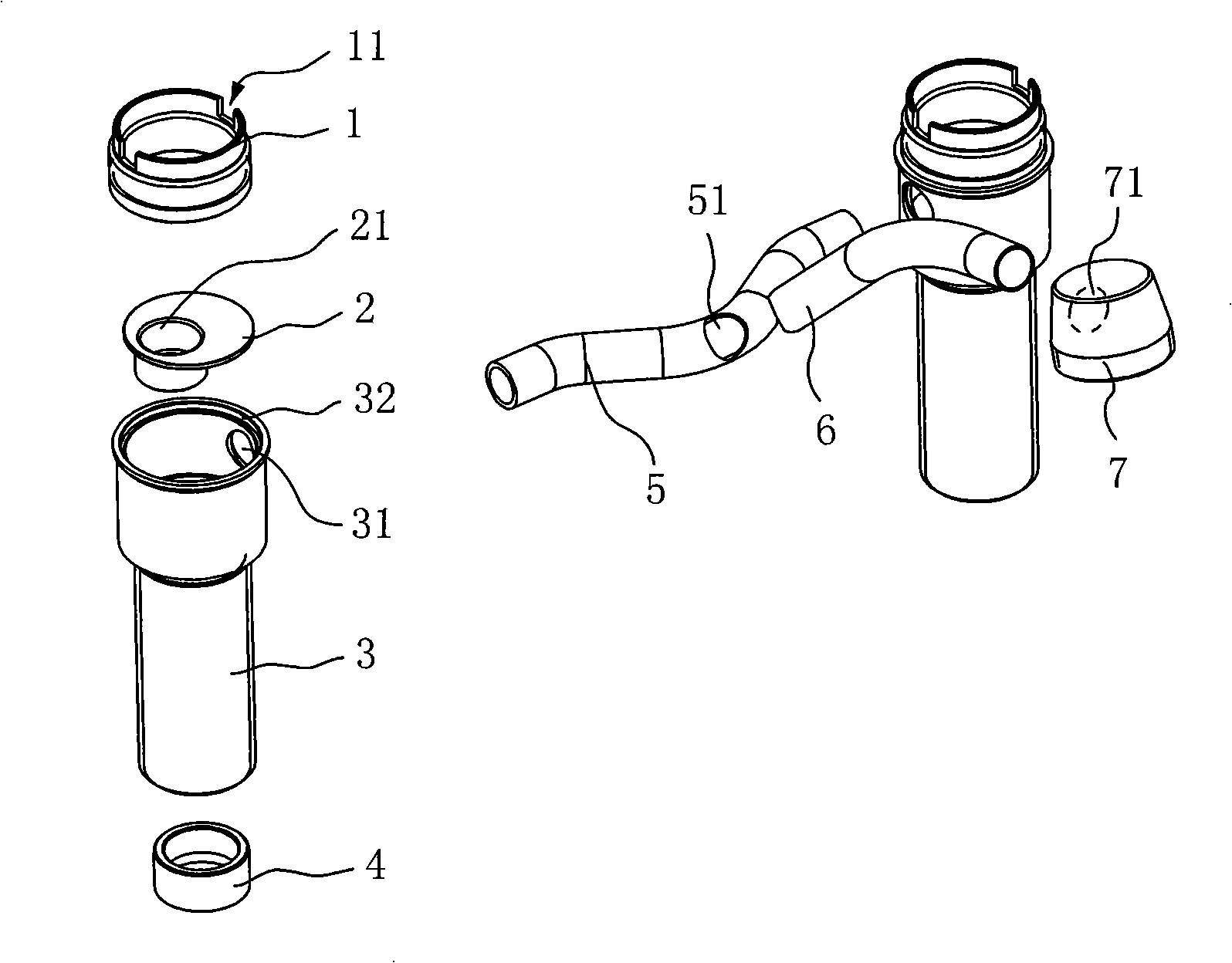

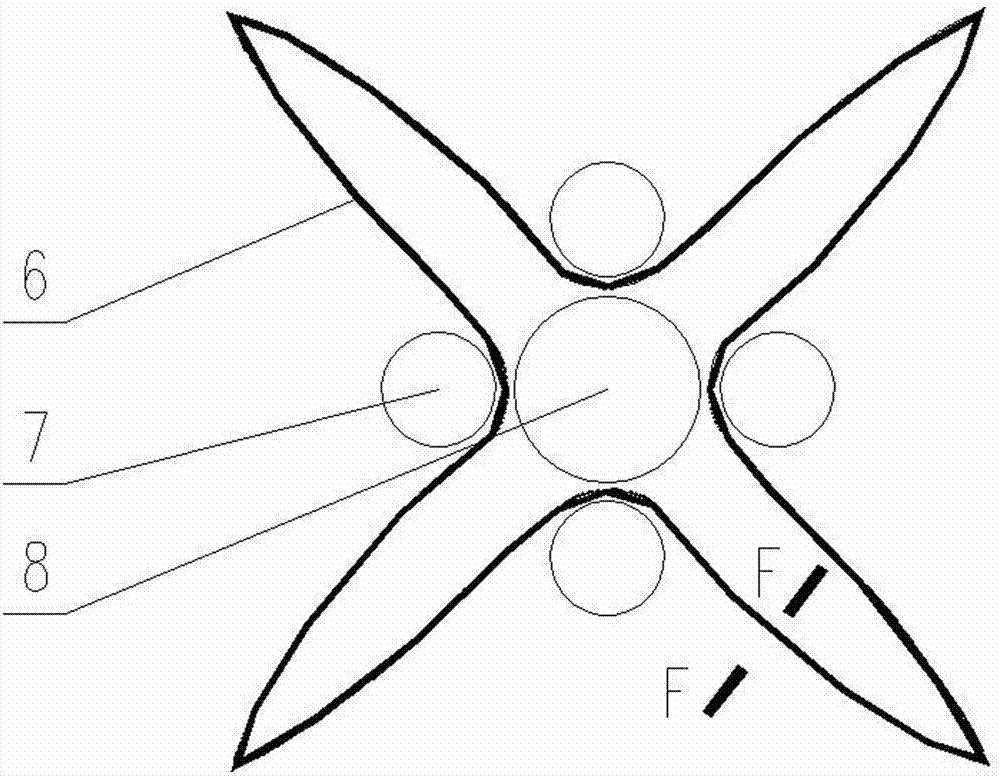

Hollow fiber membrane filtering assembly

InactiveCN101362053ANot easy to foulNot easy to damageSemi-permeable membranesHollow fibre membraneFiber

The invention relates to a hollow fiber porous membrane filter component which comprises a water outlet pipe connected with a water suction pump and used for discharging filtered water, a membrane bundle cup used for connecting a hollow fiber membrane bundle and communicated with the water outlet pipe by a water outlet hose, an aeration pipe communicated with air supply and provided with aeration holes on the surrounding wall, and the hollow fiber membrane bundle immersed in sewage to be treated and arranged in a U-shape form, with the two ends connected with the membrane bundle cup and the bending part arranged on the aeration pipe. The aeration holes on the aeration pipe are arranged at positions corresponding to the bending part of the hollow fiber membrane bundle. The component has the advantages that the membrane surface of the whole membrane bundle is not easy to be fouled and blocked, the connecting root part of the membrane bundle is not easy to be damaged, the structure is simple and easy to be maintained, scale production is easy to form and the like.

