Patents

Literature

371results about How to "Reduce magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

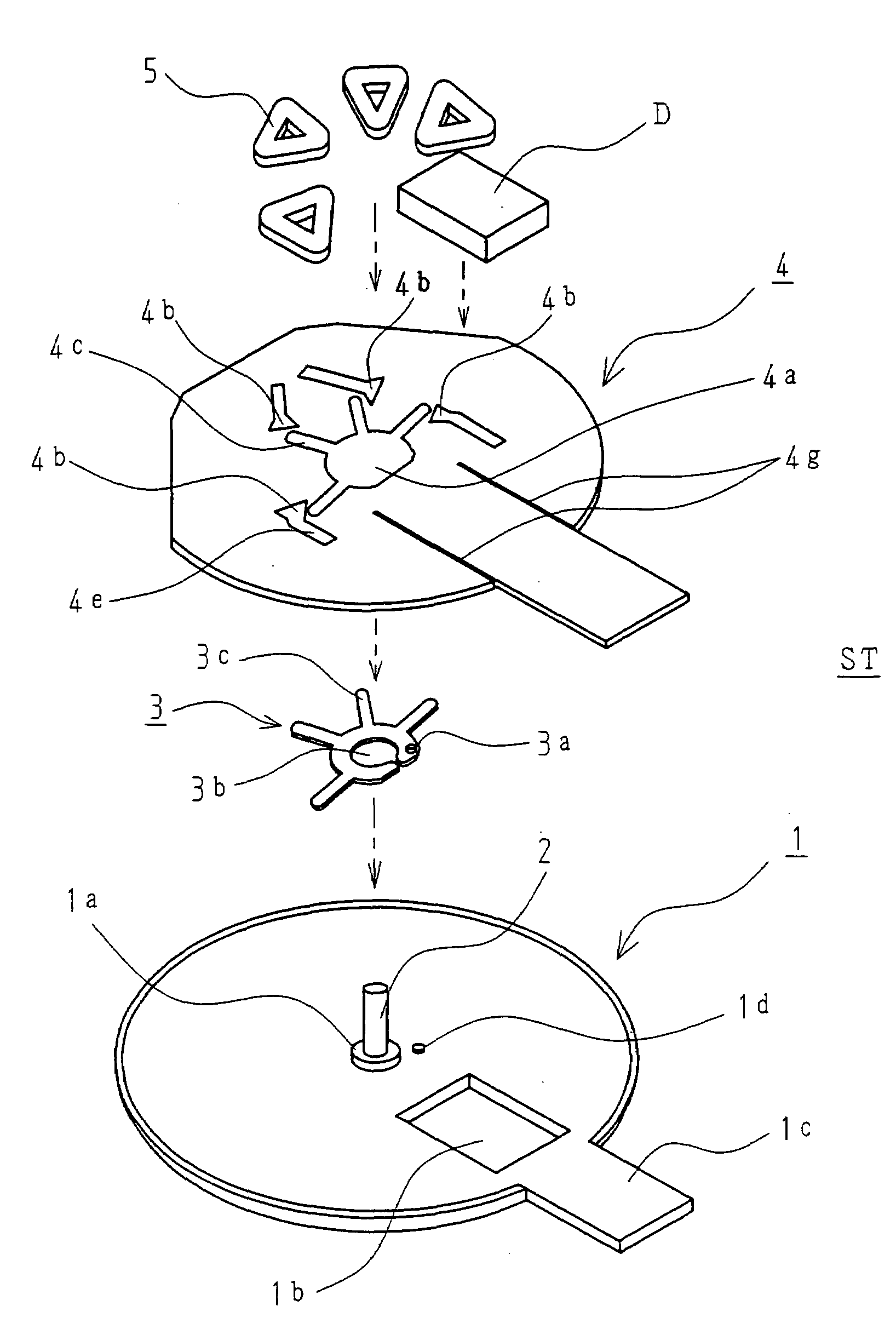

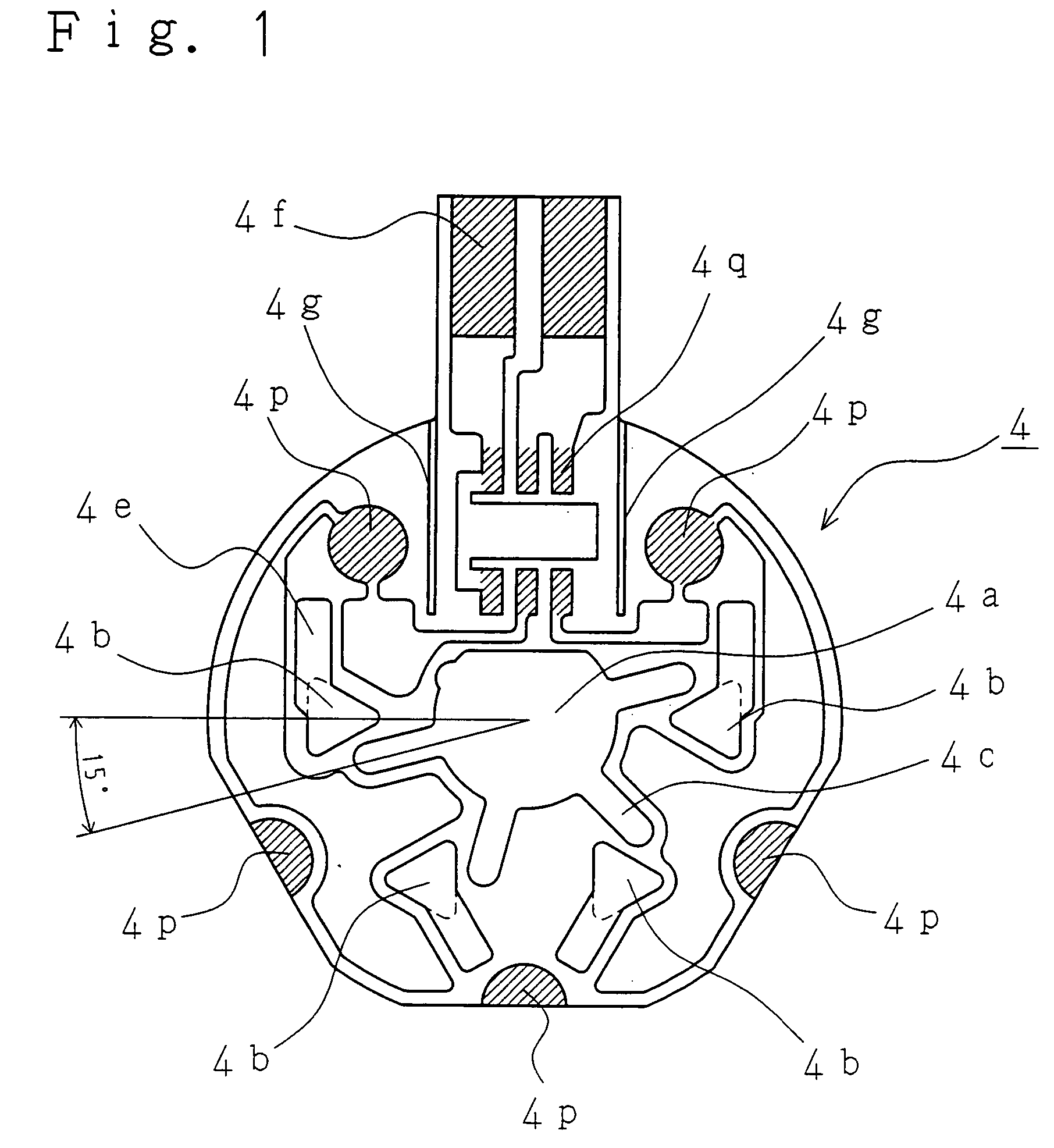

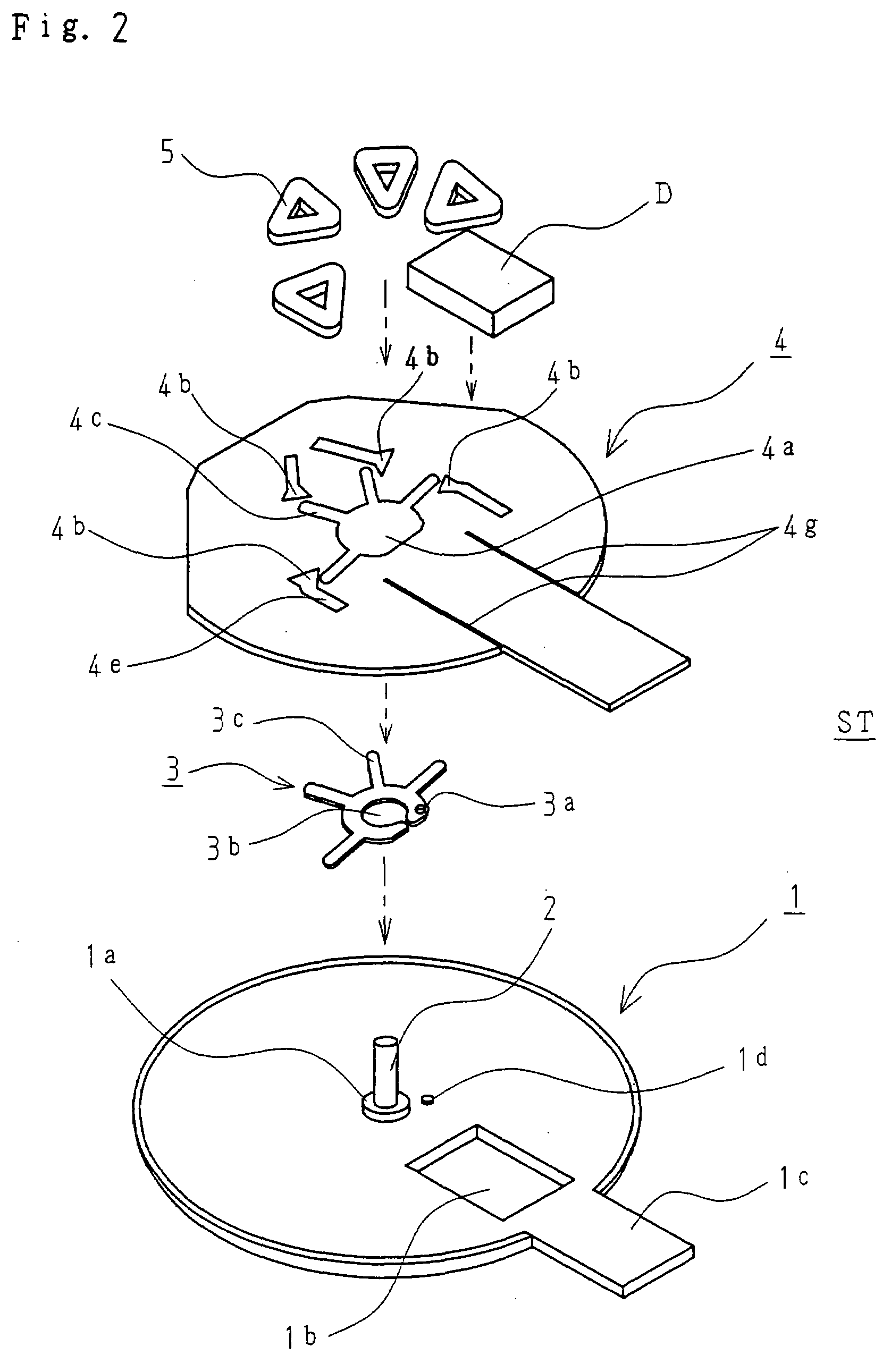

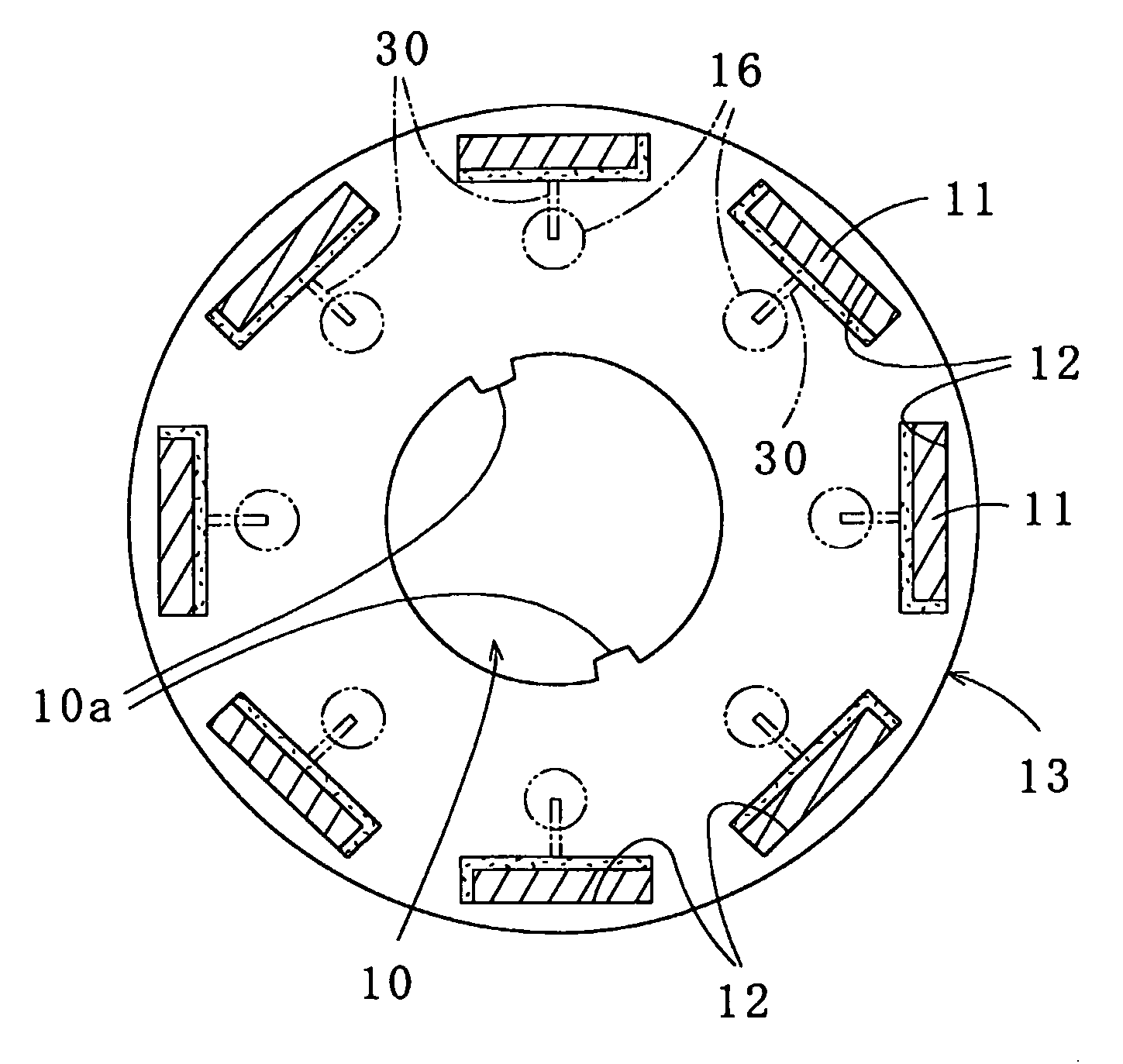

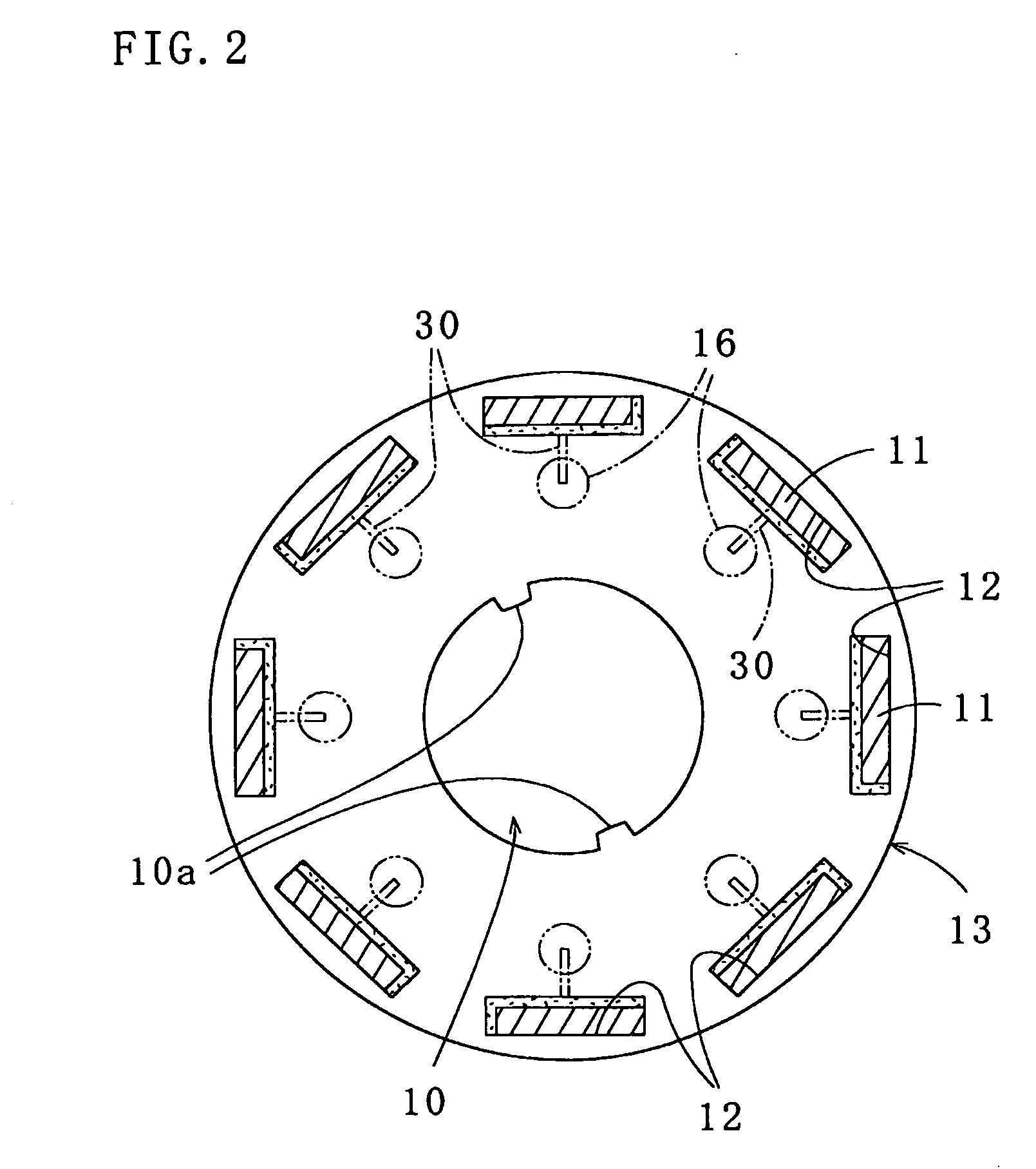

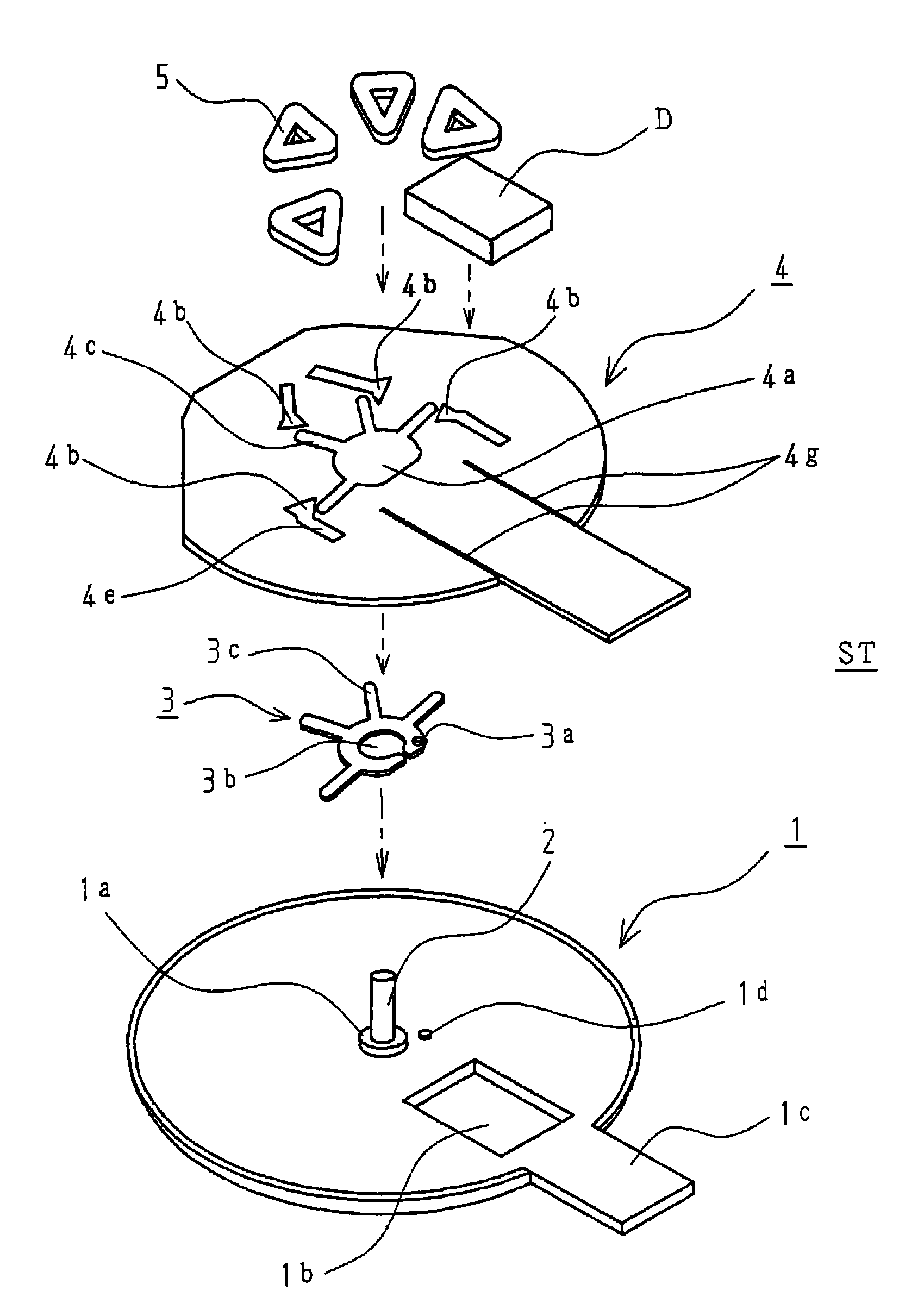

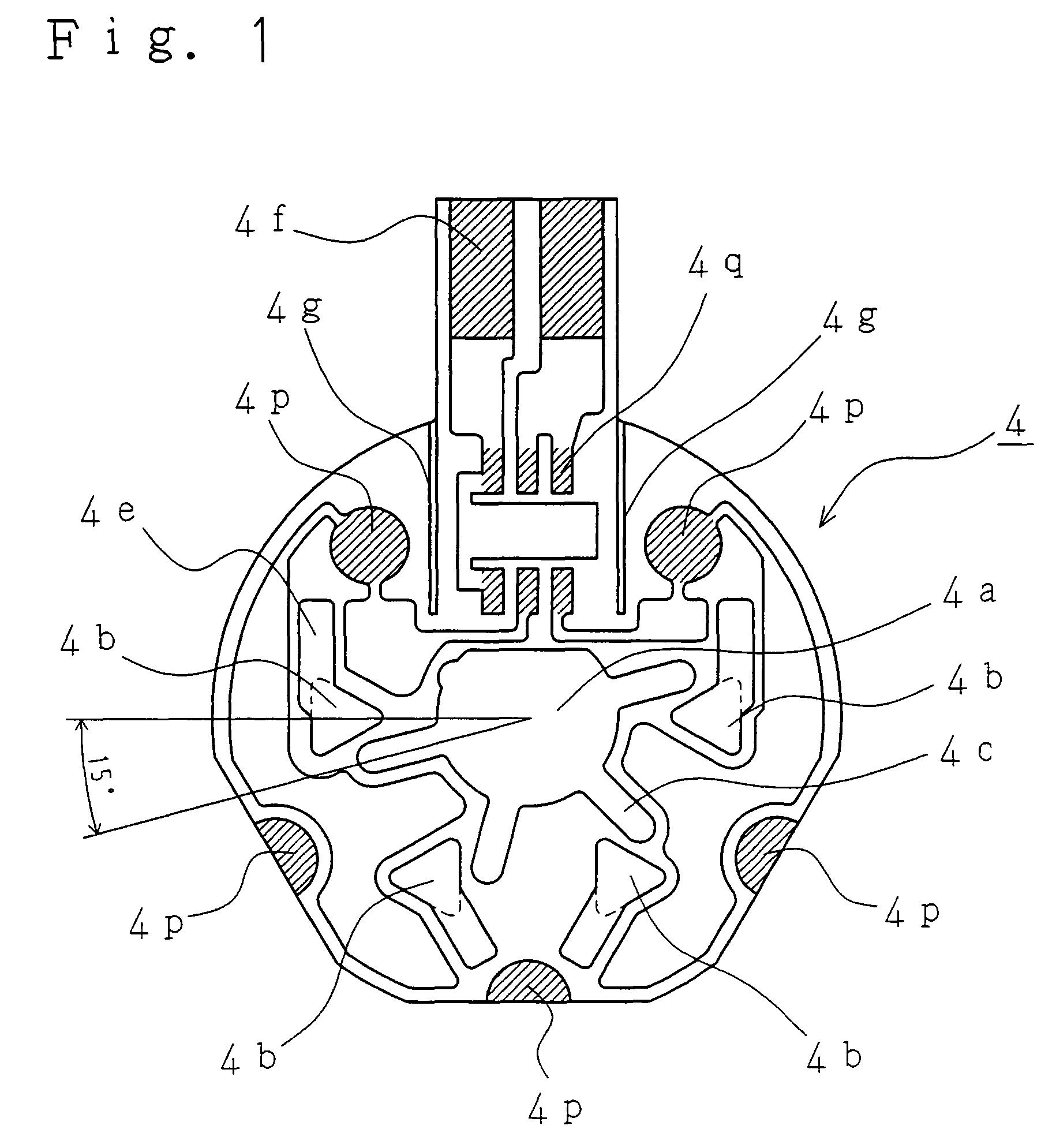

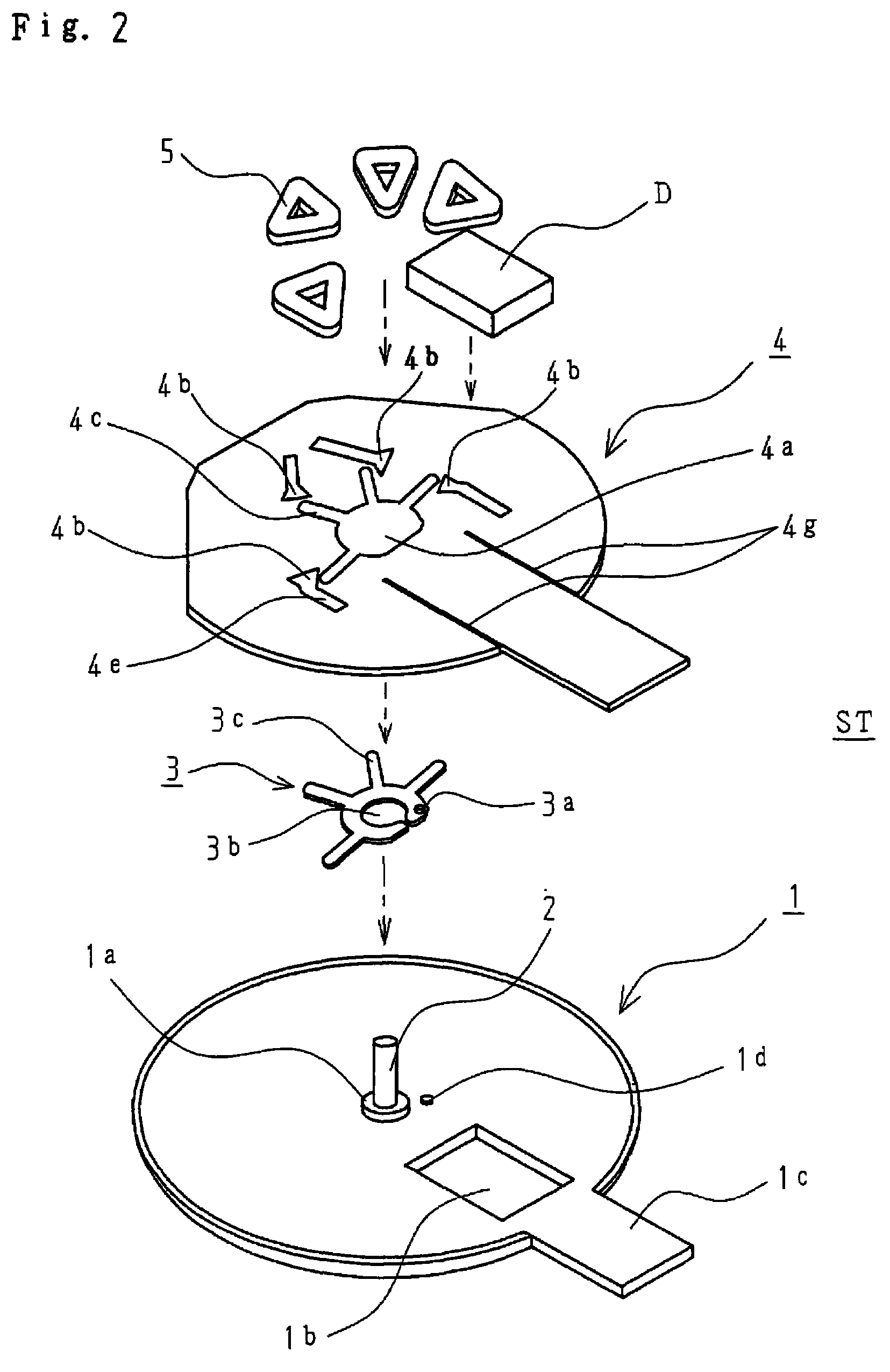

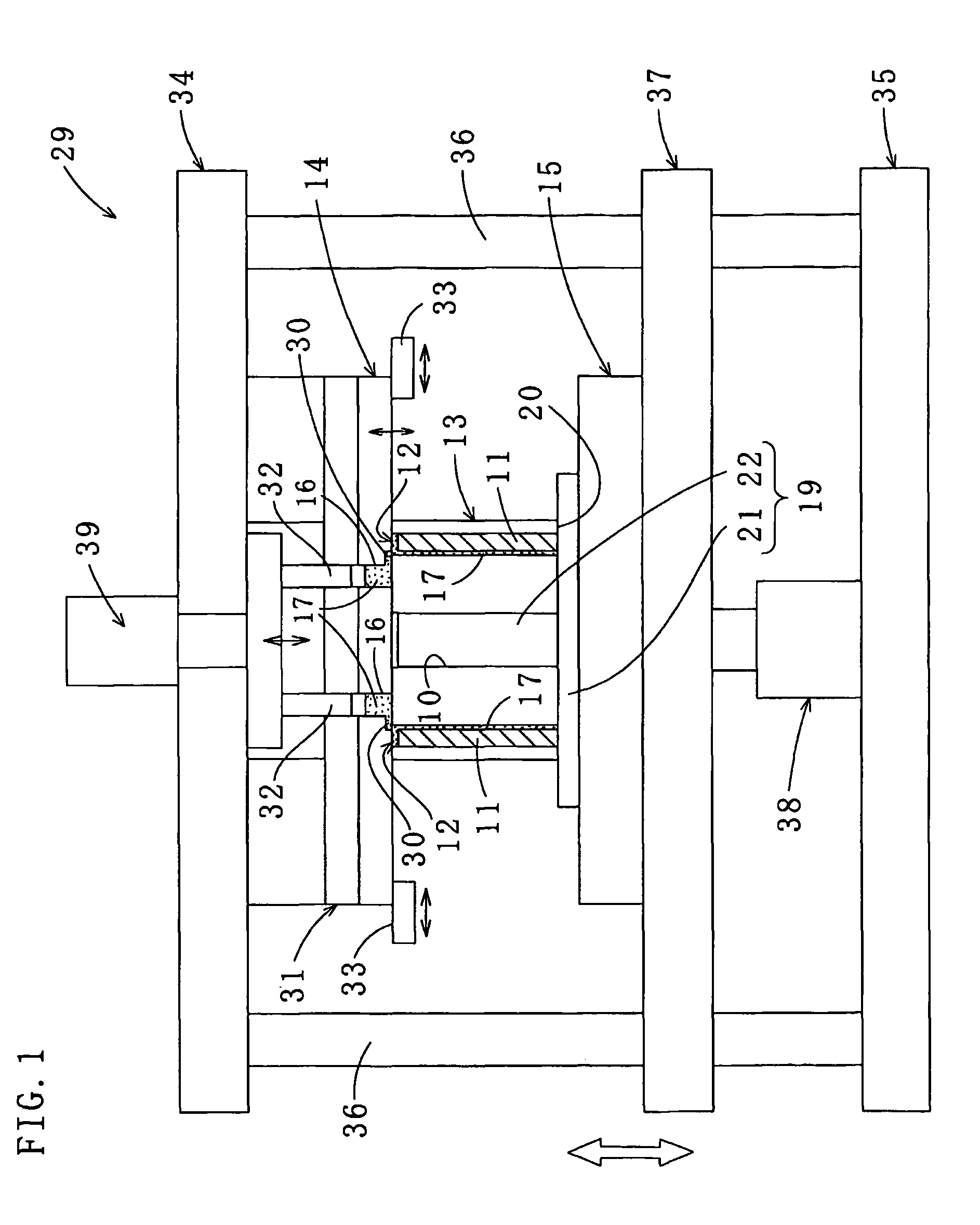

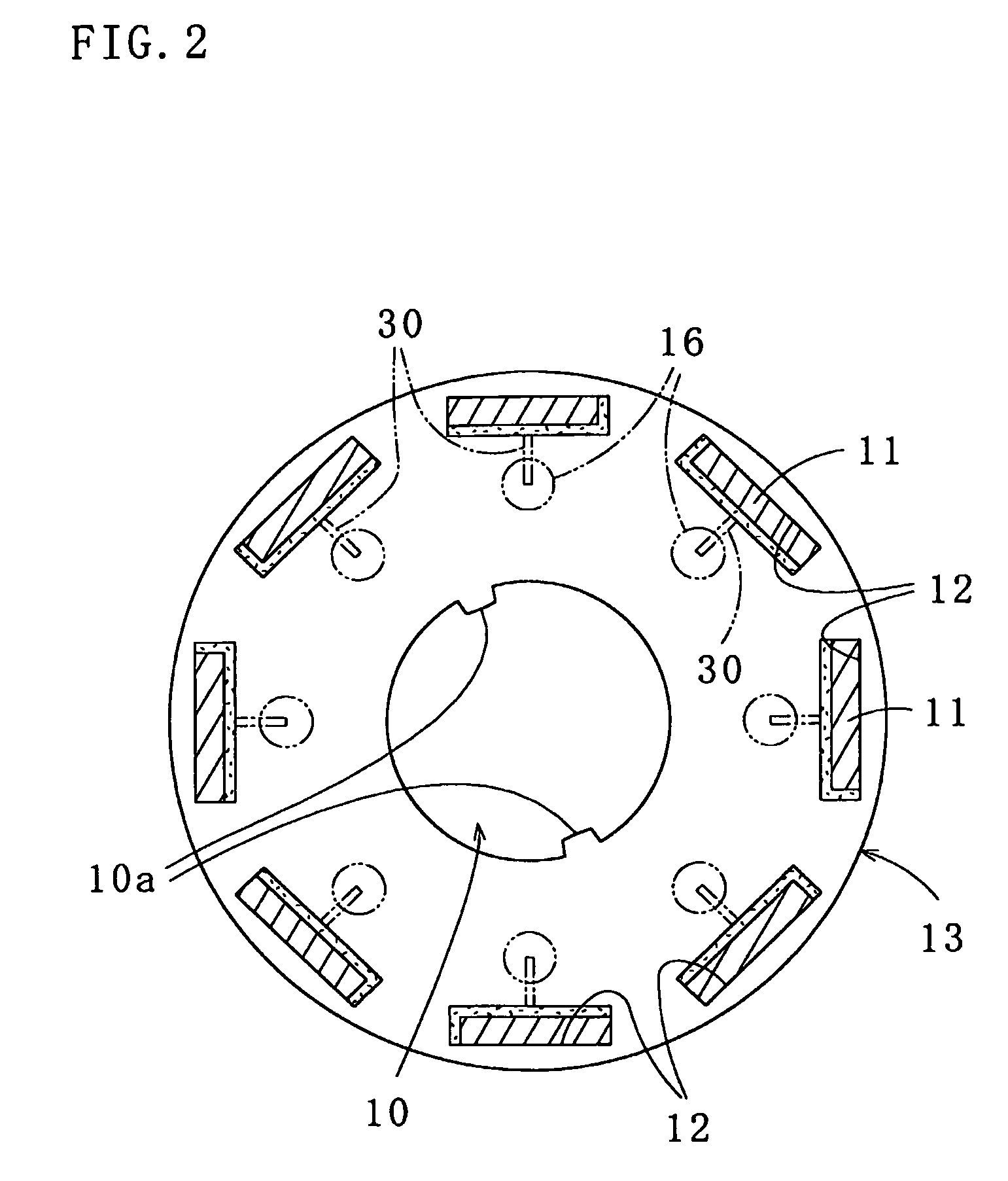

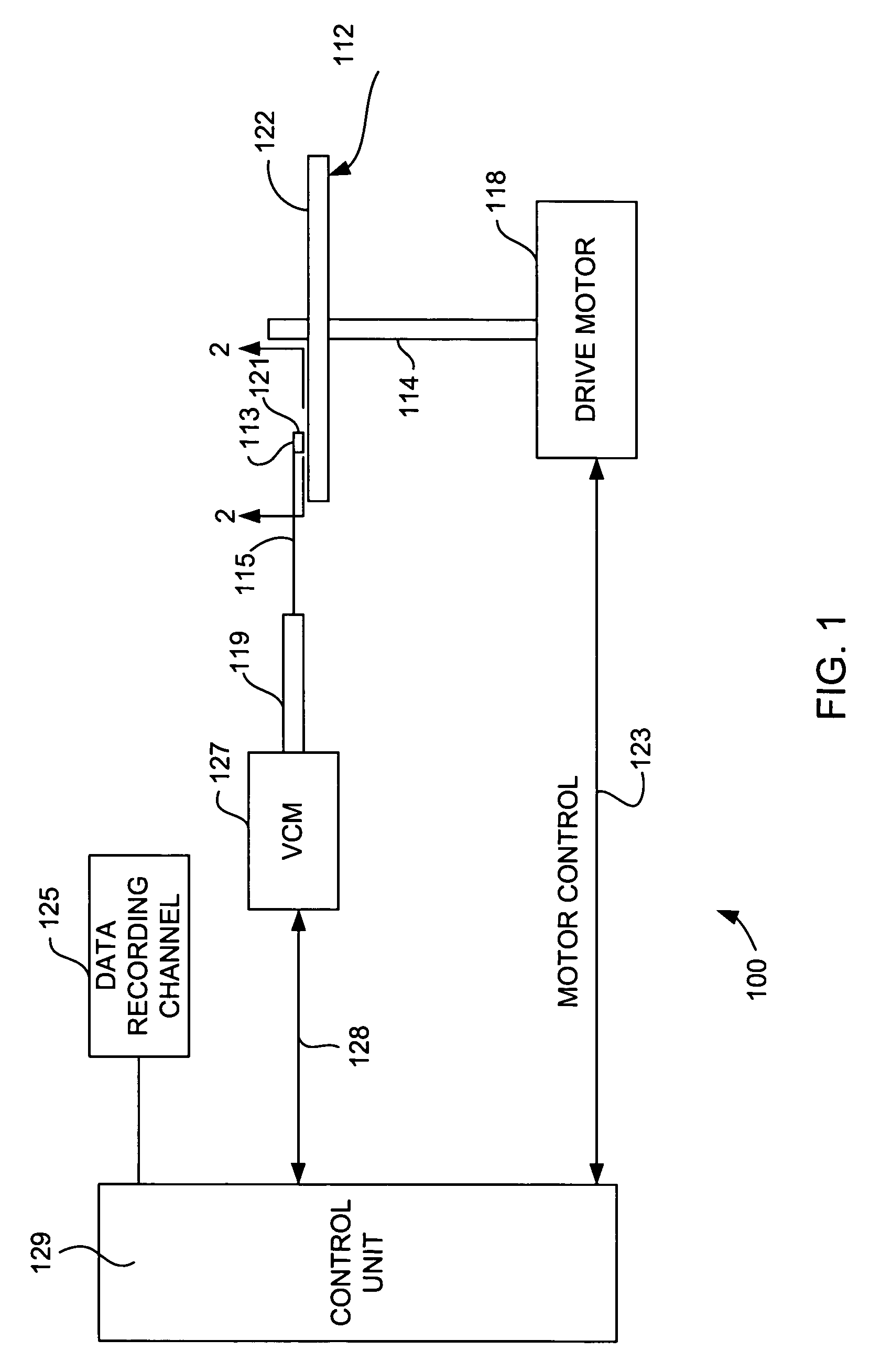

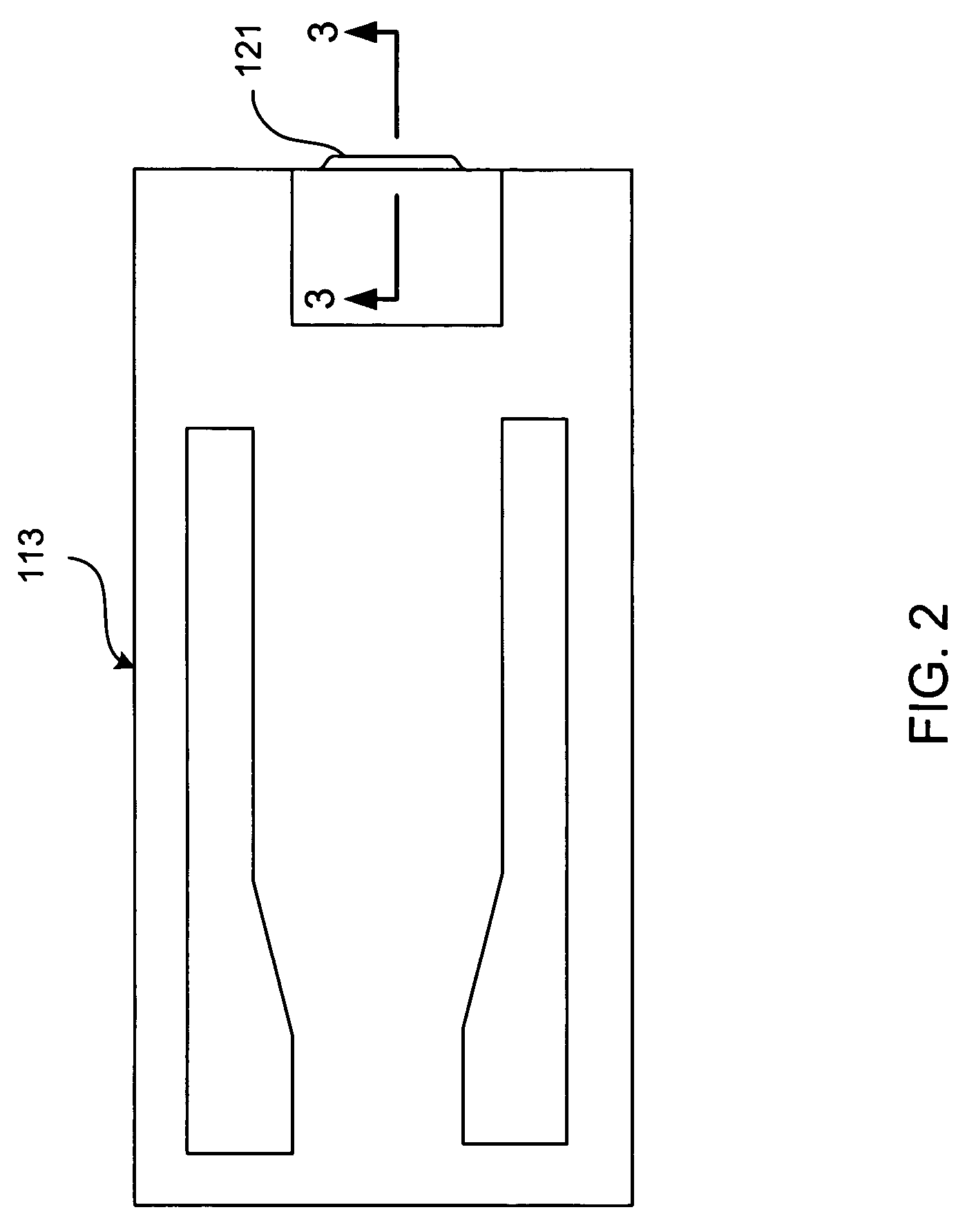

Thin stator, eccentric motor and axial air-gap brushless vibration motor equipped with the same

InactiveUS20080018187A1Sufficient starting torqueInfluence of bracket magnetic force can be suppressedMagnetic circuit stationary partsMechanical energy handlingDetentAir core

A stator includes a bracket having a shaft bearing portion at a center, a stator base including a flexible printed wiring board outwardly attached to the shaft bearing portion, single-phase air-armature coils disposed on the stator base, and a drive circuit member disposed on the stator base so as not to overlap with the single-phase air-core armature