Two-sided assembly plastic tray

A plastic pallet, double-sided technology, applied in the field of double-sided assembled plastic pallets, can solve problems such as damage, waste, and pallet collision, and achieve the effects of reducing costs, increasing service life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

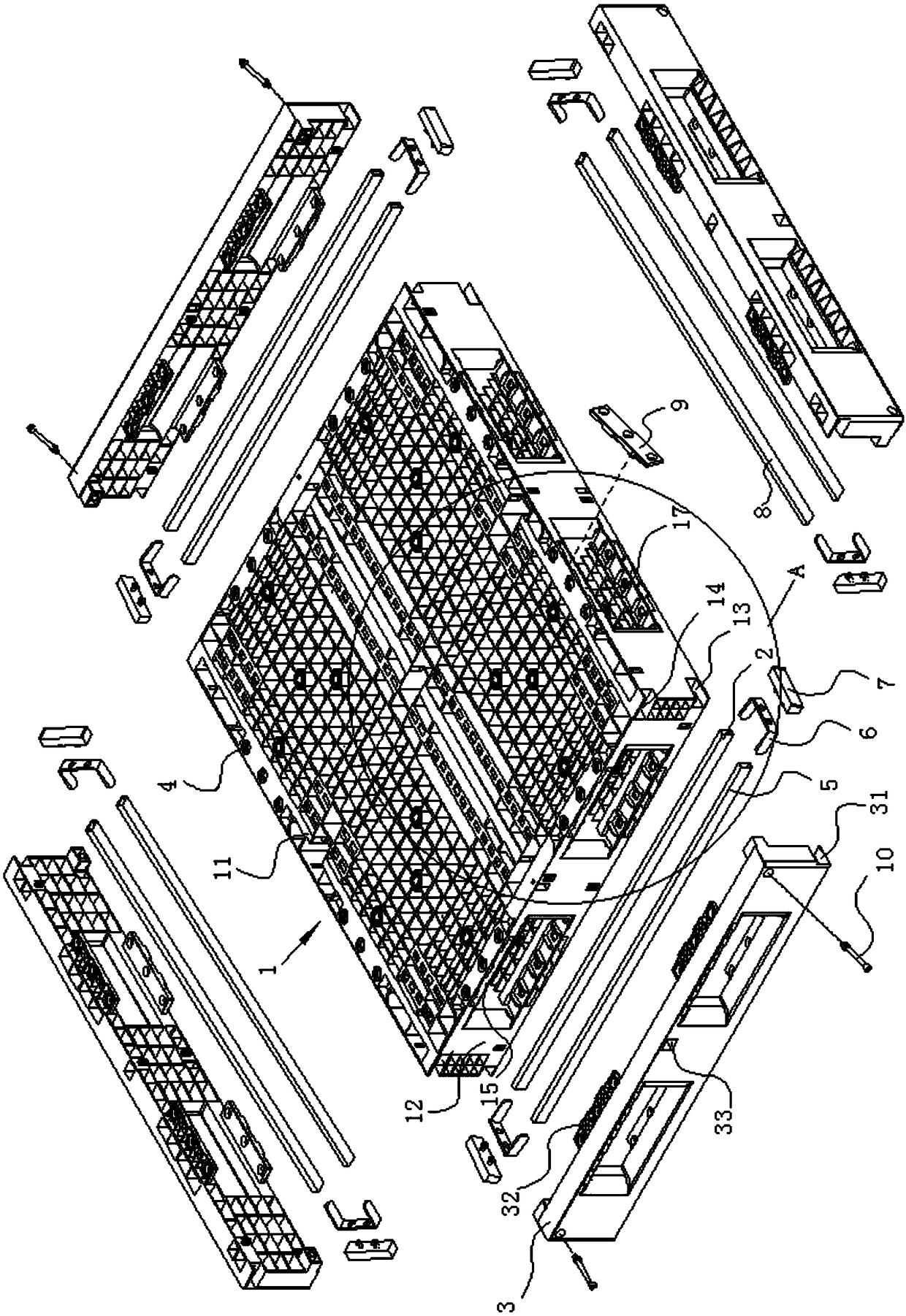

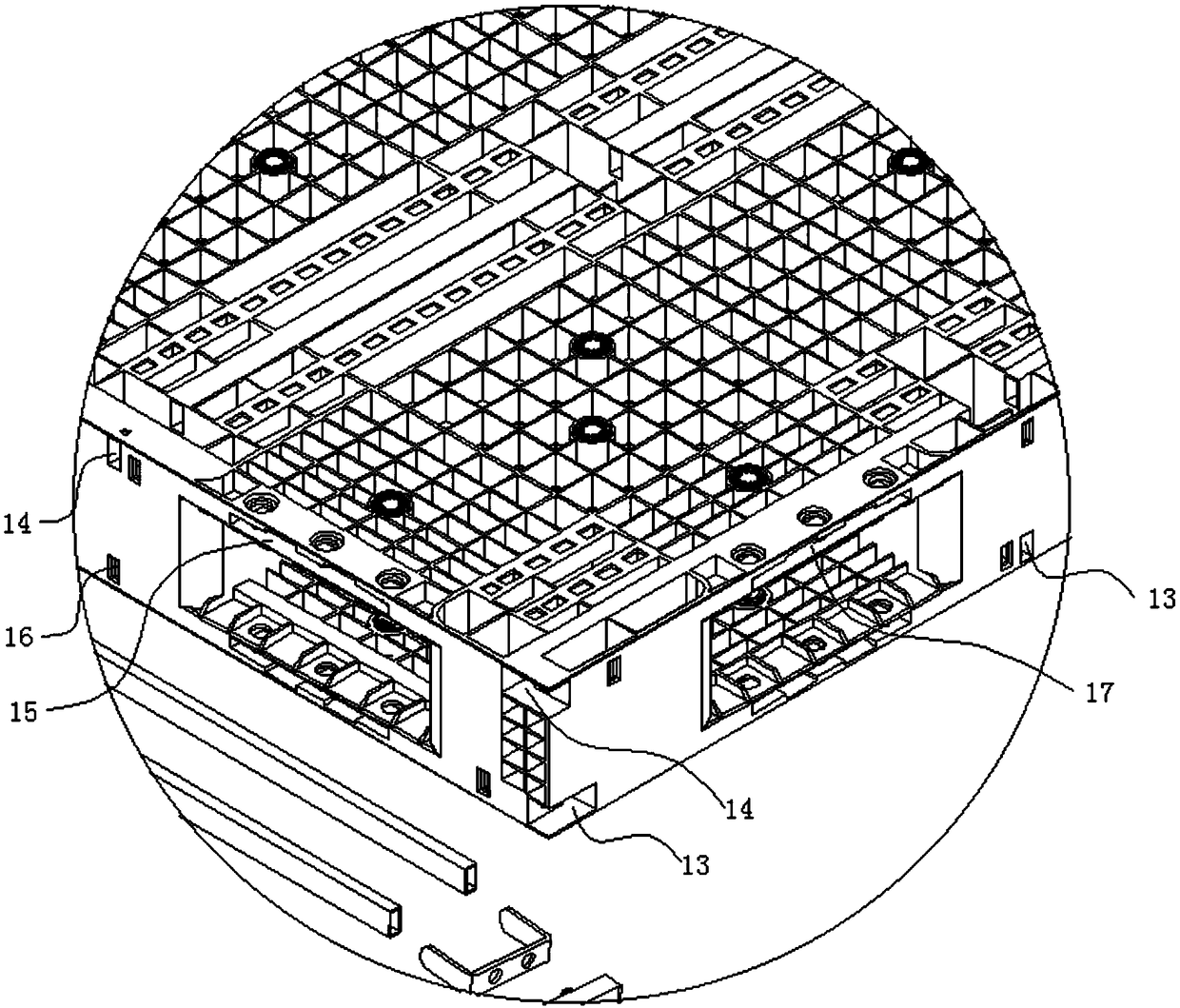

[0048]Such as Figure 1-10 The described double-sided assembled plastic tray includes a main board 1 and side strips 3 fixed on both sides of the main board 1. The main board 1 includes two rib frames 11 and is evenly distributed between the two rib frames 11. A plurality of feet 12 also includes the first main board steel pipe 2, the second main board steel pipe 8, the side bar steel pipe 5, the steel pipe connector 6 and the steel pipe blocking block 7;

[0049] The front and rear sides of the rib frame 11 are provided with a second main board steel pipe hole 14 for installing the second main board steel pipe 8, and the two ends and the middle of the rib frame 11 are provided with at least one second main board steel pipe hole. 14. The two ends of the second main board steel pipe 8 located in the middle of the rib frame 11 extend out of the main board 1, and the side bar 3 is provided with a placement groove 33 corresponding to the second main board steel pipe 8; the front a...

Embodiment 2

[0056] Such as Figure 4 As shown, this embodiment is improved on the basis of Embodiment 1. The side bar connecting block 4 includes a clamping portion 41 and a first elastic buckle 42 and a second elastic buckle 43 symmetrically formed on the lower end of the clamping portion 41. The outer sides of the first elastic buckle 42 and the second elastic buckle 43 are respectively formed with a first locking protrusion 44 and a second locking protrusion 45 . The side strip connection block 4 includes a clamping portion 41 and a first elastic buckle 42 and a second elastic buckle 43 symmetrically formed on the lower end of the clamping portion 41 for the convenience of installation, and when the side strip connection block 4 connects the side strip 3 with the rib When the frame 11 is connected, it is clamped by the first clamping protrusion 44 and the second clamping protrusion 45 to make its structure more stable.

