Patents

Literature

62 results about "Tungsten atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

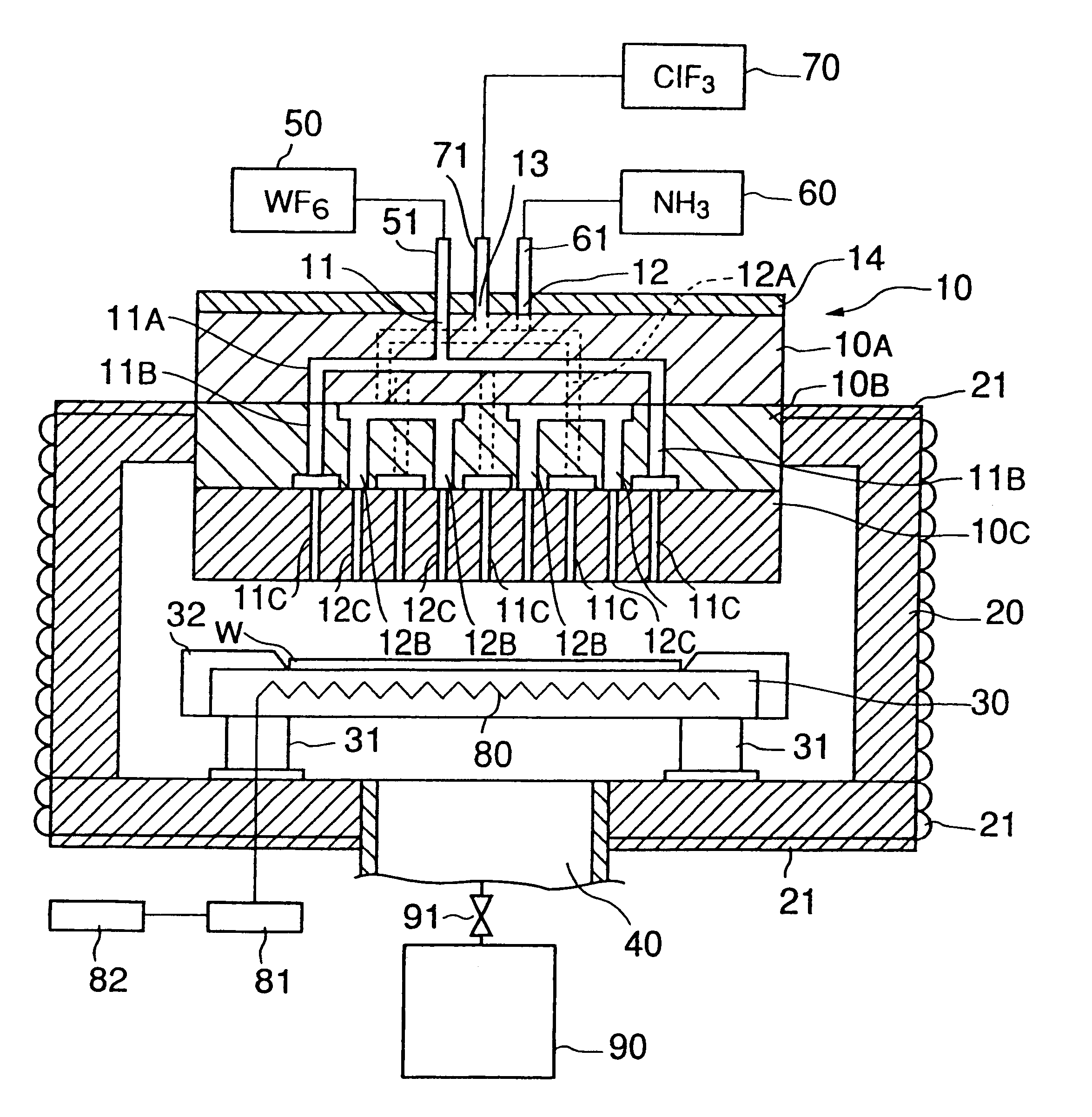

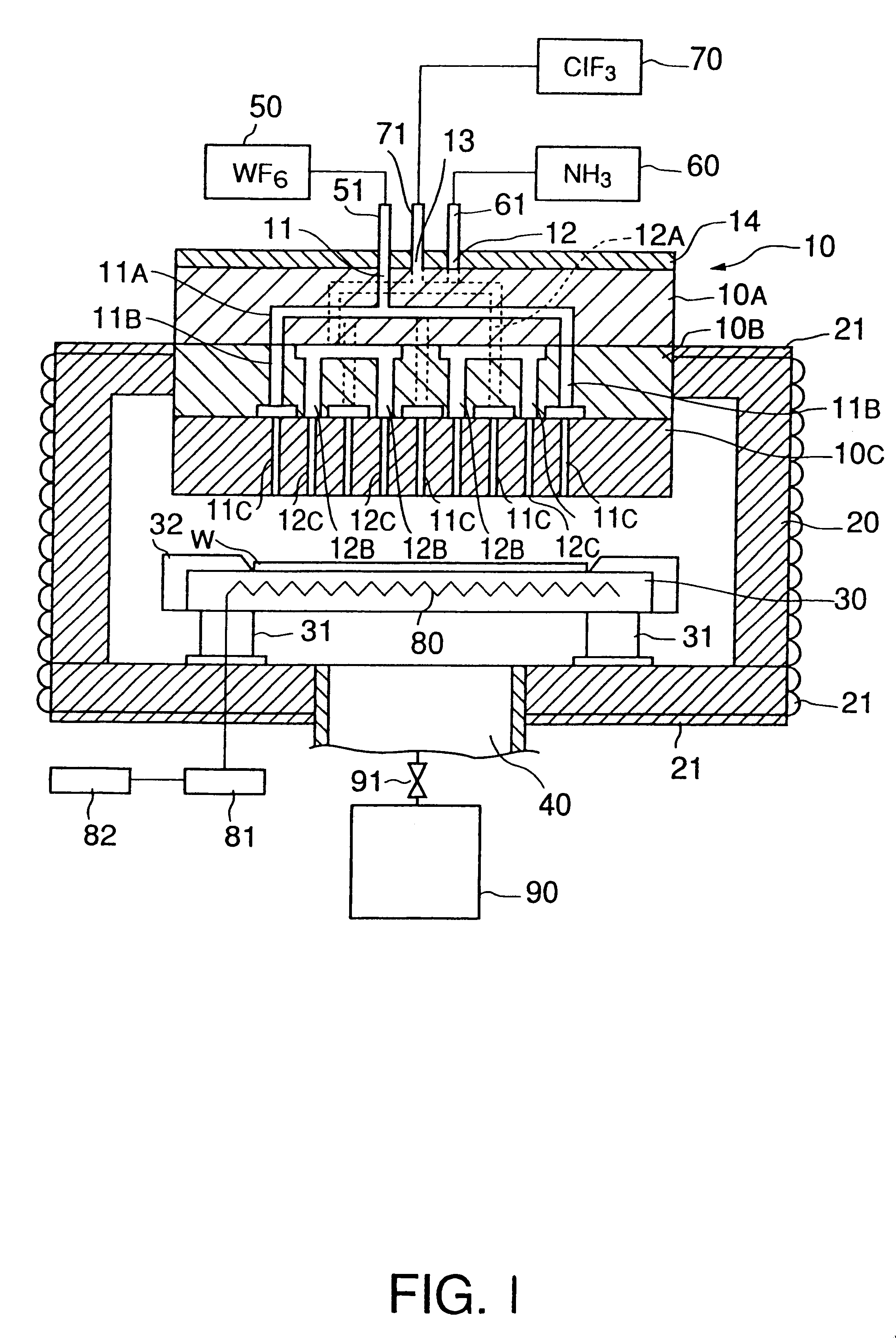

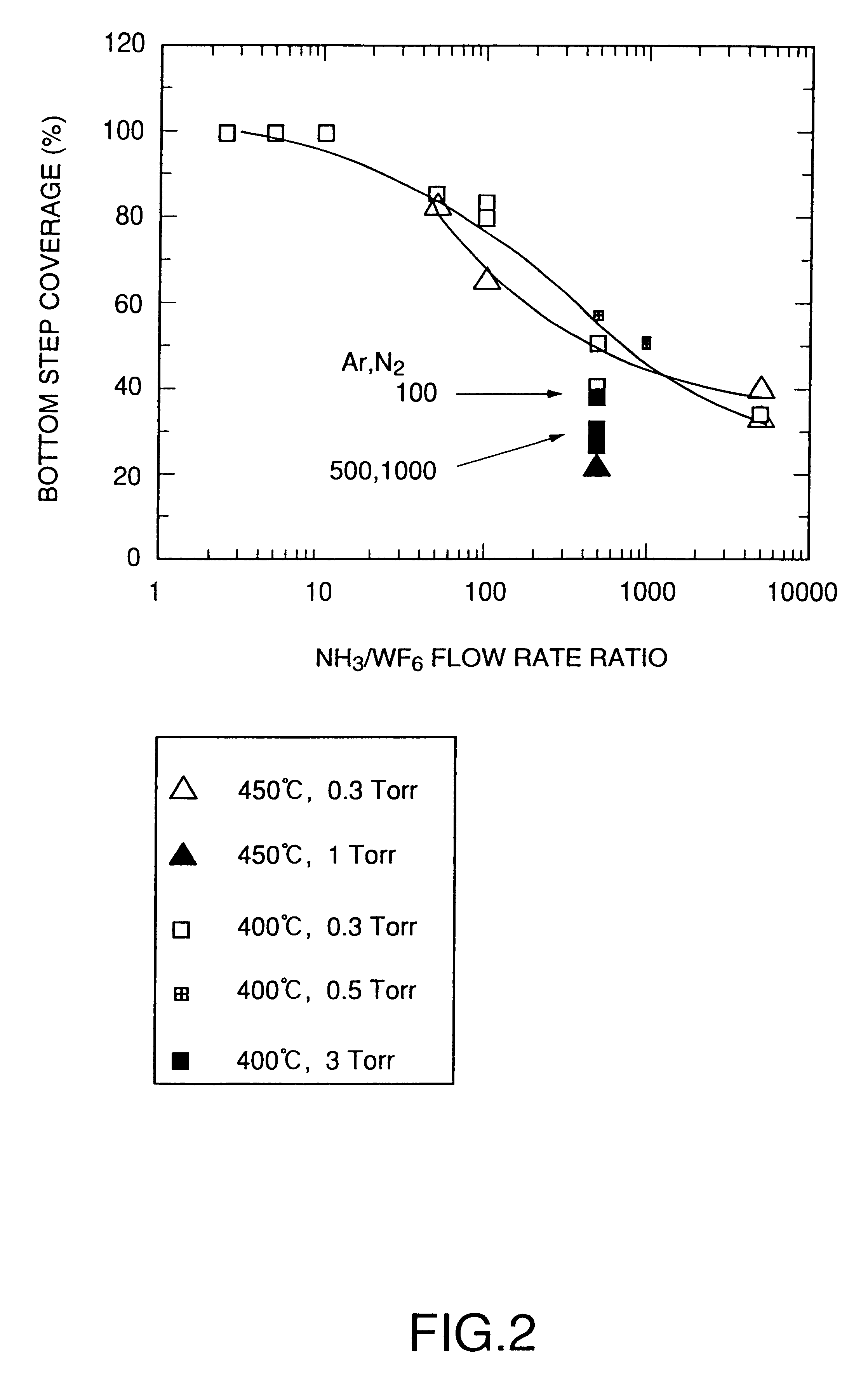

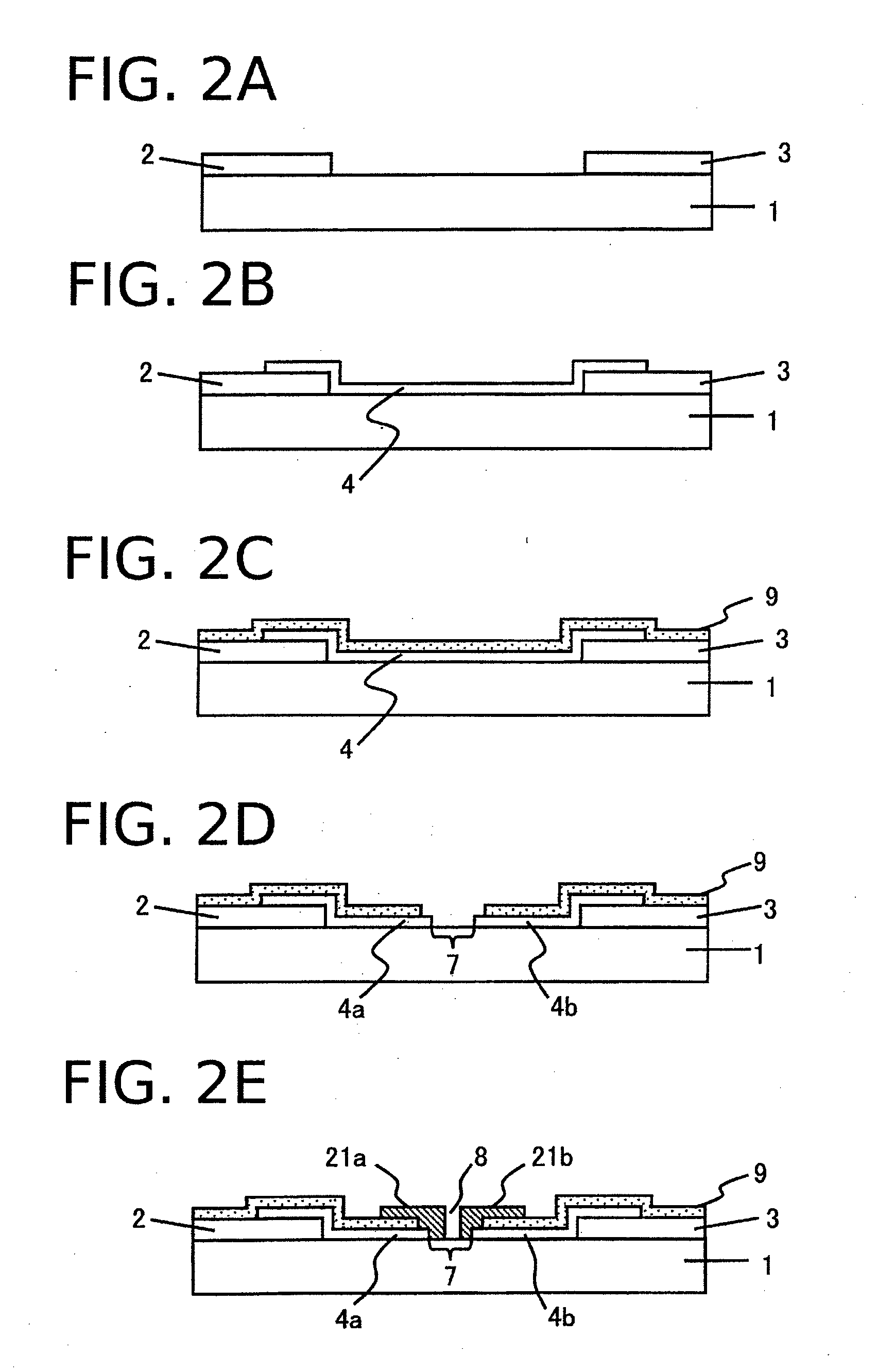

Semiconductor device fabricating method and system for carrying out the same

InactiveUS6399484B1Reduced form requirementsAvoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTungsten nitrideNitrogen

A semiconductor device fabricating method includes a preparatory process that brings a first source gas containing tungsten atoms into contact with a workpiece and that does not bring a second source gas containing nitrogen atoms into contact with the workpiece, and a film forming process that forms a tungsten nitride film on the workpiece by using the first and the second source gases so as to fabricate a semiconductor device. The semiconductor device fabricating method is capable of preventing the tungsten nitride film from peeling off from a layer underlying the same when the tungsten nitride film is subjected to heat treatment.

