Patents

Literature

209results about How to "With acid and alkali corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

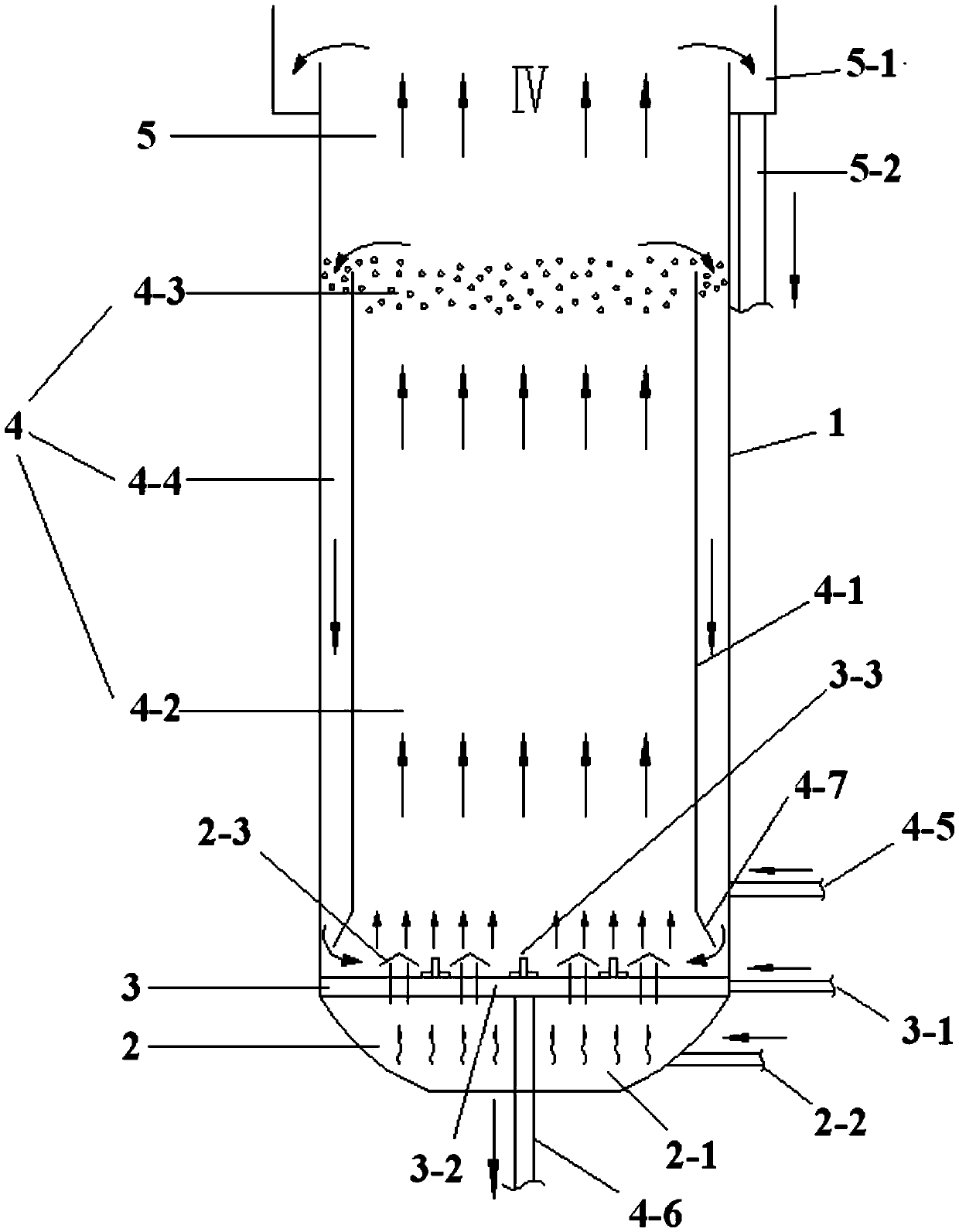

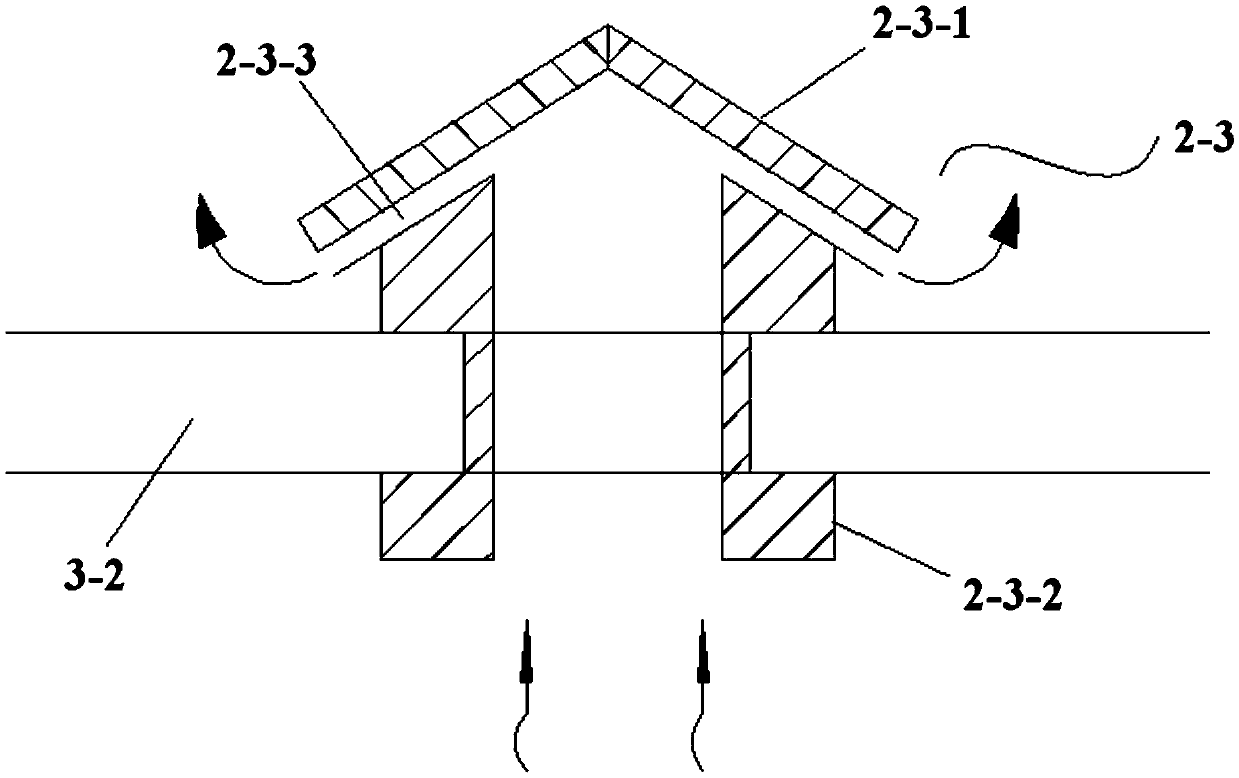

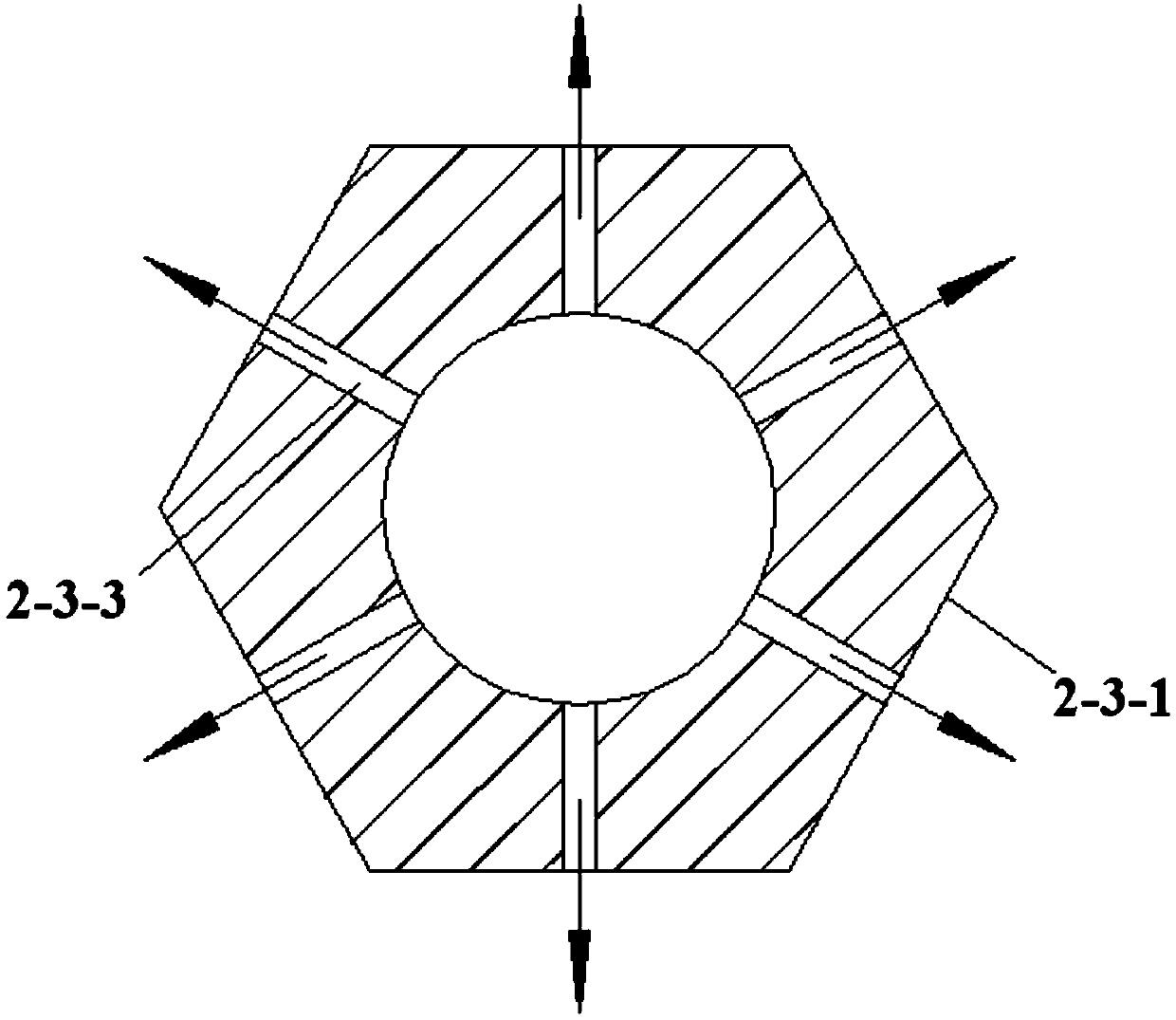

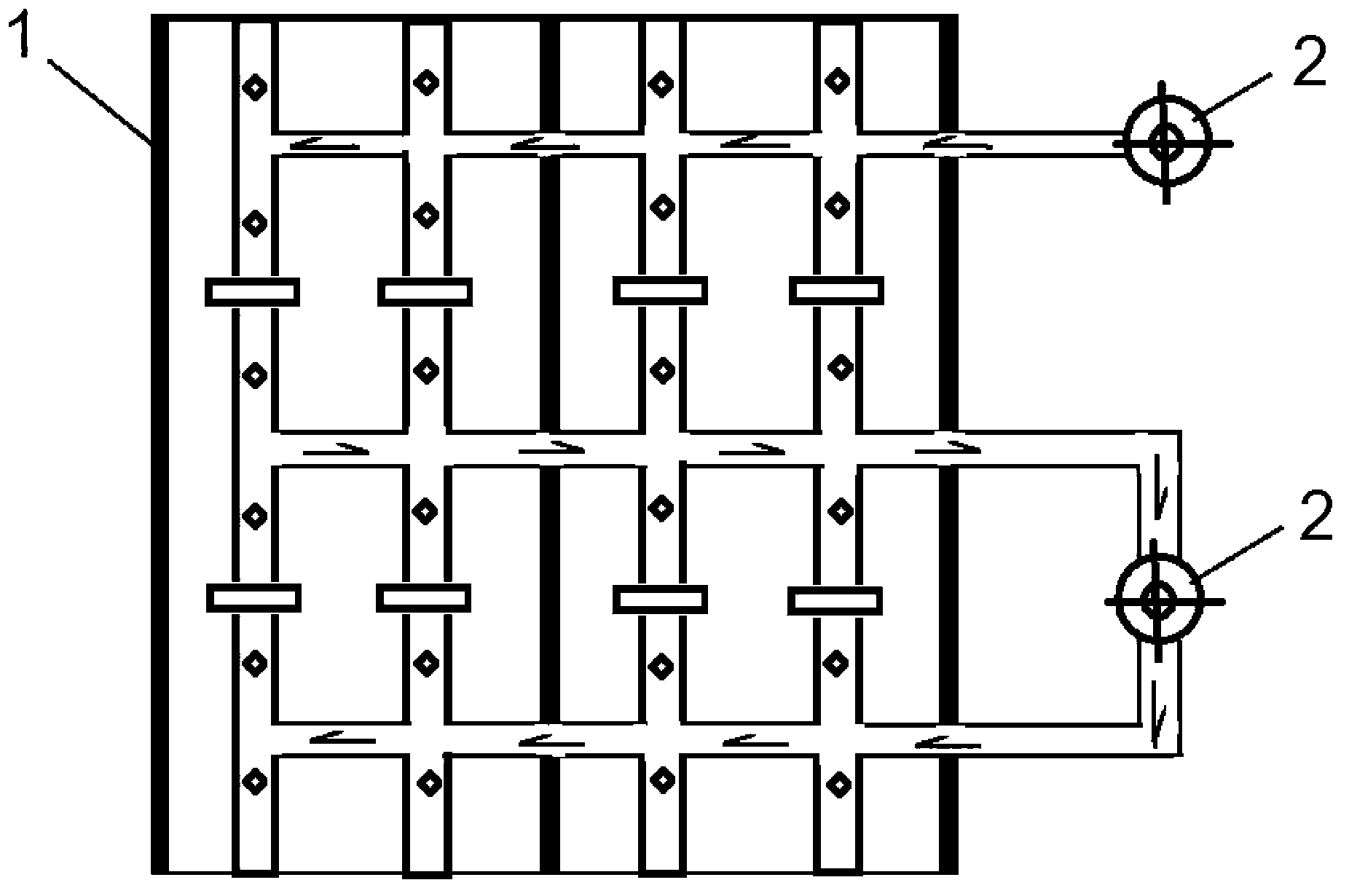

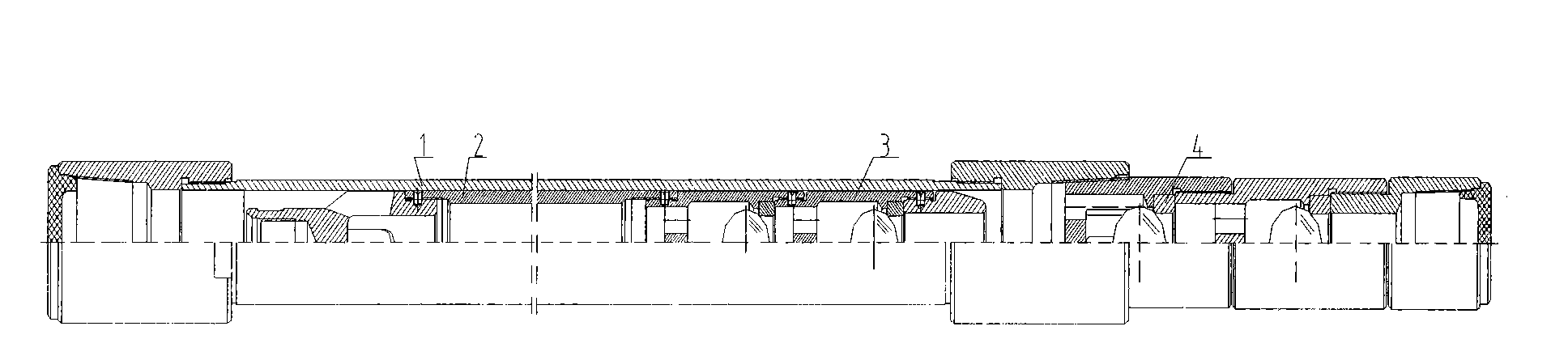

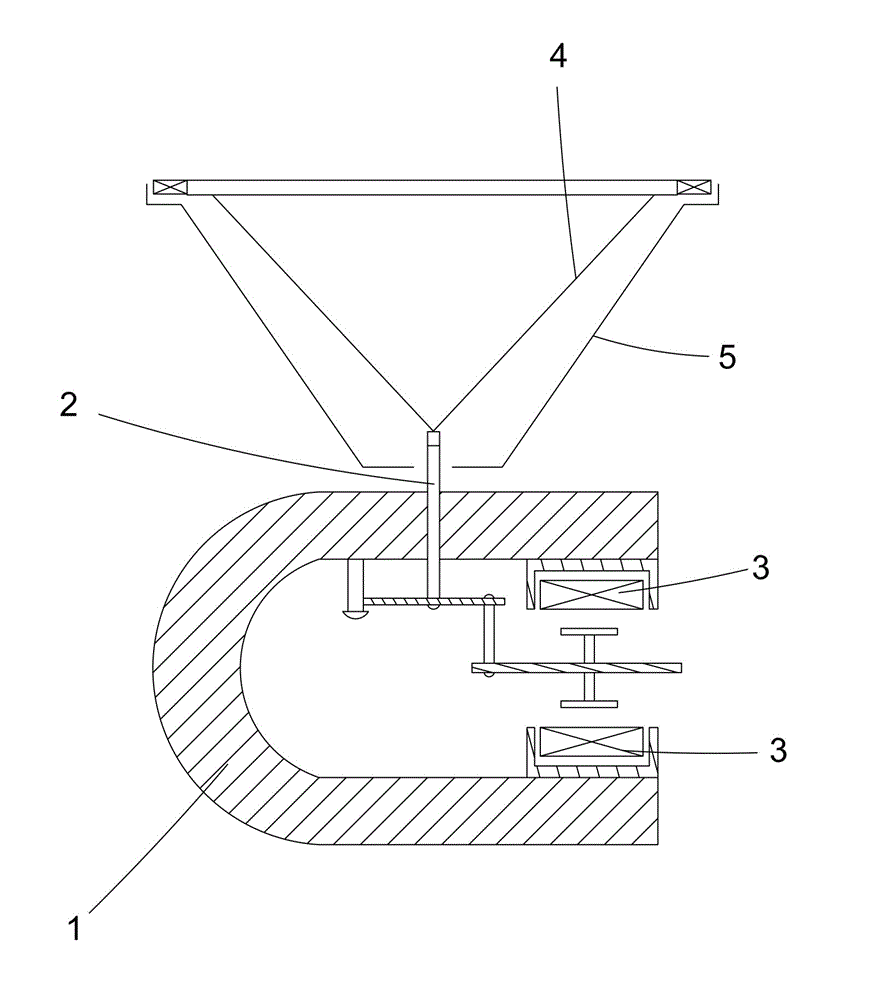

Fluidized bed water treatment device realizing chemical crystallization circulating granulation

ActiveCN105502692AGood processing effectExtended discharge cycleWater contaminantsWater softeningChemical distributionEngineering

The invention provides a fluidized bed water treatment device realizing chemical crystallization circulating granulation. The device is characterized in that a water distribution area, a chemical distribution area, a granulation area and a clear water area are sequentially arranged in a cylinder from bottom to top; the granulation area is divided into three areas by an inner cylinder, an area close to the bottom in the inner cylinder is a fluidization area, an area close to the top in the inner cylinder is a separation area, an interlayer between the inner cylinder and the cylinder is a static settling area; the fluidization area is communicated with a seed crystal adding pipe, seed crystals circularly flow among the fluidization area, the separation area and the static settling area, and ions in water realize the chemical crystallization circulating granulation in the flowing process; the fluidization area is further communicated with a grain discharge pipe, and grains formed through the chemical crystallization circulating granulation are settled to the bottom in the fluidization area and discharged from the grain discharge pipe finally. The overall structure is clear, function units are compactly connected, the plane utilization rate is high, the operation is convenient, a certain single ion in multiple kinds of ions can be removed, and multiple kinds of ions in water can be removed efficiently and synchronously.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

