Double-pipe heat interchanger suitable for sewage with high solid content

A high solids content, heat exchanger technology, applied in heat exchanger types, indirect heat exchangers, fixed tubular conduit assemblies, etc., can solve the problem of no sewage research and related patents, low convective heat transfer efficiency, and inability to strengthen and other problems, to achieve the effect of no obstruction, low power consumption of pump transmission, and smooth interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the following description should not be construed as limiting the scope of the present invention.

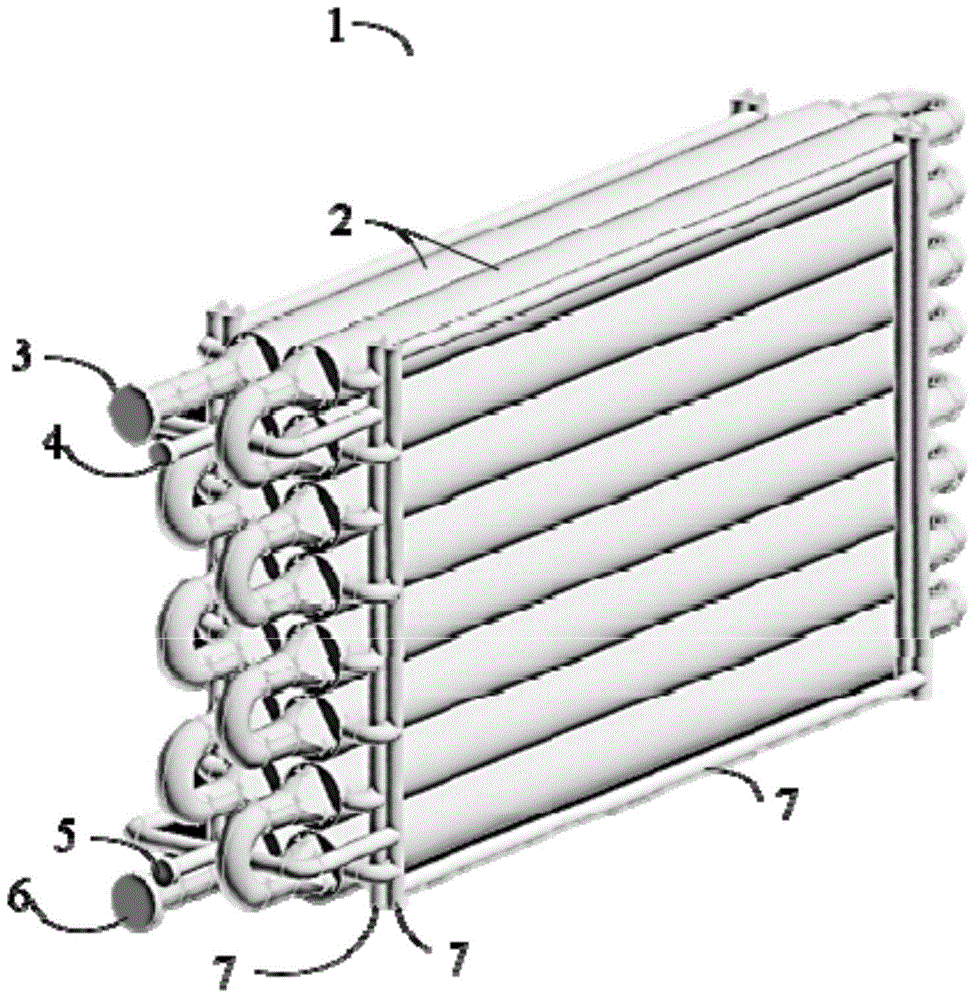

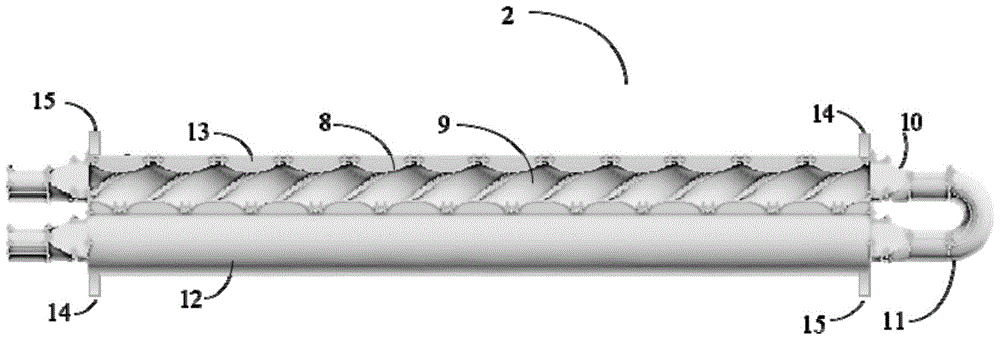

[0032] The casing type heat exchanger suitable for sewage with high solid content of the present invention is mainly used for treating sewage with a high solid particle content of TS of 4-10% (wt%), and has the functions of anti-scaling and anti-clogging and high heat transfer performance. It includes an inner sleeve and an outer sleeve, the inner sleeve is located inside the outer sleeve, the inner sleeve is mainly used as a sewage channel, and the gap between the inner and outer sleeves forms a heat exchange medium channel.

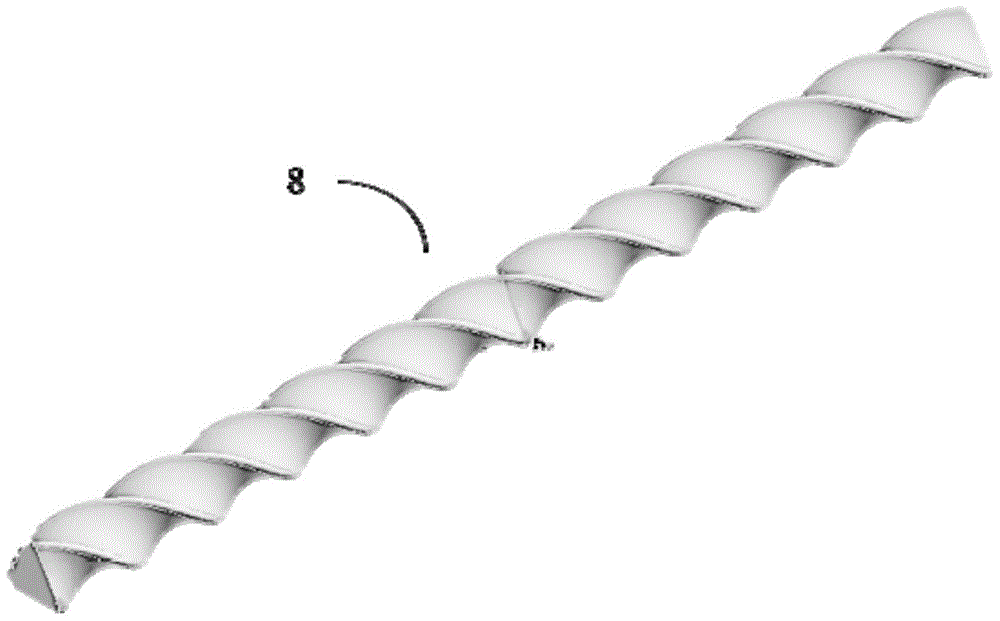

[0033] Such as image 3As shown, the inner sleeve of the present invention is a triangular twisted tube with a triangular cross section and a tube wall helically deformed in one direction along the central axis of the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com