Preparation method of imitation jade microcrystalline glass

A technology of glass-ceramics and imitation jade, which is applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., and can solve the problems of lack of imitation jade glass-ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

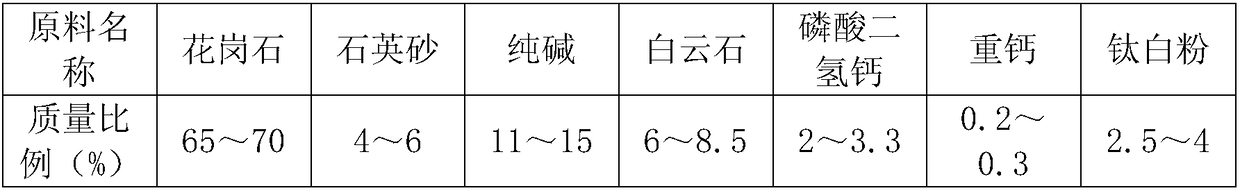

[0031] 1. Accurately weigh the following raw materials, and send them into a mixer for mixing (mixing time is 3.5 minutes, adding water accounts for 2% of the total weight of the raw materials).

[0032] raw material name

granite

Quartz sand

soda ash

heavy calcium

Titanium dioxide

Mass ratio (%)

76.8

5.7

15.9

8.2

2.9

0.2

3.0

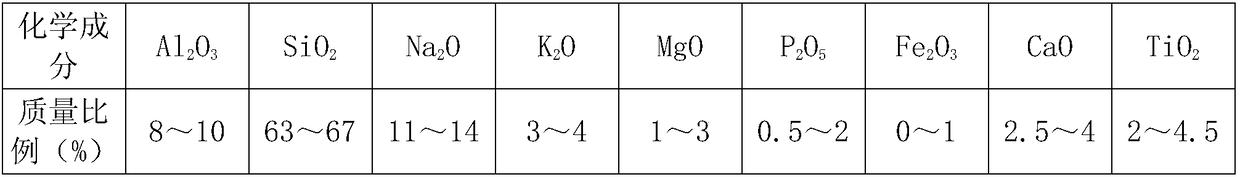

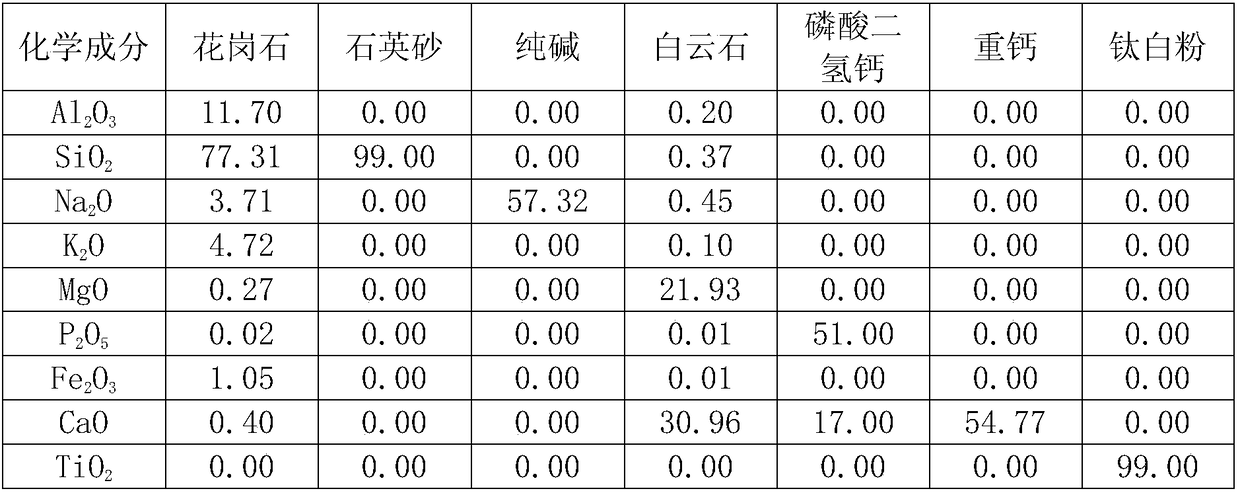

[0033] Wherein, raw material main chemical component weight percentage is formed as follows:

[0034]

[0035] 2. Send the above mixture into the all-electric melting furnace for melting. The melting temperature is 1420°C. After clarification and homogenization, the melted glass enters the material channel through the liquid flow hole and the ascending channel, and the temperature drops to 1280°C, and then enters the calendering process. The working pool is calendered and formed by a calender (forming temperature 1150°C), and then enters the ann...

Embodiment 2

[0041] 1. Accurately weigh the following raw materials and send them to the mixer for mixing (mixing time is 4 minutes, add 10kg of water).

[0042] raw material name

granite

Quartz sand

soda ash

heavy calcium

Titanium dioxide

Mass ratio (%)

68.2

14.4

14.7

8.3

2.9

0.2

3.0

[0043] 2. Send the above-mentioned mixture into the all-electric melting furnace for melting. The melting temperature is 1450°C. After clarification and homogenization, the melted glass enters the material channel through the liquid flow hole and the ascending channel, and the temperature drops to 1320°C, and then enters the calendering process. The working pool enters the annealing kiln after being calendered by a calender (forming temperature 1180°C).

[0044] 3. Anneal the rolled glass plate annealing kiln. The temperature of entering the kiln is 700°C. After holding at 660°C for 15 minutes, cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com