A kind of MFI type molecular sieve catalyst with skeleton tungsten atom and preparation method and catalytic application

A molecular sieve and catalyst technology, which is applied in the field of catalyst preparation, can solve the problems of tungsten sublimation loss, etc., and achieve the effects of mild conditions, favorable mass transfer, and improved conversion rate of reactants and selectivity of main products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of the MFI type molecular sieve catalyst with skeleton tungsten atom of the present invention comprises the following steps:

[0035] (1) Under stirring conditions, add the silicon source reagent dropwise into the aqueous solution of the structure directing agent, and continue stirring to form a clear solution A;

[0036] (2) dissolving the tungsten source in water to form an aqueous solution of the tungsten source;

[0037] (3) Add the tungsten source aqueous solution or tungsten source dropwise to the clear solution A, heat and stir at 40°C to 60°C for 0h to 12h, then turn to room temperature and stir and age for 0h to 12h to form a milky white solution; then transfer the milky white solution to the In a stainless steel autoclave with PTFE lining, hydrothermal crystallization at 110°C to 150°C for 48h to 120h;

[0038] (4) Transfer the solution obtained in step (3) from aging at room temperature to a stainless steel reactor with a polytet...

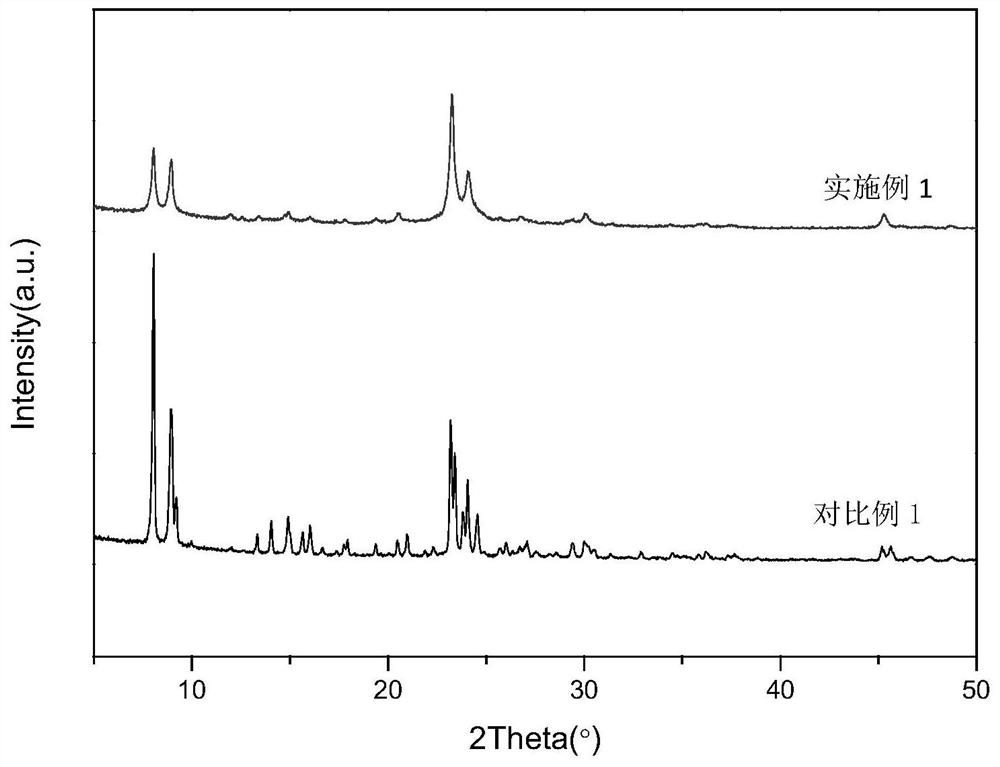

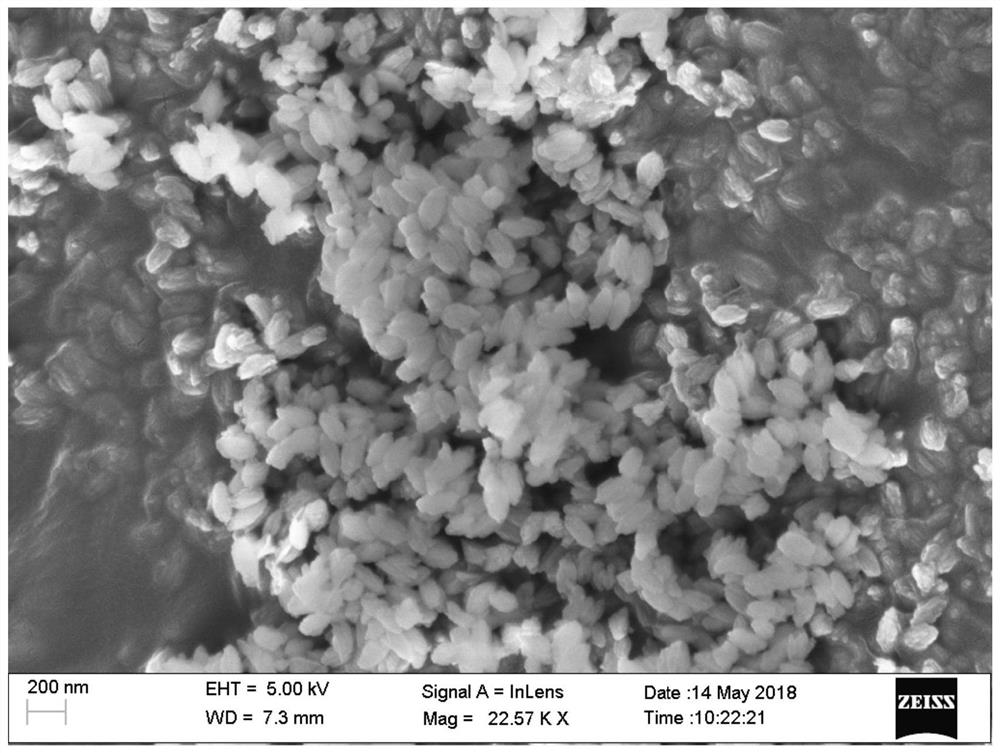

Embodiment 1

[0045] (1) Under stirring conditions, tetraethyl silicate is added dropwise to tetrabutylammonium hydroxide aqueous solution, and continuous stirring forms a clear solution A;