coils. The bracket has a through hole at the section corresponding to the bottom of the drive circuit member. The stator base is embedded at least partly in the thickness direction in the through hole and fixed using a resin, and a detent torque generation member is contained in, and is no thicker than, the stator base.

Owner:TOKYO PARTS IND CO LTD

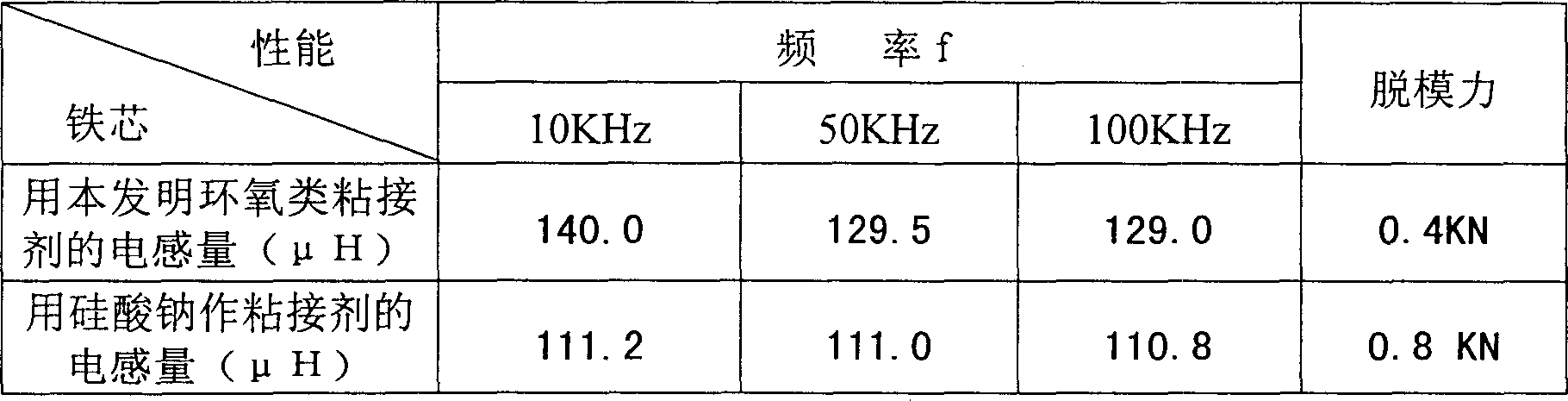

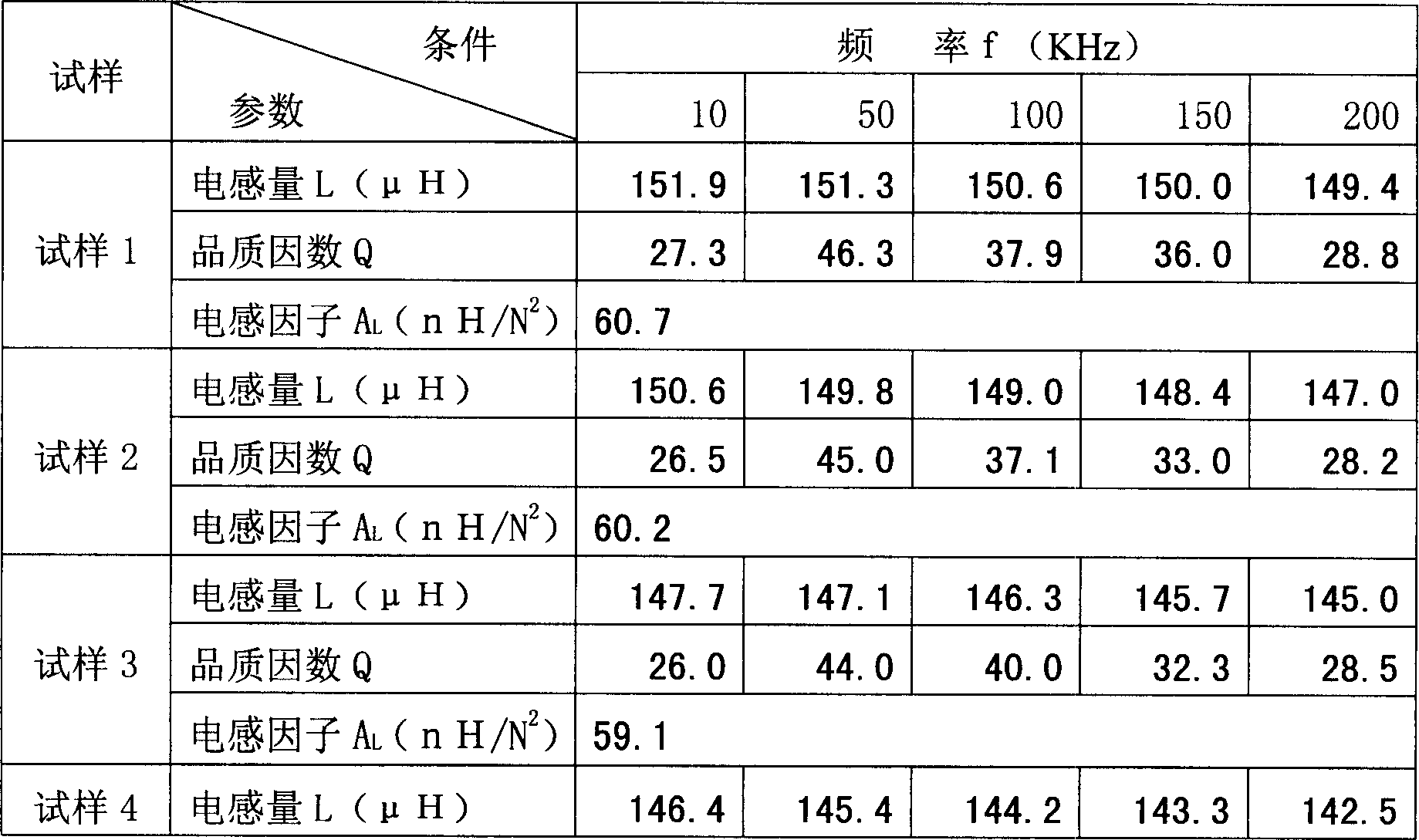

Method for making soft magnet silicon aluminium alloy powder core

InactiveCN1516204AHigh mechanical strengthImprove securityInorganic material magnetismSoft magnetIngot

The invention provides method to make a soft-magnetic inductance iron core by Fe-Si-Al alloy powder, including the steps: smelting Fe-Si-Al alloy - roughly crushing the cast ingot - heat treating - finely crushing into powder - annealing - grain mixing - passivating - adding insulating, binder, and mould-release agent - die forming - heat treating -coating surface. Its character: the binder is an epoxy one; the tempering after die forming is preserving the heat of the formed alloy powder at least 30 min on the condition of 600-800 deg.C nitrogen gas, argon gas or vacuum.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

