Patents

Literature

135results about How to "High infrared emissivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

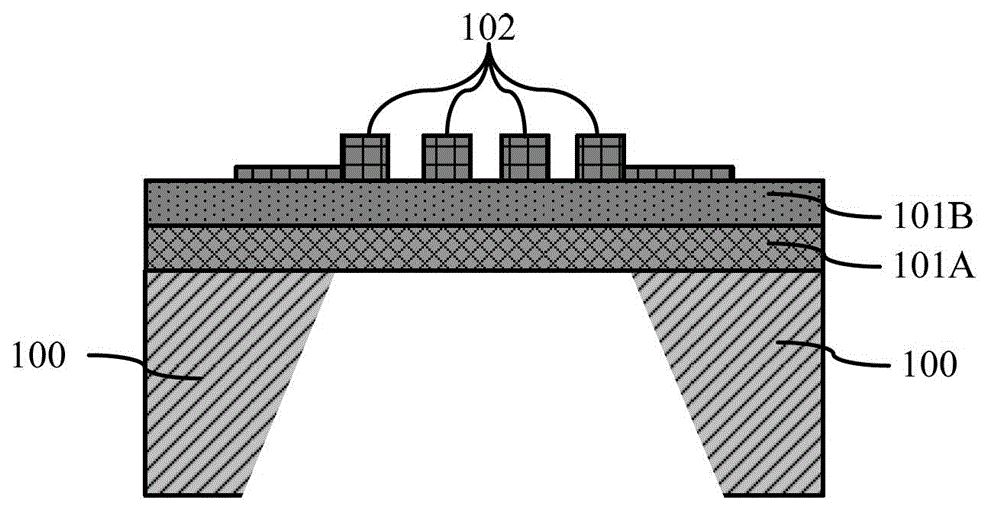

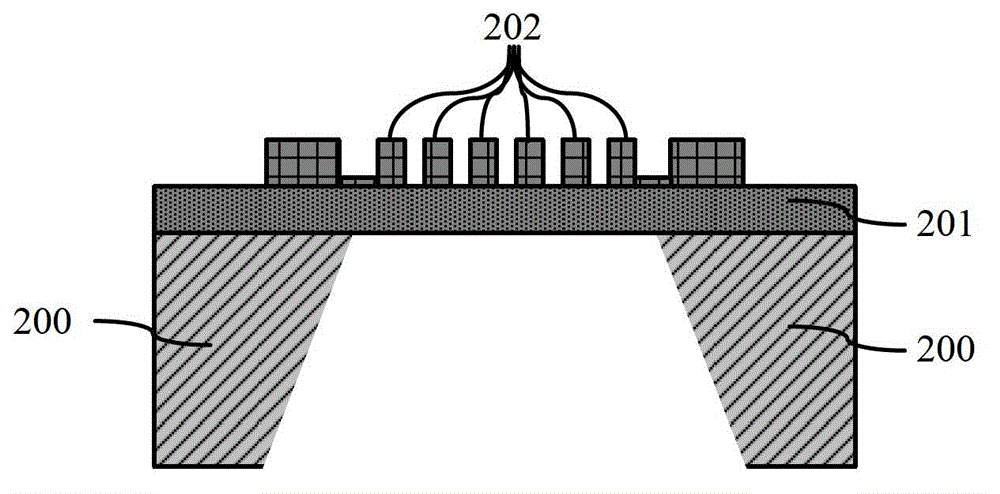

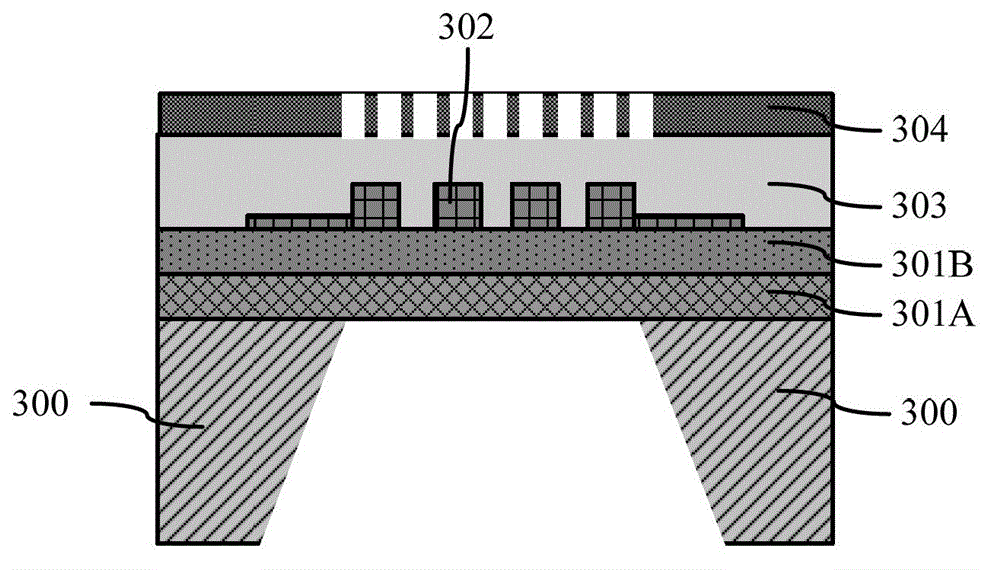

Electromodulation MEMS infrared source and fabrication method thereof

InactiveCN103332648AStable structureImprove work performanceDecorative surface effectsSolid-state devicesElectricityWork performance

The invention relates to the technical field of infrared and discloses an electromodulation MEMS (Micro-electro-mechanical Systems) infrared source and fabrication method thereof. According to the infrared source and the method, a four-side fixed support structure is adopted, heating electrodes fixed on a support film are used for generating external infrared radiation energy, so that the electromodulation MEMS infrared source is secure in structure, stable in working performance, and high in duty ratio, a fabrication technology is simple, the cost is low, and massive production with low cost is realized.

Owner:NANJING MOMANSI ELECTRONICS TECH

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

Radiation cooling passive cooling fabric and preparation method thereof

PendingCN111155332AReduce absorptionImprove Radiative Cooling PerformanceFibre typesCoatingsFiberMaterials science

The invention discloses a radiation cooling passive cooling fabric and a preparation method thereof, and belongs to the technical field of textile. The radiation cooling passive cooling fabric sequentially comprises an infrared high emission top layer, a sunlight low absorption fabric layer and a sunlight high reflection bottom layer from top to bottom; the infrared high emission top layer is 0.5-0.9 in emissivity on infrared light with the wavelength of 8-13[mu]m; the sunlight low absorption fabric layer is 0.3-0.9 in sunlight emissivity; the sunlight high reflection bottom layer is 0.5-0.9 in sunlight emissivity; and the sunlight low absorption fabric layer is woven by fibers, wherein the cross sections of the fibers are triangular. According to the fabric, through synergic matching of three layers, a high infrared emissivity and strong sunlight reflectivity effect is realized in daytime, and the radiation cooling performance of the material in daytime is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

High-infrared-radiance insulating heat conduction adhesive and preparing method thereof

ActiveCN105602485AImprove thermal conductivityLarge specific surface areaNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRadianceAdhesive

The invention discloses a high-infrared-radiance insulating heat conduction adhesive. The high-infrared-radiance insulating heat conduction adhesive comprises, by mass, 10%-60% of matrix resin materials, 10%-70% of thinning agent, 1%-10% of surface treating agent, 1%-10% of curing agent, 0.1%-1% of accelerant and 10%-60% of functional filler. According to the high-infrared-radiance insulating heat conduction adhesive, high-infrared-radiance tourmaline nanometer particles are applied to the insulating heat conduction adhesive for the first time, the high-infrared-radiance insulating heat conduction adhesive has the insulation characteristic, the heat-conduction characteristic and the infrared-radiation characteristic at the same time accordingly, and the whole heat dissipation performance of a composite material is improved; the prepared adhesive can be widely applied to the fields of electronic products and related insulation heat conduction.

Owner:铠博新材料(天津)有限公司

Preparing method of nanometer titanium oxide modified hollow glass beads

ActiveCN105820602AHigh infrared emissivityGood effectPigment flushingEpoxy resin coatingsReaction temperatureTitanium oxide

The invention relates to the field of composite materials, in particular to a preparing method of brand-new nanometer titanium oxide modified hollow glass beads. The obtained hollow glass beads have excellent heat reflecting performance. By controlling technological parameters of concentration of tetrabutyl titanate in a precursor, reaction temperature and time and the dispersant amount, the modified technology of the hollow glass beads is optimized, and the method is easy and convenient to operate. Test results show that the hollow glass beads modified by nanometer titanium oxide particles have low heat conductivity coefficient and high heat reflectivity and can meet the actual needs.

Owner:QINGDAO UNIV OF SCI & TECH

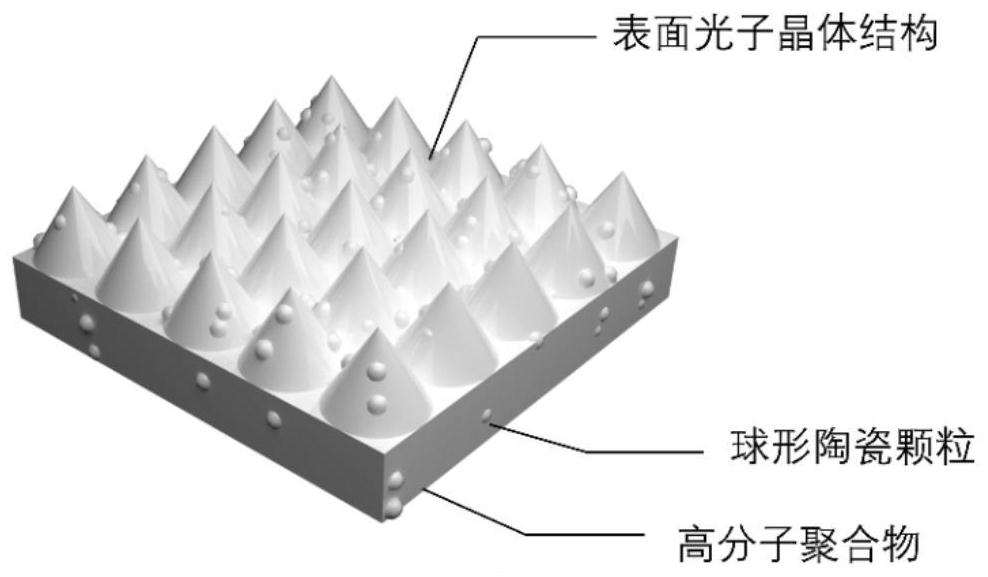

Radiation cooling film and preparation method and application thereof

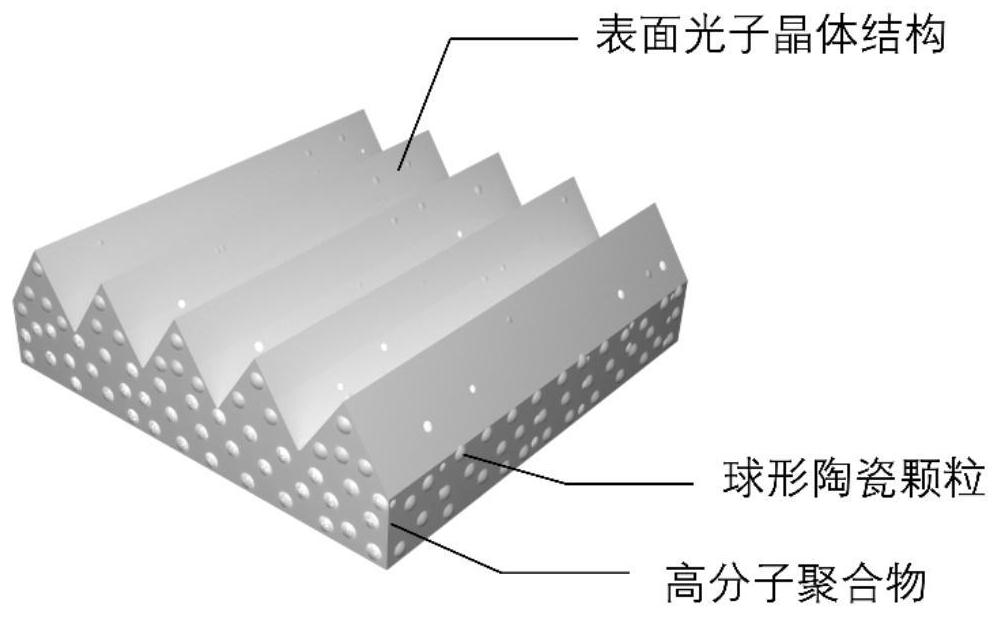

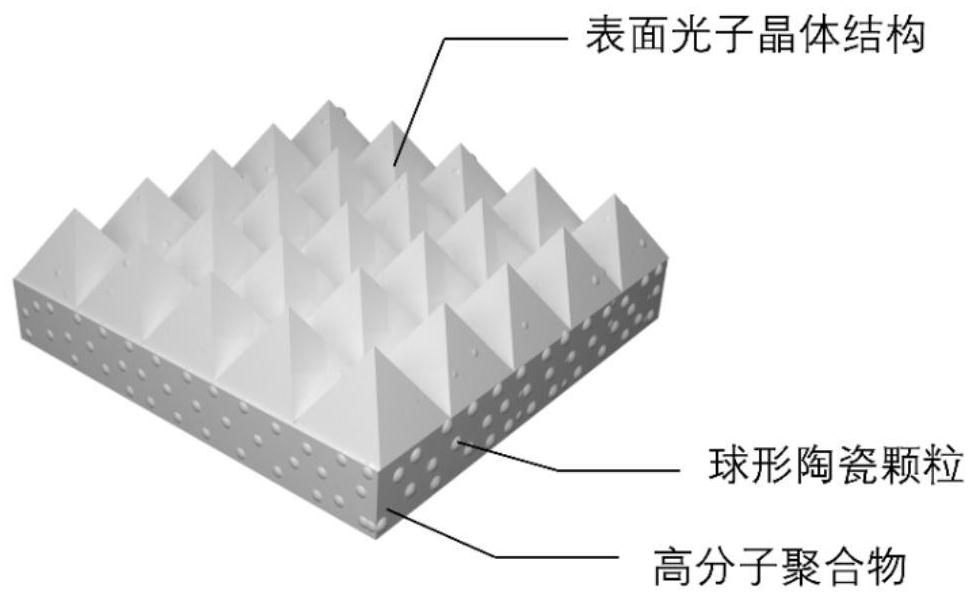

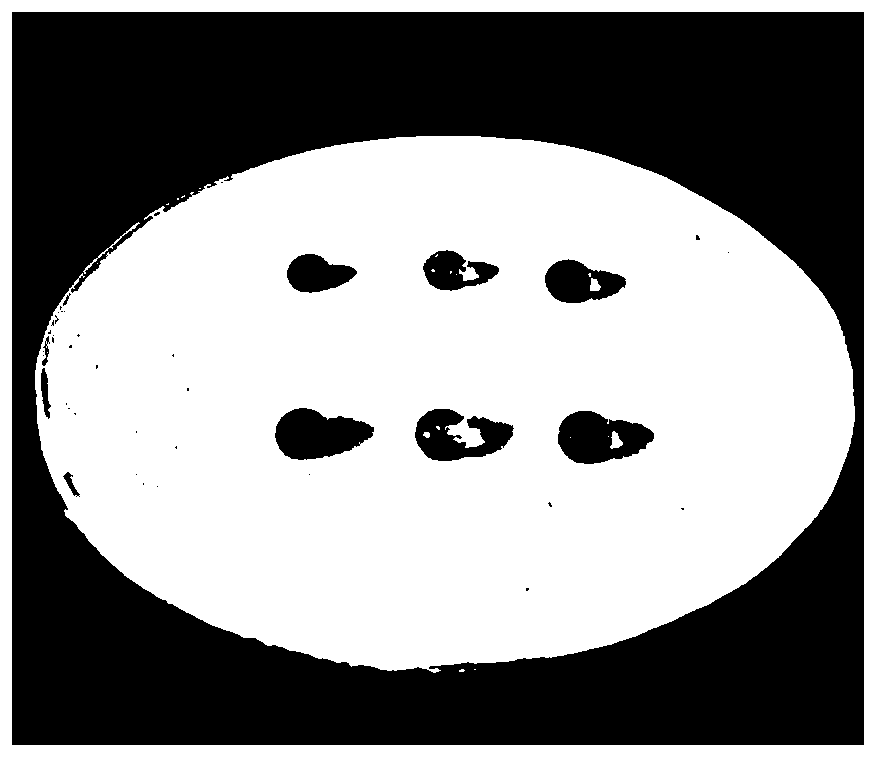

The invention discloses a radiation cooling film which is formed by mixing ceramic particles, an organic solution and a curing agent, mixing the ceramic particles with an organic curing precursor solution, and curing, a micro-nano photon structure array is formed on the surface of the film, and the micro-nano photon structure array comprises a plurality of arrayed micro-nano photon structure elements. The invention further discloses a preparation method and application of the radiation cooling film. The film has the reflectivity of 95% in the sunlight band and the radiance of 96% in the atmospheric window band, can be lower than the ambient environment by 10 DEG C at most under the illumination condition, and also has good flexibility and strength and excellent hydrophobicity. The radiation cooling film is prepared in a low-cost and large-area manner by adopting a multi-etching double-spin-coating vacuum thermocuring process. The radiation cooling film is applied to the aspects of human body wearable cooling, cooling umbrellas and device heat dissipation, and a cooling method is achieved by removing heat from the surface and the interior of a main body in a heat radiation mode.