[0046] (2) Sodium tungstate dihydrate is dissolved in water to form a clear colorless solution B; wherein, the total amount of water in the clear colorless solution B and tetrabutylammonium hydroxide aqueous solution to the molar ratio of tetraethyl silicate 10:1;

[0047] (3) Add solution B dropwise to solution A, heat and stir at 50°C for 0.5h, then turn to room temperature and stir and age for 12h to form a milky white solution; the silicon source is SiO 2 In terms of tungsten source, WO 3 SDA is the structure-directing agent tetrabutylammonium hydroxide, and the molar ratio of each material is: SiO 2 :SDA:WO 3 :H 2 O=1:0.3:0.04:10;

[0048] (4) Transfer the solution obtained from aging at room temperature in step (3) to a stainless steel reactor with a polytetrafluoroethylene liner, and conduc...

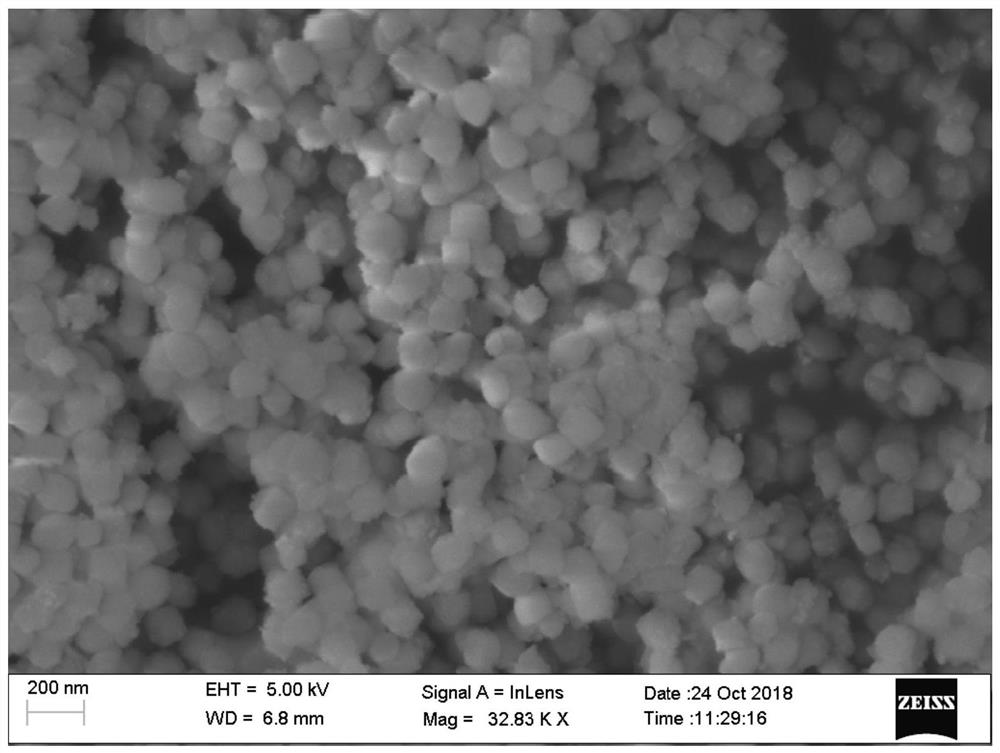

Embodiment 2

[0050] (1) Under stirring conditions, tetraethyl silicate is added dropwise to tetrabutylammonium hydroxide aqueous solution, and continuous stirring forms a clear solution A;

[0051] (2) Sodium tungstate dihydrate is dissolved in water to form a clear colorless solution B; wherein, the total amount of water in the clear colorless solution B and tetrabutylammonium hydroxide aqueous solution to the molar ratio of tetraethyl silicate 50:1;

[0052] (3) Add solution B dropwise to solution A, and heat and stir at 60°C for 12 hours to form a milky white solution; the silicon source is SiO 2 In terms of tungsten source, WO 3 SDA is the structure-directing agent tetrabutylammonium hydroxide, and the molar ratio of each material is: SiO 2 :SDA:WO 3 :H 2 O=1:0.3:0.02:10;

[0053] (4) Transfer the solution obtained from aging at room temperature in step (3) to a stainless steel reactor with a polytetrafluoroethylene liner, and conduct hydrothermal crystallization at 115° C. for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com