Hollow fiber membrane filtering assembly

A filter module and porous membrane technology, which is applied in the field of hollow fiber porous membrane filter modules, can solve the problems of easy damage to the connection parts of membrane bundles, difficulty in large-scale production, complex structure, etc., and achieve easy maintenance, simple structure, and no fouling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

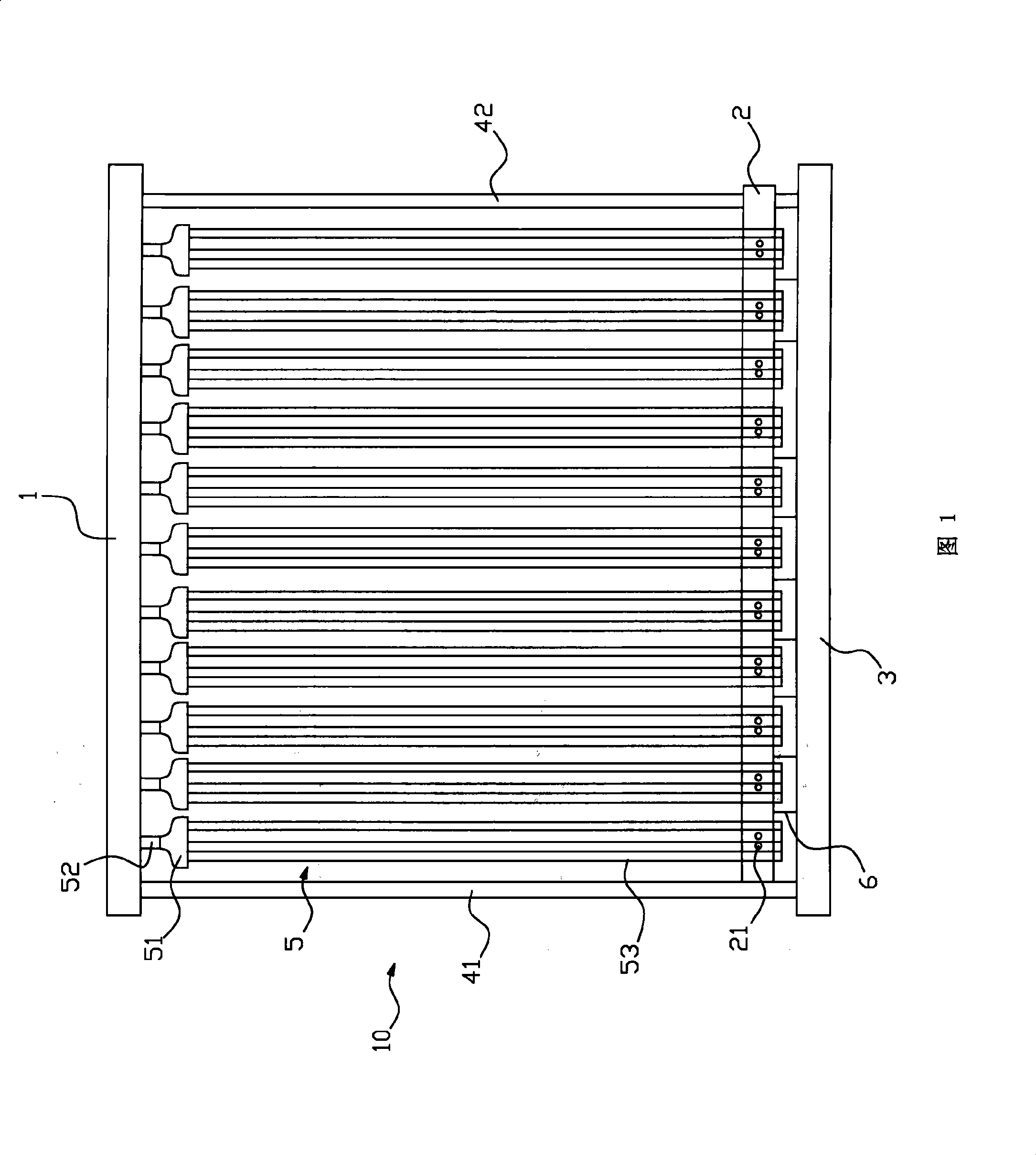

