Preparation method of carbon-aerogel-based spherical anticorrosion magnetic material

A carbon aerogel and magnetic material technology, which is applied in the field of preparation of carbon aerogel-based spherical corrosion-resistant magnetic materials, can solve the problem of unprovided magnetic strength, uncomfortable surface coating, uneven pore size distribution, etc. problem, to achieve the effect of short preparation cycle, get rid of harsh restrictions, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

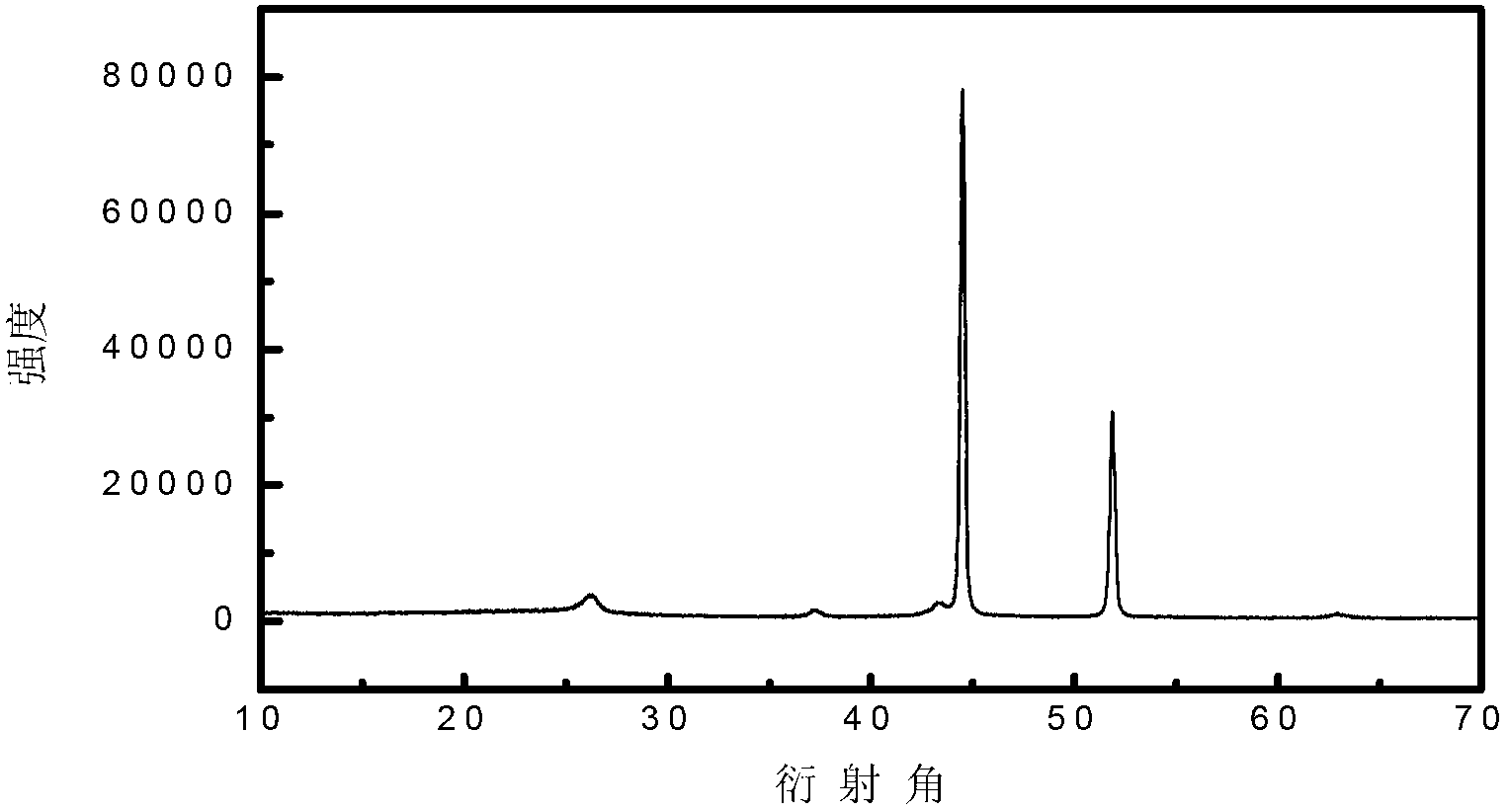

Embodiment 1

[0030] In this embodiment, the preparation method of the carbon airgel-based spherical corrosion-resistant magnetic material is carried out as follows:

[0031] 1. Weigh 0.1mol nickel nitrate, 0.01mol m-phenylenediamine and 0.2mol formaldehyde solution and place in 5.4g distilled water to prepare an aqueous solution, add 0.002mol citric acid and 0.005mol sodium lauryl sulfate to obtain a mixed solution, and obtain The mixed solution was gelled in an incubator at 80°C for 15 hours to form a nickel-containing gel;

[0032] 2. Dry the prepared nickel-containing gel at 110°C under vacuum for 3 hours, then carbonize at 600°C for 2 hours under the protection of a reducing atmosphere, and then continue to cool down to room temperature with reducing gas to obtain coated carbon gas condensation Glue Ni composite material; the reducing gas is a mixed gas of hydrogen and nitrogen, the content of hydrogen is 10% by volume, and the gas flow rate of the reducing gas is 0.1-10L / min.

[0033...

