C/Li2MSiO4-xNy/C (M=Fe, Mn, Co) composite positive electrode material for lithium ion battery and preparation method thereof

An ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of difficult two lithium ion deintercalation, low electron conductivity lithium ion diffusion rate, poor specific capacity performance and rate performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

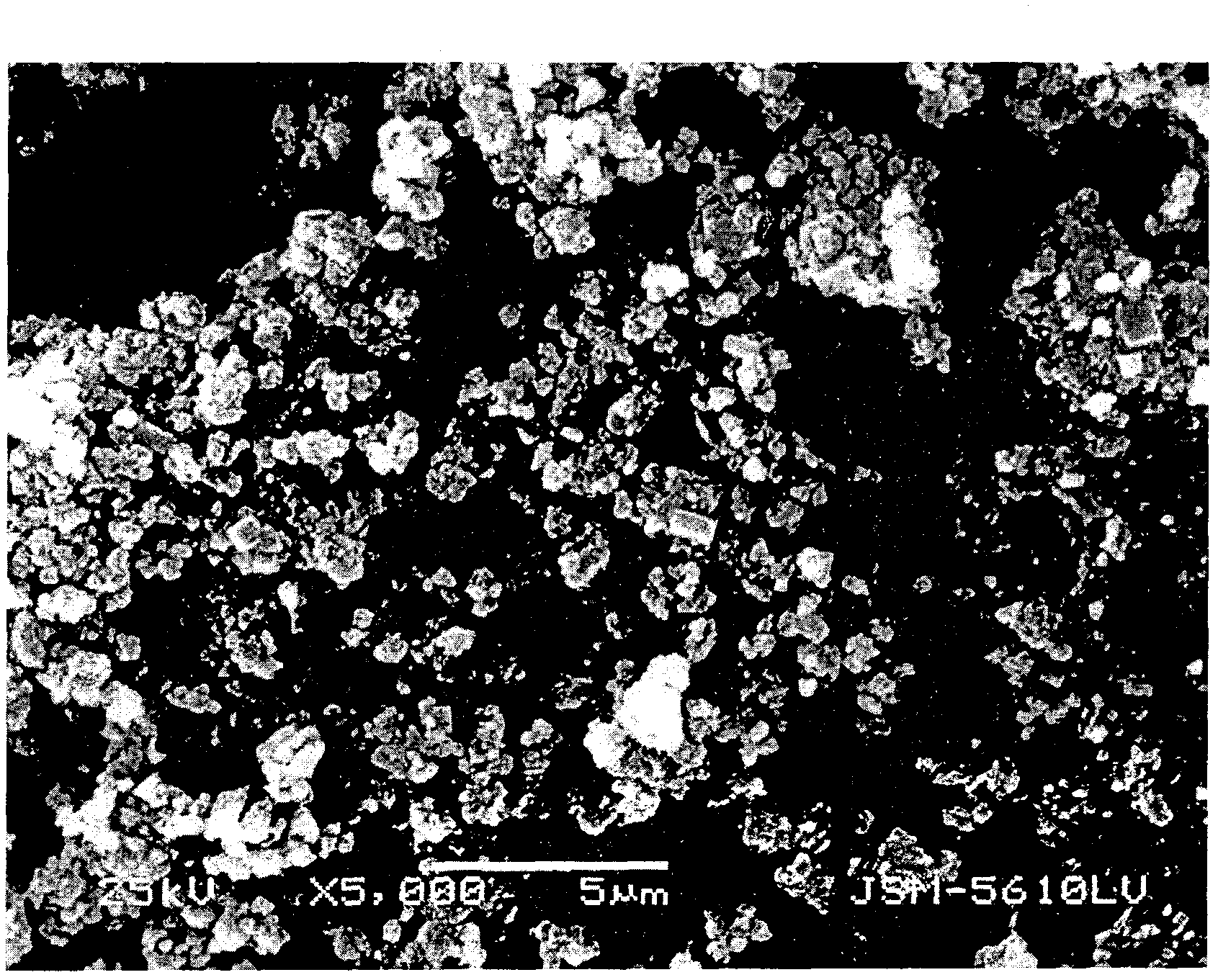

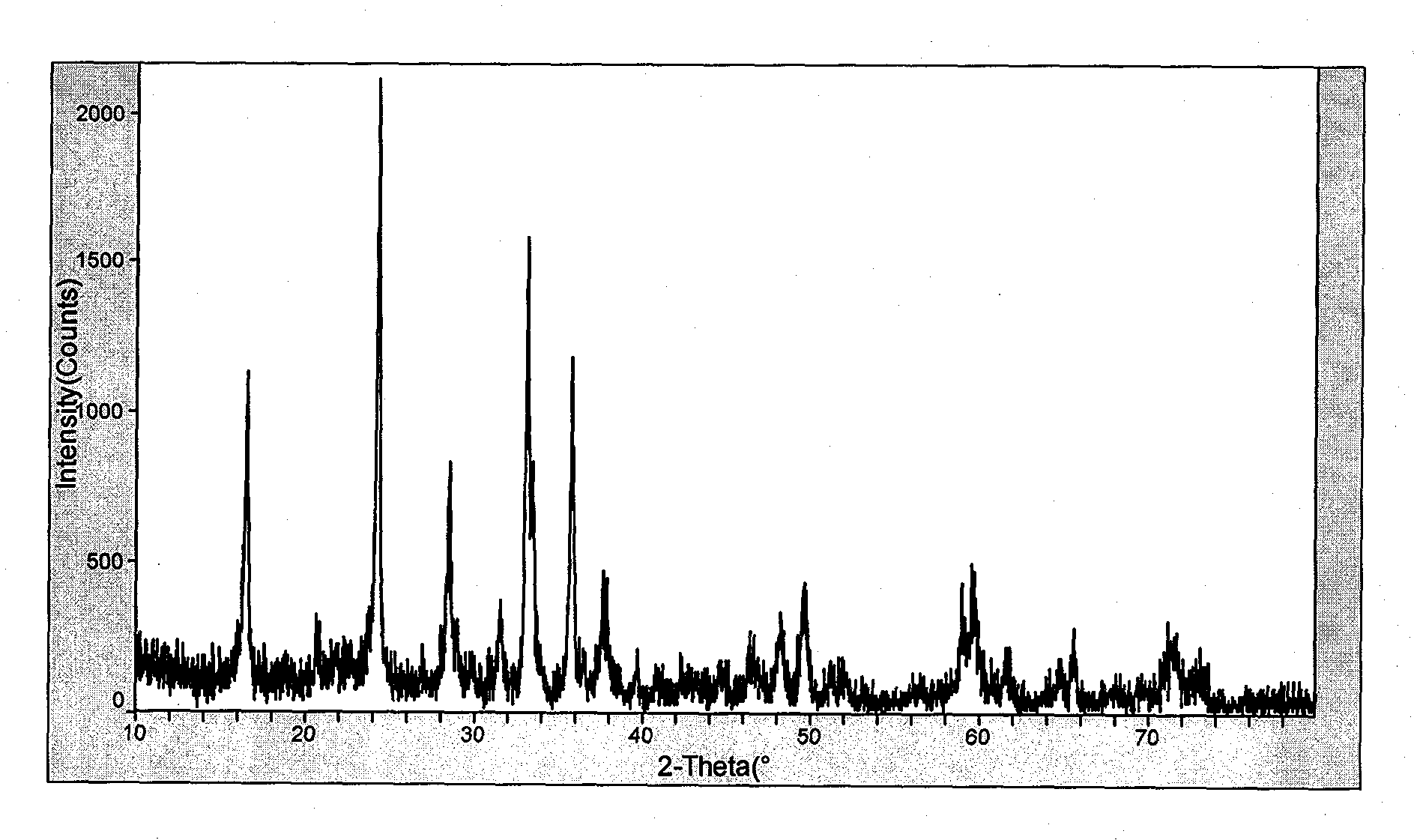

[0029] 2.0 grams of conductive activated carbon XC-72 was acid-treated for 24 hours, then washed with a solvent until neutral, dried at 120°C, ground and dispersed in 100ml of absolute ethanol. 20.4 g of LiAc· 2 h 2 O, 24.6 g FeAc 2 4H 2 O, 20.8 g Si(OC 2 h 5 ) 4 and 7.7 g CH 3 COONH 4 Dissolve in 200ml of absolute ethanol, and stir magnetically at room temperature for 24h. Then the dispersed porous carbon after the acid treatment was miscible with the metal ion solution, stirred at room temperature for 1-24 hours, then slowly raised to 100°C, and adjusted to a pH value of 13, magnetically stirred for 24 hours, and finally added 2 grams of glucose and stirred 1-24h, vacuum dried at 110°C. Transfer it to a porcelain boat in a tube resistance furnace under Ar / H 2 (H 2accounted for 3% of the volume), first heated to 450°C at a rate of 10°C / min for 12 hours, then cooled to room temperature at a rate of 10°C / min, took out the powder and pressed it into tablets, and then ...

Embodiment 2

[0032] 3.0 grams of conductive activated carbon acetylene black was acid-treated for 24 hours, then washed with a solvent until neutral, dried at 120°C, ground and dispersed in 100ml of absolute ethanol. 