Self-cleaning and automatic deslagging filter

An automatic slag discharge and filter technology, applied in the direction of purification using physical methods, can solve the problems of easy blockage and scaling of heaters, high scaling components, and low flow rate of sugarcane juice, etc., achieving simple structure, easy cleaning, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

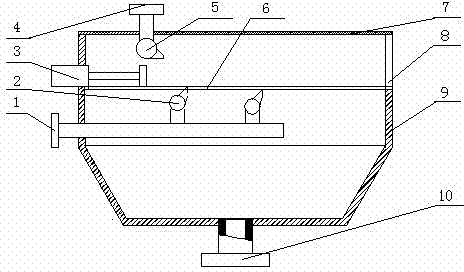

[0016] like figure 1 As can be seen in the schematic diagram of the front view of the structure of the present invention, the self-cleaning automatic slag discharge filter consists of an air inlet pipe 1, a cleaning screen injector 2, a piston pusher 3, sugarcane juice inlet pipe 4, and a sugarcane juice distributor. 5, wedge-shaped screen 6, cover plate 7, solid waste residue discharge outlet 8, housing 9, sugarcane juice outlet pipe form 10 components, wherein the rectangular wedge-shaped screen 6 is housed in the housing 9; A sugarcane juice distributor 5 is established, which is connected to the sugarcane juice inlet pipe 4; a piston slag pusher 3 is installed on the upper surface of the wedge-shaped screen 6, and the solid waste filter cake is continuously pushed from the surface of the wedge-shaped screen 6 to the solid at the other end. The waste residue is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com