Owner:SHANGHAI JIAO TONG UNIV

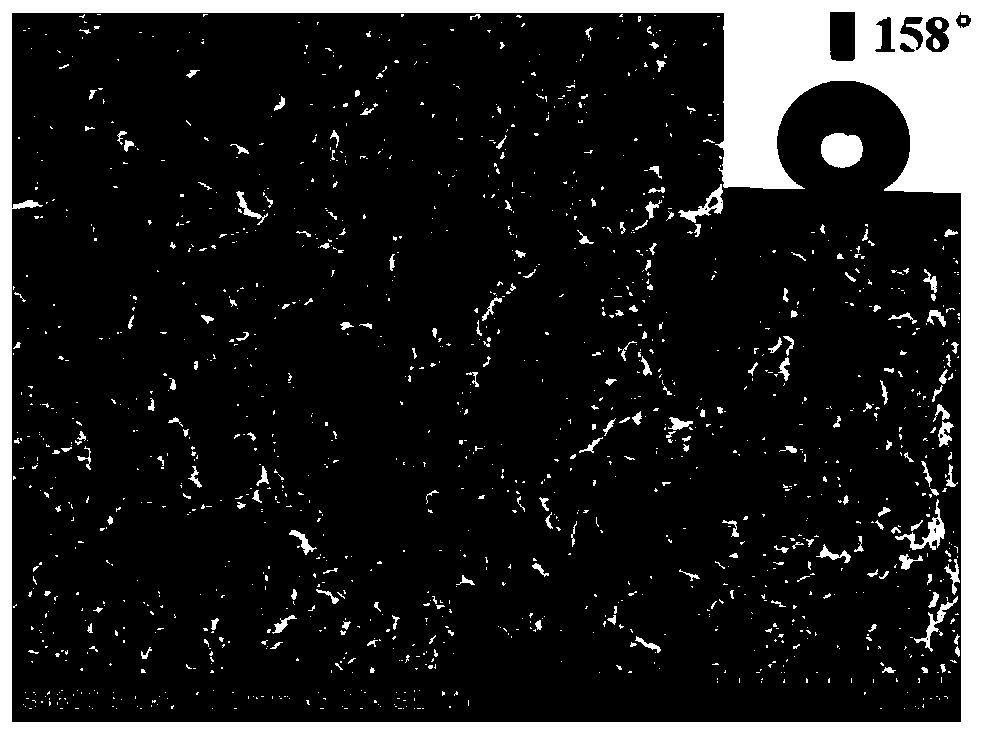

Super-hydrophobic self-cleaning radiation cooling film and preparation method thereof

ActiveCN110483924AMild conditionsLow surface energy propertiesFlat articlesCoatingsNon solventMicro nano

The invention discloses a super-hydrophobic self-cleaning radiation cooling film and a preparation method thereof. The preparation method comprises the following steps: dissolving P (VDFx-Co-HFPy) andPDMS in a composite polar solvent to form a P (VDFx-Co-HFPy) / PDMS polymer composite semitransparent solution; dropwise adding a non-solvent into the solution to enable P (VDFx-Co-HFPy) / PDMS to be subjected to phase separation to form sol; and casting and drying the sol to obtain the film with the micro-nano dual porous structure. The preparation process is simple, the method is easy to implement,and large-area production can be achieved.

Owner:SHAANXI UNIV OF SCI & TECH

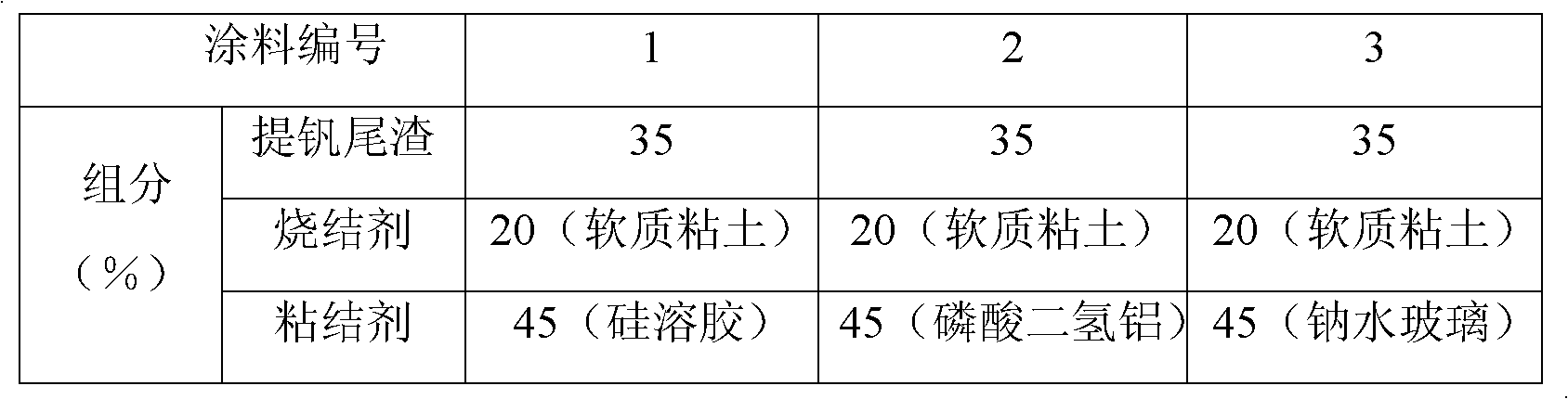

Anti-oxidation decarburized coating in process of billet rolling and preparation method thereof

InactiveCN101857452AGood porcelainReduce oxidation rate and carbon lossOxidation rateMetallic materials

The invention belongs to the technical field of inorganic non-metal materials, and in particular relates to an anti-oxidation decarburized coating in the process of billet rolling and a preparation method thereof. The invention provides a low-cost and good-performance anti-oxidation decarburized coating in the process of billet rolling, which comprises the following raw materials in parts by weight: 20-60 parts of vanadium extraction tailings, 0-40 parts of agglutinant and 30-60 parts of binding agent. The coating is used in the process of billet rolling, can effectively reduce the oxidation rate and carbon loss of billets and can improve the heating efficiency of a heating furnace for the billets. The preparation method is a solution to the problem of pollution of vanadium extraction tailings, and can reduce the production cost of the anti-oxidation decarburized coating by changing the tailings into valuables.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

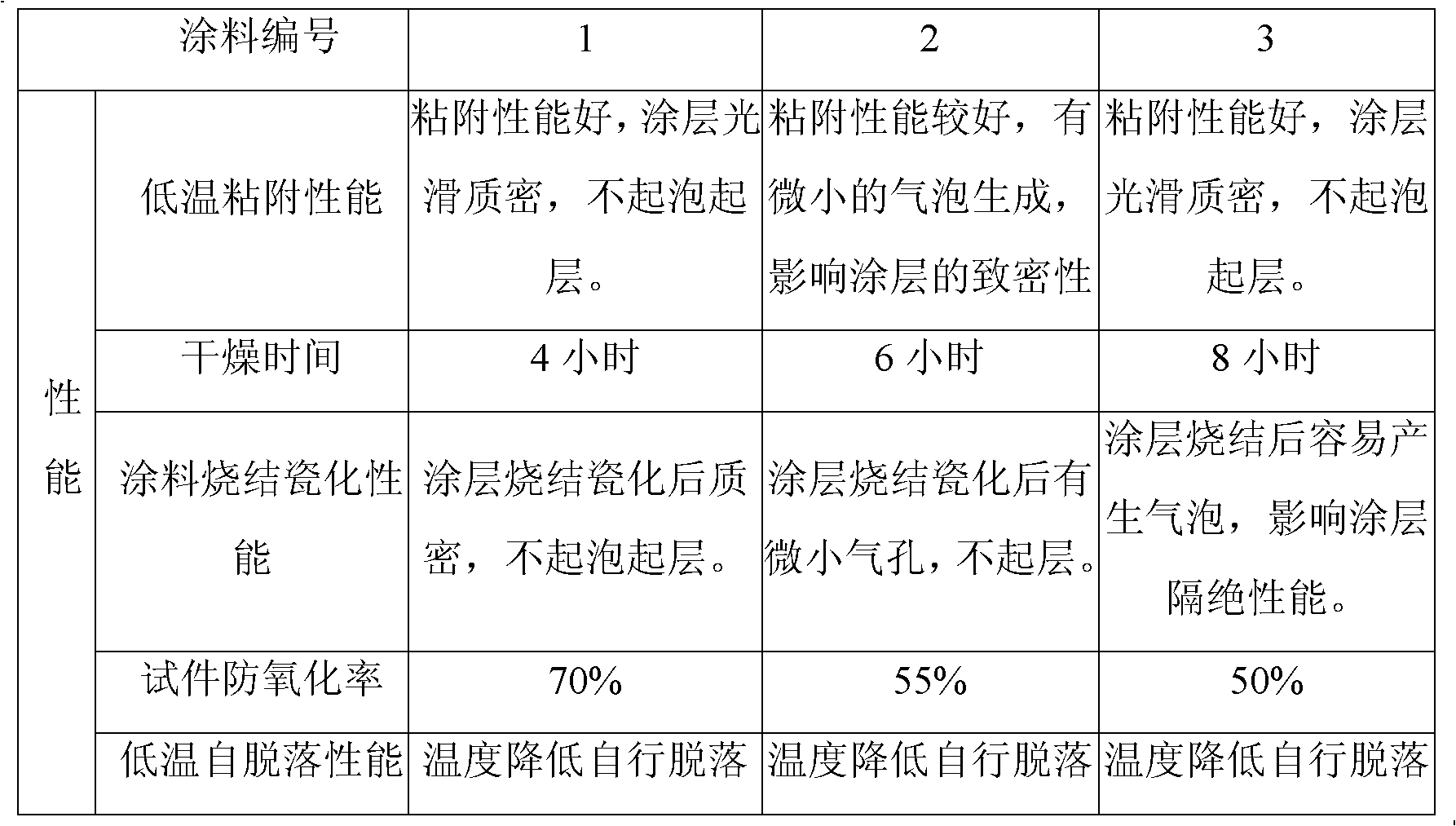

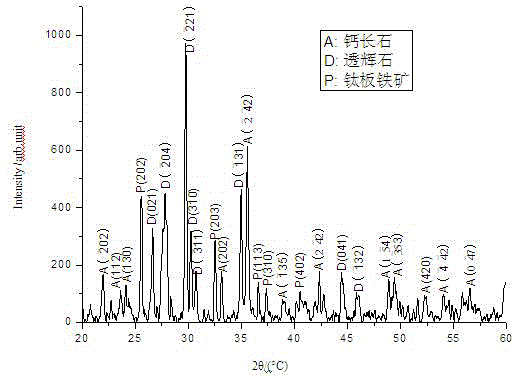

Iron tailing far-infrared ceramic material and preparation method thereof

The invention discloses an iron tailing far-infrared ceramic material and a preparation method thereof. The ceramic material is characterized by being prepared from the following components in percentage by weight: 35-75% of iron tailings, 1-9% of clay, 11-25% of silicon dioxide, 11-25% of calcium carbonate and 2-6% of aluminum oxide, wherein the sum of the percentage of the components is 100%; the iron tailing comprises the following main components: 30-35% of SiO2, 20-25% of Fe2O3, 10-15% of Al2O3, 10-15% of TiO2 and a small amount of CaO, Na2O and MgO, and the sum of percentage of the components is 100%; XRD shows that the main components of the ceramic material are anorthite, diopside and titanium sheet iron ore. According to the preparation method, the iron tailing, the clay, silicon dioxide, calcium carbonate and aluminum oxide are used as raw materials, and are subjected to ball-milling, screening, allocation, stirring, drying, mixing, dry pressing forming and sintering, thereby preparing the iron tailing far-infrared ceramic material.

Owner:南京中蓝智能科技有限公司

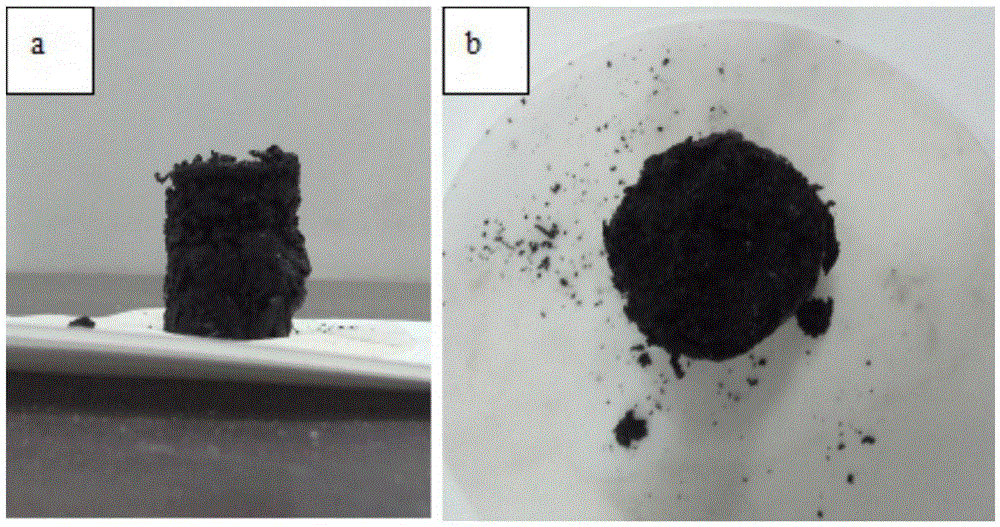

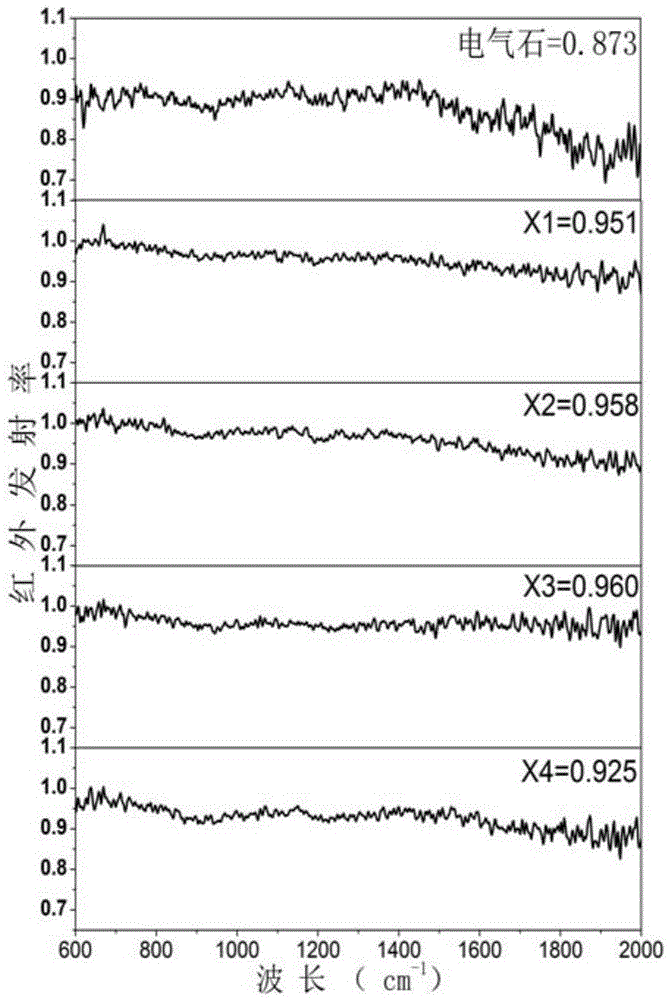

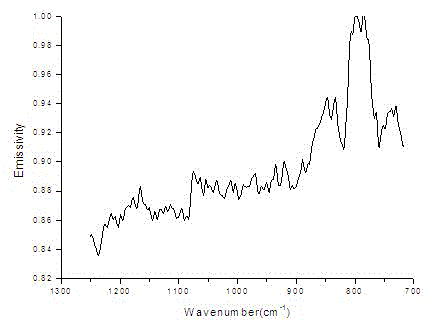

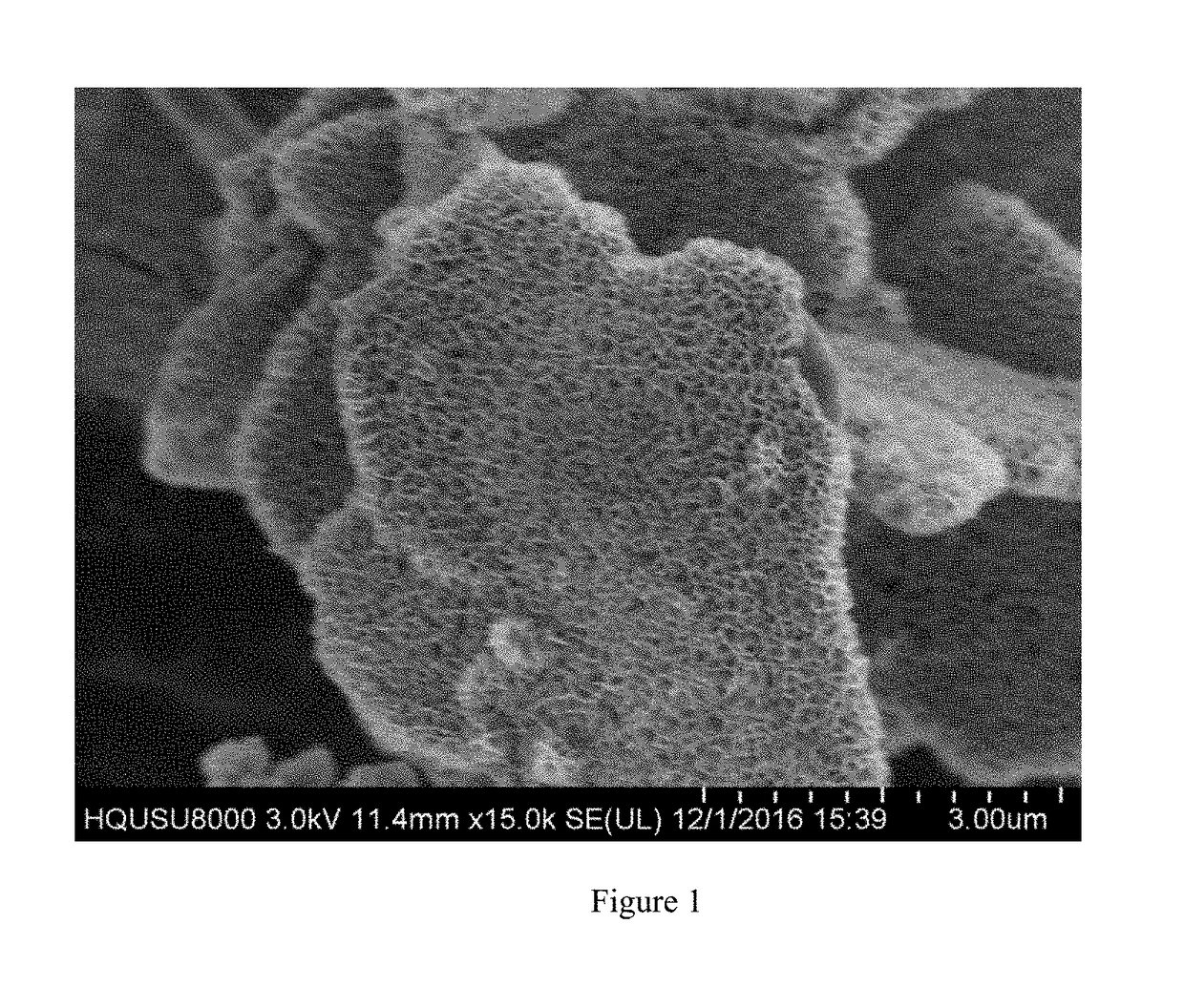

METHOD FOR PREPARING GRAPHENE/MnO2 POROUS MATERIAL HAVING HIGH INFRARED EMISSIVITY

InactiveUS20180320067A1Easy to getHigh far-infrared emissivityLuminescent compositionsCvd graphenePotassium permanganate

A method for preparing a graphene / MnO2 porous material having a high infrared emissivity; the method adopts graphene and potassium permanganate as raw materials, and uses a simple ultrasonic dispersion method to uniformly disperse the graphene and the potassium permanganate in the water solution; subsequently, the graphene / MnO2 porous material can be obtained through the hydrothermal reaction; the present invention is simple and easy-operating, and the infrared emissivity of the porous material prepared according to the method of the present invention is 0.94-0.98 at a distance of 8-14 μm, which is stable, eco-friendly, and can be widely applied to far-infrared products.