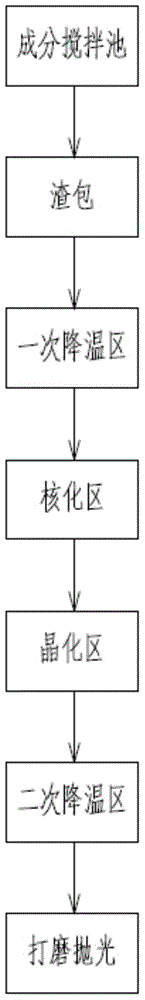

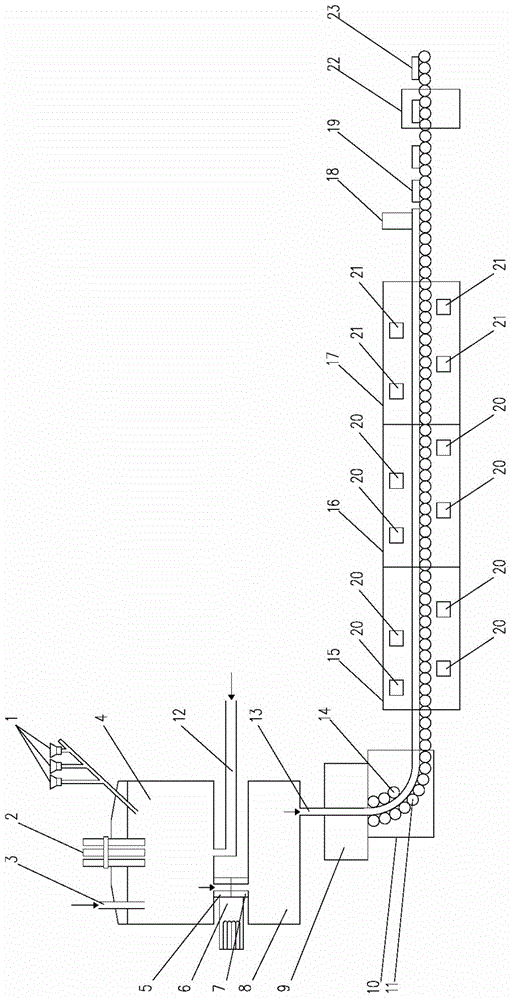

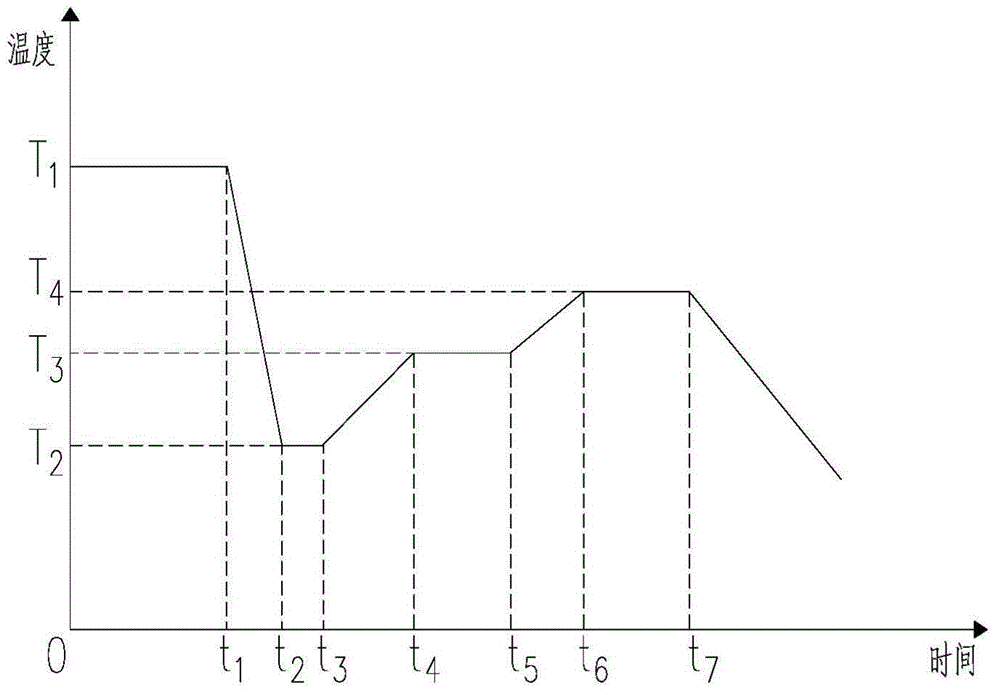

Continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace slag

The invention belongs to the fields of metallurgy and inorganic nonmetal materials, and provides a continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace molten slag. The method comprises the following steps of (1) transferring a temperature interval when the blast-furnace molten slag is maintained in a blast-furnace tapping hole to a component tempering mixing pool, adding and uniformly stirring corresponding modifiers, coloring agents and nucleating agents, and ensuring that the molten slag stays in a high-temperature interval; (2) driving the molten slag to enter a rolling forming area through a slag port and then enter a primary cooling area, and ensuring that the molten slag enters a nucleating area before the temperature of the surface of a shell is not lower than 500DEG C; (3) continuously heating to a crystallization area; (4) entering a cooling area, and cooling the molten slag to obtain a formed product; (5) cutting the formed product in a fixed size and polishing the surface of the formed product to obtain finished product glass ceramics. By adopting the continuous casting and rolling method and the device, the blast-furnace slag and solid waste resource are utilized, the produced glass ceramics have the advantages of high strength and acid and alkali corrosion resistance, and the economic benefit and the environment-friendly benefit are obvious.

Owner:UNIV OF SCI & TECH BEIJING

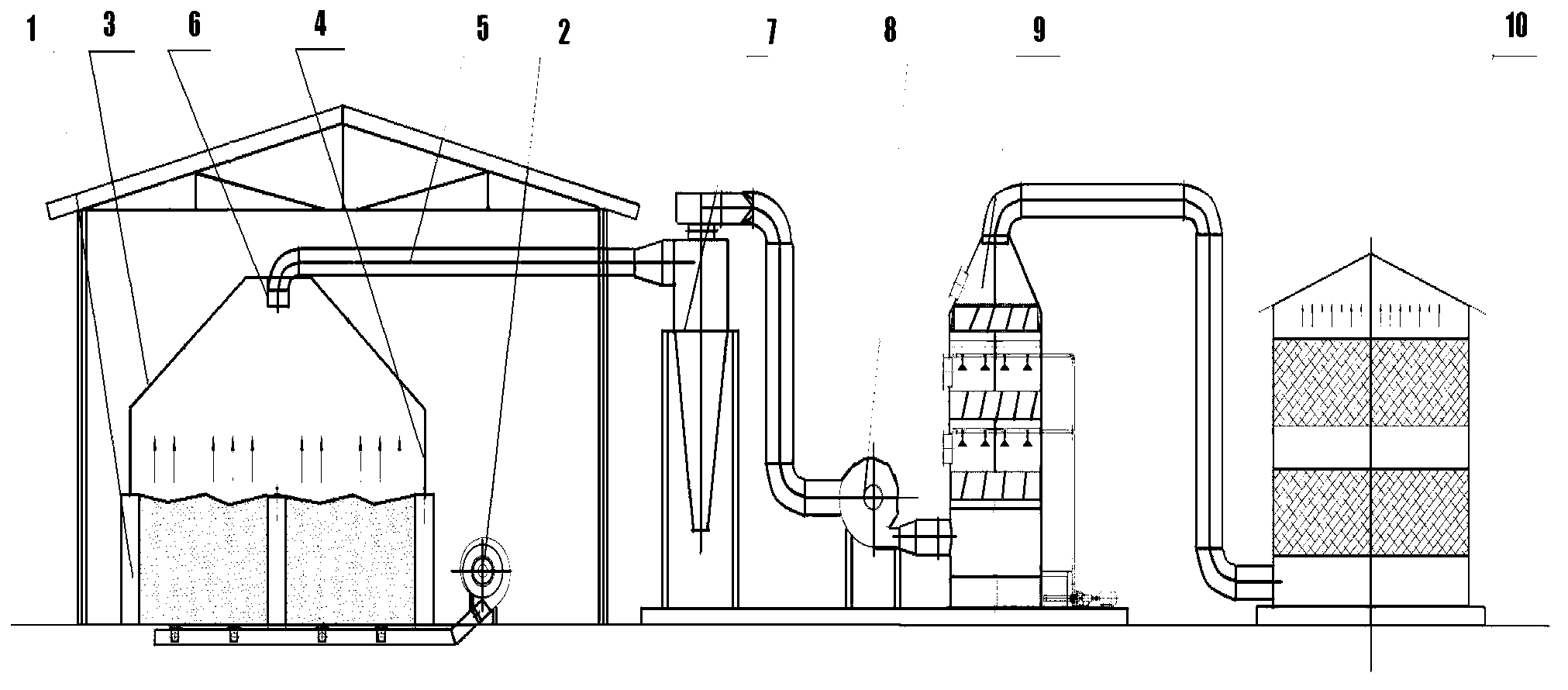

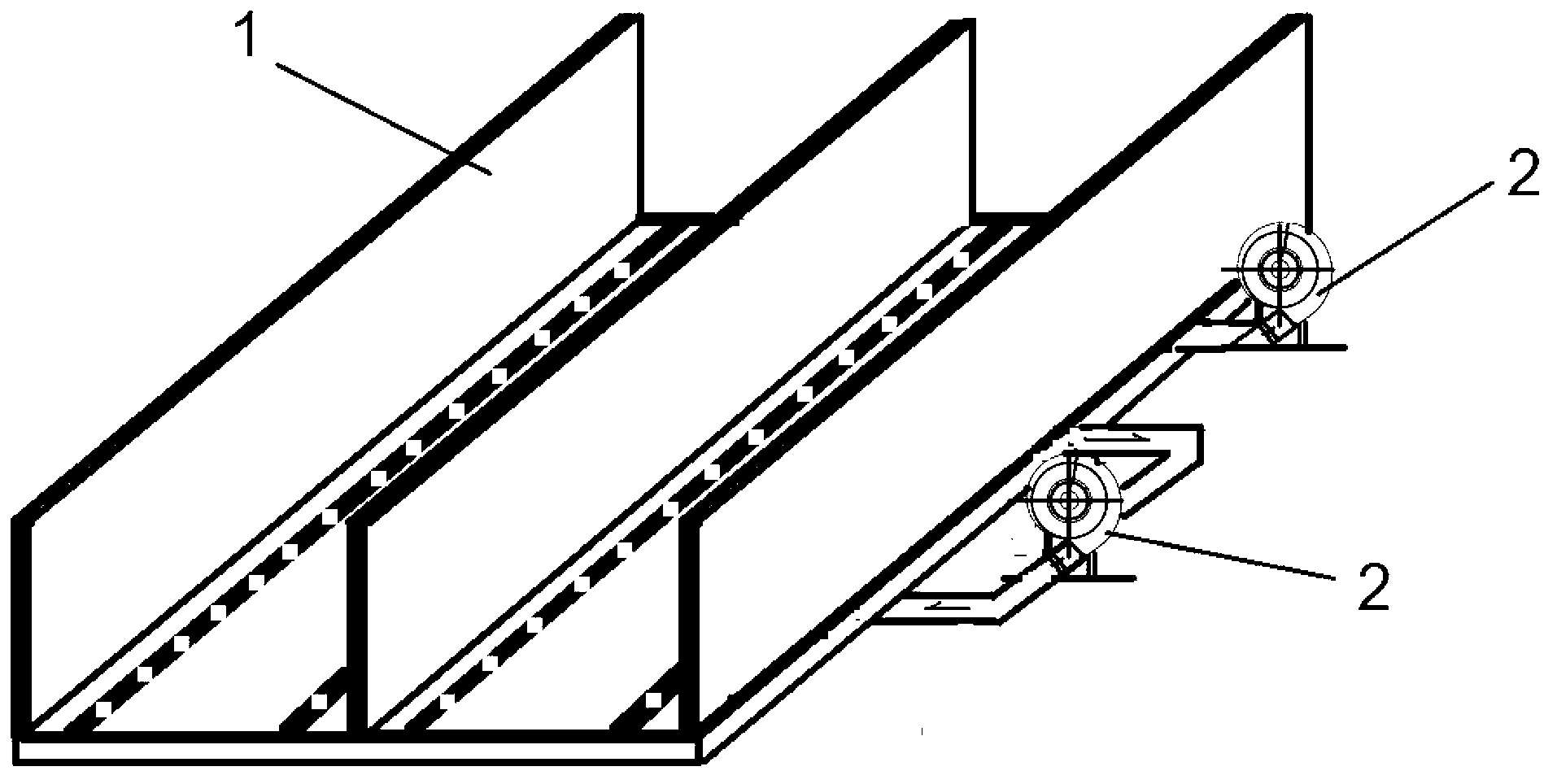

Emission reduction, collection and processing method for trough-type aerobic composting odors