Owner:TOKYO ELECTRON LTD

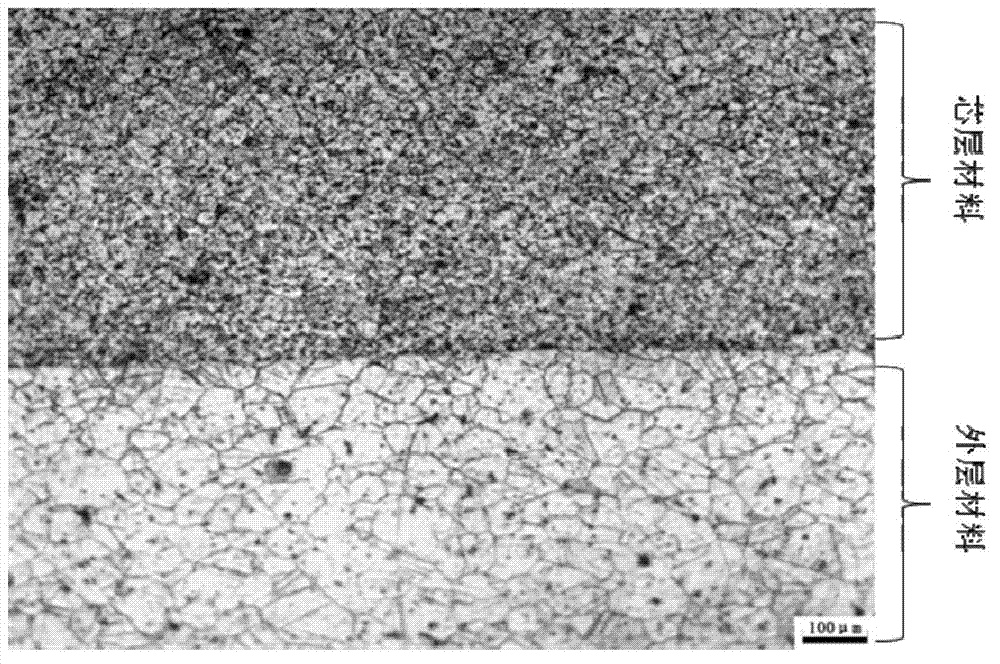

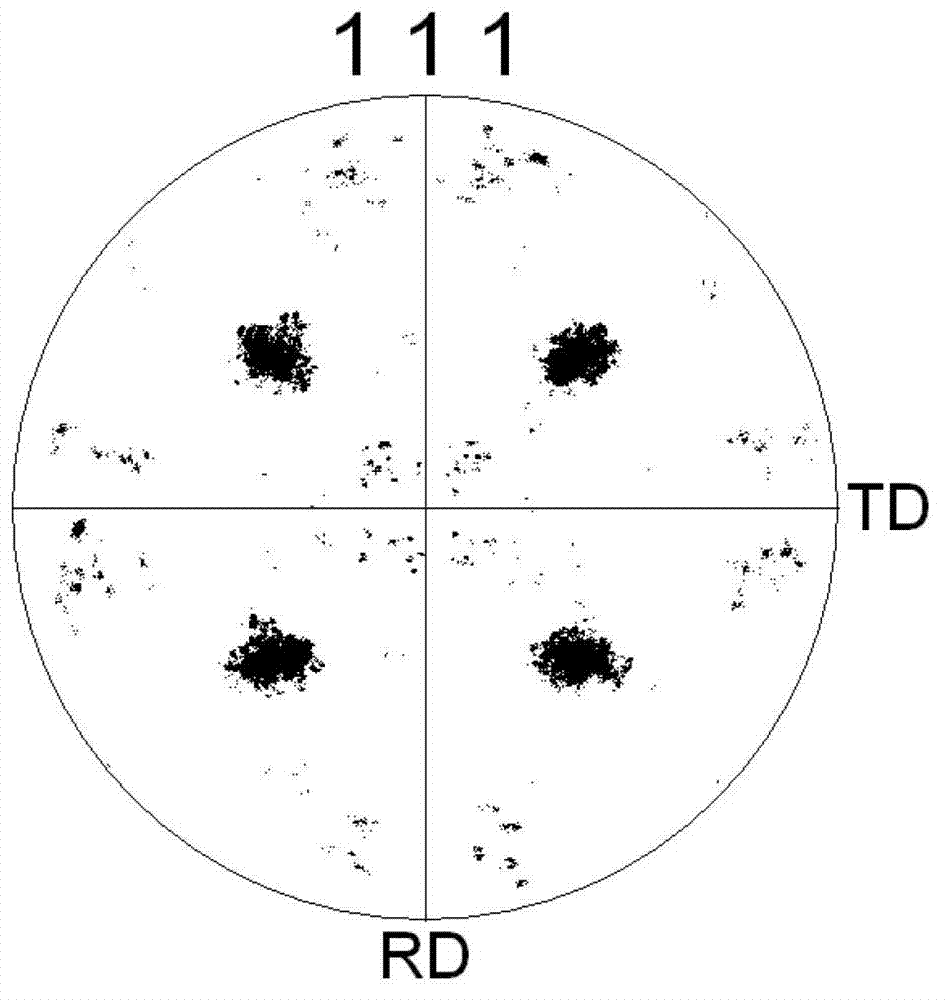

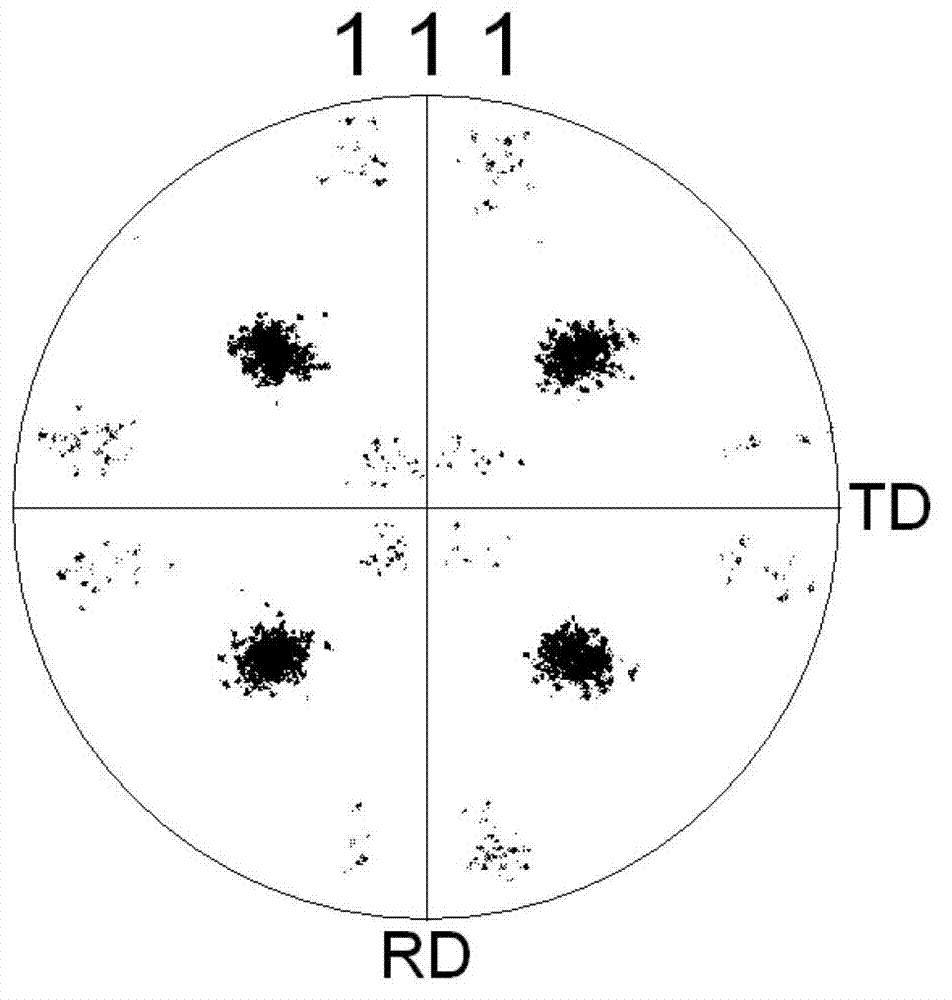

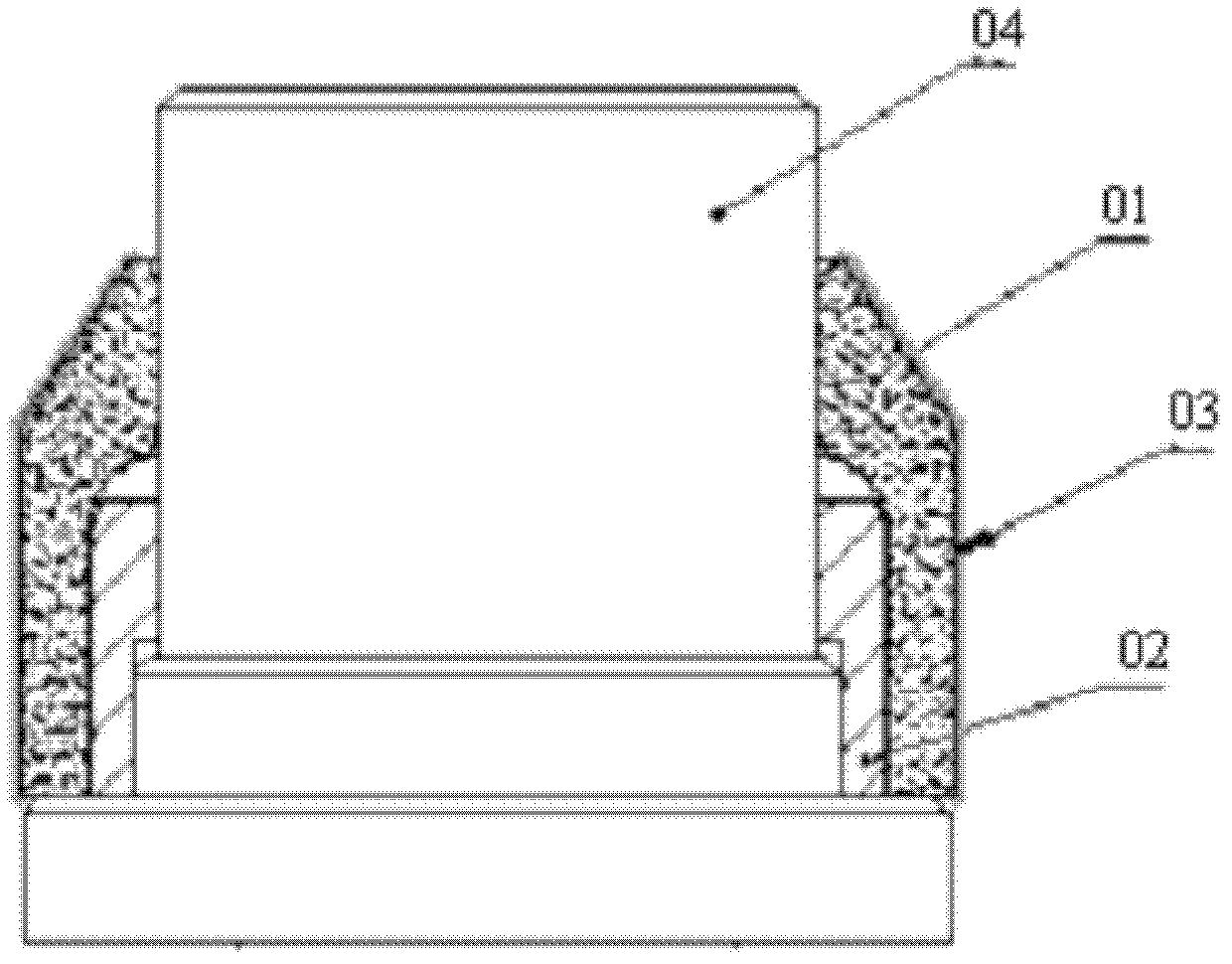

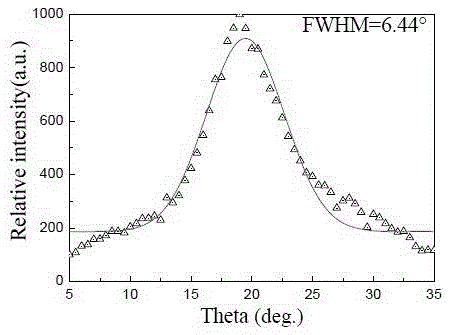

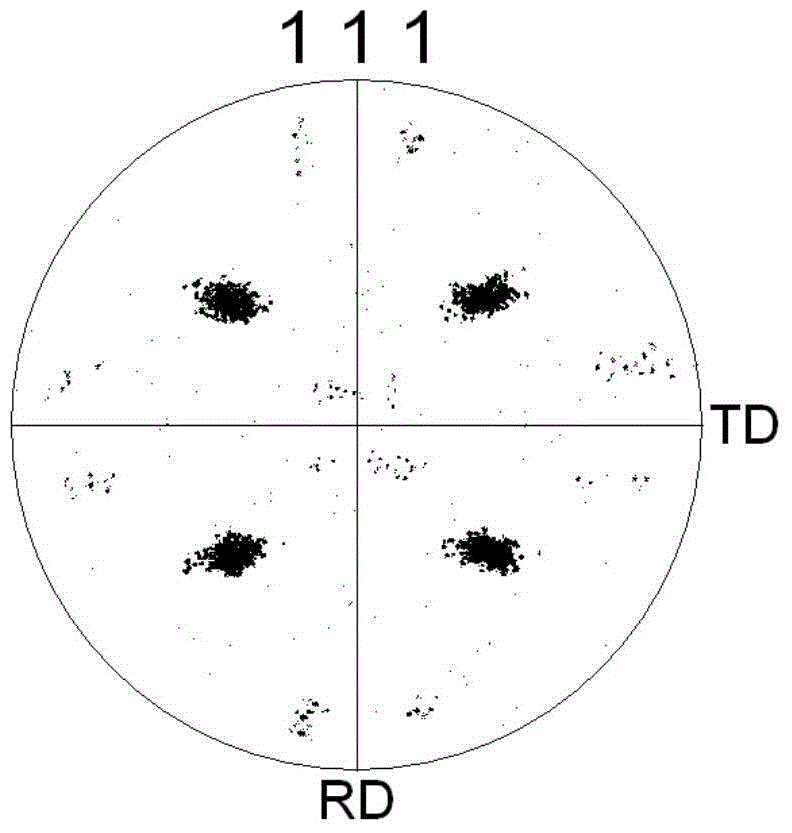

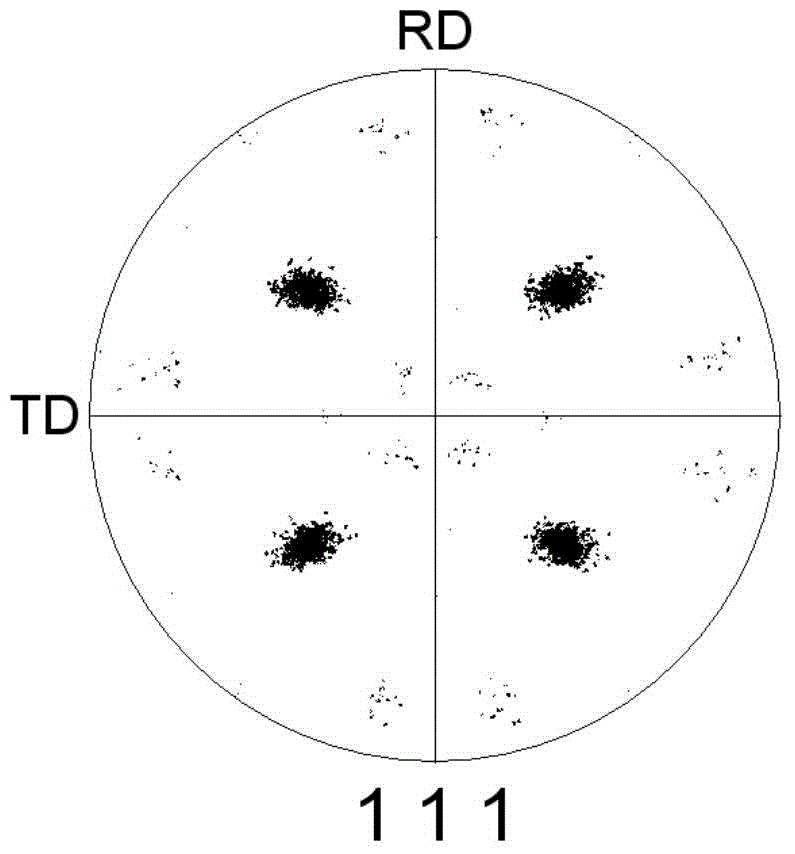

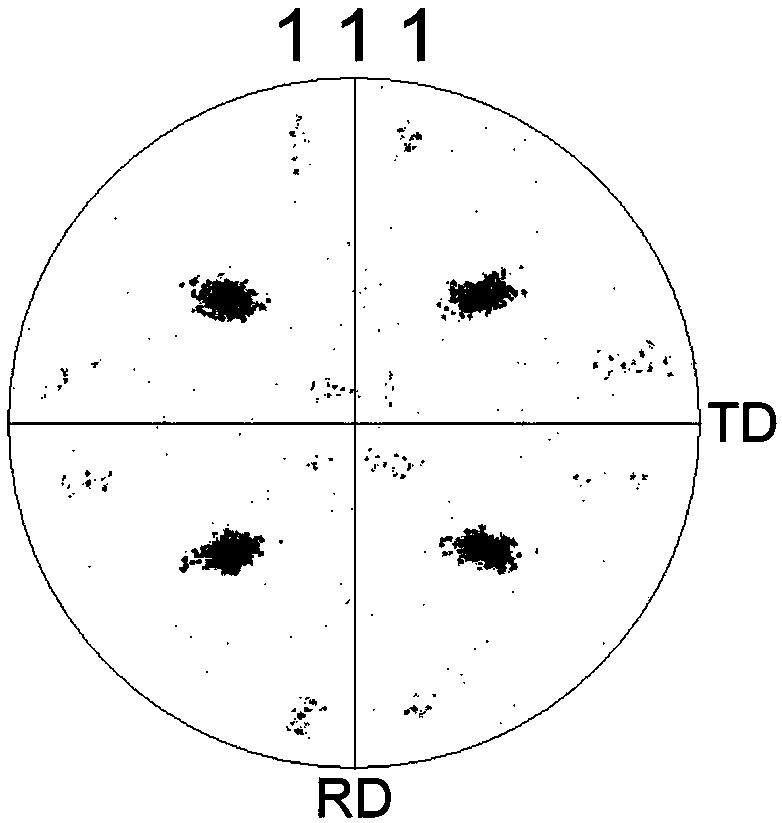

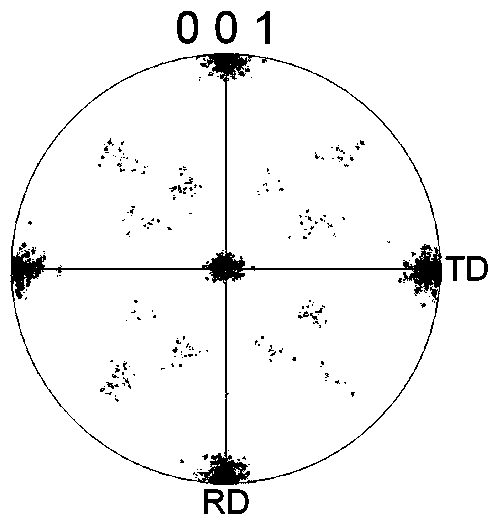

Low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and preparation method thereof

ActiveCN102756512AAchieve associativityImprove bindingMetal layered productsTungsten atomAlloy composite

The invention provides a low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and a preparation method thereof, belonging to the technical field of a high-temperature super-conductive coating conductor texture metal base band. According to the Ni-W alloy composite base band disclosed by the invention, a surface layer is a Ni-W alloy with high W content and the atom percentage content of the W is 7.5-9.3%; and a core layer is a nickel-tungsten alloy with the tungsten atom percentage content of 9.3-12%. The preparation method comprises the following steps of sequentially placing a high-W-content Ni-W alloy blank ingot (A) which is prepared by a smelting method and has the atom percentage content of the W of 7.5-9.3%, and Ni-W mixed powder (B) with the atom percentage content of the W of 9.3-12% into a mould according to the sequence of A-B-A; utilizing a discharge plasma sintering technology to sinter to obtain a composite blank ingot; then, carrying out hot rolling and carrying out cold rolling treatment on a hot rolling blank ingot; and then, crystallizing and annealing, carrying out cold rolling to obtain the composite base band, and re-crystallizing and annealing the base band under the protection of Ar / H2 mixed gas to obtain the Ni-W alloy composite base band. The composite base band has the advantages of high strength, low magnetism or no magnetism and strong cubic structure, and can further meet the requirement of further improving the performance of an YBCO (Yttrium Barium Copper Oxide) coating conductor.

Owner:深创超导(深圳)科技有限公司

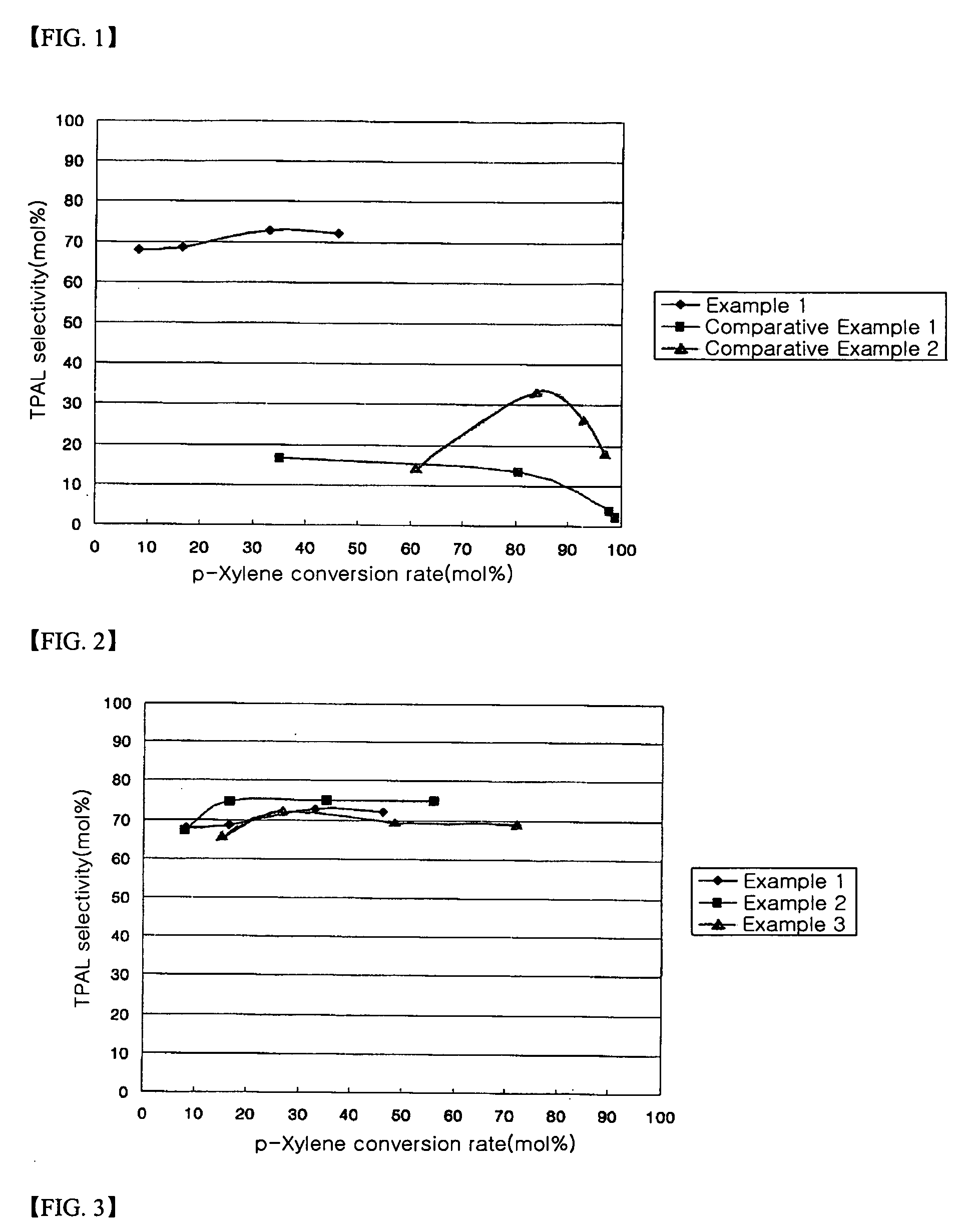

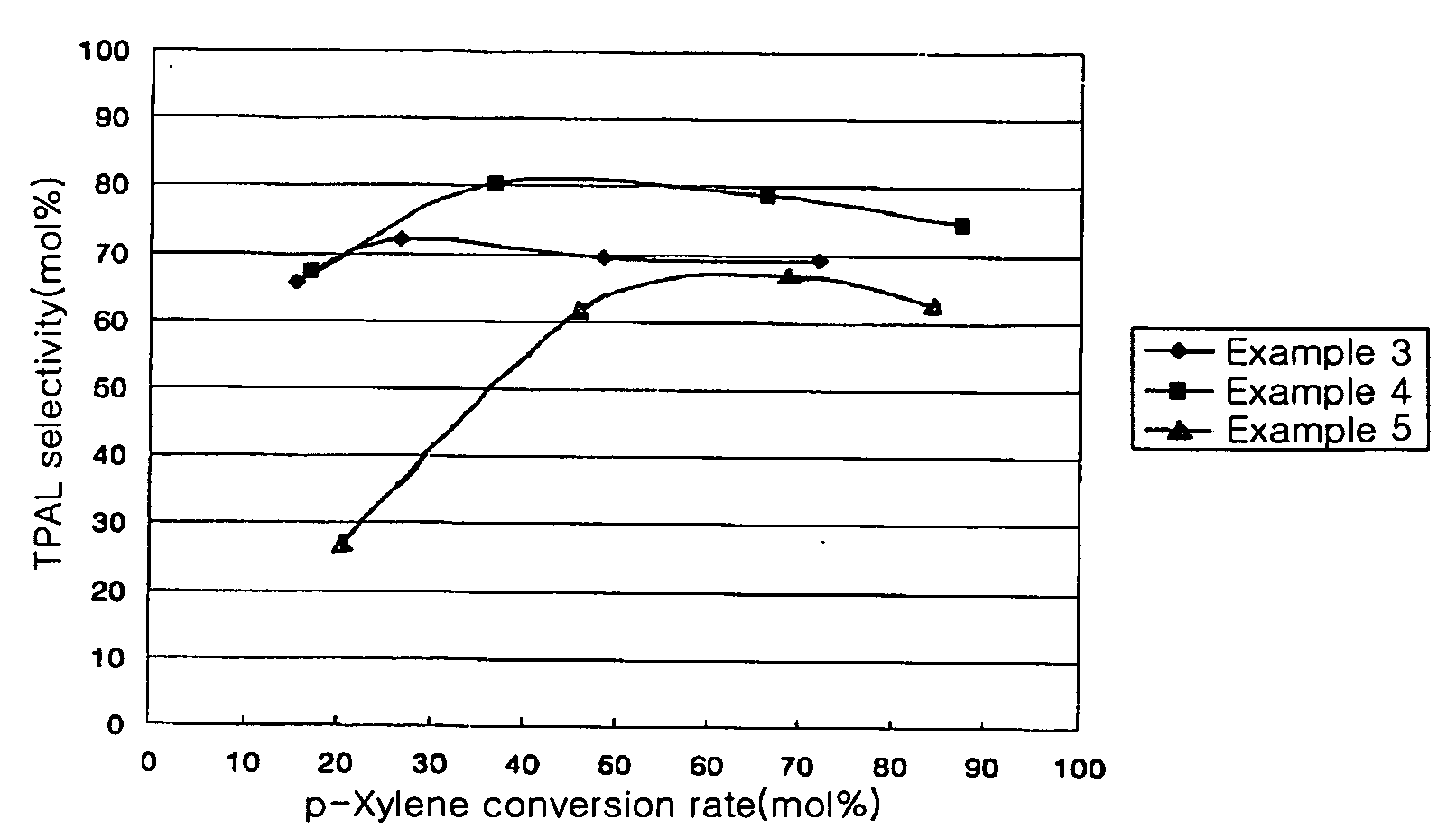

Catalyst for partial oxidation of methylbenzenes and method for producing aromatic aldehydes using the same

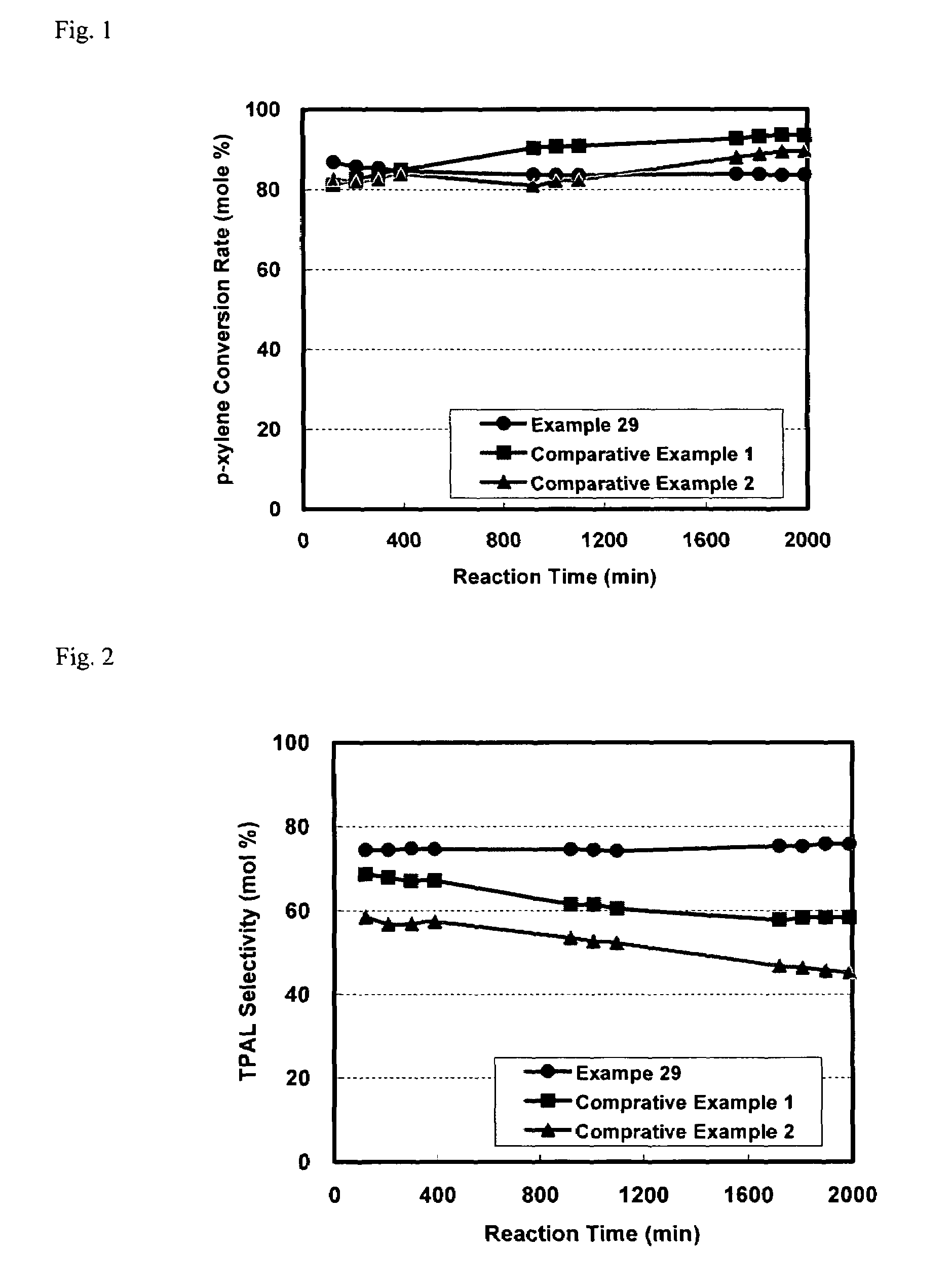

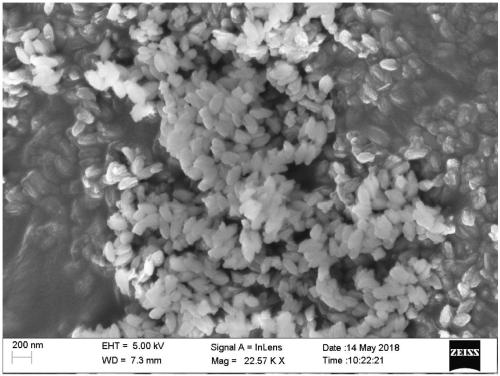

InactiveUS20060094906A1Good choiceHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPartial oxidationGas phase

Provided is a catalyst for partial oxidation of methylbenzenes comprising the compound represented by the following formula 1 and, optionally, a fire-resistant inorganic support: WOx (1) where W stands for a tungsten atom, O stands for an oxygen atom and x is a number determined by the oxidation state of W. Also provided is a method for producing aromatic aldehydes from partial oxidation of methylbenzenes in gas phase using molecular oxygen using the afore-mentioned catalyst. The catalyst of the present invention can be prepared easily compared with conventional multi-component oxide catalysts. And, aromatic aldehydes can be produced from methylbenzenes with high selectivity and yield.