Owner:DING AIE +2

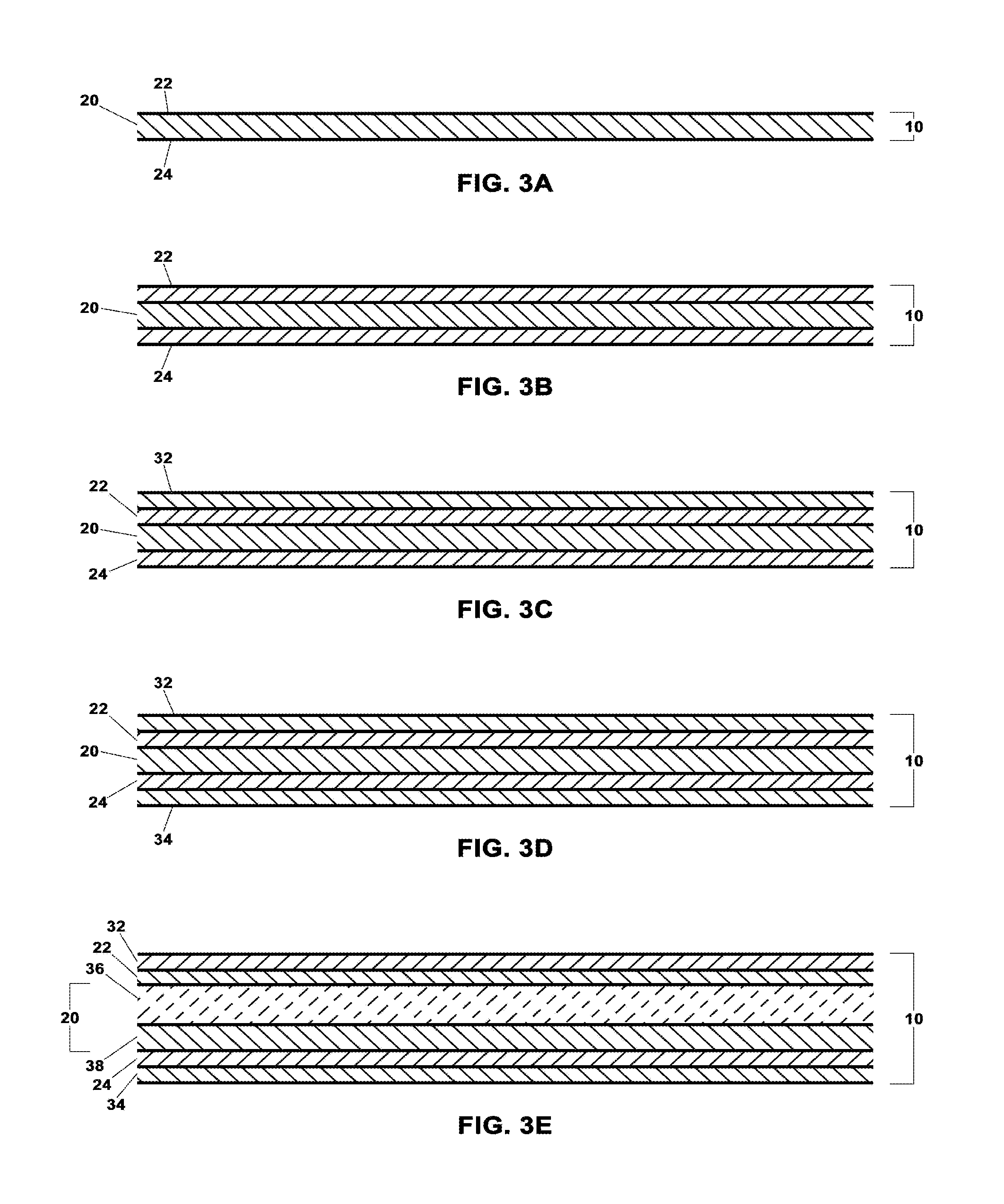

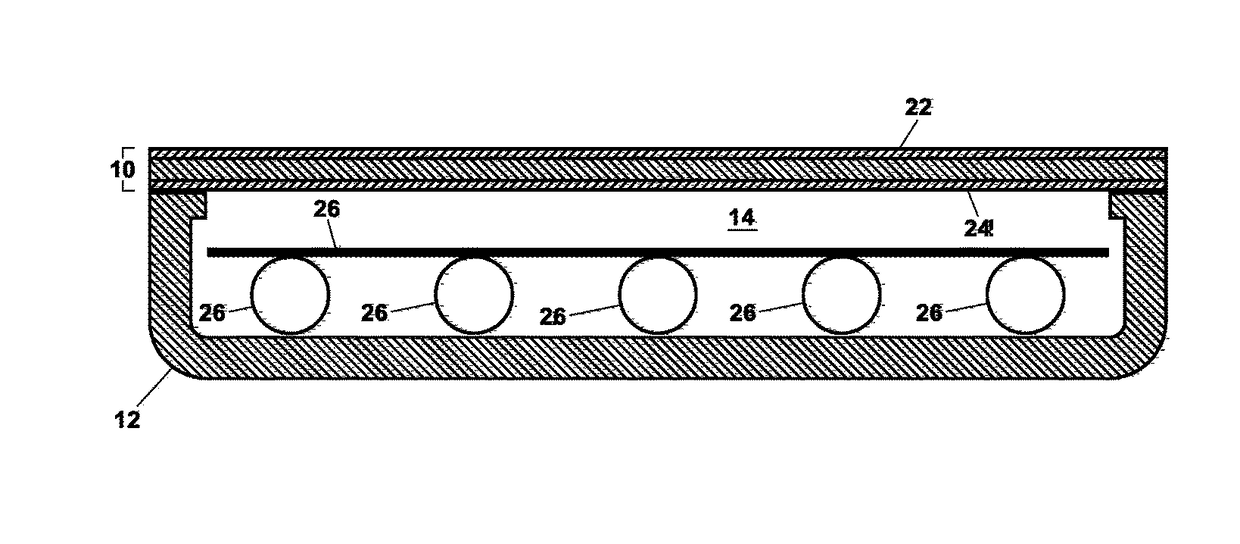

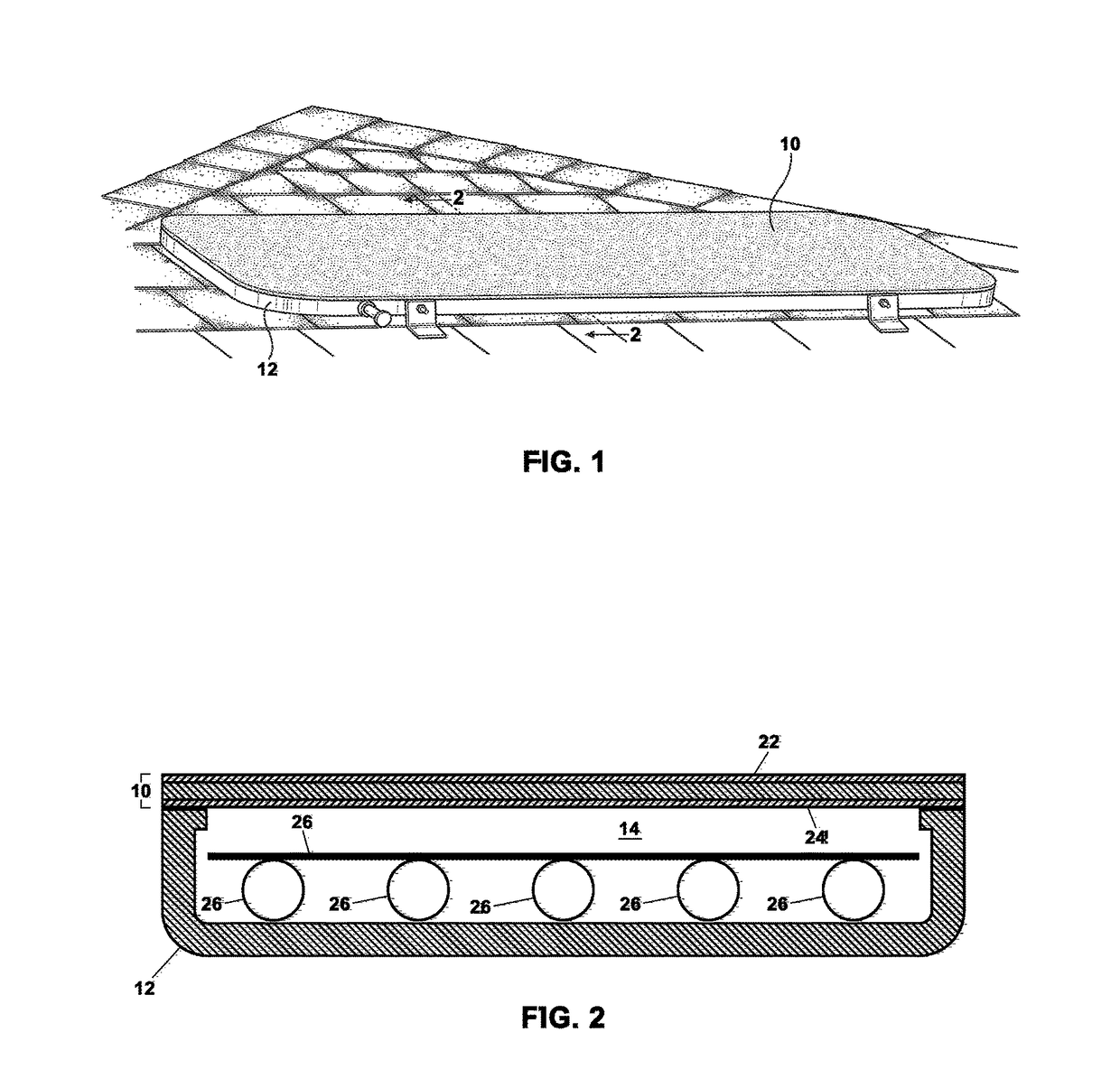

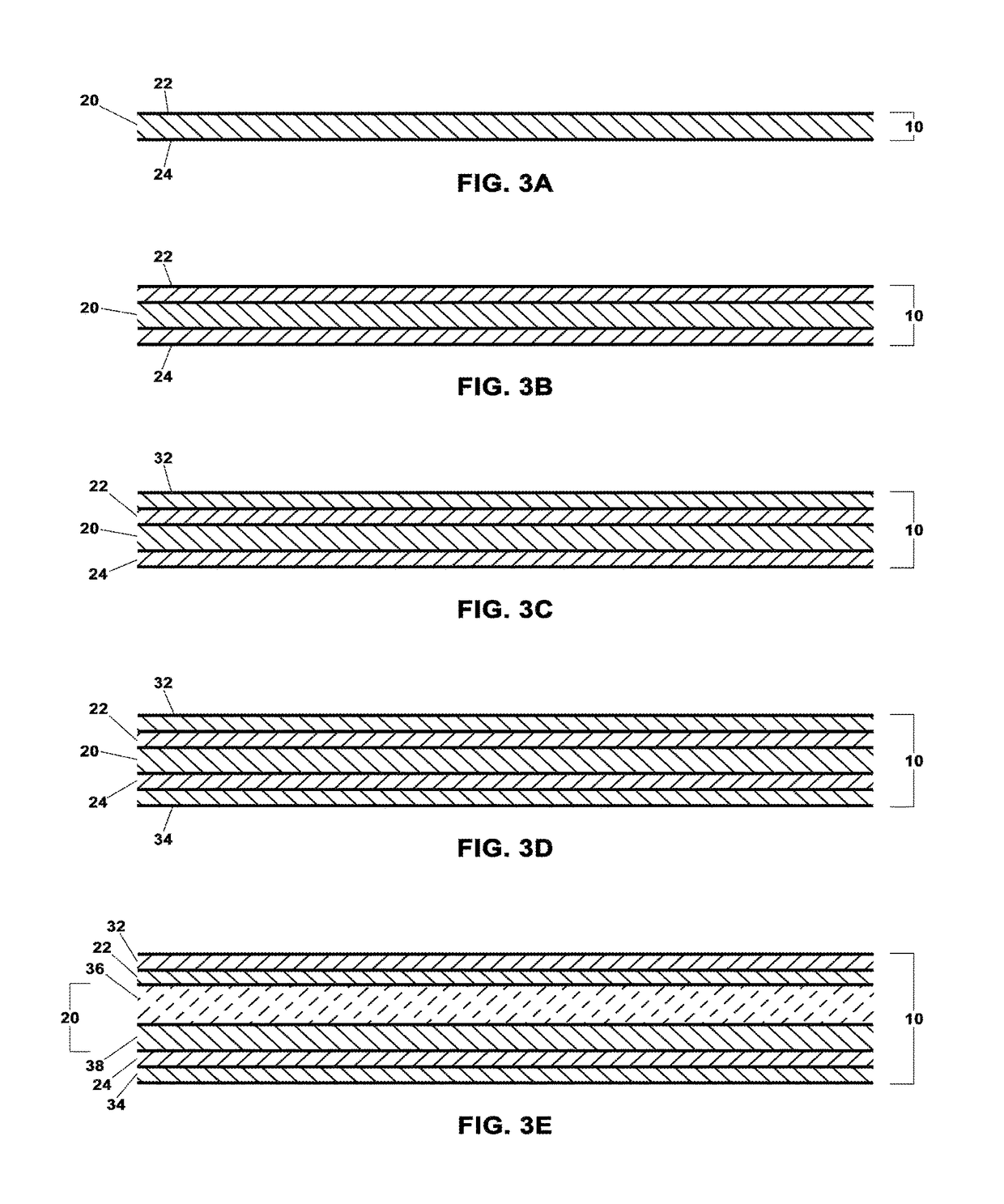

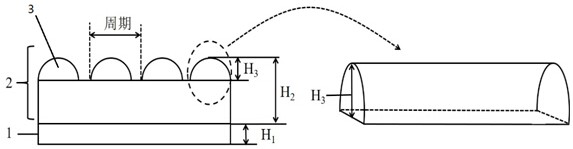

Solar collector comprising an opaque cover

ActiveUS20140305425A1High solar energyHigh energySolar heating energySolar heat devicesAbsorptanceHeat flow

A solar collector has an opaque cover heated by solar energy. Heat flows from the opaque cover by conduction, convection, and infrared emittance across a gap within an at least substantially airtight enclosure to an absorber containing a working fluid. The exterior surface of the opaque cover has high solar energy absorptance and the interior surface has high infrared emittance. The exterior surface preferably has low infrared emittance. In one embodiment, fully wetted surface geometry permits direct and reflected infrared absorption by the absorber. The opaque cover eliminates the weight, cost and other shortcomings of glass. A hollow continuous side wall with rounded corners provides an embodiment that is robust yet economical, that is easy to manufacture and seal, that permits a reduced thickness of the opaque cover and mitigates the destructive potential of severe winds, and that can withstand the compressive forces experienced by an evacuated solar collector.