ActiveCN103242073AEmission reductionHeating up fastClimate change adaptationOrganic fertiliser preparationEngineeringTower

The invention discloses an emission reduction, collection and processing method for trough-type aerobic composting odors. The method comprises the steps that composting raw materials are added to composting troughs, and odors produced by the composting troughs are collected by a gas collecting hood under the sheltering of a roller shutter, are led into a wind pipe through a draught fan, enter a cyclone dust remover so as to be subjected to dust removal, enter a deodorization tower and then enter a biofilter after the odors are processed by the deodorization tower. The method disclosed by the invention has the advantages that the odor emission can be effectively reduced, and the composting efficiency can be increased; and odor ingredients can be better collected and removed in an open aerobic composting environment.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

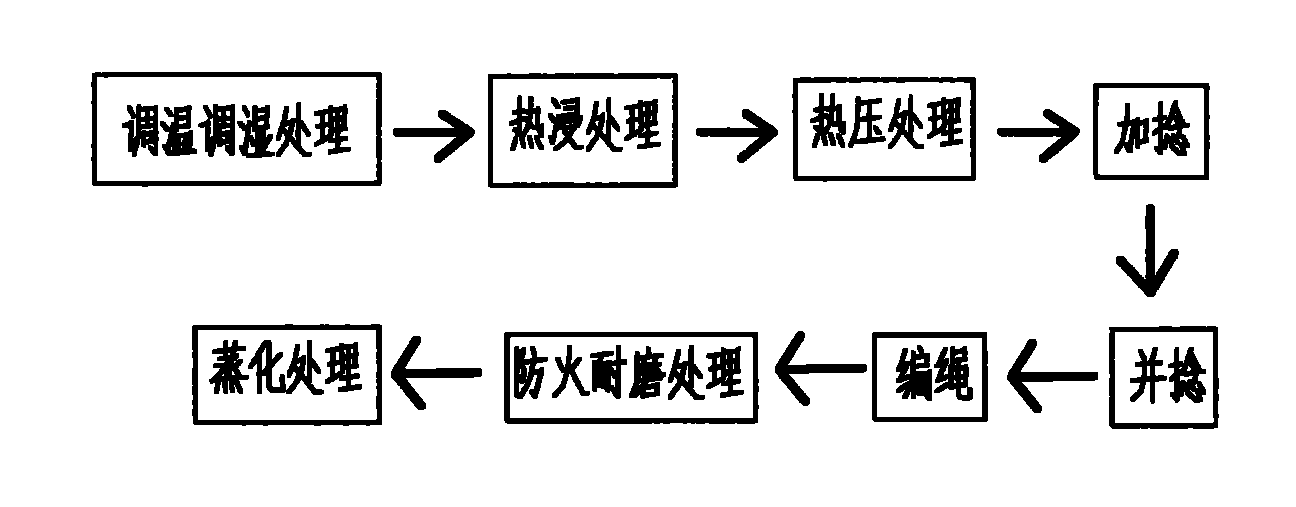

Method for producing basalt fiber rope net

ActiveCN101838885AImprove the finishHigh tensile strengthLiquid/gas/vapor removal by squeezing rollersBraidPolymer scienceActive agent

The invention discloses a method for producing basalt fiber rope nets, which comprises the following processes of: heat soaking treatment, hot-pressing treatment, weaving ropes, fireproof and wear-resistant treatment, steaming treatment, and the like. The heat soaking treatment solution contains an anionic surfactant, sodium alga acid and other aids; a tension regulation device is arranged on a high-speed braiding machine; and the fireproof and wear-resistant treatment solution contains PTFE, neutral salts, and other active agents. The method has reasonable process and advanced treatment technology and method, and the produced rope nets have the advantages of high temperature resistance, corrosion resistance, high intensity, high safety, and high cost performance.

Owner:TAIAN ROPE NET PLASTIC

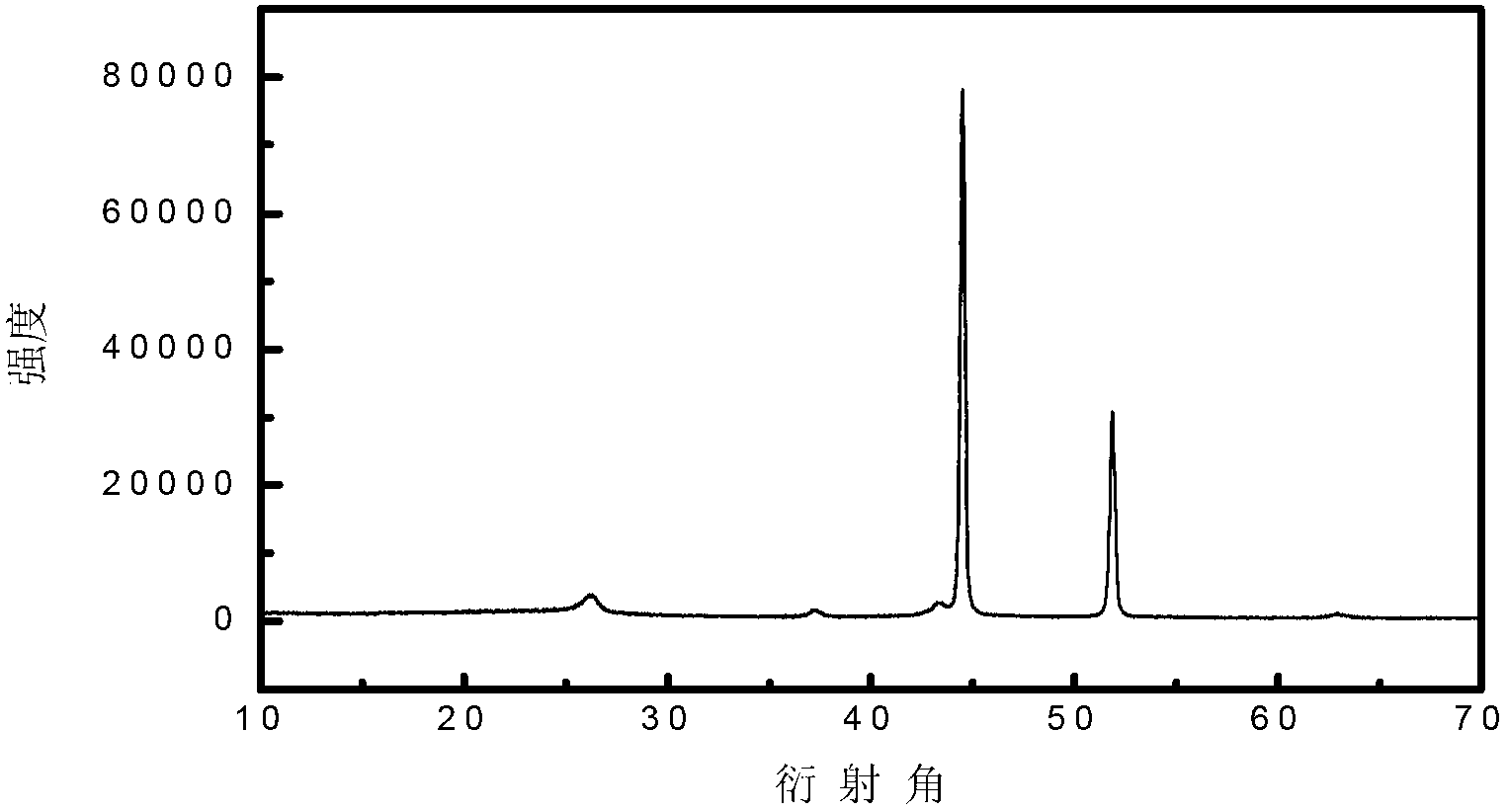

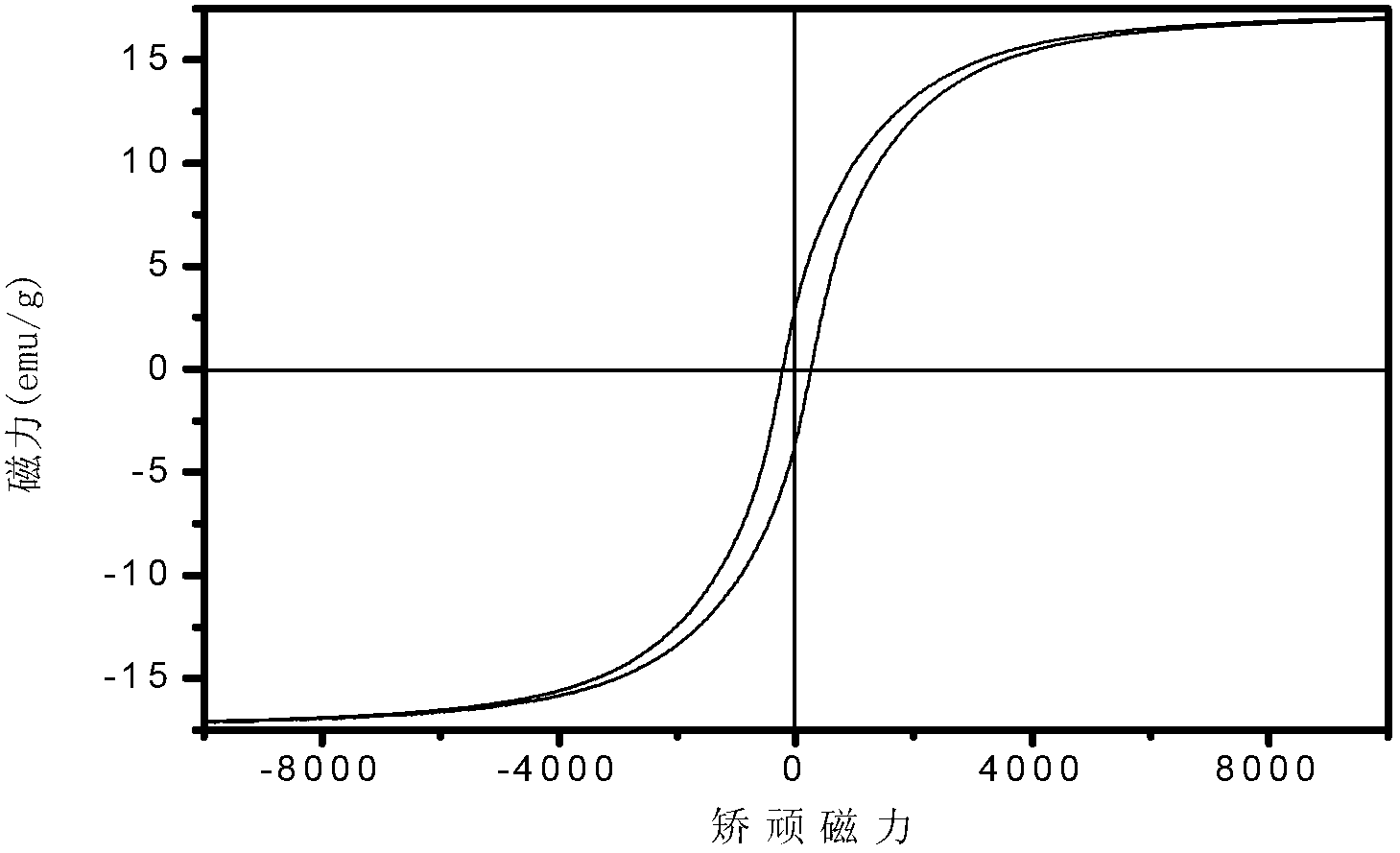

Preparation method of carbon-aerogel-based spherical anticorrosion magnetic material

InactiveCN102709017AReduce magnetismEasy to operateInorganic material magnetismCarbon preparation/purificationNickel saltReducing atmosphere

The invention relates to a preparation method of a carbon-aerogel-based spherical anticorrosion magnetic material, wherein nickel salts, aldehydes substances and aromatic amine phenols are taken as raw materials. The method comprises the process of preparing, drying and carbonizing nickel-containing gel, and is characterized in that the gel is prepared in a manner that the nickel salts are added into a solution prepared from the aldehydes substances and aromatic amine phenols substances according to proportion, a catalyst and a dispersant are added for gelation, vacuum drying is performed to form xerogel, and the nickel-containing gel is carbonized in a reducing atmosphere to prepare the carbon-aerogel-based spherical anticorrosion magnetic material. The method disclosed by the invention is easy to implement, short in preparation period and suitable for large-scale production.

Owner:HEFEI UNIV OF TECH

Electromagnetic shielding polyethylene material and preparation process thereof

InactiveCN101701083AEasy to produce and purchaseLow costMagnetic/electric field screeningThermoplasticCorrosion

The invention relates to an organic polymer composite material, in particular to a polyethylene material capable of electromagnetic shielding and a preparation method thereof. The polyethylene material comprises the following components in percentage by weight: 49.5-90 percent of polyethylene, 5-35 percent of carbon fiber, 2-30 percent of conductive graphite, 0.2-1.0 percent of antioxidant, 0.2-2.0 percent of coupling agent and 0.3-5.5 percent of other auxiliary agent. The electromagnetic shielding polyethylene material can replace metal raw materials to produce spare and accessory parts or casings, and combines the favorable performance of thermoplastic plastics which can be processed easily and the electromagnetic shielding function of metal materials, therefore, the production purchasing of the electromagnetic shielding polyethylene material can be realized conveniently, and the relevant cost can be greatly reduced. The electromagnetic shielding polyethylene material also has the advantages of acid-resistant and alkali-resistant corrosion, certain mechanical strength and temperature toleration, thereby comprehensively improving the competitiveness.