Owner:XIAMEN LEEBAM MEMBRANE TECH

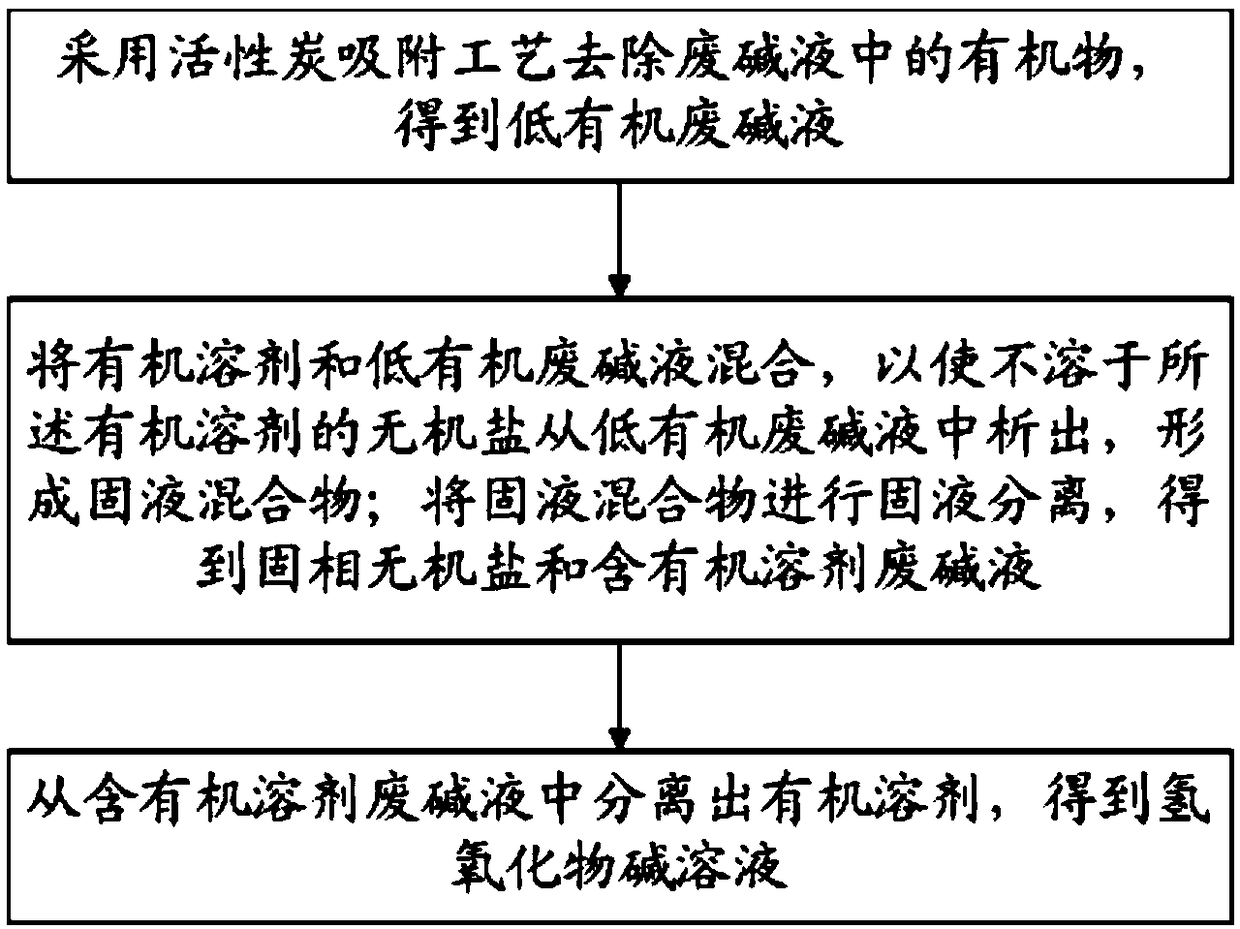

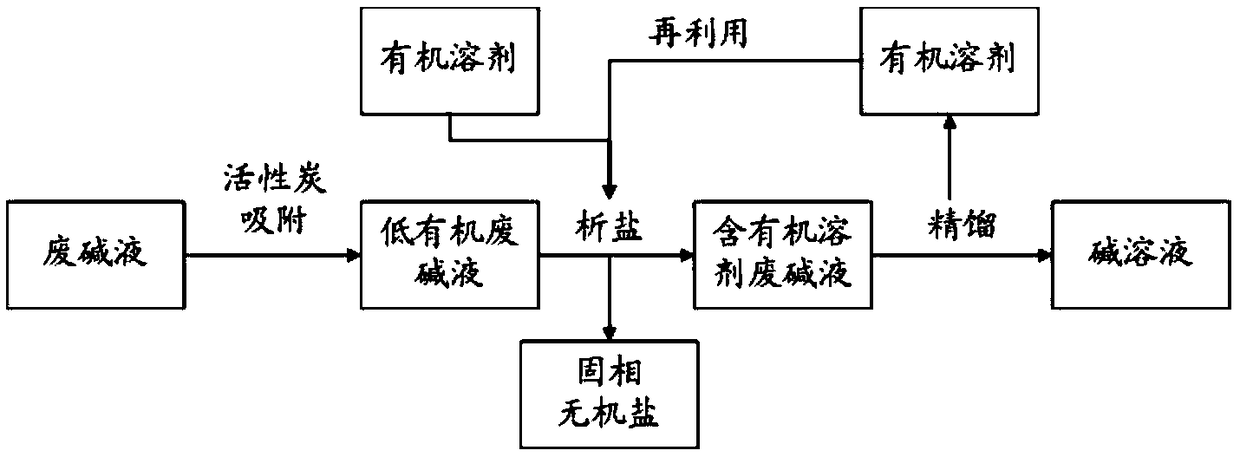

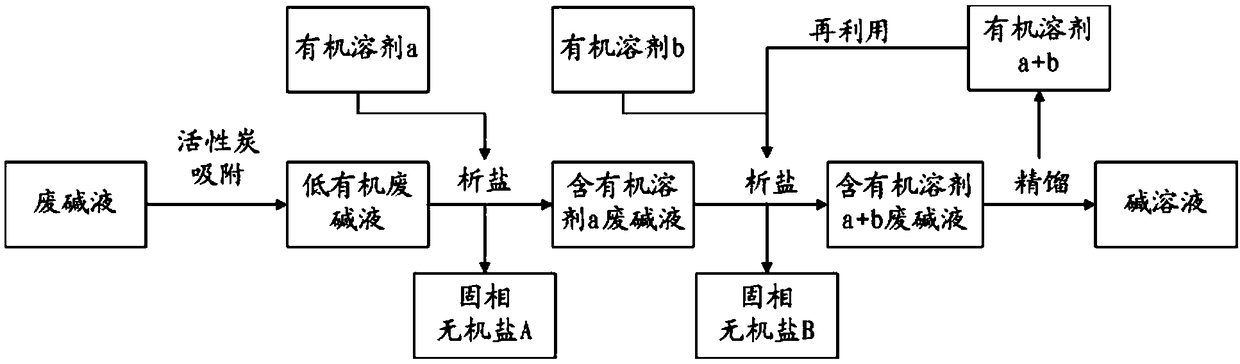

Treatment method and system for waste lye

PendingCN109437424AAvoiding Difficult Biochemical Processing ProblemsEffective precipitationWater/sewage treatment by centrifugal separationWater contaminantsInorganic saltsOrganic solvent

The invention discloses a treatment method and system for waste lye. The treatment method comprises the following steps: removal of organic matters: removing organic matters in the waste lye to obtainlow-organic waste lye; salting: mixing an organic solvent and the low-organic waste lye to separate out inorganic salt which is insoluble in the organic solvent from the low-organic waste lye in order to form a solid-liquid mixture; performing solid-liquid separation on the solid-liquid mixture to obtain solid-phase inorganic salt and waste lye containing the organic solvent; and recovery of theorganic solvent: separating the organic solvent from the waste lye containing the organic solvent to obtain a lye solution. Compared with the prior art, the treatment method and system for the waste lye disclosed by the invention has the advantages that a high-purity hydroxide lye solution can be obtained, and hydroxide resources in the waste lye are recycled effectively; moreover, the whole system is easy to operate; the energy consumption is low; and pollution and plugging are not prone to occur.

Owner:SUZHOU QINGRAN ENVIRONMENTAL PROTECTION TECH

Deep sand filter

InactiveCN1528489ALarge dirt holding capacityAct as a coarse sand filterLoose filtering material filtersGravity filtersNormal filterEngineering

The invention is a depth-type sand filter, the size of sand gradually diminishing with the flow direction of the normal filtering fluid. It leads the fluid to the inlet of the sand filter through the pipeline, firstly holds back big suspension through big sand area, then holds back medium suspension through medium sand area, finally eliminates most fine suspension through fine sand area, and then makes the fluid flow out from the outlet. It is composed of wall body, filtering sand and ground leak; the wall body is set with inlet and outlet, the ground leak is set under the wall body, the filtering sand is spread in the liquid flow direction in turn according to the size. It can adopt upflow and downflow modes. It can stably and economically run in a wide range. It is applied to economical sand filtering field, especially the field where the sand filter is used infrequently or discontinuously.