Owner:PRUTSMAN JEFFREY D +1

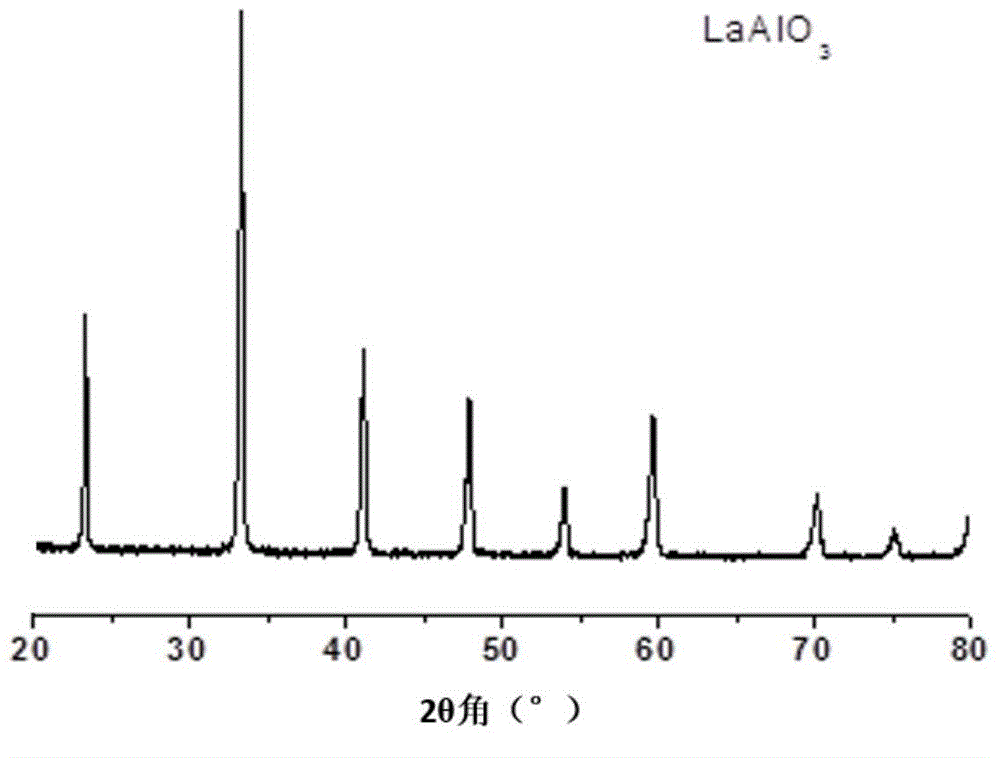

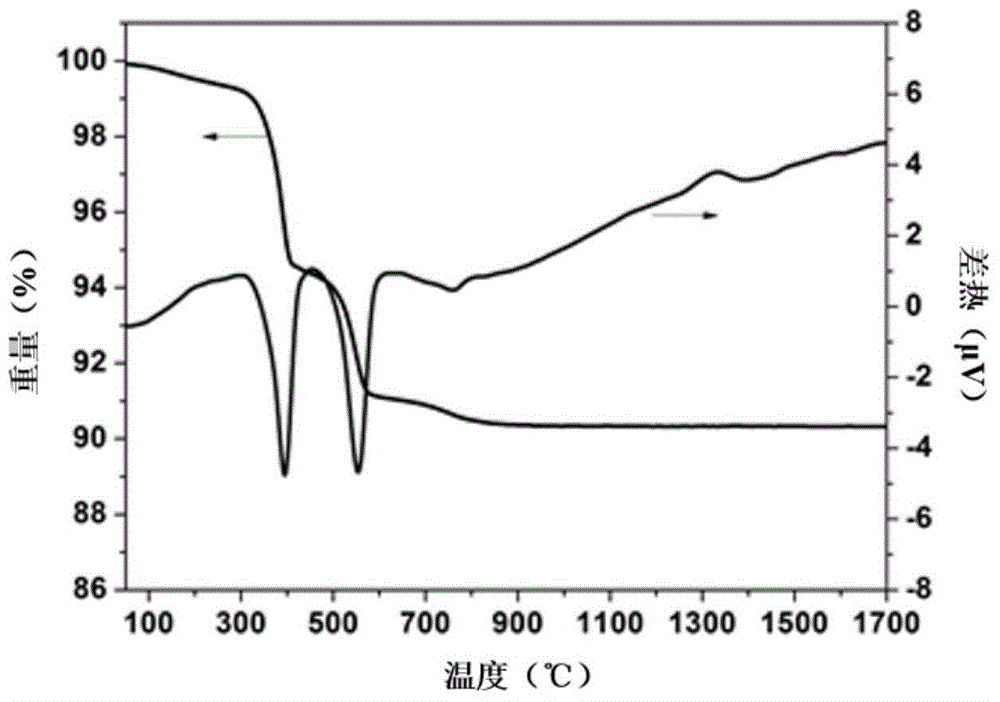

Infrared energy-saving coating material and applications thereof

InactiveCN104987763AHigh infrared emissivityStable serviceChemical industryCoatingsCore componentLanthanum

The present invention provides an infrared energy-saving coating material and applications thereof, and belongs to the technical field of infrared energy-saving materials, wherein a high-emissivity infrared energy-saving material is adopted as a core component, and a dispersant accounting for 3-5% of the mass of the infrared energy-saving coating material, a liquid binder accounting for 10-50% of the mass of the infrared energy-saving coating material, and a stabilizer accounting for 2-5% of the mass of the infrared energy-saving coating material are added to prepare the infrared energy-saving coating material, wherein the high-emissivity infrared energy-saving material adopts lanthanum aluminate of the perovskite structure as a main phase, 0.01-0.25 mole of second main group element ions is doped at the lanthanum site, and 0.02-0.5 mole of transition metal element ions is doped at the aluminum site. According to the present invention, the highest emissivity of the prepared infrared energy-saving coating material can achieve 0.95, and the prepared infrared energy-saving coating material has good high temperature stability, and has great application potential in the high temperature thermal industry furnace kiln energy saving field.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High-temperature nanometer energy-saving coating

InactiveCN101928479AStabilized Infrared RadiationStable lattice structureCoatingsPhosphateNano al2o3

The invention discloses a high-temperature nanometer energy-saving coating, which consists of a component A, a component B and a component C, the component A contains the following components in parts by weight: 5-20 parts of feldspar, 5-15 parts of kaolin, 1-15 parts of Suzhou clay, 5-15 parts of mullite, 10-40 parts of cordierite, 1-10 parts of mineral glass-ceramics, 1-20 parts of zeolite, 0.5-3 parts of nanometer alumina, 0.5-15 parts of ferroferric oxide, 0.5-10 parts of mica, 1-15 parts of talcum powder and 1-25 parts of zircon sand; the component B contains the following components in parts by weight: 1-10 parts of nanometer titanium dioxide, 20-60 parts of titanium dioxide, 1-10 parts of nanometer silica and 20-60 parts of silica; and the component C is water glass or aluminum dihydrogen phosphate. The high-temperature nanometer energy-saving coating has long-term stable and high infrared emissivity and long service life, does not need high-temperature doped synthesis, is convenient for industrialization and has good energy-saving effect after industrial application.

Owner:中油新星纳米工程技术有限公司

Anti-interference infrared temperature measurement method and apparatus thereof

InactiveCN102207406AEasy to install and debugImprove interferenceRadiation pyrometryElectrical testingElectromagnetic interferenceChalcogenide glass

The invention, which can be used for various voltage grade GIS equipment to on-line monitor internal buses and joints so as to provide a monitoring means for safe operation of the GIS equipment, relates to an anti-interference infrared temperature measurement method and an apparatus thereof. The apparatus comprises an infrared temperature sensor and GIS equipment which is full of SF6 seal gas under a pressure of about 0.4MPa. The invention is characterized in that: a seal tank shell of the GIS equipment has a window which is provided with chalcogenide glass; positions of the measured buses and joints are coated with paints which can increase infrared emissing ability; the infrared temperature sensor, which is installed out of the seal tank, on-line collects temperature signals of the measured buses and joints through the chalcogenide glass window of the seal tank; accurate temperature values of the measured buses and joints can be acquired through corrections made by software. An anti-electromagnetic interference effect is good.

Owner:STATE GRID ELECTRIC POWER RES INST

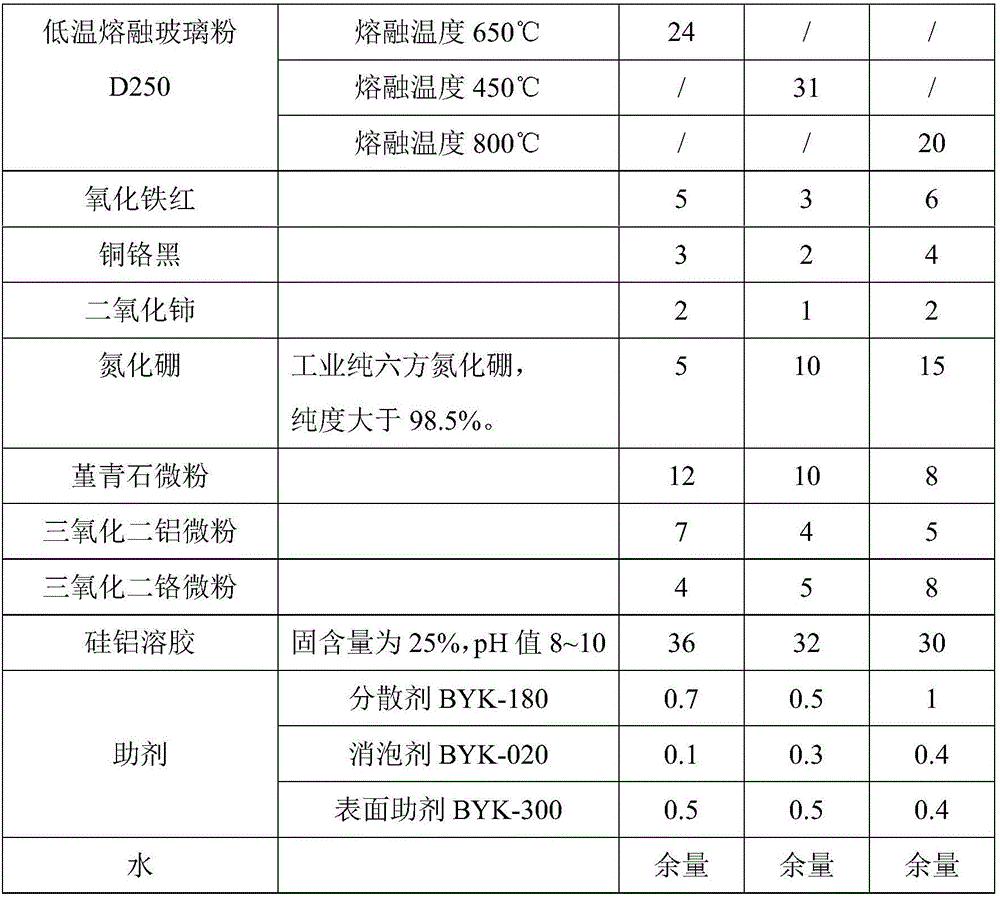

Low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and preparation method and application thereof

The invention discloses a low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and a preparation method and an application thereof. The paint comprises the following raw materials: low-temperature molten glass powder, iron oxide red, copper-chrome black, cerium dioxide, boron nitride, iolite micro powder, alumina micro powder, chromium sesquioxide micro powder, 20-50% of silicon aluminium sol, 0.5-3% of an auxiliary agent, and the balance of water. The method comprises the following steps: a metal matrix is processed, then the surface of the metal matrix is uniformly coated with a paint and dried in shade; and the coated metal matrix is heated at the temperature of 650-900 DEG C to form the low-temperature sintering high-heat conduction ceramic paint. The paint has the advantages of easy acquisition of the raw materials and low cost, is tightly combined with the metal matrix, has effective high temperature oxidation resistance, acid corrosion resistance and abrasion resisting effects of a heating furnace flue heat exchanger on a metal heat exchanger, ceramic coating surface is smooth and clean, slag buildup of the heat exchanger is effectively reduced, the service life of the metal heat exchanger is prolonged, and the heat exchange efficiency effect is increased.

Owner:武汉钢铁有限公司

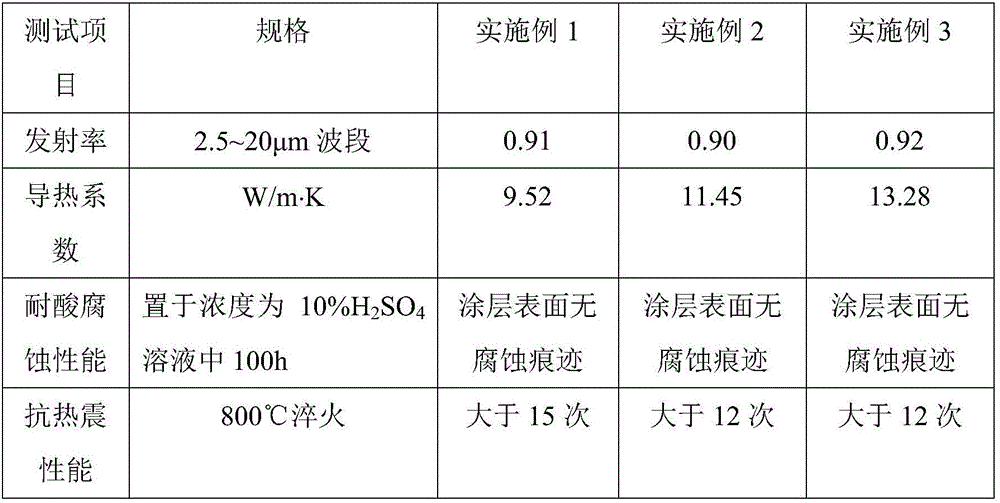

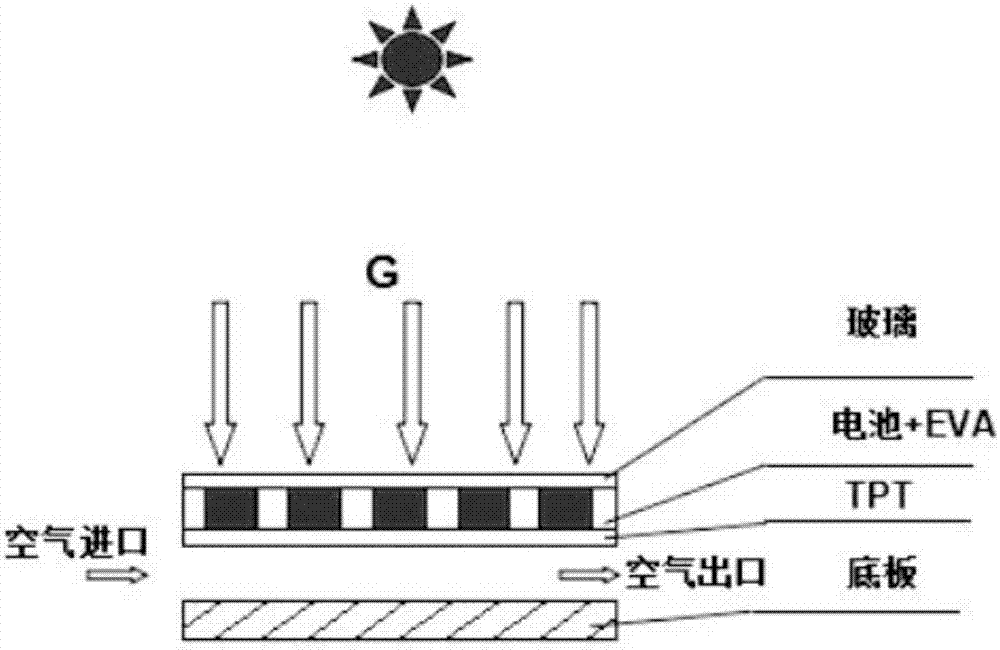

Method for improving photovoltaic conversion efficiency of solar energy photovoltaic power generating panel

InactiveCN106972068AImprove photovoltaic conversion efficiencyIncrease cooling powerPhotovoltaic energy generationSemiconductor devicesMicrosphereUltrasonic vibration

The invention provides a method for improving the photovoltaic conversion efficiency of a solar photovoltaic power generation panel, comprising: using an EVA adhesive film to bond a composite metamaterial film to the light-receiving surface of a solar photovoltaic power generation panel; the composite metamaterial film is prepared by the following method : Micron-sized SiO 2 The microspheres are dispersed in the dispersant and ultrasonically oscillated to obtain SiO 2 microsphere dispersion; make SiO 2 The microsphere dispersion is evenly distributed on the polymethylpentene film, so that the SiO 2 The microsphere dispersion is volatilized, and the distribution of SiO 2 Polymethylpentene thin film of microspheres; using rolling machine to distribute SiO 2 The polymethylpentene film of the microspheres was rolled to obtain the composite metamaterial film. The invention utilizes the principle of radiation cooling to significantly reduce the surface temperature of the solar photovoltaic power generation panel, thereby improving the photovoltaic conversion efficiency of the solar photovoltaic power generation panel, and also has the advantages of low energy consumption, high efficiency and simple structure.