Owner:KECHUANG POLYMER SUZHOU

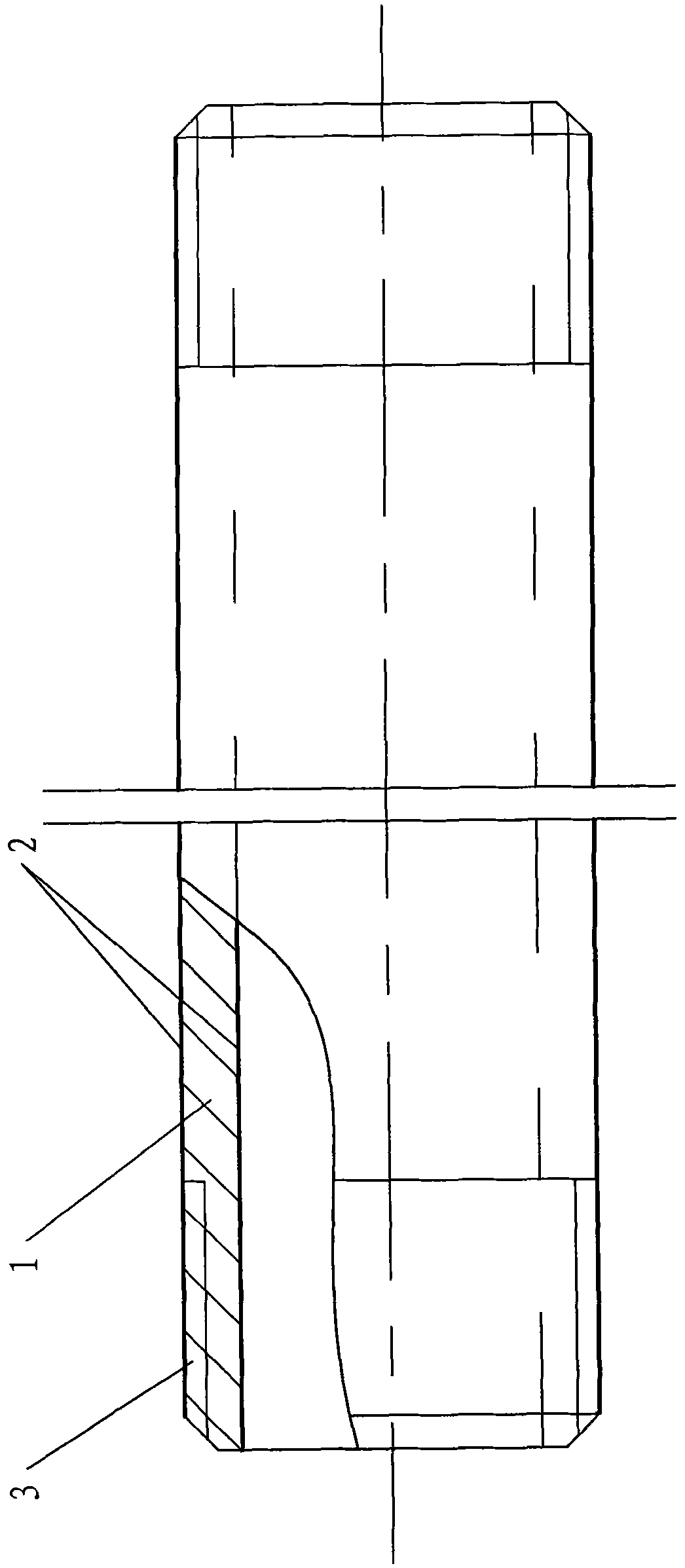

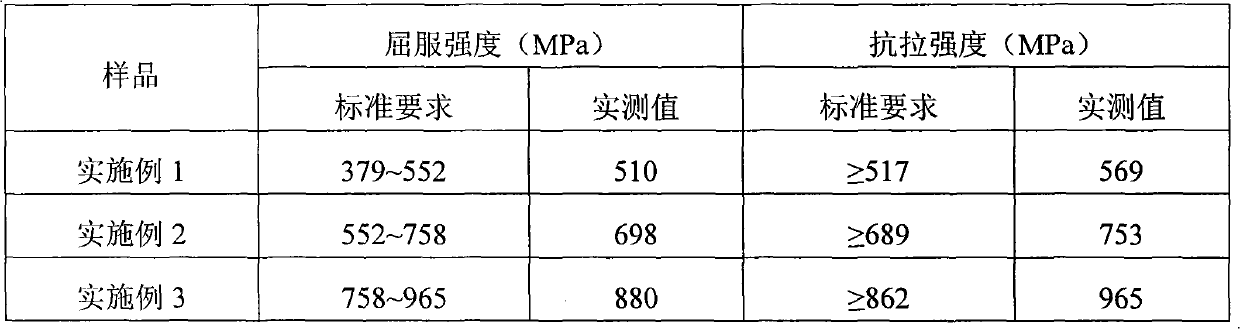

Oil casing pipe resisting CO2 corrosion and production method thereof

InactiveCN102003148ACompact structureIncreased microhardnessDrilling rodsDrilling casingsSmooth surfaceTungsten

The invention discloses an oil casing pipe resisting CO2 corrosion and a production method thereof, relating to petroleum mechanical equipment and a production method thereof, and aiming to provide an oil casing pipe which can economically and effectively resist CO2 corrosion, has compact and smooth surface, wear resistance, anticorrosion, low scaling and paraffinning probability and a production method thereof. The production method of the oil casing pipe comprises the following steps: (1) processing a tubular matrix of an oil outlet casing pipe; and processing external treaded parts at the two ends of the tubular matrix; (2) carrying out oil-removing and dust-removing treatment on the tubular matrix; (3) performing the activating treatment on the treated tubular matrix by adopting a sodium nitrate activation process; and (4) rinsing the tubular matrix after activating treatment through deionized water, soaking into an electro-deposition tank, and coating one layer of tungsten-based amorphous alloy on the tubular matrix by adopting an electro-deposition method.

Owner:北京百利时能源技术股份有限公司

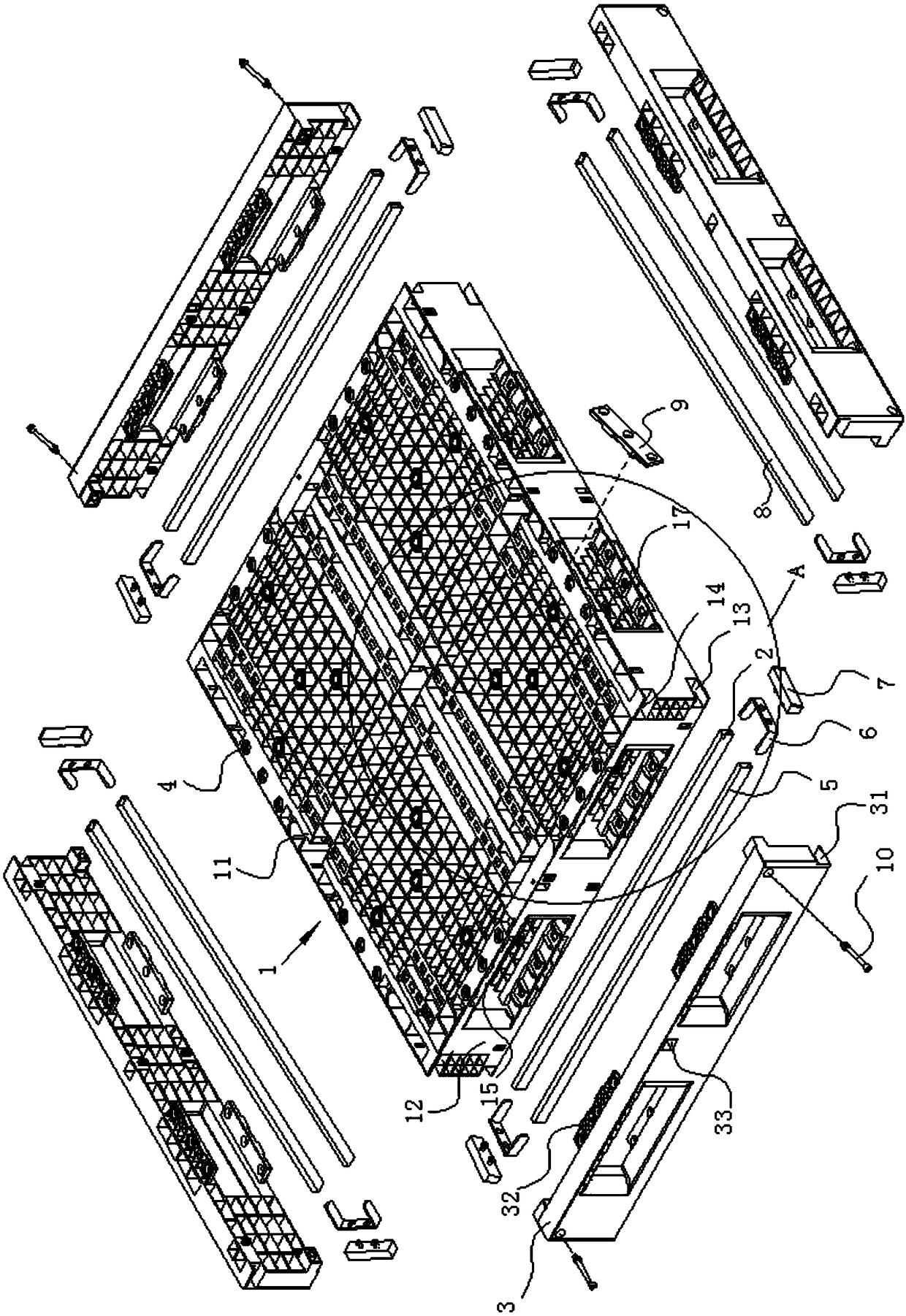

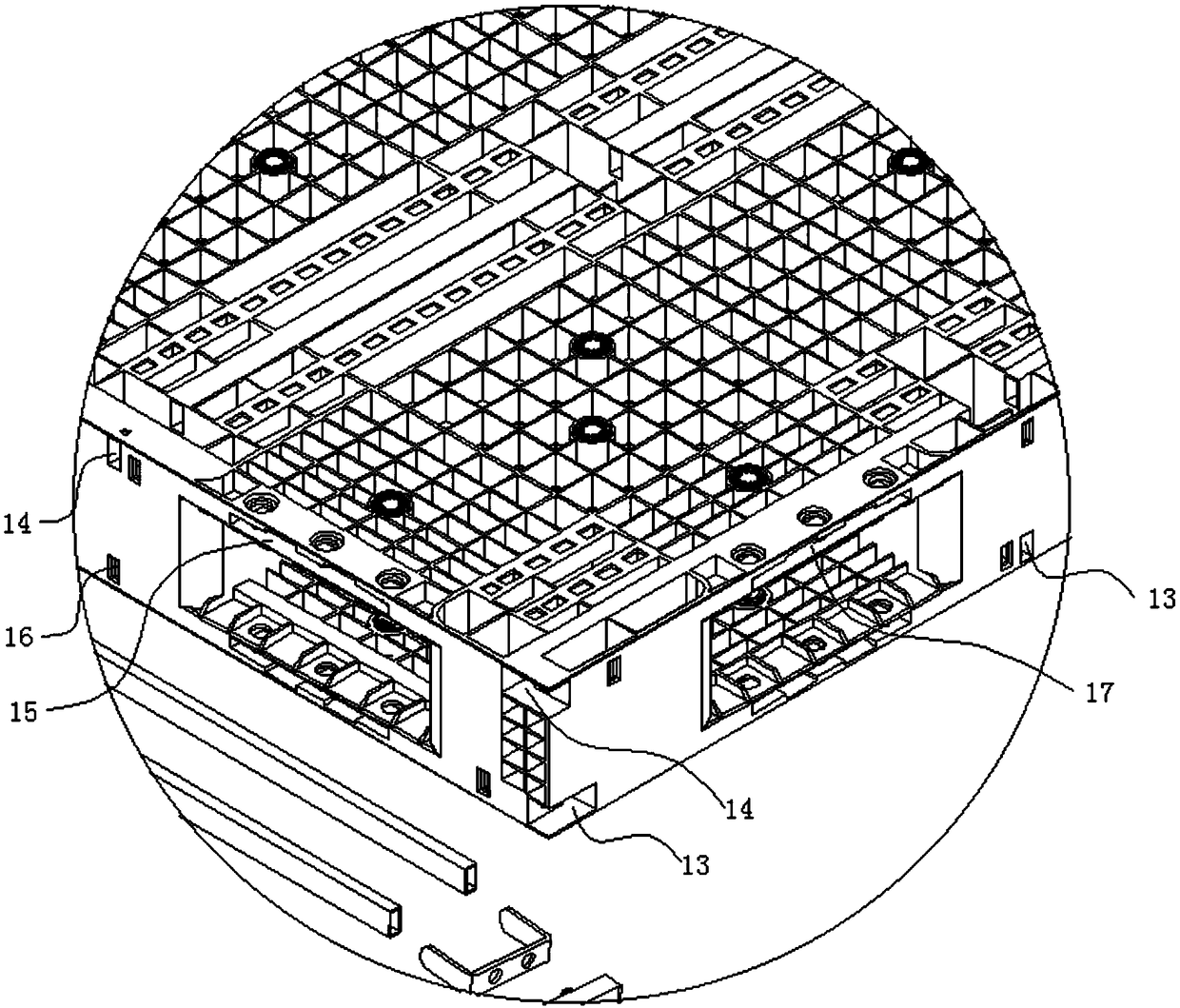

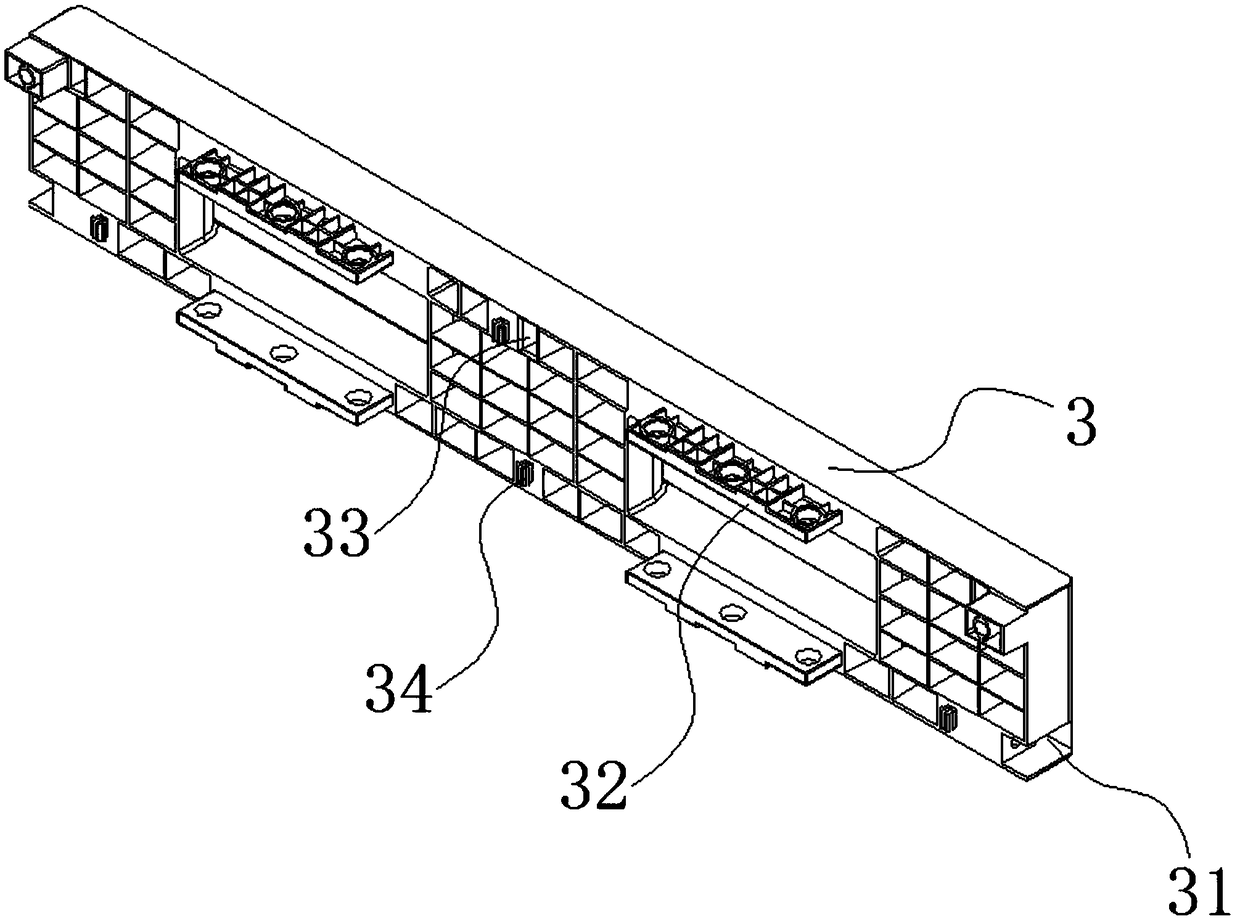

Two-sided assembly plastic tray

The invention discloses a two-sided assembly plastic tray. The two-sided assembly plastic tray comprises a main board and edge strips fixed to the two sides of the main board; the main board comprisestwo rib frames and a plurality of pad feet uniformly arranged between the two rib frames; due to the fact that a first main board steel pipe and a second main board steel pipe are correspondingly inserted into the main board, bosses on the edge strips are inserted into first penetrating and inserting grooves in the main board to complete connection; and edge strip steel pipes in the edge strips are connected with the first main board steel pipe through edge strip connection blocks so that fixing is completed. According to the two-sided assembly plastic tray, due to double fixing, edge strip fixing is firmer, edge strip replacing is convenient, and meanwhile cost is saved.

