Patents

Literature

83results about How to "Improve photovoltaic conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

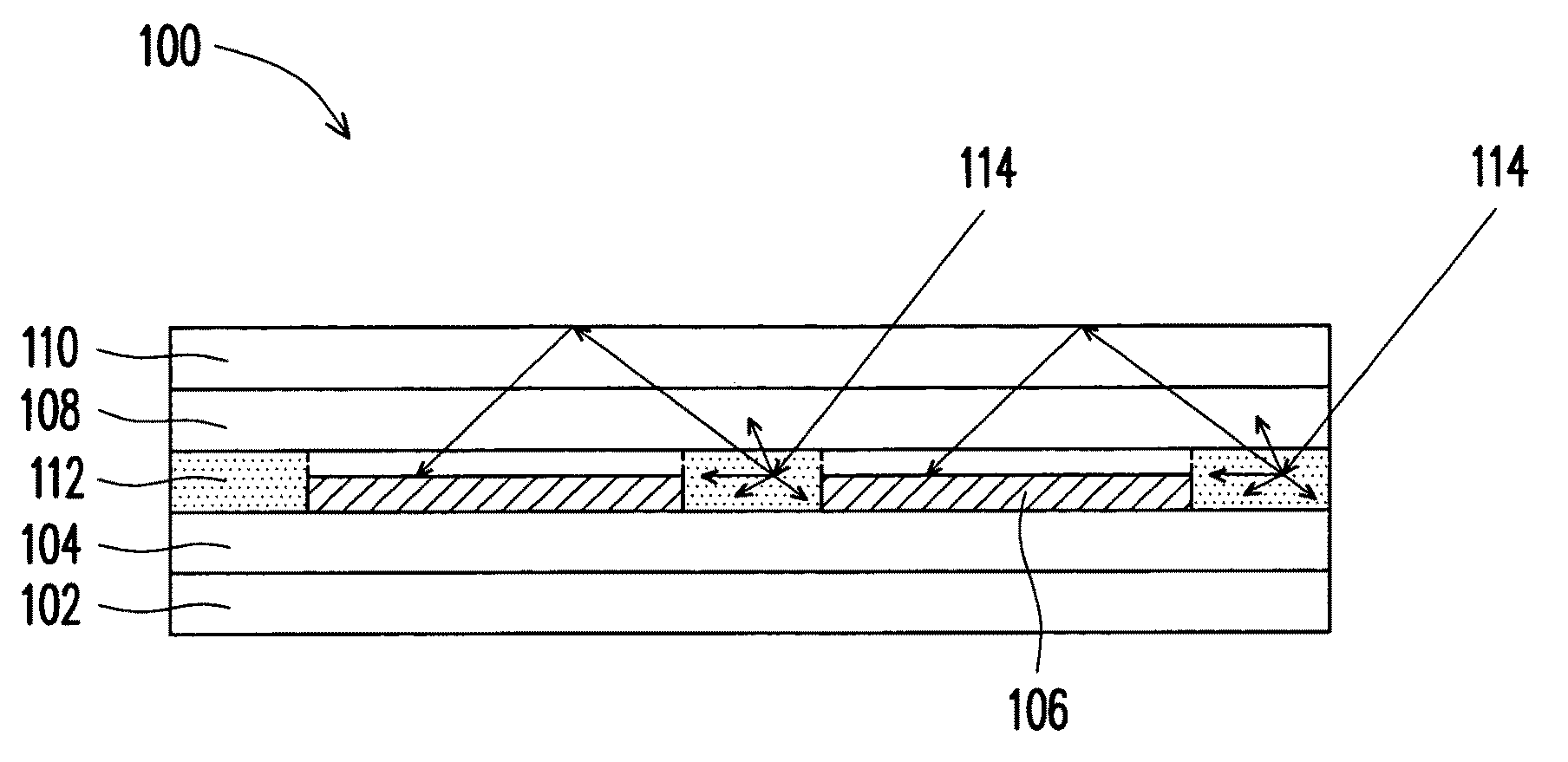

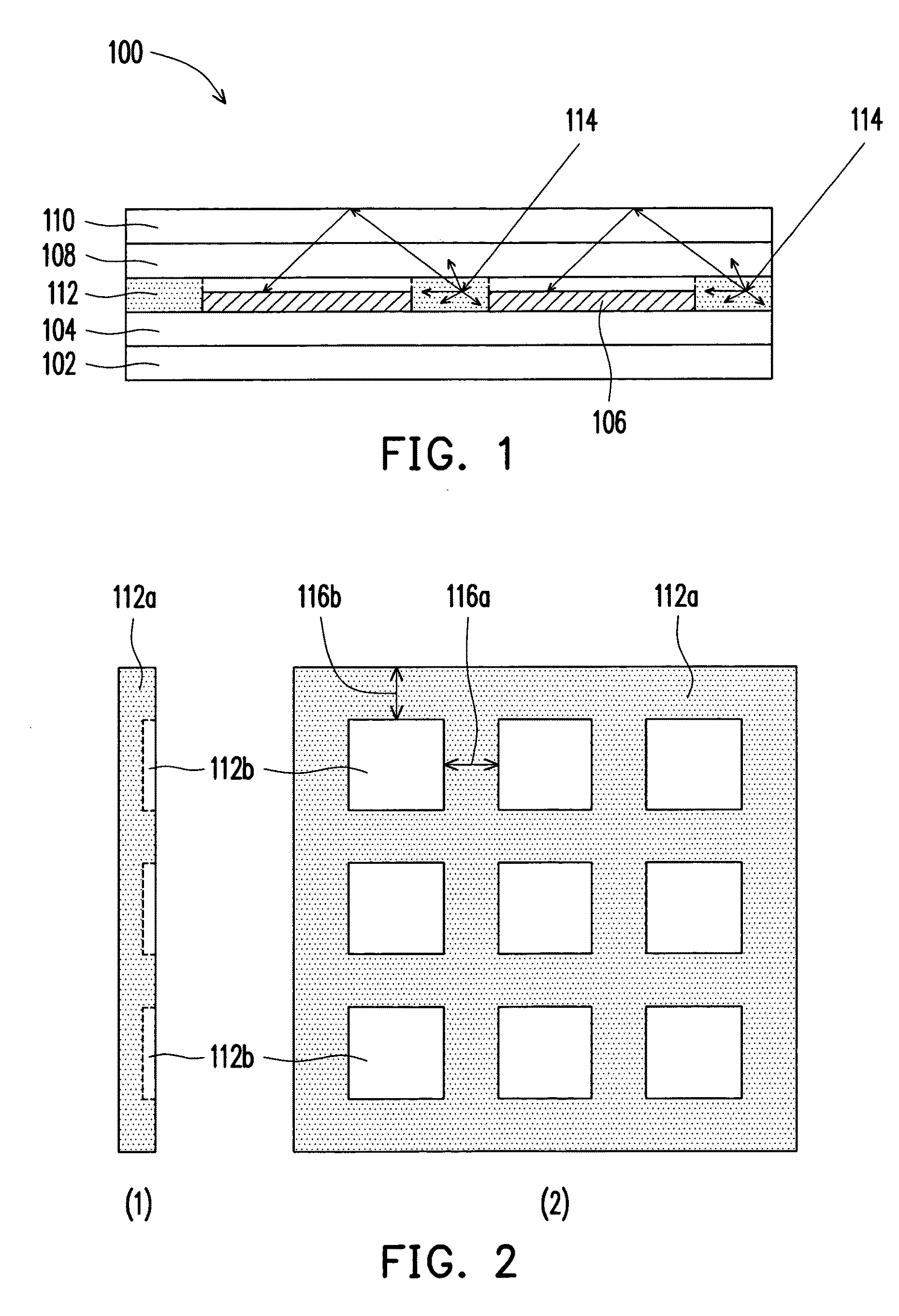

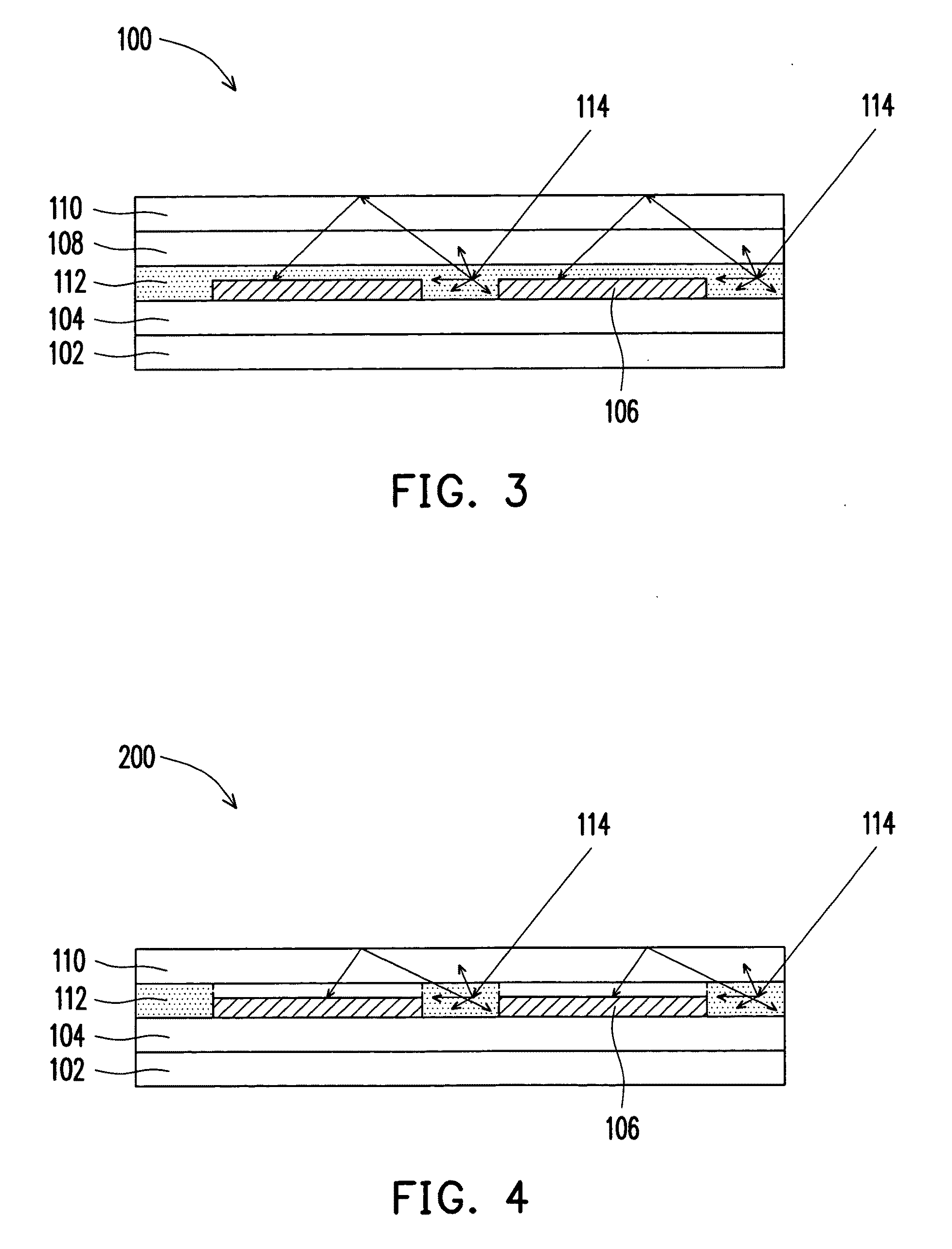

Encapsulant material, crystalline silicon photovoltaic module and thin film photovoltaic module

ActiveUS20100147363A1High light reflectivityImprove light trappingPV power plantsSynthetic resin layered productsHeat resistanceMicrometer

An encapsulant material with enhanced light reflectivity, a crystalline silicon photovoltaic module and a thin film photovoltaic module are provided. The encapsulant material has a porous structure therein, and an average pore diameter of the porous structure is between several hundreds of nanometers and several hundreds of micrometers, so that the light reflectance of the encapsulant material is improved. Moreover, the encapsulant material is crosslinked by a physical or chemical crosslinking method, so heat resistance thereof is improved. Therefore, the encapsulant material is suitable for the crystalline silicon photovoltaic module and the thin film photovoltaic module, so as to increase power conversion efficiency of these modules.

