Honeycomb nickel selenide nanosheet array electrode material and preparation method thereof

A nanosheet array and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem of less research on nickel selenide, and achieve the effects of low cost, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Add 0.0125mol of Se powder to 500mL of Na with a concentration of 0.1mol / L 2 SO 3 solution, stirred and heated to 110°C, refluxed for 6 hours until completely dissolved, and Na with a concentration of 0.025mol / L was obtained 2 SeSO 3 solution.

[0024] ②The commercially available thickness is 1.5mm, surface density is 280-420g / m 2 The nickel foam with a pore size of 0.2-0.6 mm is cut into a size of 1×4 cm, and treated with 3 mol / L hydrochloric acid for 30 minutes to remove oxides on the surface. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

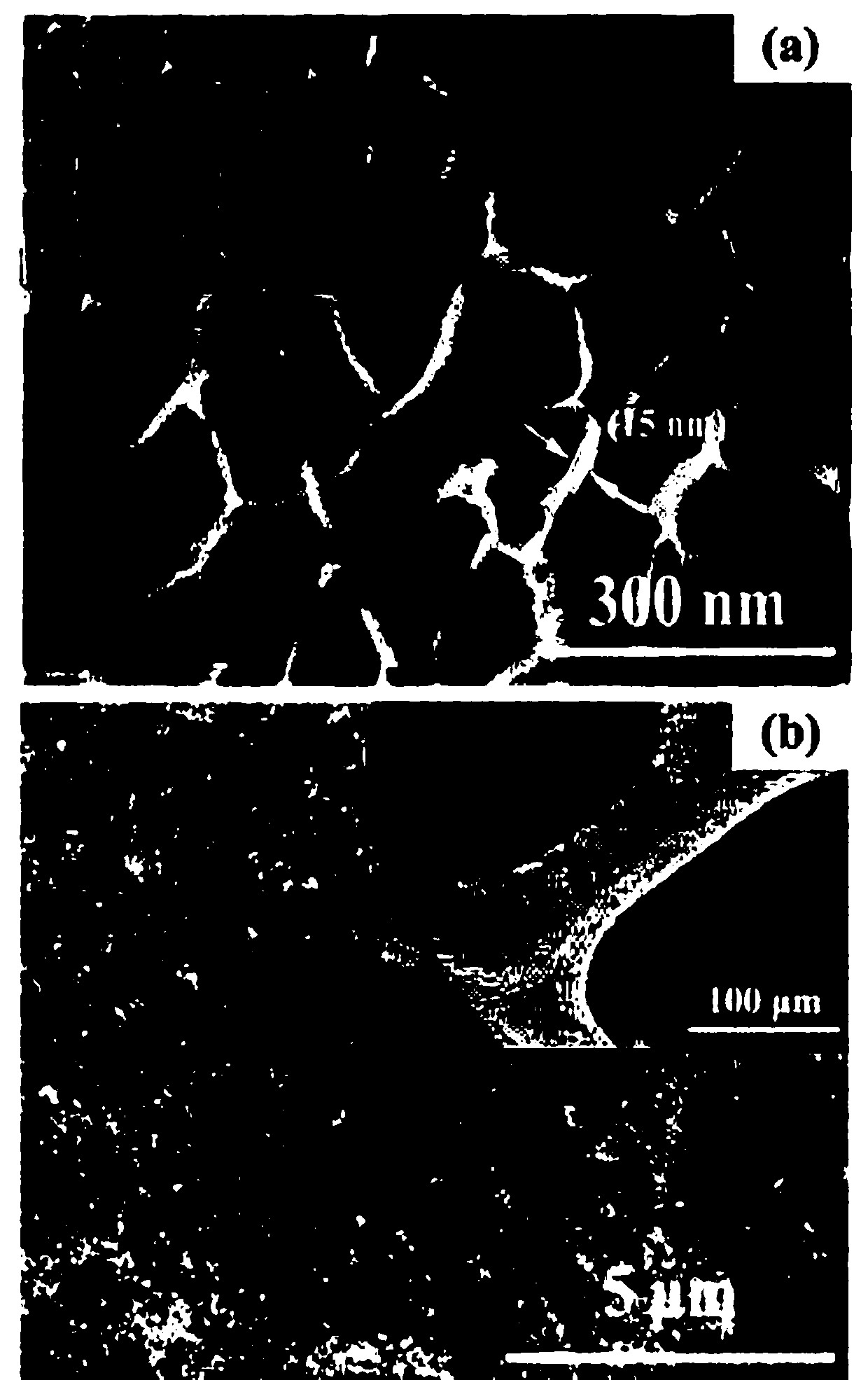

[0025] ③Add 40mL of 0.025mol / L Na 2 SeSO 3 solution, and then put the nickel foam treated in step ② into it, and after heating in water at 180°C for 12 hours, the reaction kettle was naturally cooled to room temperature, washed several times with absolute ethanol and deionized water, and vacuum-dried the sample to obtain Honeycomb NiSe nanosheet arrays.