Owner:安逢龙

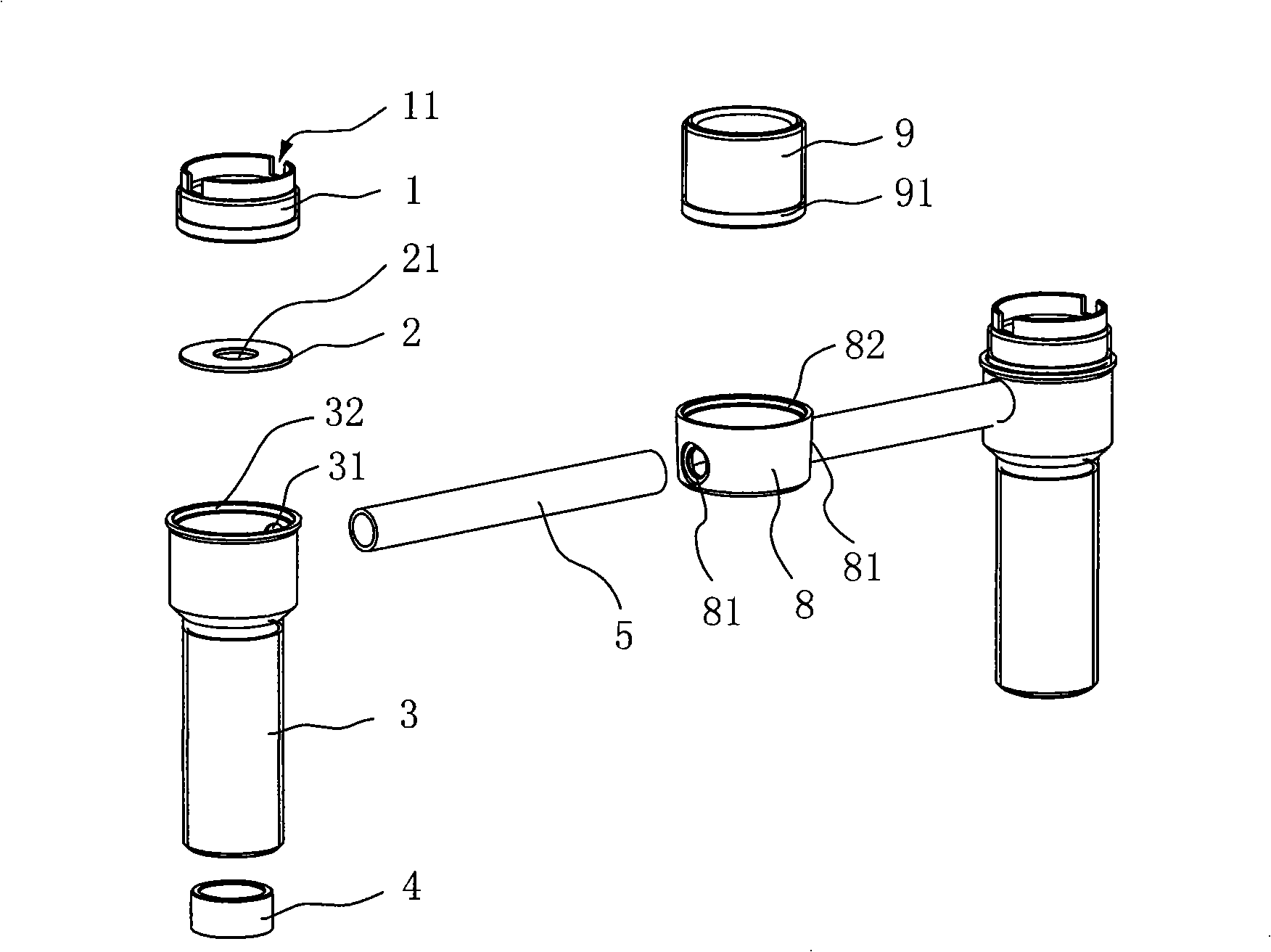

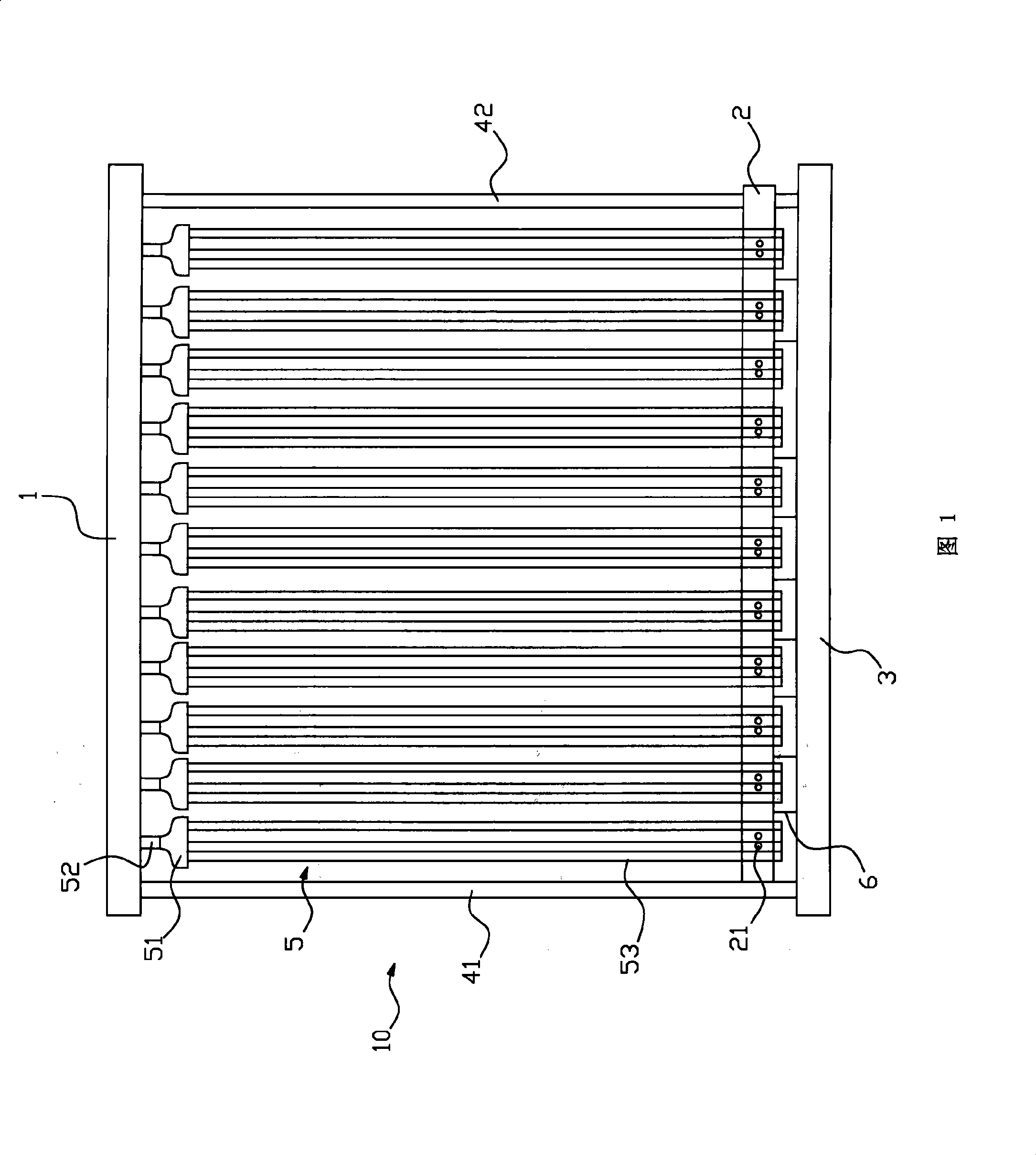

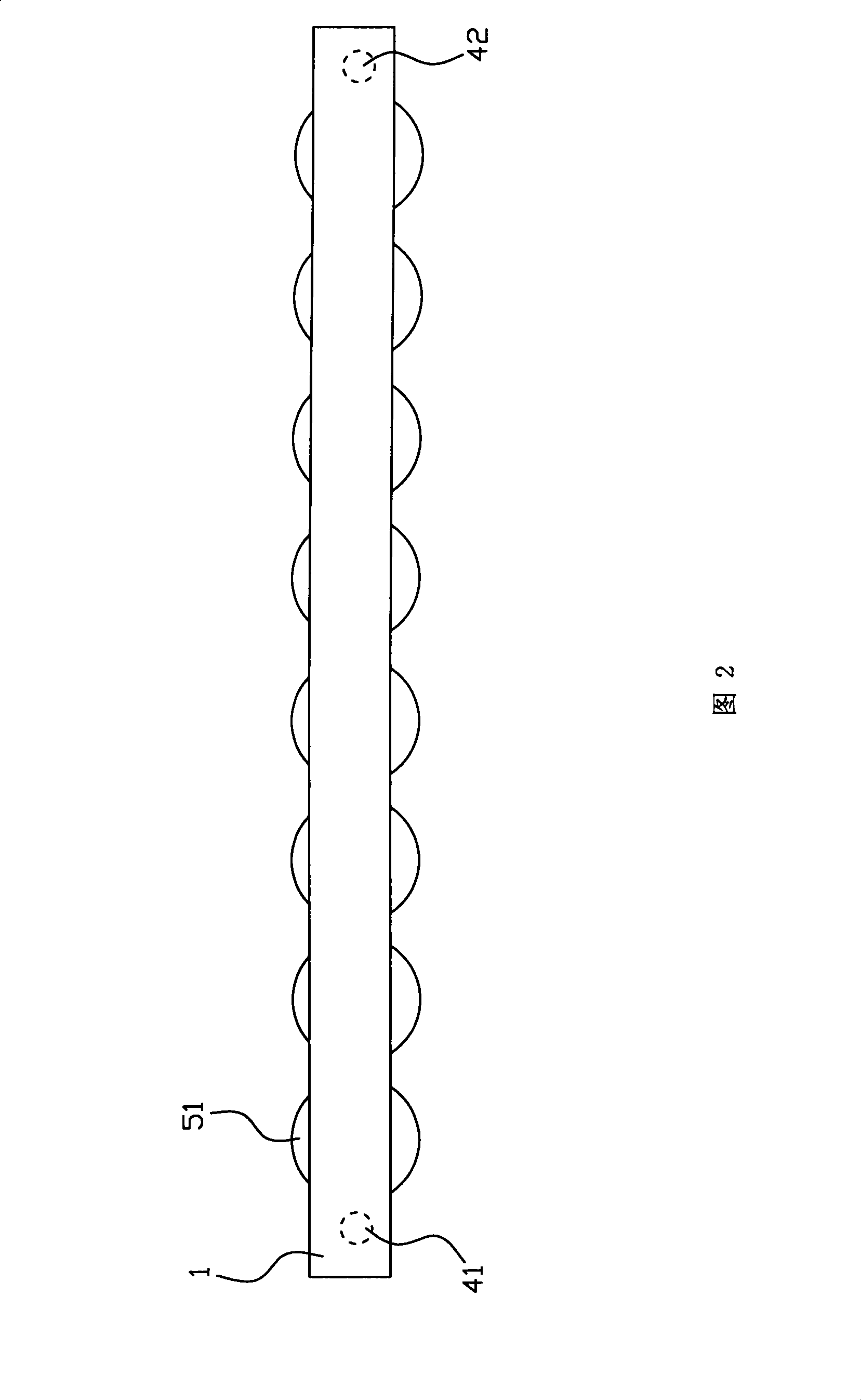

Pore shaft water supply filter assembly and filter system

ActiveCN102764527ASave waterReduce water pollutionSemi-permeable membranesStationary filtering element filtersWave shapeFilter material

The invention discloses a pore shaft water supply filter assembly and a filter system. A filter layer of the pore shaft water supply filter assembly is a filter material which surrounds outside an inner cylinder body to be folded into a wave shape, a pore shaft is arranged outside each folding point of the filter material, which is adjacent to the inner cylinder body, the axial line of each pore shaft is parallel to the axial line of the inner cylinder body, each pore shaft is a pipe body, and all hinges of the filter material are tightly wound on a combination body of the inner cylinder body and all pore shafts along the same direction. According to the filter system, a plurality of filter assemblies are adopted. The filter material is supported by the pore shafts to form an arc surface, clear water of concentrated water, which is filtered from the arc surface, enters the inner cylinder body, and the filter material has no bevels in the arc surface without forming dead angles or causing impurity accumulation or blocking a filter layer; and during backwashing after filtering, a cleaning solution enters the pore shafts from the inner cylinder body through the arc surface of the filter material, so that impurities on the filter layer can be easily washed out and can be discharged out together with the cleaning solution.