Owner:LG CHEM LTD

Lacunary keggin type heteropolyanion based on tungsten for hydrocracking

ActiveUS20110230691A1Raise the ratioCatalytic crackingHydrocarbon by hydrogenationNickel saltTungsten atom

The invention describes a heteropolycompound constituted by a nickel salt of a lacunary Keggin type heteropolyanion comprising tungsten in its structure, with formula:Nix+y / 2AW11-yO39-5 / 2y,zH2Owherein Ni is nickel, A is selected from phosphorus, silicon and boron, W is tungsten, O is oxygen, y=0 or 2, x=3.5 if A is phosphorus, x=4 if A is silicon, x=4.5 if A is boron, and x=m / 2+2 for the rest, and z is a number in the range 0 to 36, in which said heteropolycompound has no nickel atom in substitution for a tungsten atom in its structure, said nickel atoms being placed in the counter-ion position in the structure of said compound.

Owner:INST FR DU PETROLE

Catalyst for partial oxidation of methylbenzenes, method for preparing the same, and method for producing aromatic aldehydes using the same

ActiveUS7429682B2High selectivityHomogenous compositionOrganic compound preparationOther chemical processesPartial oxidationGas phase

Owner:LG CHEM LTD

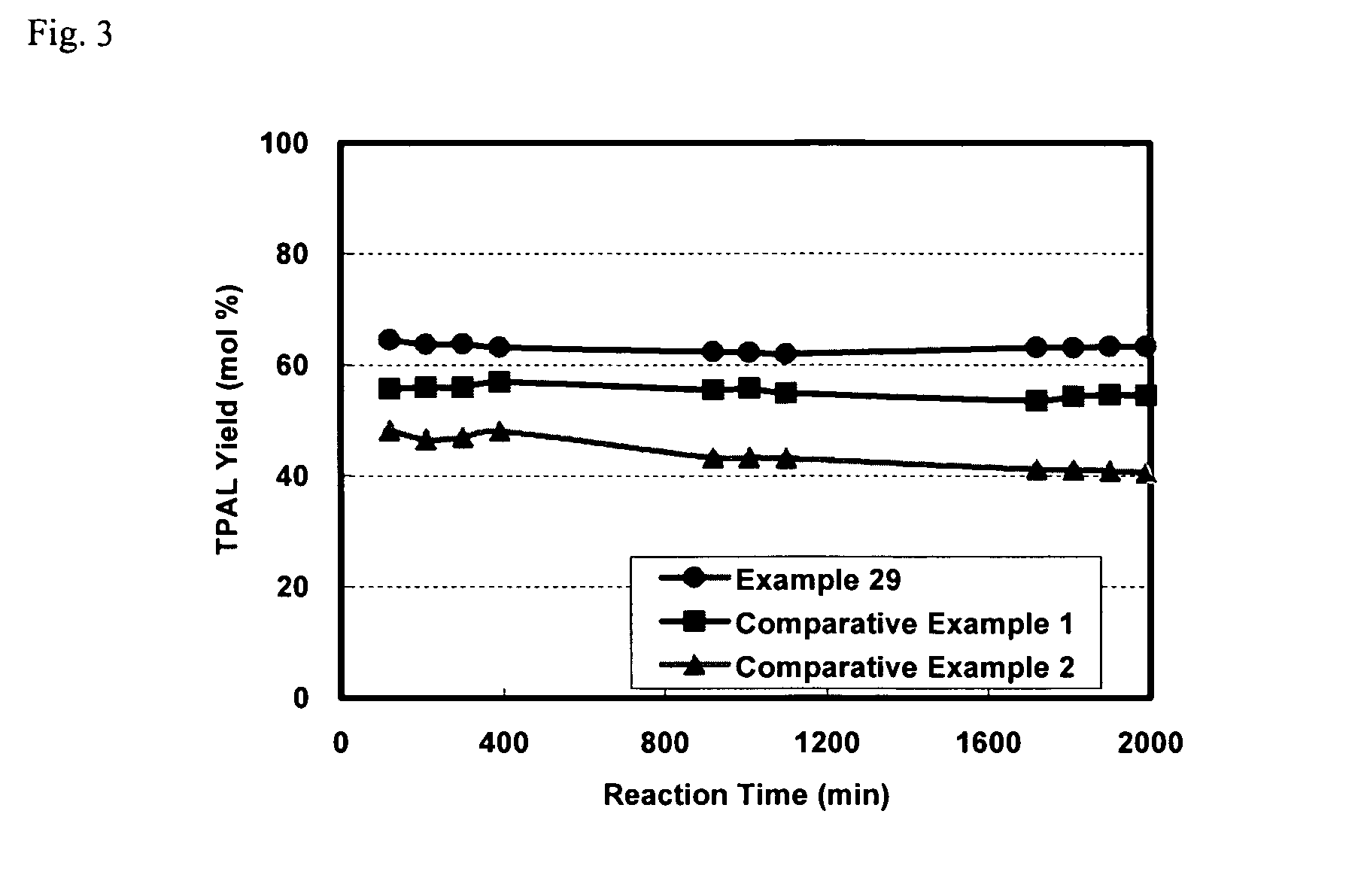

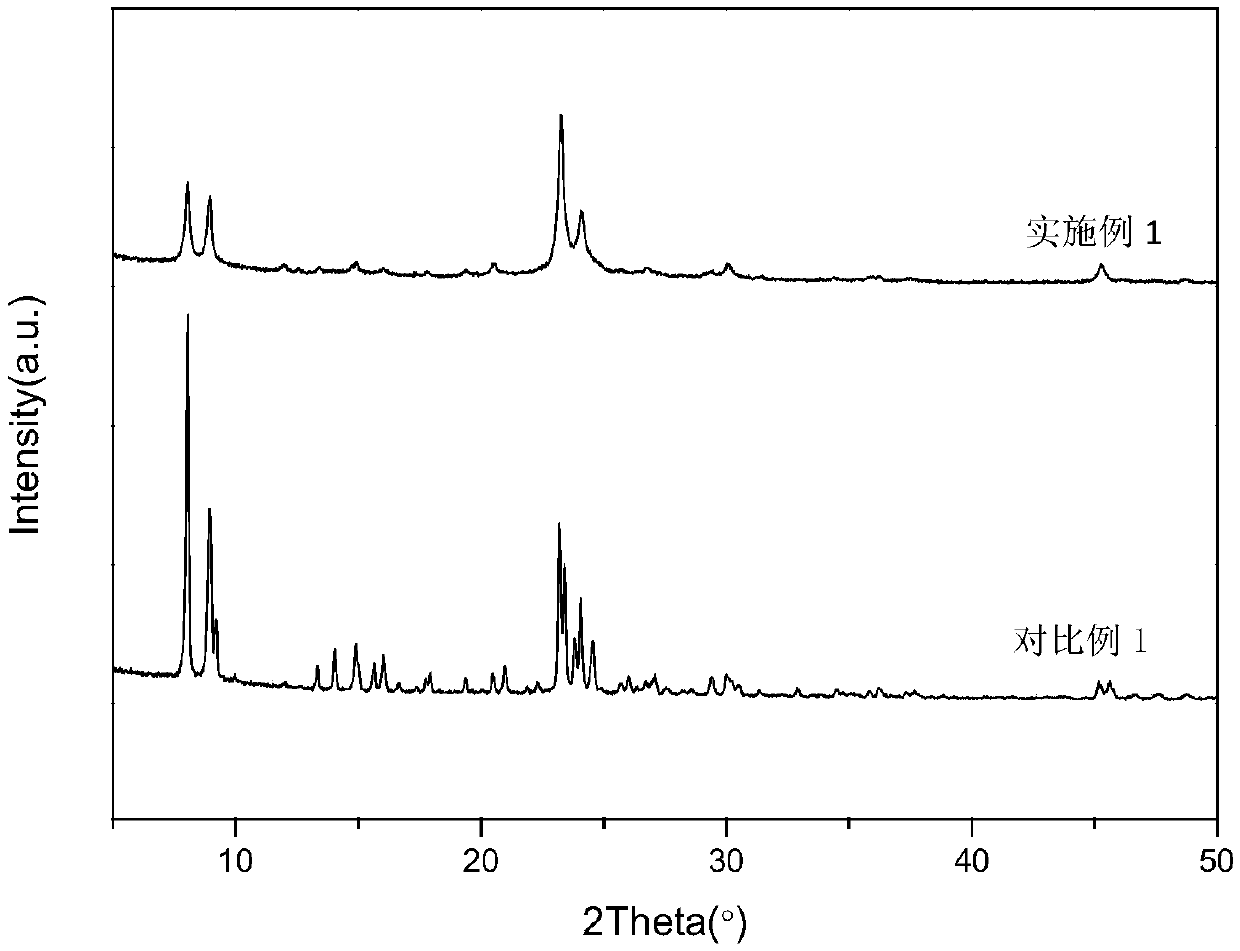

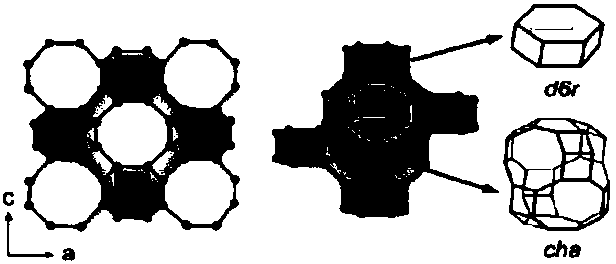

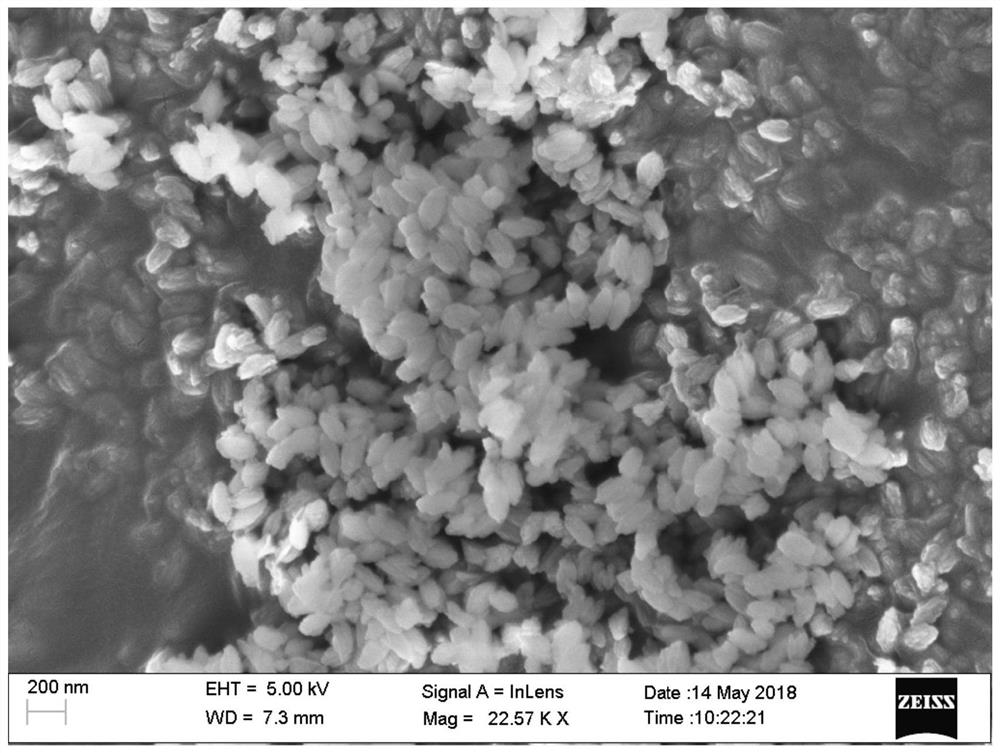

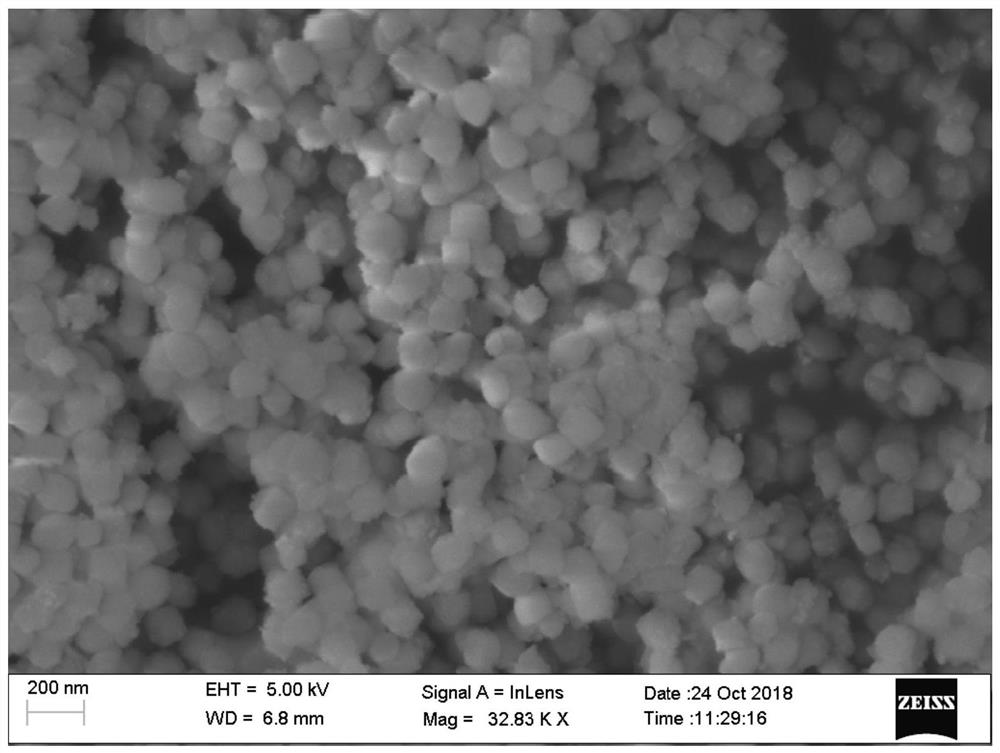

MFI type molecular sieve catalyst with framework tungsten atoms and preparation method and catalytic application thereof

ActiveCN109513458AShorten the diffusion pathAddress reactivityOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to an MFI type molecular sieve catalyst with framework tungsten atomsand a preparation method and a catalytic application thereof. The preparation method comprises the followingsteps: dropwise adding a silicon source into a structural guiding agent aqueous solution to form a clear solution A; and dropwise adding a tungsten source aqueous solution or a tungsten source into the solution A and carrying out hydrothermal crystallization at 110-150 DEG C for 48-120 h to obtain the MFI type molecular sieve catalyst with framework atomic atoms. The amygdaloidal MFI type molecular sieve nanoparticles containing framework tungsten atomsare prepared by means of a hydrothermal synthetic method in one step and the preparation process is simple and the condition is mild. The MFI type molecular sieve catalyst has relatively small particle size, so that the material diffusing path is shortened, mass transfer is facilitated, and problems that reactants and product molecules are not favorably diffused in the ducts as a result of the relatively long diffusing path of the conventional MFI type molecular sieve are solved. By introducing the framework atomic atoms, the molecular sieve has a catalytic oxidizing action to tungsten, and can be applied to catalyzing epoxidation reaction of cycloolefin.

Owner:NORTHWEST UNIV(CN)