Owner:SICHUAN LICHUAN PLASTIC PROD CO LTD

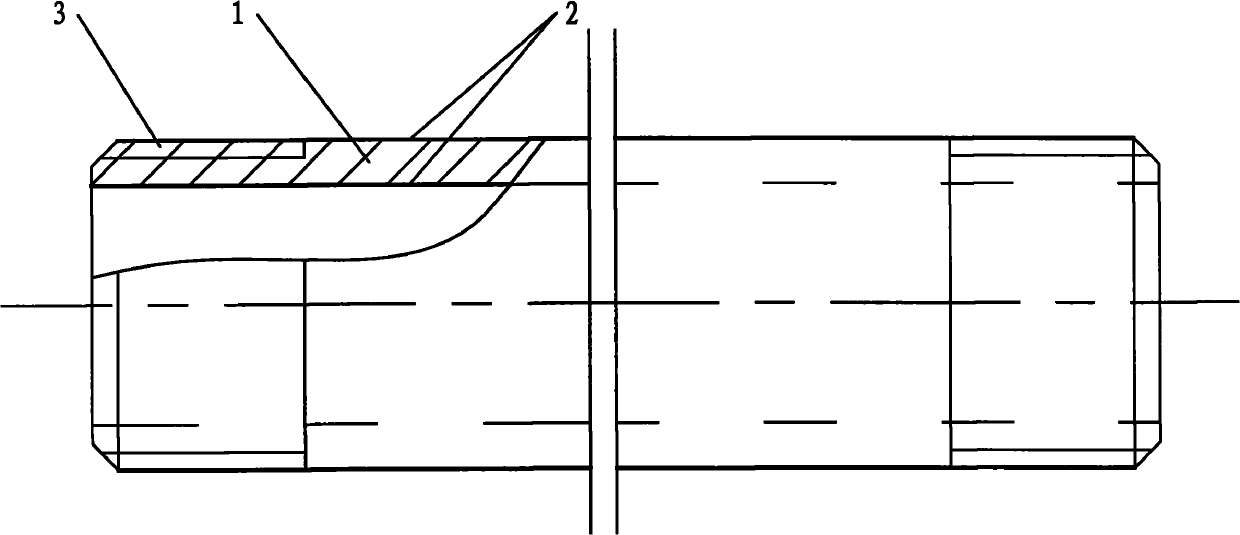

Electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe

ActiveCN103982142AExtended service lifeIncreased microhardnessDrilling rodsCorrosion preventionWear resistantAcid washing

The invention relates to an electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe, and belongs to the field of oil field oil pipes. The inner surface of the oil pipe is electroplated with an amorphous state nickel-based alloy corrosion-resistant wear-resistant protection layer. The thickness of the protection layer is 20-50 microns. The protection layer is electroplated by the steps of oil removing, water washing, acid washing, water washing, activating, deionized water cleaning, electroplating, water washing and thermal treatment. Treatment is performed in oil removing liquid for 5-10 minutes; in acid washing, an oxide film is removed from a sulfur solution till the natural color of metal is exposed; in electroplating, nickel alloy electroplating liquid is adopted, the PH value is adjusted to 2-6 by using nickel carbonate, the temperature is more than or equal to 60 DEG C, the current density is 2-8 A / dm<2>, and the electroplating time is 2 hours; in thermal treatment, the temperature is kept at 200-300 DEG C for 1.5 hours. The oil pipe has the advantages of high microhardness, resistance to acid and alkali corrosion, high wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司

Aerated concrete block capable of adsorbing toxic and harmful gases and preparation method of aerated concrete block

InactiveCN104556934AHigh strengthImprove insulation effectSolid waste managementCeramicwareOrganic compoundRaw material

The invention discloses an aerated concrete block capable of adsorbing toxic and harmful gases and a preparation method of the aerated concrete block. The aerated concrete block is prepared from the following raw materials in parts by weight: 42-68 parts of yellow sands, 10-15 parts of nano black stones, 12-16 parts of a zeolite molecular sieve, 18-26 parts of allophone, 22-28 parts of wood dust, 15-20 parts of ground calcium carbonate powder, 26-34 parts of sea mud, 16-22 parts of attapulgite, 10-15 parts of alpha type semi-hydrated gypsum, 3-6 parts of carbomer resin, 1-2 parts of modified aluminum powder, 2-3 parts of sodium thiosulfate, 2-3 parts of zinc sulfate and 1-2 parts of azodiisobutyronitrile. The substances including the nano black stones, the zeolite molecular sieve and the like with outstanding physical adsorption functions are added into the aerated concrete block disclosed by the invention, so that the aerated concrete bock can adsorb harmful gases of formaldehyde, benzene compounds, sulfur oxide, nitrogen oxide, carbon monoxide, hydrogen sulfide, ammonia, isovaleric acid, methyl mercaptan, trimethylamine (fishy), TVOC (total volatile organic compounds) and the like to achieve a function of purifying air; and meanwhile, the aerated concrete block has the characteristics of high strength, good heat insulation and heat preservation properties, good sound isolation effect, heat resistance, moisture resistance, acid and alkali corrosion resistance and the like, and has a broad market prospect.

Owner:安徽中龙建材科技有限公司

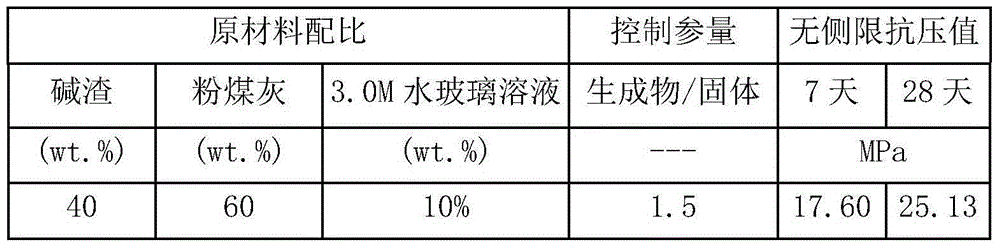

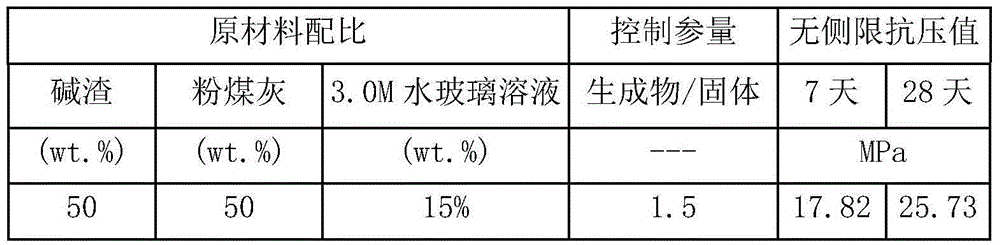

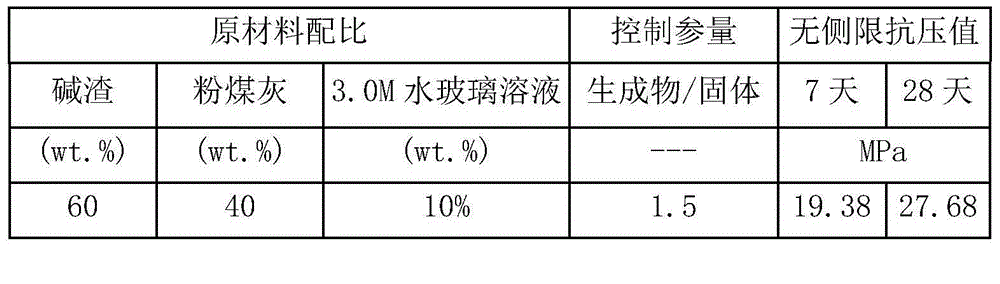

Alkali residue-based cement gel material

The invention discloses an alkali residue-based cement gel material and relates to a building material of a waste composition in alkaline industry. The building material is a composition which is prepared from 40-60% by mass of alkali residues, 40-60% by mass of coal ash and 10-20% by mass of an active agent based on total mass of the alkali residues and coal ash. The alkali residue-based cement gel material is prepared by the following steps: firstly, uniformly mixing the alkali residues in required use level by a regulated mass percent and coal ash; then, adding 10-20% by mass of active agent based on total mass of the mixture; and then uniformly stirring to obtain the alkali residue-based cement gel material which is an alkali residue geopolymer prepared from large-dope waste alkali residues. The alkali residue geopolymer which replaces cement is used for related projects such as a waterproof curtain of a mine, so that not only is the defect that the cost is high and the environment is indirectly and severely polluted due to cement used in the existing gel material solved, but also a lot of waste alkali residues are effectively utilized, thereby turning wastes into wealth.

Owner:HEBEI UNIV OF TECH

Electroplating amorphous ferrum-nickel-tungsten alloy corrosion-resistant wear-resistant oil pump

InactiveCN101666302AExtended service lifeCompact structurePumpsPositive-displacement liquid enginesEtchingWear resistant

The invention relates to an electroplating amorphous ferrum-nickel-tungsten alloy corrosion-resistant wear-resistant oil pump comprising a pump barrel, a plunger piston, an oil inlet valve and an oiloutlet valve, wherein the internal surface of the pump barrel is plated with an amorphous ferrum-nickel-tungsten corrosion-resistant wear-resistant protective layer, and the thickness of the protective layer is at least 75 mu m. The method for plating the protective layer comprises the following steps: electrolyzing to remove oil, washing with clear water, etching, washing with deionized water, electroplating, washing with weater and heat-treating. The electrolyzing to remove oil is realized by treating in an oil removing solution at 65-75 DEG C for 5-10 minutes, and the current density is 5-10 A / dm<2>. The etching is realized by removing oxidation films in a NaNO3 solution with the current density of 5-10 A / dm<2> until the natural color of the metal is exposed. The electroplating is realized in such as way that: a tungsten alloy plating solution is adopted, sodium hydroxide or ammonia is used for regulating the pH value to 7-8, the temperature for the electroplating is at least 70 DEGC, the current density is 5-10 A / dm<2>, and the electroplating time is 3-4 hours. The heat treatment is realized by keeping the temperature at 500-600 DEG C for 1.5 hours. The oil pump has the advantages of high microhardness, acid resistance, corrosion resistance, favorable wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司 +1

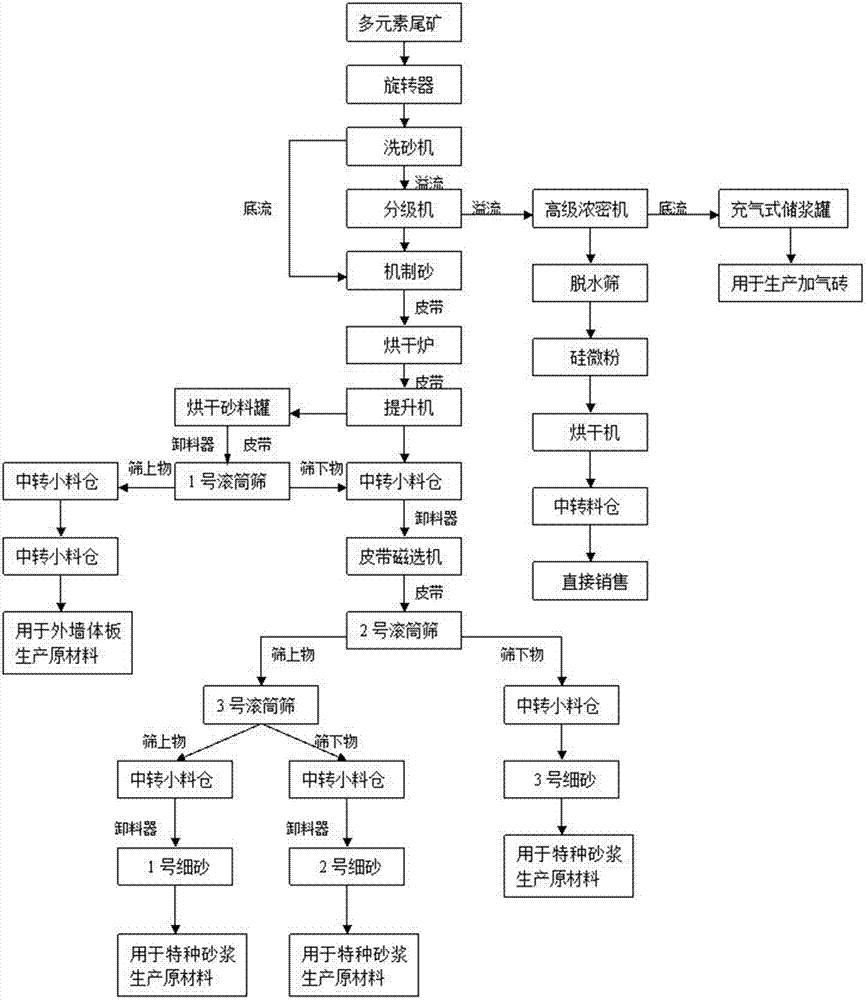

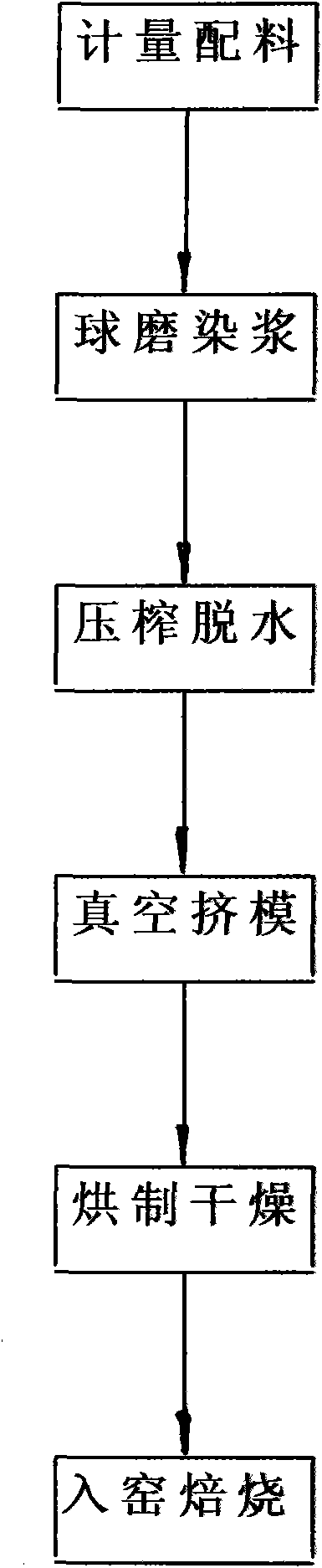

Method for fully utilizing gold tailings

ActiveCN107876206AImprove temperature resistanceWith acid and alkali corrosion resistanceSievingScreeningBrickSlurry

The invention belongs to the field of gold tailing treatment, and particularly relates to a method for fully utilizing gold tailings. The method mainly comprises the following steps that multi-elementtailings are subjected to swirler grading, are further screened through a sand washer, are further graded by a grader, and are screened after being dried to obtain fine sand with different levels; meanwhile, an overflow part with smaller specific gravity graded by the grader is dehydrated and precipitated through a high-efficiency thickener, then layer-by-layer screening is carried out through amulti-stage desliming hopper, finally dehydrating is carried out on the most fine overflow part by using a dewatering sieve to obtain silicon micropowder which is excellent in performance and is widely applied; and a bottom flow which is precipitated by the high-efficiency thickener can be stored in an air-inflation type slurry storage tank, and is used for producing an aerated brick. According tothe method, the multi-element tailing treatment method is more refined, the gold tailings can be thoroughly utilized, no harmful gas is emitted to the environment, the method can be applied to different fields and occasions, maximum utilization of the tailings can be achieved, and the method is the most environment-friendly and most economical tailing treatment method.