Owner:孙世博

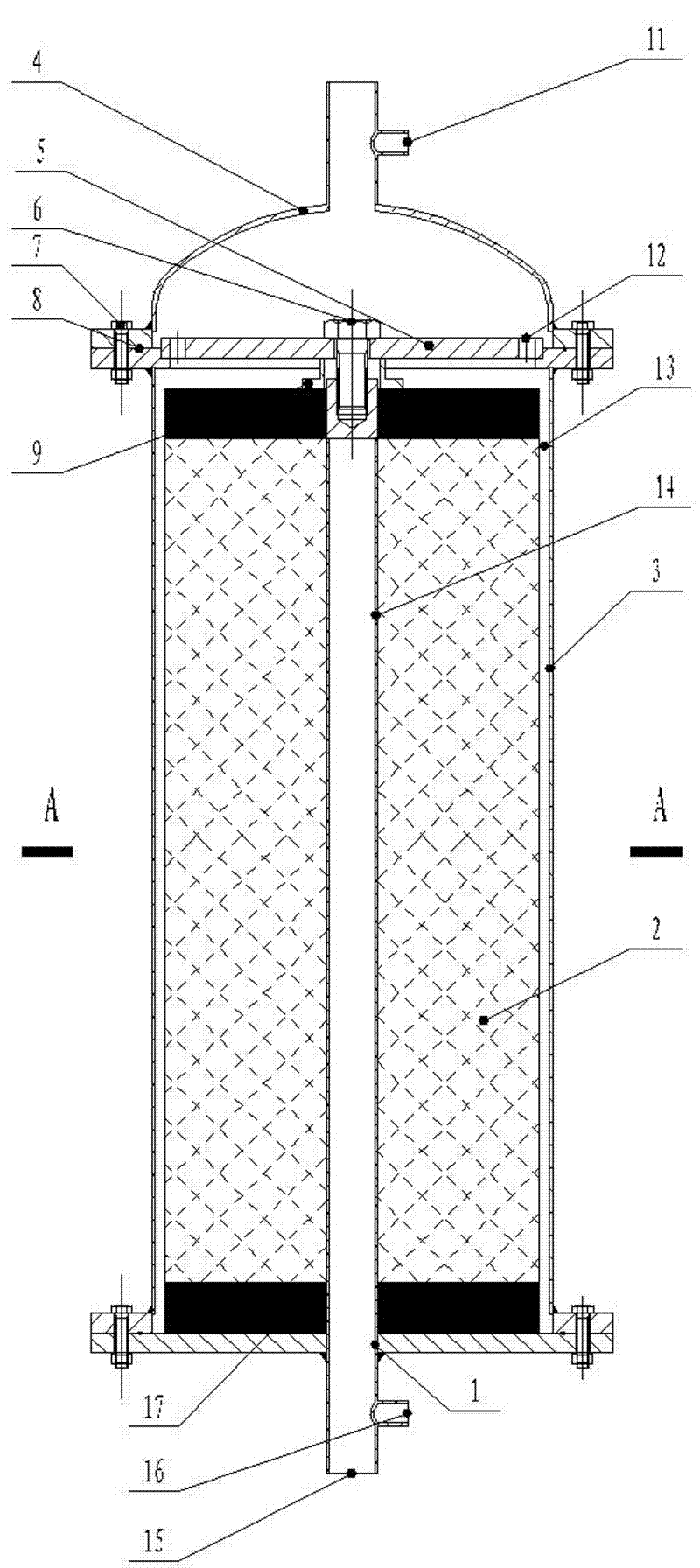

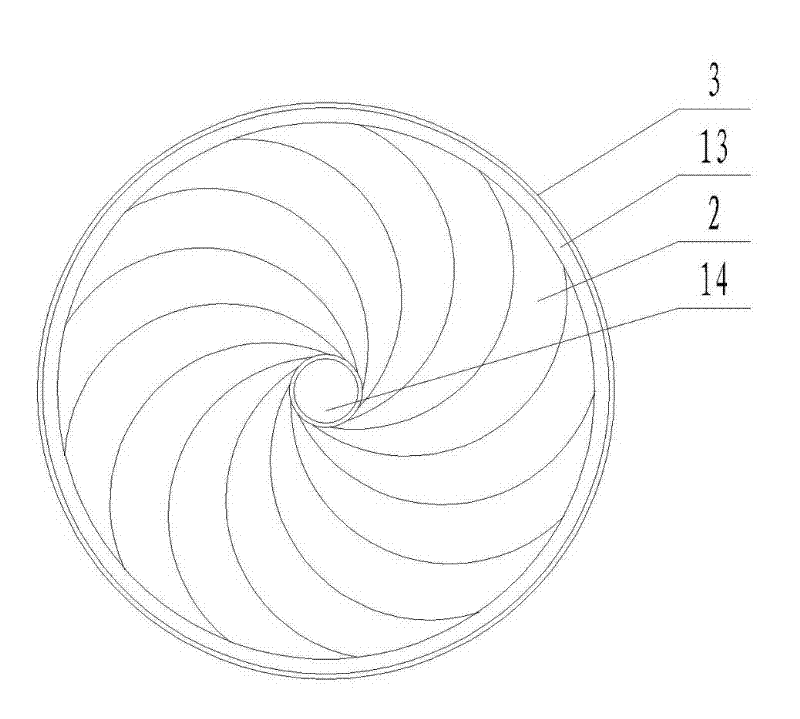

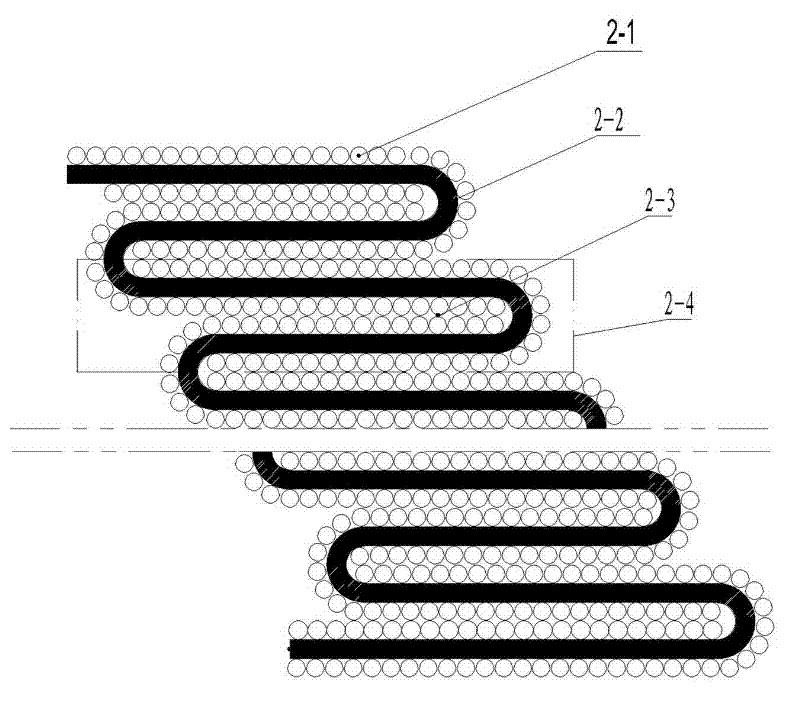

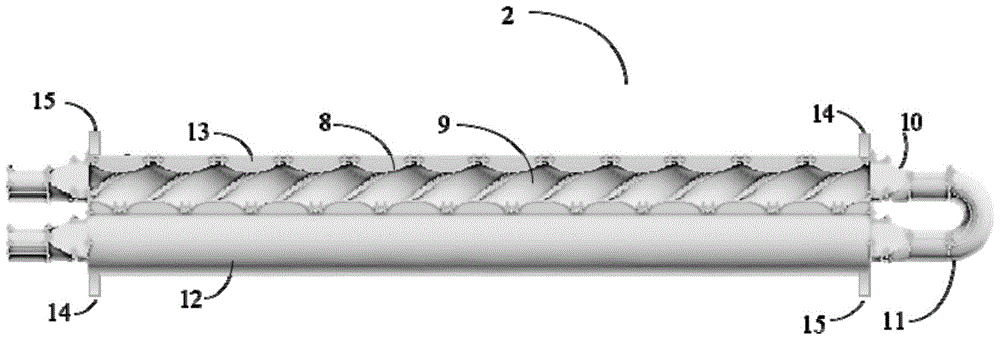

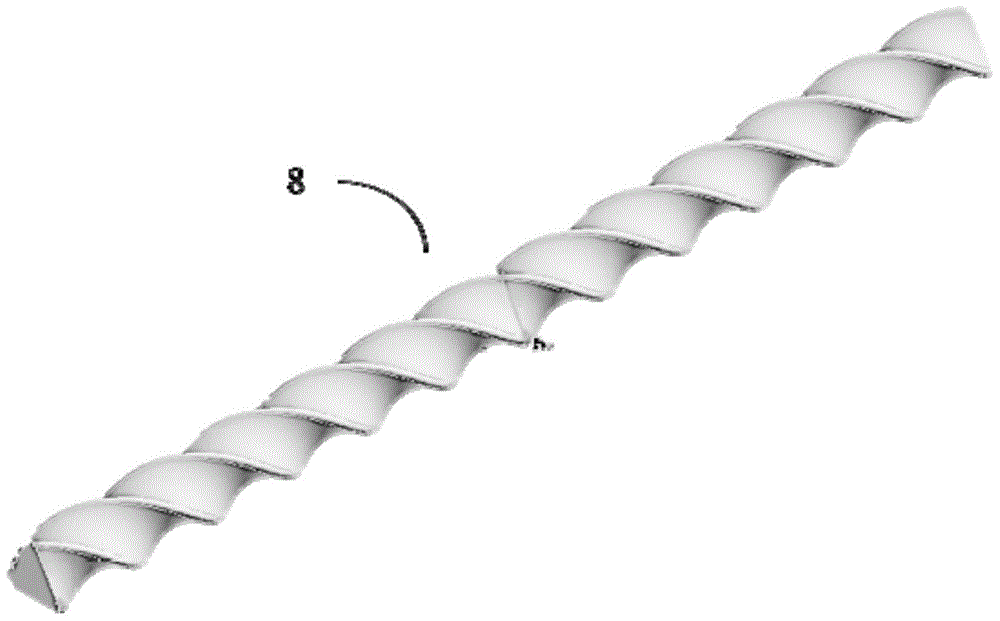

Spiral runner type sewage heat exchanger

InactiveCN102798302ALow flow resistanceSpeed up the flowCorrosion preventionHeat exchanger casingsPlate heat exchangerSewage

The invention provides a spiral runner type sewage heat exchanger. The sewage heat exchanger comprises a barrel, a sewage runner and a clear water runner. The sewage runner and the clear water runner are arranged in the barrel vertically at interval and have common dividing walls, and sewage and clear water exchange heat through the dividing walls. The sewage and the clear water conversely flow in the runners respectively, and trends of the sewage runner and the clear water runner in the barrel are double-head cylindrical spirals. The barrel is a shell of the spiral runner type sewage heat exchanger, is cylindrical, and is placed vertically. The sewage runner comprises a sewage inlet, a sewage pipeline and a sewage outlet; the cross section of the sewage pipe is rectangular and is encircled by an inner wall, the barrel and the upper and lower dividing walls; the swage enters from the sewage inlet on the top of the heat exchanger, and flows from top to bottom along the cylindrical spirals in the sewage pipeline; and the clear water enters from a clear water inlet at the bottom of the heat exchanger, and flows from top to bottom along the cylindrical spirals in a clear water pipeline. The sewage heat exchanger has the advantages of low flowing resistance, scaling prevention and good heat exchange effect.