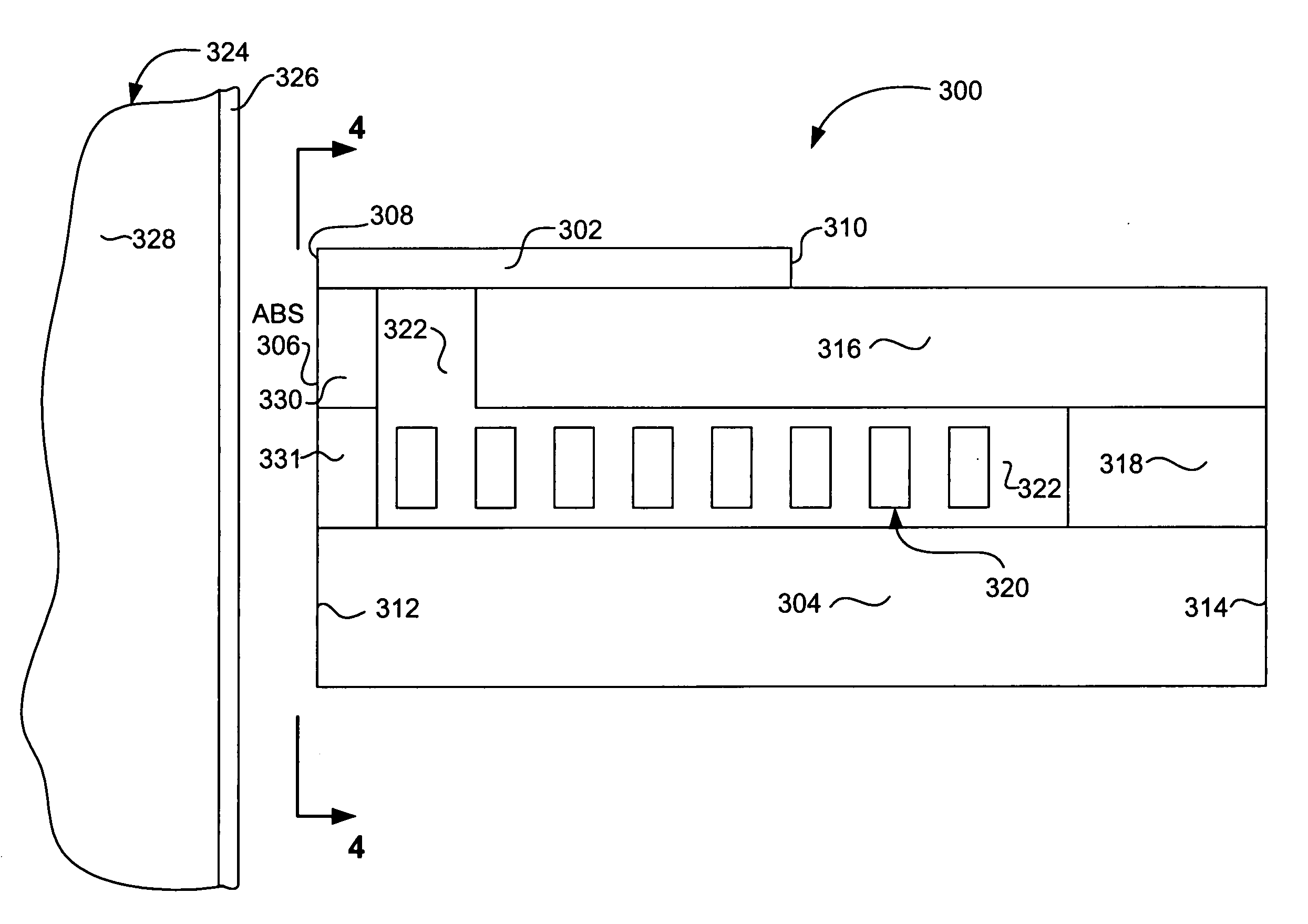

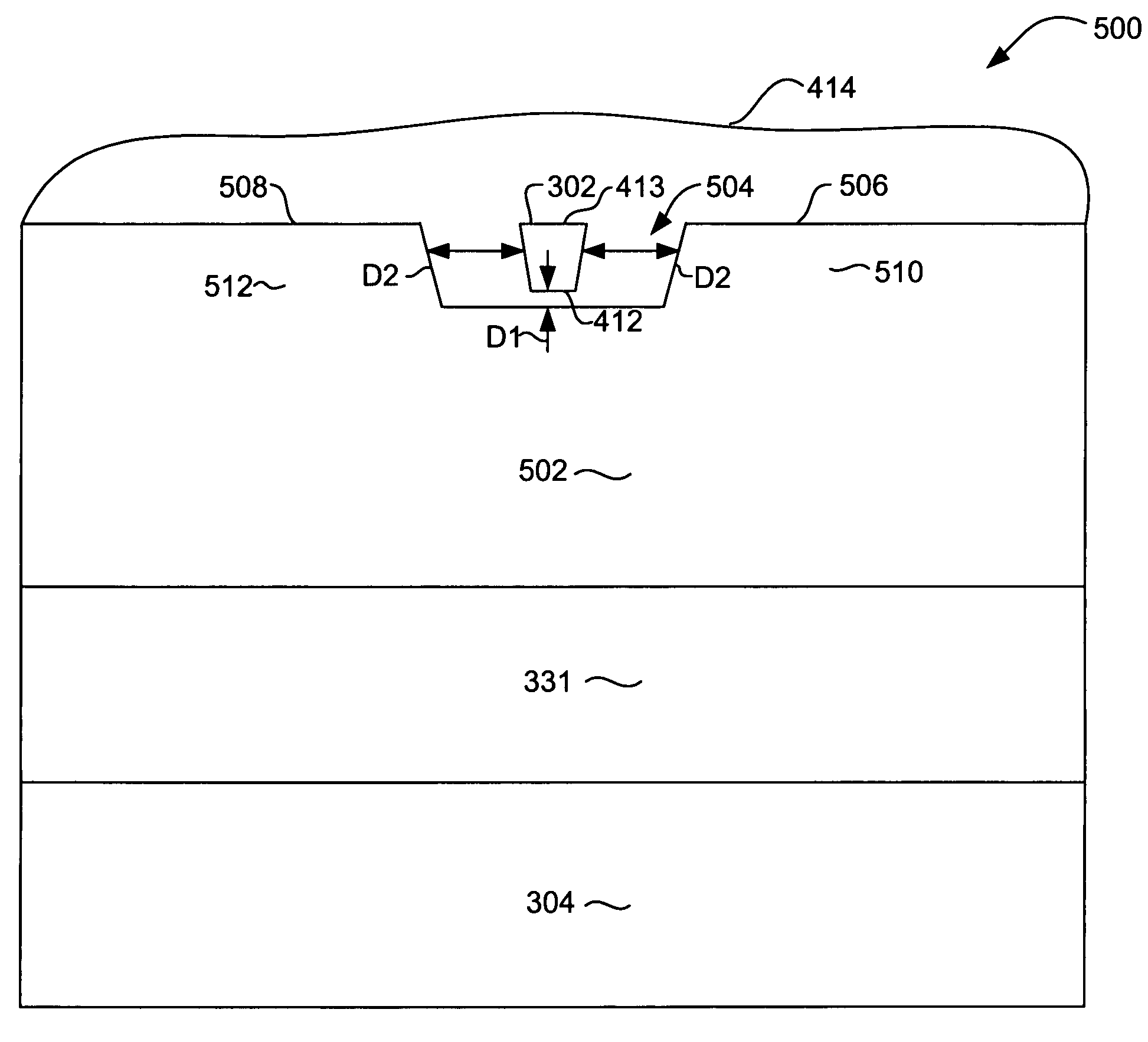

Flux shunt structure for reducing return pole corner fields in a perpendicular magnetic recording head

InactiveUS20060245108A1Improve protectionSufficient magnetic separationManufacture head surfaceHeads using thin filmsEngineeringMagnetic shield

A magnetic head for use in a perpendicular recording system having a novel shield structure that provides exceptional magnetic shielding from extraneous magnetic fields such as from a write coil, shaping layer or return pole of the write head. The magnetic head includes a write pole, a return pole and a magnetic shield that is magnetically connected with the return pole near the ABS and extends toward the write pole. The shield is formed with a notch at its edge closest to the write pole. The notch assures adequate physical, magnetic, and electrical separation between the write pole and the shield, while allowing un-notched portions of the shield to provide additional magnetic shielding.

Owner:WESTERN DIGITAL TECH INC

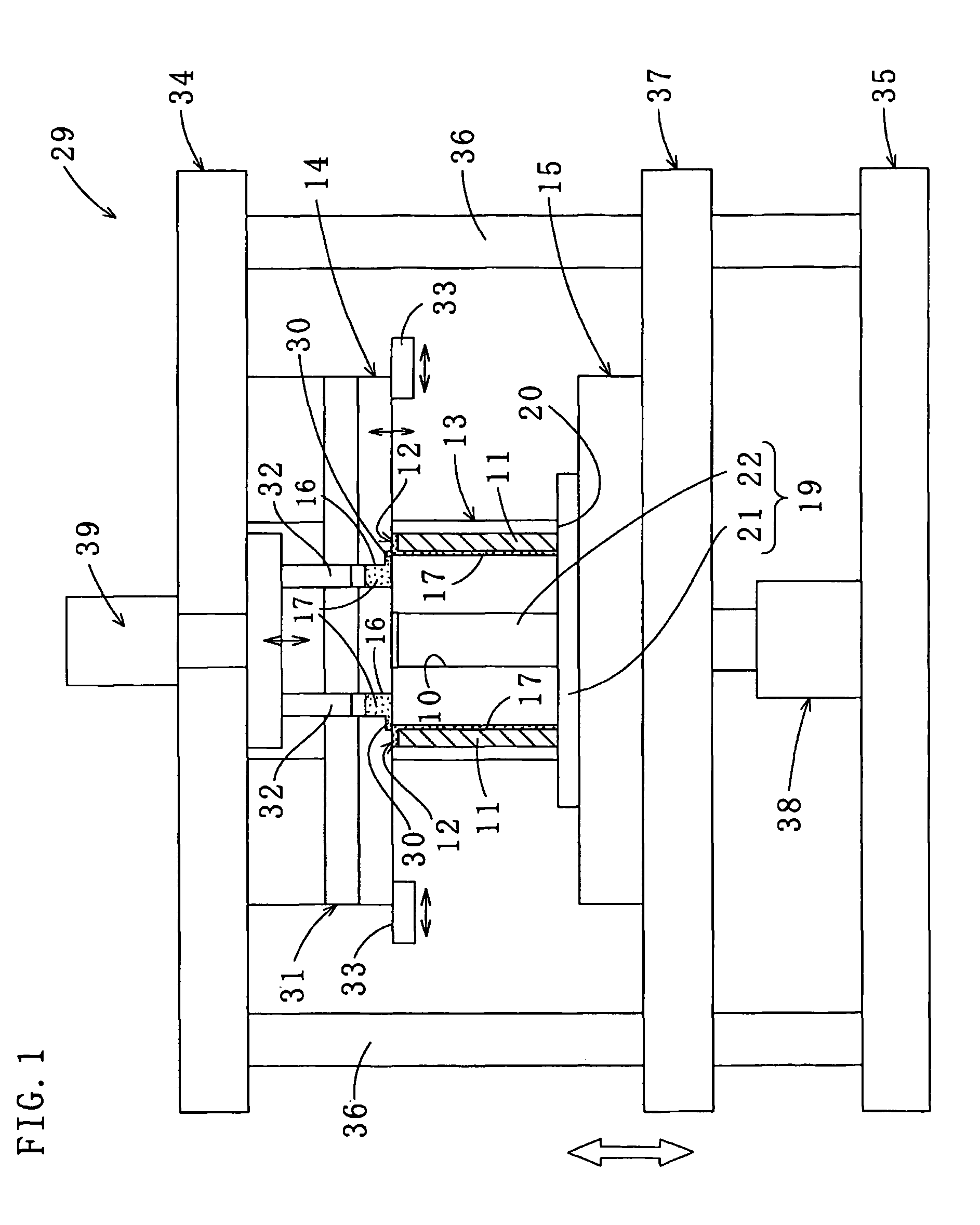

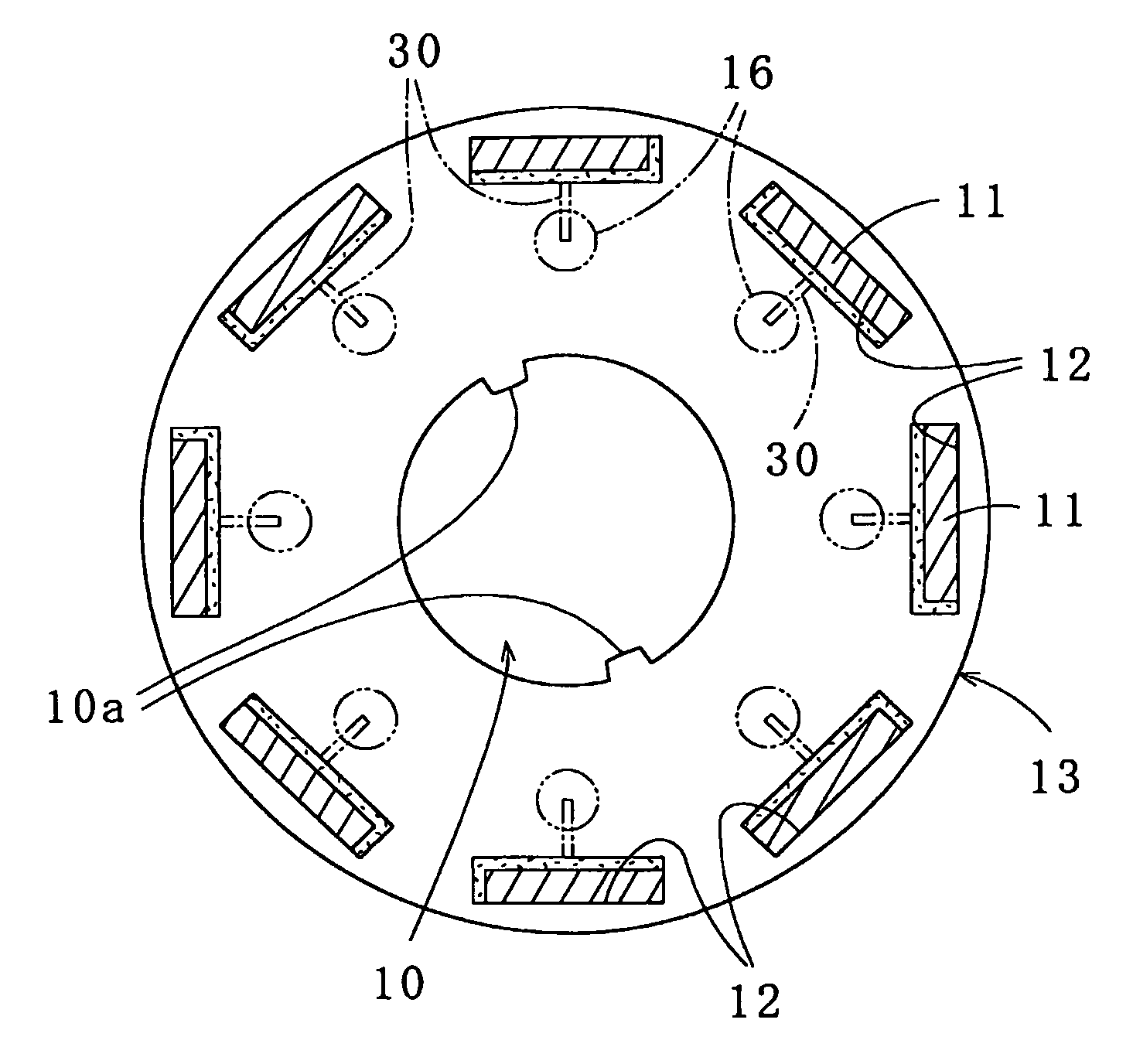

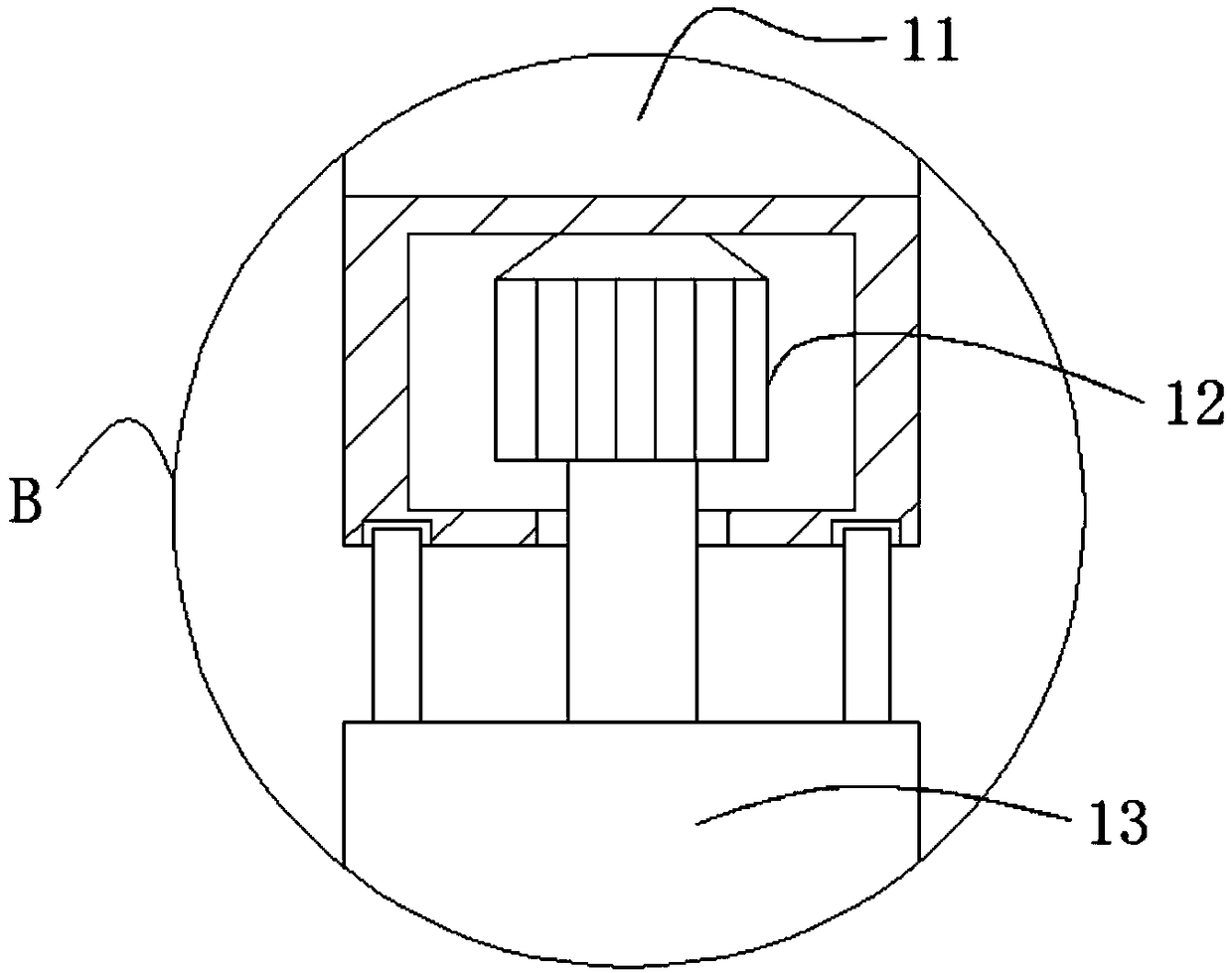

Method of Resin Sealing Permanent Magnets in Laminated Rotor Core

ActiveUS20080276446A1Improve filling efficiencyLess affectedMagnetic circuitInductances/transformers/magnets manufacturePlungerMagnet

A method comprising: a first process of placing a laminated rotor core (13) in a preheating device (18) to preheat the laminated core (13); a second process of removing the preheated laminated core (13) from the preheating device (18) and disposing the laminated core (13) between upper and lower dies (14, 15) of a resin sealing apparatus (29); a third process of pressing the laminated core (13) by the upper and lower dies (14, 15) and liquefying resin material (17) in resin reservoir pots (16) by heating; and a fourth process of ejecting the liquefied resin material (17) from the pots (16) into the magnet insertion holes (12) by plungers (32) inserted and moving vertically in the pots (16) and thermally curing the resin material (17). The method improves efficiency of resin sealing the permanent magnets (11) in the laminated core (13).