Owner:SHANDONG JIUQU SHENGJI NEW BUILDING MATERIALS

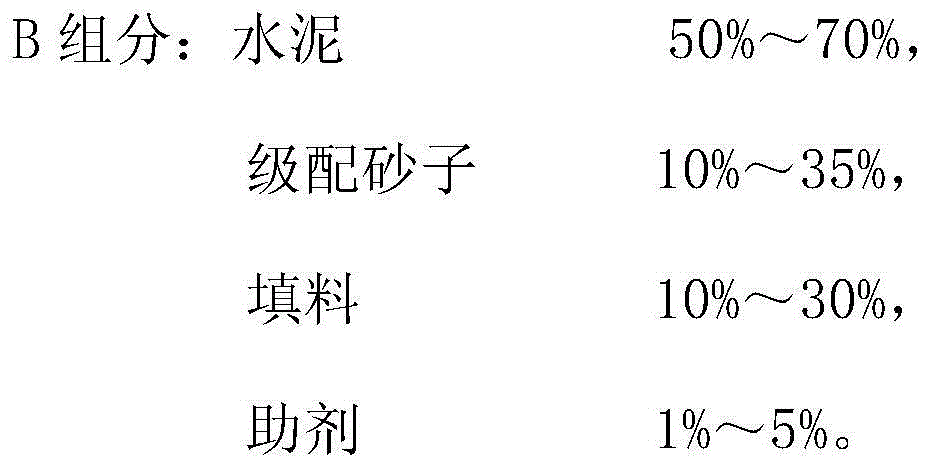

Wet base surface treating agent

Wet base surface treating agent comprises a component A and a component B, wherein the component A comprises the following raw materials in percentage by weight as follows: 50%-80% of emulsified asphalt, 10%-40% of modified emulsion and 1%-5% of an auxiliary; and the component B comprises the following raw materials in percentage by weight as follows: 50%-70% of cement, 10%-35% of graded sand, 10%-30% of filler and 1%-5% of an auxiliary. The wet base surface treating agent has the advantages of rapid drying, low cost, good waterproof performance, high sealing capacity and the like; experiments prove that the surface drying time of the wet base surface treating agent ranges from 13 min to 15 min; the wet basesurface primer is mainly applied to a building basement, a road or bridge surface and a wet tunnel base surface for basic layer processing, and can improve the adaptability of self-adhesive roll materials, SBS (styrene butadiene styrene) modified asphalt roll materials and high polymer roll materials to construction of the wet base surface.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Anticorrosive coating, preparation method and applications of anticorrosive coating

ActiveCN102863877AWear-resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPolyether coatingsEpoxyHigh pressure

The invention discloses an anticorrosive coating, a preparation method and applications of the anticorrosive coating, wherein the anticorrosive coating comprises an A component and a B component, wherein the mass ratio of the A component to the B component is 100:20-35, and the A component comprises the following components by weight: 35-50 parts of novolac epoxy resin F51; 12-14 parts of xylene; 10-12 parts of 1,4-butanediol diglycidyl ether; 6-8 parts of quartz powder; 7-9 parts of mica powder; 5-8 parts of talc powder; 8-10 parts of titanium dioxide; 1-2 parts of defoaming agent dimethyl silicone; and 1-2 parts of coupling agent KH570; and the B component is modified polyether amine-1784. The anticorrosive coating prepared by adopting the technical scheme has the advantages of resistance to wear, resistance to acid and alkali corrosion, and resistance to high temperature and high pressure, and can meet the requirements of corrosion protection of oil drill pipe for exploitation.

Owner:北京碧海云智新材料技术有限公司

Environment-friendly building brick and preparation method thereof

InactiveCN107814557AGood physical propertiesHigh strengthCeramic materials productionClaywaresBrickMaterials science

The invention discloses an environment-friendly building brick and a preparation method thereof. The environment-friendly building brick is prepared from the following raw materials in parts by weight: 60 to 80 parts of construction waste, 10 to 18 parts of coal ash, 15 to 30 parts of mineral residue, 3 to 10 parts of marble, 1 to 2 parts of magnet, 1 to 3 parts of medical stone, 3 to 7 parts of fluorite, 1 to 2 parts of alundum powder, 15 to 30 parts of clay, 0.1 to 0.5 part of shell active carbon, 0.1 to 0.3 part of nanoscale aluminum oxide, 0.08 to 0.12 part of sodium rosinate, 0.05 to 0.1part of sodium tripolyphosphate, and 10 to 15 parts of water. The building brick has the advantages of high strength, good wear resistance, acid and alkali corrosion resistance, high compactness and the like, also has insecticidal and healthcare functions, and has a good visual effect.

Owner:QINGYANG DUNBO TECH DEV CO LTD

Corrosion resistant aerated building block and making method thereof

InactiveCN105272337AImprove mechanical propertiesImprove fire resistanceCeramicwareCrack resistanceSlag

The invention discloses a corrosion resistant aerated building block and a making method thereof. The corrosion resistant aerated building block is made from, by weight, 23-27 parts of waste concrete, 28-36 parts of quartz sand, 16-29 parts of pine sawdust, 13-21 parts of porous ceramsite, 18-34 parts of zirconium-silicon slag, 32-46 parts of high sulfate resistance Portland cement, 17-33 parts of pumice, 14-26 parts of kyanite, 22-34 parts of marine dredged sludge, 11-22 parts of desulfurized gypsum, 19-28 parts of calcium carbide slag, 10-15 parts of hawthorn fruit seed powder, 8-12 parts of sodium polystyrene sulfonate, 3.5-5 parts of calcium hydride and a proper amount of water. The aerated building block has the advantages of strong corrosion resistance, strong resistance to acids, alkali, salts and other corrosive media, high strength, good durability, impermeability, low heat conduction coefficient, good crack resistance, safety, environmental protection and durability.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

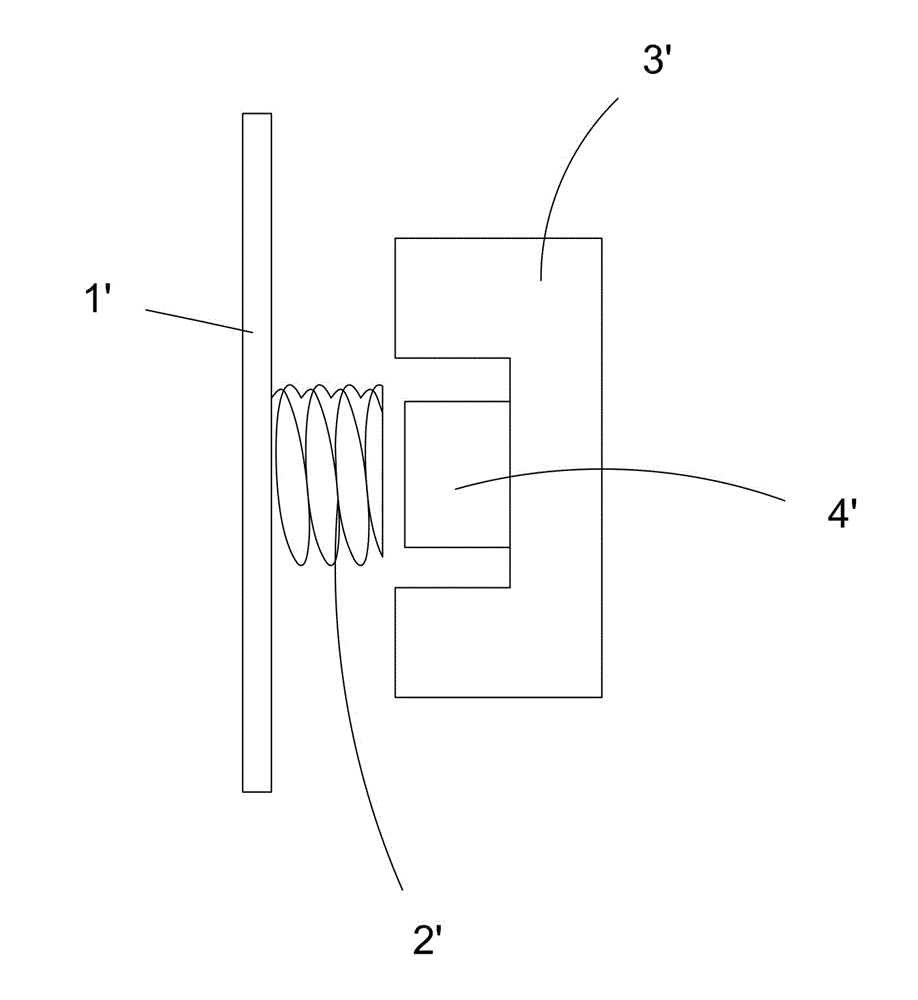

Electromagnetism transient magnetic loudspeaker

InactiveCN103152679AReduce weightLighter and thinnerElectrical transducersMagnetizationSound quality

The invention provides an electromagnetism transient magnetic loudspeaker, which comprises a vibrating diaphragm, wherein a magnetizer is arranged on the vibrating diaphragm; an electromagnetic device is arranged on an opposite position of the magnetizer, and comprises a coil opposite to the magnetizer, and a magnetic bar; and the magnetic bar penetrates through an inner opening of the coil so as to be opposite to the magnetizer. The weight of the vibrating diaphragm is reduced; due to the removal of a voice coil, the axial movement of the voice coil in a magnetic gap is avoided; an electromagnetic type power structure is adopted, so that compared with an existing permanent magnet, the magnetic density is higher, a sound signal can be performed at high speed; a plane vibrating diaphragm design is adopted, so that voice frequency can be parallely transmitted, the defect of emission of voice frequency of a bowl type vibrating diaphragm is overcome, and the sound signal can be highly positioned; and a nickel ring has the characteristics of magnetization, inoxidizability, acid and alkali corrosion and the like, so that the service life of the loudspeaker is greatly prolonged, the problems that the magnetic force of a permanent magnet is reduced, and the tone quality is affected are solved, and graceful sound with high sound quality, clearness, enriched detail and wonderful layering performance is realized.

Owner:胡宗科

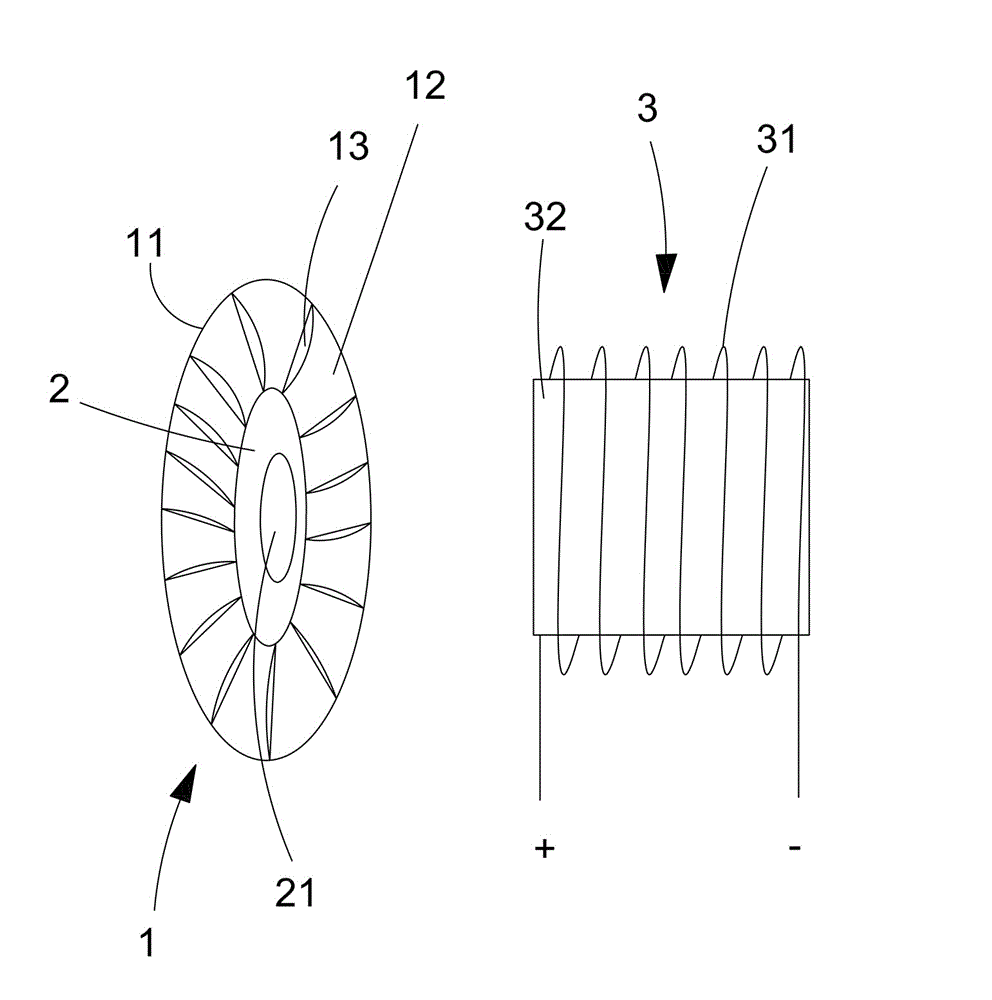

Blank formulation for generating tile decorative building materials by carbon black coloring and manufacturing method

The invention provides a blank formulation for generating tile decorative building materials by carbon black coloring and a manufacturing method, which originates in a new dyeing-coloring formulation comprising carbon black, iron powder, vanadium titanium slag, soft shale, soft clay and the like, and a new technique of products in series, such as grey roof tile, black facing tile, black floor tile and the like prepared by tunnel kiln and pushed slab kiln. The products prepared in the invention have congelifraction resistance, pure color and outlook, acid-base erosion resistance and non-discoloring characteristic, which can meet the quality requirements of maintaining and installing on old buildings in culture tourism regions. The invention has the advantages of simple procedure, high automation and high working efficiency, and the novel blank formulation widens abundant sources of raw materials for decorative tile building materials industry which conforms to the industrial policy of waste utilization and environmental protection, has energy-saving and emission-reduction environmental protection benefit and better economical benefit and good market prospect.