Owner:HIT HARBIN INST OF TECH KINT TECH

Multifunctional slotted disc type liquid phase distributor

ActiveCN101607169ALow costReduce the overall heightDispersed particle separationFractional distillationSocial benefitsEngineering

The invention relates to a multifunctional slotted disc type liquid phase distributor which is formed by a supporting bottom disc, and is characterized in that the supporting bottom disc is fixedly connected with at least one paratactic rising air cylinder, the inner wall of which is provided with at least one drip tube, the lower part of the drip tube is provided with a drip hole, and the upper part thereof is provided with an overflow hole; a V-shaped liquid collecting plate having the same direction as the rising air cylinder is respectively arranged above the rising air cylinder. The distributor has three functions of liquid collection, liquid separation and gas separation and the like, and has the advantages of simple and compact structure, small volume, light weight, low manufacturing cost and high cost performance; the parameter adjustment range of all parts is large, and the operational flexibility ratio is within the range of 25-120%; the V-shaped liquid collecting plate can be used for catching droplet entrainment in the gas, so that the working efficiency is high; the distributing points are more, gas-liquid distribution is uniform, the gas resistance is small, and the drip hole and filler are not easy to pollute and block up, thus the liquid phase distributor is applicable to the production occasions which easily have entrainment and are easy to block up; in addition, the liquid phase distributor is convenient for installation and wide in application scope. After being popularized and applied, the liquid phase distributor has remarkable economical and social benefits.

Owner:SHALIN METALLIC PRODS JILIN CITY

Ethylene-vinyl alcohol copolymer hollow fiber microporous film and preparation method thereof

The invention discloses an ethylene-vinyl alcohol copolymer hollow fiber microporous film and a preparation method thereof. The hollow fiber microporous film of the invention comprises the following components in percentage by weight: 25 to 60 percent of ethylene-vinyl alcohol copolymer, 40 to 75 percent of thinner and 0 to 15 percent of additive. The preparation method for the hollow fiber microporous film is implemented on the basis of a thermally induced phase separation process. The hollow fiber microporous film prepared by the preparation method has the characteristics of high strength, uniform pore size distribution, high porosity and the like; the pore size of the hollow fiber microporous film is of between 0.1 and 0.5 mu m generally; and the porosity is of between 40 and 75 percent. Therefore, the hollow fiber microporous film of the invention has the characteristics of high water flux and not easy fouling when in use, and can be widely used in membrane bioreactors and other water treatment fields.

Owner:三泰(青岛)膜科技有限公司

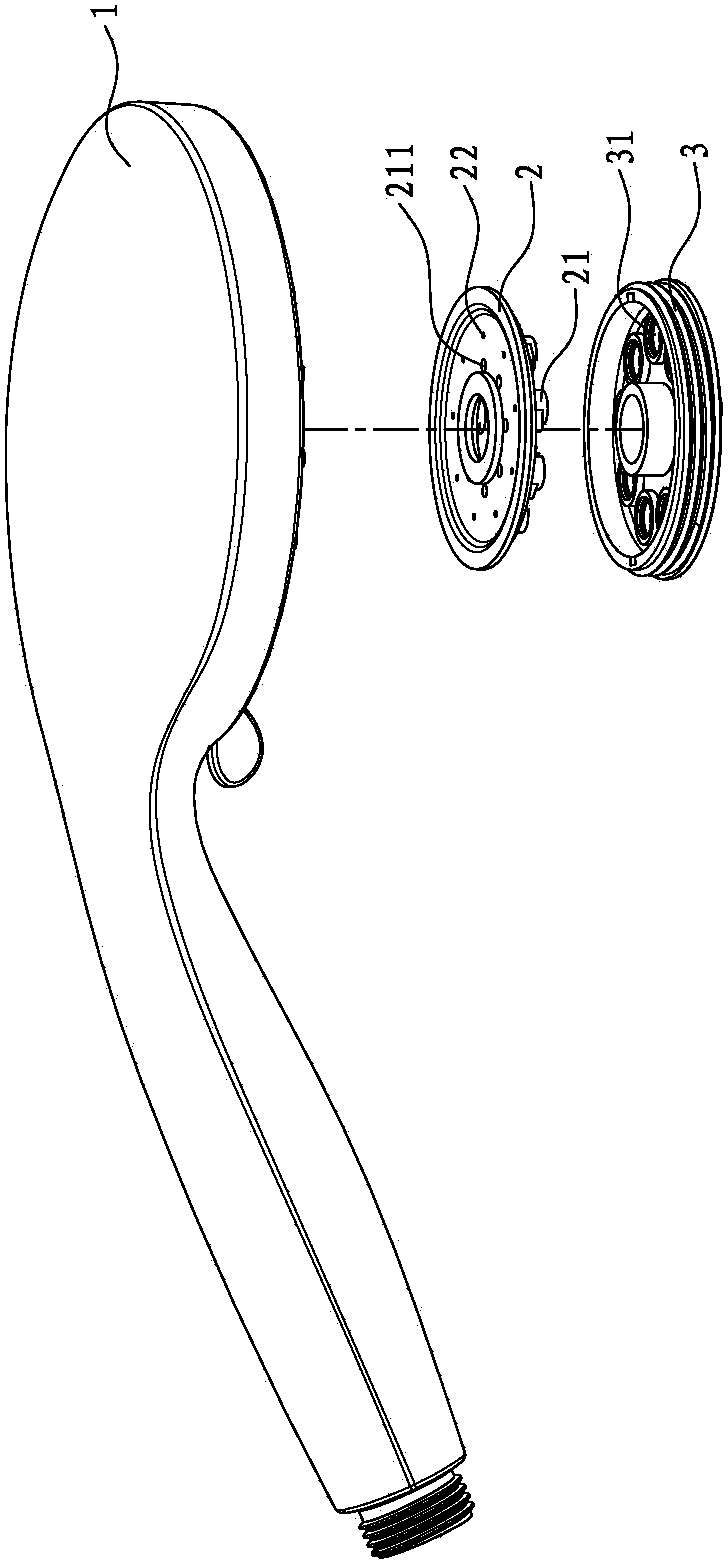

Stainless filiform water sprinkler

InactiveCN103801467ANot easy to accumulate waterNot easy to foulSpray nozzlesSprinkler systemEngineering

The invention discloses a stainless filiform water sprinkler, comprising a sprinkler assembly, a water inlet sheet and a water outlet panel, wherein a plurality of water outlets are formed in the water outlet panel, the upper part of each water outlet forms a hopper port, the surface of each hopper port is a glaze, the water inlet sheet is arranged between the sprinkler assembly and the water outlet panel, and the water inlet sheet is provided with inclined water openings corresponding to the water outlets of the water outlet panel. The phenomena of scale depositing and blocking can be improved, so that filiform spray is generated, and showering is enabled to be more comfortable.