Owner:MITSUI HIGH TEC INC

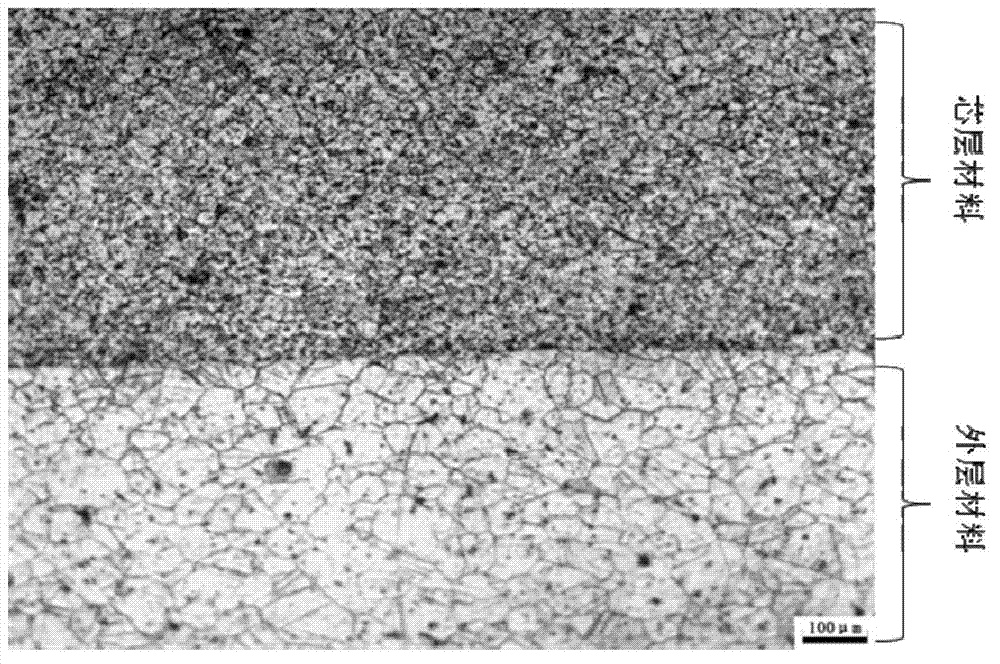

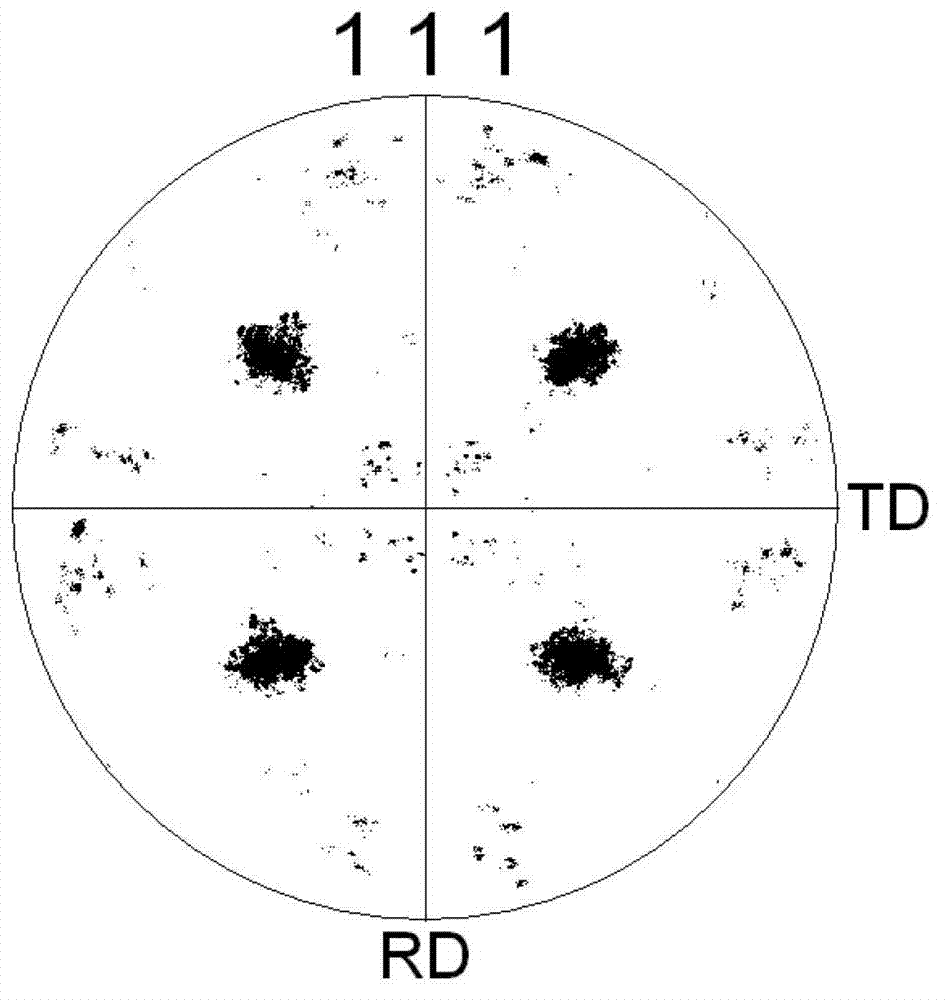

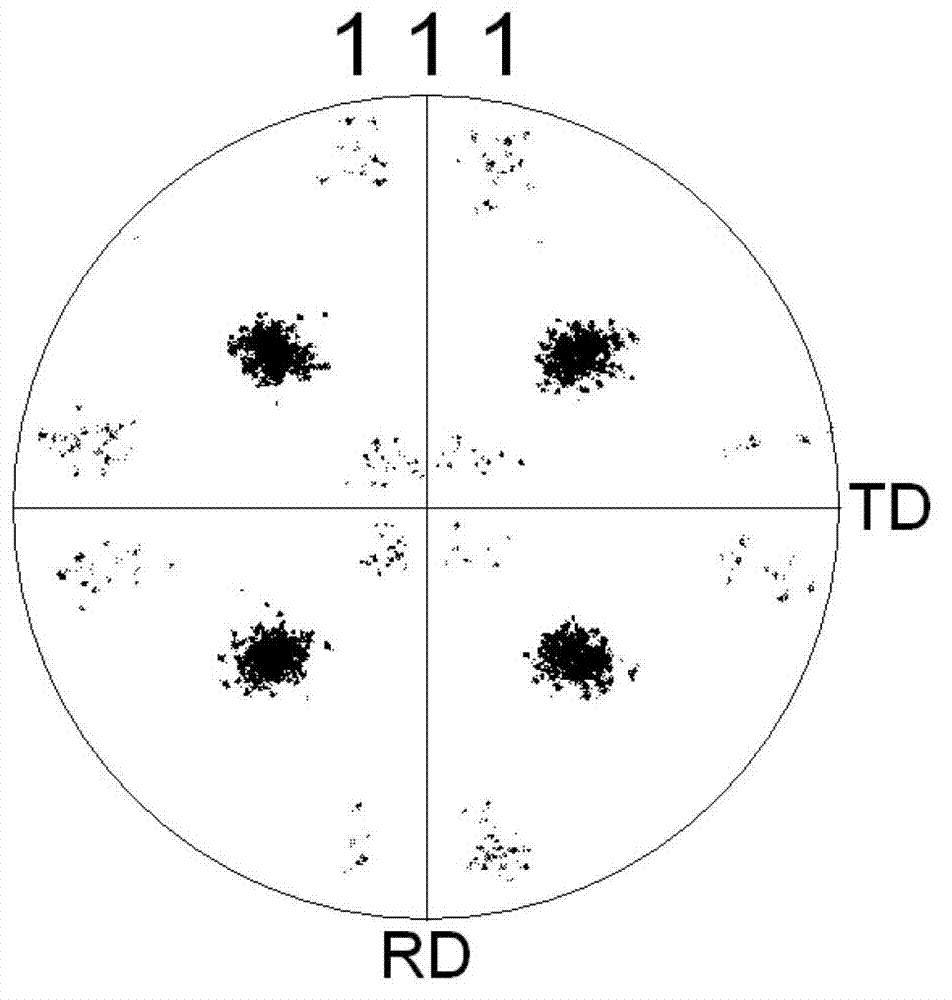

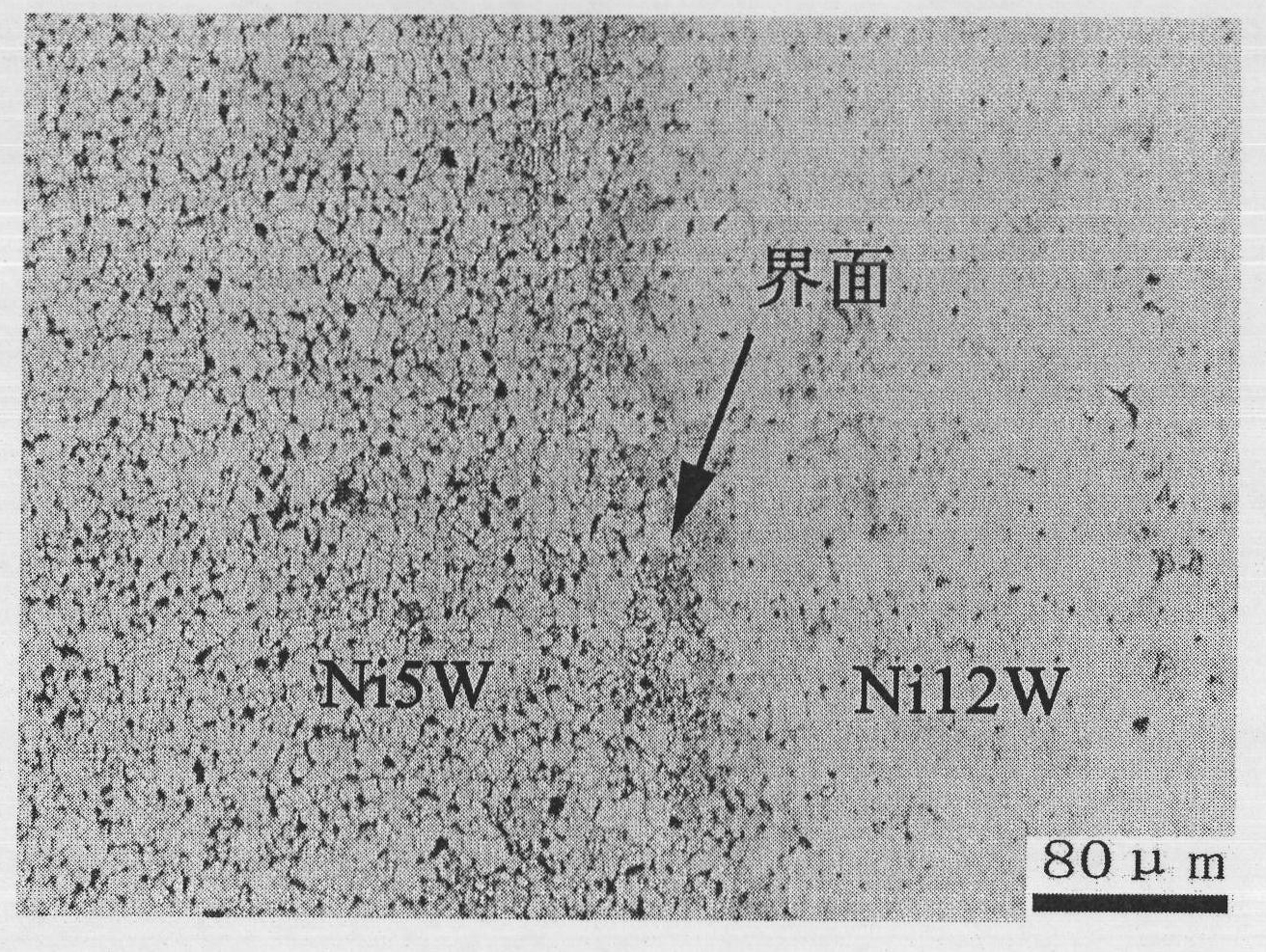

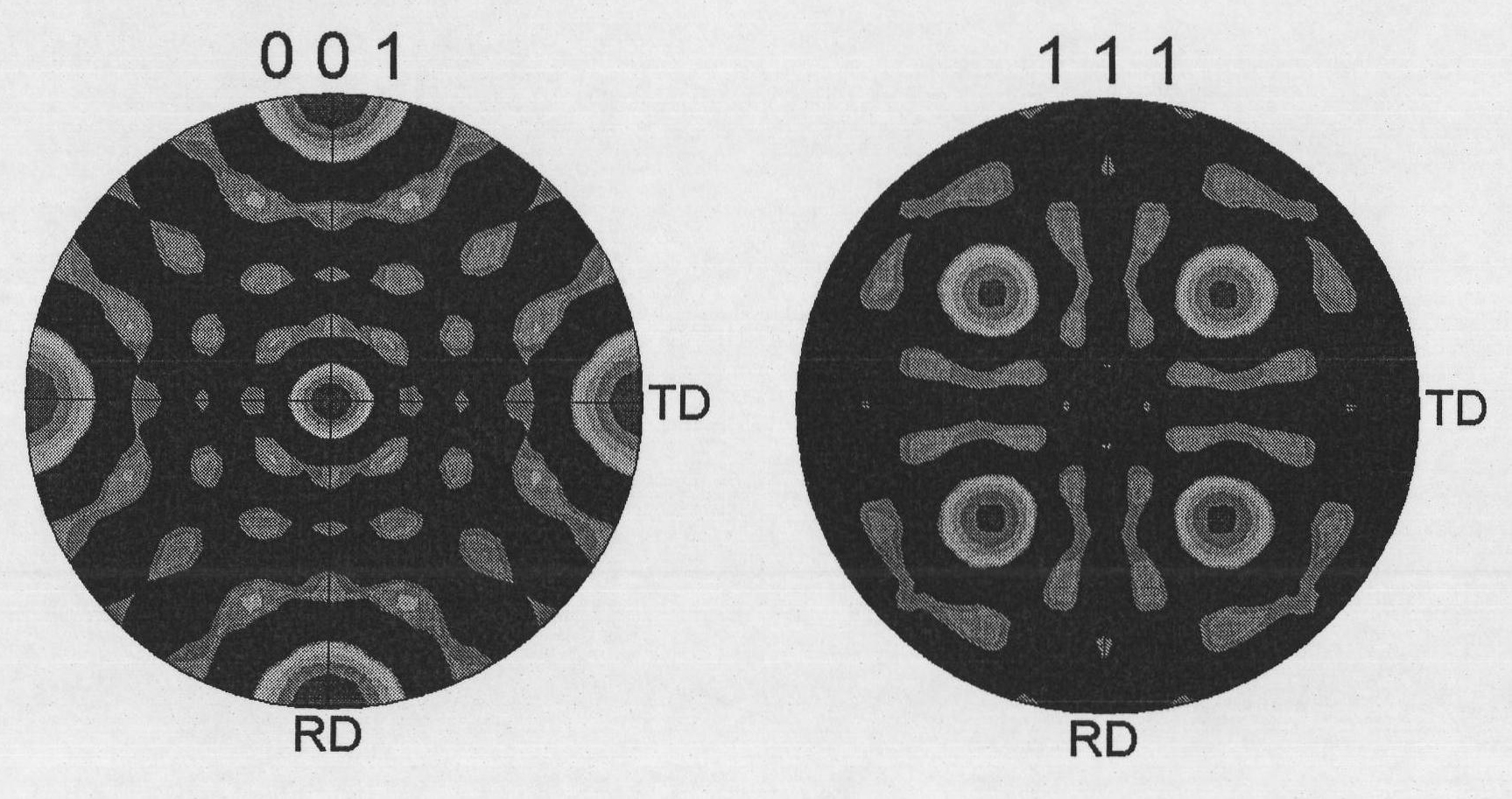

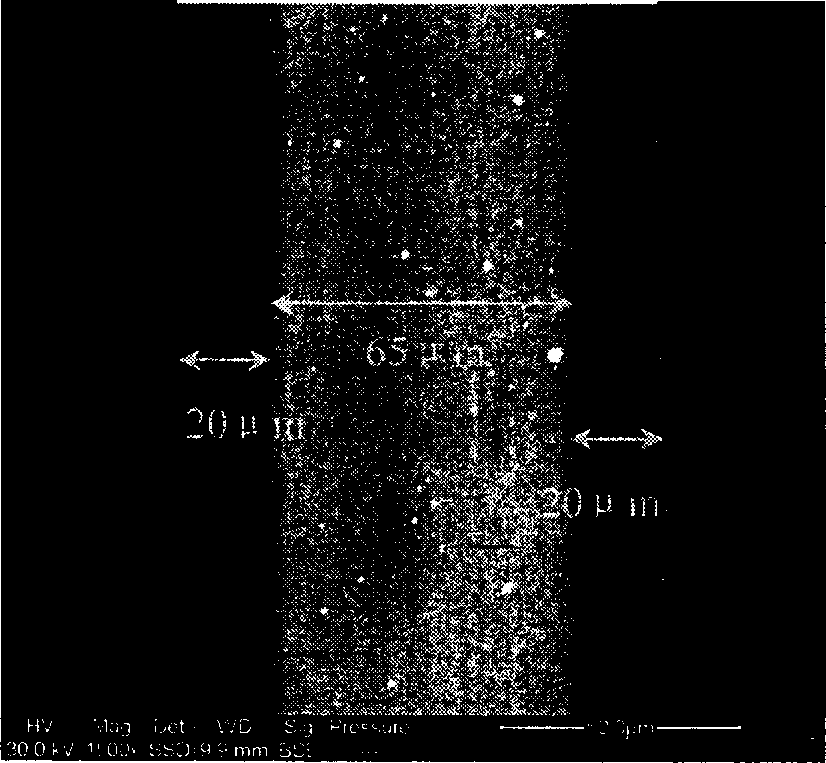

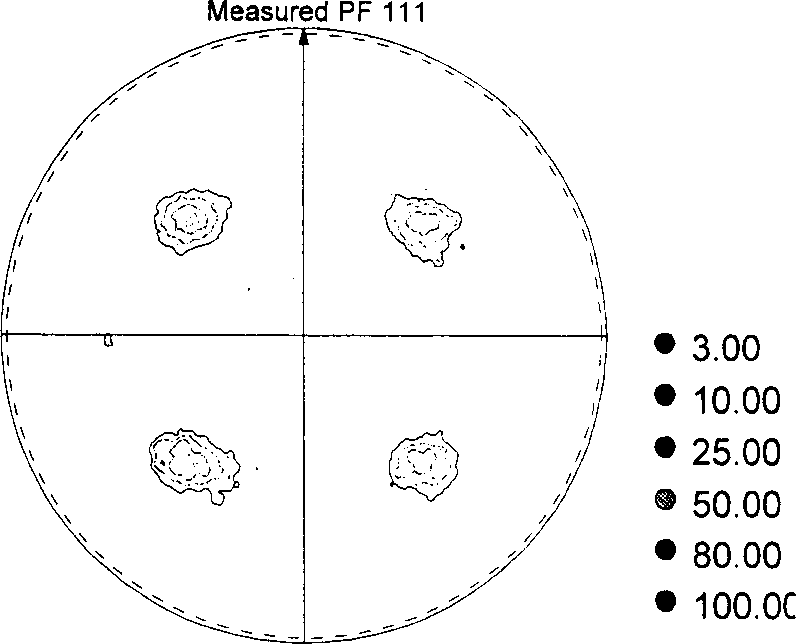

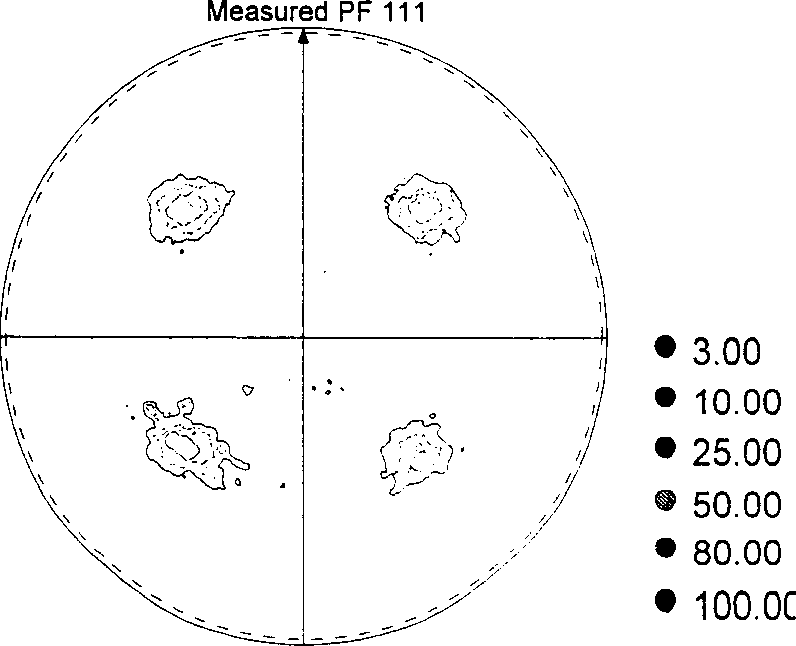

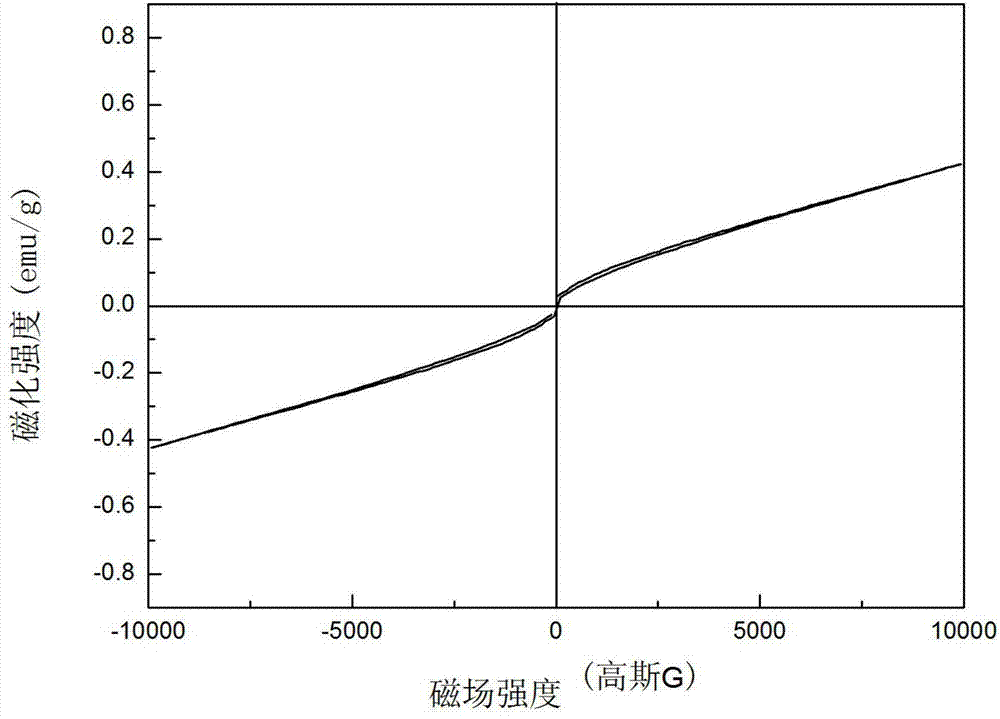

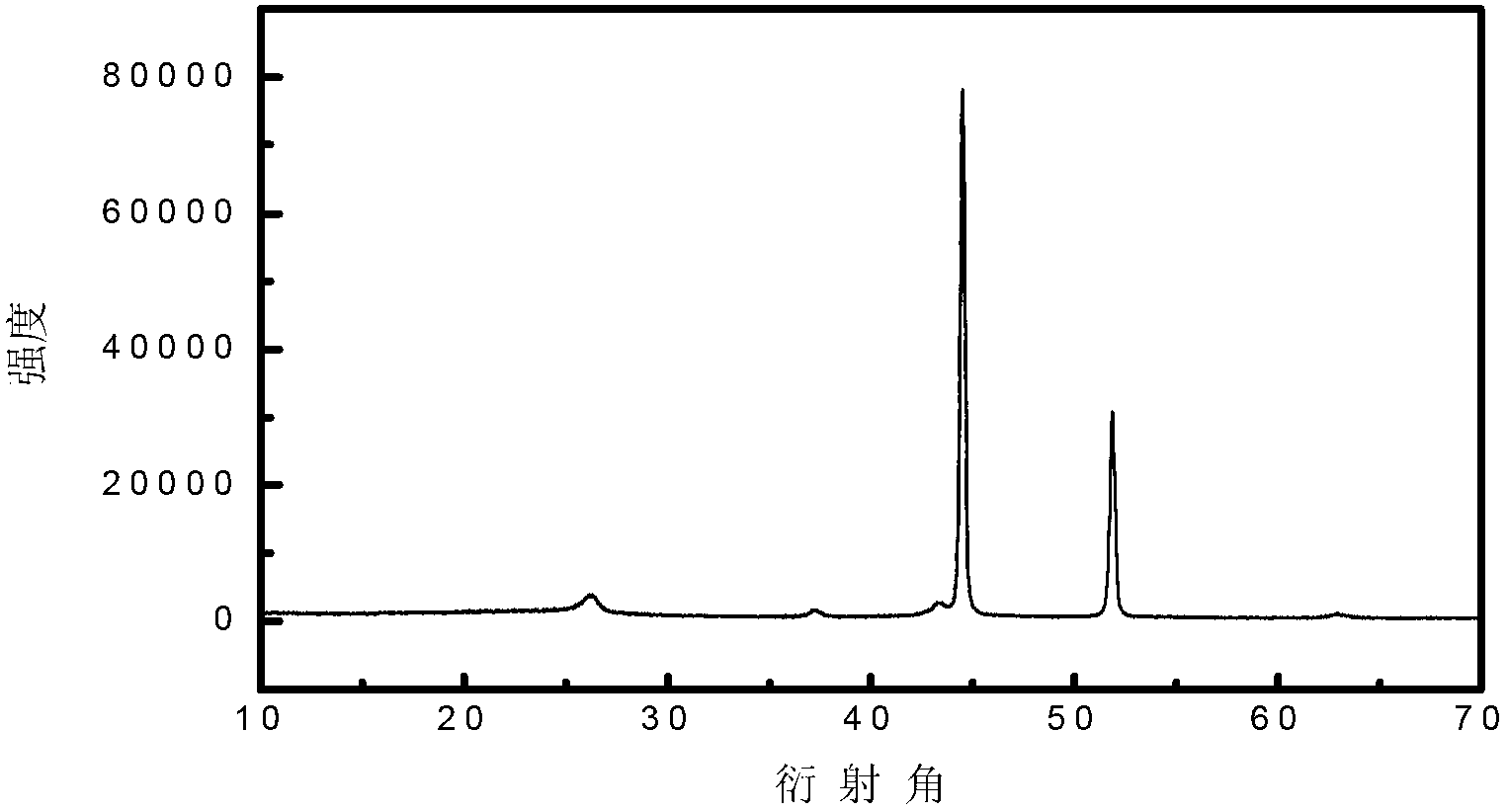

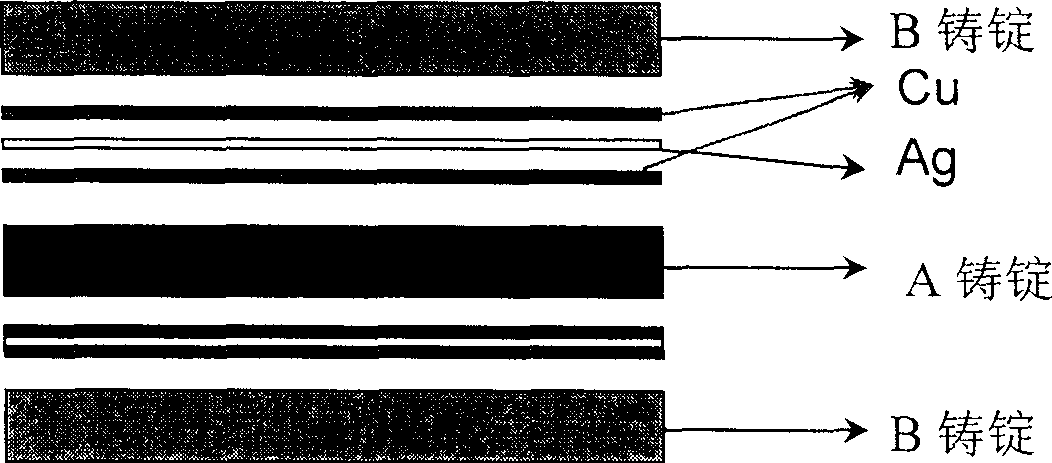

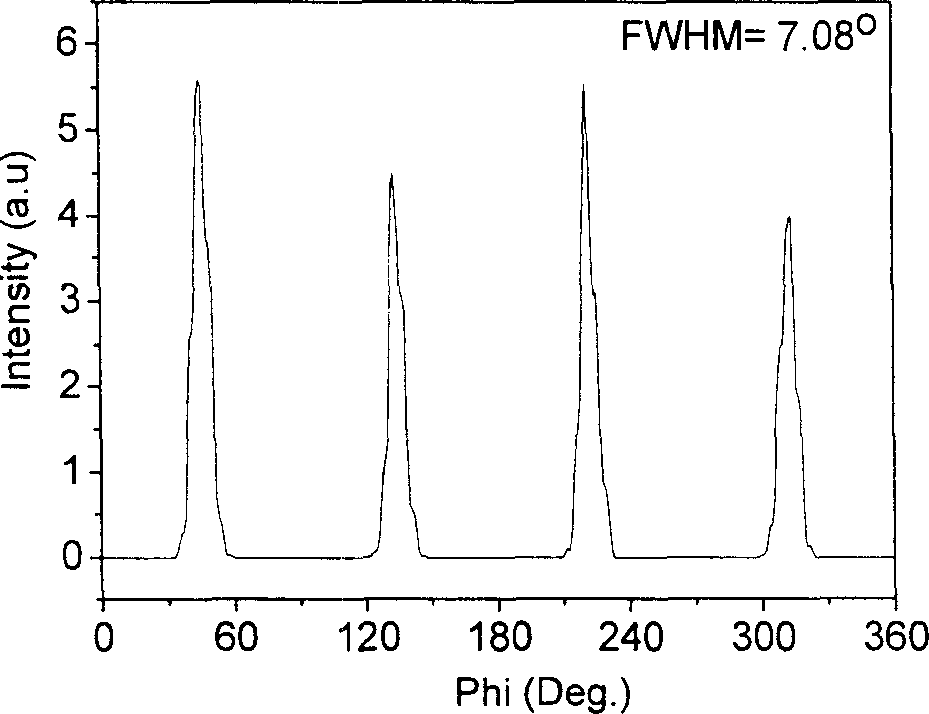

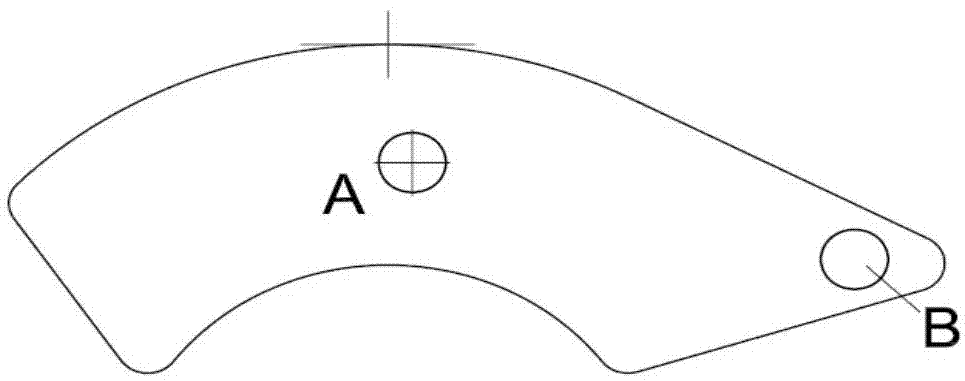

Low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and preparation method thereof

ActiveCN102756512AAchieve associativityImprove bindingMetal layered productsTungsten atomAlloy composite

The invention provides a low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and a preparation method thereof, belonging to the technical field of a high-temperature super-conductive coating conductor texture metal base band. According to the Ni-W alloy composite base band disclosed by the invention, a surface layer is a Ni-W alloy with high W content and the atom percentage content of the W is 7.5-9.3%; and a core layer is a nickel-tungsten alloy with the tungsten atom percentage content of 9.3-12%. The preparation method comprises the following steps of sequentially placing a high-W-content Ni-W alloy blank ingot (A) which is prepared by a smelting method and has the atom percentage content of the W of 7.5-9.3%, and Ni-W mixed powder (B) with the atom percentage content of the W of 9.3-12% into a mould according to the sequence of A-B-A; utilizing a discharge plasma sintering technology to sinter to obtain a composite blank ingot; then, carrying out hot rolling and carrying out cold rolling treatment on a hot rolling blank ingot; and then, crystallizing and annealing, carrying out cold rolling to obtain the composite base band, and re-crystallizing and annealing the base band under the protection of Ar / H2 mixed gas to obtain the Ni-W alloy composite base band. The composite base band has the advantages of high strength, low magnetism or no magnetism and strong cubic structure, and can further meet the requirement of further improving the performance of an YBCO (Yttrium Barium Copper Oxide) coating conductor.

Owner:深创超导(深圳)科技有限公司

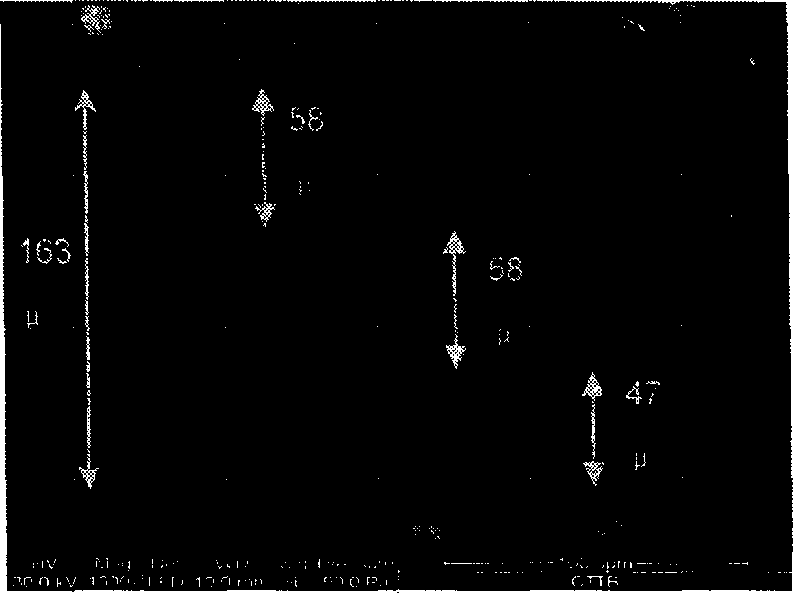

Ni-base alloy composite base band prepared by hot isostatic pressing method

The invention discloses a Ni-base alloy composite base band prepared by a hot isostatic pressing method, belonging to the technical field of a high-temperature coating superconductivity base band. The preparation method comprises the following steps: putting NiW powders (code A) and NiW alloy powders (code B) into a die according to an A-B-A sequence, wherein the atom percent of W of the NiW powders is 3-7%, and the atom percent of W of the NiW alloy powders is 9-12%; pressing and sintering by the hot isostatic pressing to obtain an initial composite billet with even diffused ingredients and favorably combined inner and outer layers and; cold rolling the composite billet with the pass distortion of 3-15% and the total distortion of more than 95%; and obtaining a cold rolling base band with a thickness of 80-150 mu m; annealing the base band for 0.5-2 hours under the protection of an Ar / H2 mixed gas at the temperature of 1000-1400 DEG C to obtain the Ni-based alloy composite base band. The composite base band has high mechanical strength and strong double-shaft texture.