Owner:李石牛

Oil and gas field environment-friendly fracturing propping agent and preparation method thereof

ActiveCN105777024AReasonable control of curing rateStable performanceSolid waste managementFluid removalSlagDefoaming Agents

The invention relates to an oil and gas field environment-friendly fracturing propping agent prepared by well drilling solid waste and a preparation method thereof; the oil and gas field environment-friendly fracturing propping agent adopts the well drilling solid waste as a raw material, and comprises, by the weight percentage, 20%-60% of the well drilling solid waste, 3%-7% of sand, 1%-5% of ironmaking waste slag, 5%-8% of portland cement, 6%-10% of sulphoaluminate cement, 5%-10% of a curing agent, 2%-3% of manganese dioxide, 4%-6% of sodium sulfate, 2%-5% of barium carbonate, 5%-8% of water-swelling rubber particles, 0.5%-1% of an excitation agent, 0.4%-0.8% of a reinforcing agent, 0.2%-0.5% of a defoaming agent, 0.1%-0.5% of a water reducing agent, 0.3%-0.6% of an impregnating agent, and 1.2%-1.5% of sodium methyl cellulose. The oil and gas field environment-friendly fracturing propping agent provided by the invention has the advantages of good compressive strength, strong crush resistant capability, small density and low production cost; the well drilling solid waste can be fully utilized, the waste is turned into treasure, the environment is protected, and the resources are saved.

Owner:北京融达环科新材料科技有限公司

Preparation method for preparing silica powder from ordinary quartz raw mineral materials

InactiveCN108864765AHigh molecular weightGood flocculation effectSilicaPigment treatment with macromolecular organic compoundsAmmonium hydroxideCorrosion

The invention discloses a preparation method for preparing silica powder from ordinary quartz raw mineral materials. The preparation method comprises the steps: selecting ore, breaking, cleaning, grinding, removing iron, separating, drying, ball milling, grading, grading again, removing surface residues, adding into a reactor, adding ammonium hydroxide with a mass ratio of 1 to 1, adjusting a pH to be equal to 8 to 9, controlling a temperature as 100 to 110 DEG C, preheating 1 to 1.5 hours to removing moisture, cooling to 80 to 90 DEG C, adding a modifying agent to perform surface modification, stirring 50 to 60 min and drying to obtain high-purity silica powder. The prepared silica powder is hydrophobic (lipophilic) high-purity white micro powder without toxin, odor and pollution and hasexcellent performance of good temperature resistance, acid and alkali corrosion resistance, poor thermal conductivity, high insulation, low expansion, stable chemical performance, large hardness and the like.

Owner:安徽东阳矿业科技有限公司

Firebrick dust-containing aerated building block and making method thereof

The invention discloses a firebrick dust-containing aerated building block and a making method thereof. The aerated building block is made from, by weight, 12-23 parts of silicon-calcium slag, 24-37 parts of firebrick dusts, 26-39 parts of Portland cement, 19-35 parts of gangue, 14-26 parts of anorthite, 18-32 parts of porous ceramsite, 28-42 parts of flue dust, 6-12 parts of locust bean gum, 10-15 parts of boron slag, 16-28 parts of blast furnace water quenching slag, 4-8 parts of sodium tripolyphosphate, 3-4 parts of silicon-aluminum alloy powder, 1-2 parts of sodium peroxide and a proper amount of water. The firebrick dusts added in the invention cooperate with gangue, anorthite and silicon-calcium slag to improve the mechanical performances, the acid and alkali corrosion resistance and the weatherability of the aerated building block, and cooperate with the porous ceramsite, the boron slag and the blast furnace water quenching slag to improve the fire resistance and the heat insulation property of the aerated building block. The aerated building block made in the invention has the advantages of excellent comprehensive performances, excellent mechanical performances, excellent weatherability, excellent acid and alkali corrosion resistance, excellent ageing crack resistance, excellent heat insulation property and excellent fire resistance.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

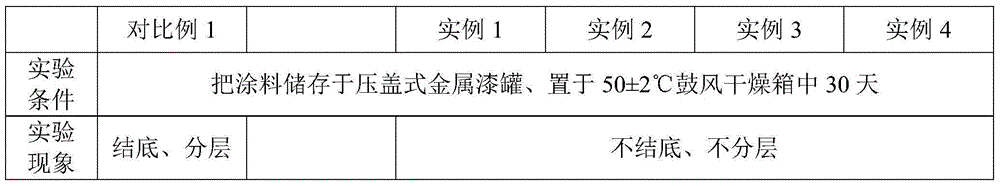

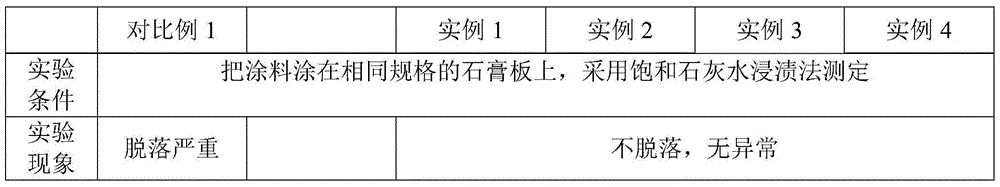

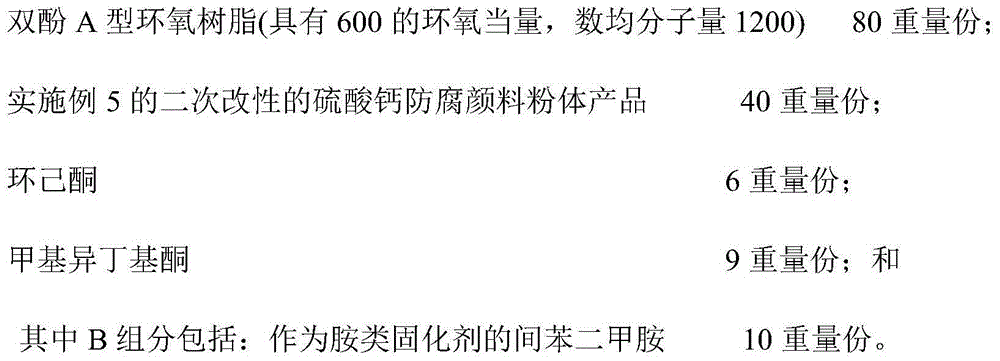

Modified calcium sulphate anticorrosive pigment as well as preparation method and application thereof

ActiveCN104945955AHigh temperature resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPigment treatment with organosilicon compoundsGas phaseBall mill

The invention discloses a modified calcium sulphate anticorrosive pigment as well as a preparation method and an application thereof. The preparation method comprises the following steps: preparing calcium sulphate extracted from industrial by-product gypsum into a suspension with a certain solid content, adding a modifier according to a certain mass percent, and then placing the modifier in a ball mill and uniformly mixing and grinding; drying the ground mixture for 3-6 hours at 80-150 DEG C, cooling the mixture and then grinding the mixture into a powder and crushing, wherein preferably, aminosilane-modified gas-phase silica is added during the grinding and crushing process. The calcium sulphate anticorrosive pigment disclosed by the invention is capable of effectively solving the pressure brought to an environment by the industrial by-product gypsum, and capable of improving the industrial by-product gypsum, wear resistance and corrosion resistance of a coating film in case of being mixed and used with other anticorrosive pigments; the pigment is good in dispersibility in resin, simple in production process, low in production cost, and capable of bringing good social and economic benefits.

Owner:HUNAN RUISHI SCI & TECH DEV

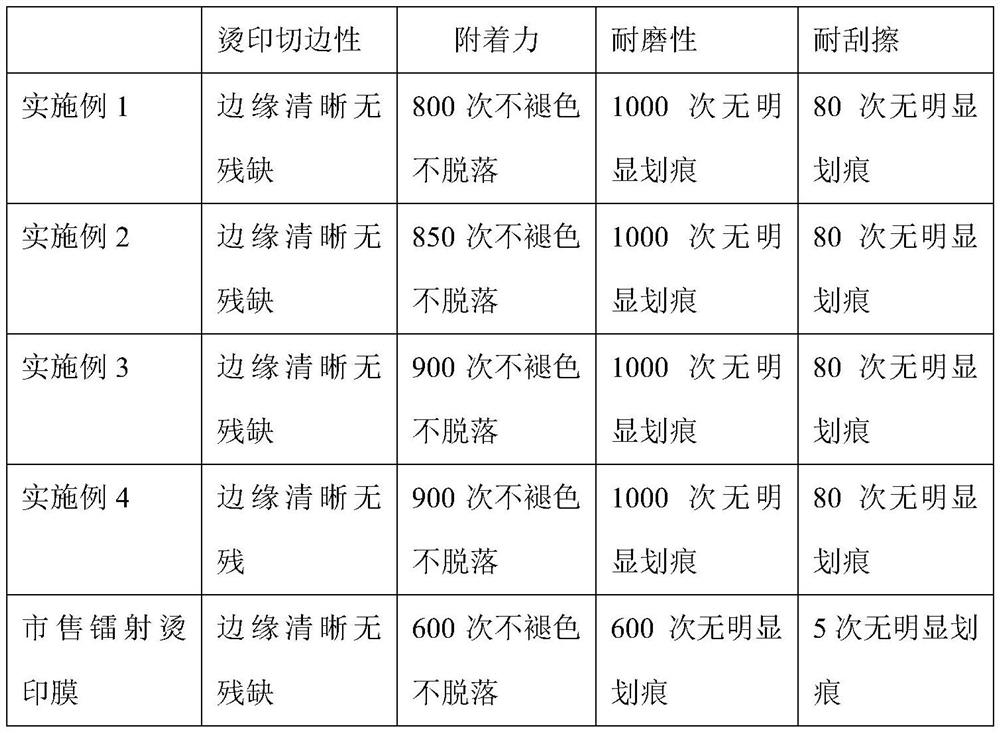

Preparation method of corrosion-resistant and friction-resistant holographic laser hot stamping film

InactiveCN112322202AExtended service lifeBrightness and anti-counterfeiting guaranteeNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyurethane membraneHot stamping

The invention belongs to the technical field of package anti-counterfeiting, and relates to a preparation method of a holographic laser hot stamping film, in particular to a preparation method of a corrosion-resistant and friction-resistant holographic laser hot stamping film. The corrosion-resistant and friction-resistant holographic laser hot stamping film is characterized by sequentially comprising a base layer, a stripping layer, a color layer, an electroplated layer and a glue layer from bottom to top, wherein the base layer comprises the following components in parts by weight: 50-70 parts of modified acrylic resin, 30-40 parts of a polyurethane film and 5-13 parts of a covalent organic framework material. According to the preparation method of the corrosion-resistant and friction-resistant holographic laser hot stamping film provided by the invention, the prepared holographic laser hot stamping film has the advantages of wear resistance, acid and alkali corrosion resistance andlong service life, meanwhile, the brightness and the anti-counterfeiting strength of the color layer, containing holographic information patterns, of the hot stamping film in a high-temperature hot stamping process are guaranteed, the production is simple, and the construction is convenient.

Owner:JIANGSU XINGGUANG PACKAGING SCI & TECH CO LTD

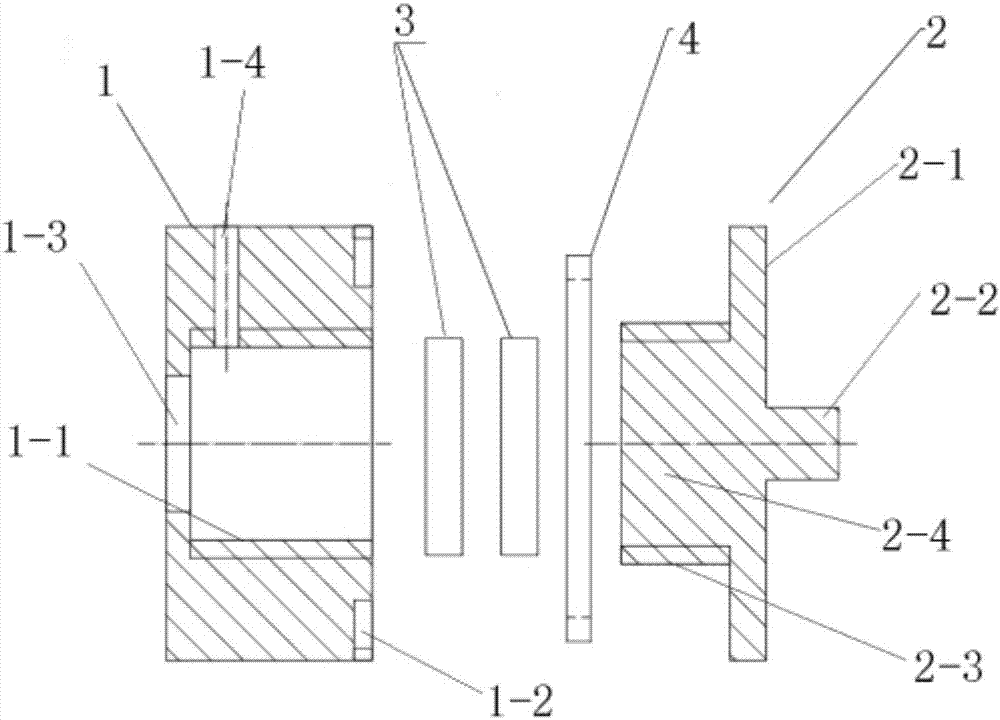

Corrosive sample fixture structure

PendingCN106979919AHigh temperature resistantWith acid and alkali corrosion resistanceWeighing by removing componentWeather/light/corrosion resistanceMetallic materialsEngineering

The invention relates to the field of pipeline interference testing, in particular to testing and testing under high-voltage AC and DC interference, and is mainly used for a new type of corrosion sample fixture structure for electrochemical testing and weight loss testing of samples under high-current and high-voltage conditions . Its structure includes: an insulating seat for containing samples, an insulating cover for fixing the sample and a sealing ring for sealing the insulating seat and the insulating cover. The exposure size and area of the sample in the new corrosion sample fixture are controllable; the sample can be taken out at any time to measure the quality change and surface change; the sample can be connected to a wire, and currents of different directions and sizes can be applied; the fixture body can be reused , It has the advantages of high temperature resistance, acid and alkali corrosion resistance. The fixture is especially suitable for polarization characteristics and corrosion tests of metallic materials in various environments.