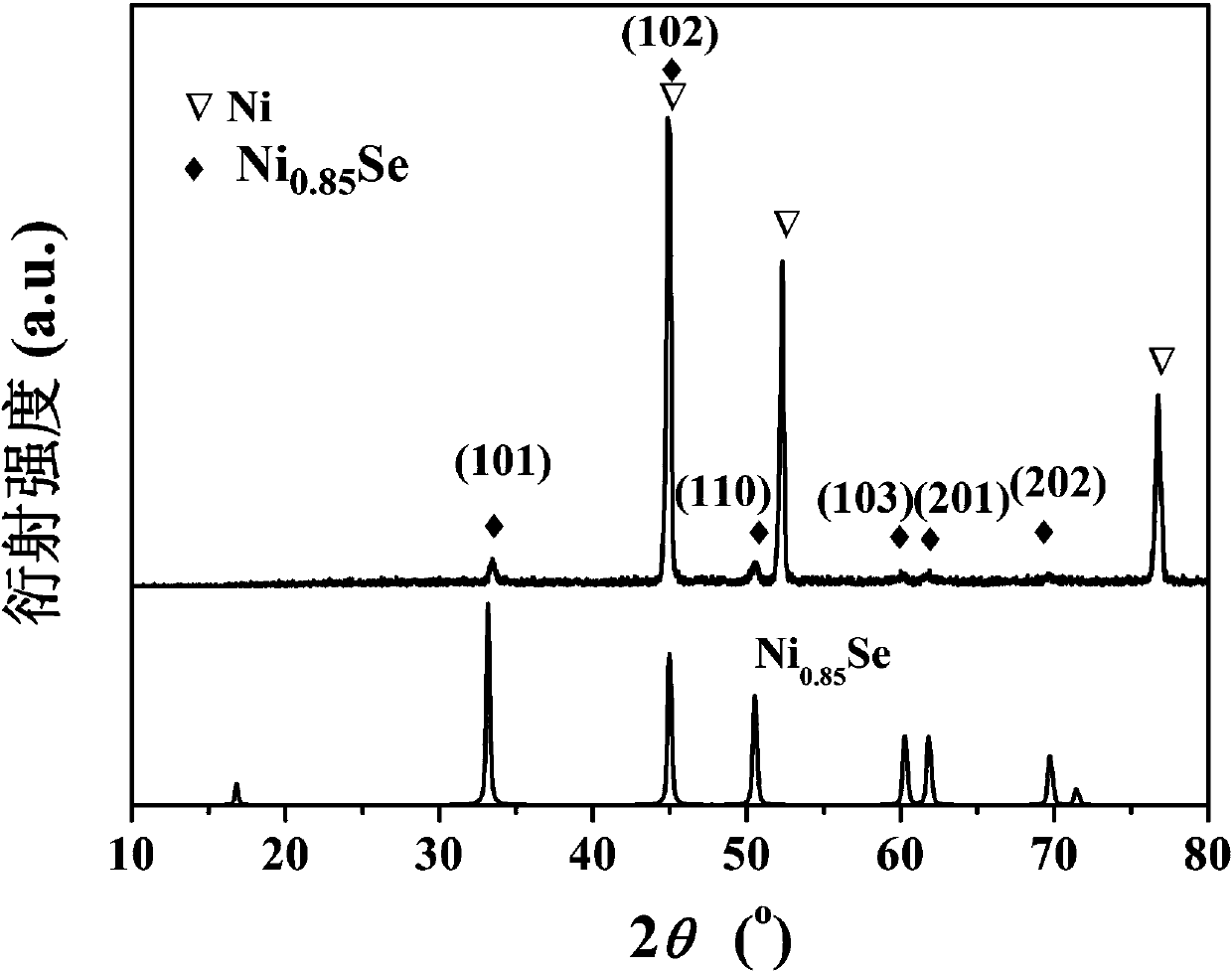

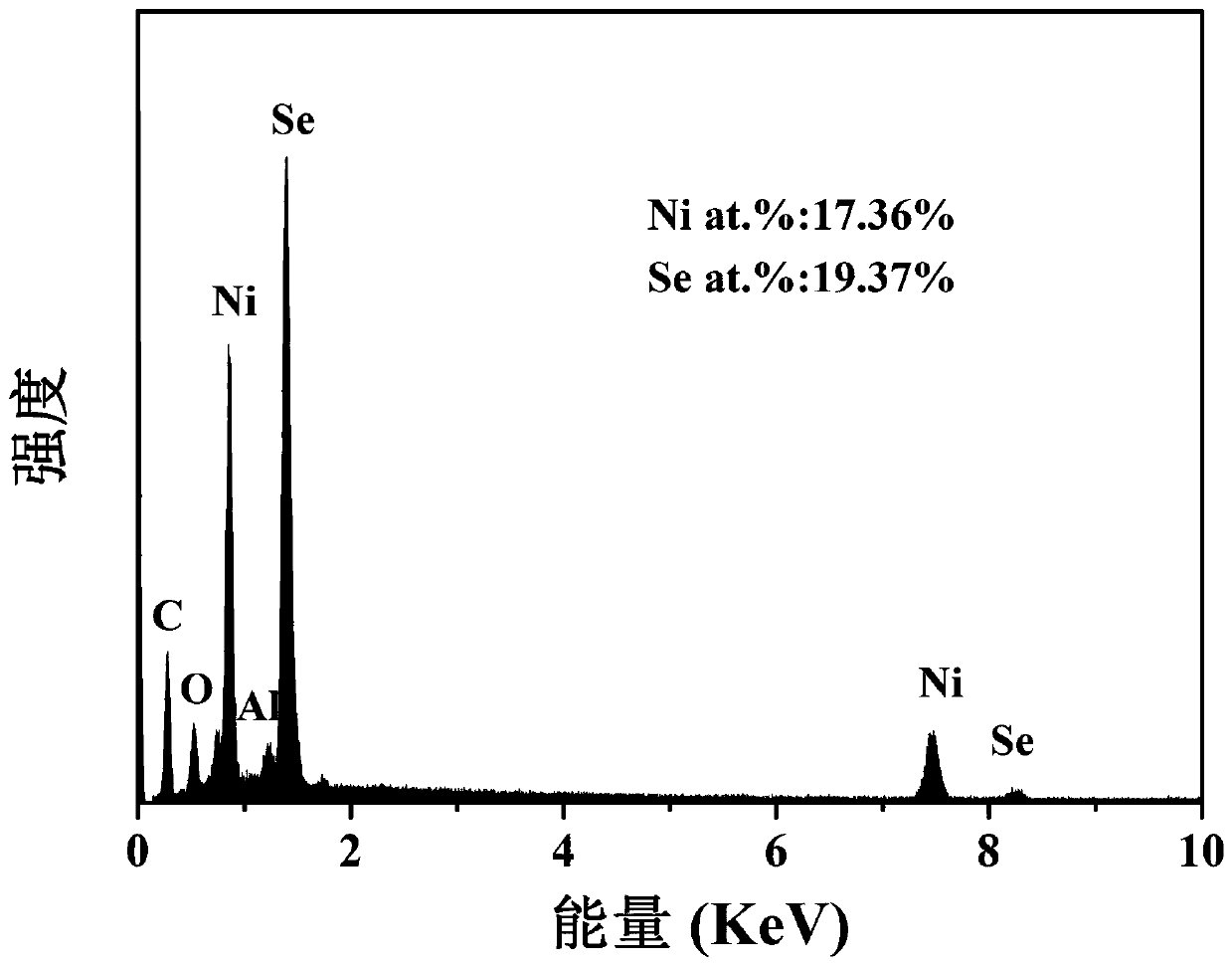

[0026] The X-ray dif...

Embodiment 2

[0028] ① Add 0.010mol of Se powder to 500mL of Na with a concentration of 0.1mol / L 2 SO 3 solution, stirred and heated to 120°C, refluxed for 6 hours until completely dissolved, and obtained Na with a concentration of 0.020mol / L 2 SeSO 3 solution.

[0029] ②Cut commercially available nickel foam into a size of 1×4cm, and ultrasonically treat it with 3mol / L hydrochloric acid for 30 minutes to remove oxides on the surface. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

[0030] ③Add 40mL of 0.020mol / L Na 2 SeSO 3 solution, and then put the nickel foam treated in step ② into it. After heating in water at 160°C for 12 hours, the reaction kettle was naturally cooled to room temperature, washed several times with absolute ethanol and deionized water, and vacuum-dried the sample to obtain a honeycomb NiSe nanosheet arrays.

[0031] The obtained honeycomb nickel selenide nanosheet arrays were directly used as working electrodes of s...

Embodiment 3

[0033] ① Add 0.0083mol of Se powder to 500mL of Na with a concentration of 0.1mol / L 2 SO 3 solution, stirred and heated to 110°C, refluxed for 6 hours until completely dissolved, and Na with a concentration of 0.017mol / L was obtained 2 SeSO 3 solution.

[0034] ②Cut commercially available nickel foam into a size of 1×4cm, and ultrasonically treat it with 3mol / L hydrochloric acid for 30 minutes to remove oxides on the surface. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

[0035] ③In a polytetrafluoroethylene liner autoclave with a volume of 50mL, move into the 0.017mol / L Na prepared in step ① 2 SeSO 3 solution 40mL, then put the nickel foam treated in step ② into it, heat it in water at 180°C for 24 hours, cool the reaction vessel to room temperature naturally, wash it with absolute ethanol and deionized water several times, and dry the sample in vacuum to obtain Honeycomb NiSe nanosheet arrays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com