Owner:深创超导(深圳)科技有限公司

Thin stator, eccentric motor and axial air-gap brushless vibration motor equipped with the same

InactiveUS7800274B2Sufficient starting torqueInfluence of bracket magnetic force can be suppressedMagnetic circuit stationary partsMechanical energy handlingDetentAir core

A stator includes a bracket having a shaft bearing portion at a center, a stator base including a flexible printed wiring board outwardly attached to the shaft bearing portion, single-phase air-armature coils disposed on the stator base, and a drive circuit member disposed on the stator base so as not to overlap with the single-phase air-core armature coils. The bracket has a through hole at the section corresponding to the bottom of the drive circuit member. The stator base is embedded at least partly in the thickness direction in the through hole and fixed using a resin, and a detent torque generation member is contained in, and is no thicker than, the stator base.

Owner:TOKYO PARTS IND CO LTD

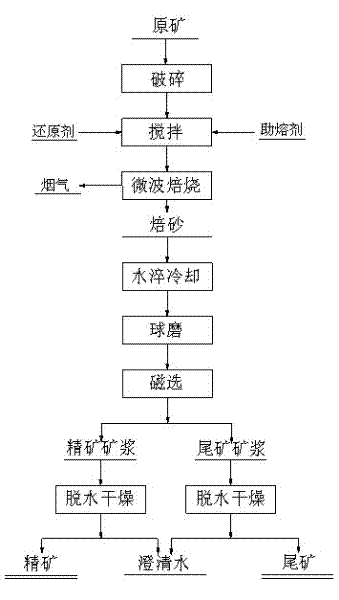

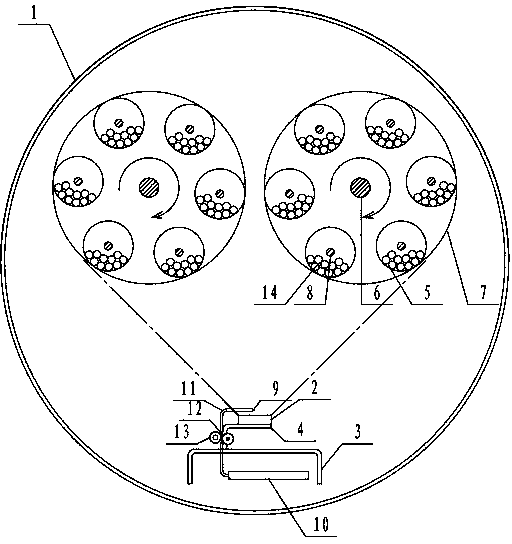

Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

InactiveCN102212677AReduce grinding energy consumptionShorten milling timeMagnetic separationMixed materialsQuenching

The invention relates to a method for refining iron and removing phosphorus from complex refractory high-phosphorus iron ore, in particular to a method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation, and belongs to the technical field of mineral processing, particularly iron ore beneficiation. The method comprises the following steps: crushing refractory high-phosphorus iron ore used as raw material into granules with granularity of less than 2mm; mixing the crushed raw ore with a fluxing agent and a reducing agent in a certain proportion; transferring the obtained mixed material into a microwave reaction furnace for reduction roasting; and carrying out water-quenching, cooling, ball-milling and wet-magnetic-separating on the obtained roasted ore to finally obtain iron ore concentrate. In the method, the ore is reduced by utilizing a microwave roasting technology, wherein microwave reduction roasting time is short, and the temperature of the ore is raised quickly; and meanwhile the fluxing agent is added so as to promote gangue softening and improve refractory ore structure together with microwave roasting reaction. By utilizing the method for sorting the high-phosphorus iron ore, the iron ore concentrate with grade of more than 58.39% can be obtained, and phosphorus removal rate reaches over 70.44%, thus a new technique is provided for sorting the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS7653984B2Improve filling efficiencyLess affectedMagnetic circuitInductances/transformers/magnets manufactureEngineeringPlunger

Owner:MITSUI HIGH TEC INC

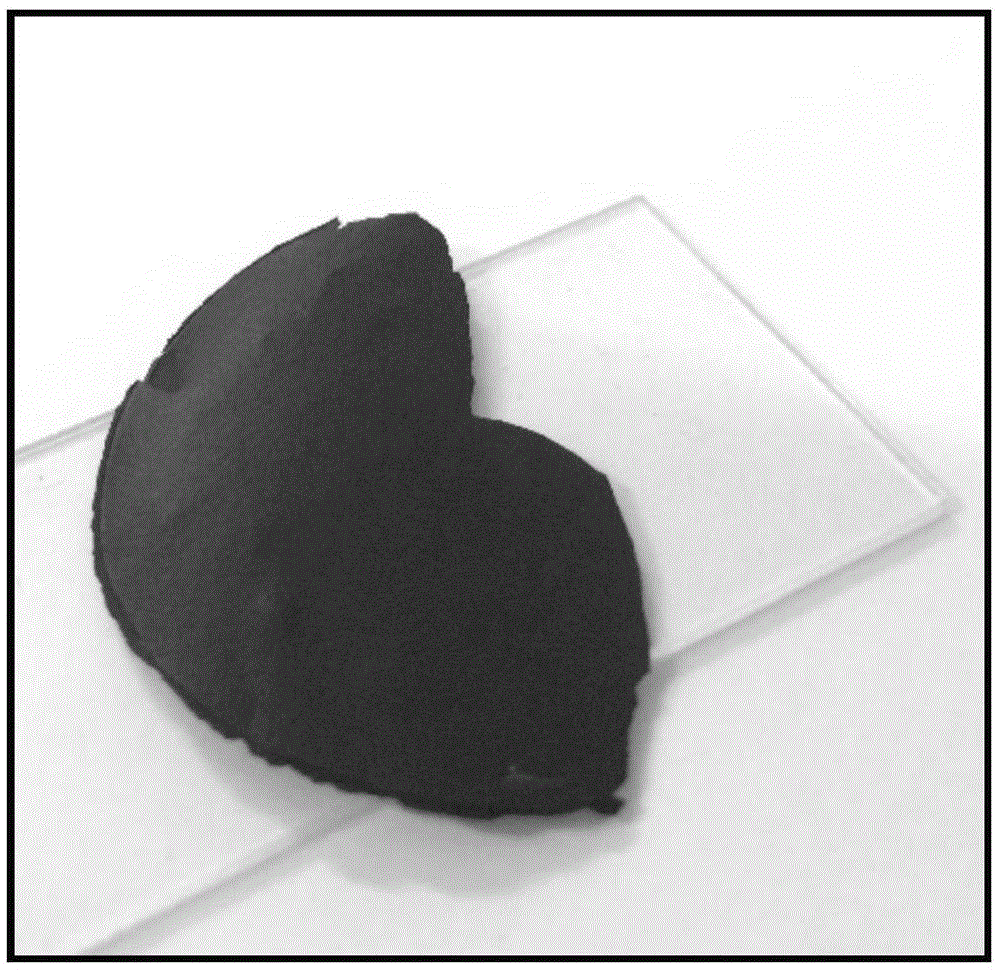

Rare-earth permanent magnet with high magnetic performance and high electric resistance and preparation method thereof

ActiveCN101740193AImproved surface insulation propertiesImprove magnetic propertiesMixing methodsPermanent magnetsMagnetic powderAdhesive

The invention relates to the technology of rare-earth permanent magnet materials, and particularly discloses a rare-earth permanent magnet with high magnetic performance and high electric resistance and a preparation method thereof. The permanent magnet comprises the following components in part by mass: 100 parts of neodymium iron boron and samarium cobalt type magnetic powder with granularity of 20 to 300 microns, 0.1 to 5 parts of titanate coupling agent, 1 to 10 parts of bisphenol A epoxy resin and 0.2 to 2 parts of bisphenol F epoxy resin; the components are evenly mixed, and then are molded to form a cured substance at the temperature field of between 20 and 200 DEG C under the orientation field of which the magnetic field intensity is 0.5 to 3T; and the preparation method for the rare-earth permanent magnet comprises the following steps: coupling the surface of the magnetic powder and the coupling agent, then mixing the magnetic powder, the coupling agent and the resin, drying and grinding the mixture, and molding the mixture at the temperature field under the orientation field. The magnetic performance of the permanent magnet of the invention can keep higher level and has no obvious decline compared with the magnetic performance of the high-end adhesive NdFeB magnet, and the electric resistance of the magnet is improved by over 10 times; and the permanent magnet has no obvious temperature rise under the high-frequency alternating field for 1 hour.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

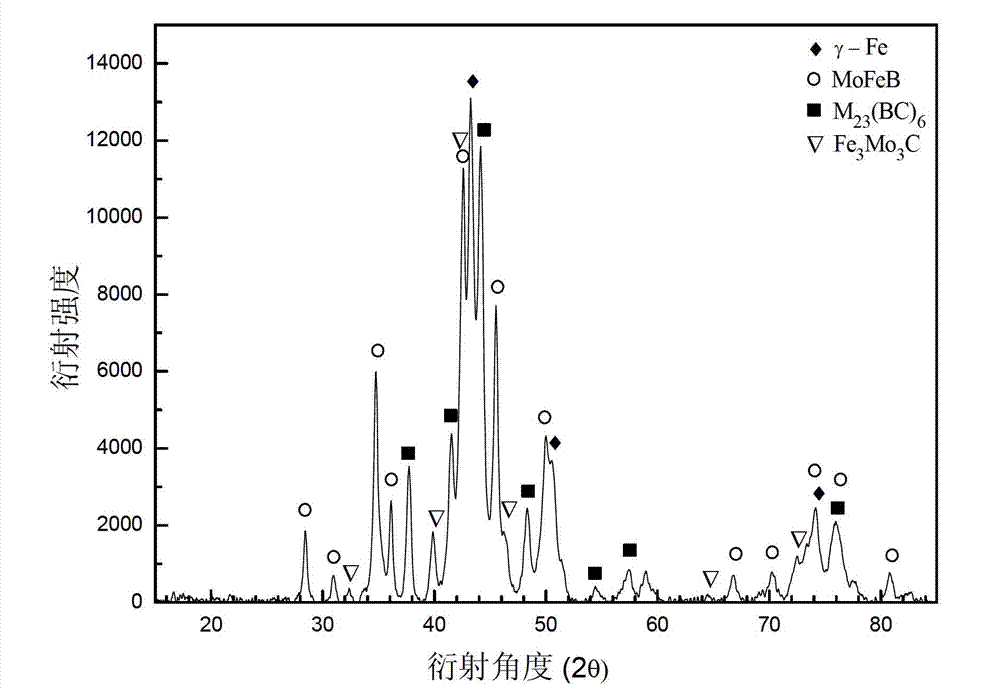

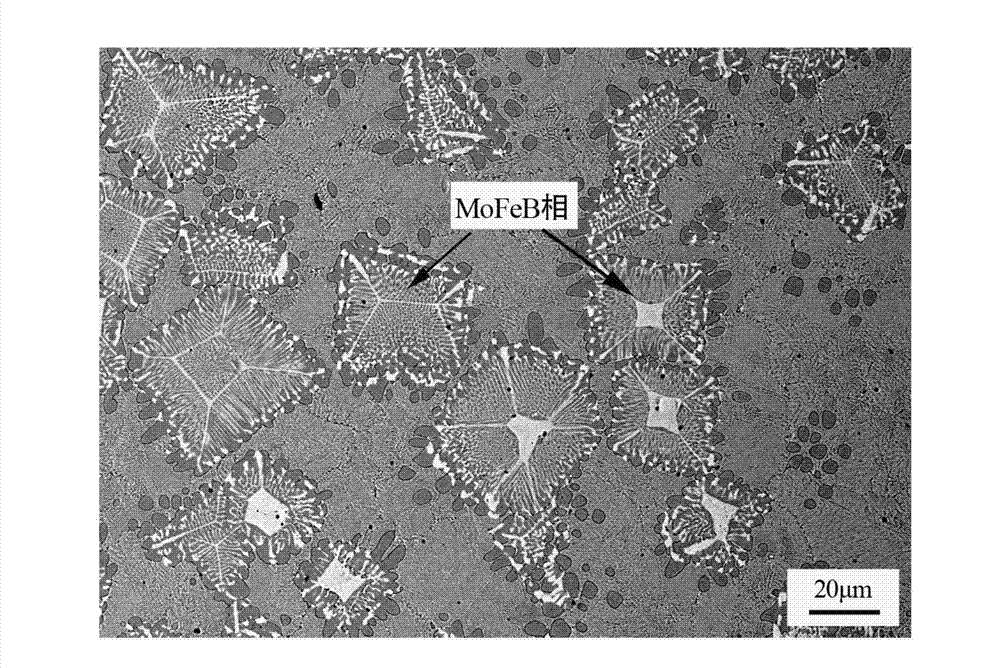

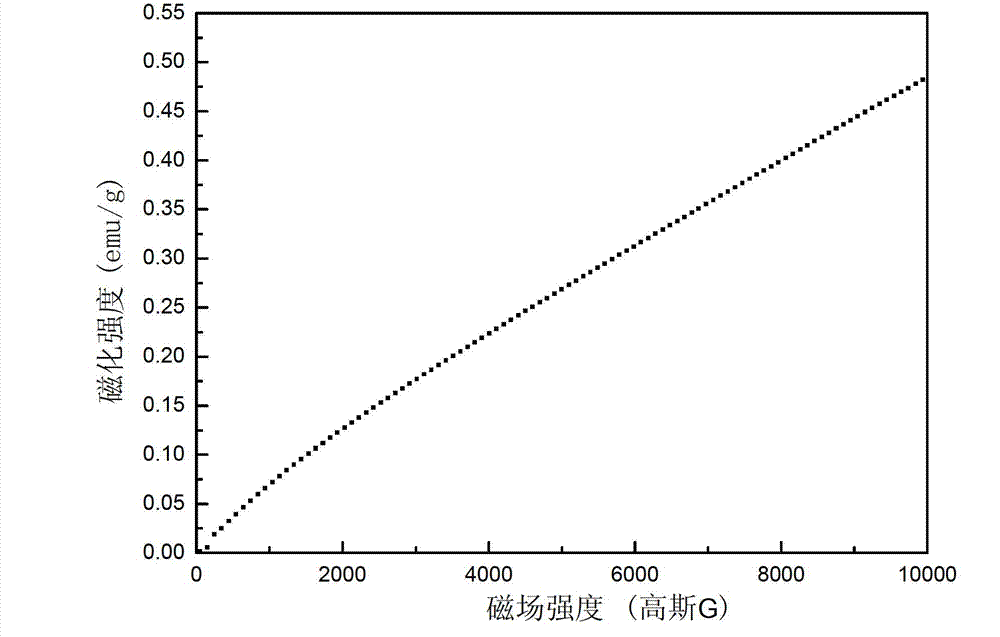

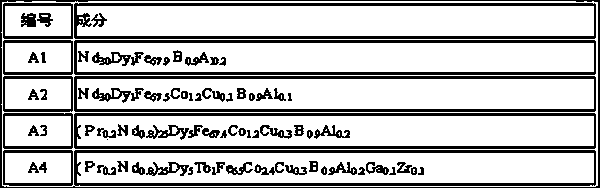

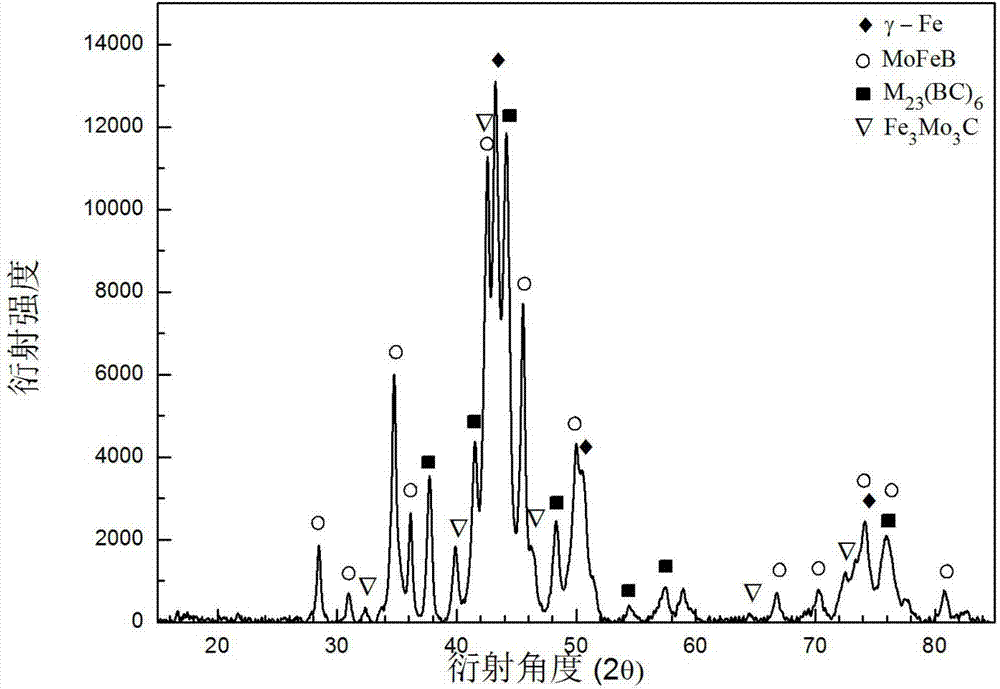

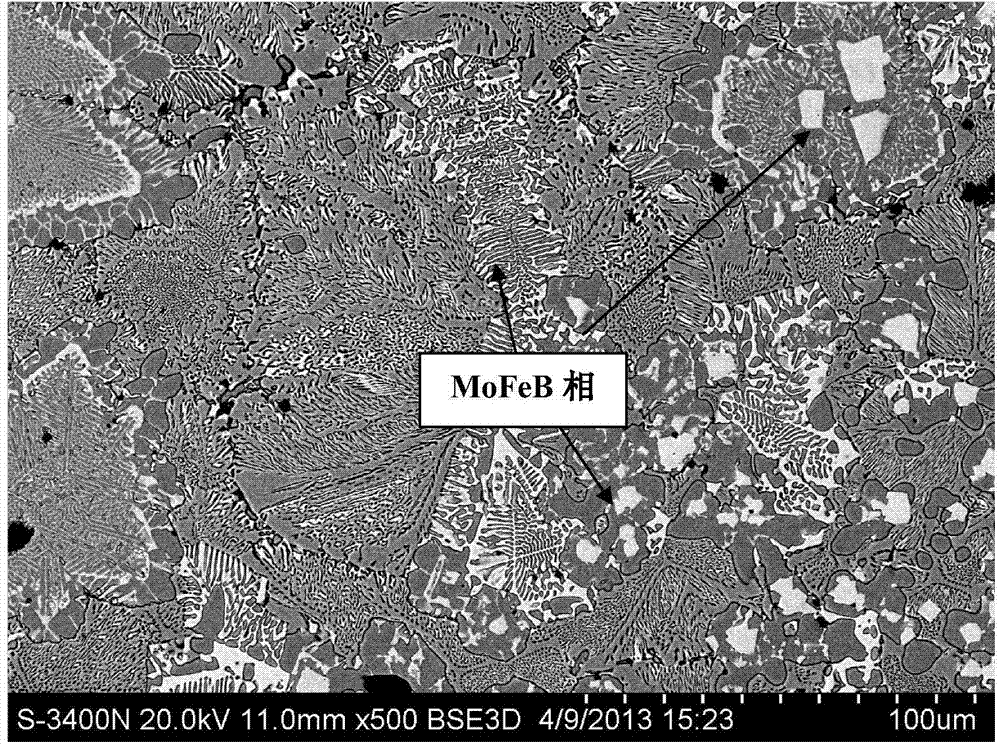

Alloy powder material for Fe-based nonmagnetic cladding layer and cladding layer preparing method

InactiveCN103042317AHigh hardnessImprove wear resistanceMolten spray coatingPlasma welding apparatusChromium carbideFerrosilicon

The invention discloses an alloy powder material for a Fe-based nonmagnetic cladding layer and a cladding layer preparing method, and belongs to the field of surface coating. The alloy powder comprises reduction ferrous powder, electrolytic manganese powder, high carbon ferro-chrome, ferro-molybdenum, ferrosilicon, ferro-boron, chromium carbide and boron carbide, and comprises following elementary compositions: 5-20wt% of Cr, 15-30wt% of Mo, 1-4wt% of C, 0.5-3wt% of B, 0.1-1.5wt% of Si, 0-15wt% of Mn, and the balance Fe. The Fe-based multi-element alloy cladding layer is prepared by plasma arc overlaying technology. The prepared cladding layer is nonmagnetic, high in hardness, and less prone to cracking and generating other cladding defects.

Owner:BEIJING UNIV OF TECH

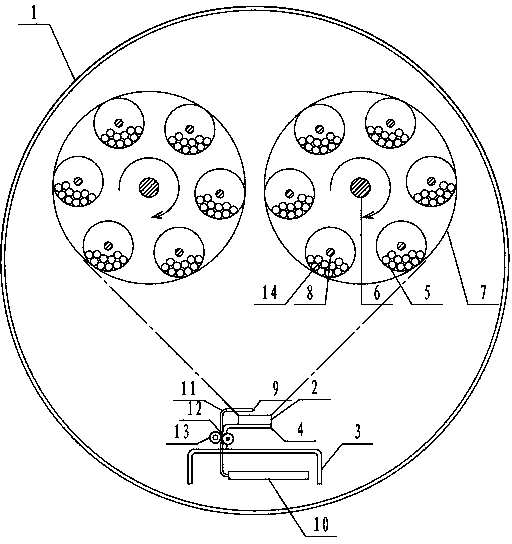

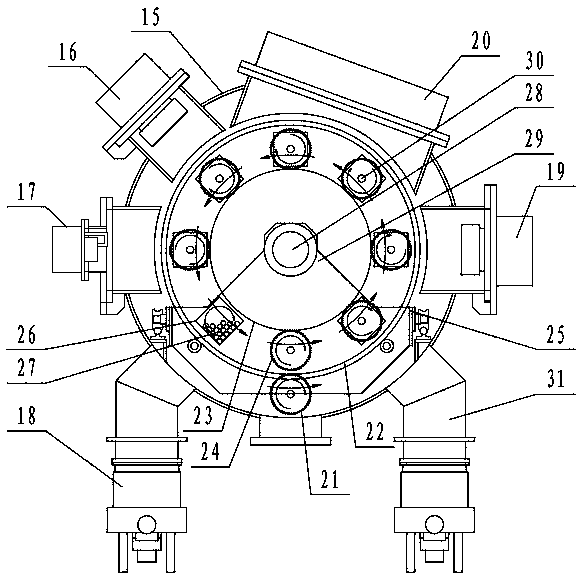

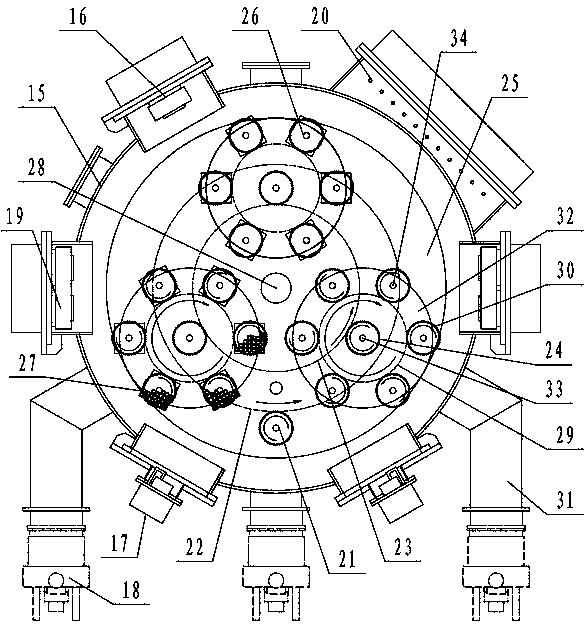

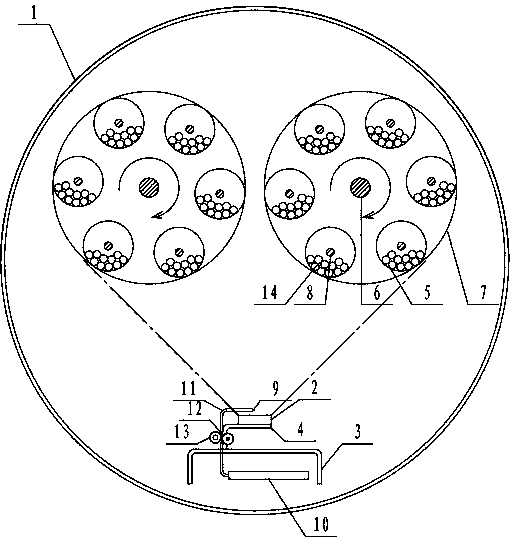

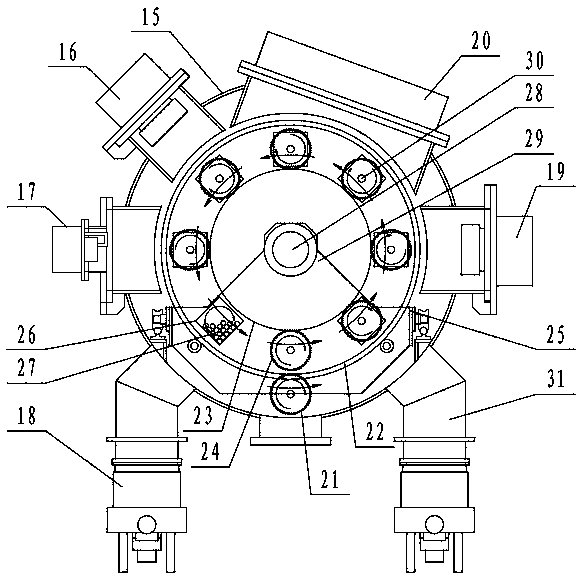

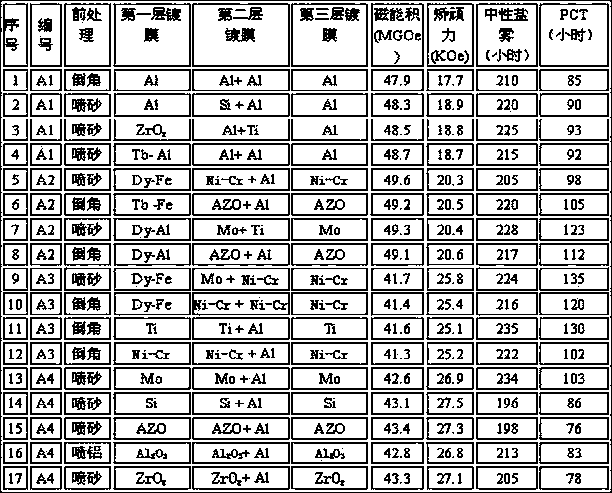

Composite coating equipment and manufacturing method for neodymium iron boron rare-earth permanent magnetic device