Owner:IND TECH RES INST

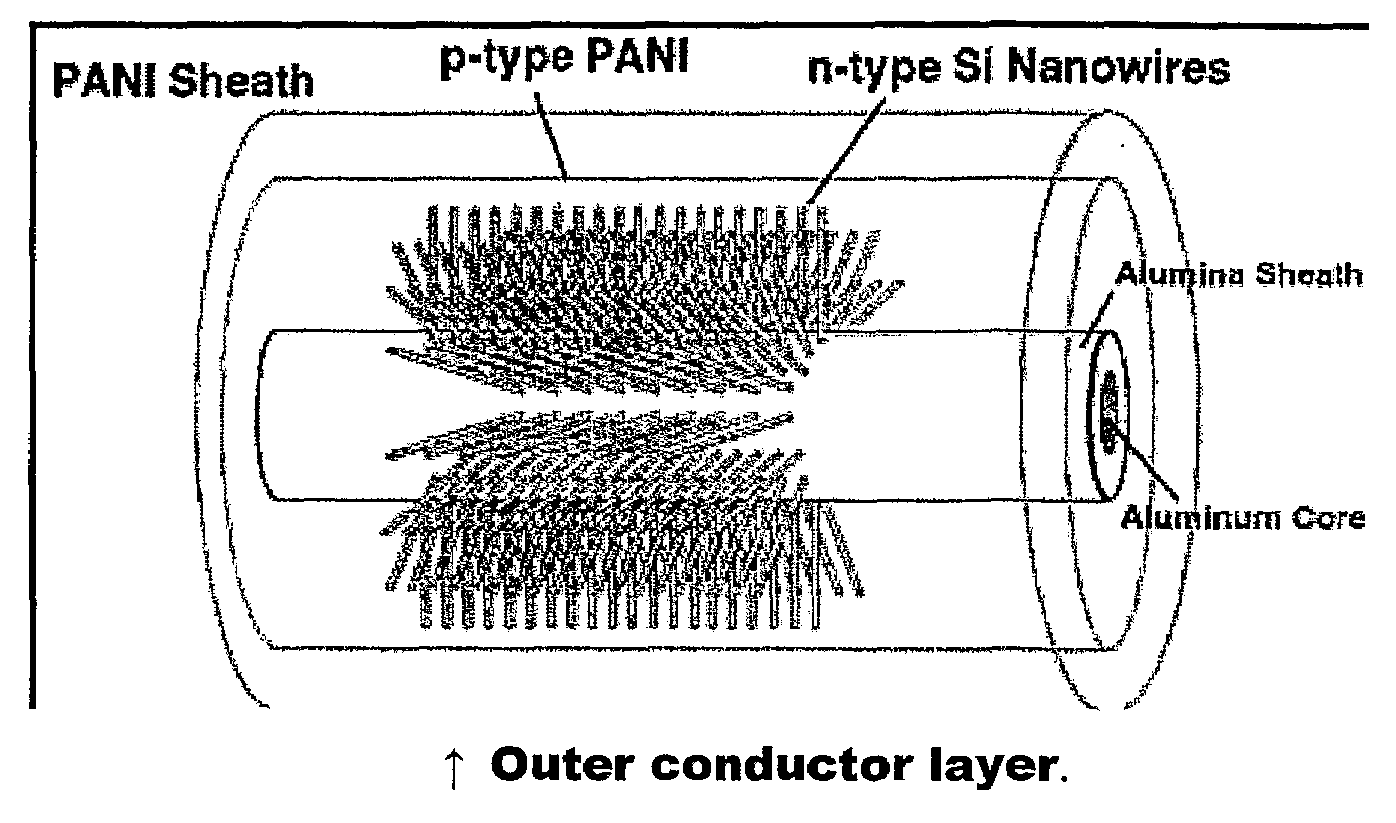

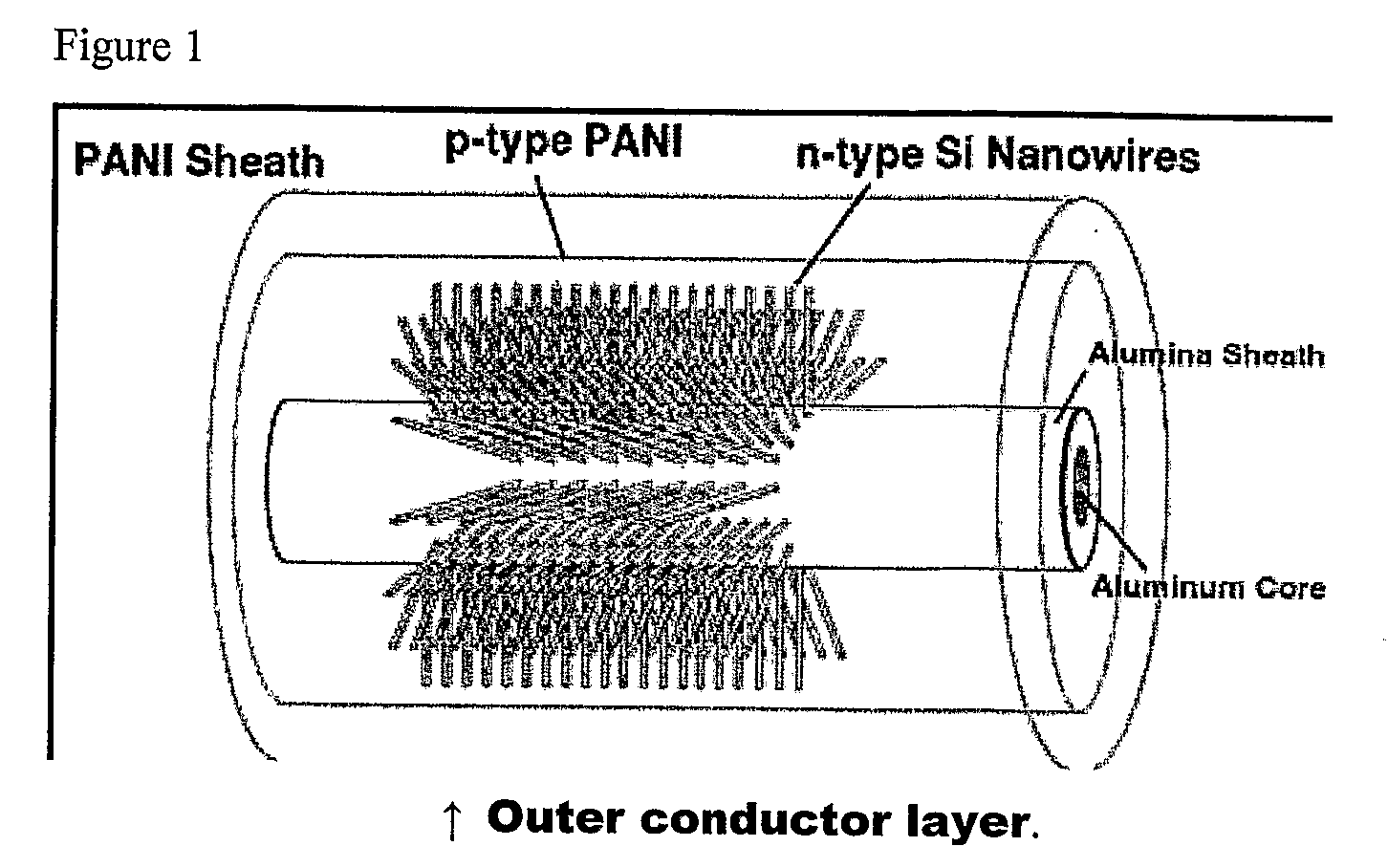

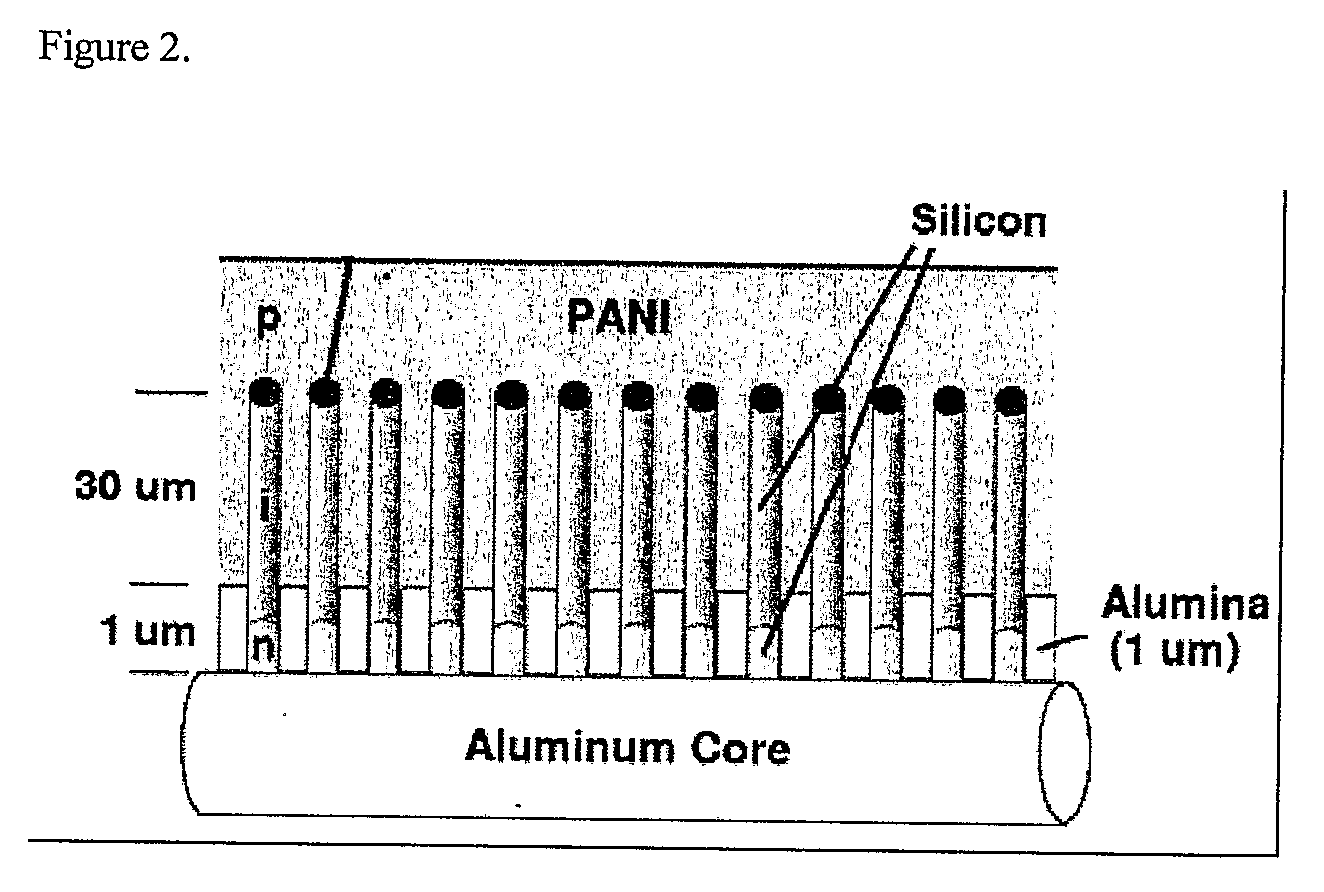

Photovoltaic wire

InactiveUS20090266411A1Efficient and economic use of materialEnhanced light absorptionSolid-state devicesPhotovoltaic energy generationPolymeric surfaceElectrical conductor

A photovoltaic wire is presented where the active layers coat a metallic wire, preferably aluminum. The active layers are an array of doped silicon nanowires electrically attached to the metallic wire that extend from the surface of the wire into a layer of semiconducting polymer, preferably polyaniline. The surface of the polymer is coated with a transparent conductor to complete the photovoltaic circuit.