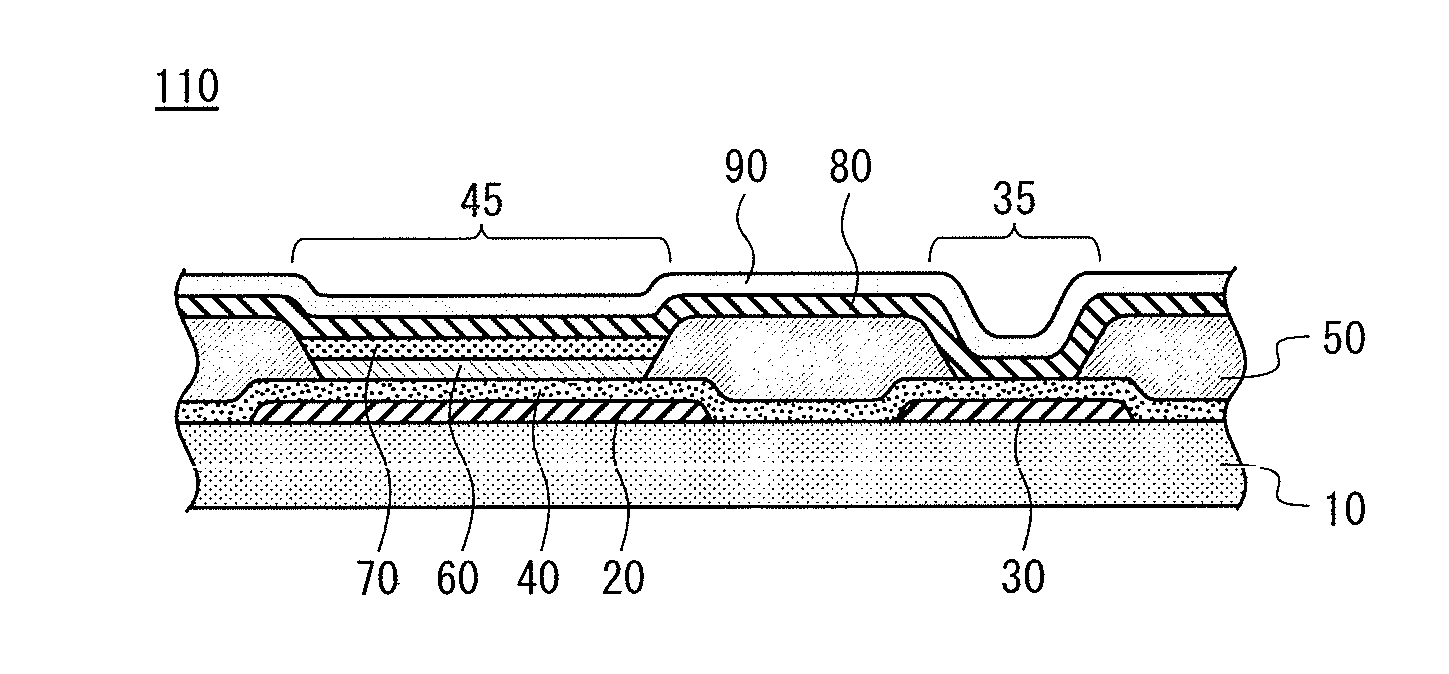

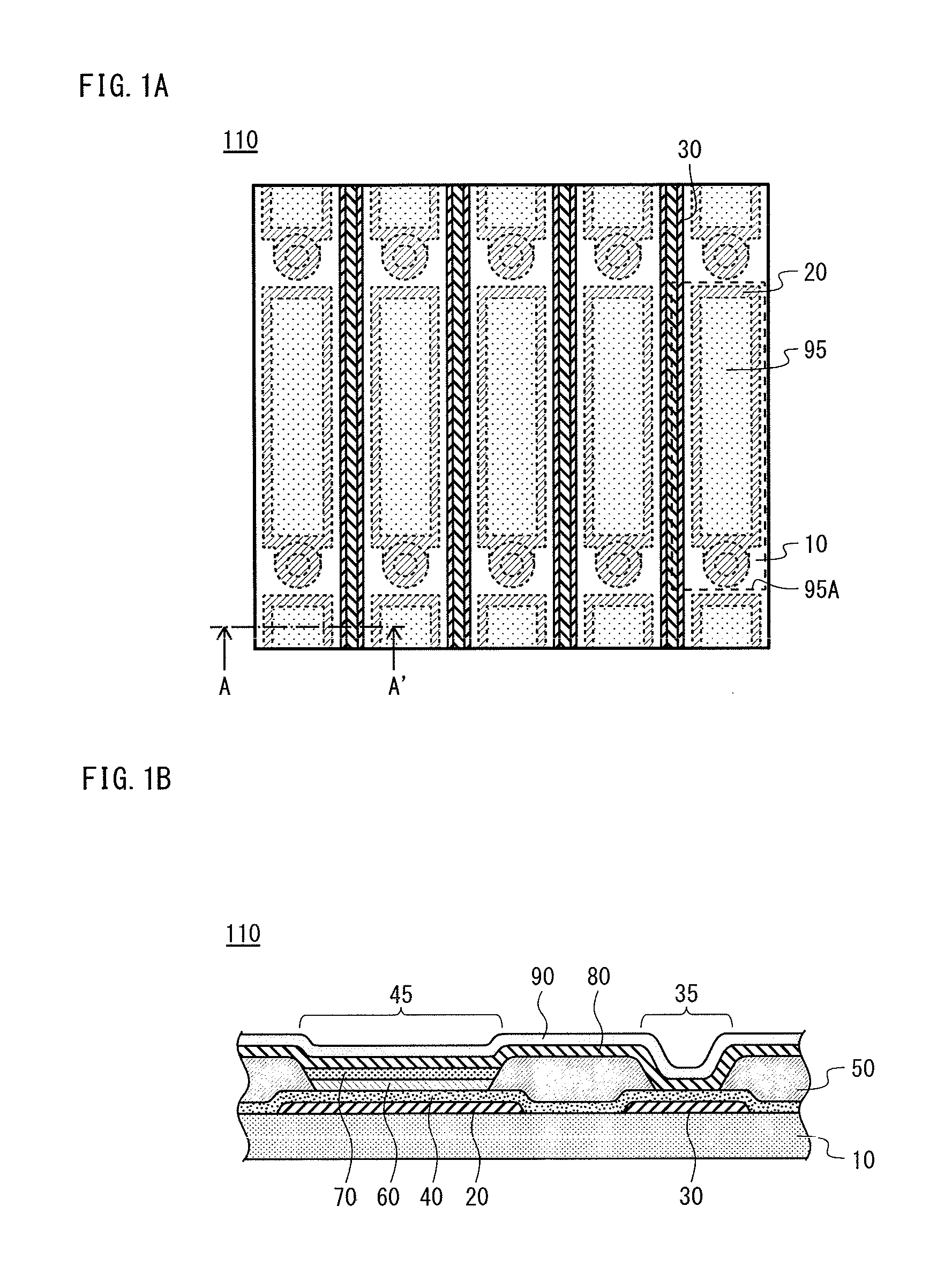

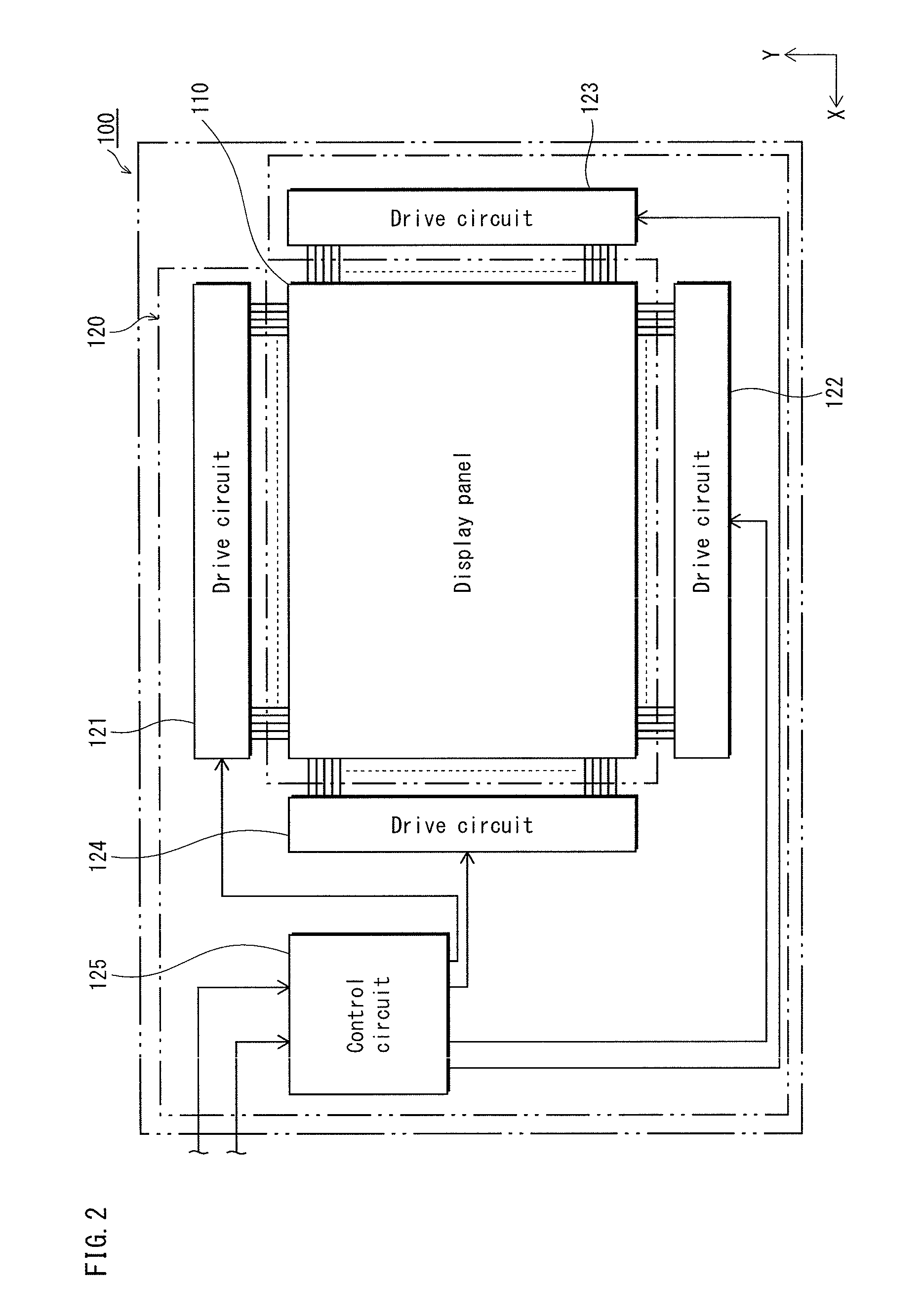

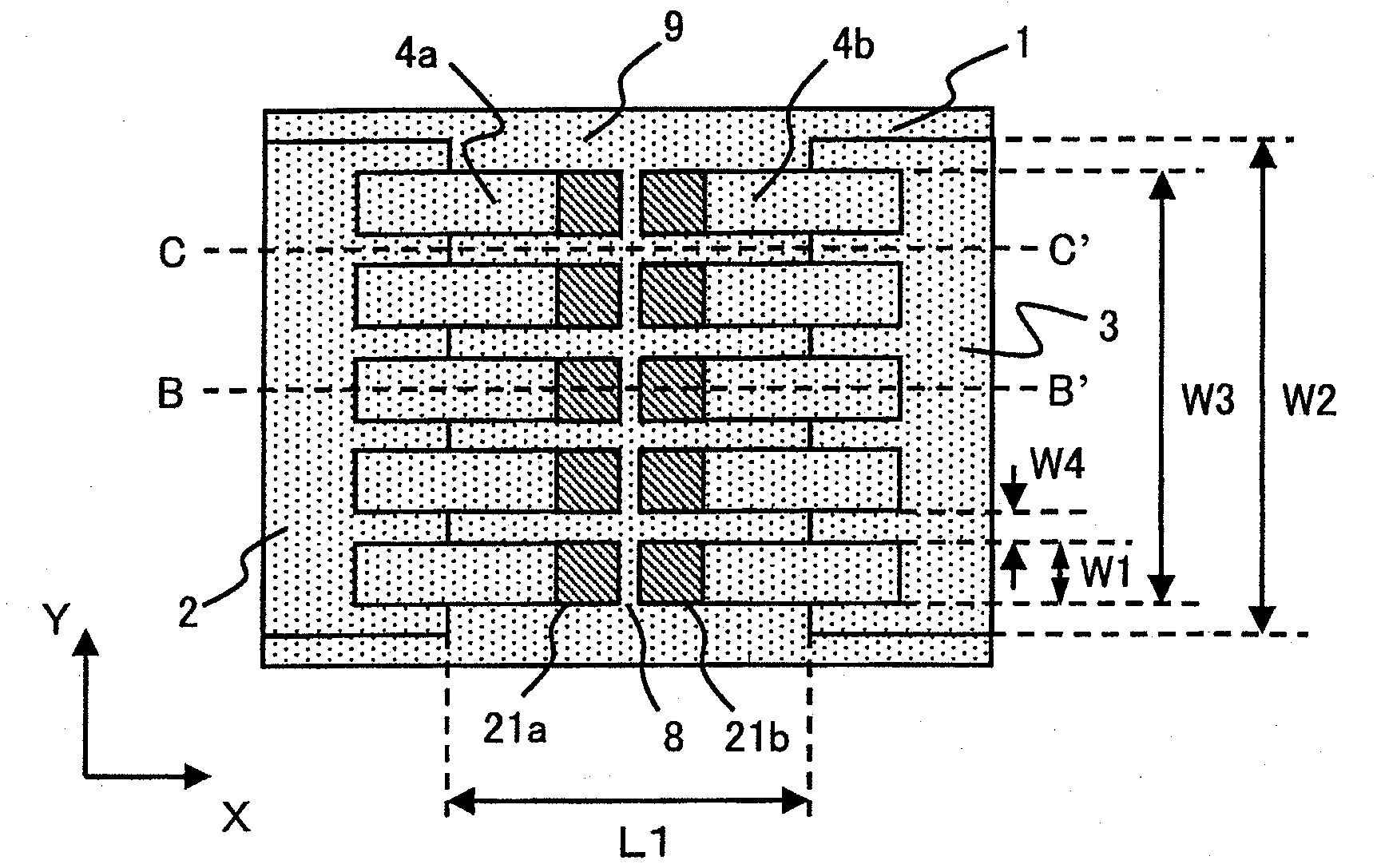

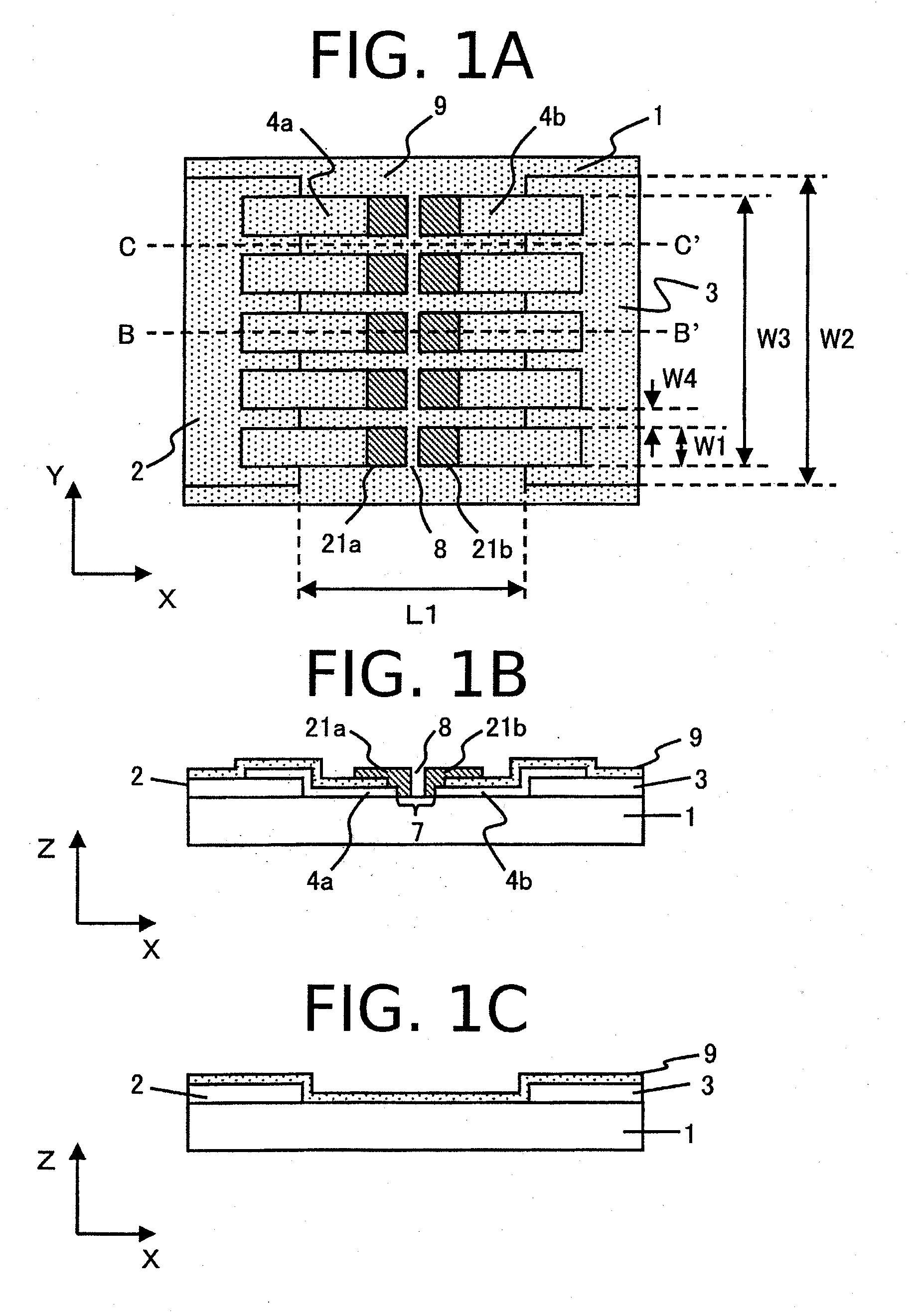

Organic electroluminescence display panel with tungsten oxide containing hole injection layer that electrically connects electrode to auxiliary wiring, and organic electroluminescence display device

ActiveUS8981361B2Improve efficiencyReduce hole injectionSolid-state devicesSemiconductor/solid-state device manufacturingTungsten atomDisplay device

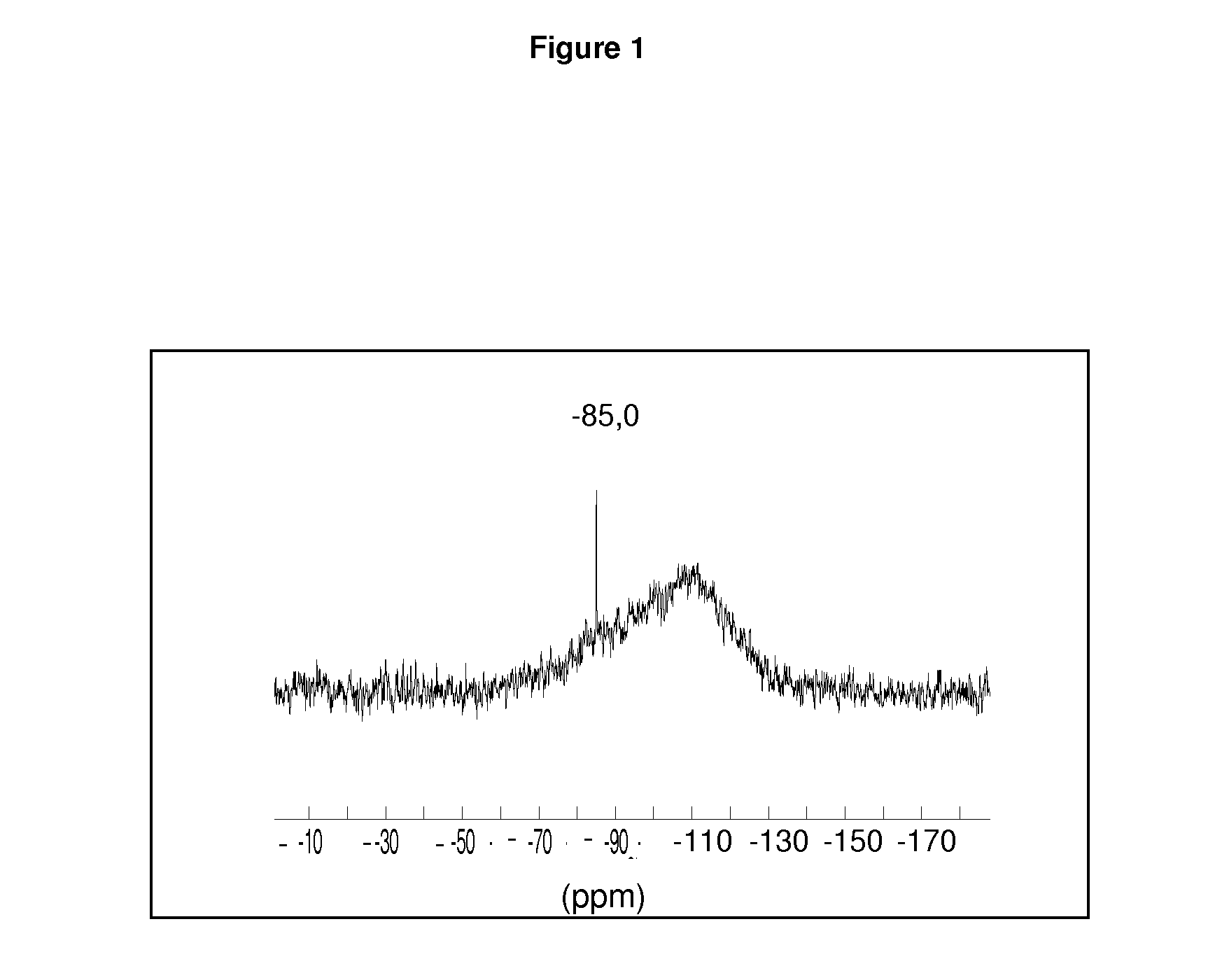

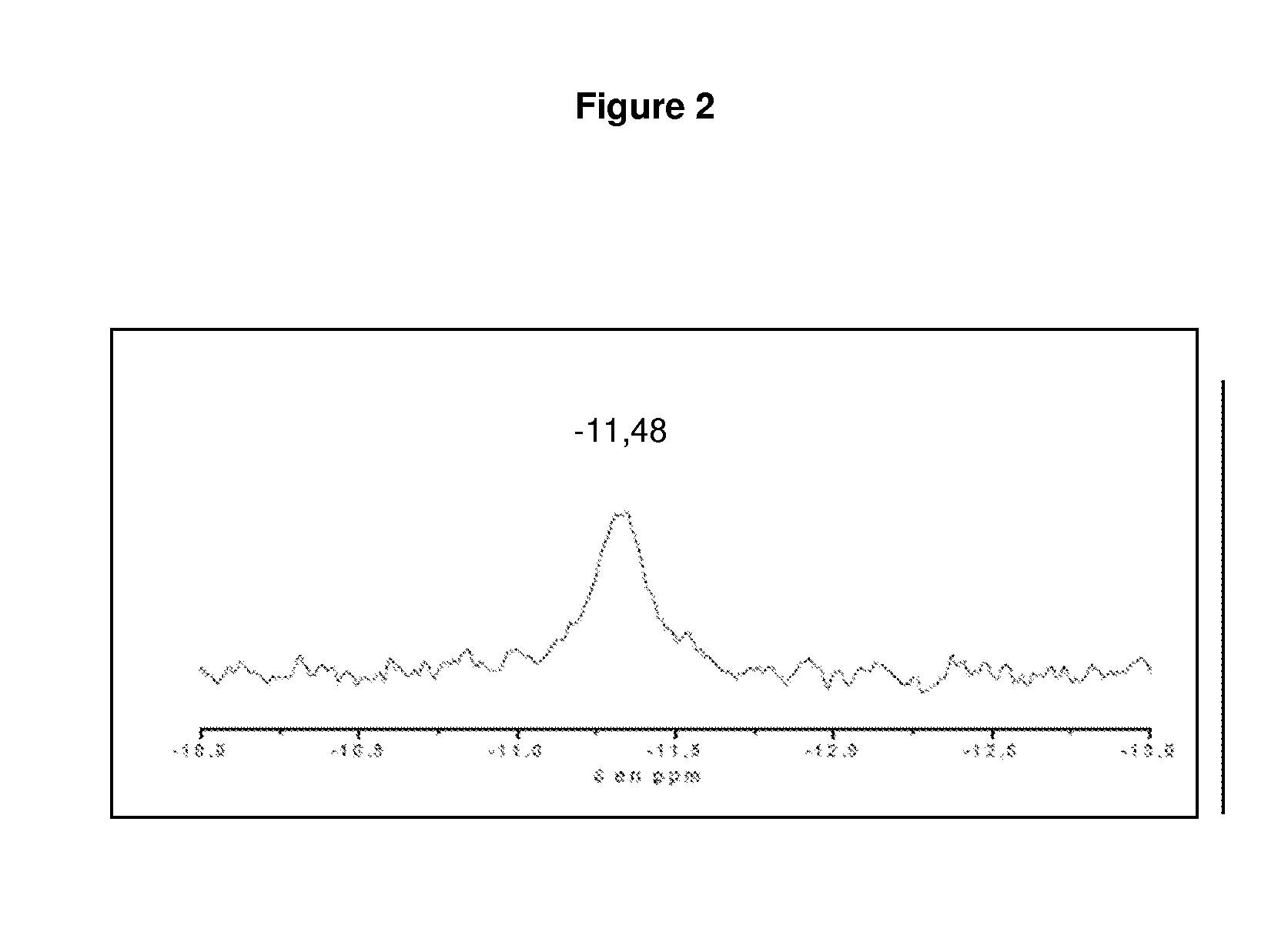

A hole injection layer and a second electrode are both formed to be continuous above a first electrode and above an auxiliary wiring. The hole injection layer contains a tungsten oxide. An UPS spectrum, obtained from a UPS measurement, has a protrusion appearing near a Fermi surface and within a region corresponding to a binding energy range lower than a top of a valence band, and the tungsten oxide satisfies a condition, determined from an XPS measurement, that a ratio in a number density of atoms other than tungsten atoms and oxygen atoms to the tungsten atoms does not exceed 0.83.

Owner:JOLED INC

Boriding method of wear-resisting composite member

InactiveCN102634752AAffects connection strengthThere will be no phenomenon of melting and welding falling offSolid state diffusion coatingTungsten atomBoriding

The invention provides a boriding method of a wear-resisting composite member. The boriding method comprises the following steps: a) preheating the wear-resisting composite member by adopting a hot spray gun so as to rise the temperature of the surface of the wear-resisting composite member to be 800 DEG C-850 DEG C; b) spraying a boriding agent to the surface of the wear-resisting composite member obtained from the step a to obtain the wear-resisting composite member with the boronized surface. When the wear-resisting composite member is subjected to boriding, the wear-resisting composite member is preheated by using the hot spray gun, so that the temperature of the surface of a workpiece is high, the internal temperature of the workpiece is lower than the surface temperature of the workpiece, the brazing connection position of the composite member can not be affected, the connection strength of the composite member can not be affected, after the wear-resisting composite member is preheated, the boriding agent is sprayed to the surface of the composite member, the boriding agent is subjected to reaction under high temperature so as to generate active boron atoms, the active boron atoms combine with cobalt atoms and tungsten atoms melt in the surface, so as to form a compound, so that a boriding layer of a boron compound is formed.

Owner:SEED TECH CORP LTD

Bleaching activator and detergent composition comprising the same

InactiveUS20090022645A1Improve bleaching effectPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetalloleTungsten atom

To provide a bleaching activator capable of improving bleaching performance of a peroxy compound and the like, and a detergent composition comprising such a compound. A bleaching activator comprising Keggin heteropolyoxometalate anions, wherein the Keggin heteropolyoxometalate anions comprise a Keggin heteropolyoxometalate anion represented by the following formula (1):[XMa(H2O)bOc]d− (1)(in the formula, X representing a silicon atom or a phosphorus atom; M being the same or different and representing a tungsten atom or a molybdenum atom; a representing an integer of 9 to 11; b representing a positive number of 0 to 6; c representing a positive number of 28 to 39; d representing a valency and being a positive number).