Embodiment 3

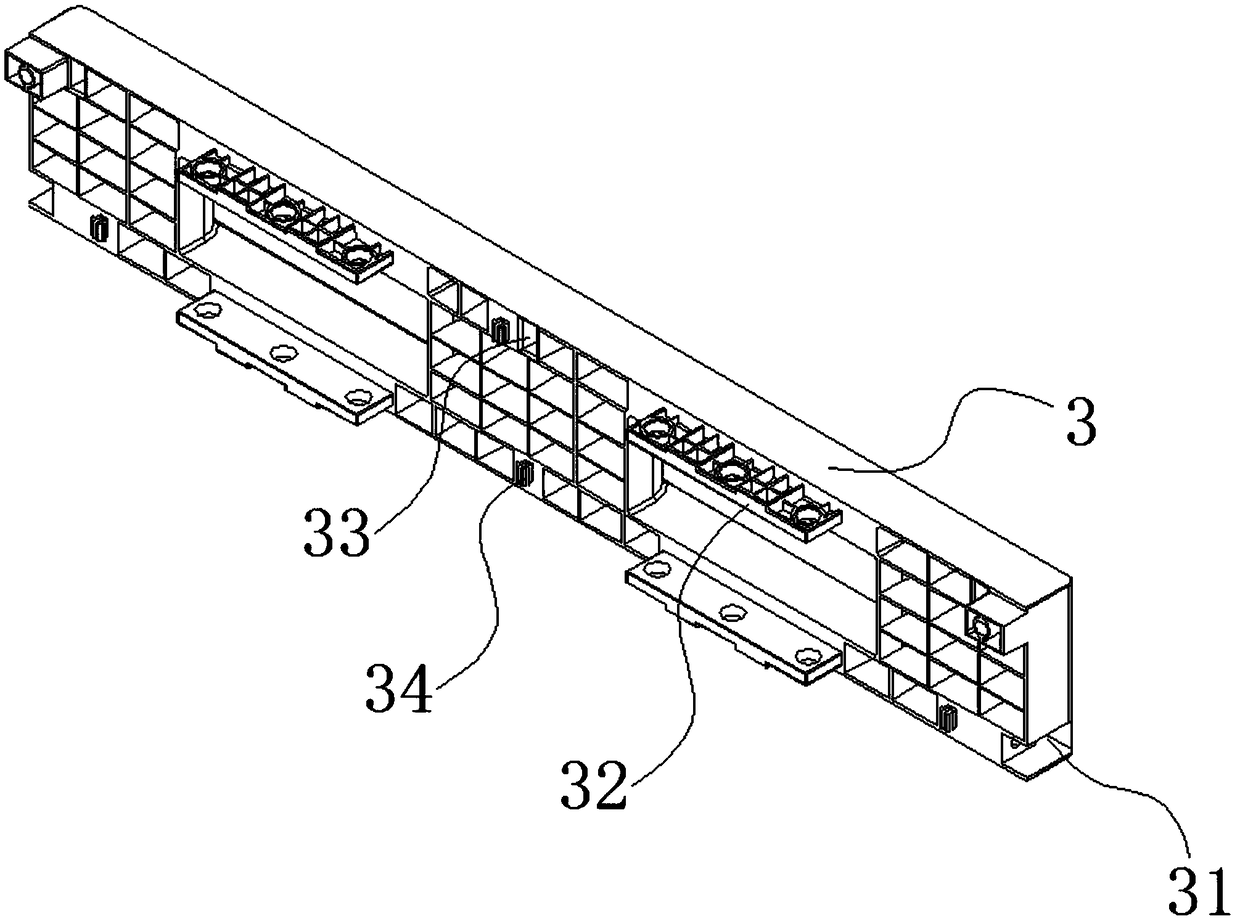

[0058] Such as image 3 As shown, this embodiment is improved on the basis of Embodiment 1. Positioning grooves 16 are provided on both sides of the main board 1 opposite to the side strips 3, and the side strips 3 are provided with protrusions corresponding to the positioning grooves 16. ear34. Positioning slots 16 are set on the strip feet 12, and lugs 34 corresponding to the positioning slots 16 on the side strips 3 are provided for convenient positioning, and at the same time limit the position of the side strips 3, so that the distance between the side strips 3 and the main board 1 The connection between them is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com