Owner:SINYU TECH FUJIAN

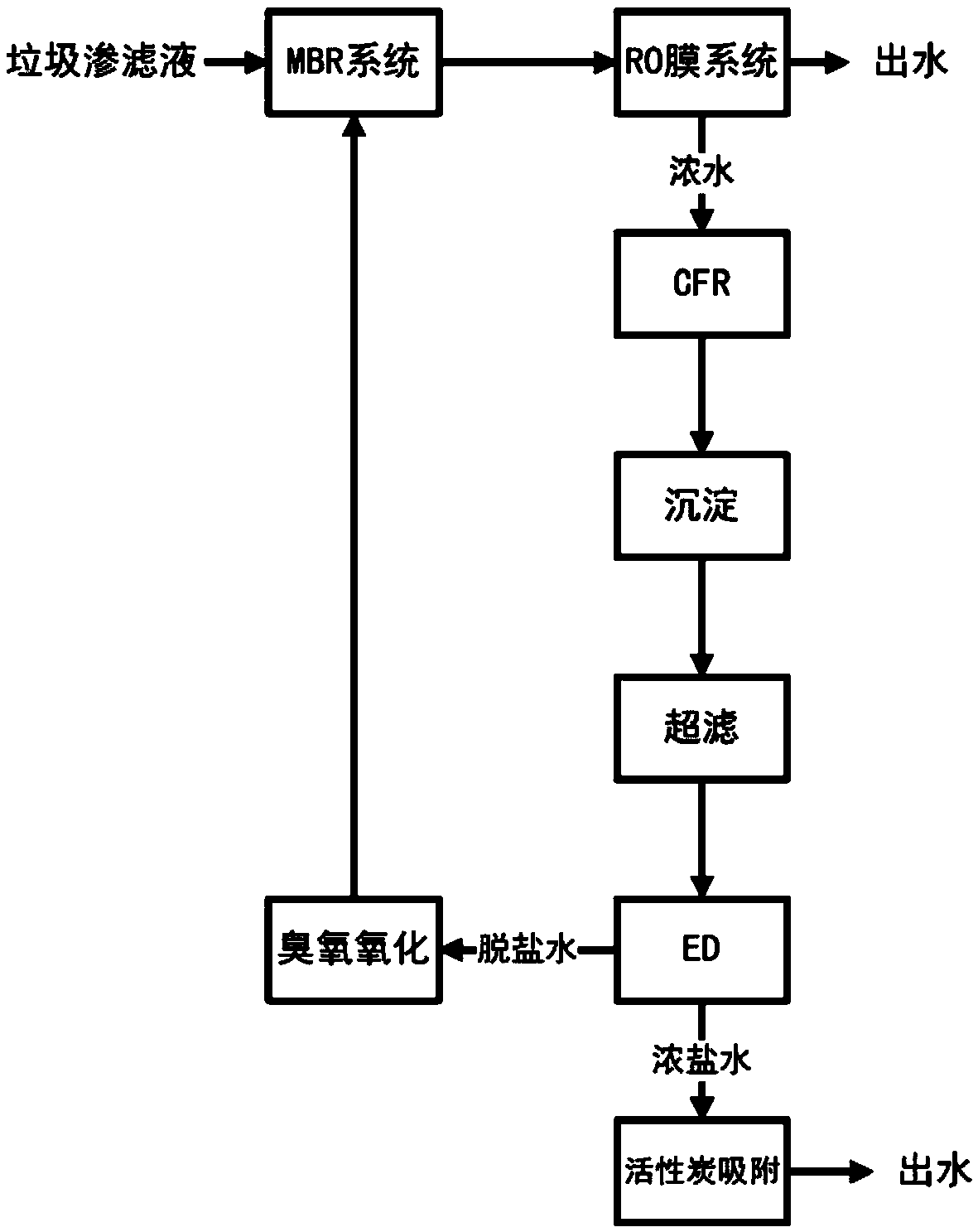

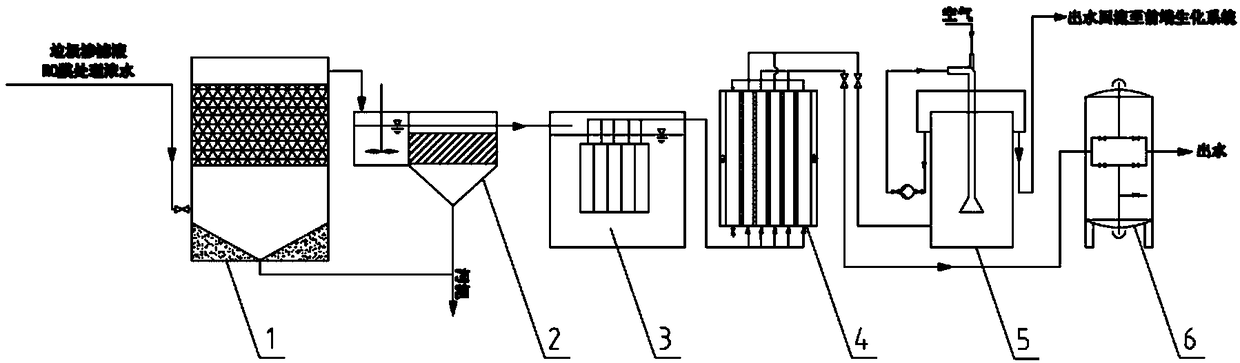

Treatment method for reverse osmosis concentrated-water of landfill leachate

PendingCN108929002AImprove processing efficiencyLow investment costWater contaminantsWater/sewage treatment by ion-exchangeUltrafiltrationCatalytic oxidation

The invention discloses a treatment method for reverse osmosis (RO) concentrated-water of landfill leachate. The method comprises the following steps: after the RO concentrated water enters a CFR forflocculation catalytic treatment, CFR effluent water is subjected to mud-water separation through a sedimentation tank, the supernatant is subjected to built-in ultrafiltration, the effluent water enters an ED system for desalting, the obtained desalted water enters an ozone catalytic oxidation device, the effluent water flows back to an original landfill leachate biochemical system, and the obtained concentrated brine enters an activated carbon adsorption tank to be discharged out or evaporated to dryness without discharge. The method disclosed by the invention can effectively separate organic matter and salts in the RO concentrated water, greatly improve biodegradability of the organic matter, and effectively reduce a concentration of RO concentrated-water pollutants; the desalted RO concentrated water flows back to the original landfill leachate biochemical system without recharge or return spraying, and treatment efficiency of wastewater is improved while secondary pollution is reduced; and in addition, compared with the prior art, the method disclosed by the invention has small activated carbon consumption, a less yield of hazardous waste, a membrane not easy to pollute and block, and significantly-reduced investment and operating costs of treatment of the RO concentrated water.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