19.8 g MnCl 2 4H 2 O, 20.4 g LiAc 2H 2 O, 20.8 g Si(OC 2 h 5 ) 4 and 7.7 g CH 3 COONH 4 Dissolve in 200ml of absolute ethanol, and stir magnetically at room temperature for 24h. Then the above-mentioned acid-treated dispersed porous carbon is miscible with the metal ion solution, stirred at room temperature for 24 hours, then slowly heated to 80°C, and adjusted to a pH value of 12, magnetically stirred for 12 hours, and finally 1 gram of sucrose was added and stirred for 12 hours, Dry under vacuum at 100°C. Transfer it to a porcelain boat in a tube resistance furnace under Ar / H 2 (H 2 accounted for 3% of the volume), first heated to 450°C at a rate of 10°C / min for 12 hours, then cooled to room temperature at a rate of 10°C / min, took out the powder and pressed it into...

Embodiment 3

[0035] 1.0 grams of conductive activated carbon BP2000 was treated with acid for 24 hours, then washed with solvent until neutral, dried at 110°C, ground and dispersed in 100ml of absolute ethanol. 28.1 g CoSO 4 ·7H 2 O, 20.4 g LiAc 2H 2 O, 20.8 g Si(OC 2 h 5 ) 4 and 7.7 g CH 3 COONH 4 Dissolve in 200ml of absolute ethanol, and stir magnetically at room temperature for 8h. Then the dispersed porous carbon after the above acid treatment was miscible with the metal ion solution, stirred at room temperature for 12 hours, then slowly heated to 100°C, and adjusted to a pH value of 11, magnetically stirred for 6 hours, and finally added 3 grams of asphalt and stirred for 12 hours, Dry under vacuum at 100°C. Transfer it to a porcelain boat in a tubular resistance furnace in Ar, first heat it to 450°C at a rate of 10°C / min for 12 hours, then cool it down to room temperature at a rate of 10°C / min, take out the powder and press it into a tablet, and then Calcined at 800 °C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com