Owner:WUHAN UNIV

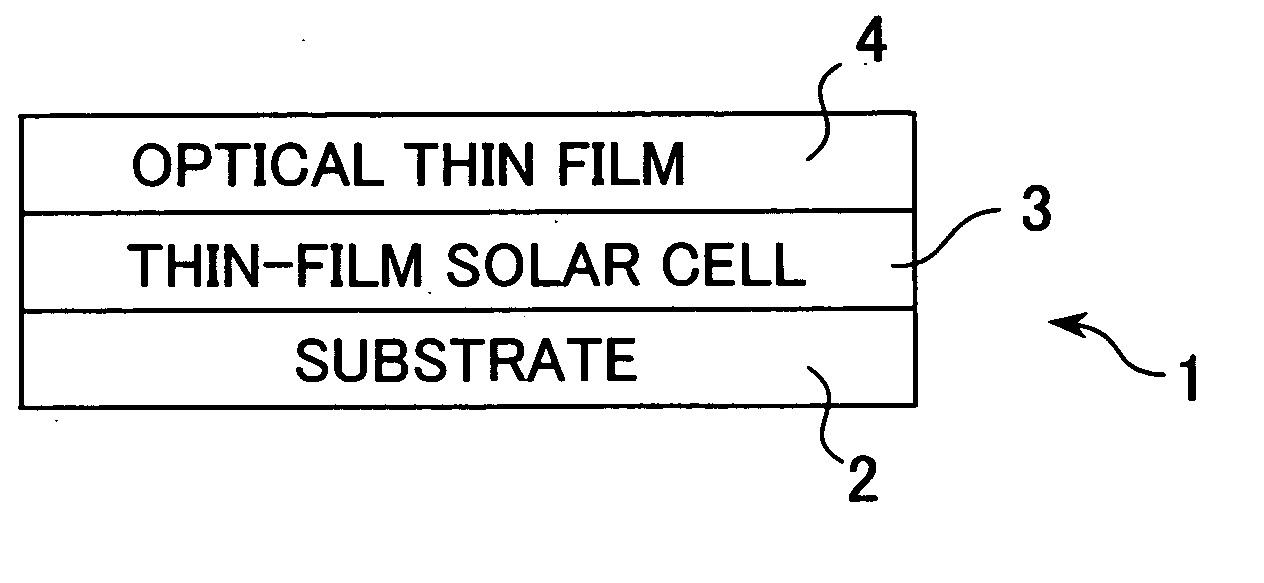

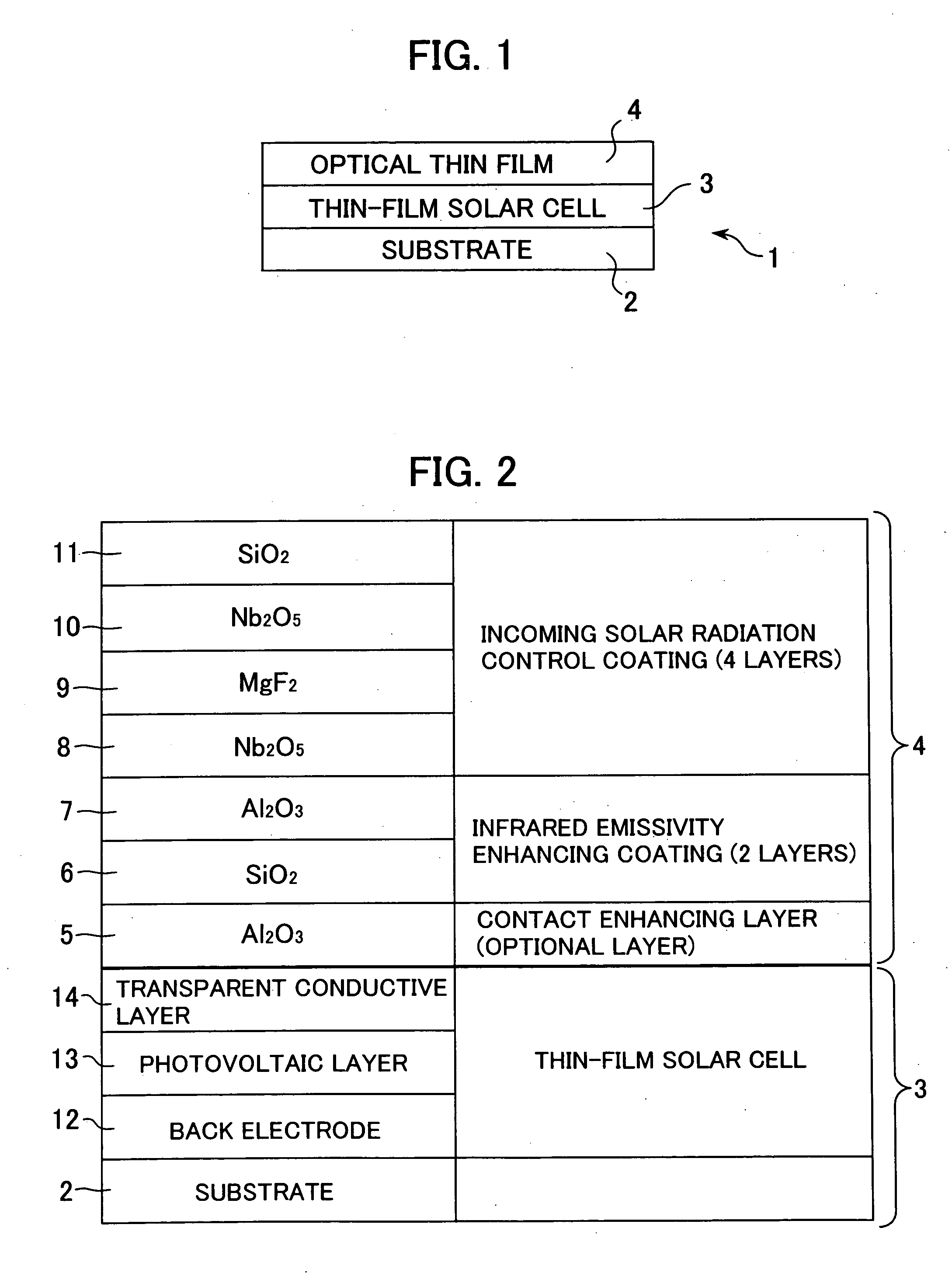

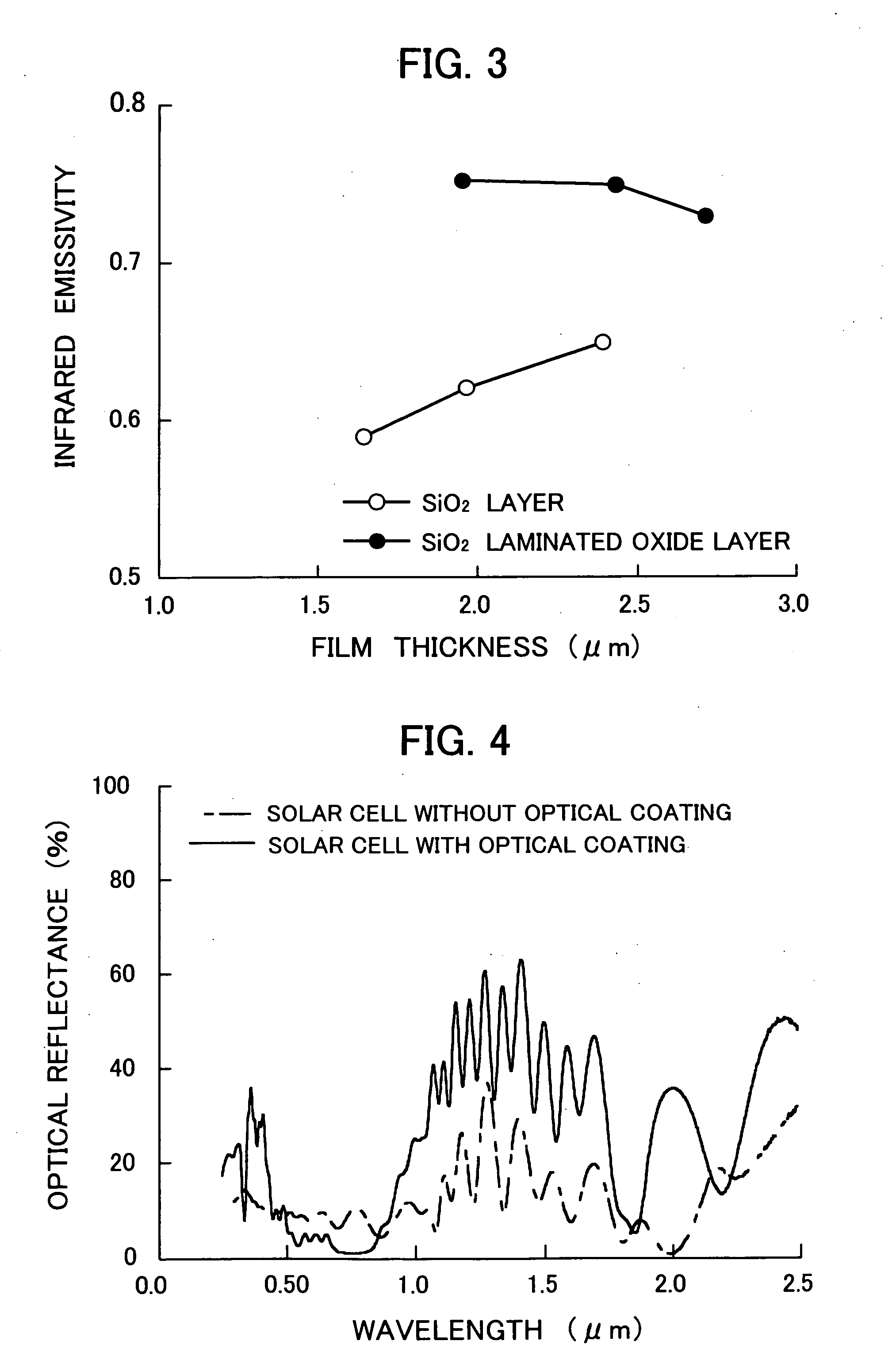

Optical thin film for solar cells and method of forming the same

InactiveUS20060243320A1Adequate thermal radiative characteristicEliminate needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSpace environmentGas phase

Disclosed is an optical thin film for a thin-film solar cell, which is formed directly on a top surface of the thin-film solar cell having a transparent conductive film layer to provide a high infrared emissivity and a lower solar absorptivity to the thin-film solar cell. The optical thin film is formed through a vacuum vapor deposition process. The thin film makes it possible to provide enhanced infrared emissivity based on its reduced thickness, while suppressing unnecessary incoming solar radiation in a simplified structure to achieve a reduced solar absorptivity so as to maintain desired cell efficiency. The optical thin film of the present invention is capable of achieving reduction in weight of a solar cell, and suitable for use, particularly, in space environments.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

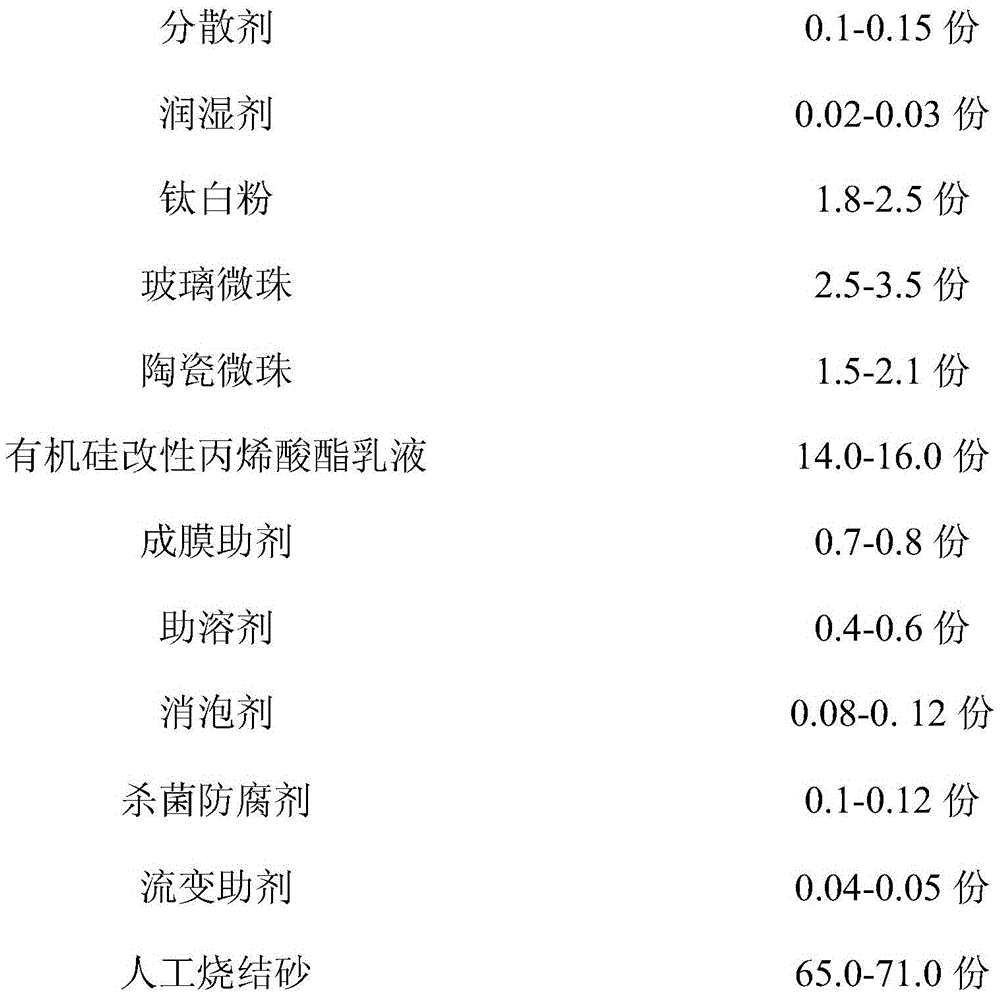

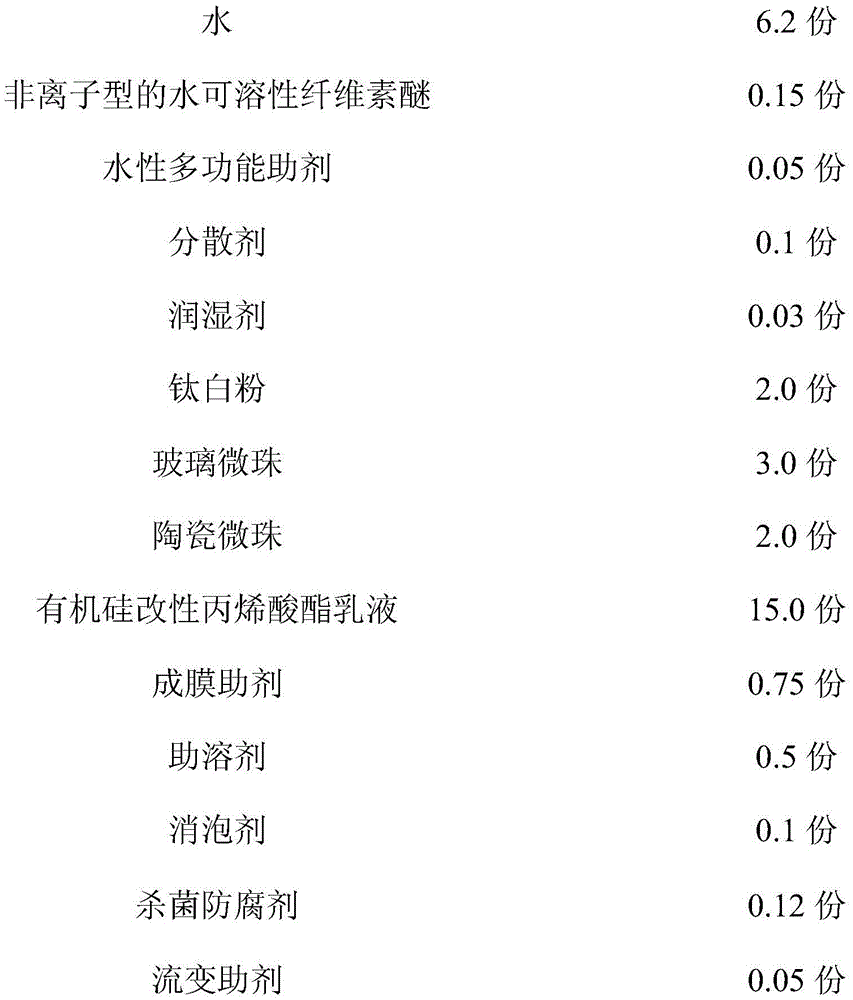

Thermal insulation reflective stone-like coating and preparation method thereof

The present invention relates to a thermal insulation reflective stone-like coating, which is made from the following components by weight: water, non-ionic water-soluble cellulose ethers, a water-based multi-functional additive, a dispersant, a wetting agent, titanium dioxide powder, glass beads, ceramic beads, a organosilicon-modified acrylate emulsion, a coalescent, a cosolvent, a defoamer, an antiseptic, a rheological additive and artificial sintering sand. The invention overcomes the disadvantage of safety hidden trouble caused by large dead load of the coating in the matching operation of insulation system and a stone-like coating of the prior art. The thermal insulation reflective stone-like coating has the advantages of simple operation, light weight, and good heat reflection properties and film properties.

Owner:SKSHU PAINT

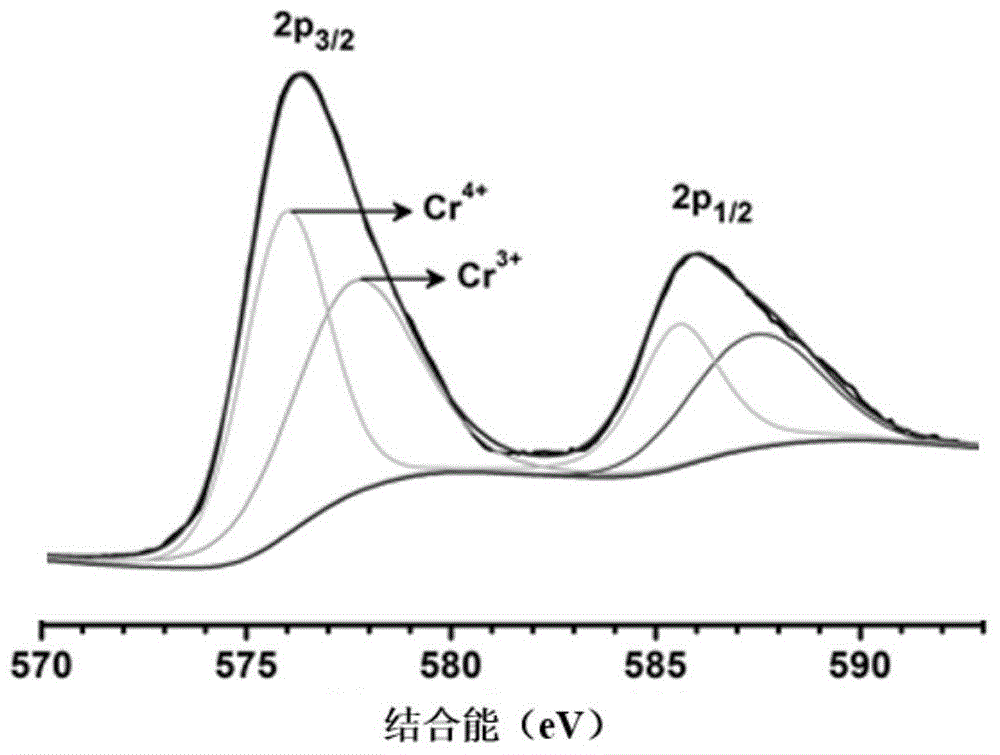

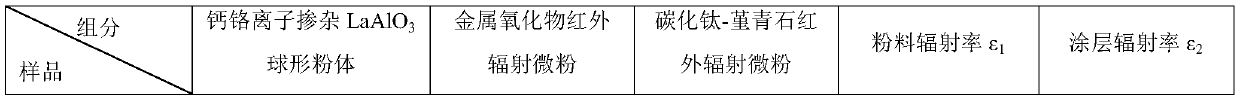

High-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating

InactiveCN110117457AImprove mechanical propertiesSolve crackingFireproof paintsChemical industryFull waveAdhesive

The invention discloses a high-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating. The coating is prepared from, by weight, 10-20 parts of LaAlO3 spherical powder doped with calcium and chromium ions, 10-20 parts of metallic oxide infrared radiation micro powder, 5-10 parts of titanium carbide-cordierite infrared radiation micro powder, 15-25 parts of filler, 0.1-0.2 part of a retardant, 30-50 parts of an adhesive, 10-20 parts of a solvent, 0.15-0.25 part of a dispersion agent, 0.1-0.35 part of a coupling agent and 0.05-0.15 part of a defoaming agent. The invention further discloses a preparation method of the coating. The coating comprises the following steps of step one, raw material preparation; step two, high temperature treatment; step three, high shearing dispersion; step four, coating preparation. The infrared radiation rate of the full-wave band of the provided energy-saving coating is 0.94-0.98, infrared radiation attenuation can be effectively prevented, after long-time using of the coating, the phenomena of cracking and coating shedding cannot occur, and the thermal shock resistance is high.