InactiveCN103820765AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingRare earthPlanar magnetron

The invention discloses composite coating equipment and a manufacturing method for a neodymium iron boron rare-earth permanent magnetic device. The coating equipment comprises a vacuum chamber, a cylindrical rotary cathode magnetron target, a planar cathode magnetron target, a cylindrical or rectangular cathode multi-arc ion target, an anode layer linear ion source, a rotating stand and a charging basket. When the coating equipment works, the rotating stand revolves in the vacuum chamber, and rotating shafts at two ends of the netlike charging basket are arranged on the rotating stand, namely that the rotating stand rotates automatically along with revolution. The cylindrical rotary cathode magnetron target is arranged in the rotating stand in the vacuum chamber; the planar magnetron target, the multi-arc ion target, the anode layer linear ion source and a heating device are arranged around the rotating stand in the vacuum chamber; a composite coating is divided into three layers, wherein the first layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m, the second layer is a magnetron sputtering and multi-arc mixed coating of which the thickness is 1-15mu m, and the third layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m. The composite coating is used for a surface treatment procedure of the rare-earth permanent magnetic device, so that the corrosion resistance of the rare-earth permanent magnetic device is improved, and the magnetic performance of the rare-earth permanent magnetic device is also improved.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

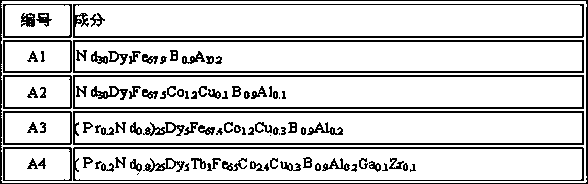

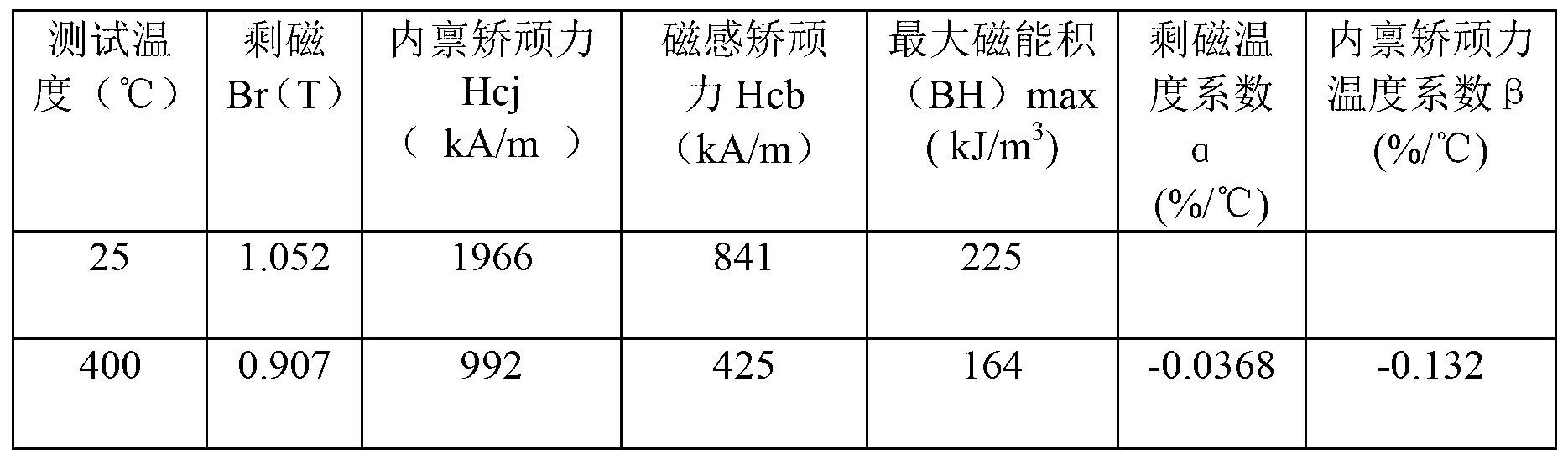

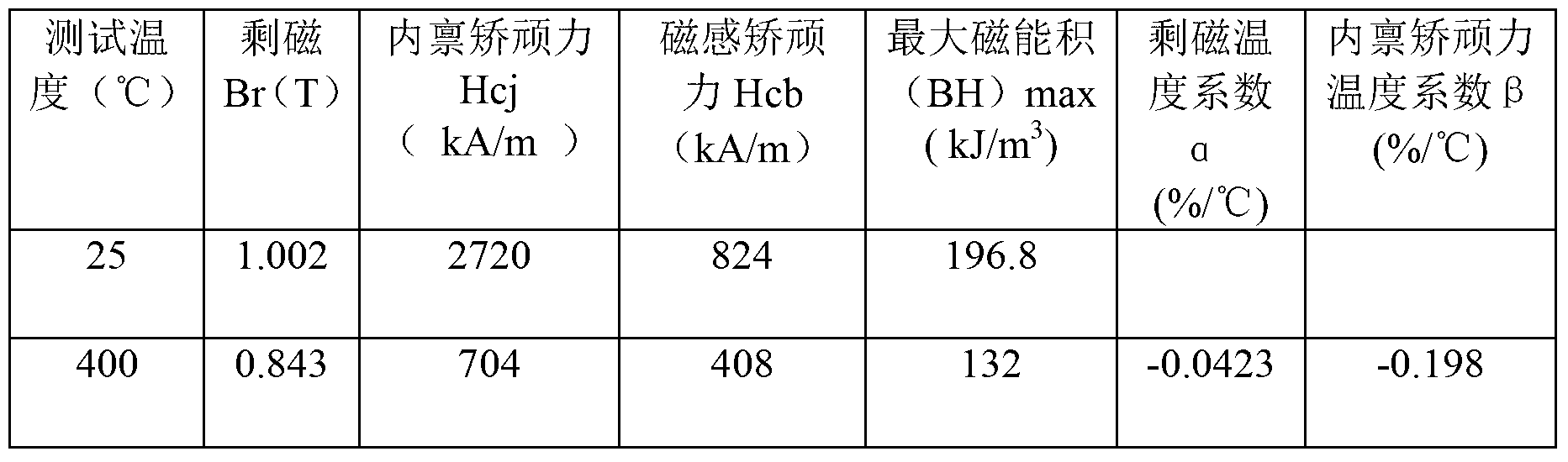

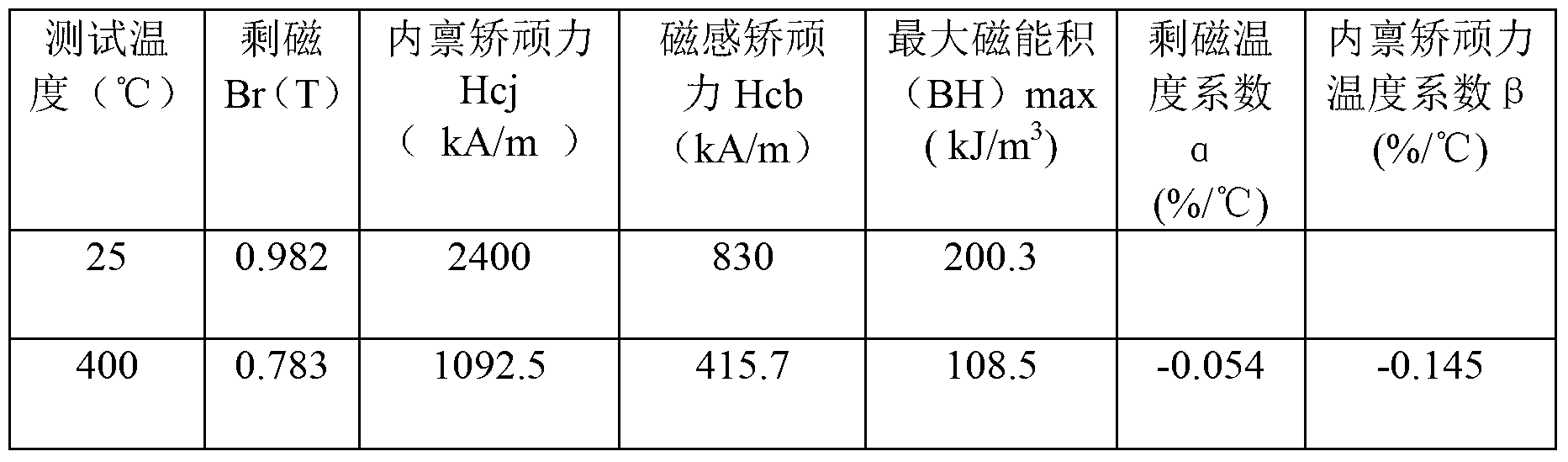

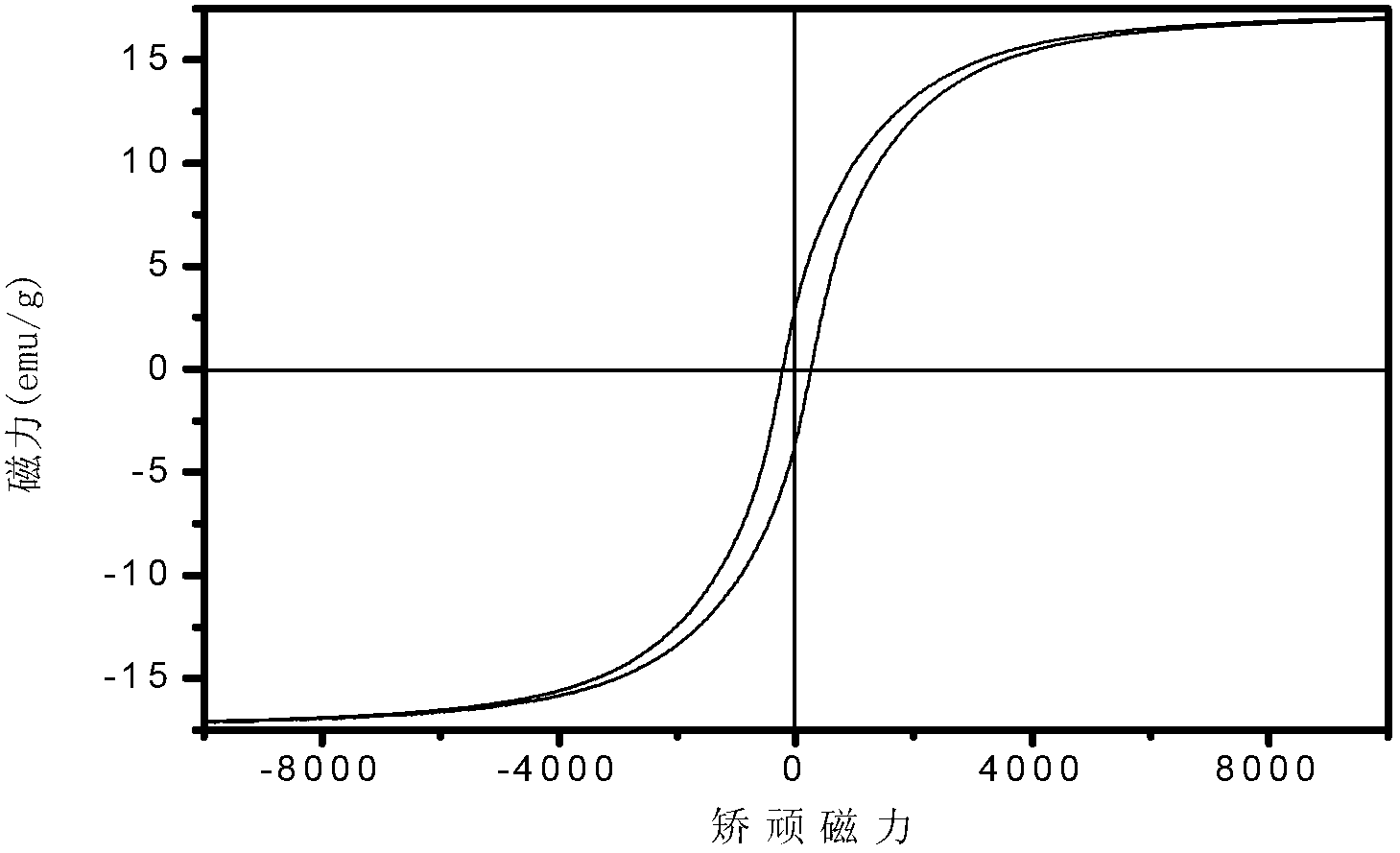

Samarium cobalt permanent magnetic material and preparation method thereof

InactiveCN103325513AHigh cost of preparationReduce raw material costsMagnetic materialsTemperature coefficientChemical Ingredients

The invention discloses a samarium cobalt permanent magnetic material and a preparation method thereof. The samarium cobalt permanent magnetic material is prepared from the following chemical ingredients by mass percent: 24.5-26% of samarium, 52-56% of cobalt, 7.5-12% of iron, 6.5-8% of copper, and 2-4% of zirconium. The samarium cobalt permanent magnet disclosed by the invention has high coercivity and low temperature coefficient; the magnetic performance at the temperature of 400-450 DEG C is that the residual magnetism Br is 0.783-0.907 T; the intrinsic coercivity Hcj is 704-1092.5 kA / m; the maximal magnetic level (BH)max is 108.5-164 kJ / m<3>; the temperature coefficient alpha of the residual magnetism is -0.0368% / DEG C to -0.054% / DEG C; and the temperature coefficient beta of the intrinsic coercivity is -0.132% / DEG C to -0.198% / DEG C. Thus, the samarium cobalt permanent magnetic material is simple in process and low in manufacturing cost.

Owner:湖南航天有限责任公司

Ni-base alloy composite baseband and method for preparing discharge plasma thereof

InactiveCN1844431AAvoid prone to stratificationAvoid crackingTemperature control deviceMetal rolling arrangementsAlloy compositeIngot

This invention relates to a Ni radical alloy compound strip and smelt preparation method, which belongs to the high temperature coat super conduct intensified tenacity strip technique filed. The W atom percent of the surface and core of the Ni alloy compound strip are 3-7% and 9.3-12% separately. The preparing method is to put the NiW alloy casting ingot or powder whose W atom percent are 3-7% and 9.3-12% separately according to B-A-B casting ingot order, and use the discharging plasma agglomeration technique to obtain the compound ingot under 850-1000deg C in vacuum. Then rolling the compound ingot to obtain the radical strip with the thickness of 60-200 mum, wherein the path distortion is 5-20%, the total distortion is more than 95%, then doing anneal with the radical strip in Ar / H2 or vacuum and under 1000-1300deg C; or doing anneal for 30-60min, and rising the temperature up to 1100deg C, then doing anneal for 30-60min to obtain the Ni radical alloy compound strip. The surface and core of the radical strip is not easy to crack, it has high mechanical strength, low magnetism, and it has strong biaxial cubic organization.

