Corrosive sample fixture structure

A technology for corroding samples and fixtures, applied in the direction of weather resistance/light resistance/corrosion resistance, by removing certain components, such as weighing, measuring devices, etc. The problem that the sample cannot be taken out, etc., is convenient for mass production, and the processing and manufacturing process plan is convenient and feasible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

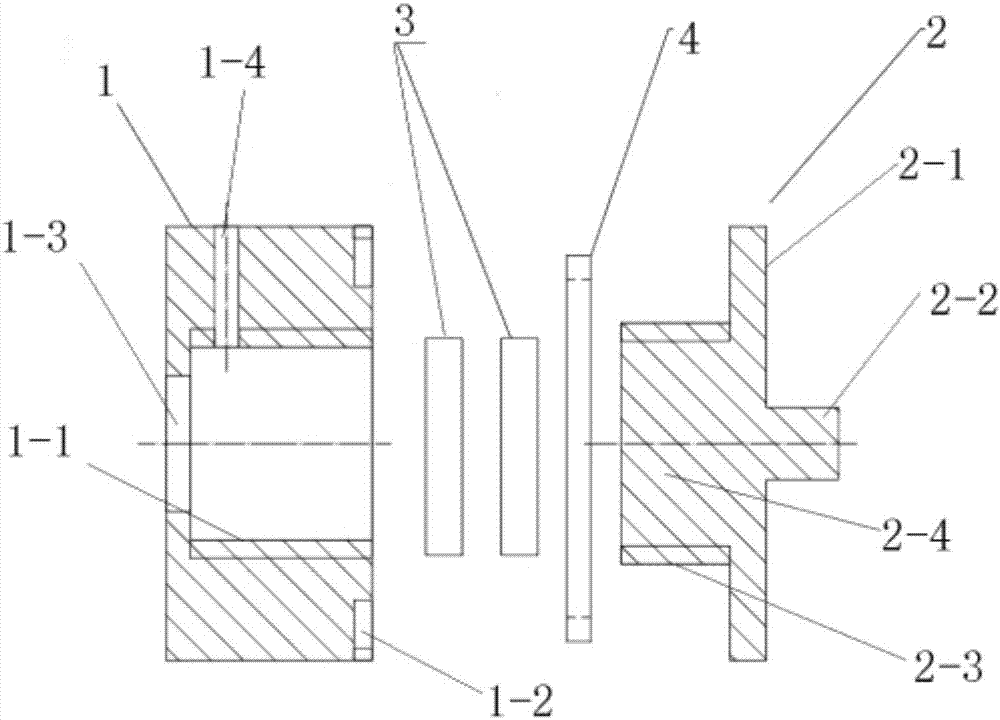

[0029] (1) Process an insulating seat 1 with polytetrafluoroethylene, the diameter of the insulating seat 1 is 36mm, the height is 17mm, the diameter of the through hole 1-3 at one end is 11.28mm, the internal thread 1-1 is M20*1.5, the thread 13mm high.

[0030] (2) Process an insulating cover 2 with polytetrafluoroethylene, the diameter of the insulating cover 2 is 36mm, the thread 2-4 on the lower fixing column 2-3 is M20*1.5, 9mm high, and the upper cuboid protrudes 2-2 It is 32*6*6mm.

[0031] (3) Process two circular samples with a diameter of 18mm and a height of 3mm.

[0032] (4) Process a sealing ring 4 with silica gel or rubber, the inner and outer diameters are 28mm and 32mm respectively, and the height is 2mm.

[0033] (5) Put two circular samples 3 into the interior of the insulating seat 1, insert metal wires from the wire holes 1-4 on the side wall of the insulating seat 1 to between the samples, and put the sealing ring 4 into the end of the insulating seat 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com