Owner:河南嘉和节能科技有限公司

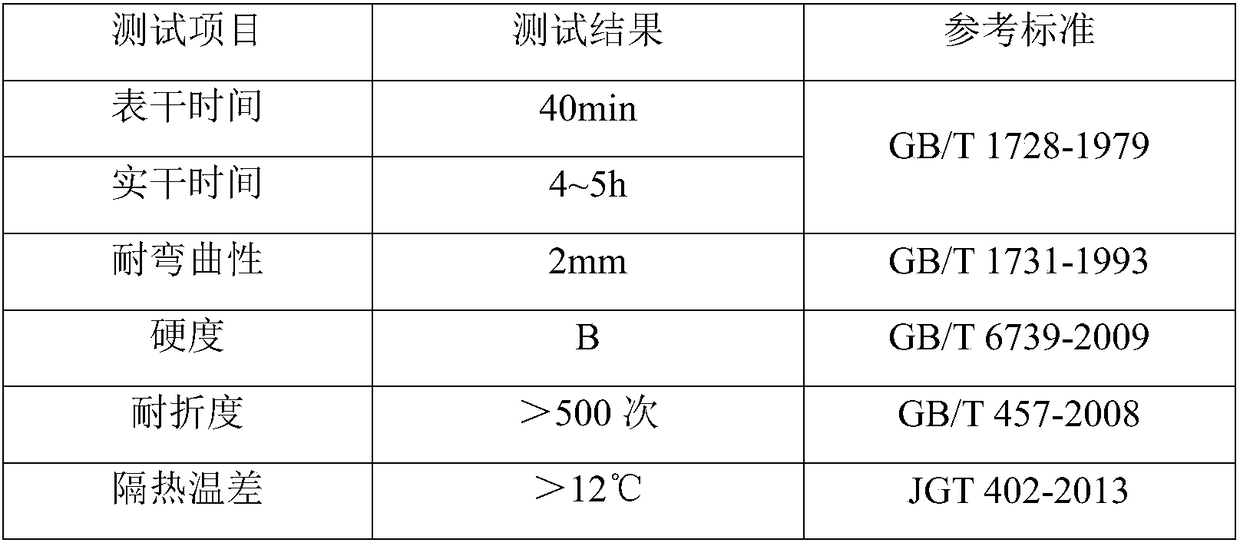

Water-based vacuum ceramic microbead insulation paint used for textile fabric substrates and preparation method thereof

InactiveCN108951181AWell mixedLow thermal conductivityTextiles and paperWater basedThermal insulation

The invention discloses a water-based vacuum ceramic microbead insulation paint used for textile fabric substrates and a preparation method thereof. The paint consists of one-component waterborne polyether polyurethane resin, organic-inorganic hybrid resin, a reflective functional filler, vacuum ceramic microbeads, an auxiliary pigment and filler, and an auxiliary agent. A coating adopts the vacuum ceramic microbeads with bi-gradation model ratios to make arrangement more compact, so that the coating cured at a normal temperature has a lower heat conductivity coefficient, and the heat insulation performance of the coating can be significantly enhanced; the vacuum ceramic microbeads can enhance the compatibility between the resin and the microbeads after being processed by the organic-inorganic hybrid resin, so that the adhesive force between the coating and base materials can be significantly improved; and the auxiliary pigment and filler have reflection functions, so that a paint filmcan have higher reflectivity and reflect most of sunlight. The coating has good compatibility with fabric base materials, and is excellent in adhesive force, flex resistance, intensity and scratch resistance, so that demands of repeatedly folding textile fabrics can be met; and the paint is excellent in heat insulation performance, thermal insulation temperature difference can reach more than 12DEG C, and therefore, water-based environmental protection can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

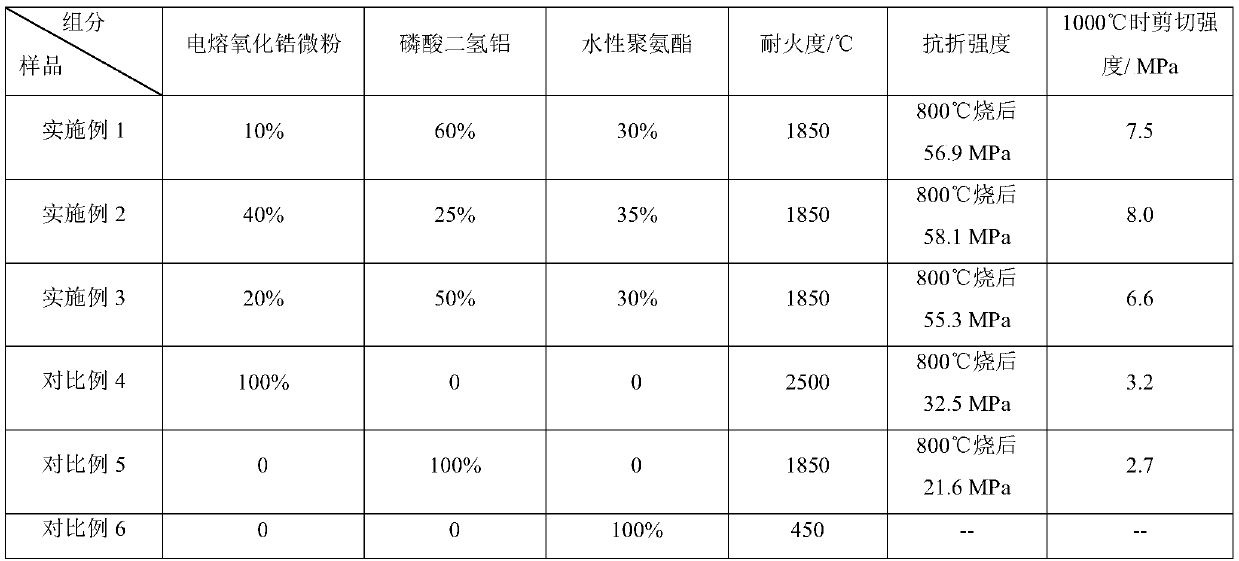

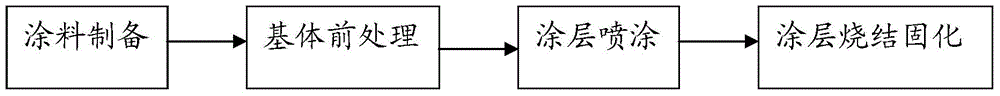

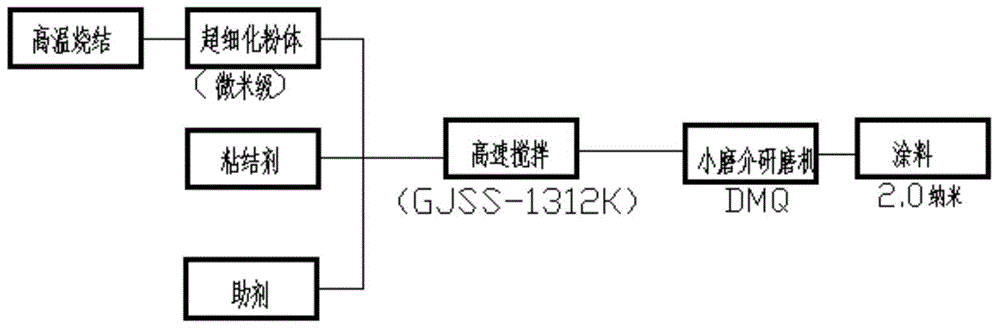

Preparation method of high-emissivity energy-saving infrared radiation coating

ActiveCN104098936AEnhanced radiation heat transferIncrease surface temperatureChemical industryCoatingsEmissivityCeramic coating

The invention discloses a preparation method of a high-emissivity energy-saving infrared radiation coating. The preparation method comprises steps as follows: step one, preparation of coating materials; step two, pretreatment of a base body; step three, spraying of the coating; and step four, sintering and curing of the coating. The coating is stable in structure under high-temperature sintering, performance is comprehensively promoted, the emissivity of the coating cannot be attenuated and aged during use, and the service life of the coating is longer than six years; glazing ceramic coating with a compact structure is formed on the furnace lining surface, the service life of a furnace is prolonged by more than two times, and maintenance and overhaul workload of a furnace lining, consumption of raw materials and maintenance cost are reduced.

Owner:北京恩吉赛威节能科技有限公司

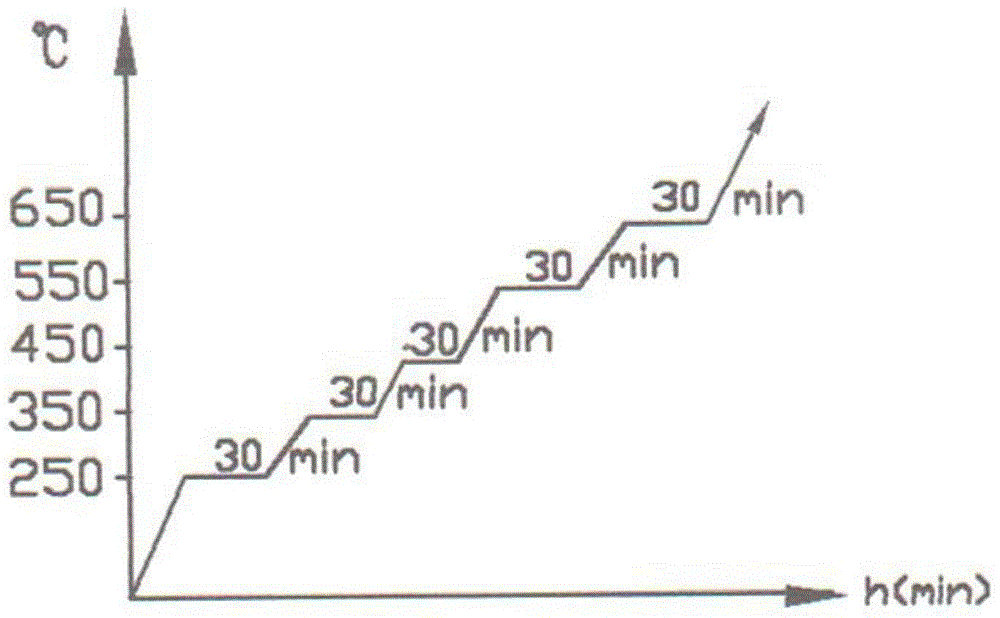

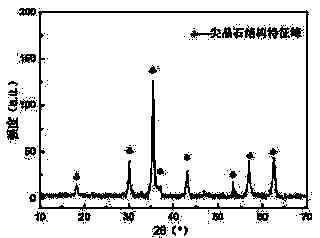

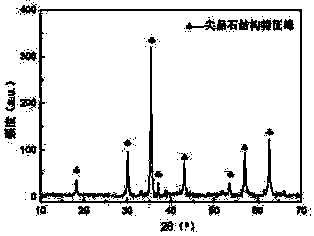

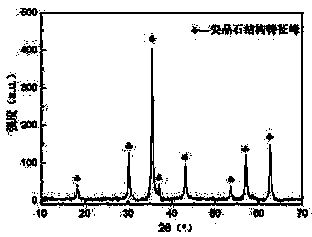

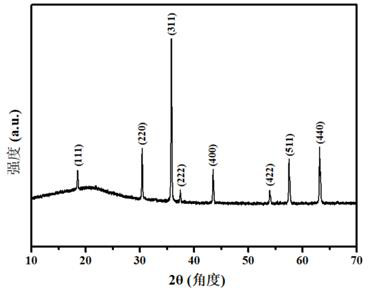

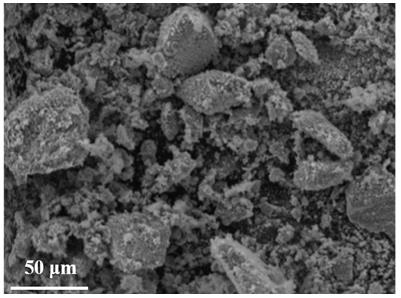

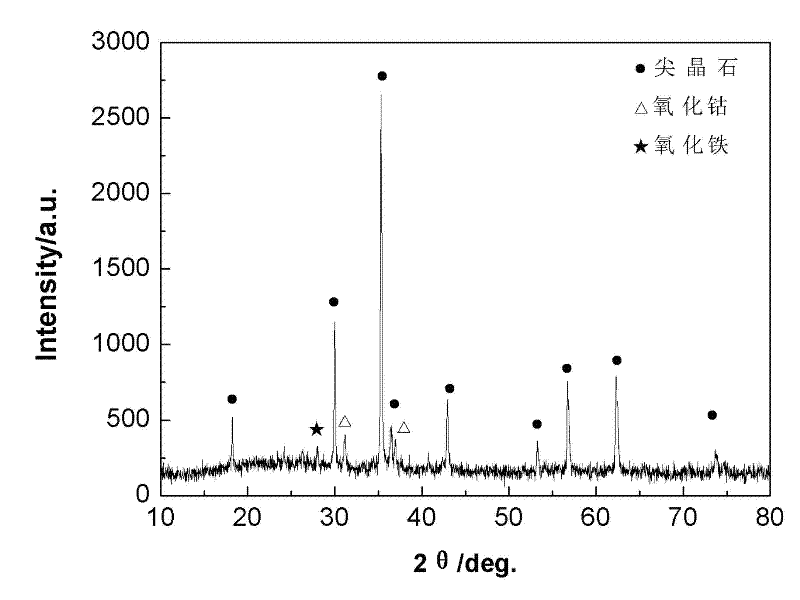

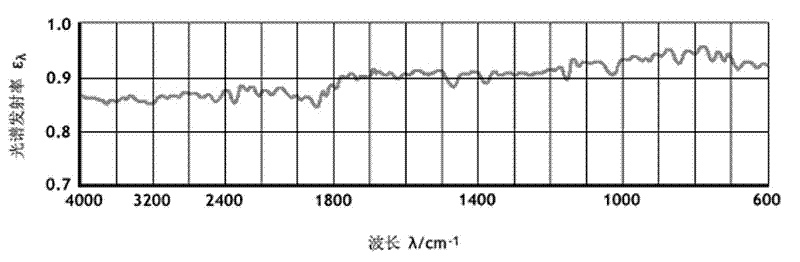

Spinel structural infrared radiation material doped with rare-earth element and preparation method

InactiveCN103771530AHigh infrared emissivityWide variety of sourcesOther chemical processesChemical industryRare-earth elementWater baths

The invention relates to a spinel structural infrared radiation material doped with a rare-earth element. The general chemical formula of the material is AFe[2-x]RExO4, wherein A is the mixture of Co, Cu or Co and Cu in any ratio; RE is the rare earth element such as Ce, La, Y or Nd. The preparation method comprises the following steps of dissolving metal nitrate of A, Fe AND Re into deionized water; adding citric acid until the metal nitrate is completely dissolved; dropwise adding ammonia water to adjust the pH value of the solution to 5 to 7, and stirring the solution to form gel under the water-bath condition; placing the mixture into a drying oven to be dried to obtain dry gel, igniting the dry gel to be completely burned, grinding the obtained powder, and sintering, thermally preserving and cooling the powder to obtain a target object. The spinel structural infrared radiation material has the advantages that the infrared transmitting rate at the wave band of 8 to 14 micrometers is high, and the material is applicable to the infrared heating; the preparation method is wide in raw material source, short in preparation period, low in sintering temperature, energy-saving, high-efficient and favorable of being popularized to use.