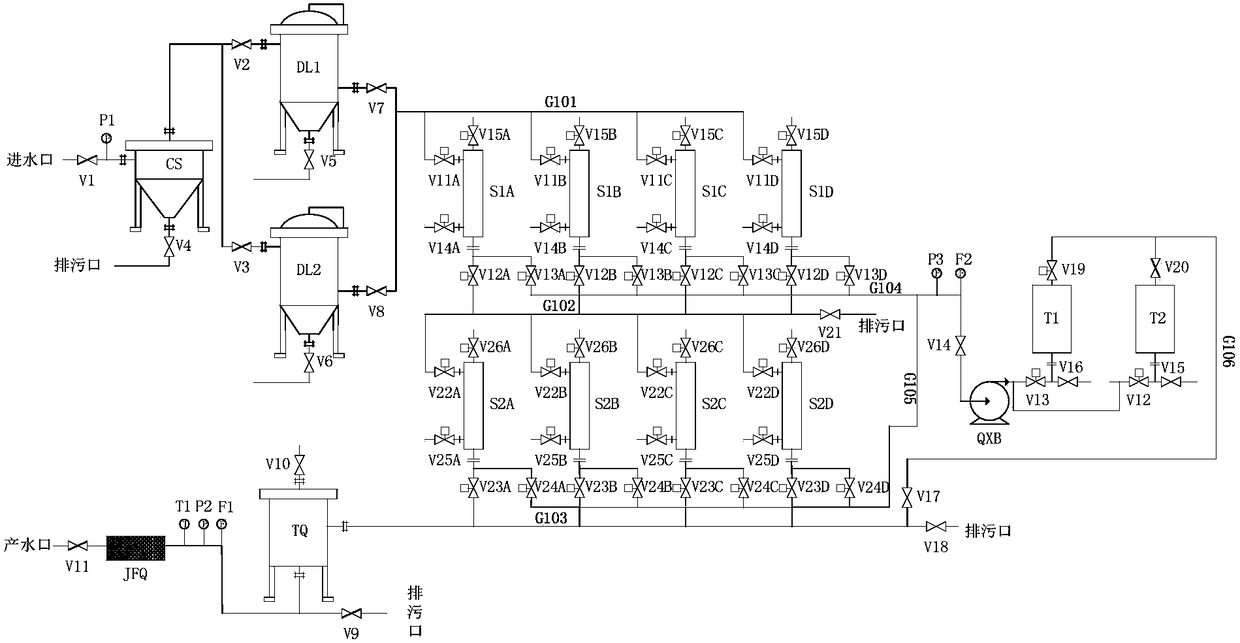

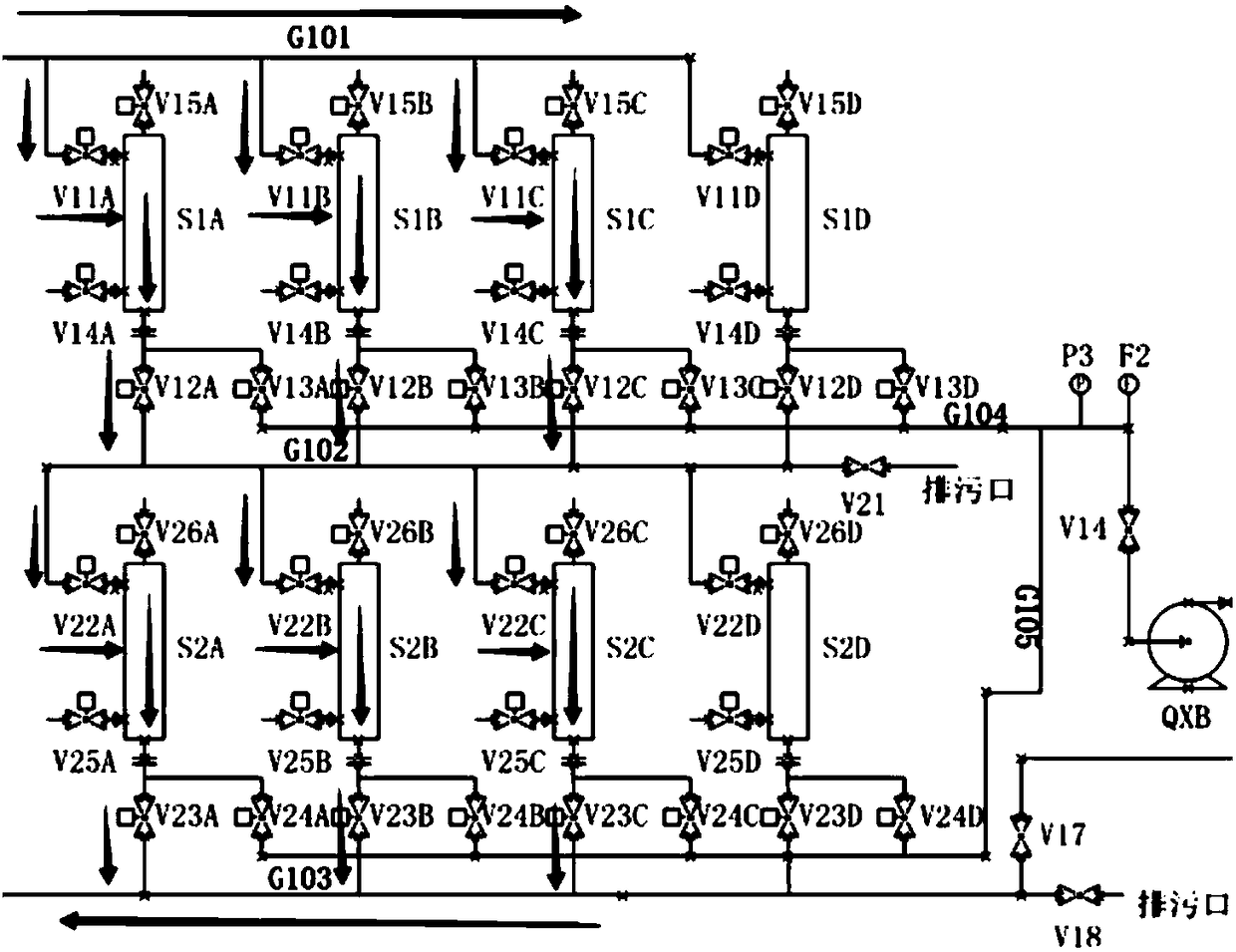

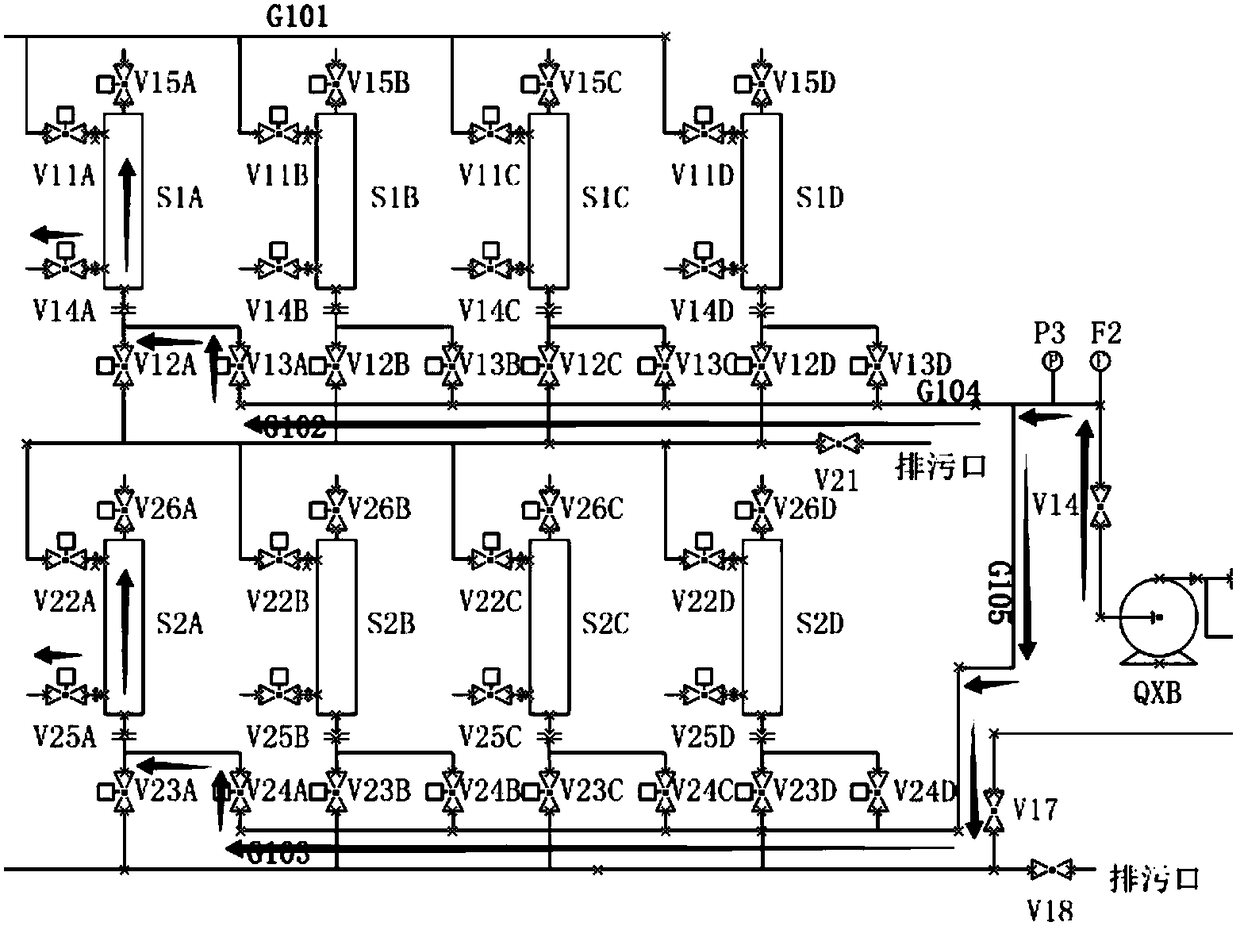

Technological system for treating terrestrial heat tail water by utilizing tubular membrane

PendingCN108314204AReduce processing costsImprove processing efficiencyWater/sewage treatment by centrifugal separationScale removal and water softeningWater treatment systemTechnological system

The invention creatively provides a technological system for treating terrestrial heat tail water by utilizing a tubular membrane. The technological system comprises a cyclone sand remover, bag type filters, a tubular membrane filtering device, a washing tank, a washing ump, a degassing tank and an electric control device; two sets of the bag type filters are arranged; one bag type filter is usedand one bag type filter is standby, and the two bag type filters are alternatively used; the tubular membrane filtering device is divided into two grades; each grade comprises four tubular membrane filters which are arranged in parallel, three tubular membrane filters are used and one tubular membrane filter is standby; the system is provided with a thermometer, a pressure meter and a flow meter;the electric control device comprises a PLC (Programmable Logic Controller) and can realize online automatic backwashing of equipment and prevent fouling and blocking, so that stable operation of equipment is ensured. The technological system takes a tubular membrane as a core and integrates equipment including the cyclone sand remover, the bag type filters and the like to form a technology of treating the terrestrial heat tail water by utilizing a set of water treatment system; the technological system has the advantages of high integration degree, high automation degree, high treatment efficiency and long service life; water treatment can reach reinjection water quality requirements and the treatment cost of reinjection water is greatly reduced.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

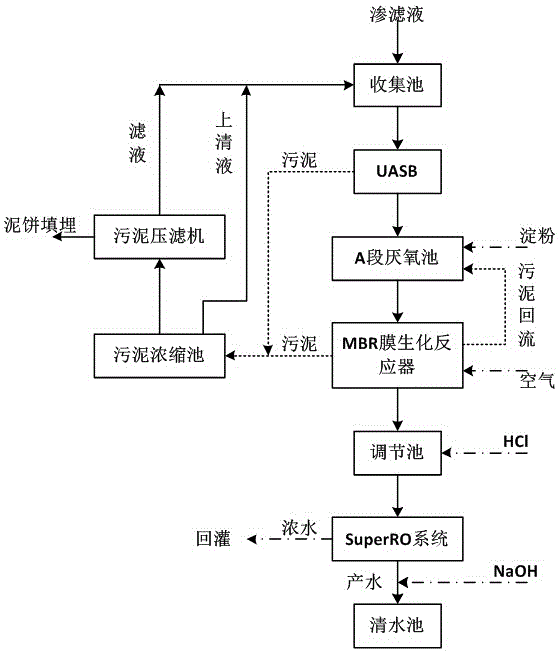

Treatment process for leachate of municipal refuse landfill

InactiveCN105152485AImprove stabilitySimple processSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesNitrationOxygen

The invention discloses a treatment process for leachate of a municipal refuse landfill. The treatment process comprises the steps of collecting to centralize refuse leachate; firstly, carrying out primary anaerobic treatment by using UASB (upflow anaerobic sludge blanket); then, carrying out nitration reaction in an A-section anaerobic tank to remove a great number of suspended matters and ammonia nitrogen; then, carrying out aerobic biochemical treatment and denitrification reaction by using an MBR membrane biochemical reactor to remove most of organic pollutants and COD, and sufficiently removing water entering a SuperRO system in a regulating tank; and finally, carrying out advanced treatment by using the SuperRO system to ensure that effluent reaches the standard. The process is relatively simple, the cost is easily controlled, a membrane system is not easily blocked by pollutants, the stability of the system is better, and the treatment process is particularly suitable for treating the leachate of the refuse landfill; in addition, the treatment process is novel in concept, artful in design, simple, easy to use, wide in application prospect and suitable for popularization and application.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

Novel Ball-ring, and process for making same

InactiveCN101003013AWith acid and alkali corrosion resistanceWith temperature resistance and aging resistanceChemical/physical/physico-chemical processesPunchingTower

Owner:徐关兴

Rapid-radiating water-based aluminium wire drawing liquid

ActiveCN103952220AHigh specific heat capacityFast heat conductionLubricant compositionWater basedSucrose

The invention relates to a wire drawing liquid and particularly relates to a rapid-radiating water-based aluminium wire drawing liquid. The wire drawing liquid is made from the following raw materials of 18 to 22 parts by weight of calcium sulfonate complex grease, 20 to 25 parts by weight of peanut oil, two to three parts by weight of carboxymethyl cellulose sodium, four to five parts by weight of triethanolamine oleic soap, one to two parts by weight of disodium EDTA, six to eight parts by weight of sucrose fatty acid ester, one to three parts by weight of sodium polyacrylate, 0.5 to one part by weight of thiourea, 10 to 12 parts by weight of ethyl carbitol, four to five parts by weight of an auxiliary agent, and 800 to 1000 parts by weight of deionized water. The wire drawing liquid integrates advantages of mineral oil and plant oil, has excellent extreme-pressure and anti-wear properties, and can remain good lubricating properties under high-temperature and high-pressure conditions. By adding the ethyl carbitol, the specific heat capacity and viscosity of the wire drawing liquid can be effectively regulated, a thermal conduction coefficient is improved, heat radiation is accelerated, and damage to dies and wire rods caused by a lot of heat in the wire drawing process is alleviated. The wire drawing liquid is excellent in high-temperature lubricating performance, corrosion-resistant, rust-resistant, not liable to incrustation, uniform and stable in emulsion, and long in service life.