Owner:NIPPON SHOKUBAI CO LTD

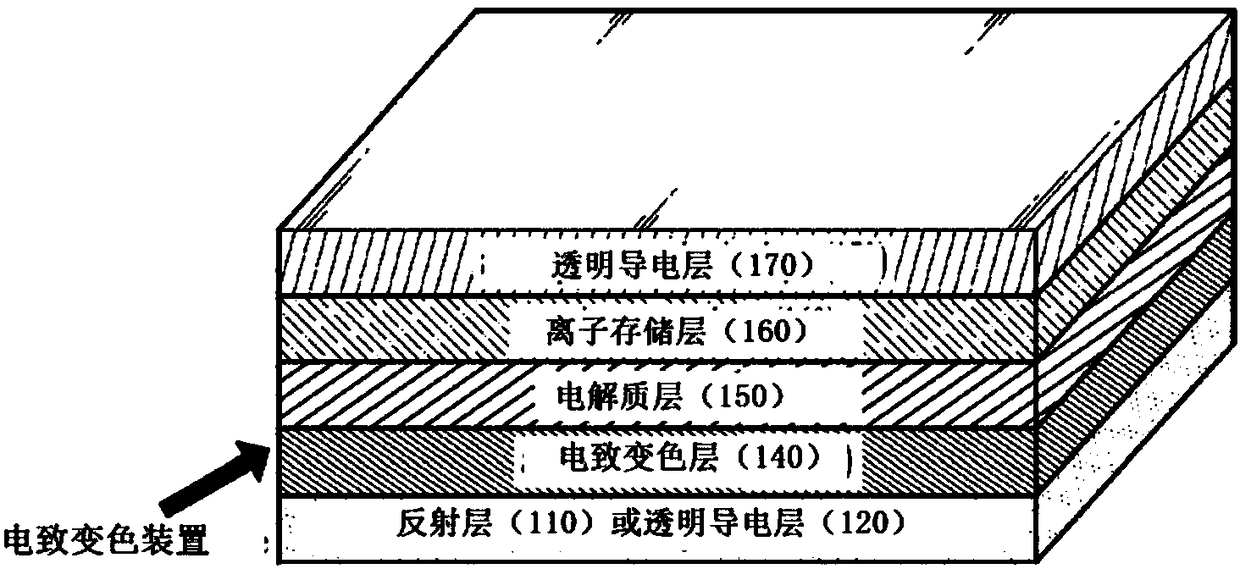

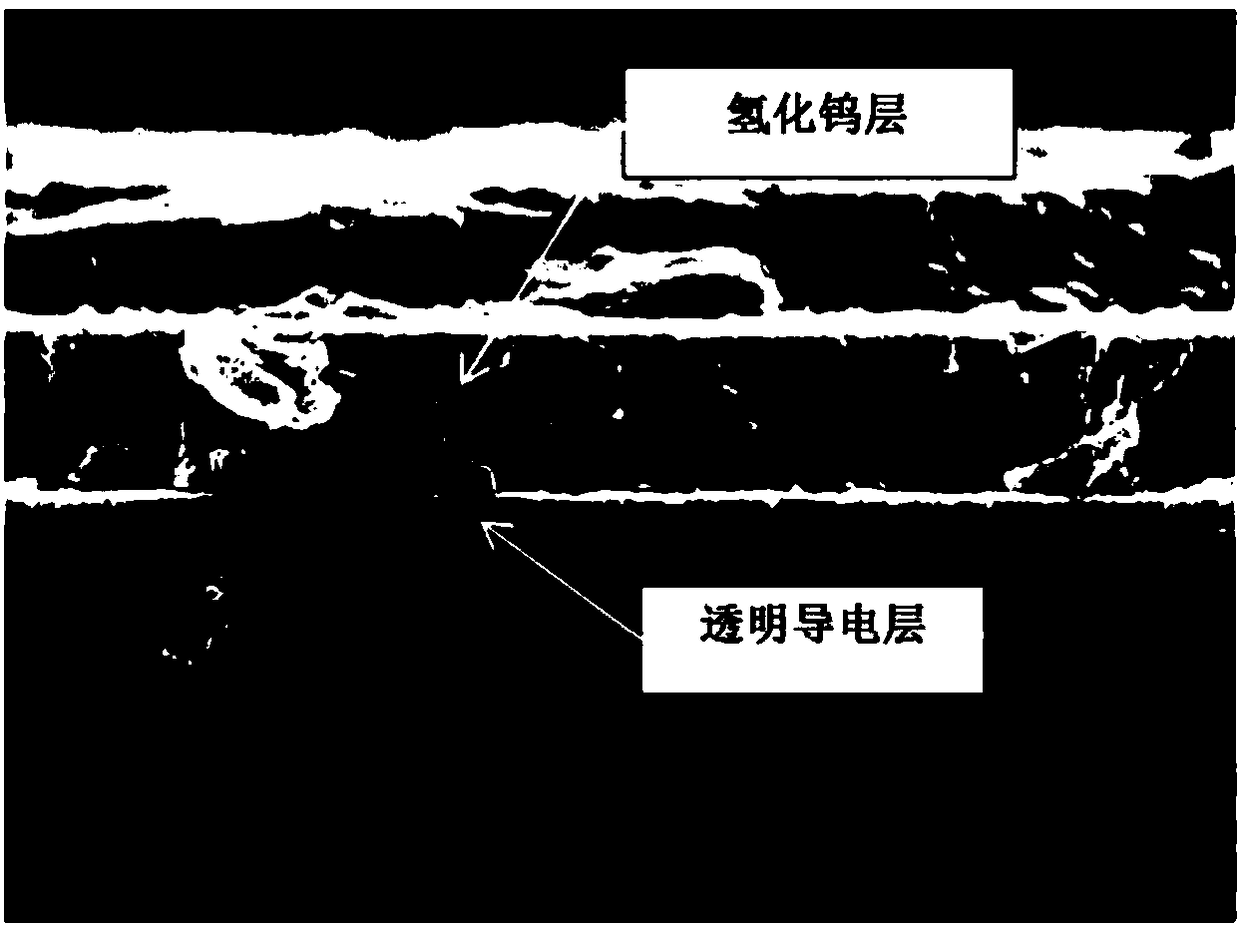

Electrochromic device

ActiveCN108474990ASolve problems such as short circuitsConductive materialVacuum evaporation coatingTungsten atomEngineering

An electrochromic device according to an embodiment is an electrochromic device comprising a transparent conductive layer, an ion storage layer, an electrolyte layer, an electrochromic layer, and a reflective layer or transparent conductive layer, wherein the ion storage layer includes an iridium atom and a tantalum atom, the electrolyte layer includes a tantalum atom, the electrochromic layer includes a tungsten atom, and at least one of the iridium atom and the tantalum atom of the ion storage layer and the tungsten atom of the electrochromic layer is hydrogenated, and the reflective layer is non-porous.

Owner:LEAPHIGH INC

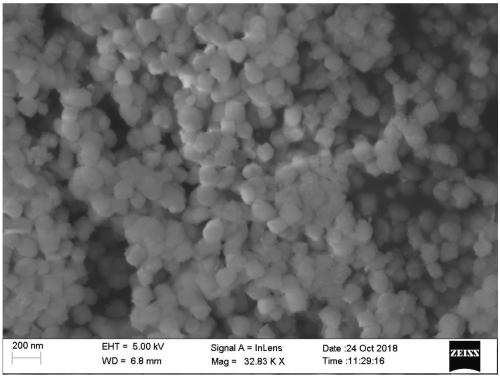

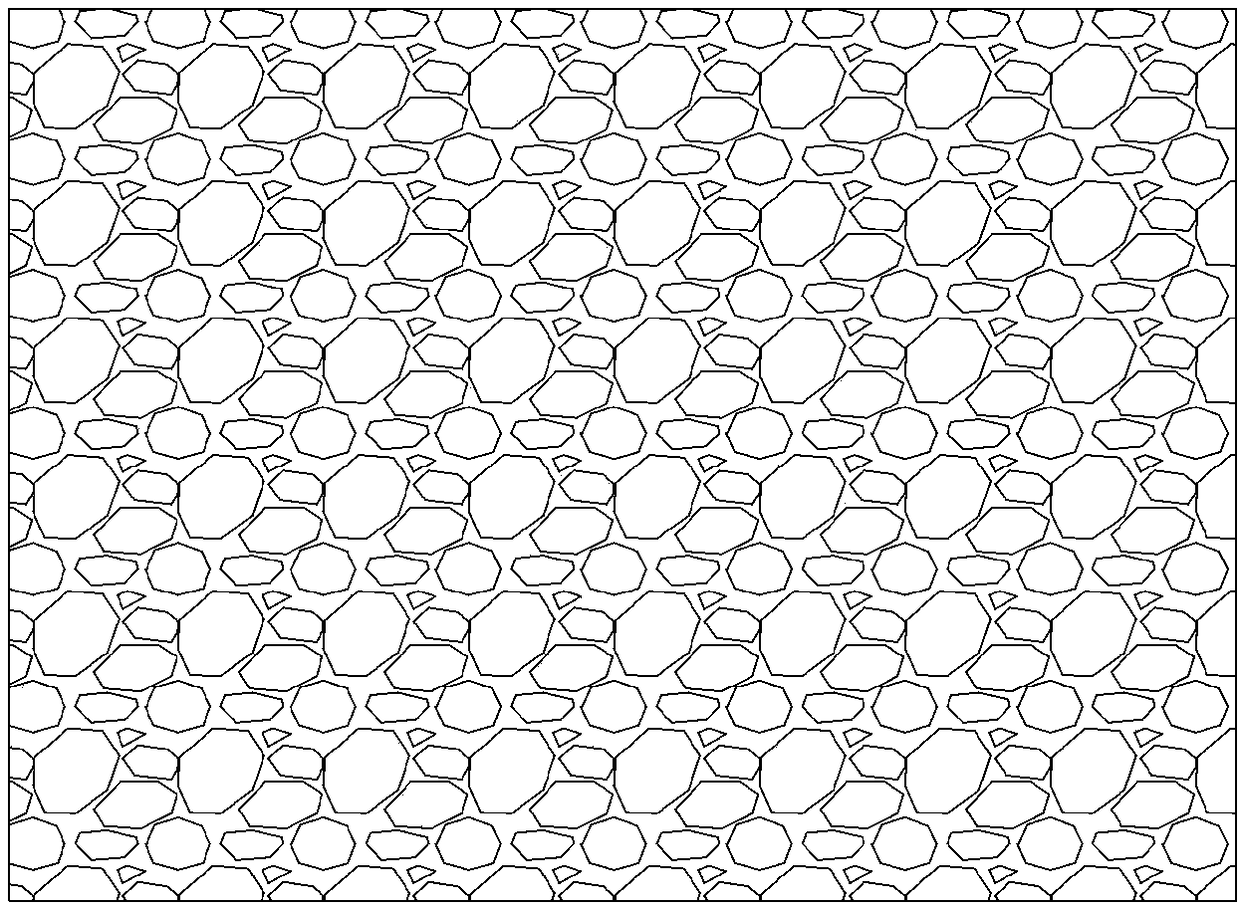

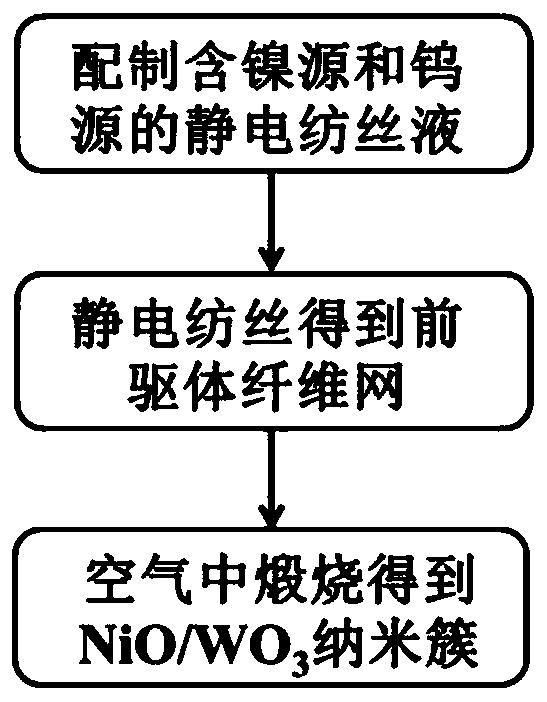

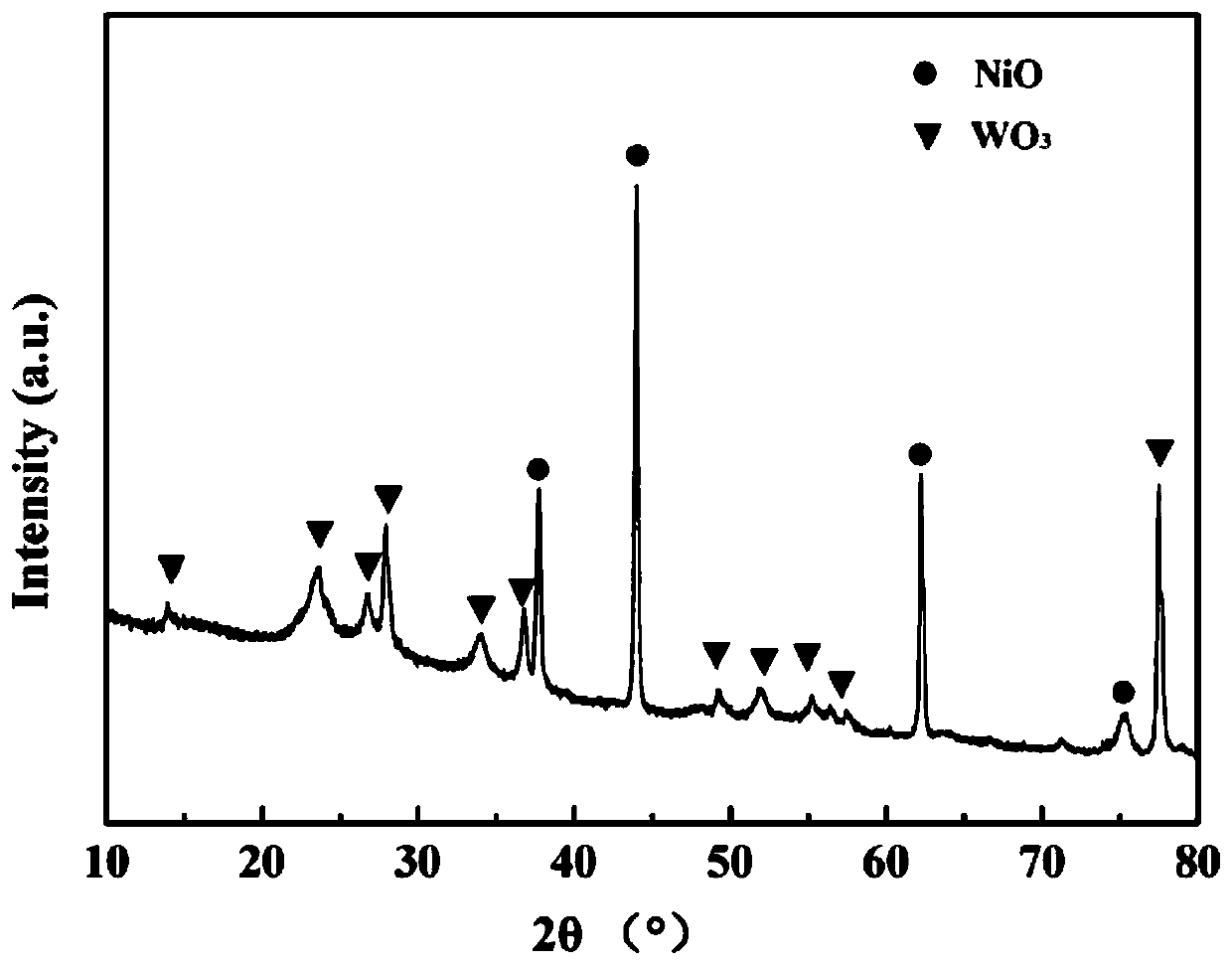

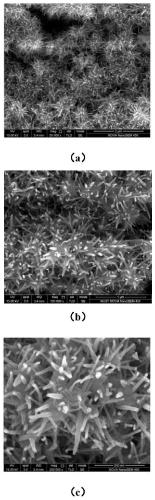

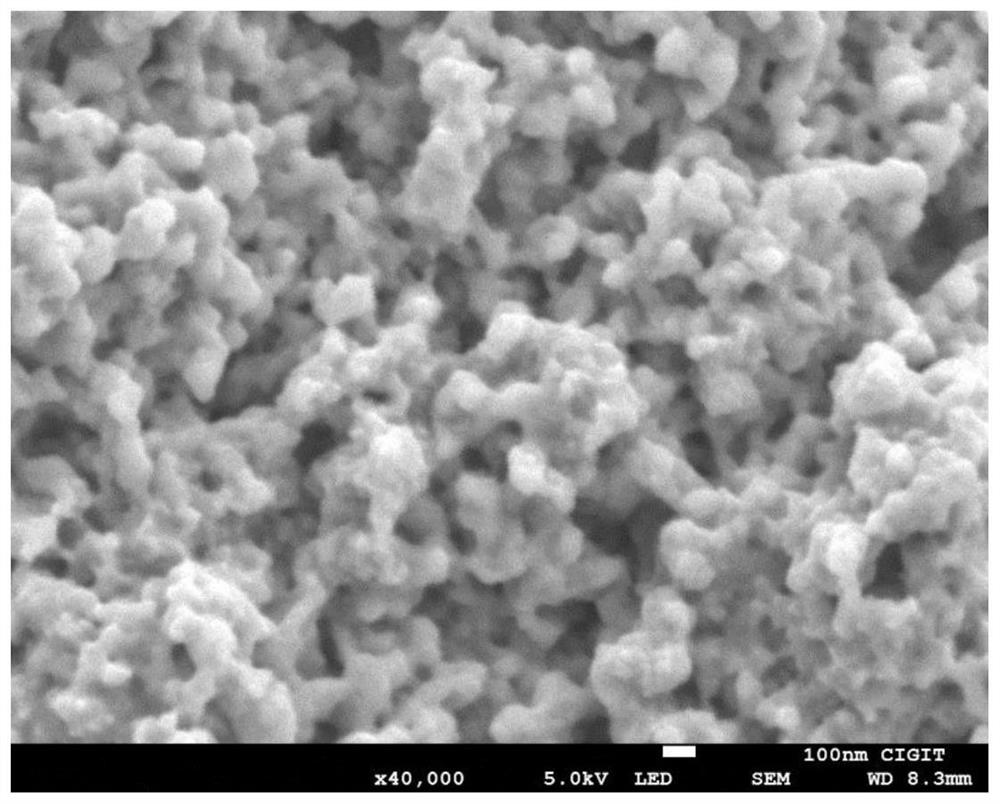

NiO/WO3 photocatalyst with hierarchical nanostructure, and preparation method and application thereof

PendingCN111111681ASelf-supportingEasy to recycleWater/sewage treatment by irradiationWater treatment compoundsNickel saltPtru catalyst

The invention relates to a NiO / WO3 photocatalyst with a hierarchical nanostructure, and a preparation method and an application thereof. The preparation method comprises the following steps: dissolving a nickel salt and a tungsten salt in a mixed solvent of water and an organic solvent, then adding a polymer binder, and uniformly mixing to obtain a spinning solution; carrying out electrostatic spinning on the spinning solution to obtain a precursor fiber net; calcining the precursor fiber net to obtain the NiO / WO3 photocatalyst with the hierarchical nanostructure, wherein in terms of the molarweight of nickel atoms and tungsten atoms, the molar ratio of the nickel salt to the tungsten salt is (0.2-1.5): 1; and the calcining condition is that the temperature is kept at 400-900 DEG C for 1h or more. NiO is added as a cocatalyst, and the NiO / WO3 photocatalyst with the hierarchical nanostructure is prepared by adopting electrostatic spinning and calcining processes, so that the photocatalytic efficiency of the catalyst is remarkably improved, the microstructure of the catalyst is improved, and the catalyst is of a self-supported moss cluster nanostructure and is convenient to recycle.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