Owner:NANKAI UNIV

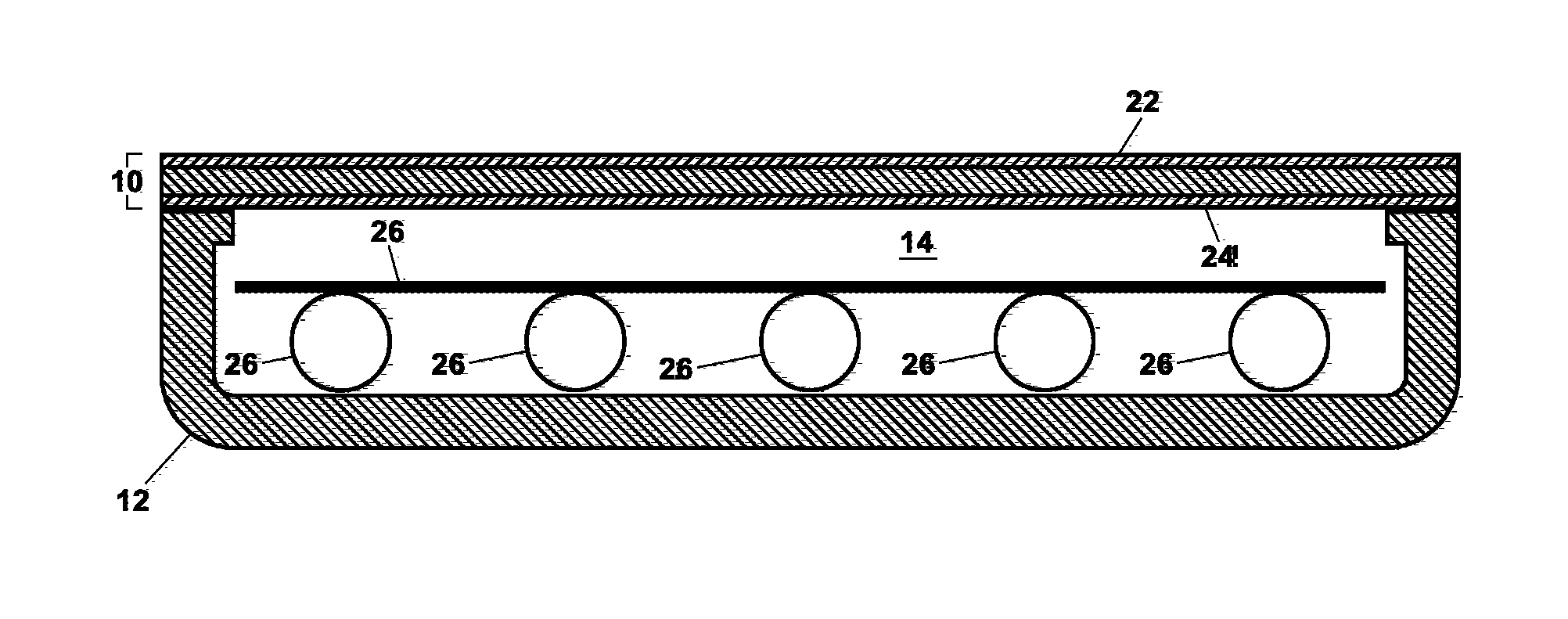

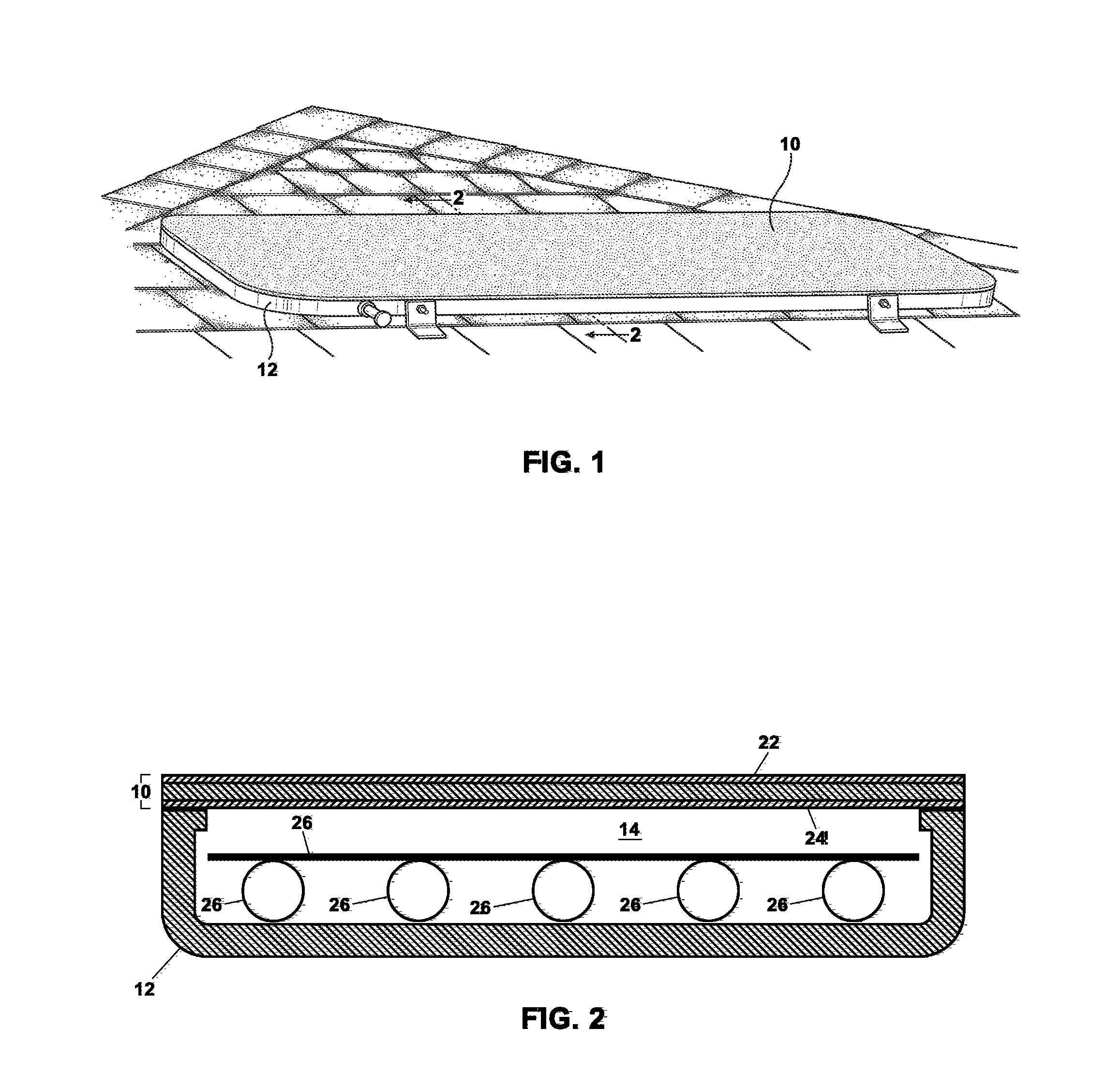

Solar collector comprising an opaque cover

ActiveUS9829216B2High energyHigh infrared emissivitySolar heating energySolar heat devicesAbsorptanceWorking fluid

A solar collector has an opaque cover heated by solar energy. Heat flows from the opaque cover by conduction, convection, and infrared emittance across a gap within an at least substantially airtight enclosure to an absorber containing a working fluid. The exterior surface of the opaque cover has high solar energy absorptance and the interior surface has high infrared emittance. The exterior surface preferably has low infrared emittance. In one embodiment, fully wetted surface geometry permits direct and reflected infrared absorption by the absorber. The opaque cover eliminates the weight, cost and other shortcomings of glass. A hollow continuous side wall with rounded corners provides an embodiment that is robust yet economical, that is easy to manufacture and seal, that permits a reduced thickness of the opaque cover and mitigates the destructive potential of severe winds, and that can withstand the compressive forces experienced by an evacuated solar collector.

Owner:PRUTSMAN JEFFREY D +1

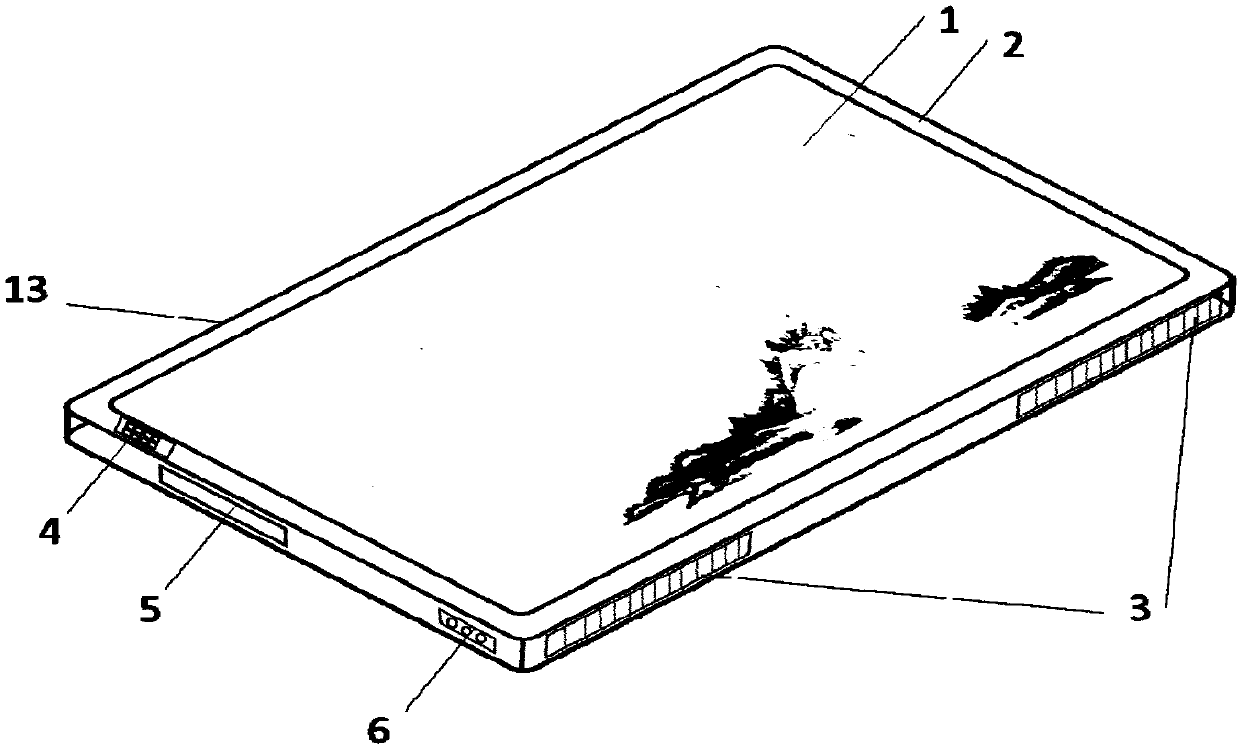

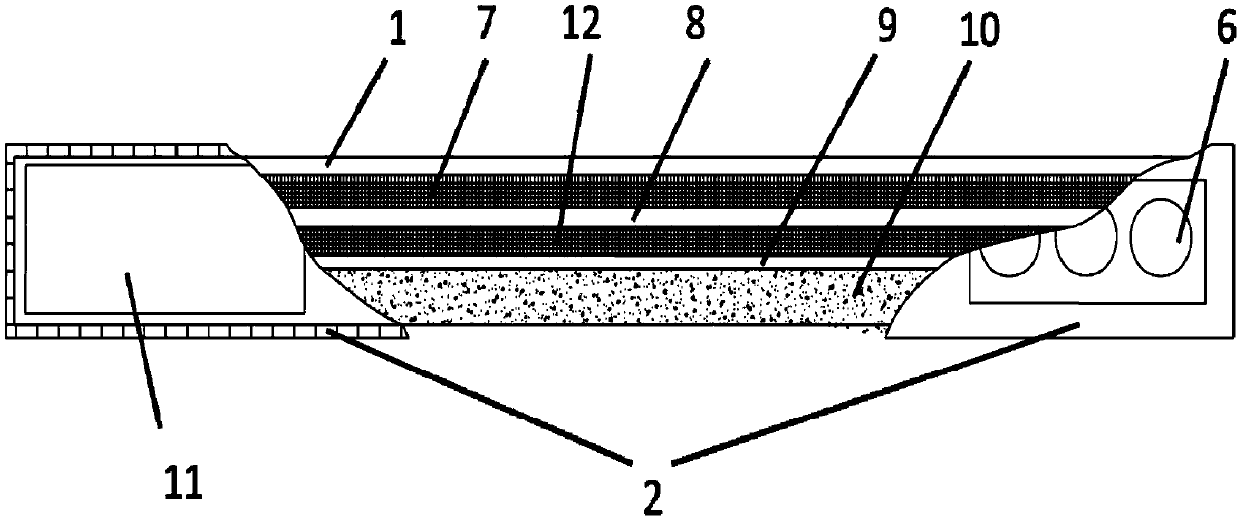

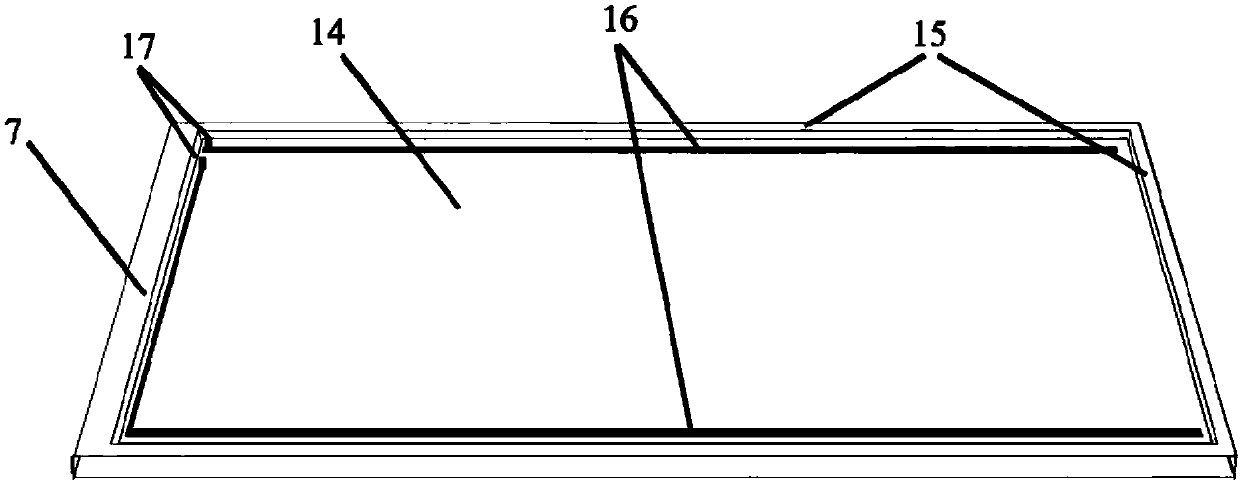

Intelligent graphene heating mural

PendingCN109579118ASolve the problem of remote controlImprove feverLighting and heating apparatusElectric heating systemTemperature controlRemote control

The invention discloses an intelligent graphene heating mural. The intelligent graphene heating mural comprises a decorative picture (1), an outer frame (2), an air outlet (3), a temperature controlling and humidity and power monitoring multifunction integrated module (4), an external temperature / humidity module (5) and a power interface (6), the decorative picture (1), a first-layer high-molecular packaging layer (7), a heating function coating (8), a second-layer high-molecular packaging layer (12), a heat / infrared reflection layer (9) and a heat insulation foam layer (10) are sequentially stacked from top to bottom layer by layer to be embedded into the outer frame (2), the air outlet (3) is located on the lower edge of the outer frame (2), an air inlet (13) is located on the upper edgeof the outer frame (2), and the temperature controlling and humidity and power monitoring multifunction integrated module (4), the external temperature / humidity module (5), the power interface (6) and a WIFI module (11) are internally embedded in the left edge or the right edge or the left edge and the right edge of the outer frame (2). The intelligent graphene heating mural has the advantages that remote control can be realized, the use is simple, and the set temperature is highly consistent with the indoor temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

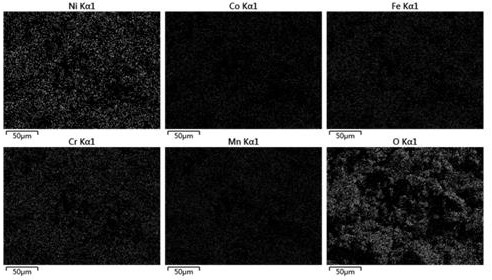

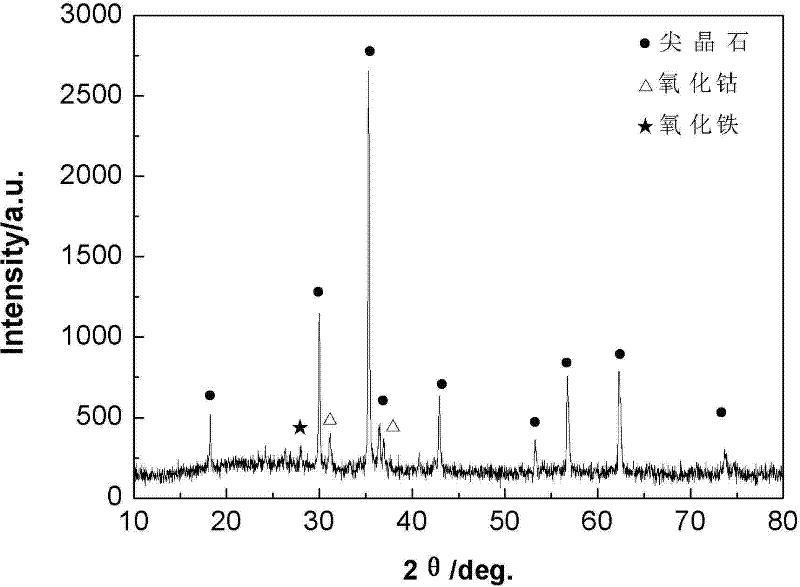

Method for synthesizing spinel type high-entropy oxide material (MCoFeCrMn)3O4 by hydrothermal method

The invention provides a method for synthesizing a spinel type high-entropy oxide material (MCoFeCrMn)3O4 by a hydrothermal method. The method comprises the steps: fully dissolving nickel nitrate or / and copper nitrate, cobalt nitrate, ferric nitrate, chromic nitrate and manganous nitrate in ultrapure water in an equimolar manner to obtain a mixed solution of metal salts; and adding a precipitant into the mixed solution, uniformly stirring, transferring into a stainless steel high-pressure reaction kettle with a polytetrafluoroethylene lining, carrying out a hydrothermal reaction, cooling to room temperature after the reaction is finished, carrying out reduced pressure filtration on a reaction solution, washing with ultrapure water, carrying out suction filtration, separating, precipitating and drying, and carrying out crystallization treatment on obtained solid powder to obtain the high-entropy oxide (MCoFeCrMn)3O4, wherein M is Ni or / and Cu. The high-entropy oxide is of a spinel structure, has high infrared emissivity at the wave band of 3-12 microns, can be suitable for infrared heating, has high light absorptivity at the wave band of 0.3-2.5 microns, and can be suitable for solar energy absorption.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

