Ni-base alloy composite baseband and its smelting preparation method

A composite baseband and base alloy technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of reducing baseband magnetism, low magnetism, surface layer and core layer are easy to crack, and achieve good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

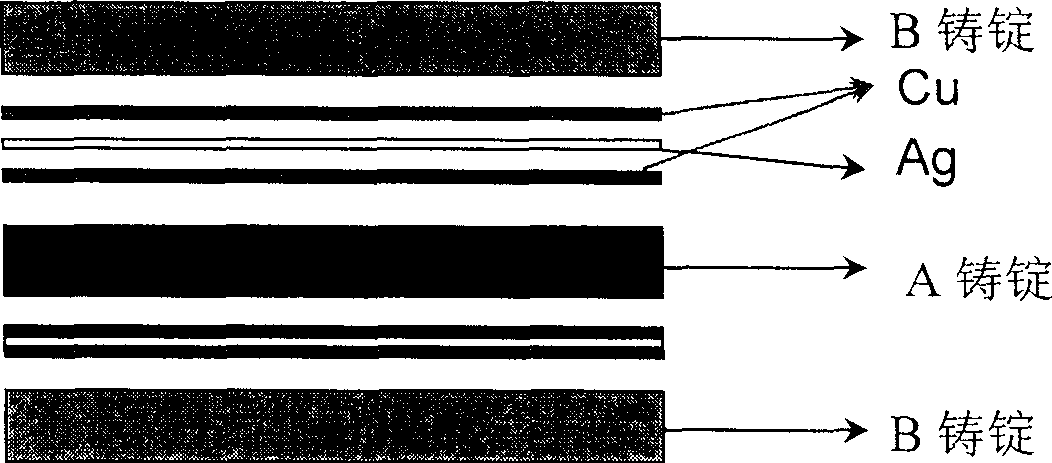

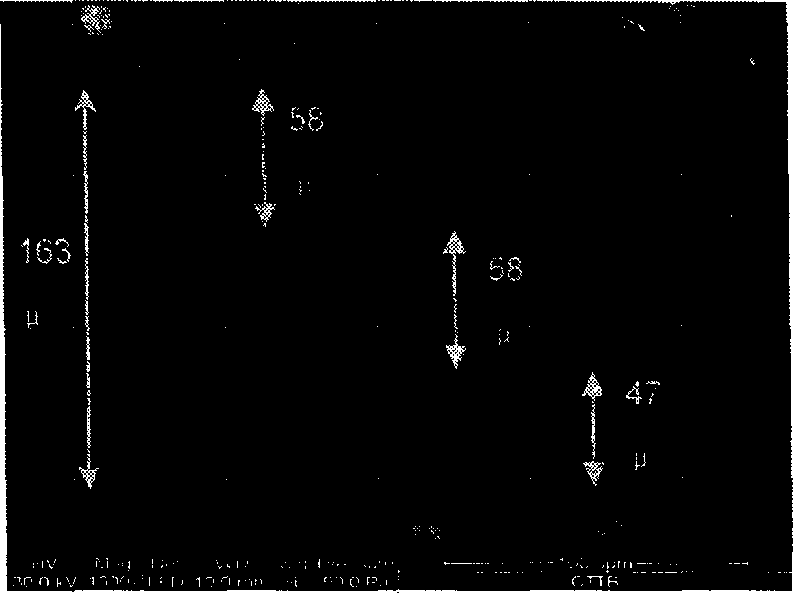

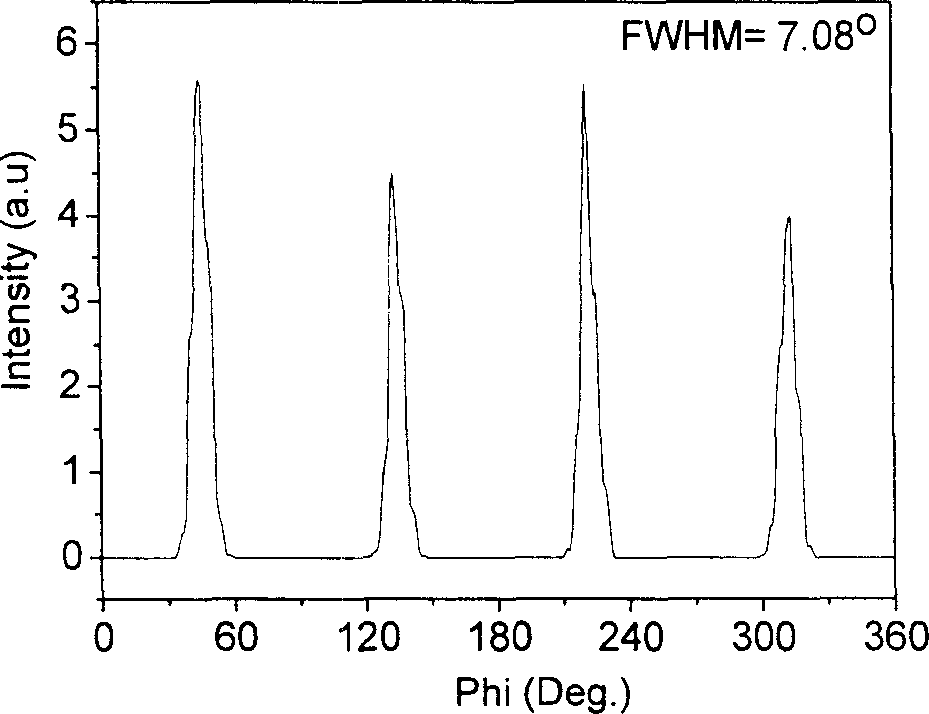

[0027] The NiW mixed block with 5 atomic percent of W and the NiW mixed block with 9.3 atomic percent of W were melted under vacuum conditions at 1500°C to form NiW alloy solid solution, then cast and forged to obtain high Initial ingots of Ni alloy with W content (code named A) and Ni alloy with low W content (code named B); the initial ingots B and A are cut into small pieces of certain thickness according to the thickness ratio of 1:1 , cold pressed together in the order of B-connecting layer-A-connecting layer-B to obtain a composite ingot, and the thickness of the composite ingot is 6mm. Composite ingots of the above mechanically pressed together in Ar / H 2 Sintering at 750°C for 8 hours in a mixed gas protective atmosphere can obtain a sintered Ni-based alloy composite ingot; cold-roll the sintered Ni-based alloy composite ingot with a deformation of 10-20% per pass, and the total The amount of deformation is greater than 95%, and a cold-rolled base strip with a thicknes...

Embodiment 2

[0029] The NiW mixed block with 5 atomic percent of W and the NiW mixed block with 12 atomic percent of W were melted under vacuum conditions at 1500°C to form NiW alloy solid solution, then cast and forged to obtain high Initial ingots of Ni alloy with W content (code named A) and Ni alloy with