Owner:BEIJING UNIV OF TECH

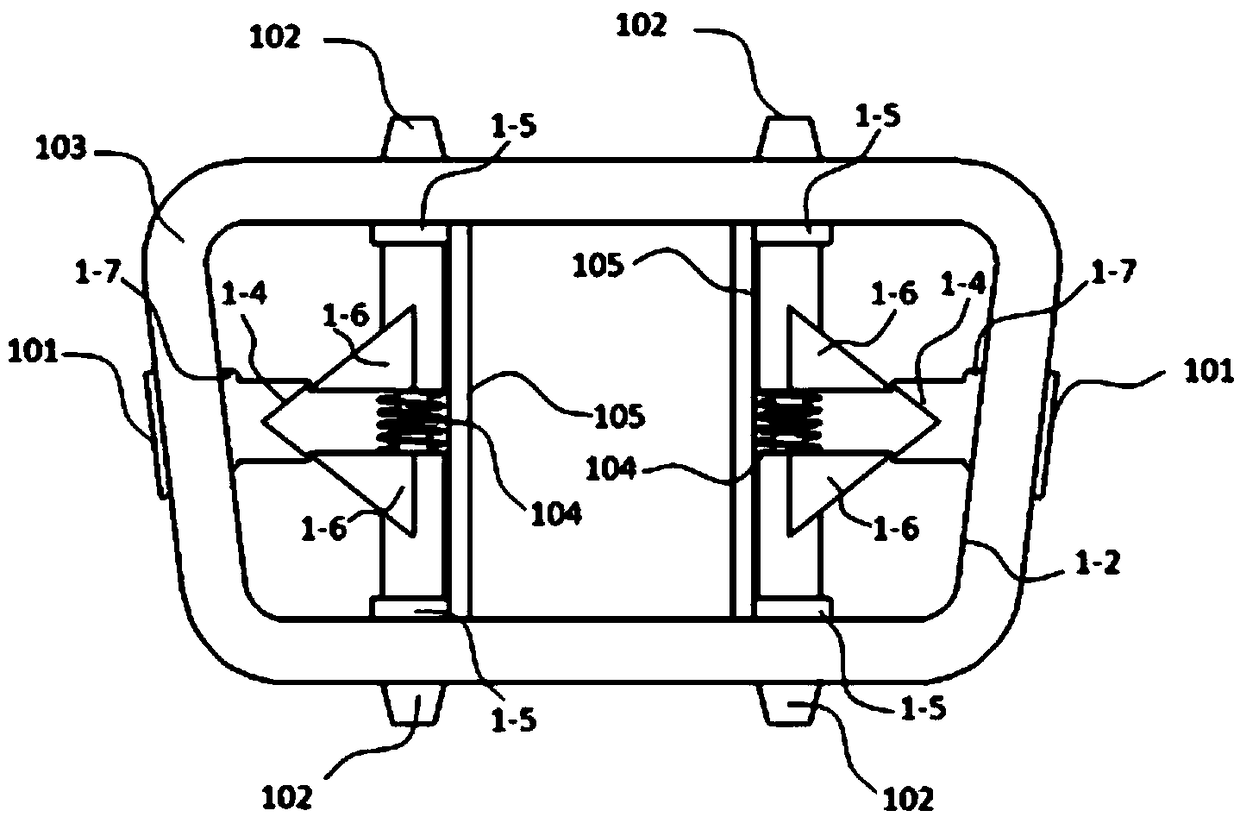

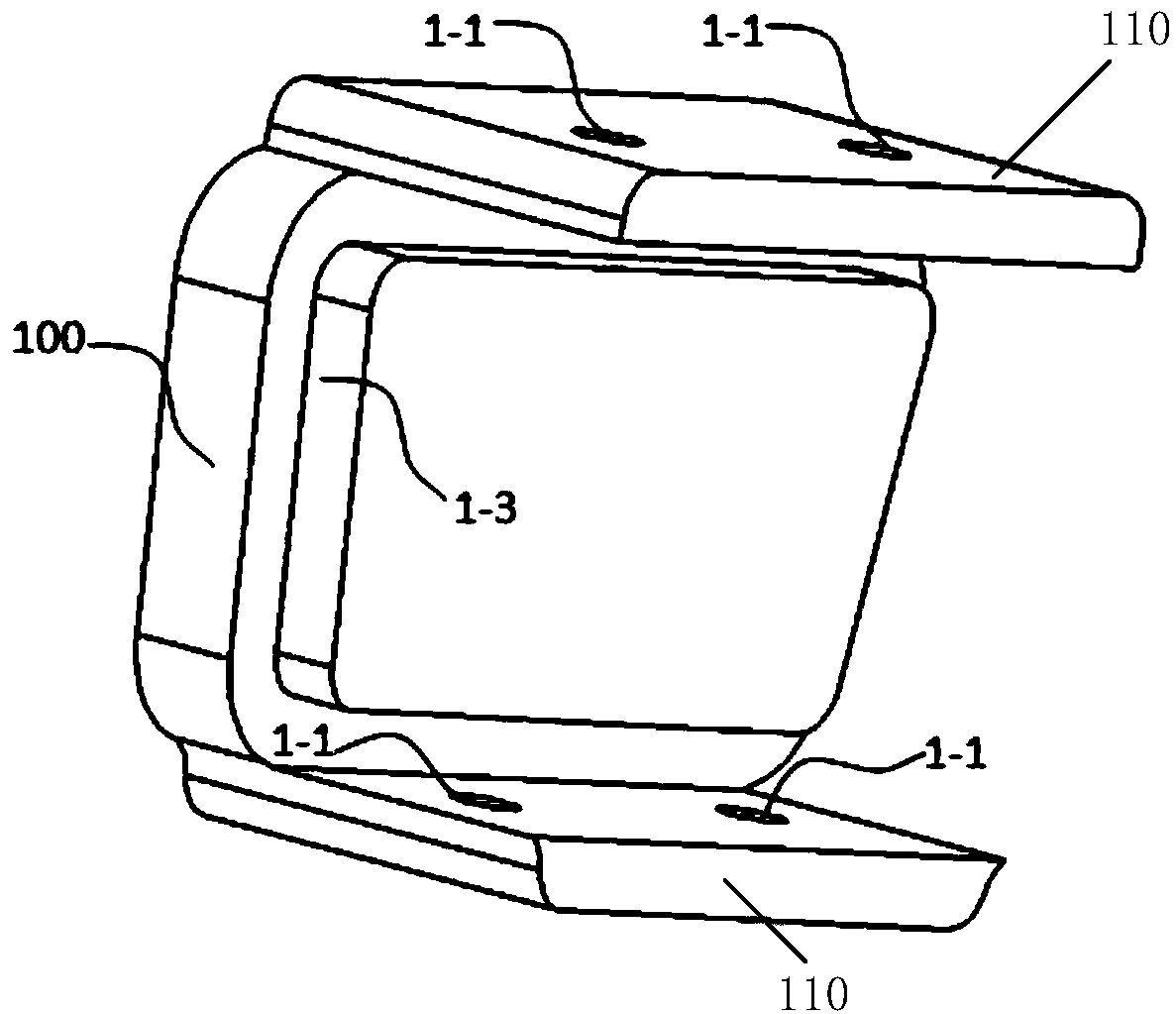

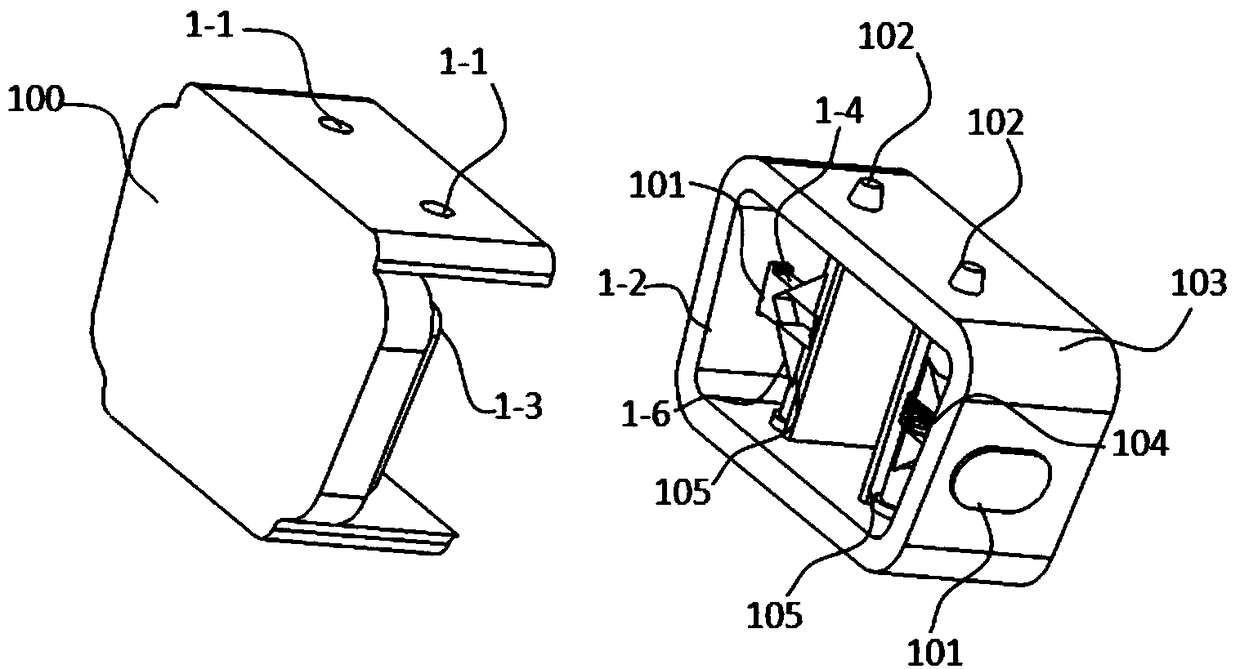

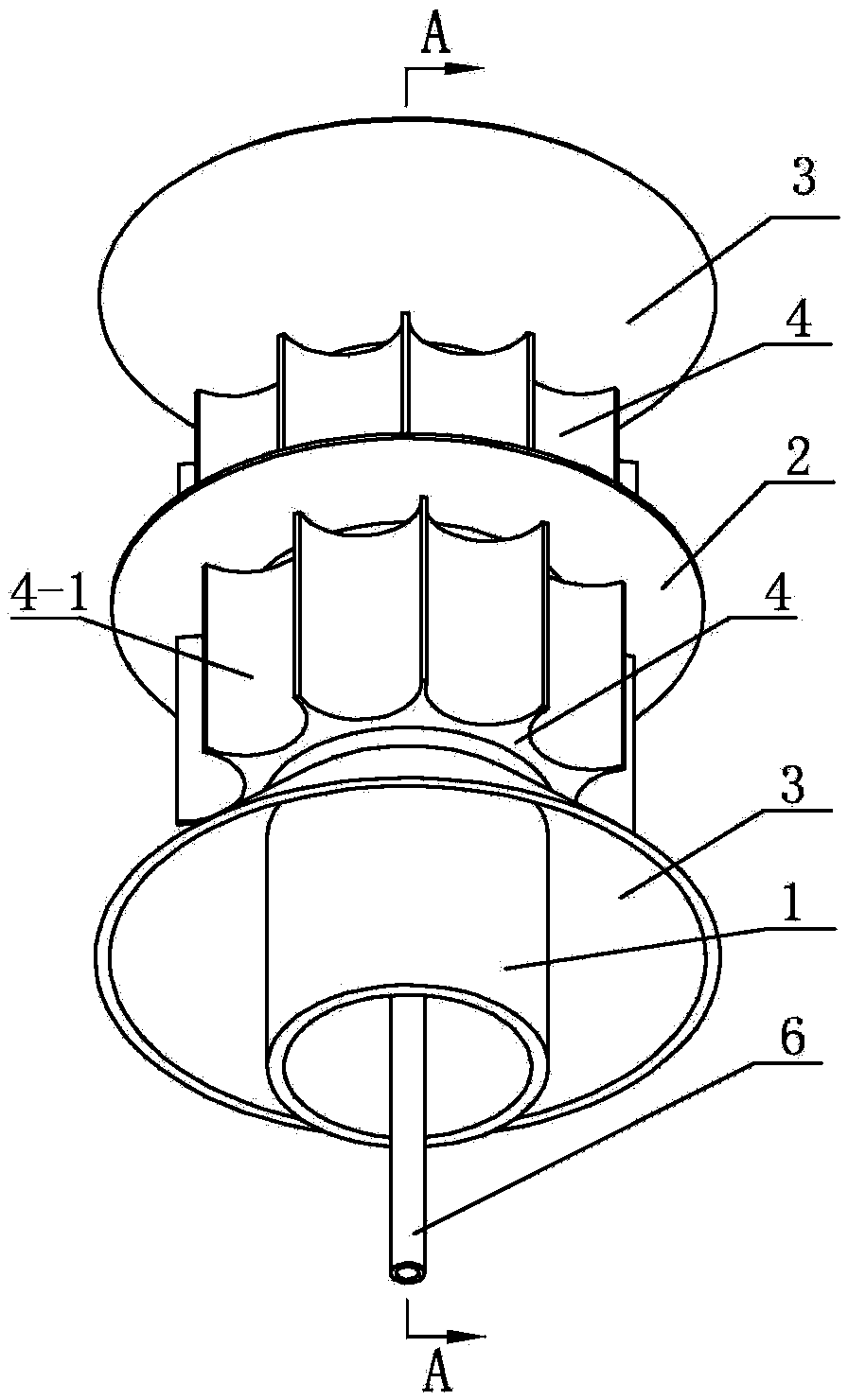

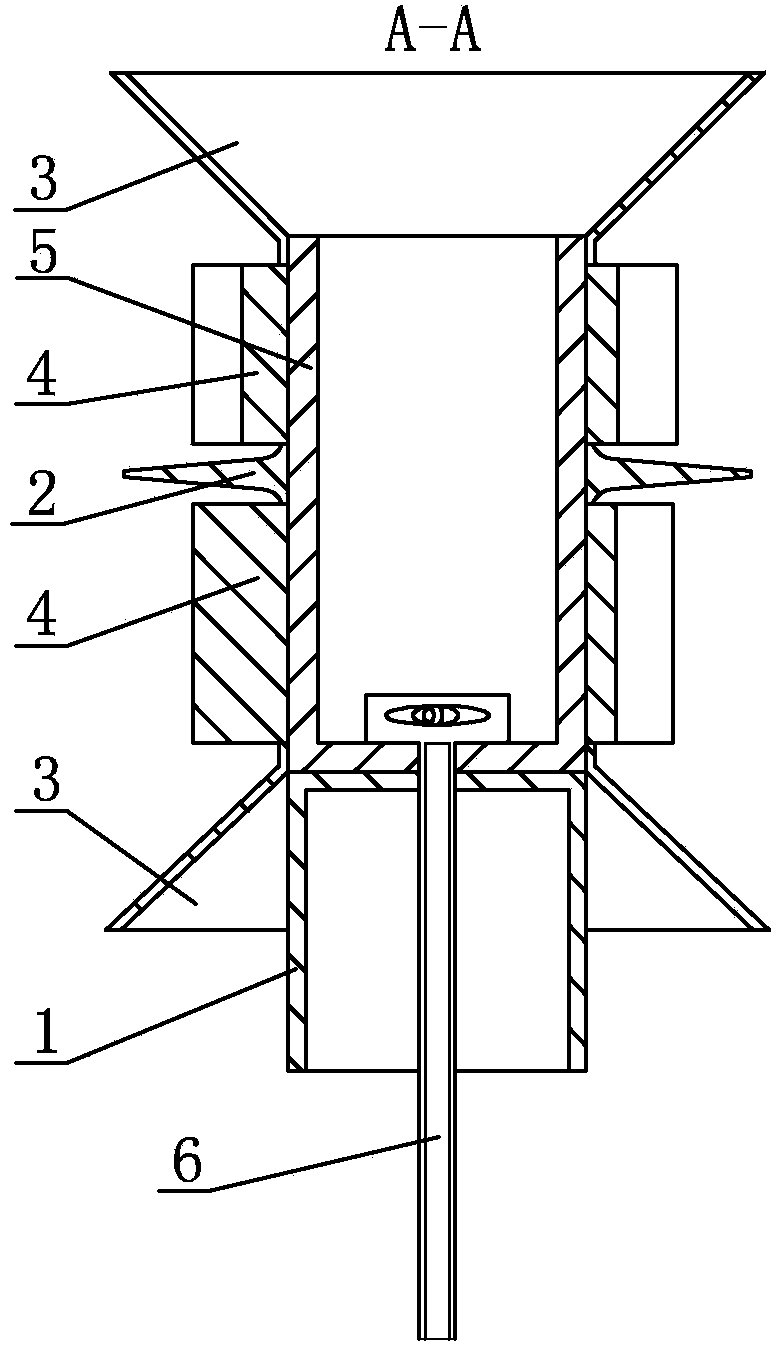

A quick changing device for a surgical instrument

ActiveCN109171966AQuick installationQuick releaseSurgical manipulatorsSurgical robotsLocking mechanismEngineering

The invention relates to a quick changing device for a surgical instrument, which realizes quick connection and disassembly between the surgical instrument and the end of a robot arm. The quick changing device comprises a mounting base, a mounting joint, a positioning mechanism and a locking mechanism. The positioning mechanism comprises a first positioning part and a second positioning part matching the same, wherein the first positioning part and the second positioning part are respectively arranged on the mounting base and the mounting joint; the locking mechanism includes a first connectordisposed on the mounting joint, and a control device and a second connector disposed on the mounting base. The control device is configured to control the second connector to be locked with the firstconnector so that the first positioning portion and the second positioning portion remain in mating contact, thereby realizing the assembly between the mounting joint and the mounting base. The control device is further configured to control the second connection member and the first connection member to be unlocked so that the first positioning portion and the second positioning portion are in adetachable state, thereby realizing unloading between the mounting joint and the mounting base.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

ActiveCN103854819AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

The invention discloses a hybrid film coating method of a neodymium iron boron rare earth permanent magnet device. According to the method, firstly, alloy smelting is carried out, alloy in a molten state is cast onto a rotary copper roller with a water cooling effect for being cooled to be manufactured into an alloy sheet, then, the alloy sheet is subjected to hydrogen decrepitation, material mixing and airflow powder grinding, next, materials are mixed by a material mixing machine and are then sent to a nitrogen gas protection magnetic field orientation pressing machine to be formed, the mixed materials are subjected to isostatic pressing after being encapsulated in a protection box, then, the sintering and the aging are carried out, a neodymium iron boron rare earth permanent magnet blank is prepared, the blank is subjected to machining, a neodymium iron boron rare earth permanent magnet is prepared, next, the neodymium iron boron rare earth permanent magnet is subjected to film coating, the neodymium iron boron rare earth permanent magnet device is formed, the film coating comprises three layers, the first layer and the second layer are magnetron sputtering coatings, and the second layer is a magnetron sputtering and multi-arc ion plating hybrid coating. The hybrid film coating is adopted as a surface treatment work procedure of the rare earth permanent magnet device, the anti-corrosion capability of the rare earth permanent magnet device is improved, and meanwhile, the magnetic performance of the rare earth permanent magnet device is also improved.

Owner:SHENYANG GENERAL MAGNETIC

High-manganese and high-strength full-austenite welding rod with low thermal crack sensitivity

ActiveCN102059470AReduce magnetismGood welding performanceWelding/cutting media/materialsSoldering mediaCrack resistanceIron powder

The invention discloses a high-manganese and high-strength full-austenite welding rod with low thermal crack sensitivity. The core wire of the welding rod is prepared from 0.005-0.03% of C, 0.01-1.0% of Si, 6.5-8.5% of Mn, 16.0-18.5% of Ni, 20.5-22.5% of Cr, 3.0-5.0% of Mo, 0.20-0.30% of N, not more than 0.040% of S+P and the balance of Fe; and a coating comprises 38-42% of marble, 32-38% of fluorite, 4-5% of feldspar, 4-6% of manganese metal, 4-6% of ferrosilicon, 4-6% of ferrotitanium, 2-4% of iron powder, 1-2% of soda ash and 1-2% of carboxymethylcellulose. The weld metal of the welding rod is of a full-austenite structure and has extremely low magnetism, yield strength capable of reaching above 400MPa, tensile strength capable of reaching above 600MPa, good welding manufacturability and particularly outstanding thermal crack resistance sensitivity.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Powdered alloy material for Fe-based non-magnetic clad layer

The invention discloses a powdered alloy material for a Fe-based non-magnetic clad layer, and is applied to the surface coating field. The powder comprises reduced iron powder, electrolytic manganese powder, high-carbon ferro-chrome, ferromolybdenum, ferroboron, ferrotungsten, chromium carbide and boron carbide. The powdered alloy material comprises the following element contents: 6-18wt% of Cr, 5-10wt% of Mo, 2-5wt% of W, 0.5-2wt% of C, 0.5-3wt% of B, 0-15wt% of Mn and the balance of Fe. The powdered alloy material is subjected to a plasma arc surfacing process to prepare the Fe-based multi-element clad layer. The prepared clad layer is non-magnetic, has relatively high hardness, and is not likely to generate cracks or other cladding defects.

Owner:BEIJING UNIV OF TECH

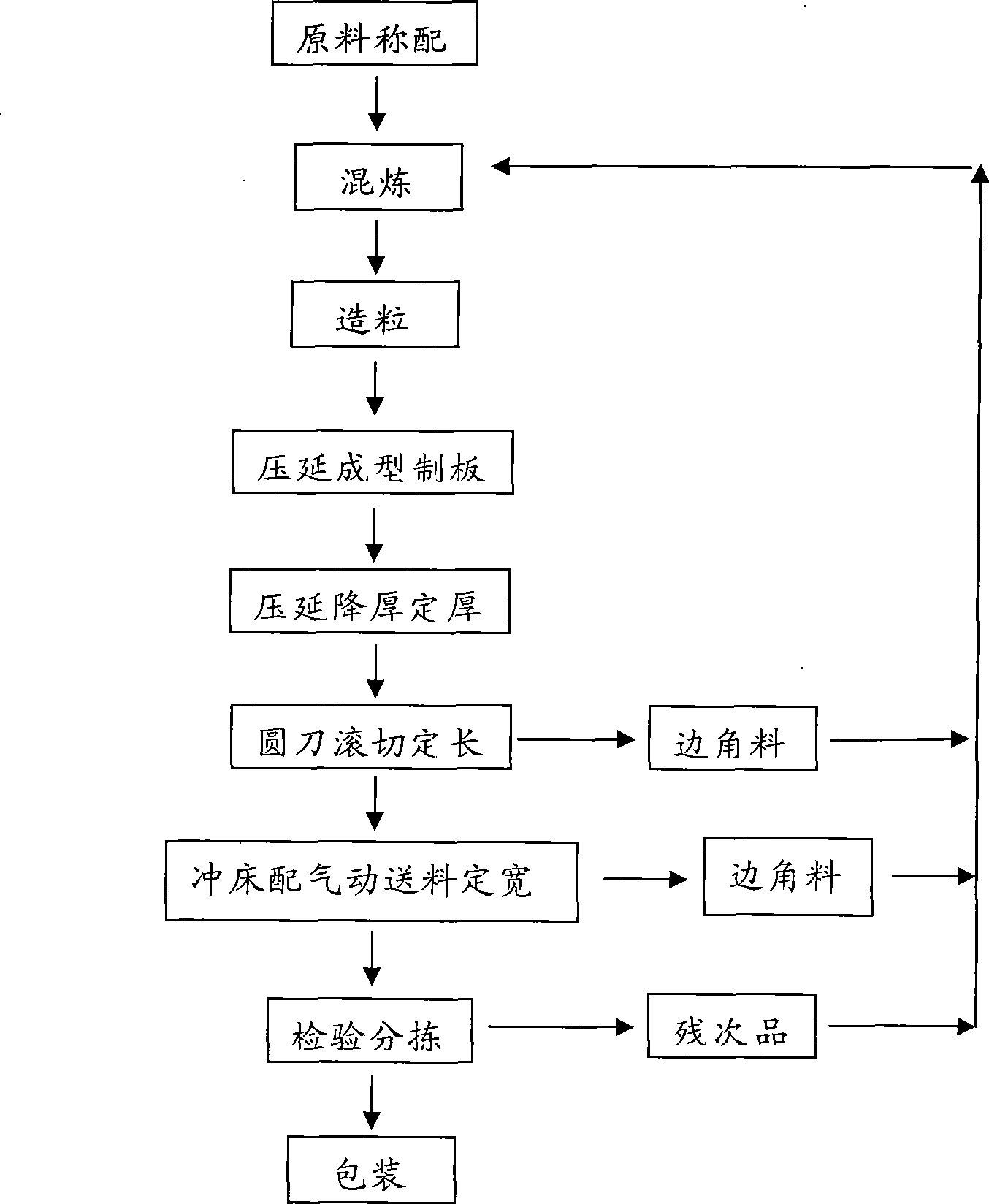

High rigidness saturated polarity rubber adhesive permanent magnet and preparation thereof

InactiveCN101383211AImprove product hardnessImprove physical propertiesInorganic material magnetismTarChemistry

The invention provides a high-hardness permanent magnet which is bonded by saturated polar rubber and comprises components in weight percentage: 85 to 97 percent of magnetic powder, 2 to 15 percent of saturated polar rubber, 0.5 to 4 percent of plasticizing agent, 0 to 1 percent of lubricating agent, 0.1 to 2.5 percent of surface active agent and anti-aging agent for the rest, wherein the plasticizing agent is one or a plurality of petroleum resin and paraffin in petroleum series plasticizing agents, coumarone indene resin in a coal tar series, pine tar, colophony and retinol in a pine oil series and epoxidized soybean oil in an epoxidized type. The invention also provides a method for preparing the high-hardness permanent magnet which is bonded by the saturated polar rubber. The high-hardness permanent magnet which is bonded by the saturated polar rubber has the advantages of hardness increase, physical property improvement, fraction defective reduction of downstream manufacturer products, convenient and safe processing and production cost reduction, and is greatly beneficial for enlarging the adaptability of the permanent magnet.

Owner:江显涛

Preparation method of carbon-aerogel-based spherical anticorrosion magnetic material

InactiveCN102709017AReduce magnetismEasy to operateInorganic material magnetismCarbon preparation/purificationNickel saltReducing atmosphere

The invention relates to a preparation method of a carbon-aerogel-based spherical anticorrosion magnetic material, wherein nickel salts, aldehydes substances and aromatic amine phenols are taken as raw materials. The method comprises the process of preparing, drying and carbonizing nickel-containing gel, and is characterized in that the gel is prepared in a manner that the nickel salts are added into a solution prepared from the aldehydes substances and aromatic amine phenols substances according to proportion, a catalyst and a dispersant are added for gelation, vacuum drying is performed to form xerogel, and the nickel-containing gel is carbonized in a reducing atmosphere to prepare the carbon-aerogel-based spherical anticorrosion magnetic material. The method disclosed by the invention is easy to implement, short in preparation period and suitable for large-scale production.

Owner:HEFEI UNIV OF TECH

Manufacturing method for neodymium iron boron lanthanon permanent magnet device with composite plated film

ActiveCN103824693AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

Owner:SHENYANG GENERAL MAGNETIC

Vanadium-containing non-magnetic Ti(C, N)-based metal ceramic and preparation method thereof

The invention provides vanadium-containing non-magnetic Ti(C, N)-based metal ceramic and a preparation method thereof, and belongs to metal ceramic and preparation methods. The vanadium-containing non-magnetic Ti(C, N)-based metal ceramic comprises a hard phase and a binding phase, and raw materials are powder and comprise, by weight, 42.11%-53.48% of TiC, 7.91%-9.99% of TiN, 27.78%-32.82% of Ni, 9.30%-15.16% of Mo and 0.50%-1.99% of VC. The metal ceramic is prepared by mixing, wet grinding, drying, compression molding, degreasing and vacuum sintering. The preparation method of the metal ceramic sequentially includes the steps of mixing, wet grinding, drying, compression molding, degreasing and vacuum sintering. The preparation method is simple, low in cost and suitable for industrial production. The prepared metal ceramic is simple in composition and does not contain scarce strategic resource W, the hardness can reach 89 HRA, the bending strength can reach 2673 MPa, the metal ceramic has no magnetism at the room temperature, the relative permeability is not higher than 1.003, the abrasion resistance and the chemical stability are good, and the friction coefficient with materials such as steel is small; and the metal ceramic has good application prospects in the aspects of molding tools and molds for magnetic elements and wear-resistant parts of electronic products and automobile instruments.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of oriented carbon nanotube film

The invention discloses a preparation method of an oriented carbon nanotube film, and belongs to the field of film material preparation. The preparation method is characterized by comprising the following steps: step A, adopting a magnetic multi-walled carbon nanotube, which is prepared by steps of subjecting carboxylated multi-walled carbon nanotubes to polymeric modification and evenly loading magnetic particles on the modified multi-walled carbon nanotubes through a chemical co-precipitation method; step B, adding the obtained magnetic carbon nanotubes obtained in the step A into a solvent, mixing, and fully dispersing the carbon nanotubes to obtain a stable carbon nanotube solution; step C, adopting a vacuum suction filtration method: pouring the magnetic carbon nanotube solution obtained in the step B into a vacuum suction filtration device, applying a magnetic field on the device, and changing the direction of the magnetic field so as to obtain an in-plane vertical oriented film or an in-plane horizontal oriented film; step D, removing the substrate film by liquid nitrogen so as to obtain the oriented carbon nanotube film. The method is simple and efficient, the film structure is uniform and complete; the orientation degree can be controlled by changing the strength of magnetic field and the grafting rate of magnetic nano particles on the carbon nanotubes, and the integrity of oriented film structure is guaranteed by spraying liquid nitrogen.

Owner:BEIJING UNIV OF CHEM TECH

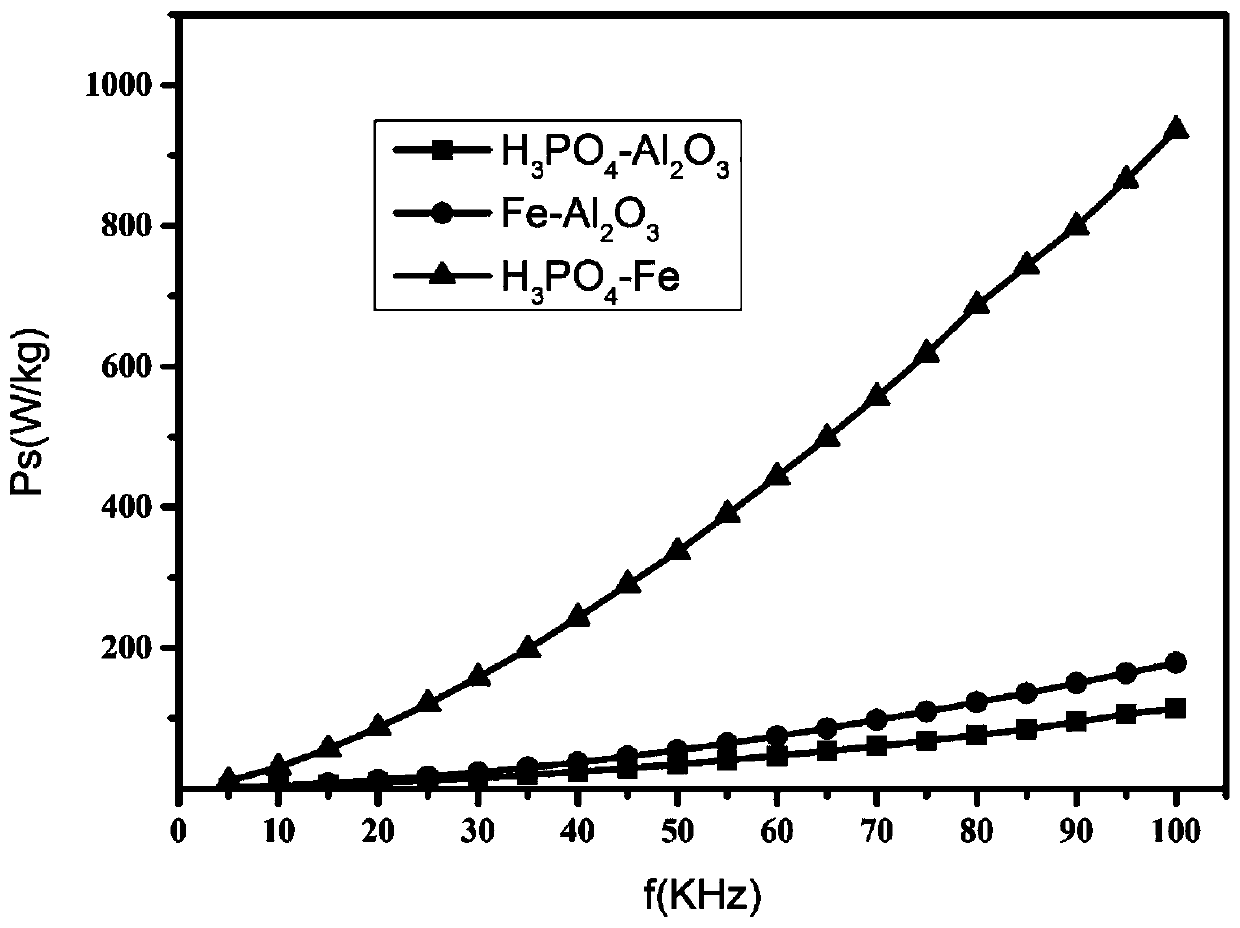

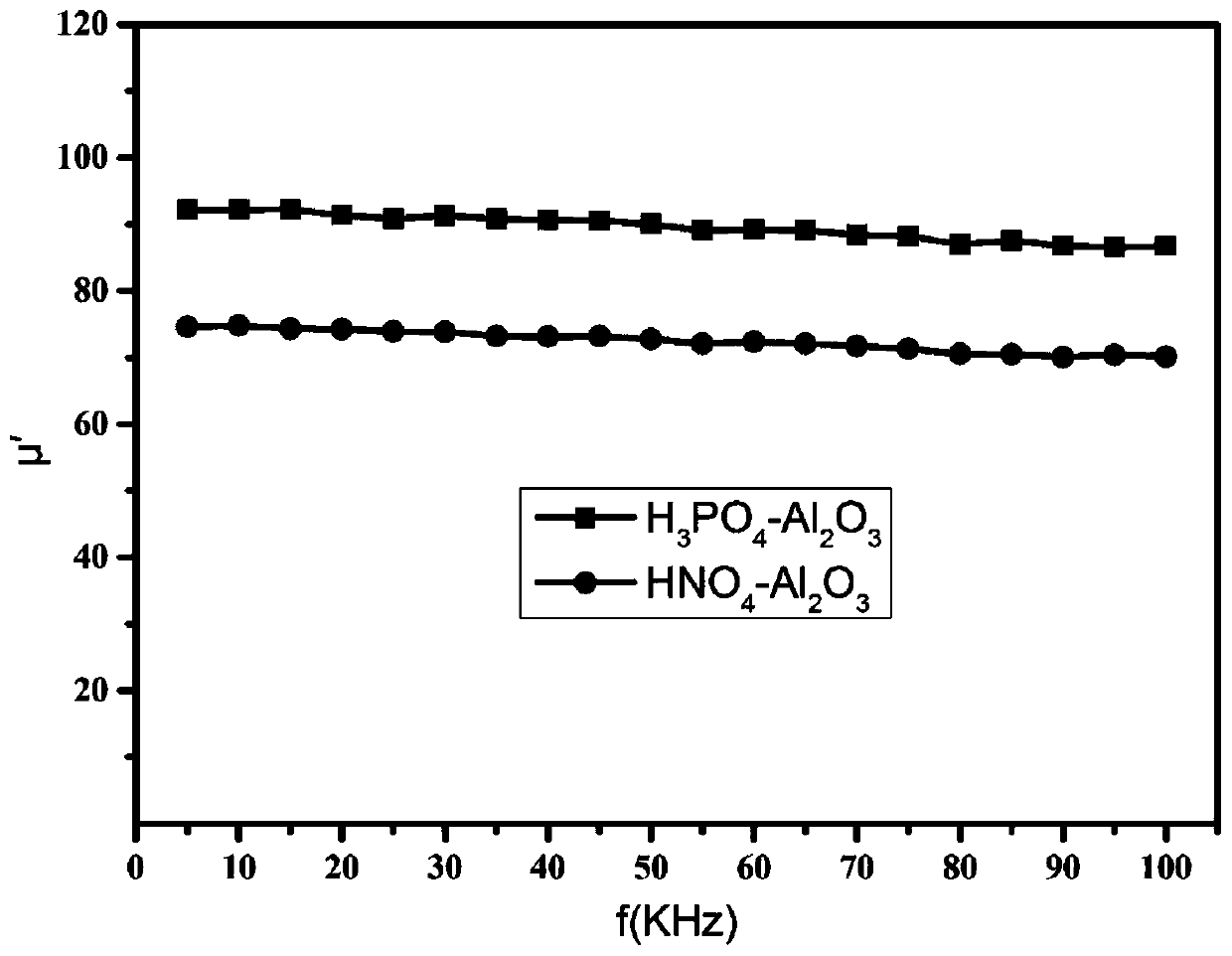

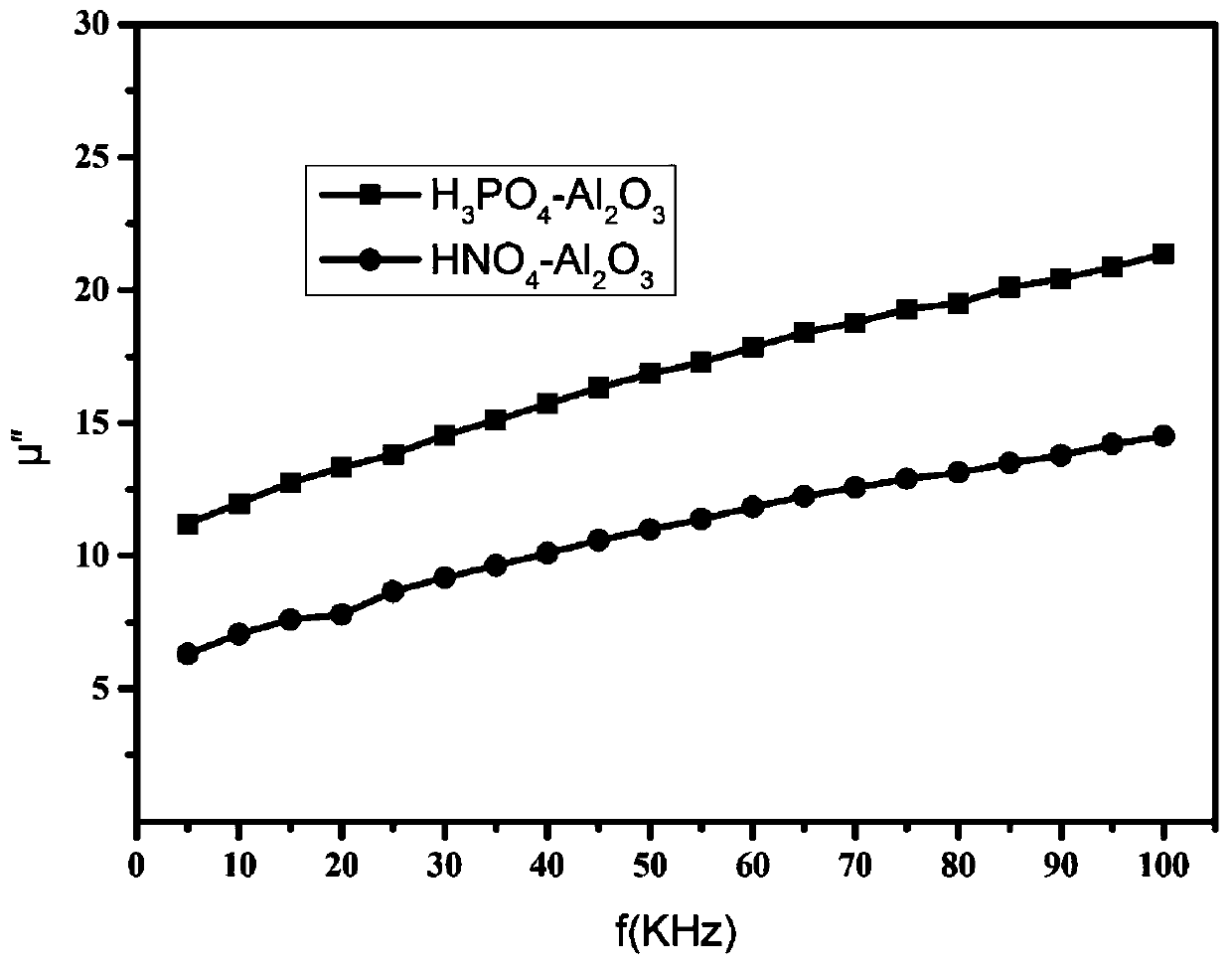

Multilayer-coated soft magnetic composite material and preparation method thereof

ActiveCN109754979AImprove uniformityPrecise thickness controlInorganic material magnetismInductances/transformers/magnets manufactureState of artHeat stability

The invention relates to a multilayer-coated soft magnetic composite material and a preparation method thereof. The composite material is of a core-shell structure, iron-based alloy powder is taken asa core, and a passivation layer and an Al2O3 coating layer are sequentially coated on the surface of the iron-based alloy powder. The preparation method comprises the following steps: performing reaction on the iron-based alloy powder in passivation solution, so that powder A is obtained; preparing Al2O3 colloid; performing ball-milling reaction on the powder A and the Al2O3 colloid; and performing high temperature calcining on the powder subjected to ball milling, so that a multilayer-coated soft magnetic composite material with high magnetic permeability and low loss is obtained. Compared with the prior art, the multilayer-coated soft magnetic composite material provided by the invention has the advantages that high-resistivity insulating substances are coated for multiple layers, so that magnetic loss of the composite material is relatively low under high frequency application condition, and an insulated coating layer which is better in uniformity and has the thickness capable of being accurately controlled can be obtained; and Al2O3 sol-gel has strong heat stability, density of magnetic powder can be improved to the utmost extent, and magnetic permeability of the magnetic powder is improved.

