Alkali residue-based cement gel material

A gel material, alkali slag-based technology, applied in cement production, etc., can solve the problems of high cost, environmental pollution, etc., and achieve the effect of fast hardening, simple manufacturing process, hardening acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

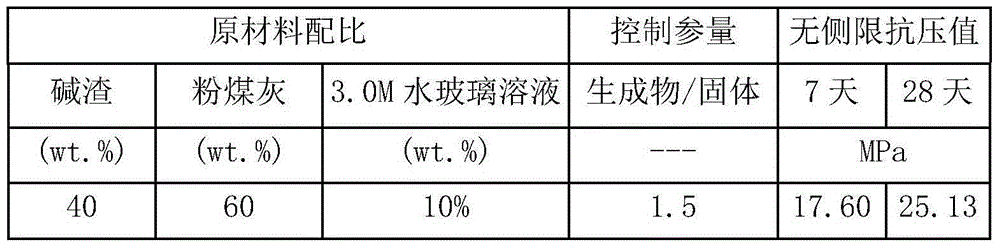

[0014] Get the actual required amount of alkali slag and fly ash for construction projects, and mix evenly with 40% (quality) of alkali slag and 60% (quality) of fly ash, then add 10% ( mass) molar concentration of 3.0M water glass as an active agent, then stir evenly to obtain a kind of alkali slag-based cement gel material.

[0015] The unconfined compressive strength measurement results of a kind of alkali slag-based cement gel material obtained in the present embodiment are as follows:

[0016] The alkali slag-based cement gel material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is greater than that of the 7-day-old sample. Table 1 lists the unconfined compressive strength of an alkali slag-based cement gel material prepared in this example. The measured unconfined compressive strength is 17.60MPa-25.13MPa, which can meet the strength requirements for mine water-stop curtains and other related projects.

...

Embodiment 2

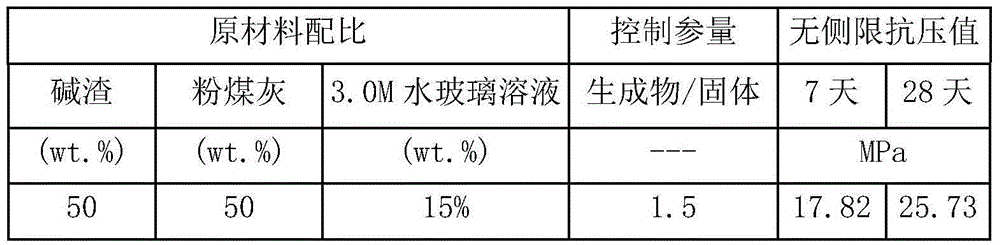

[0020] Get the actual required amount of alkali slag and fly ash for construction projects, and mix the alkali slag and 50% (quality) fly ash uniformly by percentage, and then add 15% ( mass) molar concentration of 3.0M water glass as an active agent, then stir evenly to obtain a kind of alkali slag-based cement gel material.

[0021] The unconfined compressive strength measurement results of a kind of alkali slag-based cement gel material obtained in the present embodiment are as follows:

[0022] The alkali slag-based cement gel material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is increased compared with that of the 7-day-old sample. Table 2 lists the unconfined compressive strength of an alkali slag-based cement gel material prepared in this example. The measured unconfined compressive strength values range from 17.82MPa to 25.73MPa, which can meet the strength requirements for mine water-stop curtains ...

Embodiment 3

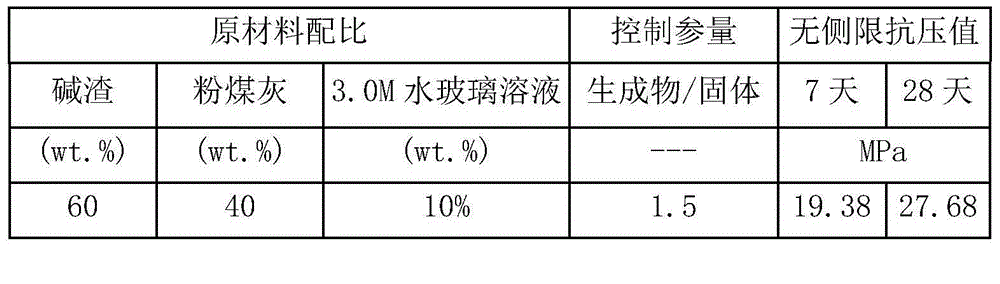

[0026] Get the actual required amount of alkali slag and fly ash for construction projects, mix evenly with 60% (quality) of alkali slag and 40% (quality) of fly ash, and then add 10% ( mass) molar concentration of 3.0M water glass as an active agent, then stir evenly to obtain a kind of alkali slag-based cement gel material.

[0027] The unconfined compressive strength measurement results of a kind of alkali slag-based cement gel material obtained in the present embodiment are as follows:

[0028] The alkali slag-based cement gel material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is increased compared with that of the 7-day-old sample. Table 3 lists the unconfined compressive strength of an alkali slag-based cement gel material prepared in this example. The measured unconfined compressive strength values range from 19.38MPa to 27.68MPa, which can meet the strength requirements for mine water-stop curtains ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com