Owner:ANHUI LEESOV IND

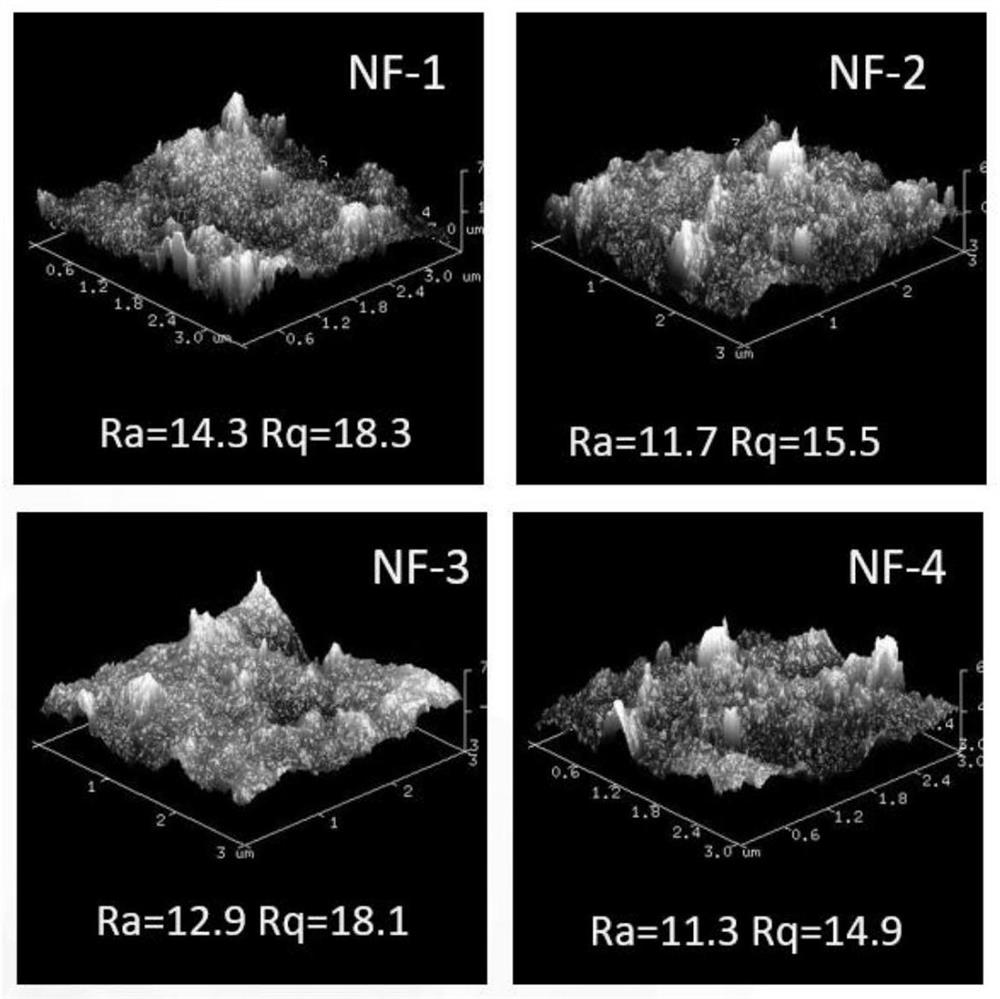

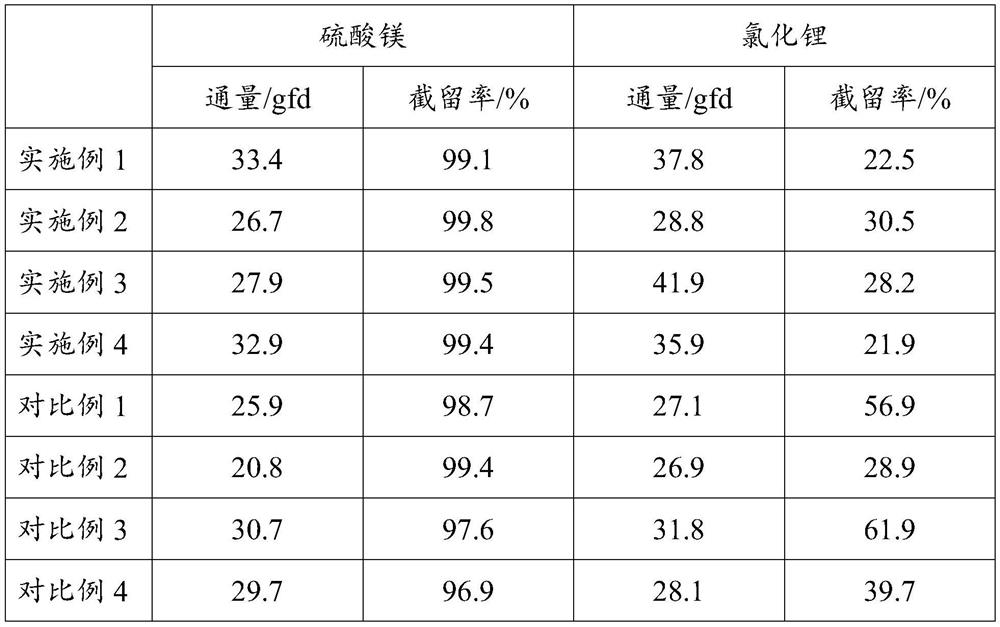

Nanofiltration membrane for extracting lithium from salt lake and preparation method of nanofiltration membrane

The invention belongs to the technical field of water treatment, and particularly relates to a nanofiltration membrane for extracting lithium from a salt lake and a preparation method of the nanofiltration membrane. According to the invention, by using a conventional preparation process, (S)-2, 6-diamino-1-hexanol, polyvinyl alcohol and the like are added into a water phase for preparing a functional layer, and the addition amount of (S)-2, 6-diamino-1-hexanol, polyvinyl alcohol and the like is controlled to prepare a nanofiltration membrane, so that the magnesium-lithium ratio of salt lake brine with a high magnesium-lithium ratio is remarkably reduced after the salt lake brine passes through the nanofiltration system while a relatively good interception effect on boron is achieved, and the lithium extraction efficiency is effectively improved; the membrane is low in surface roughness, good in pollution resistance and low in operation cost; and the method is simple to operate and high in controllability, and large-scale production and commercialization are easy to realize.

Owner:WAVE CYBER SHANGHAI

Double-pipe heat interchanger suitable for sewage with high solid content

InactiveCN106288873ANot easy to foulAvoid easy cloggingCorrosion preventionStationary tubular conduit assembliesSewageEngineering

The invention discloses a double-pipe heat interchanger suitable for sewage with the high solid content. The double-pipe heat interchanger comprises an inner casing pipe used as a sewage channel, and an outer casing pipe providing a heat exchange medium channel. The inner casing pipe is located in the outer casing pipe. The section of the inner casing pipe is triangular, and the inner casing pipe is a triangular twisted pipe formed by spiraling and deforming the pipe wall in the pipe center axial direction. The double-pipe heat interchanger is suitable for sewage with the high solid content, dirt impurities in the sewage are not prone to scaling on the four walls of the sewage channel or blockage, and the heat exchange efficiency and continuous and stable operation of the heat interchanger are ensured; and the pipe pass and shell pass convective heat transfer efficiency of the heat interchanger is quite high, so that the heat interchanger has high heat transfer enhancement performance, and the power consumption of a process pump is small.

Owner:NANJING UNIV OF TECH

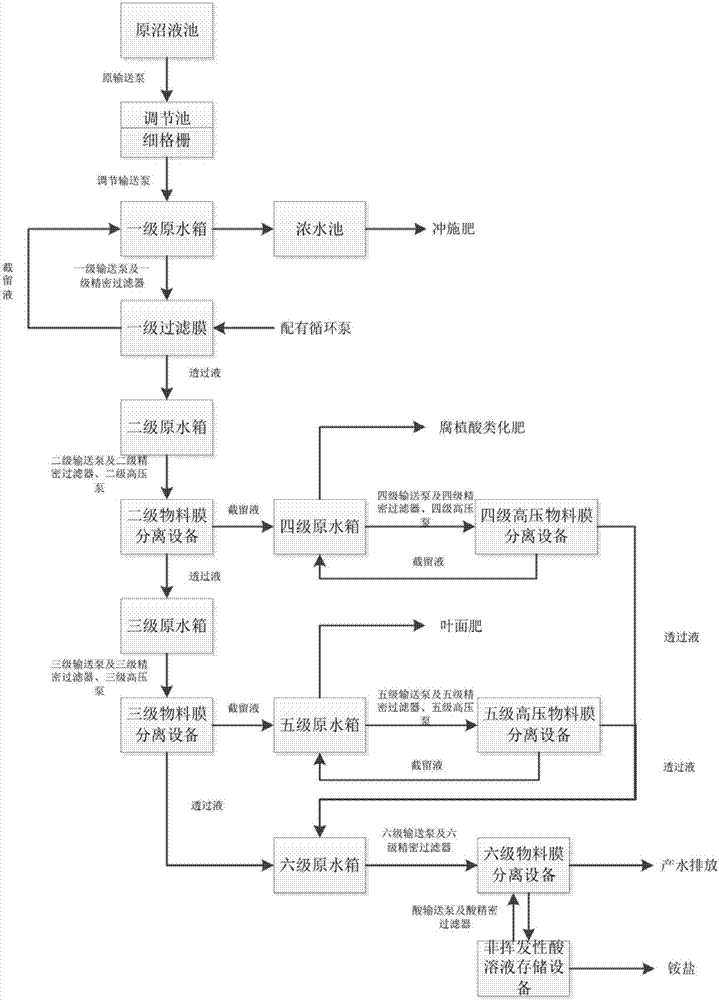

Biogas slurry concentration system and method

ActiveCN107487882AEfficient use ofRealize separation and concentrationWater contaminantsClimate change adaptationAmmoniacal nitrogenProcess engineering

The invention discloses a biogas slurry concentration system and method. The biogas slurry concentration system comprises an original biogas slurry tank, an original conveying pump, an adjusting tank, a fine rack, an adjusting conveying pump, a primary raw water tank, a concentrated water tank, a primary conveying pump, a primary precise filter, a primary filtering membrane, a secondary raw water tank, a secondary conveying pump, a secondary precise filter, a secondary high-pressure pump, secondary material membrane separation equipment, a third raw water tank, a third conveying pump, a third precise filter, a third high-pressure pump, third material membrane separation equipment, a fourth raw water tank, a fourth conveying pump, a fourth precise filter, a fourth high-pressure pump, fourth high-pressure material membrane separation equipment, a fifth raw water tank, a fifth conveying pump, a fifth precise filter, a fifth high-pressure pump, fifth high-pressure material membrane separation equipment, a sixth raw water tank, a sixth conveying pump, a sixth precise filter, sixth material membrane separation equipment, an acid conveying pump, an acid precise filter and non-volatile acid solution storage equipment. By adopting the system, grading and high-magnification concentration of effective components in biogas slurry are achieved, and ammonia nitrogen can be completely extracted.

Owner:杭州碟滤膜技术有限公司

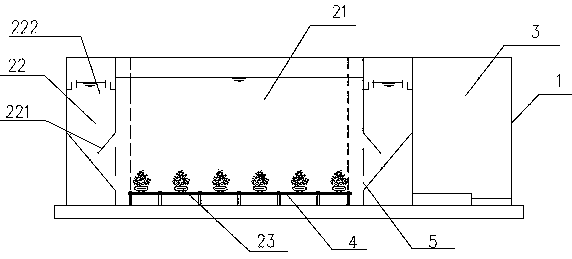

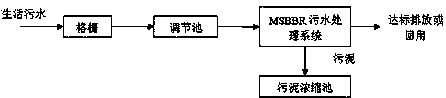

MSBBR wastewater treatment system and wastewater treatment process applying system

InactiveCN108751610APremium removalIncrease concentrationWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemSludge

The invention discloses an MSBBR wastewater treatment system. The MSBBR wastewater treatment system comprises a pond body outer wall, a reaction zone and an equipment zone, wherein the reaction zone comprises a biological reaction zone and a settling zone; the biological reaction zone is arranged at the middle part of the pond body; the settling zone is arranged at the periphery of the biologicalreaction zone; the biological reaction zone is connected with the settling zone through a draining fine seam; an aeration device and a sludge collecting pipeline are arranged at the bottom of the biological reaction zone. Besides, the invention also discloses a wastewater treatment process applying the MSBBR wastewater treatment system. The MSBBR wastewater treatment system disclosed by the invention has the advantages of stable system / technology, high-quality effluent, few constructs, land conservation, low investment cost, low energy consumption, low operation cost and the like.

Owner:四川美源环能科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com