Treatment process for leachate of municipal refuse landfill

A technology of municipal waste and treatment process, which is applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficulty in starting, shrinking, and failure to operate. Achieve the effect of good system stability, wide application prospects, and not easy to be blocked by pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

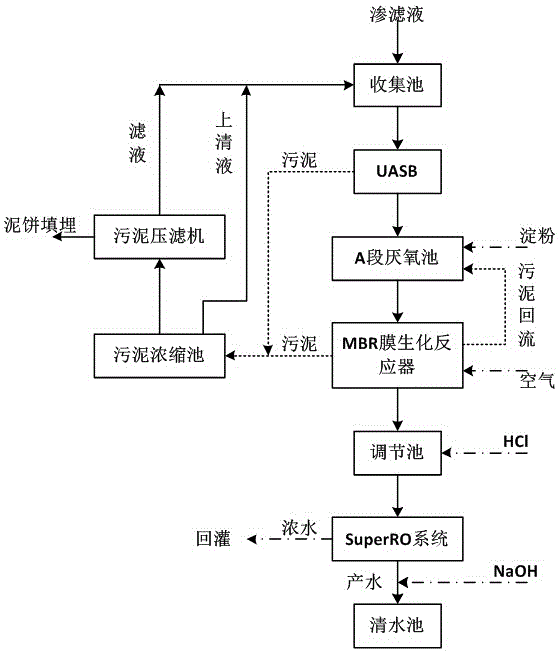

[0036] Such as figure 1 As shown, the leachate treatment process for municipal waste landfills includes the following steps:

[0037] (1) Introduce landfill leachate into the collection tank for accumulation;

[0038] (2) Pass the leachate into the upflow anaerobic bioreactor for anaerobic biochemical treatment, and the generated sludge enters the sludge thickening tank;

[0039] The upflow anaerobic bioreactor (UASB, upflowanaerobicsludgeblanket) consists of three parts: reaction zone, settling zone and air chamber. At the bottom of the reactor is a sludge layer with a high concentration, which is called a sludge bed. On the upper part of the sludge bed is a suspended sludge layer with a relatively low concentration. The sludge layer and the suspended layer are collectively called the reaction zone. Equipped with gas, liquid and solid three-phase separator. Wastewater enters from the bottom of the sludge bed and mixes with the sludge in the sludge bed. Microorganisms decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com