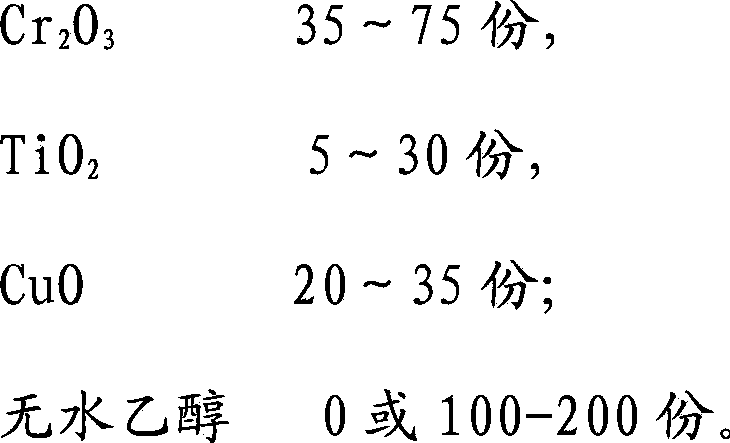

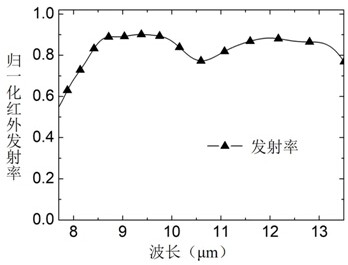

Preparation method of infrared coating used for household cooking utensils, and preparation method of infrared coat

The invention relates to a preparation method of an infrared coating used for household cooking utensils, and a preparation method of an infrared coat. The problems of low emissivity, large thermal efficiency loss and limited coating shape of coats existing in the prior art at a high temperature are mainly solved in the invention. The infrared coating is synthesized by using an infrared composite filler and a high temperature resistant adhesive, wherein the composite filler is synthesized by using the following raw materials, by weight, 35-75 parts of Cr2O3, 5-30 parts of TiO2, 20-35 parts of CuO, and 0 / 100-200 parts of anhydrous ethanol. The preparation method of the infrared coating comprises the following steps: mixing the raw materials according to above proportions, ball-milling, carrying out high temperature roasting to prepare the infrared composite filler, ball-milling the infrared composite filler and the high temperature resistant adhesive in proportion, and mixing to prepare the infrared coating. The preparation method of the infrared coat is characterized in that the infrared coat with high emissivity is prepared by coating the infrared coating on the household cooking utensils through a reverse dip-coating process. The coat prepared in the invention still has a high emissivity at a high temperature, has a total infrared emissivity of above 0.90, has a superior thermal shock resistance, and can obviously improve the heating efficiency in order to realize energy saving. The reverse dip-coating process adopted in the invention is suitable for coating the cooking utensils with complex shapes.

Owner:辽宁省乌科新材料产业研究有限公司

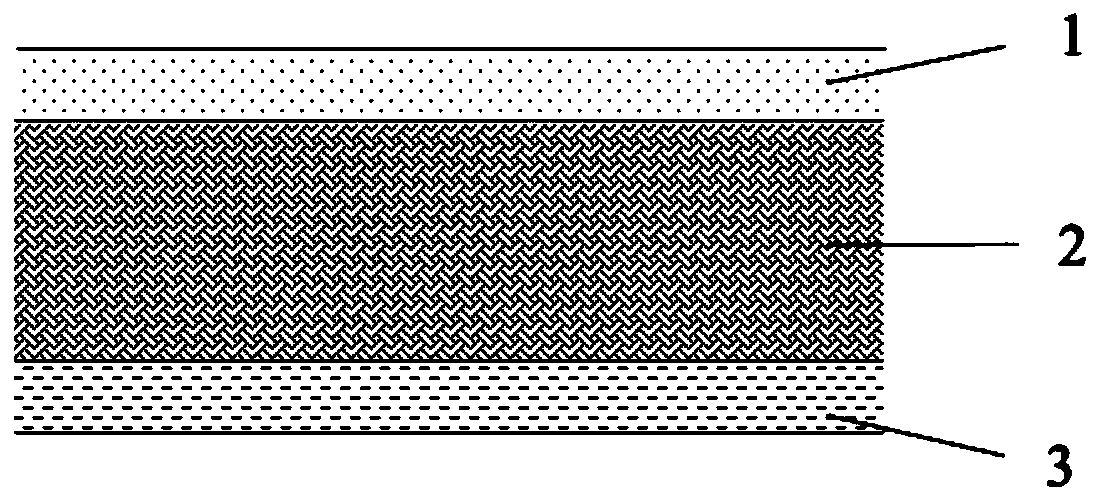

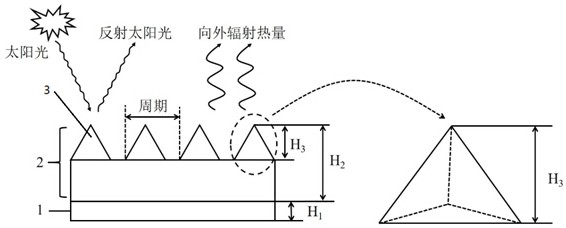

Passive radiation cooling composite film

InactiveCN112460836AHigh infrared emissivityTo achieve the effect of radiative coolingRefrigeration machinesComposite filmCooling effect

The invention relates to the technical field of cooling and discloses a passive radiation cooling composite film. The passive radiation cooling composite film comprises a planar metal reflecting layer(1) and an infrared light emitting layer (2) made of polydimethylsiloxane, and the planar metal reflecting layer and the infrared light emitting layer are sequentially arranged from bottom to top; and a one-dimensional or two-dimensional micron-scale optical microstructure unit (3) is arranged on the upper surface of the infrared light emitting layer (2). Compared with the prior art, in the filmdisclosed by the invention, when infrared light passes through the infrared light emitting layer, the infrared light emitting layer has relatively high infrared emissivity, so that heat can be radiated to an external cosmic space through an 'atmospheric window ' of a specific waveband of 8-13 microns as much as possible; and meanwhile, most of incident sunlight is reflected by the planar metal reflecting layer, so that the radiation cooling effect is achieved. The passive radiation cooling composite film has the advantages of flexibility, foldability, ultra-thinness, no consumption of externalenergy, environmental friendliness, green sustainable development and the like, and can be applied to electronic equipment, mechanical equipment and other occasions where active cooling means cannotbe adopted.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Black-increasing agent for high-temperature infrared-radiation energy-saving coating and preparation method of black-increasing agent

InactiveCN102604466AGood chemical stabilityLow thermal emissivityChemical industryCoatingsBrickRadiance

The invention discloses a black-increasing agent for a high-temperature infrared-radiation energy-saving coating. The black-increasing agent is prepared by the following raw materials in percentage by weight: 20-60% of MnO2, 10-20% of Fe2O3, 1-5% of Co2O3, 5-10% of CuO, 0-10% of Cr2O3, 0-10% of NiO, and 20-40% of emery powder. The invention also discloses a preparation method of the black-increasing agent for a high-temperature infrared-radiation energy-saving coating. The black-increasing agent provided by the invention has the advantages of wear resistance, high temperature resistance and stable radiance, and is mainly used for fireproof base materials such as alumina bricks and mullite and metal base materials for boiler water wall tubes. The prepared coating has high infrared emitting ability at the temperature below 1300 DEG C within a broadband of 2.5-16.7 mum, with the average value being 0.88-0.92. The service temperature reaches up to 1450 DEG C, the black-increasing agent is stable at high temperature, the service life is not less than three years, the process is simple, and the cost is low.

Owner:KING STRONG MATERIAL ENG LTD

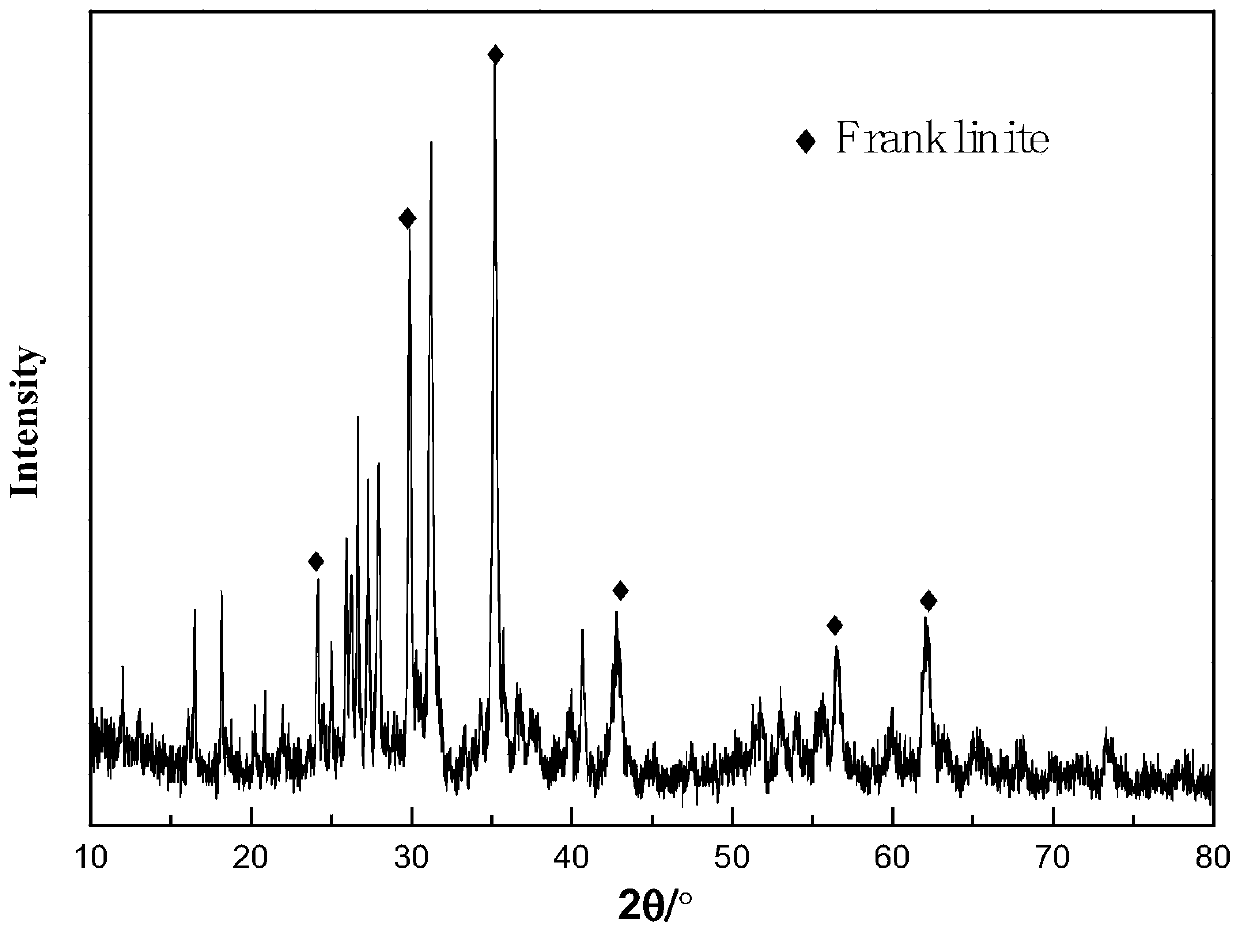

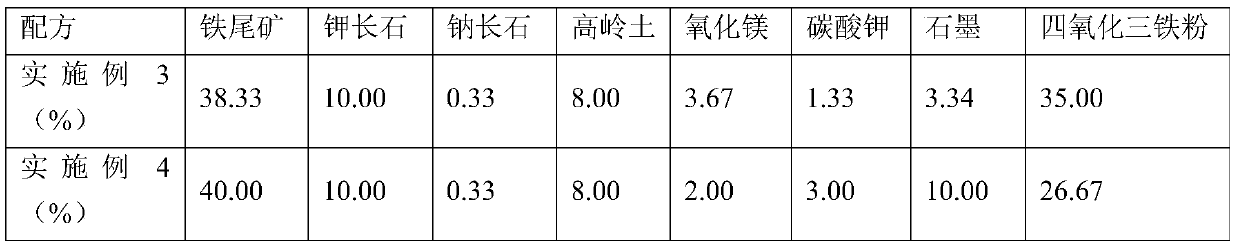

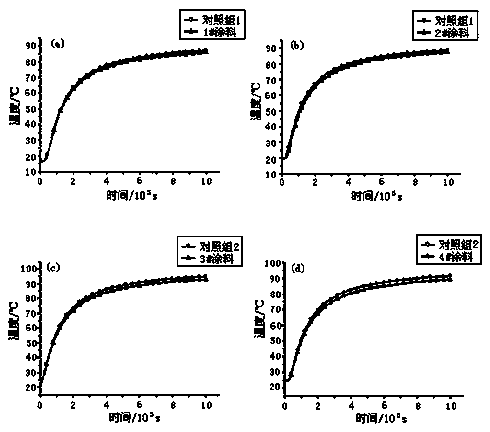

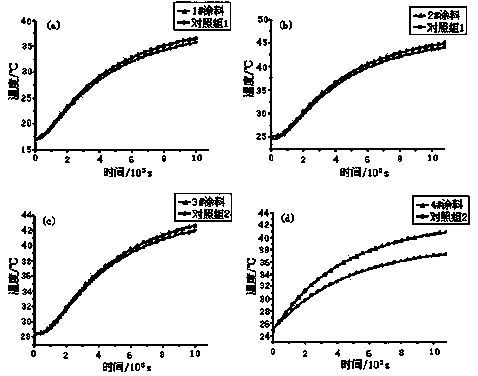

Iron tailing heat-adsorption ceramic material, and preparation method thereof

ActiveCN110194653AReduce manufacturing costReduce dependenceCeramic materials productionClaywaresKaolin clayThermal coefficient

The invention discloses an iron tailing heat-adsorption ceramic material, and a preparation method thereof. 100% of iron tailing heat-adsorption ceramic material comprises, by mass, 37-42% of iron tailings, 6-10% of kaolin, 1-13.33% of graphite, 5-12% of potassium feldspar, 0.2-0.5% of albite, 1-3% of potassium carbonate, 1 to 4% of magnesium oxide, and 26-35% of ferriferrous oxide. The infrared emission rate of the ceramic material is 0.75 or higher, the 300 DEG C heat conductivity coefficient is 1.70W / (m.K) or higher, the compressive strength is 70MPa or higher, after 25 times of thermal shock resistance tests, no surface cracking is caused (from room temperature to 400 DEG C), and the ceramic material is black. According to the preparation method, the novel heat-adsorbing function ceramic is prepared from iron tailings, adsorption on solar energy is realized, and waste is turned into valuables.

Owner:HEBEI UNIV OF TECH

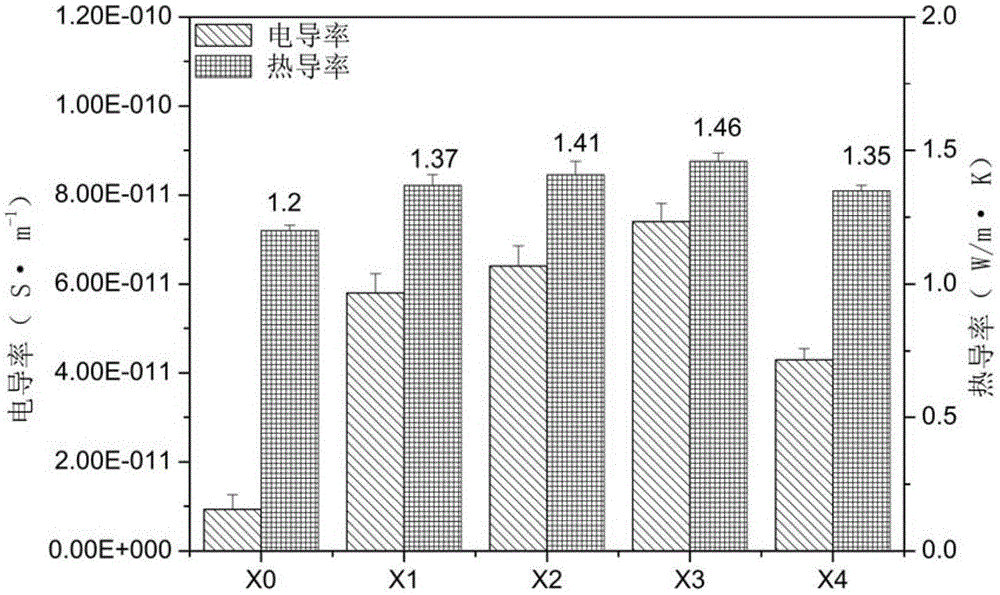

Composite intensified heat dissipation coating containing graphene or graphene oxide and preparation method of coating

ActiveCN102964972BHigh infrared emissivityWith infrared radiation functionPolyester coatingsComparative testEmissivity

The invention discloses a composite intensified heat dissipation coating containing graphene or graphene oxide and a preparation method of the coating. The performances of the coating are combined with the performances of infrared ray radiation of tourmaline and transition metal oxide, larger specific surface areas and high thermal conductivity coefficients of the graphene and the graphene oxide, excellent adhesive property of resin, high strength and excellent high-temperature resistance. The functional powder and the graphene or the graphene oxide are dispersed in the resin under the synergistic effect of various auxiliaries so as to prepare the composite intensified heat dissipation coating. In the preparation method, the graphene or the graphene oxide wraps the surface of the infrared emission powder by a reflux method; based on the higher thermal conductivity coefficient of the graphene or the graphene oxide, the thermal resistance of infrared particles can be lowered effectively and the infrared emissivity of the infrared particles is improved; in comparative test with the normal heat dissipation coating, the infrared emissivity of the coating provided by the invention can be 0.96 and is improved by 6.6%, 6.37% of energy is saved, and better energy-saving effect is realized.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com