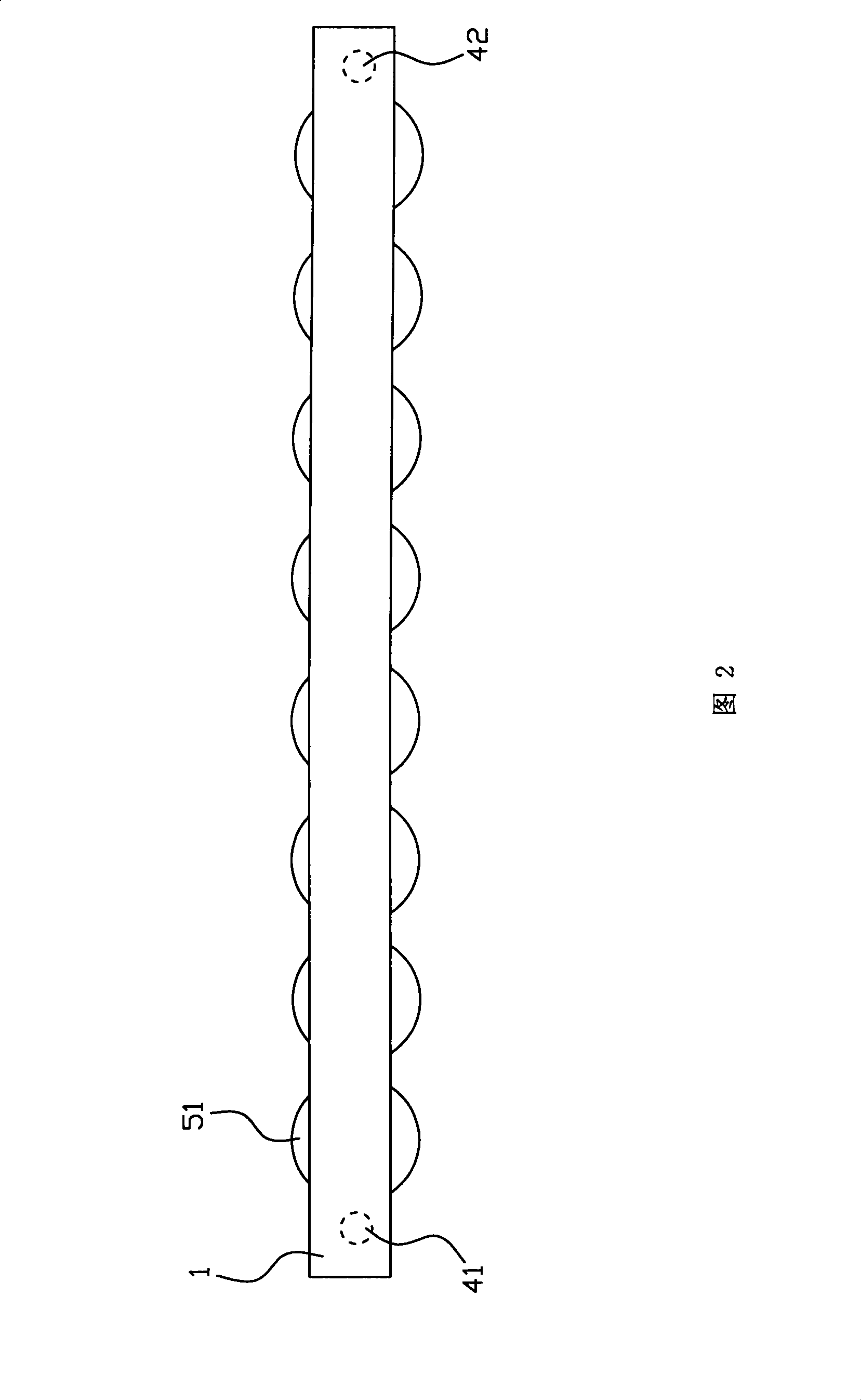

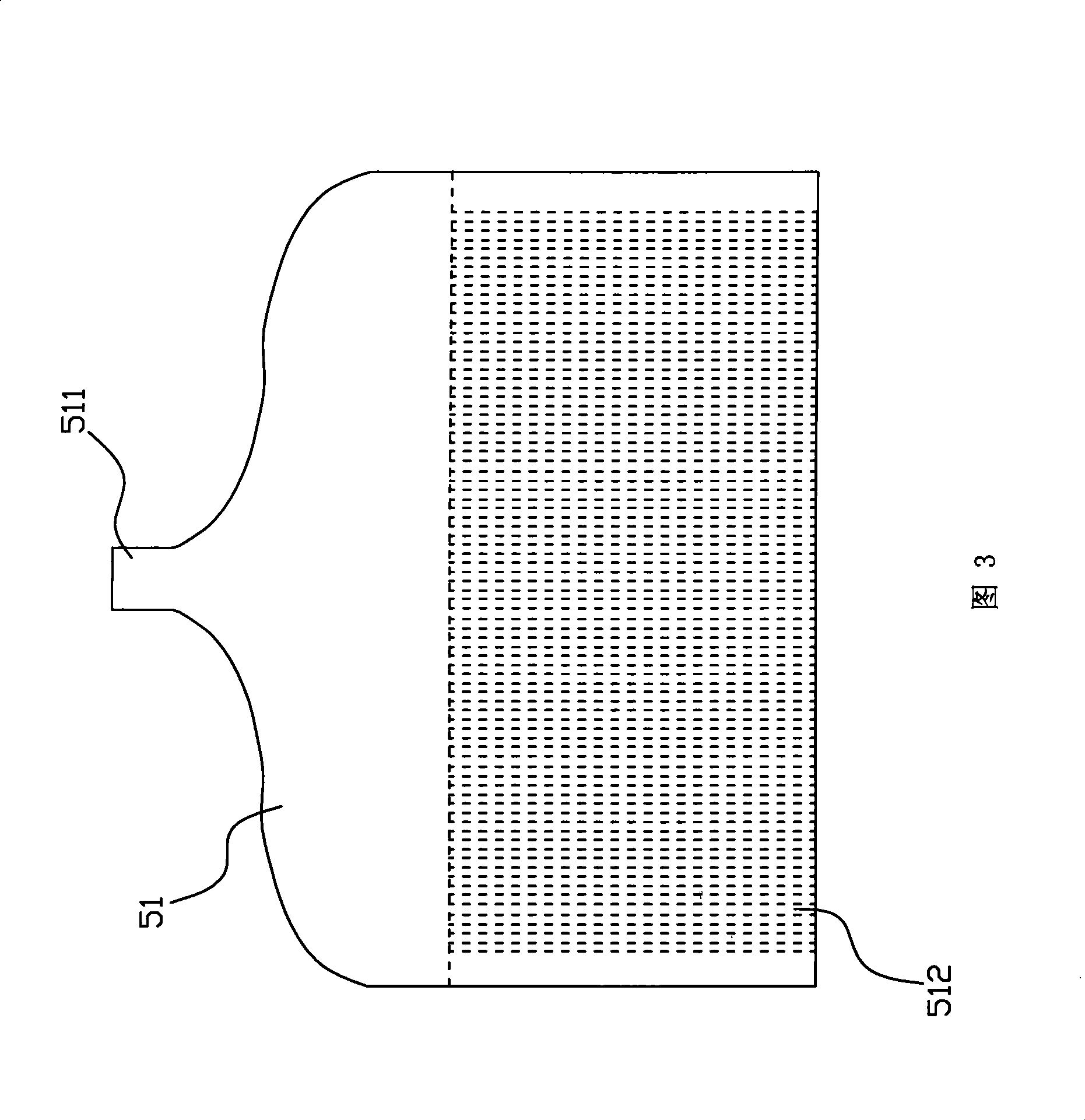

[0024] A hollow fiber porous membrane filtration module, referring to Fig. 1 and Fig. 2, its main structure includes a water outlet pipe 1, a membrane bundle cup 51, an aeration pipe 2 and a hollow fiber membrane bundle 53. Wherein, the water outlet pipe 1 is connected with a water suction pump for discharging filtered water. The water suction pump is not shown in the figure, and the water outlet pipe can be designed as openings at one end or openings at both ends as required. The membrane bundle cup 51 is used for connecting the hollow fiber membrane bundle 53 and communicates with the outlet pipe 1 through the outlet hose 52 . The aeration pipe 2 is communicated with the air source, and its peripheral wall is provided with aeration holes 21 . The hollow fiber membrane bundle 53 is immersed in the sewage to be treated, while referring to Figure 4 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com