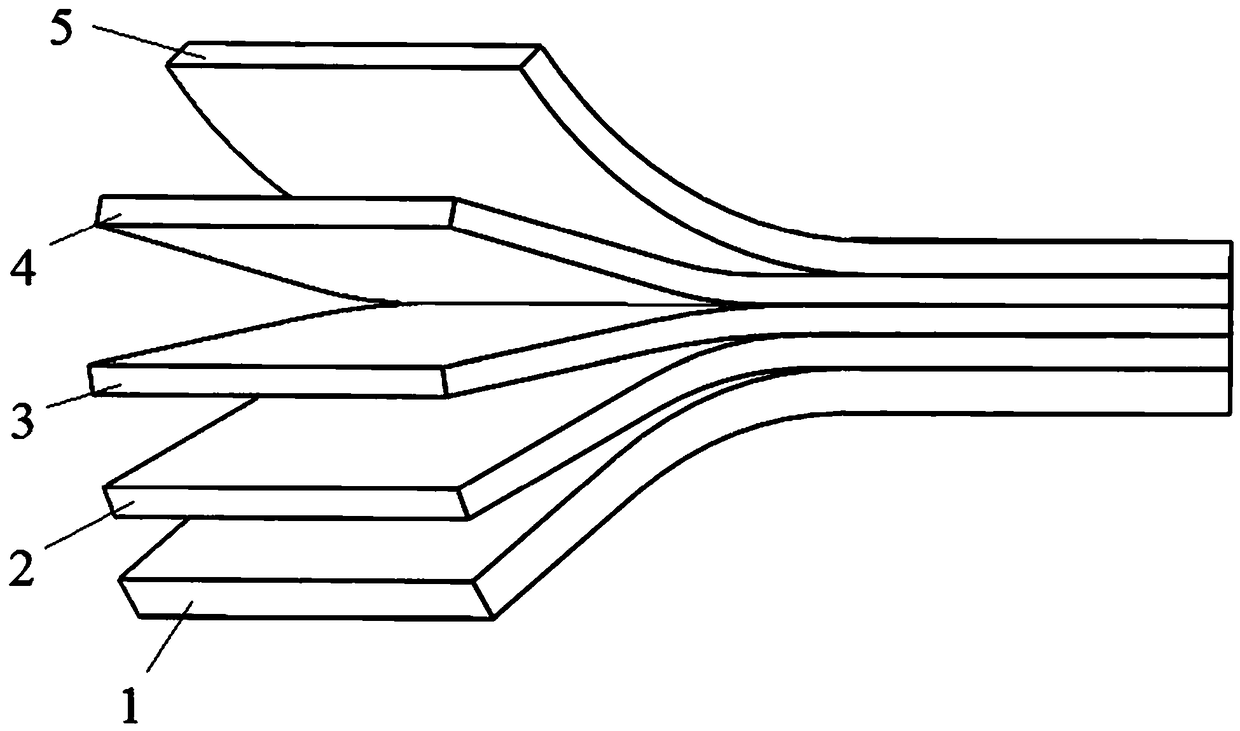

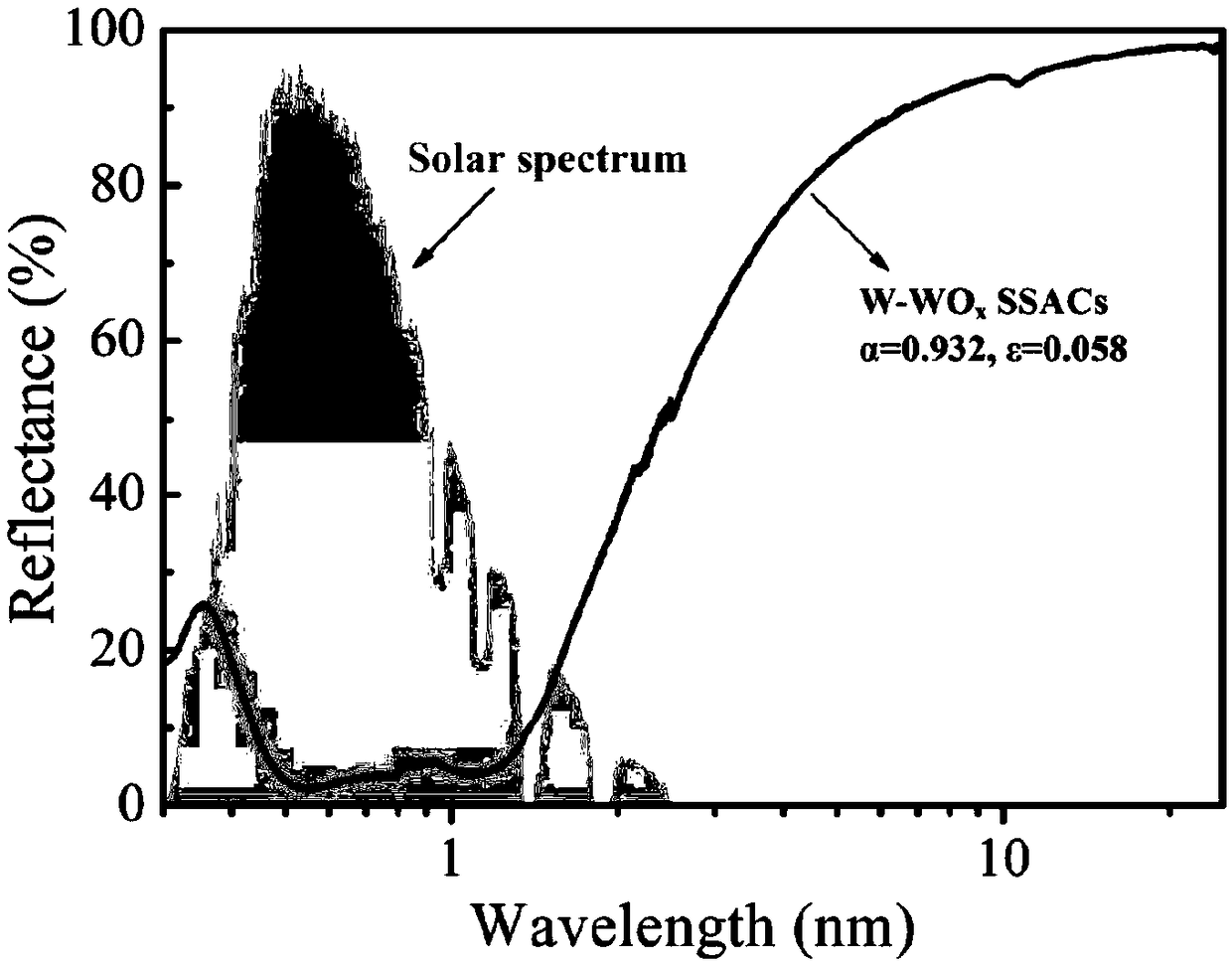

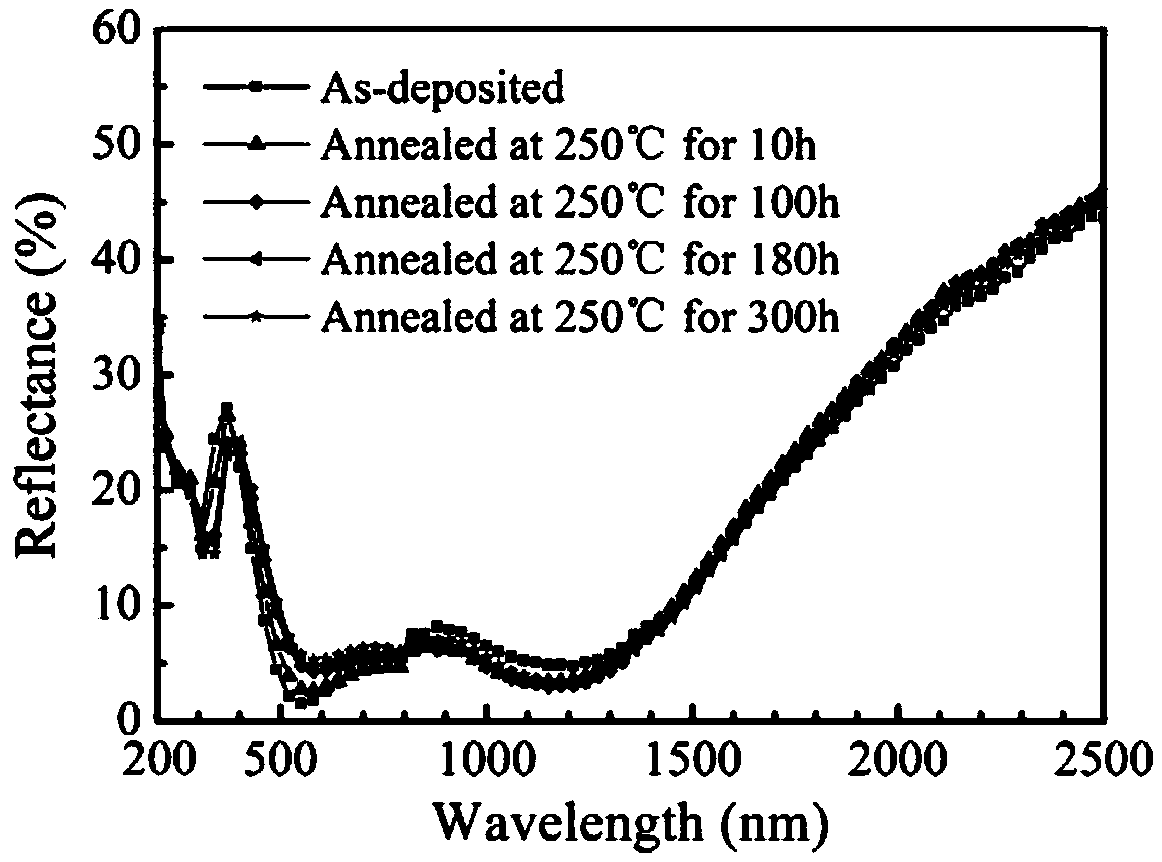

Self-doped nano composite photothermal conversion coating and preparation method thereof

InactiveCN108917210AImprove thermal stabilityImprove light absorption efficiencyVacuum evaporation coatingSputtering coatingTungsten atomOxygen

The invention provides a self-doped nano composite photothermal conversion coating. The self-doped nano composite photothermal conversion coating comprises a diffusion impervious layer, a self-doped composite absorbing layer and an antireflection layer which are sequentially arranged on a substrate from bottom to top; the self-doped composite absorbing layer is a composite layer obtained by dopingdifferent contents of plasma tungsten nano particles on a tungsten oxide matrix, the self-doped composite absorbing layer is prepared by limited reactive sputtering, in a preparation process, limitedoxygen atoms only react with part of tungsten atoms to form tungsten oxide, thus, the plasma tungsten nano particles are doped into the tungsten oxide matrix, and a self-doped absorbing coating is formed; transition metal tungsten has perfect energy gap, after oxide of the transition metal tungsten is doped, the oxide can become a material with excellent absorbing performance; the composite absorbing layer has a double-layered gradient structure, due to the interference effect of light, the gradient structure can effectively absorb sunlight, and the light absorbing efficiency of the coating is enhanced; and meanwhile, during preparation, only one metal tungsten target is deposited on substrate by a magnetron sputtering method, a preparation process of the coating is greatly simplified, and the self-doped nano composite photothermal conversion coating is suitable for low-cost and large-scale industrialized production.

Owner:SHAANXI UNIV OF SCI & TECH

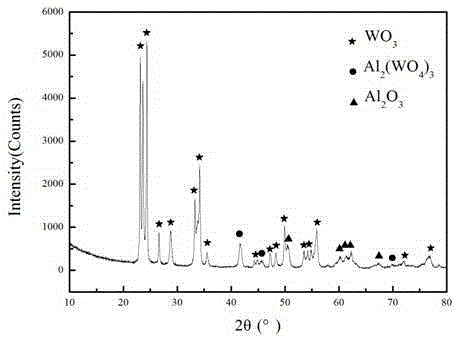

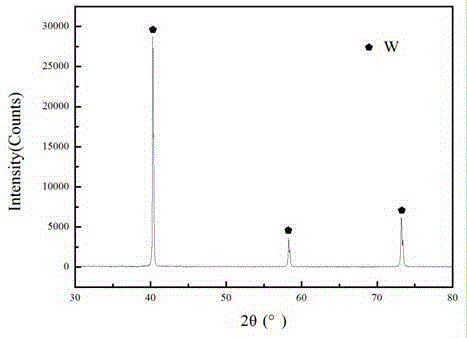

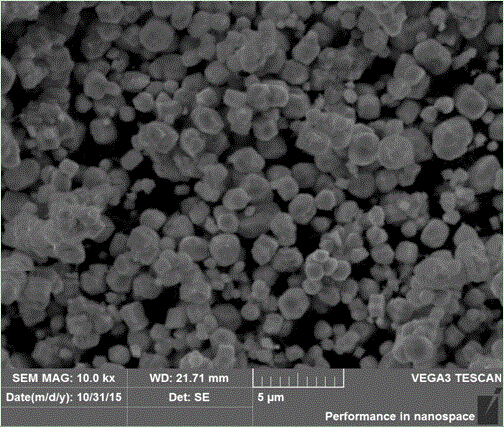

Preparation method aluminum oxide coating tungsten powder

ActiveCN105397102AGood dispersionInhibit growthTransportation and packagingMetal-working apparatusSurface layerHydrogen atmosphere

The invention discloses a preparation method aluminum oxide coating tungsten powder. Firstly, coating powder formed by coating AlO(OH) on a WO3 surface layer is prepared; then, the coating powder is calcined by 6-12 hours under the condition of 300-500 DEG C; and finally, the coating powder is fully reduced in a hydrogen atmosphere to obtain the aluminum oxide coating tungsten powder. The preparation method prepares an aluminum oxide uniform coating tungsten powder composite material through calcining and secondarily reducing hydrated aluminum oxide coating tungsten oxide powder; the particle diameter distribution of the powder can be controlled through controlling the content of aluminum oxide in the composite material, so that the powder dispersibility is better; the powder finally formed through the calcining and reducing processes has no other impurities; a layer of film is formed on the tungsten particle surface through the generation of aluminum oxide in the reducing process; the film stops the deposition of secondarily reduced tungsten on the surface thereof so as to inhibit the growth of tungsten particles; and the aluminum oxide is mingled to limit the polymerization of tungsten atoms to inhibit the growth of elementary tungsten particles so as to achieve a grain refining effect.

Owner:HENAN UNIV OF SCI & TECH

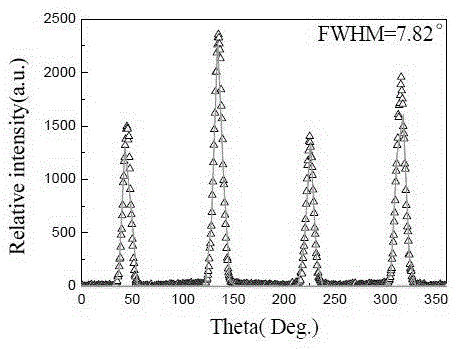

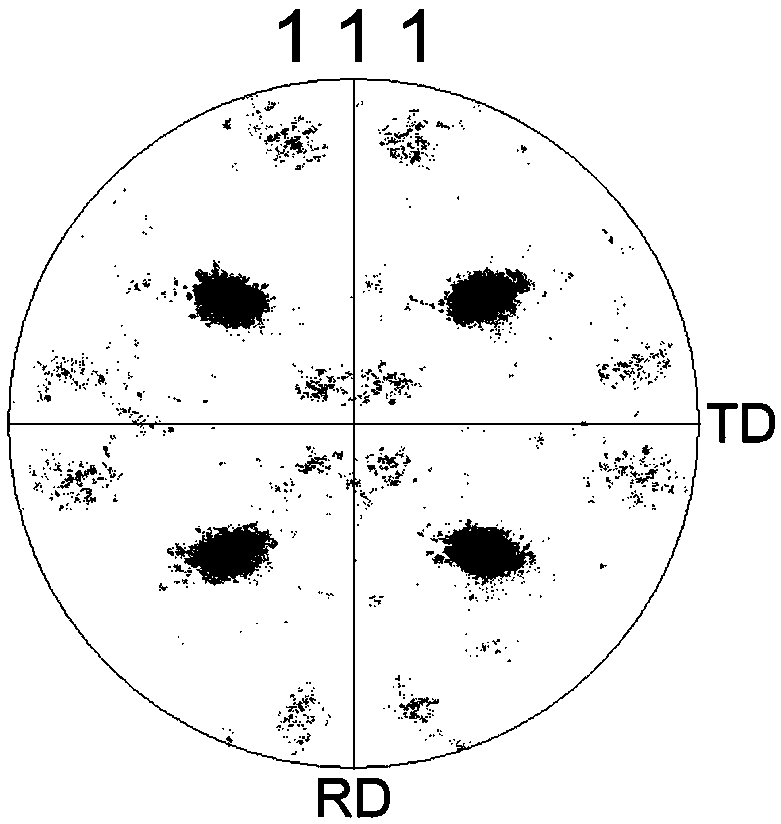

Preparing and cutting method for textured nickel-tungsten alloy composite base band

The invention discloses a preparing and cutting method for a textured nickel-tungsten alloy composite base band. The method includes the steps that a hot-rolled nickel-tungsten alloy billet with the tungsten atom percent being 5.5%-6.3% is subjected to cold rolling to become 1.6 mm thick from being 7 mm thick, and then cracked edges are cut with the gap between an upper single-side disc cutter and a lower single-side disc cutter being 0.1-0.5 mm and the blade overlapping amount being 0.8-1.0 mm; the nickel-tungsten alloy continues to be subjected to cold rolling to become 95 micrometers thick, and then a tension-free disc cutting machine is adopted for cutting cracked edges with the gap between the upper single-side disc cutter and the lower single-side disc cutter being 8-10 micrometers and the blade overlapping amount being 50-70 micrometers; the edge-cut cold-rolled nickel-tungsten alloy composite base band which is 95 micrometers thick is subjected to continuous recrystallization heat treatment, and finally the tension-free disc cutting machine is adopted for carrying out cutting and splitting with the gap between the upper single-side disc cutter and the lower single-side disc cutter being 9-11 micrometers and the blade overlapping amount being 60-90 micrometers, wherein the edge cutting widths of the two sides of the nickel-tungsten alloy composite base band are both 2-4 mm. The cutting method is suitable for industrial production of high-performance textured nickel-tungsten alloy composite base bands and can well meet the requirement for follow-up preparation of high-performance transition layers and superconduction layers.

Owner:广州市海派科技有限责任公司

High-intensity texture copper-nickel/nickel-tungsten alloy double-layered composite base band and preparation method thereof

The present invention discloses a high-intensity texture copper-nickel / nickel-tungsten alloy double-layered composite base band and a preparation method thereof. The preparation method comprises the following steps: conducting high-temperature forging and hot-rolling on a copper-nickel alloy, of which the percentage content of copper atoms is 46%, acquired from smelting to obtain billets; defining the billets as A; defining nickel tungsten mixing powder, of which the percentage content of tungsten atoms is 12%, as B; placing the A and the B in a mould layer by layer; adopting electric discharging plasma for sintering to obtain copper-nickel / nickel-tungsten double-layered composite billets; conducting cold-rolling on the obtained composite billets to strips, of which the thickness is 40 Mum; conducting recrystallization heat treatment on the cold-rolling composite base band at a high temperature; and finally obtaining the high-intensity ferromagnetism-free strong cubic texture copper-nickel / nickel-tungsten alloy double-layered composite base band.

Owner:广州市海派科技有限责任公司

Manganese-tungsten-titanium wear-resisting cast steel and machining process thereof

InactiveCN105779895AImprove performanceMorphological agglomerationProcess efficiency improvementTungsten atomManganese

The invention relates to the field of wear-resisting cast steel, in particular to manganese-tungsten-titanium wear-resisting cast steel and a machining process thereof. The wear-resisting cast steel is prepared from, by mass percent, 0.20% to 0.35% of C, 1.0% to 2.0% of W, 0.5% to 1.5% of Si, 0.8% to 1.5% of Mn, 1.0% to 2.0% of Cr, 1.0% to 2.0% of Ti, not larger than 0.04% of S, not larger than 0.04% of P and the balance iron. In the preparation process, tungsten atoms exist in molten steel and can partially replace the positions of iron atoms in carbide, and (W, Fe) 3C is formed; and but the microhardness of common cementite is about 800 Hv, the microhardness can be improved by adding the tungsten atoms and can range from about 1,600 Hv to 1,800 Hv, and therefore the hardness of the cast steel is improved. Meanwhile, an element Ti is added, so that enough nucleation material points TiC are generated by the molten liquid, and the number of particles of TiC is greatly increased.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Preparation method of high-strength and strong-cube-texture Ni-W baseband

ActiveCN109604546AWith strengthImprove mechanical propertiesFurnace typesHeat treatment furnacesOne passBinary alloy

The invention discloses a preparation method of a high-strength and strong-cube-texture Ni-W baseband. The preparation method of the high-strength and strong-cube-texture Ni-W baseband comprises the following steps of (1) alloy thin strip continuous casting and heat treatment, wherein the percentage content of tungsten atoms is 12%, a continuous casting thin strip technology is adopted to obtain aNi-W binary alloy billet, the thickness of the billet is 2.0 mm, the content of the impurity elements of S, C and P is controlled to be 30 ppm or below correspondingly, and a heat treatment on the billet is carried out, wherein the technique of the heat treatment is to preserve heat for 2 hours at the temperature of 1300 DEG C; (2) hot rolling of the alloy billet, wherein the hot rolling on the billet is carried out, and a hot rolling technique comprises the parameters that the rolling temperature is 1380 DEG C, the final rolling temperature ranges from 1150 to 1180 DEG C, the one-pass hot rolling is carried out and the deformation amount is 50%; and (3) cold rolling and heat treatment on a hot rolled plate, wherein cold rolling is carried out after the hot rolled plate is descaled, the cold rolling deformation amount is 70-78%, and a cold-rolled strip is subjected to a recovery heat treatment, wherein the technique of the recovery heat treatment comprises the step that the heat preservation is carried out for 2 min at 700 DEG C; and then a recrystallization heat treatment is carried out, wherein the technique of recrystallization heat treatment comprises the step that heat preservation is carried out for 20 min at 1260-1300 DEG C under an external magnetic field of 8-12 T. The high-strength and strong-cube-texture Ni-W baseband has the advantages of being high in strength andstrong in cube texture.