low W content (code named B); the initial ingots B and A are cut into small pieces of a certain thickness according to the thickness ratio of 1:2 , cold pressed together in the order of B-connection layer-A-connection layer-B to obtain a composite ingot, the thickness of the composite ingot is 12mm. Composite ingots of the above mechanically pressed together in Ar / H 2 Sintering at 900°C for 3 hours in a mixed gas protective atmosphere can obtain a sintered Ni-based alloy composite ingot; cold-roll the sintered Ni-based alloy composite ingot with a deformation of 8-15% per pass. The amount of deformation is greater than 95%, and a cold-rolled base strip with a thickness of 180 μm is ob...

Embodiment 3

[0031] The NiW mixed block with 7 atomic percent of W and the NiW mixed block with 10 atomic percent of W were smelted under vacuum conditions at 1500°C to form NiW alloy solid solution, then cast and forged to obtain high Initial ingots of Ni alloy with W content (code named A) and Ni alloy with low W content (code named B); the initial ingots B and A are cut into small pieces of certain thickness according to the thickness ratio of 1:1 , cold pressed together in the order of B-connecting layer-A-connecting layer-B to obtain a composite ingot, and the thickness of the composite ingot is 6mm. Composite ingots of the above mechanically pressed together in Ar / H 2 Sintering at 850°C for 4 hours in a mixed gas protective atmosphere can obtain a sintered Ni-based alloy composite ingot; cold-roll the sintered Ni-based alloy composite ingot with a deformation of 2-12% per pass. The amount of deformation is greater than 95%, and a cold-rolled base strip with a thickness of 200 μm is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com