Self-doped nano composite photothermal conversion coating and preparation method thereof

A light-to-heat conversion and nano-composite technology, which is applied in coatings, metal material coating processes, ion implantation plating, etc., can solve problems such as unfavorable industrial production, complex preparation process of light-to-heat conversion coatings, and increased preparation costs. Achieve the effects of enhancing light absorption efficiency, good adhesion, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

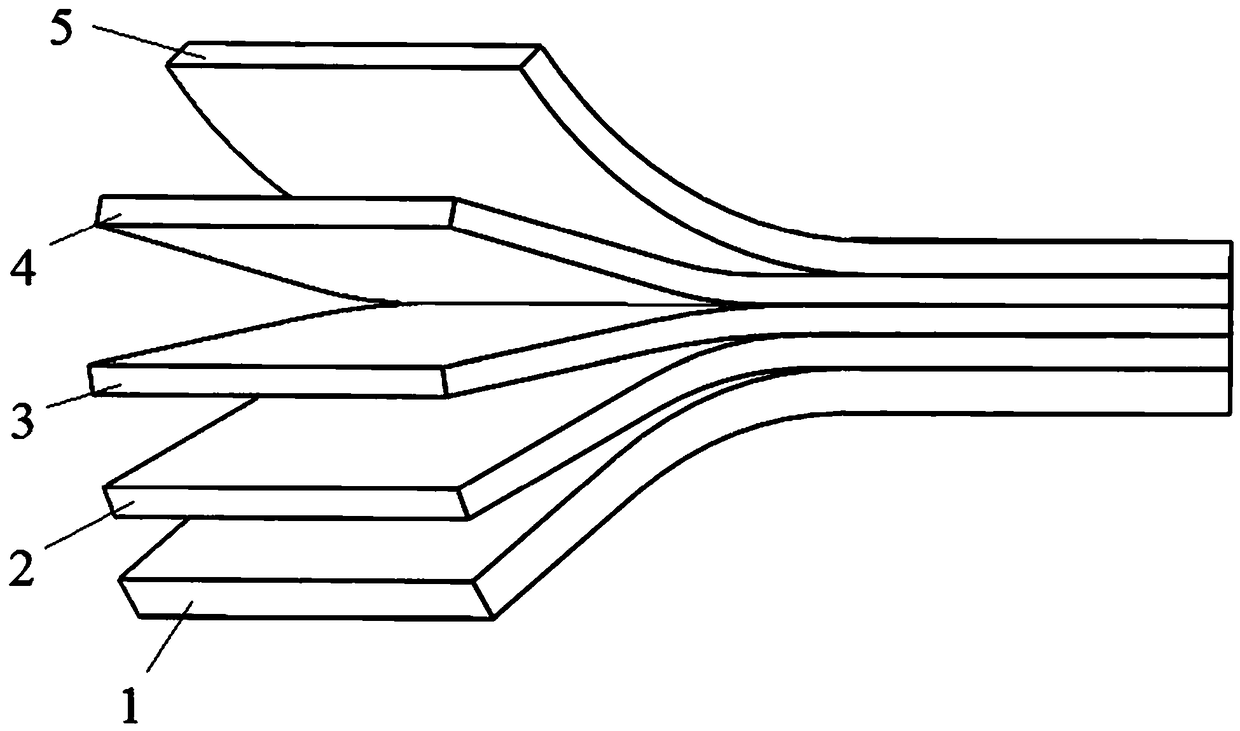

[0029] Such as figure 1 As shown, a self-doping nanocomposite light-to-heat conversion coating provided by the present invention includes a substrate 1, a diffusion barrier layer 2, a self-doping high-absorbing layer 3, a self- The low absorption layer 4 and the antireflection layer 5 are doped.

[0030] The substrate 1 is a substrate with infrared reflection function, and the material of the substrate 1 is stainless steel, aluminum, copper or glass, specifically, it can be aluminum sheet, copper sheet, stainless steel (316L, 304) or glass sheet.

[0031] The diffusion barrier layer 2 is a metal tungsten layer with a thickness of 30-100nm; the melting point of metal tungsten is very high, its chemical properties are stable, its infrared emission rate is high, and it has good adhesion to the metal as the substrate 1, ensuring The stability of the coating structure; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com