Owner:河南工学院

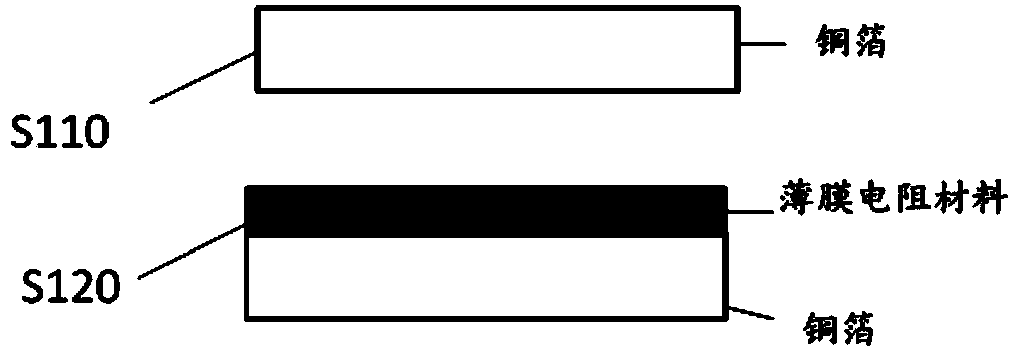

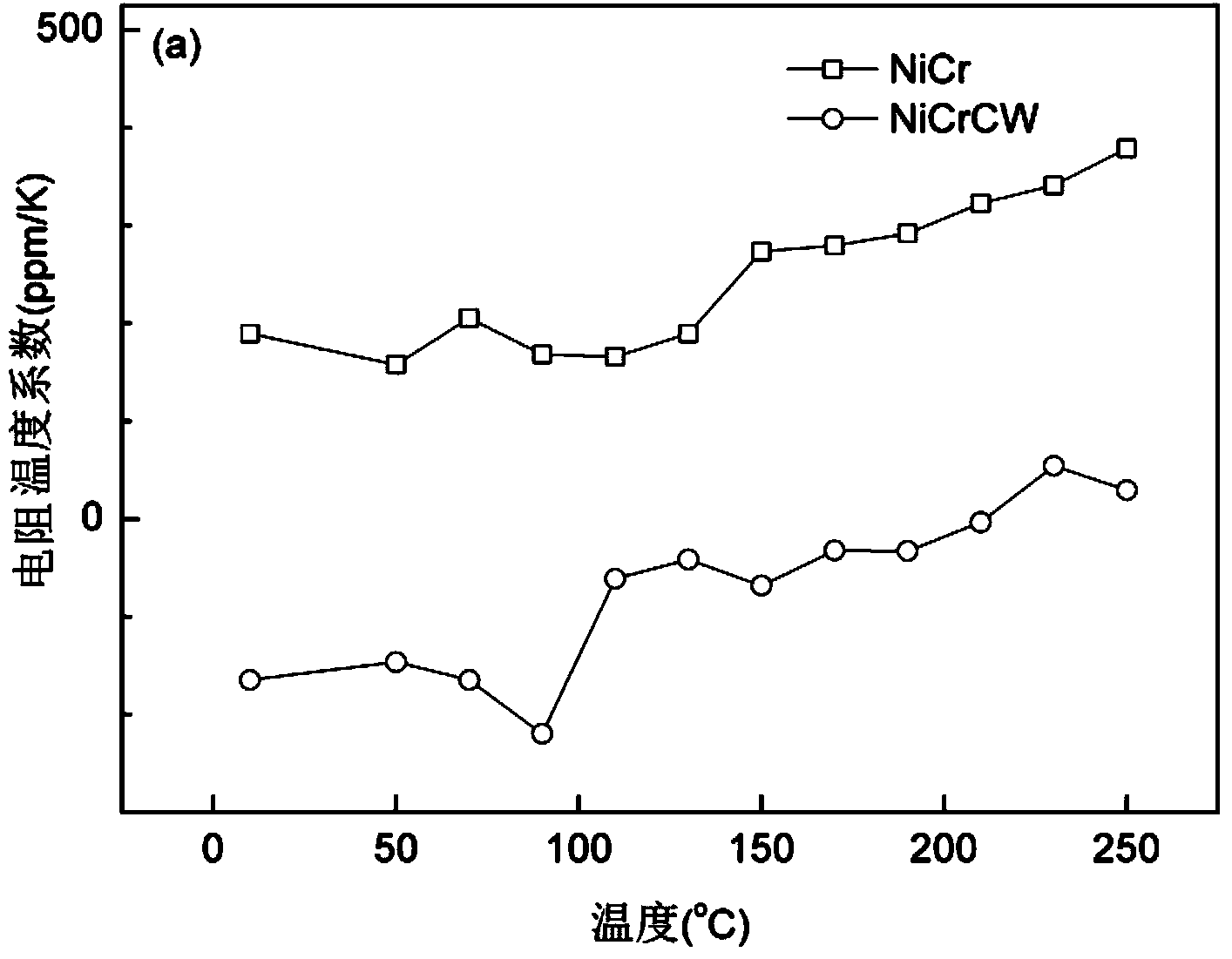

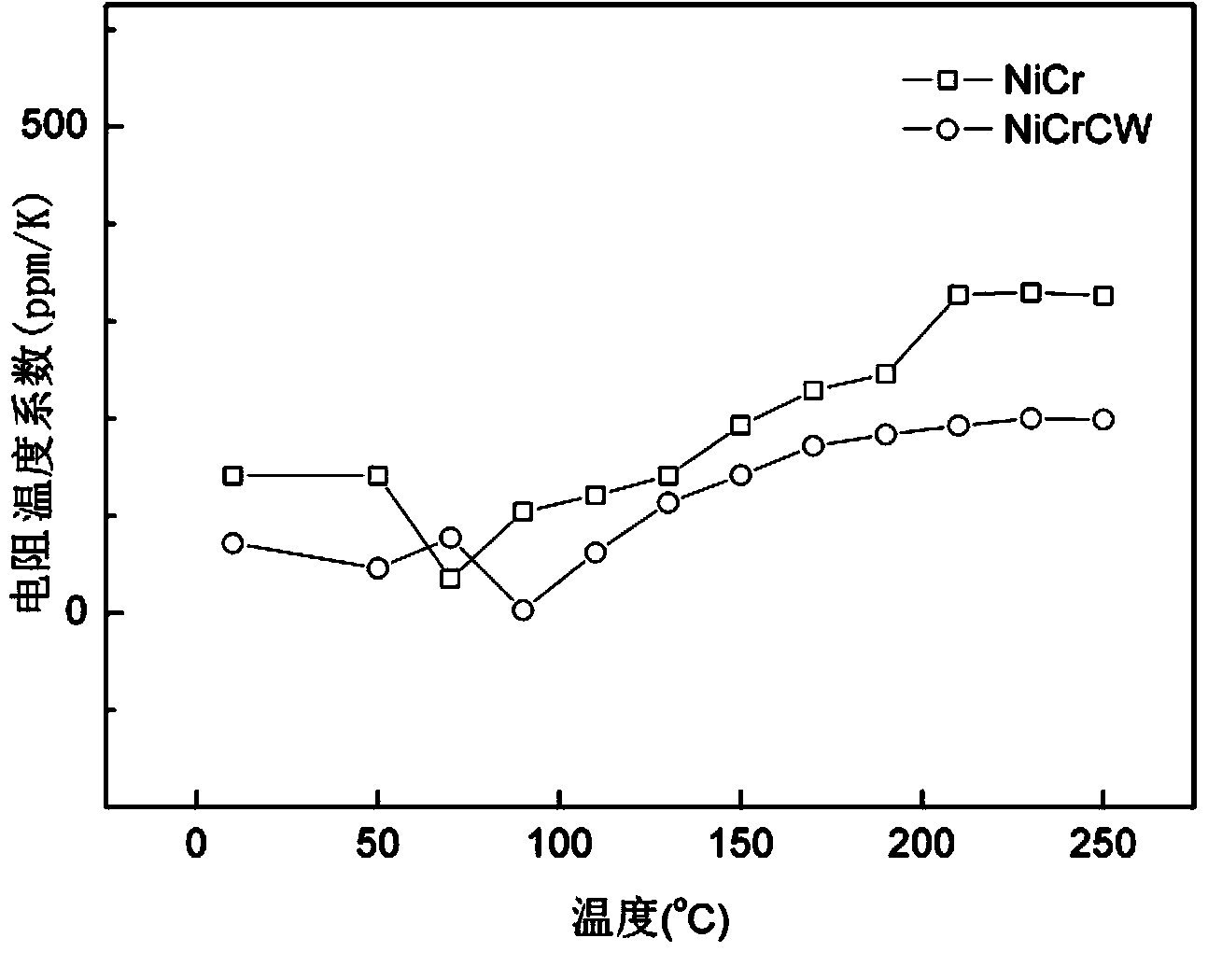

Embedded film resistor material and its preparation method

The invention relates to an embedded film resistor material and a preparation method. The embedded film resistor material comprises the following components by atom percentages: 50-76% of nickel, 10-18% of chromium, 10-30% of carbon and 0.5-5% of tungsten. A magnetron sputtering technology is used for depositing nickel atom, chromium atom, carbon atom and tungsten atom on a copper foil substrate to obtain a nickel chromium carbon tungsten film, and experiments show that the embedded film stock solution using the nickel chromium carbon tungsten film has stable electrical property and high sheet resistance.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Manganese-tungsten-titanium wear-resistant cast steel and preparation method thereof

The invention relates to the field of wear-resistant cast steel, in particular to a manganese-tungsten-titanium wear-resistant cast steel and a preparation method thereof. The wear-resistant cast steel is prepared from, by mass, 0.20-0.35% of C, 1.0-2.0% of W, 0.5-1.5% of Si, 0.8-1.5% of Mn, 1.0-2.0% of Cr, 1.0-2.0% of Ti, smaller than or equal to 0.04% of S, smaller than or equal to 0.04% of P and the balance Fe. In the preparation process, tungsten atoms exist in molten steel and can partially substitute iron atoms in carbide in position, (W,Fe)3C is formed, the microhardness of common cementite is about 800 Hv, the microhardness can be improved by adding tungsten atoms and can reach 1600-1800 Hv or so, and thus the hardness of the cast steel is improved; meanwhile, the element Ti is added, molten steel can generate adequate nucleation sites TiC, and thus the particle number of the cast steel is greatly increased.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

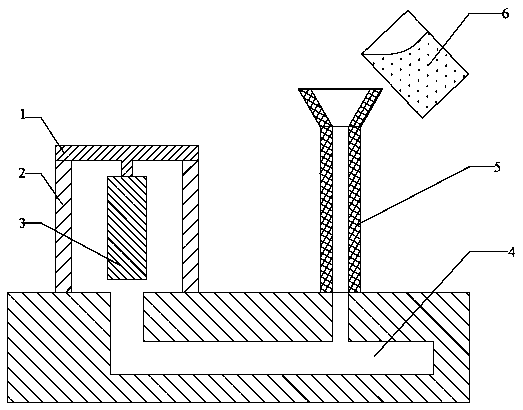

Electron source and image display apparatus

InactiveUS20100060126A1Little changeDischarge tube luminescnet screensCathode ray tubes/electron beam tubesElectron sourceTungsten atom

There is provided an electron source according to the present invention, having a plurality of electron-emitting devices wherein each of the electron-emitting devices has a pair of electrodes, and a plurality of conductive films having respective electron emitting portions, provided between the pair of electrodes so as to be electrically connected to the pair of electrodes, the electron source including: a short-circuit suppressing film which is positioned between the plurality of conductive films and is provided on the electron-emitting device so as to be electrically connected to the pair of electrodes, and mainly contains tungsten (W) and germanium (Ge) nitride, wherein a ratio of the number of tungsten atoms to the number of tungsten and germanium atoms is 0.24 or more in the short-circuit suppressing film, surface resistivity of the short-circuit suppressing film is not less than 1×1010 Ω / square and not more than 1×1013 Ω / square.

Owner:CANON KK

Preparation method for nonmagnetic and high-strength texture nickel-based alloy composite baseband

InactiveCN105499542AFully solid solutionAvoid formingMetal rolling arrangementsLiquid stateTungsten atom

The invention discloses a preparation method for a nonmagnetic and high-strength texture nickel-based alloy composite baseband. The preparation method comprises the following steps: cleaning the surface of a nickel-tungsten alloy billet with 9%-10% (in percentage by weight) of tungsten atoms, then, fixing the surface into a bottom-pouring type casting system as a core layer of the composite billet; proportioning nickel blocks and vanadium blocks in terms of 9% (in percentage by weight) of vanadium atoms, putting proportioned mixed materials into an electromagnetic induction vacuum smelting furnace to smelt, casting a refined liquid-state nickel-vanadium alloy material into a casting system, and filling a mould cavity with the liquid-state nickel-vanadium alloy material, thereby obtaining a layered composite billet, wherein the composite billet is divided into three layers, the outer layer is made of nickel-vanadium alloy with 9% of vanadium atoms, and the core layer is made of nickel-tungsten alloy with 9%-10% of tungsten atoms; and carrying out proper thermal treatment on the composite billet, then, carrying out large-deformation cold rolling and recrystallization annealing, thereby preparing the nonmagnetic and high-strength texture nickel-based alloy composite baseband. The preparation method is simple and easy to operate, is low in cost, and is suitable for industrial production.

Owner:HENAN NORMAL UNIV

Method for preparing polytetramethylene ether glycol by using imidazole polyoxometalate catalyst

The invention relates to a method for preparing polytetramethylene ether glycol by using an imidazole polyoxometalate catalyst. The method belongs to the technical field of chemical synthesis. According to the invention, imidazole polyoxometalate is adopted as a catalyst, such that tetrahydrofuran is polymerized into polytetramethylene ether glycol (PTMEG) or a PTMEG copolymer or polytetrahydrofuran. The invention especially relates to PTMEG synthesis with the imidazole polyoxometalate catalyst modified with an ionic liquid method. Through improving the synthesis method, the synthesized imidazole polyoxometalate catalyst is different from a heteropolyacid catalyst synthesized with a traditional method. The difference mainly lies in the difference in phosphorus tungsten atom state forms. Traditionally, the heteropolyacid catalyst is in a molecular state. However, with the novel synthesis method, the imidazole polyoxometalate catalyst is in an ionic state, such that great difference is shown in specific application reactions. With the catalyst provided by the invention, reaction activity and catalyst recovery rates of the reaction are better than those of the heteropolyacid catalyst prepared with a traditional method.

Owner:杭州师恩科技有限公司

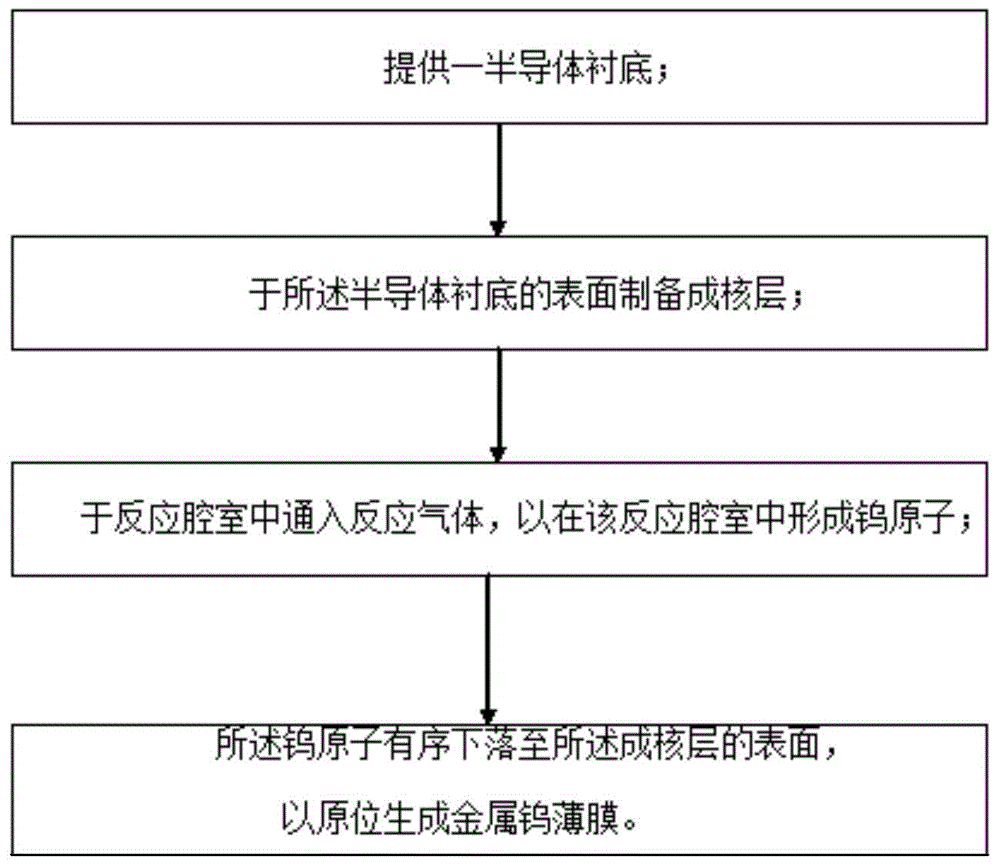

Preparation method of metal tungsten thin film

The invention relates to the technical field of manufacturing of semiconductors, in particular to a preparation method of a metal tungsten thin film. The reaction temperature of gas in a reaction cavity is changed, and the amount of reaction gas is reduced, so that metal tungsten atoms are formed on the reaction cavity as many as possible; and then, the atoms fall on the surface of a nucleating layer and grow in order, and the metal tungsten thin film is formed. According to the technical scheme, stress of the metal tungsten thin film is effectively reduced, and compared with a traditional method, the method reduces the stress by 73%.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

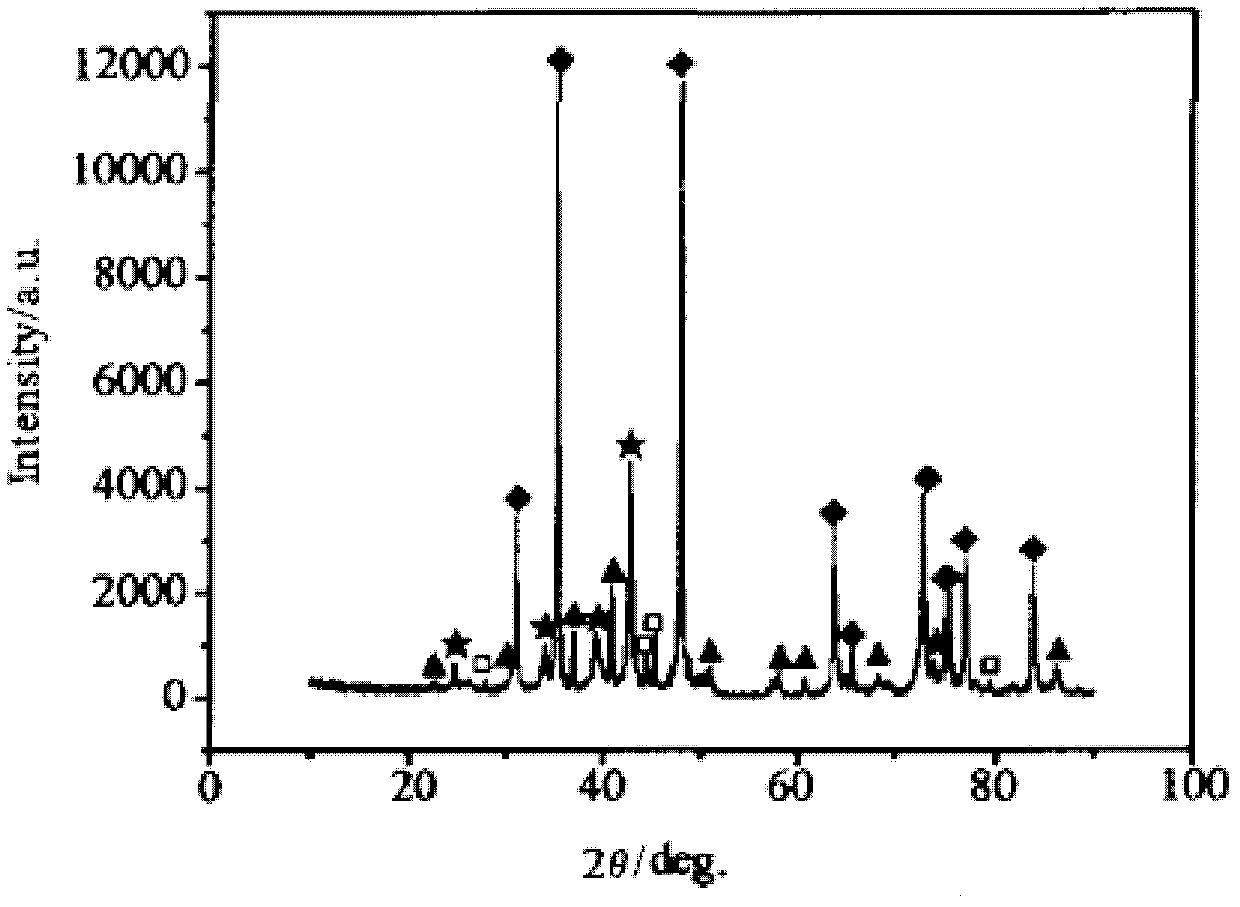

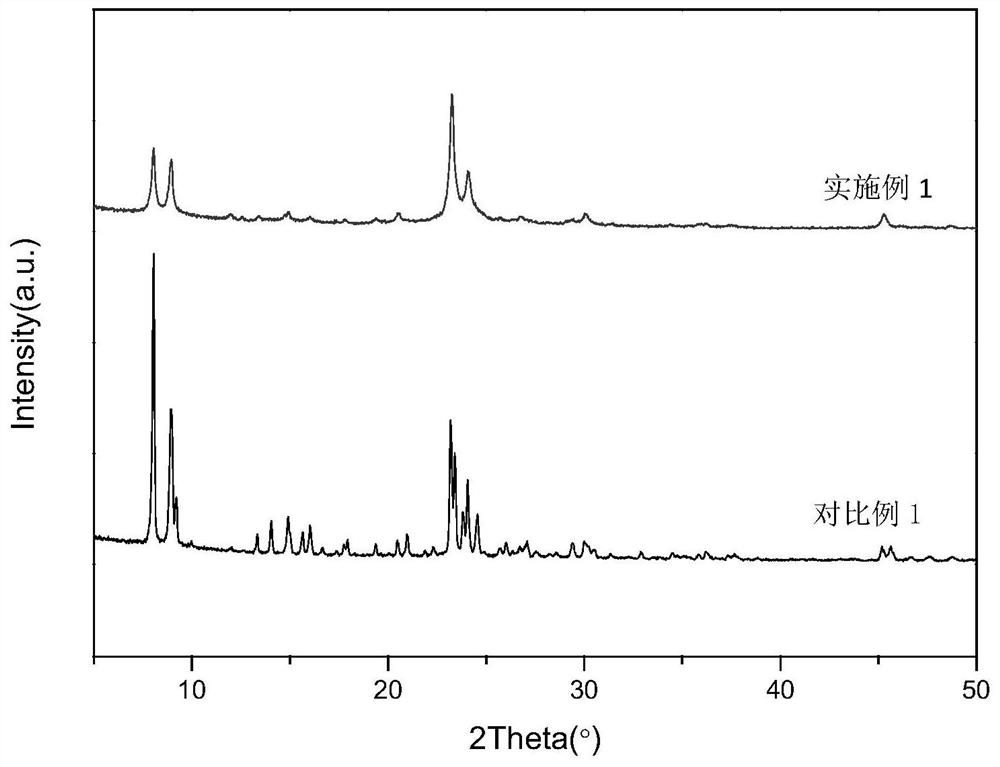

Preparation method of W-SSZ-13 zeolite with high crystallinity and high hydrophobicity

ActiveCN110950355AImprove the crystallization processLower synthesis costMolecular-sieve and base-exchange compoundsTungsten atomHeteroatom

The invention belongs to the technical field of preparation of heteroatom-containing zeolite materials, and particularly relates to a preparation method of W-SSZ-13 zeolite with high crystallinity andhigh hydrophobicity. According to the method, tungsten ions are doped into an SSZ-13 zeolite synthesis system, so that the zeolite crystallization process is promoted, the crystallization temperatureis reduced, and the crystallization time is shortened. The preparation method comprises the following specific preparation steps: sequentially adding water, an alkali source, an organic template agent, a silicon source, a tungsten source and the like into a container; stirring the substances well; putting the container into a reaction kettle, and carrying out crystallization for 1-4 days at 100-200 DEG C; and centrifugally washing a product for multiple times, and drying the product at 80-110 DEG C. Under the same reaction conditions, the crystallinity of the W-SSZ-13 zeolite is higher than that of the SSZ-13 zeolite, which indicates that the addition of tungsten ions can promote the crystallization of the zeolite and tungsten atoms can enter the framework structure of the zeolite. The W-SSZ-13 zeolite shows excellent hydrophobic performance, is high in organic matter adsorption capacity and has a wide application prospect in the fields of catalysis and adsorption.