Owner:ILLUMINEX CORP

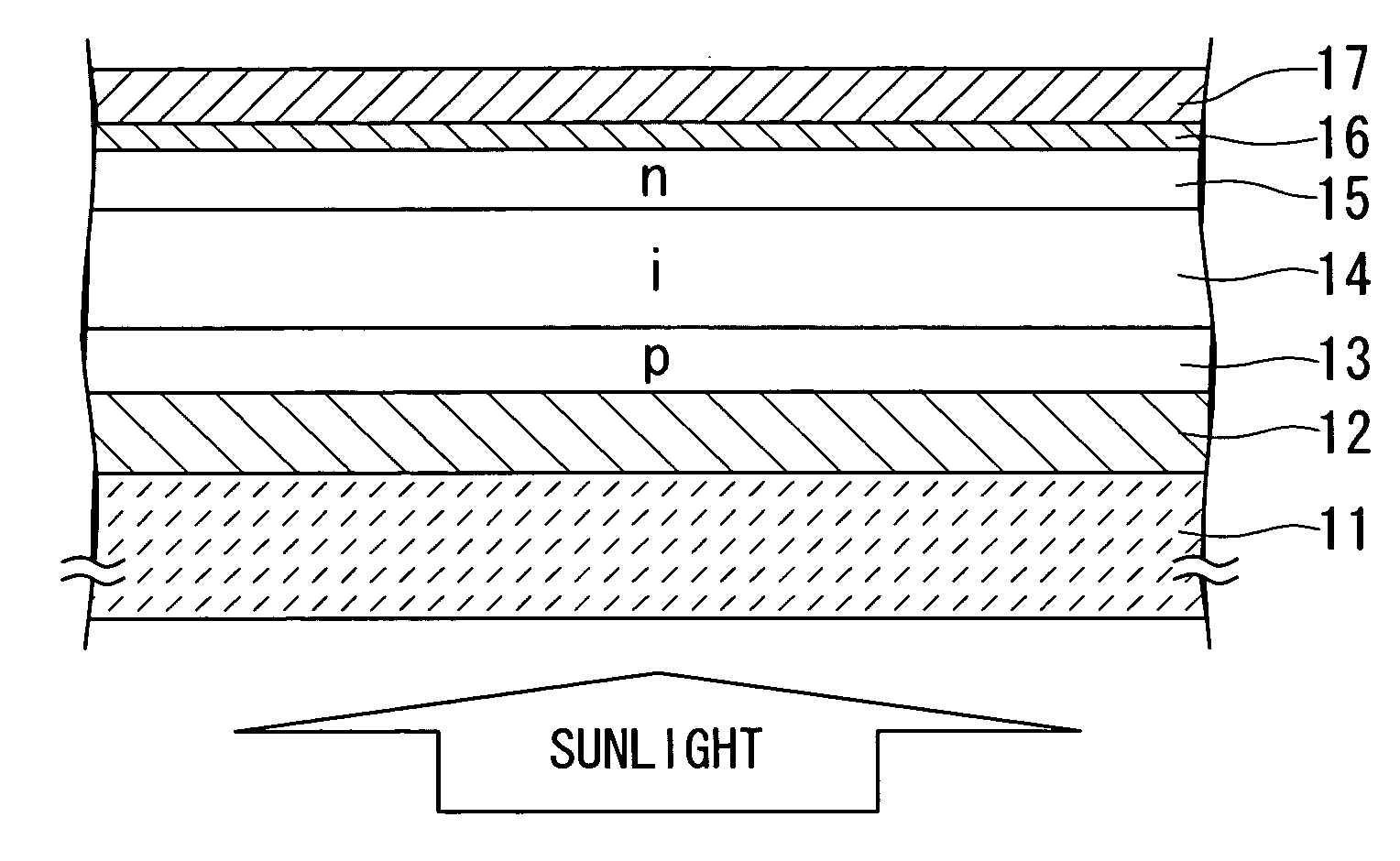

Solar cell and process for producing solar cell

InactiveUS20050103377A1Avoid reorganizationImprove photovoltaic conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingDopantManufacturing technology

