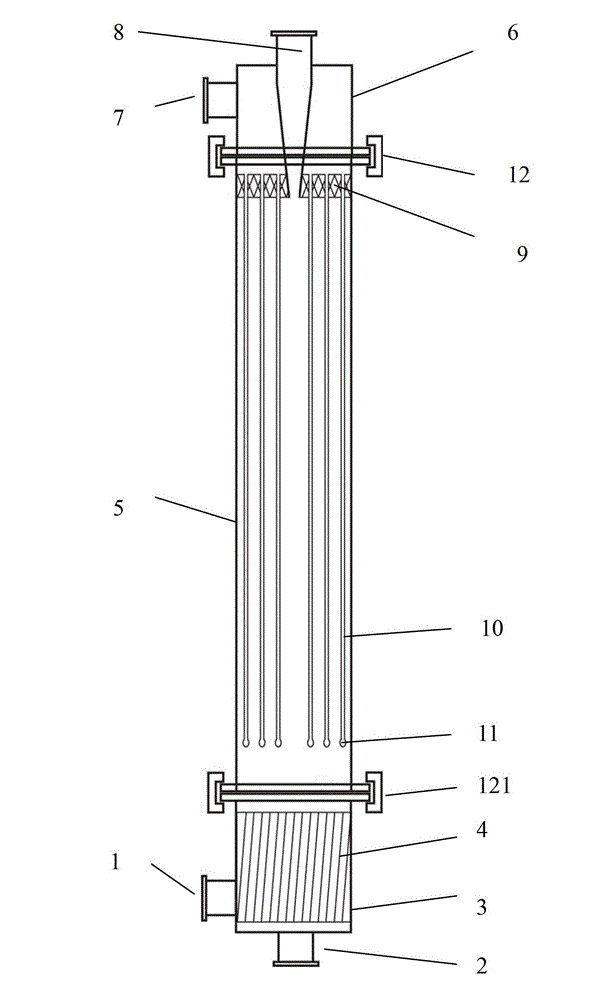

Membrane module for novel efficient membrane bioreactor

A bioreactor and membrane module technology, applied in the field of membrane separation, can solve the problems of low packing density, small effective separation area of membrane modules, high energy consumption, etc., and achieve long service life, high activated sludge concentration and high treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

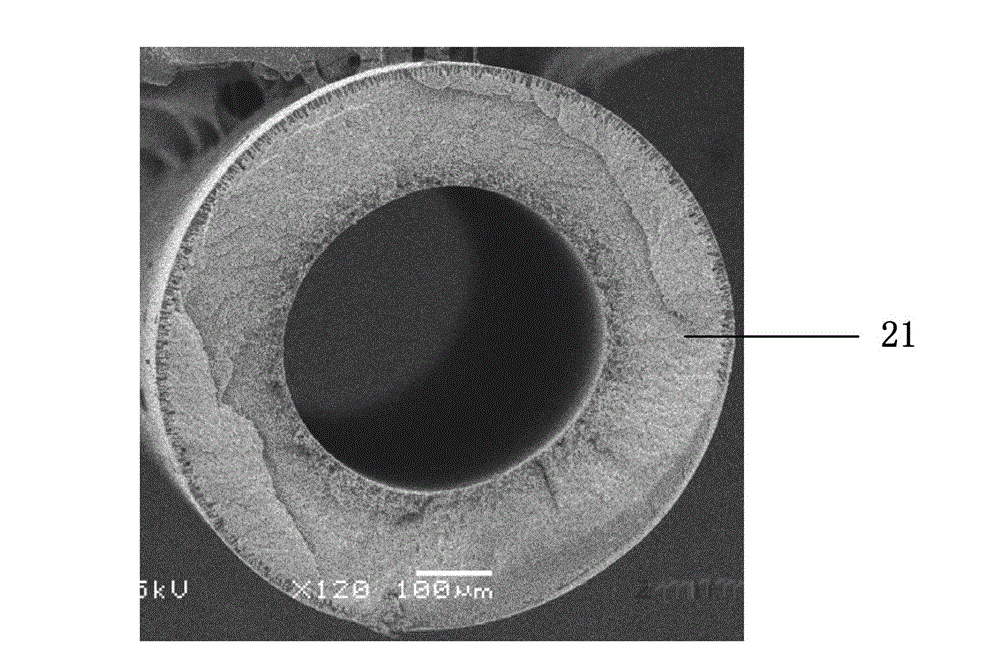

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A certain green algae water purification treatment in Taiwan, the treatment capacity is 0.5 tons / hour, the raw water contains a large amount of green algae, without any pre-filtration, it is directly filtered by the membrane module of the present invention, and the filtered water It is clear and bright, and the operating pressure of the membrane module is only 0.01MPa. The process of filtering for 30 minutes and air-water backwashing for 1 minute can effectively maintain the stable operation of the membrane system. The system has been in operation for three months and has been stable.

Embodiment 2

[0036] Example 2: The treatment of car washing water at a garbage collection station in Shanghai, the treatment capacity is 1 ton / hour, the COD of raw water fluctuates from 680 to 1700, after being treated by the membrane module of the present invention, the COD of the produced water is only 30 to 1000 55. The process of filtering for 15 minutes, air-water backwashing for 40 seconds, and adding sodium hypochlorite to sterilize the membrane system can effectively control the stable operation of the membrane system. The operating pressure is only 0.03MPa. The system runs for one month and runs stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com