Owner:FUDAN UNIV

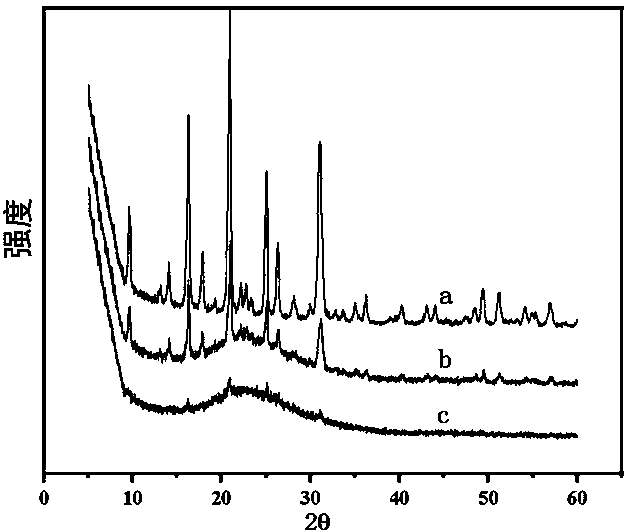

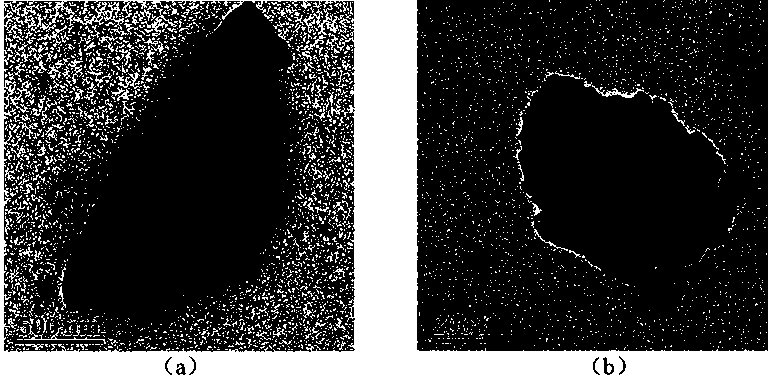

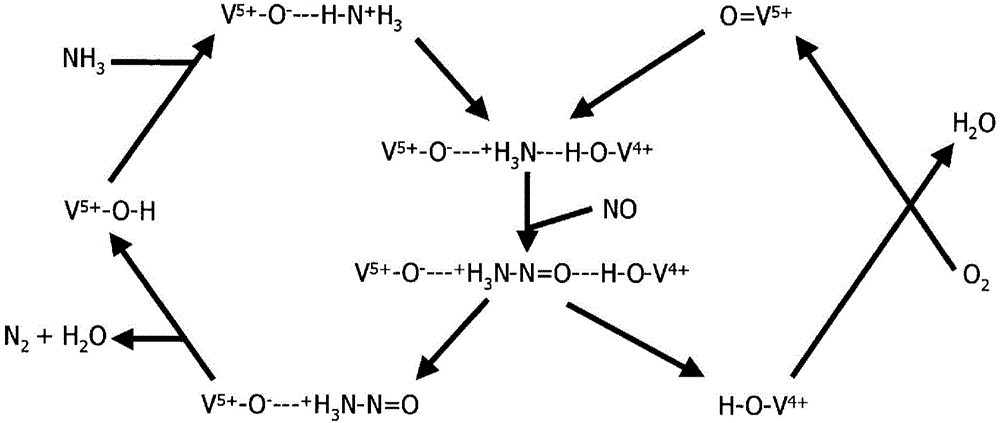

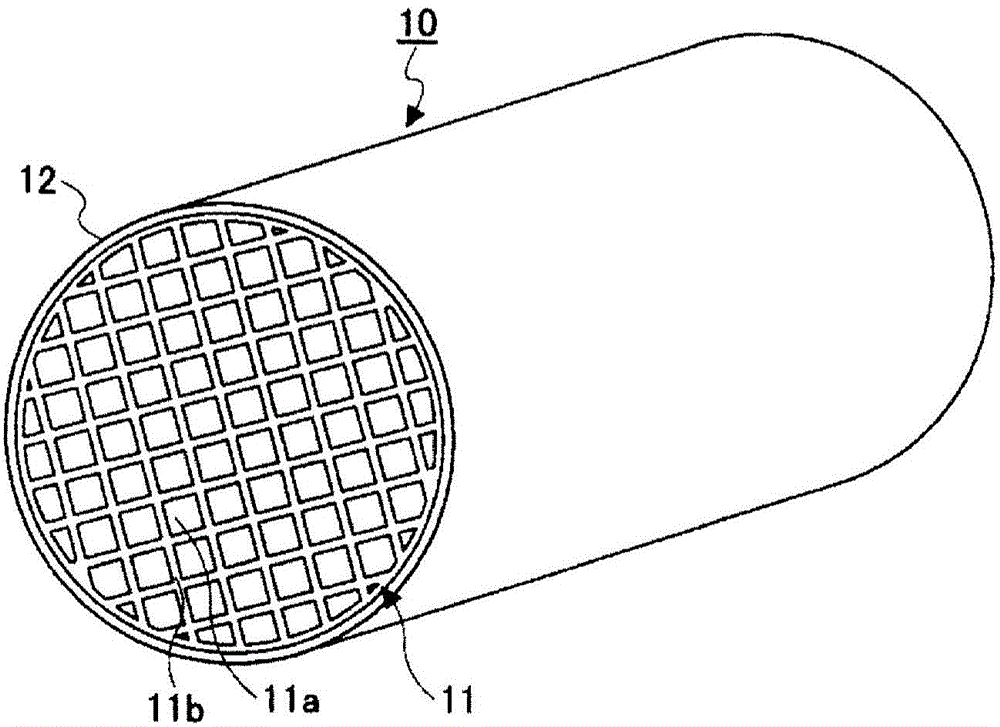

Honeycomb structure

InactiveCN104797333AImprove purification effectIncreased durabilityDispersed particle separationCatalyst activation/preparationTungsten(IV) oxideTungsten atom

Provided is a honeycomb structure which uses a TiO2 / V2O5 / WO3 catalyst, and which has excellent NOX conversion efficiency and thermal durability. This honeycomb structure is provided with a honeycomb unit in a shape in which multiple cells are partitioned by cell walls, said cells containing at least titanium oxide, vanadium oxide, tungsten oxide and an inorganic binder and extending in the longitudinal direction from one end surface to the other end surface, and is characterized in that the hydrogen consumption from vanadium reduction in temperature-programmed reduction with hydrogen (H2-TPR) is 0.6mmol or more per 1g of the honeycomb structure, and the molar ratio (W / V) of tungsten atoms to vanadium atoms is 0.8-1.2.

Owner:IBIDEN CO LTD

Manganese-tungsten-titanium alloy steel and processing process thereof

The invention relates to the field of wear resistant cast steel, in particular to manganese-tungsten-titanium alloy steel and a processing process thereof. The wear resistant cast steel consists of the following components in percentage by mass: 0.20 to 0.35 percent of C, 1.0 to 2.0 percent of W, 0.5 to 1.5 percent of Si, 0.8 to 1.5 percent of Mn, 1.0 to 2.0 percent of Cr, 1.0 to 2.0 percent of Ti, 1.0 to 1.5 percent of B, 0.1 to 0.3 percent of Mo, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of iron. When the manganese-tungsten-titanium alloy steel is prepared, tungsten atoms exist in molten steel and can partially substitute the positions of iron atoms in a carbide to form (W,Fe)3C; the microhardness of a common cementite is about 800 Hv; the microhardness can be improved by adding the tungsten atoms, and can reach about 1,600 to 1,800 Hv, so that the harness of the cast steel can be improved; meanwhile, the Ti element is also added, so that the molten liquid can form enough nucleation sites TiC, and the number of particles of the molten liquid can be greatly increased.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

A kind of MFI type molecular sieve catalyst with skeleton tungsten atom and preparation method and catalytic application

ActiveCN109513458BShorten the diffusion pathImprove conversion rateOrganic chemistryMolecular sieve catalystsPtru catalystCatalytic oxidation

An MFI molecular sieve catalyst with skeleton tungsten atoms and its preparation method and catalytic application, adding silicon source dropwise to the structure directing agent aqueous solution to form a clear solution A; adding the tungsten source aqueous solution or tungsten source to the A solution dropwise, Then hydrothermally crystallize at 110° C. to 150° C. for 48 hours to 120 hours to obtain an MFI type molecular sieve catalyst with skeleton tungsten atoms. The invention adopts a hydrothermal synthesis method to prepare almond-shaped MFI molecular sieve nanoparticles containing skeleton tungsten atoms in one step, and the preparation process is simple and the conditions are mild. Its smaller particle size shortens the material diffusion path and is more conducive to mass transfer, which largely solves the problem that the long diffusion path of conventional MFI-type molecular sieves is not conducive to the diffusion of reactants and product molecules in its pores. And other issues. Due to the introduction of tungsten heteroatoms in the framework, this type of molecular sieve has the catalytic oxidation effect of tungsten, and can be used in the epoxidation reaction of catalyzed cycloolefins.

Owner:NORTHWEST UNIV

Nickel-based alloy composite substrate and manufacturing method thereof

InactiveCN104625069AHigh mechanical strengthReduce magnetismMetal rolling arrangementsCompression moldingElectrical conductor

The invention relates to a nickel-based alloy composite substrate and a manufacturing method thereof and belongs to the technical field of manufacturing of high-temperature superconductive metal basebands. By the adoption of the manufacturing method of the nickel-based alloy composite substrate, cost is low, energy consumption is low and the process is easy and convenient. By the adoption of the manufacturing method, a nickel-tungsten alloy composite substrate is manufactured, wherein the content of tungsten atoms in the surface layer is 3%-9%, and the content of tungsten atoms in the core layer is 9%-15%. The manufacturing method comprises the steps that firstly, nickel powder and tungsten powder are mixed into nickel-tungsten powder; secondly, compression molding is conducted on the powder directly through a powder rolling method; thirdly, the nickel-tungsten powder (A) with the content of tungsten being 3%-9% and the nickel-tungsten powder (B) with the content of tungsten being 9%-15% are rolled into billets, the billets are placed in a tunnel furnace according to the sequence of A-B-A, high-temperature sintering is conducted, and then initial composite billets with even composites are obtained; fourthly, the initial composite billets are cold-rolled, the pass deformation is smaller than 10%, the total deformation is larger than 95%, and then a cold-rolled substrate is obtained; fifthly, the cold-rolled substrate is annealed at the temperature of 1000-1400 DEG C, and then the nickel-based alloy composite substrate is obtained. The nickel-based alloy composite substrate is high in overall mechanical strength and low in magnetism, a strong double-axis cube texture is formed on the surface, and the nickel-based alloy composite substrate can be well used as a coating conductor metal substrate.

Owner:SHANGHAI UNIV

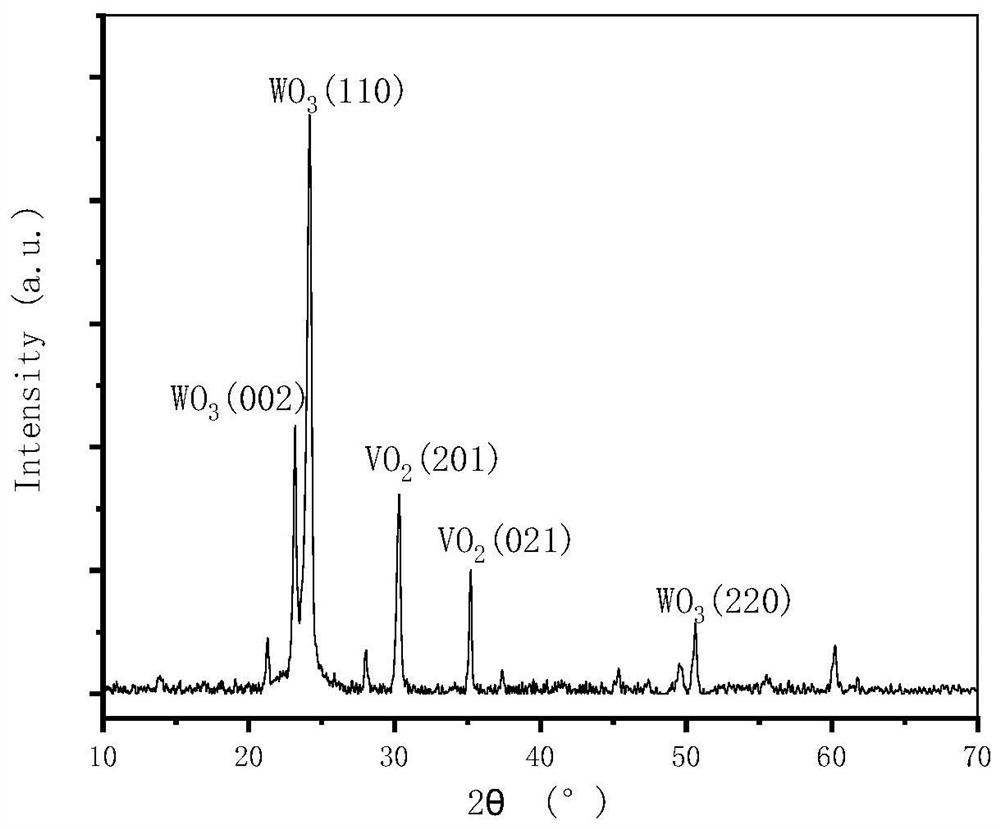

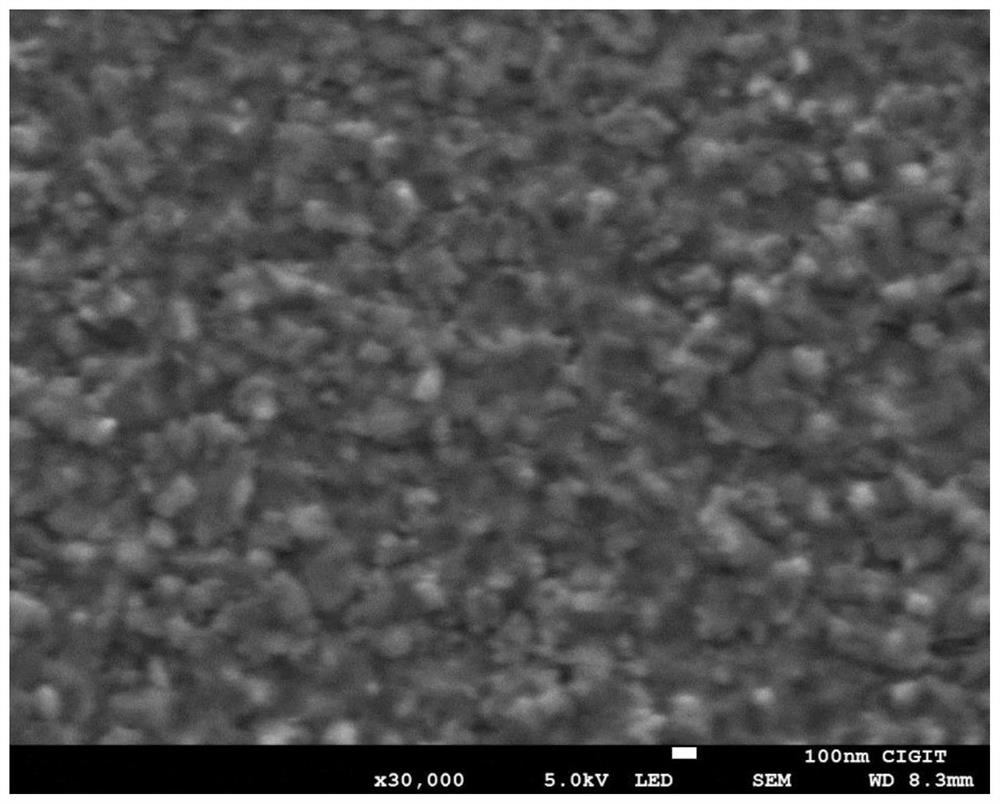

Vanadium-doped crystalline tungsten trioxide electrochromic film and preparation method thereof

The invention provides a vanadium-doped crystalline tungsten trioxide electrochromic film and a preparation method thereof.The molar ratio of vanadium atoms to tungsten atoms in the vanadium-doped crystalline tungsten trioxide electrochromic film is (0.01-0.1), and the preparation process comprises the steps that 1 cm * 4 cm ITO glass is subjected to ultrasonic cleaning through acetone, ethyl alcohol and deionized water respectively, and the ITO glass is put into a drying oven to be dried; the preparation method comprises the following steps: respectively weighing sodium metavanadate and sodium tungstate, dissolving the sodium metavanadate and the sodium tungstate in deionized water, adding a 30% hydrogen peroxide solution, adding a proper amount of a sulfuric acid solution, and adjusting the pH value; depositing by adopting a three-electrode system to obtain a tungsten oxide film; and roasting in a muffle furnace to obtain the crystalline tungsten oxide film. The method adopted by the invention is simple to operate and low in cost, a template agent does not need to be added, and the prepared film is uniform in pore structure, excellent in electrochromic performance and good in cycling stability.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

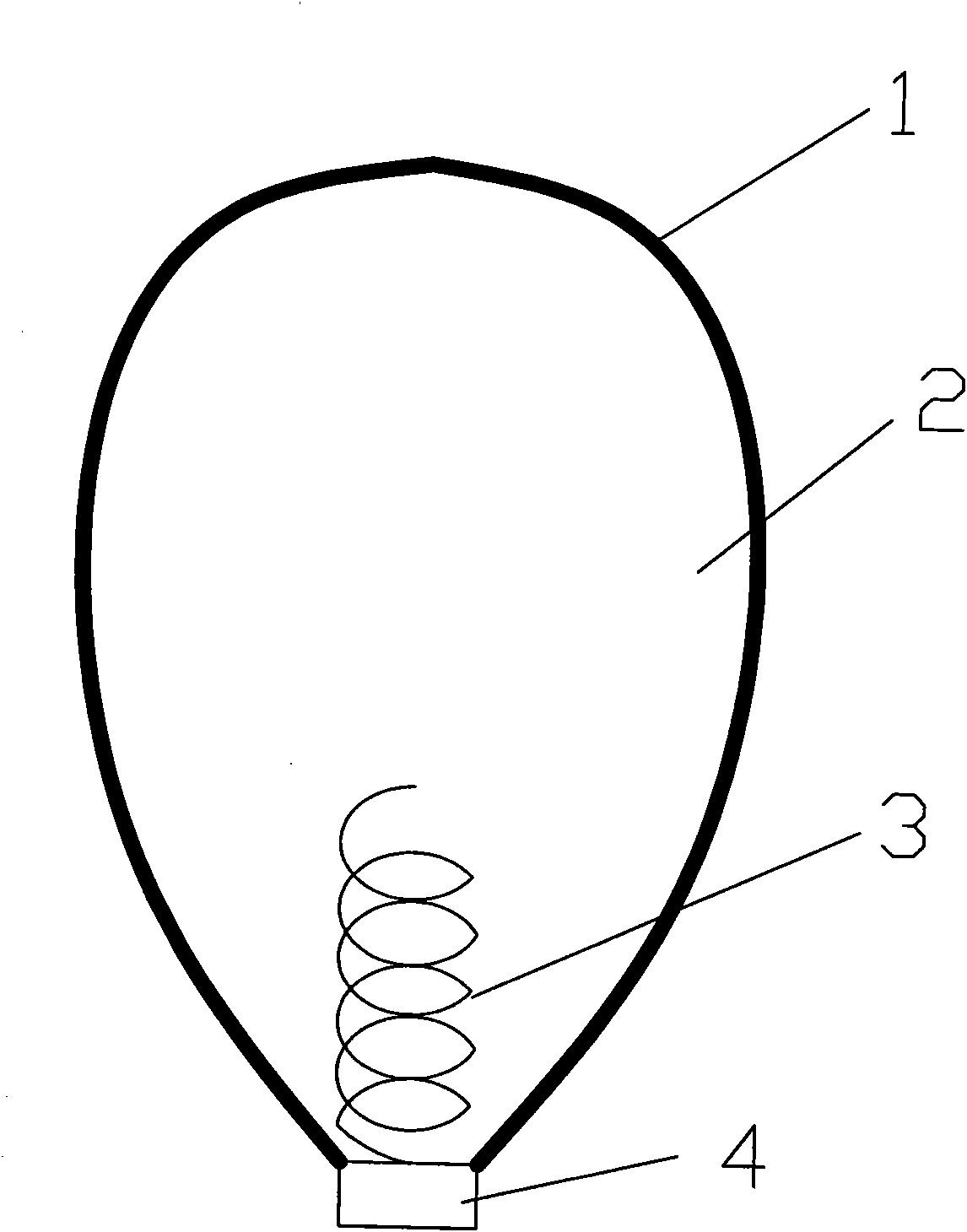

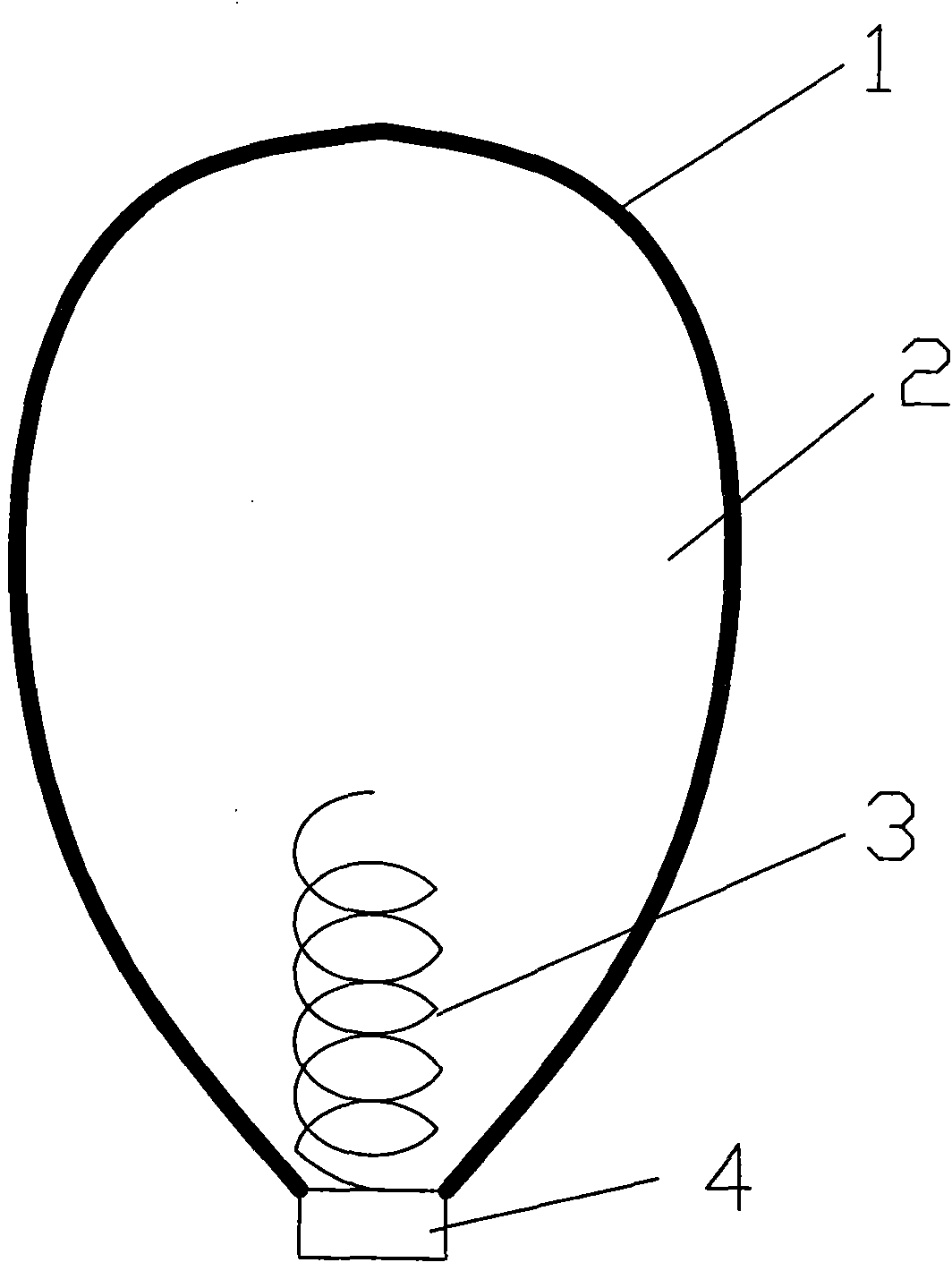

Halogen lamp containing inert gas

InactiveCN102420098AIncrease brightnessIncandescent lamp energy savingGas filling substancesGlass coverTungsten atom

The invention relates to a halogen lamp containing an inert gas. The halogen lamp comprises a transparent glass cover with a certain wall thickness, a tungsten filament as a lamp filament, a base and a filler, wherein the transparent glass cover is hollow; a lamp filament chamber is formed inside the transparent glass cover; the tungsten filament as the lamp filament is arranged in the lamp filament chamber; the base is used for mounting the halogen lamp to a required lamp cap; and the filler is filled in the transparent glass cover and is the inert gas containing halogen components. The transparent glass cover of the halogen lamp, disclosed by the invention, is filled with a proper amount of inert gas containing the halogen components; and when the halogen lamp is in use, tungsten atoms and halogen atoms can be recycled, so that the brightness of the halogen lamp is increased.

Owner:常熟市广大电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com