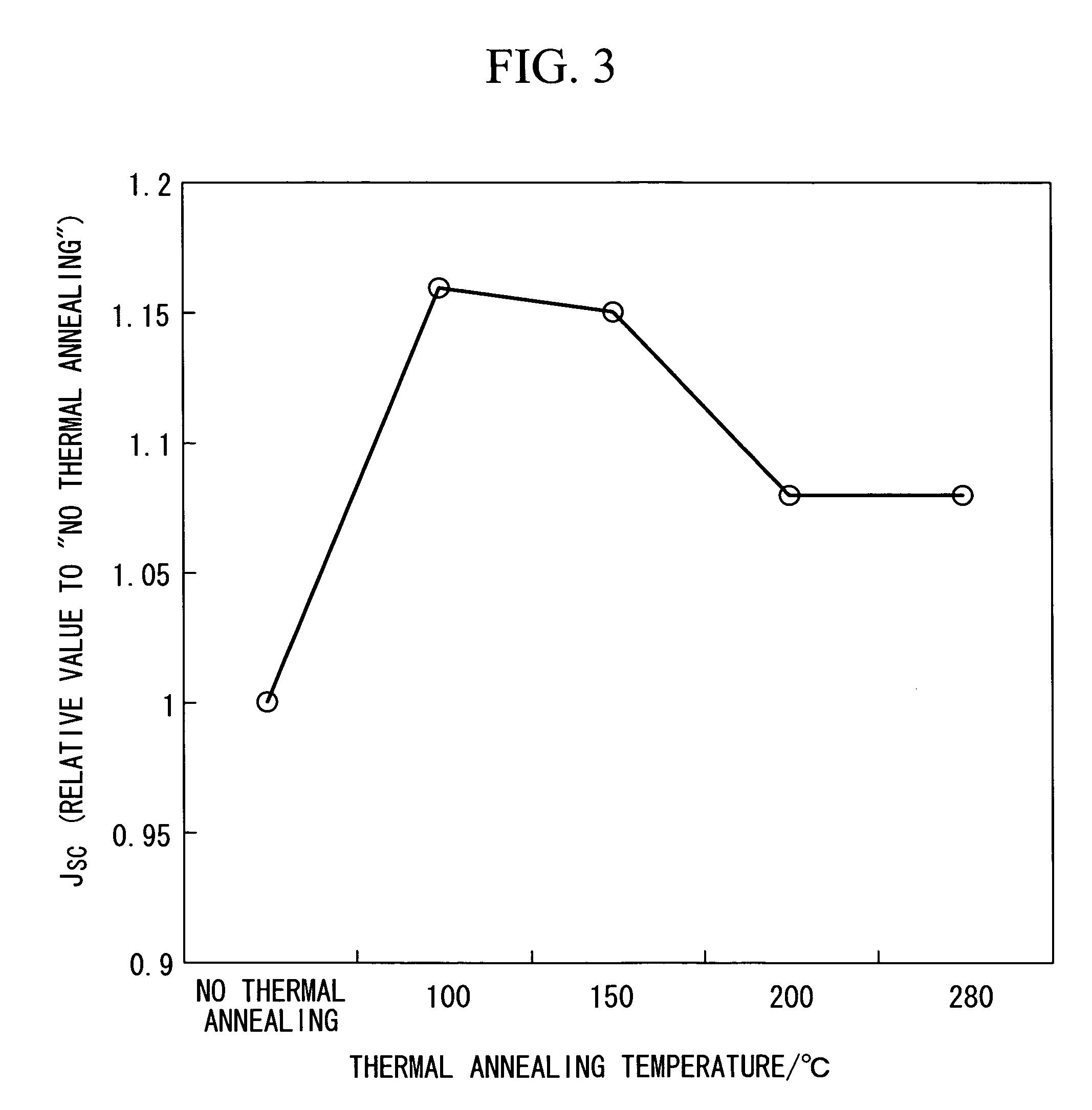

