Super-hydrophobic self-cleaning radiation cooling film and preparation method thereof

一种薄膜制备、自清洁的技术,应用在扁平制品、其他家里用具、应用等方向,能够解决没考虑环境对材料降温效果的影响、分层涂布成本高、操作过程复杂等问题,达到优异防污自清洁作用、实现大面积生产、制备工艺简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a superhydrophobic self-cleaning radiation cooling film of the present invention comprises the following steps:

[0038] S1, P(VDF x -Co-HFP y ) and PDMS are dissolved in a composite polar solvent to form P(VDF x -Co-HFP y ) / PDMS polymer composite translucent solution;

[0039] S101. Weigh a certain amount of P(VDF x -Co-HFP y ) dissolved in acetone solution and stirred at room temperature for 3 to 5 hours until completely dissolved;

[0040] P(VDF x -Co-HFP y) to acetone mass ratio of 1: (10 ~ 15).

[0041] S102, add PDMS prepolymer A component, then add tetrahydrofuran solvent, and stir evenly;

[0042] P(VDF x -Co-HFP y ) to THF in a mass ratio of (1-2):15.

[0043] S103. Add component B of PDMS curing agent and stir for 15-30 minutes until uniform and translucent.

[0044] P(VDF x -Co-HFP y ) to PDMS mass ratio is (2.0-4.0): 1.0.

[0045] S2, add non-solvent dropwise in the solution to make P(VDF x -Co-HFP y ) / PDMS undergoes ...

Embodiment 1

[0052] A superhydrophobic self-cleaning radiation cooling film and a preparation method thereof, comprising the following steps:

[0053] step 1

[0054] First weigh 3.5g of P(VDF x -Co-HFP y ) was dissolved in 49g of acetone solution, stirred at room temperature for 3h until completely dissolved, then sequentially added 1g of PDMS prepolymer component A and 30g of tetrahydrofuran solvent, after stirring evenly, added 0.1g of curing agent component B, and continued to stir for 15min to obtain half clear solution;

[0055] step 2

[0056] Add 3.0g of non-solvent water to the translucent solution drop by drop at a rate of 0.05ml every 10s while stirring to form a sol;

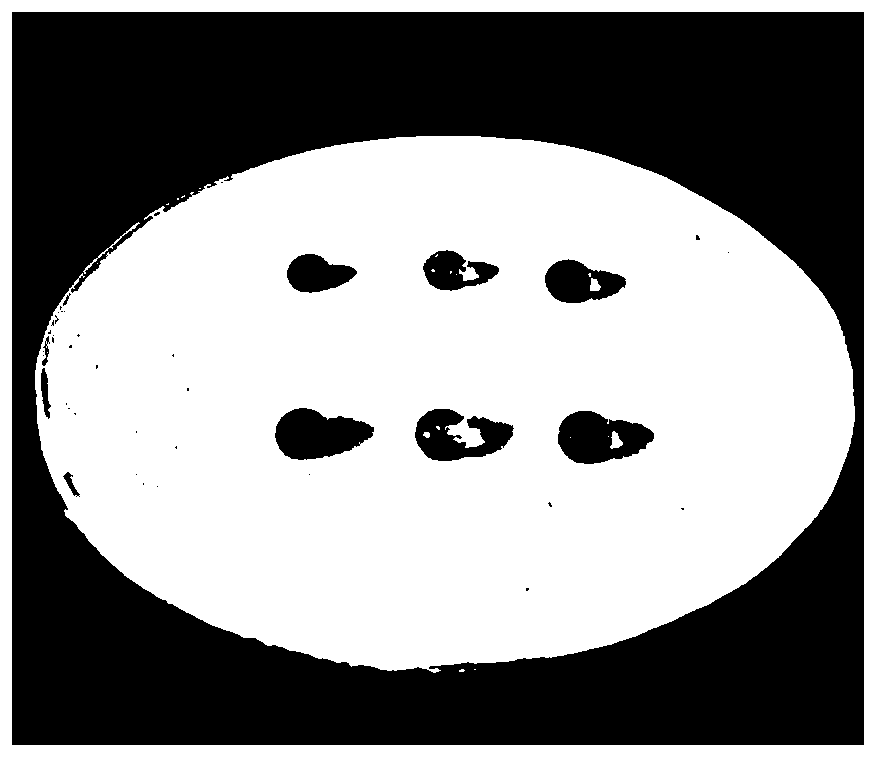

[0057] step 3

[0058] Pour the obtained sol into a 90mm petri dish, and dry it at room temperature for 3 hours until the solvent and water are completely evaporated, and then a microporous superhydrophobic self-cleaning radiation cooling film can be obtained.