Embodiment 2

[0036] 1. Weigh 0.2mol of nickel nitrate, 0.05mol of hydroquinone and .2mol of furfural in 13.2g of distilled water to prepare an aqueous solution, add 0.003mol of malonic acid and 0.006mol of cetyltrimethylammonium bromide A mixed solution was obtained, and the resulting mixed solution was gelled in a thermostat at 90° C. for 12 hours to form a nickel-containing gel;

[0037] 2. Dry the prepared nickel-containing gel at 130°C under vacuum for 2 hours, then carbonize at 800°C for 2 hours under the protection of a reducing atmosphere, and then continue to pass in reducing gas to cool down to room temperature to obtain coated carbon gas Ni composite material of gel; the reducing gas is a mixed gas of hydrogen and argon, the content of hydrogen is 5% by volume, and the gas flow rate of the reducing gas is 0.1-10L / min.

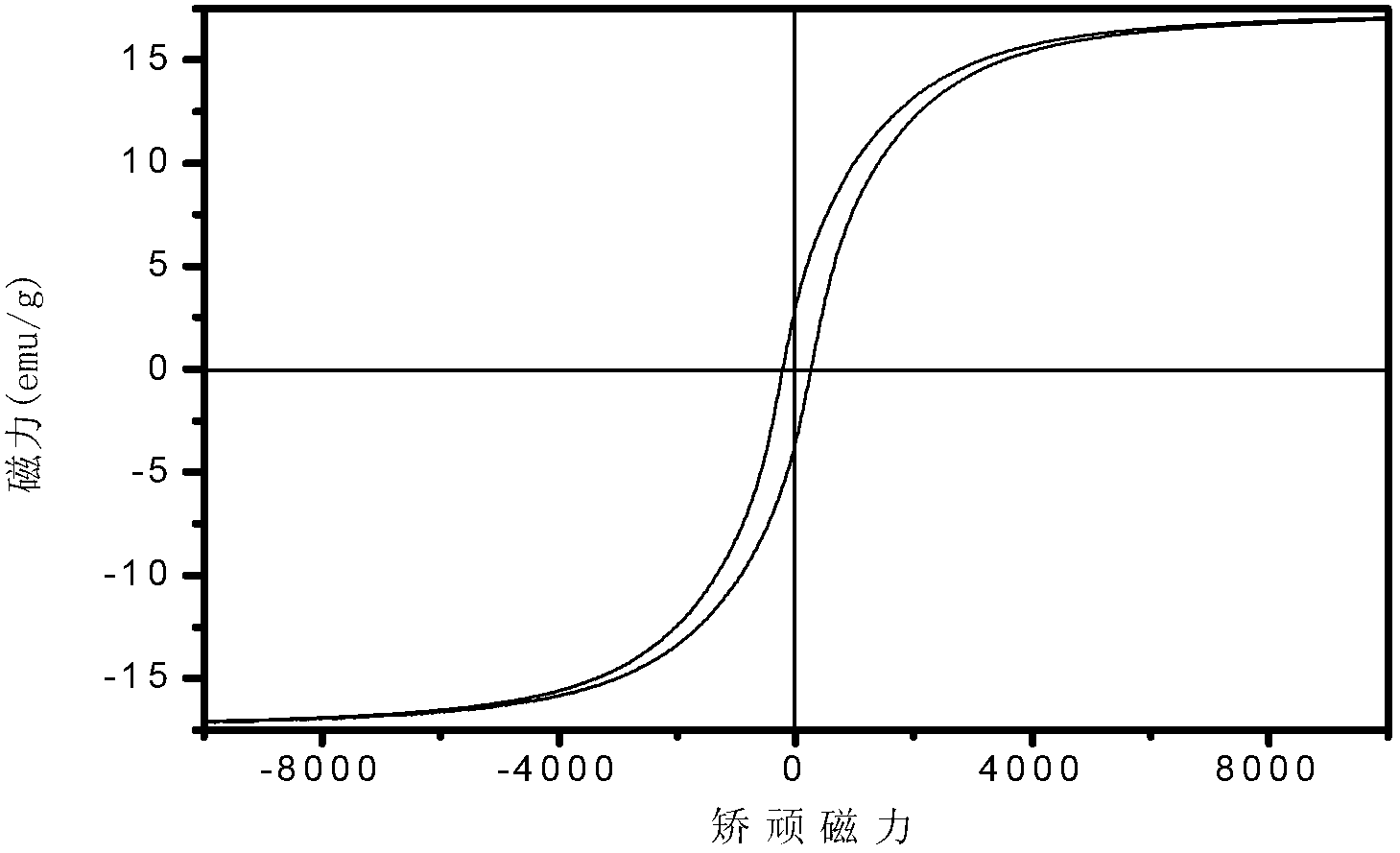

[0038] The carbon airgel-based spherical magnetic material prepared in this example is tested by a magnetometer and shows that the saturation magnetic force is 30...

Embodiment 3

[0041] 1. Weigh 0.15mol of nickel sulfate, 0.01mol of phenylenediamine and 0.2mol of formaldehyde solution in 6.8g of distilled water to prepare an aqueous solution, add 0.001mol of citric acid and 0.003mol of polyethylene glycol to obtain a mixed solution, and the resulting mixed solution Gel in a thermostat at 70°C for 24 hours to form a nickel-containing gel;

[0042] 2. Dry the prepared nickel-containing gel at 120°C under vacuum for 2.5 hours, and then carbonize it at 700°C for 2 hours under the protection of a reducing atmosphere, then continue to pass the reducing gas to cool down to room temperature to obtain coated carbon gas condensation Glue Ni composite material; the reducing gas is a mixed gas of hydrogen and helium, the content of hydrogen is 7% by volume, and the gas flow rate of the reducing gas is 0.1-10L / min.

[0043] The carbon airgel-based spherical magnetic material prepared in this example is tested by a magnetometer and shows that: the saturation magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com