Owner:CHINA PETROCHEMICAL CORP +3

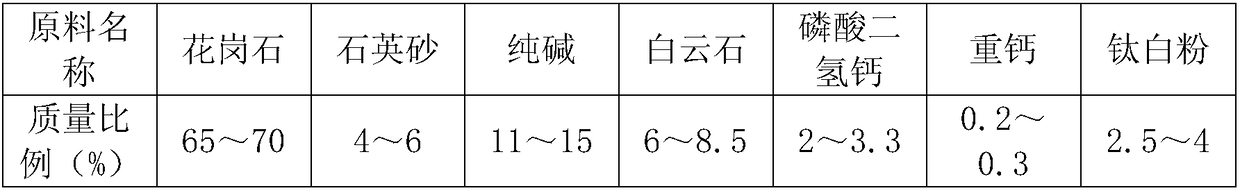

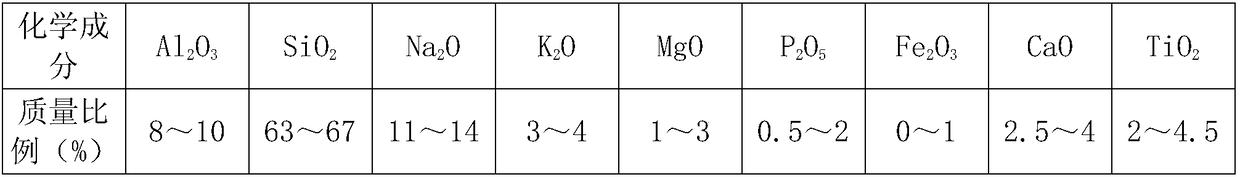

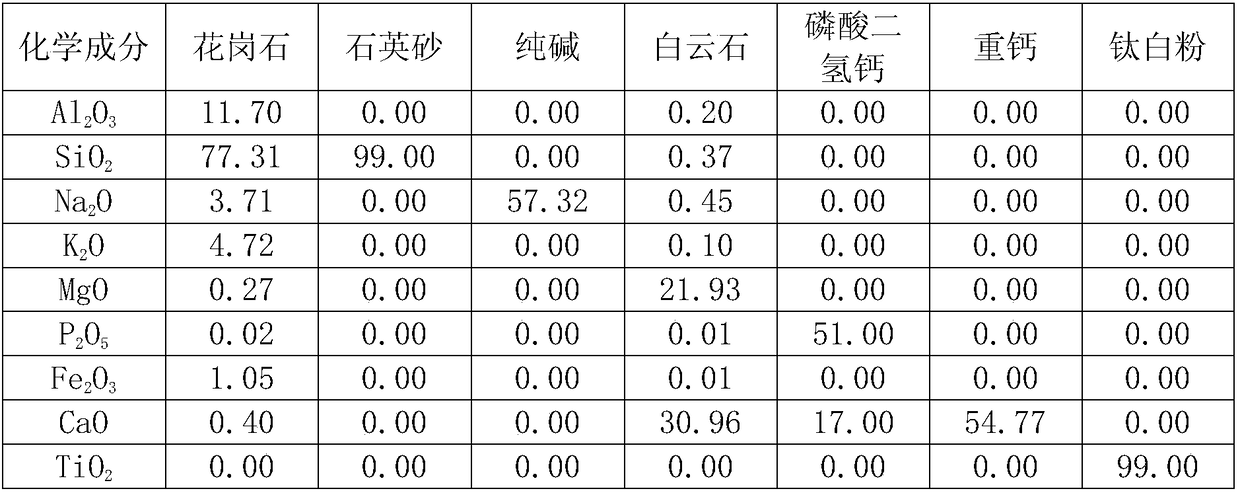

Preparation method of imitation jade microcrystalline glass

PendingCN108483922AWith acid and alkali corrosion resistanceGlass furnace apparatusGlass rolling apparatusCrystallizationRaw material

The invention discloses a preparation method of imitation jade microcrystalline glass. The method comprises the following steps of 1, raw material selection; 2, raw material mixing; 3, mixed materialmelting; 4, calendaring shaping; 5, annealing; 6, crystallization. The method can be used for producing imitation jade microcrystalline glass applicable to ground, wall surface and tabletop decoration. Meanwhile, a microcrystalline glass imitation jade product has the characteristics of acid and alkali resistance and color fastness. The advantages cannot be reached by other products. In the production process, imitation jade microcrystalline glass in various color series can be prepared by controlling the consumption of granite and changing the coloring iron ion content.

Owner:四川一名微晶科技股份有限公司

Antibacterial, wear-resistant and environment-friendly ceramic tile and preparation method thereof

InactiveCN107266024AImprove skid resistanceAntifouling GuaranteeClaywaresCrack resistanceWear resistant

The invention discloses an antibacterial, wear-resistant and environment-friendly ceramic tile which comprises the following raw materials in parts by weight: 15-25 parts of sodium silicate solution, 4-8 parts of active carbon, 2-4 parts of nano zinc oxide, 1-3 parts of nano aluminium hydroxide, 7-9 parts of glass fiber, 5-9 parts of glass bead, 2-4 parts of bamboo carbon, 25-35 parts of modified clay, 8-14 parts of transparent aggregate, 10-14 parts of rare earth ion aqueous solution and 20-30 parts of ore powder. The ceramic tile has the advantages of high strength, low water absorption, good shock and crack resistance, acid and alkali resistance, ageing resistance and long service life, and also has higher sterilization and air purification performance; a preparation method of the antibacterial, wear-resistant and environment-friendly ceramic tile is lower in material cost, concise in technology and easy to operate, facilitates industrial production, and has a higher practical value and a good application prospect; and the raw materials are easy to obtain.

Owner:合肥易美特建材有限公司

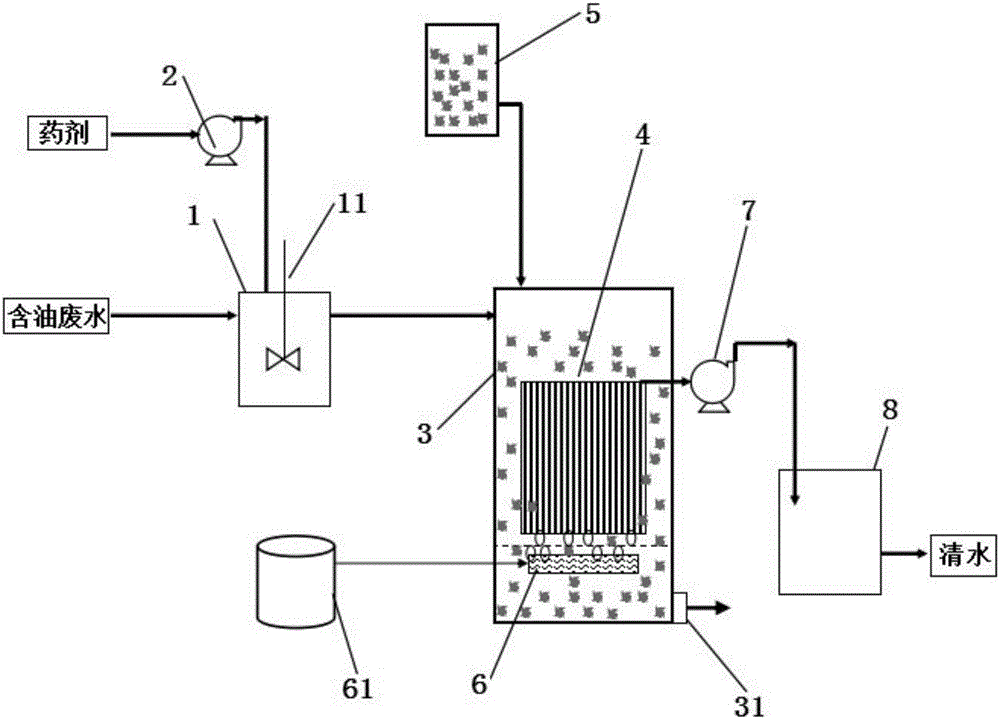

Oily wastewater treatment device and method

InactiveCN106630003AHigh temperature resistantWith acid and alkali corrosion resistanceFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisActivated carbonWater quality

The invention discloses an oily wastewater treatment device and method. The oily wastewater treatment device comprises a wastewater tank, a suction pump, a powdered activated carbon storage tank and a contact tank, wherein the contact tank comprises a tank body and a ceramic membrane module, the ceramic membrane module is installed in the tank body, the tank body is provided with a water inlet, a water outlet, a residue discharging port and a powder inlet, the wastewater tank is communicated with the water inlet, the suction pump is communicated with the water outlet, the residue discharging port is formed in the bottom of the tank body, and the powdered activated carbon storage tank is communicated with the powder inlet to add the powdered activated carbon to the tank body. The ceramic membrane module is a container structure formed by a ceramic membrane and provided with an outlet, the outlet is communicated with the water outlet, and the ceramic membrane is formed by integrally firing a supporting layer and an effective layer provided with pore channel. By the adoption of the oily wastewater treatment device and the method, the water quality requirement of reused wastewater of an oil field can be met, and the suspended matter content and oil content of output water and the median size of suspended matter can all meet the highest requirement for reinjected water of the oil yield.

Owner:深圳市康源环境纳米科技有限公司 +1

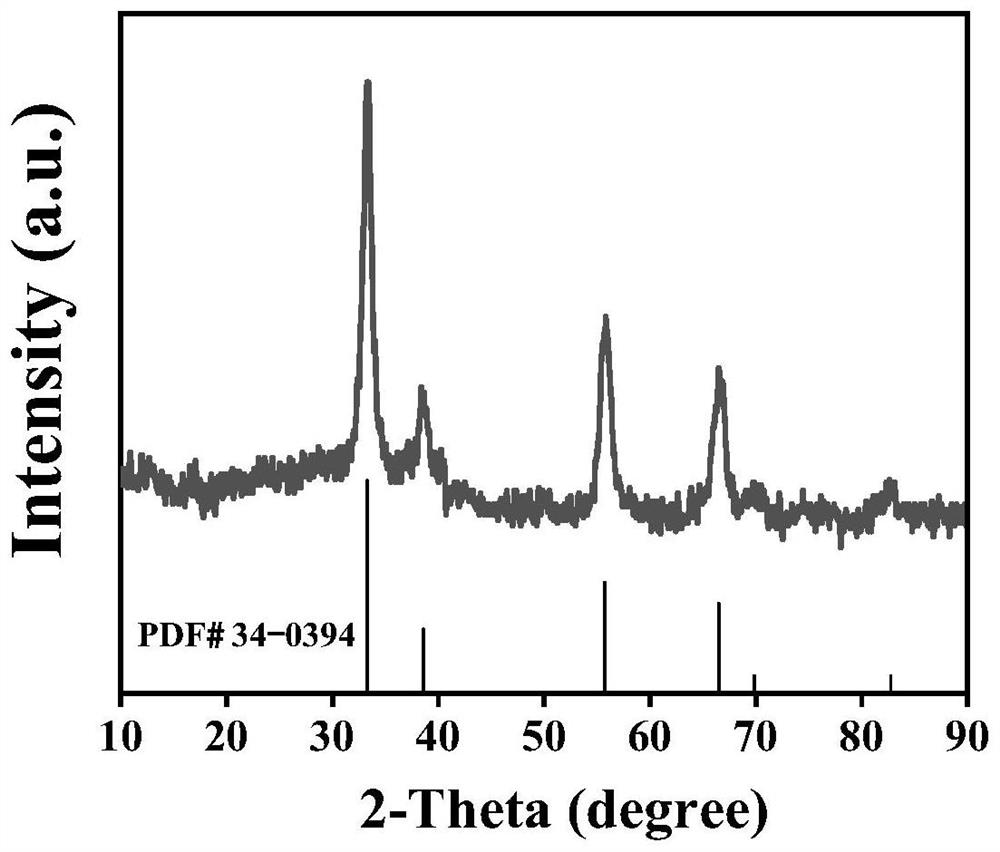

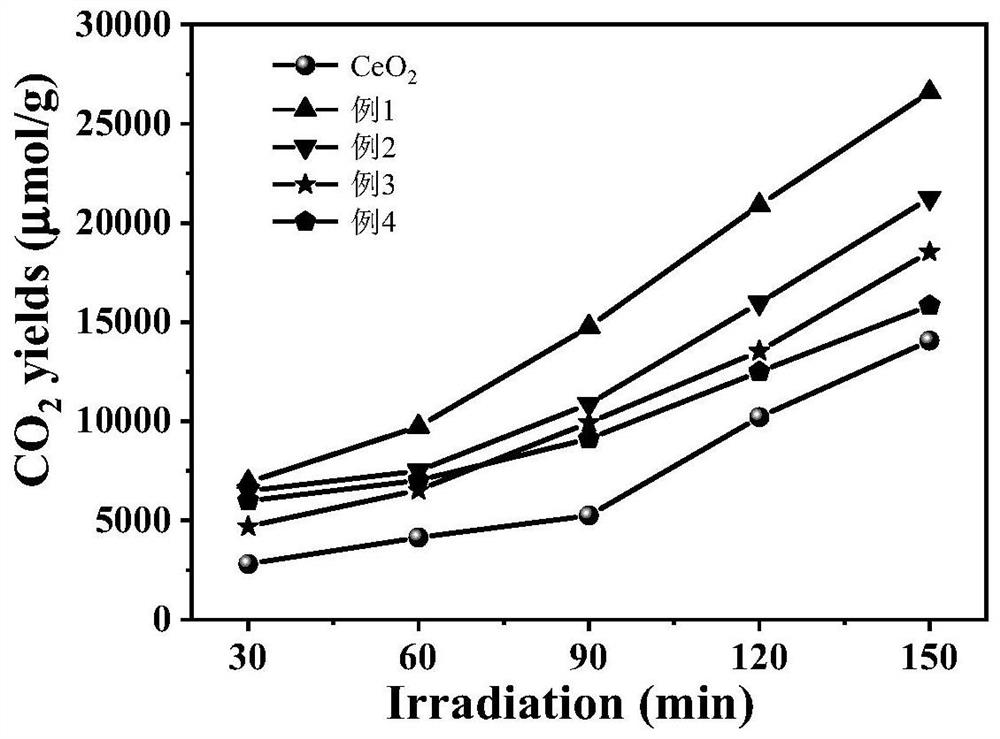

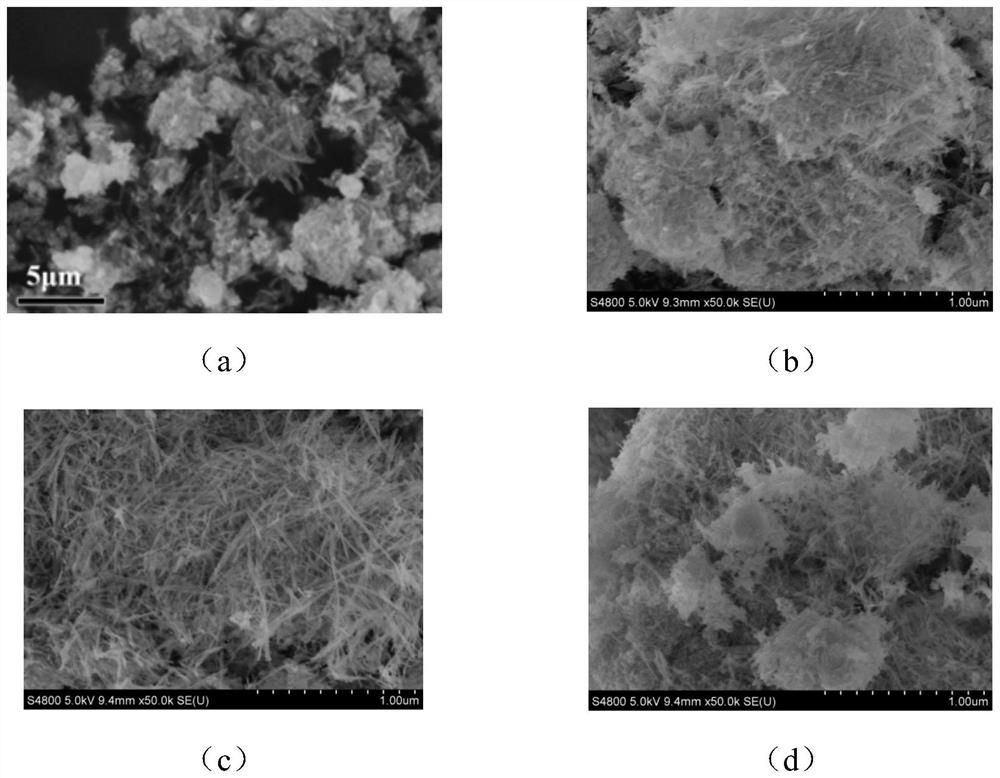

Preparation method and application of cerium dioxide nanowire

ActiveCN113772710AImprove efficiencyIncrease productionMaterial nanotechnologyCerium oxides/hydroxidesAir atmosphereNanowire

The invention discloses a preparation method and application of a cerium dioxide nanowire, and belongs to the technical field of material preparation and environmental governance. The method comprises the following steps: carrying out a strong alkaline hydrothermal reaction on an aqueous solution of a molybdenum source and an aqueous solution of a cerium source to generate a mixture of a cerium oxide precursor and the molybdenum source, and uniformly mixing the mixture through hydrothermal stirring; and finally, carrying out high-temperature calcination in an air atmosphere to obtain the cerium dioxide nanowire. After cerium dioxide is modified with molybdenum, the morphology of cerium dioxide can be changed, the yield of carbon dioxide can be increased, precious metal can be replaced to achieve the purpose of increasing the yield of carbon dioxide, and the cost is remarkably reduced. The method has the advantages of simple operation, easily available raw materials, low cost, low energy consumption and the like; the stability is good, the activity is high, and the efficiency of photo-thermal catalytic combustion of volatile organic compounds is high.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com