Owner:TONGJI UNIV

Flux shunt structure for reducing return pole corner fields in a perpendicular magnetic recording head

InactiveUS7639450B2Improve protectionEnsure sufficient separationManufacture head surfaceHeads using thin filmsEngineeringMagnetic shield

A magnetic head for use in a perpendicular recording system having a novel shield structure that provides exceptional magnetic shielding from extraneous magnetic fields such as from a write coil, shaping layer or return pole of the write head. The magnetic head includes a write pole, a return pole and a magnetic shield that is magnetically connected with the return pole near the ABS and extends toward the write pole. The shield is formed with a notch at its edge closest to the write pole. The notch assures adequate physical, magnetic, and electrical separation between the write pole and the shield, while allowing un-notched portions of the shield to provide additional magnetic shielding.

Owner:WESTERN DIGITAL TECH INC

Ni-base alloy composite baseband and its smelting preparation method

InactiveCN1844429ALower sintering temperatureSolve the disadvantagesRoll mill control devicesAuxillary arrangementsAlloy compositeIngot

This invention relates to a Ni radical alloy compound strip and smelt preparation method, which belongs to the high temperature coat super conduct intensified tenacity strip technique filed. The W atom percent of the surface and core of the Ni alloy compound strip are 3-7% and 9.3-12% separately. The method as follows: coldly pressing NiW alloy casting ingot whose W atom percent are 3-7% and 9.3-12% separately into one according to B-contiguous layer-A-contiguous layer-B order, in the Ar / H2 and under 750-900deg C agglomerating them for 3-8h to obtain the compound ingot, wherein B and A thickness ratio is 1: 1 to 1:4, the total thickness is 6-18mml; coldly rolling the compound ingot to obtain the radical strip whose thickness is 60-200 mum , wherein the deformation quantum is 5-20%, the total deformation quantum is more than 95%; operating anneal with the radical strip under Ar / H2 or vacuum and under 1000-1300deg C; or operating anneal under 700deg C, then rising temperature up to 1100deg C, and then operating anneal for 30-60min to obtain the Ni radical alloy compound strip. The surface and core of the radical strip is not easy to crack, it has high mechanical strength, low magnetism, and it has strong biaxial cubic organization.

Owner:BEIJING UNIV OF TECH

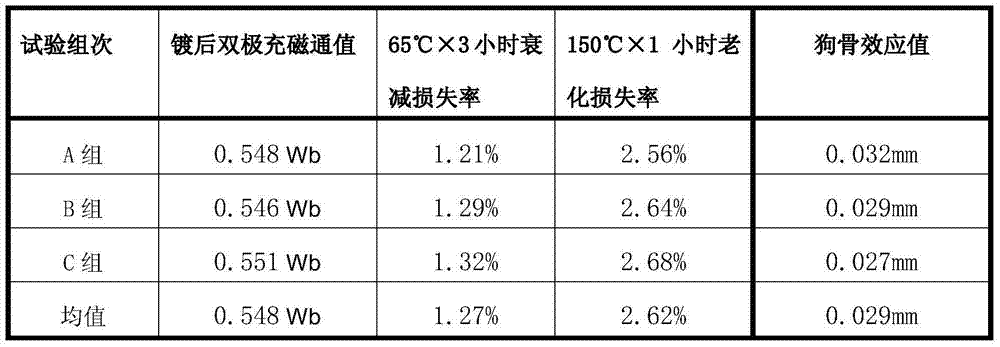

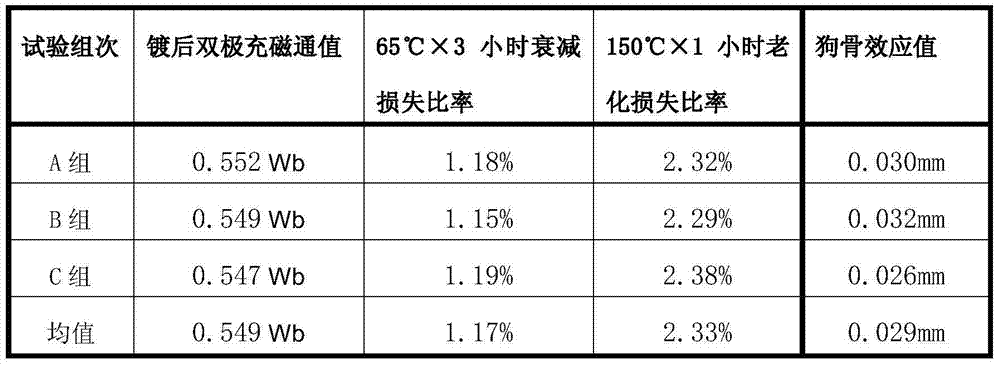

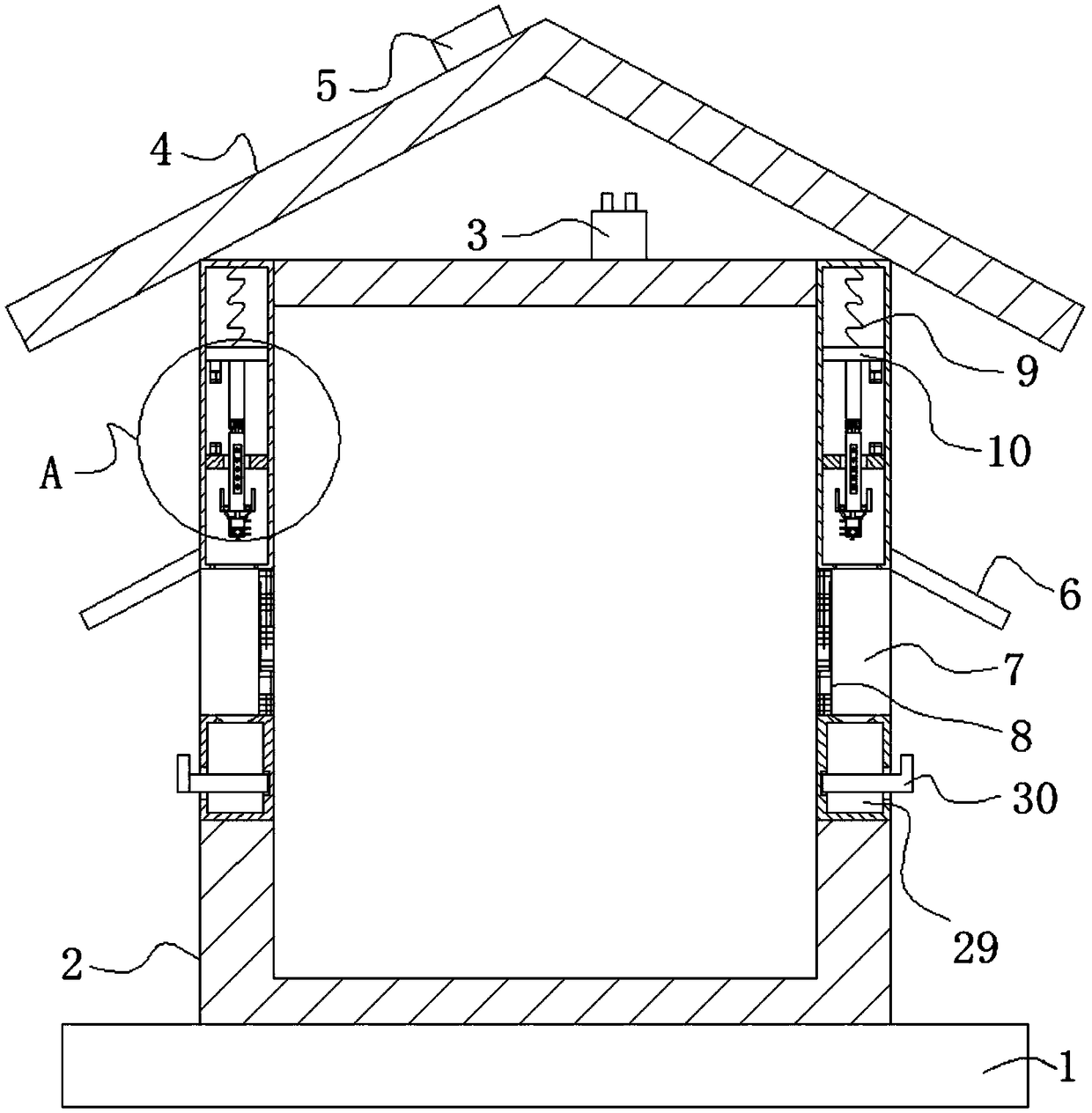

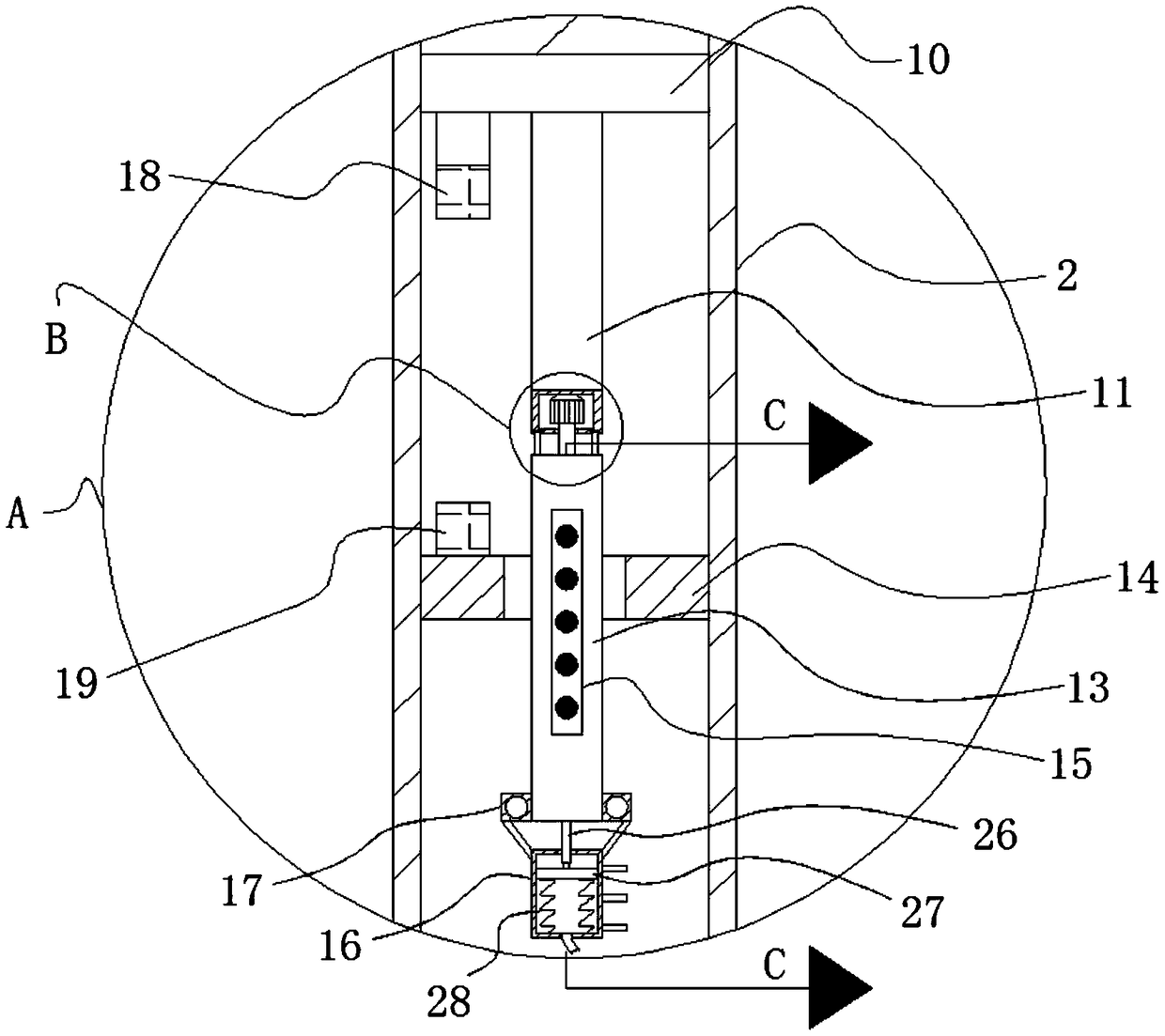

Method for carrying out electronickelling on neodymium-iron-boron magnet

The invention discloses a method for carrying out electronickelling on a neodymium-iron-boron magnet. The method particularly comprises the following steps of: carrying out a pretreatment process, a nickel preplating process, a water washing process, a semi-bright nickel plating process, the washing process, a bright nickel plating process and a water washing process on the neodymium-iron-boron magnet, wherein a first electronickelling solution which comprises nickel sulfate, boric acid, sodium succinate, sodium carboxyethyl sulfonate and water is adopted for the nickel preplating process; a second electronickelling solution which comprises nickel sulfate, diammonium hydrogen citrate, the boric acid, ammonia water and water is adopted for the semi-bright nickel plating process; the first electronickelling solution is free of chloride ions, and the first electronickelling solution contains the sodium succinate and the sodium carboxyethyl sulfonate; the second electronickelling solution contains a proper amount of diammonium hydrogen citrate. The method disclosed by the invention can ensure that the neodymium-iron-boron magnet has better magnetic property by reducing the influence of an electroplating process on the magnetic property of the neodymium-iron-boron magnet and achieves uniform distribution of coating thickness when a product with a smaller end part angle is electroplated.

Owner:NINGBO YUNSHENG +4

Multifunctional electrical equipment box with ventilation and heat dissipation functions

ActiveCN108808523AIncrease resistanceReduce magnetismDispersed particle filtrationTransportation and packagingPower equipmentMagnet

The invention discloses a multifunctional electrical equipment box with ventilation and heat dissipation functions. The electrical equipment box comprises an electrical equipment box body, the multifunctional electrical equipment box with ventilation and heat dissipation functions is simple in structure, dust can be prevented from entering the electrical equipment box body by the aid of a filter net, dust is effectively prevented from entering the electrical equipment box body while the electrical equipment box body dissipates heat, a front shielding plate can prevent rainwater entering air holes, a first conductive piece and a second conductive piece are contacted, a motor drives a second connecting rod and a large brush plate to rotate, large soft bristles on the large brush plate are used for deeply treating dust on the filter net and enlarging the clearing area, when the second connecting rod rotates, a second permanent magnet attracts an iron block intermittently, a third connecting rod drives the large brush plate and a fourth connecting rod to move up and down under the action of a pull cord, a second spring and a third spring, so that the large soft bristles on the large brush plate rotationally move up and down for sweeping, and the sweeping efficiency is improved.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

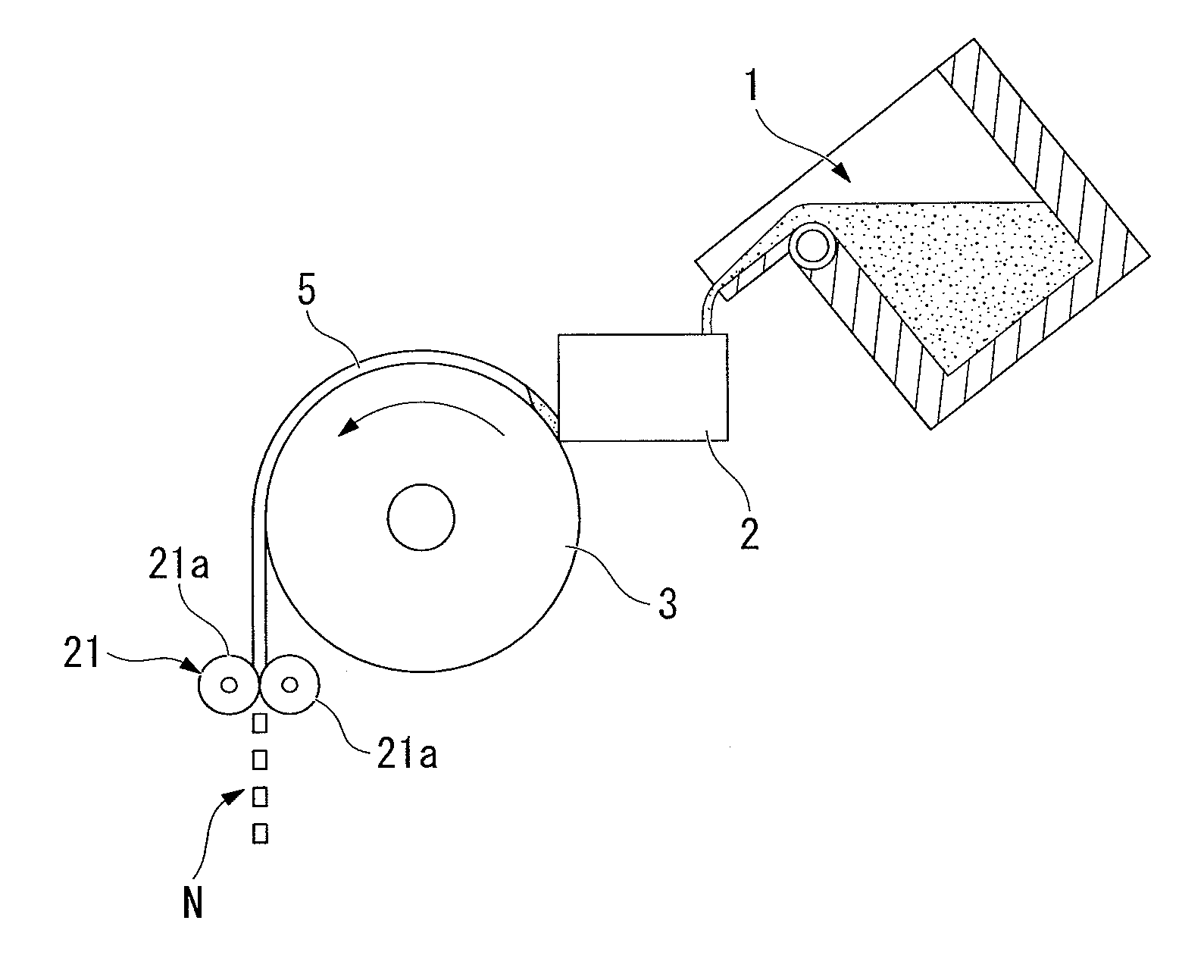

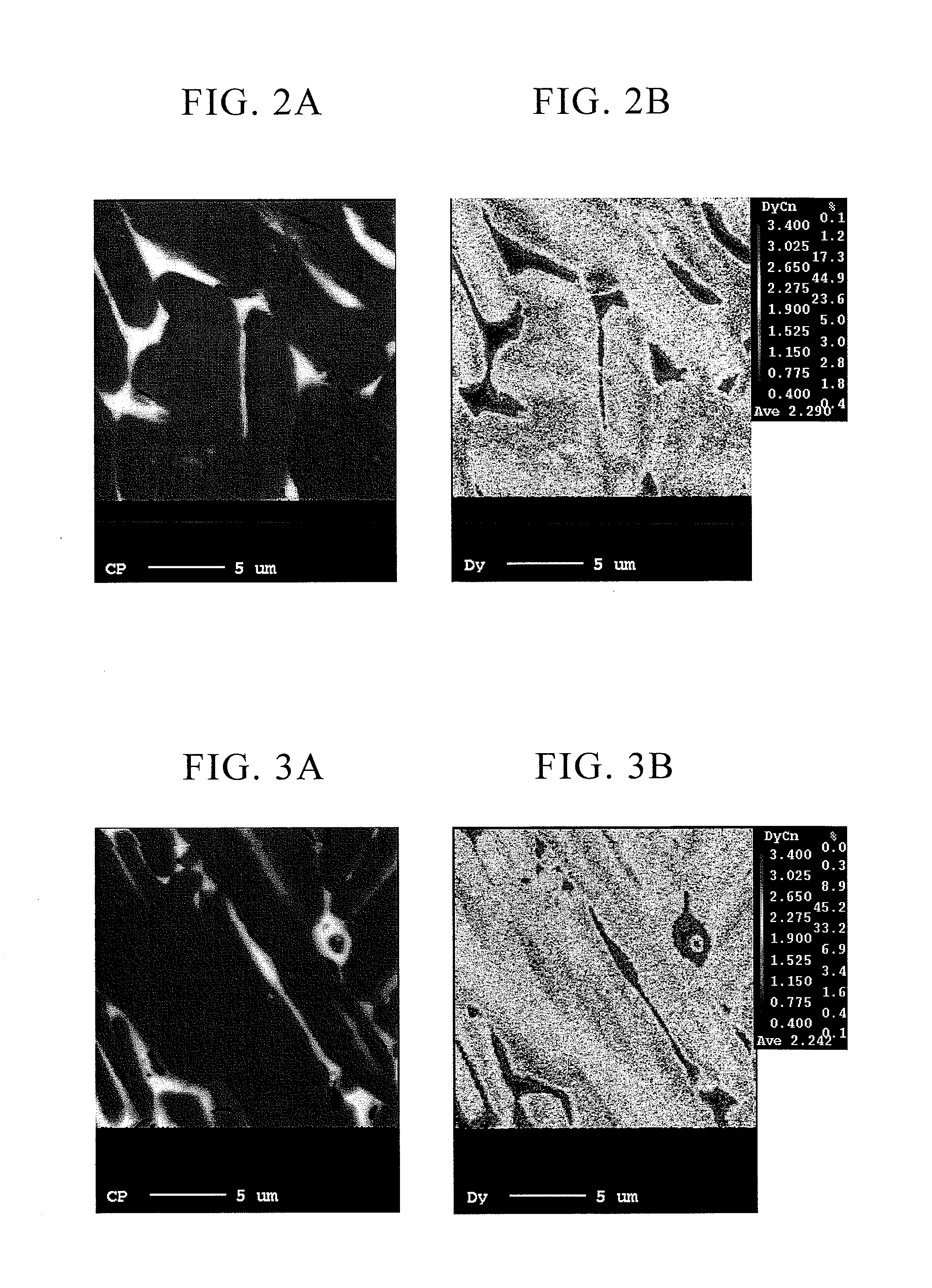

R-t-b alloy, process for production of r-t-b alloy, fine powder for r-t-b rare earth permanent magnets, and r-t-b rare earth permanent magnet

InactiveUS20100230013A1Improve uniformityLow dispersionTransportation and packagingMetal-working apparatusRare-earth elementAlloy

An R-T-B alloy used in a rare earth permanent magnet, where R is at least one element selected from rare earth elements including Y, which contains Dy and / or Tb as an essential element, T is a metal comprising Fe as an essential element, and B is boron, comprising: a main phase being an R2T14B phase, and an R-rich phase; and when a mean value of the concentration of Dy and / or Tb in the whole of said R-T-B alloy is defined as an average concentration, an area of 60% or more of an area of said main phase in an arbitrary cross-section of said R-T-B alloy contains said Dy and / or Tb at the average concentration or higher; a process for the production of the R-T-B alloy; a fine powder for R-T-B rare-earth permanent magnets which is prepared from the R-T-B alloy: R-T-B rare earth permanent magnet, and motors.

Owner:SHOWA DENKO KK

Radiation heat dissipation device for multistage cusped magnetic field plasma thruster

ActiveCN103790794AIncrease the areaReduce areaMachines/enginesUsing plasmaThermodynamicsParticle collision

The invention relates to a radiation heat dissipation device, in particular to a radiation heat dissipation device for a multistage cusped magnetic field plasma thruster. The radiation heat dissipation device for the multistage cusped magnetic field plasma thruster aims to solve the problems that due to the high anode temperature of the multistage cusped magnetic field plasma thruster, the high temperature of an outlet and the high temperature of the magnetic separatrix caused by particle collisions on the ceramic inner wall, heating carried out on the channel inner wall and the anode of the thruster is sharply enhanced within a short period, magnetism of a permanent magnet is seriously affected by heat conduction, and the thruster is poor in operation stability and reliability and short in service life. The radiation heat dissipation device for the multistage cusped magnetic field plasma thruster comprises a heat dissipation cylinder, a heat dissipation plate, two heat dissipation conical cylinders and two heat dissipaters, wherein a thruster shell is arranged between the two heat dissipation conical cylinders, the upper portion and the lower portion of the thruster shell are sleeved with the two heat dissipaters respectively, the heat dissipation plate is installed on the thruster shell in a sleeved mode and located between the two hear dissipaters, and the closed end of the heat dissipation cylinder is fixedly connected with the thruster shell. The radiation heat dissipation device is used for the multistage cusped magnetic field plasma thruster.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com