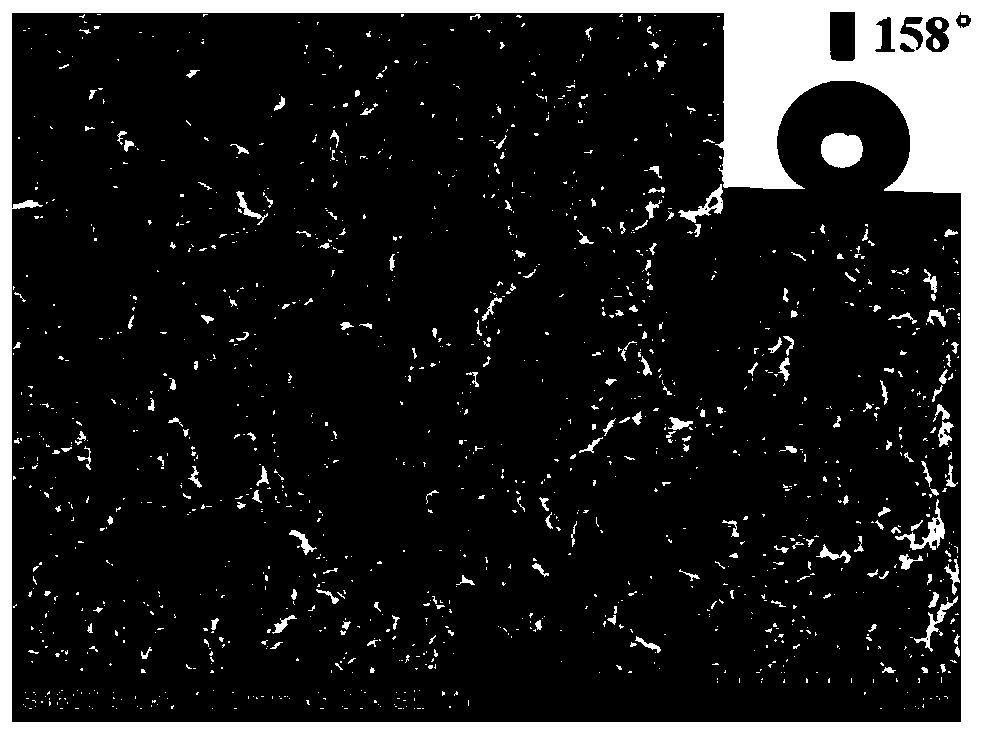

[0059] The superhydrophobic self-cleaning rad...

Embodiment 2

[0061] A superhydrophobic self-cleaning radiation cooling film and a preparation method thereof, comprising the following steps:

[0062] step 1

[0063] First weigh 3.5g of P(VDF x -Co-HFP y ) was dissolved in 42g of acetone solution, stirred at room temperature for 3.5h until completely dissolved, then sequentially added 1g of PDMS prepolymer A component and 30g of tetrahydrofuran solvent, after stirring evenly, added 0.1g of curing agent B component, and continued to stir for 30min to obtain translucent solution;

[0064] step 2

[0065] Add 5.0g of non-solvent water to the translucent solution drop by drop at a rate of 0.05ml every 10s while stirring to form a sol;

[0066] Step 3: Pour the obtained sol into a 90mm petri dish, and dry it at room temperature for 4 hours until the solvent and water are completely evaporated, and then a microporous superhydrophobic self-cleaning radiation cooling film can be obtained.

[0067] The superhydrophobic self-cleaning radiation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com