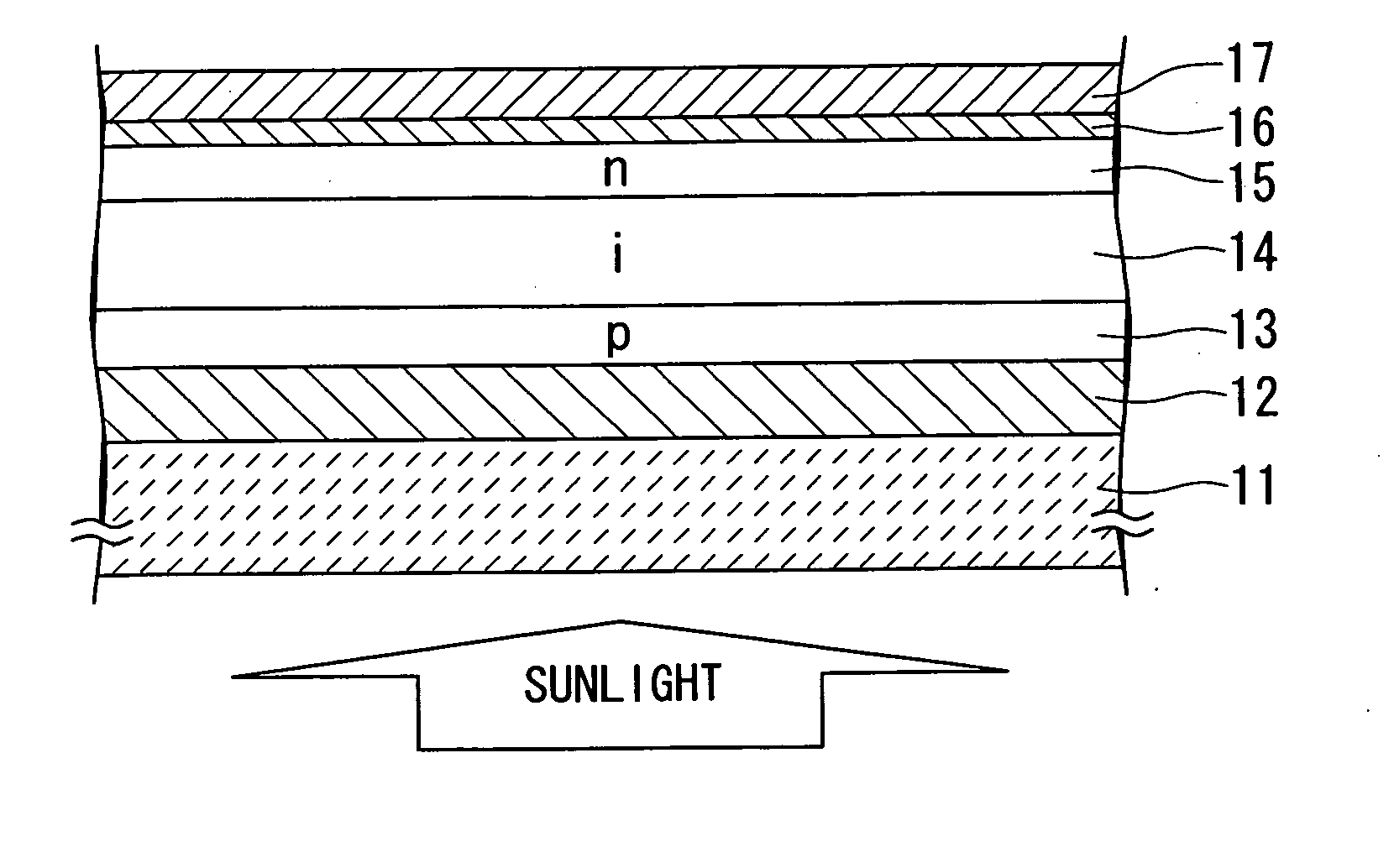

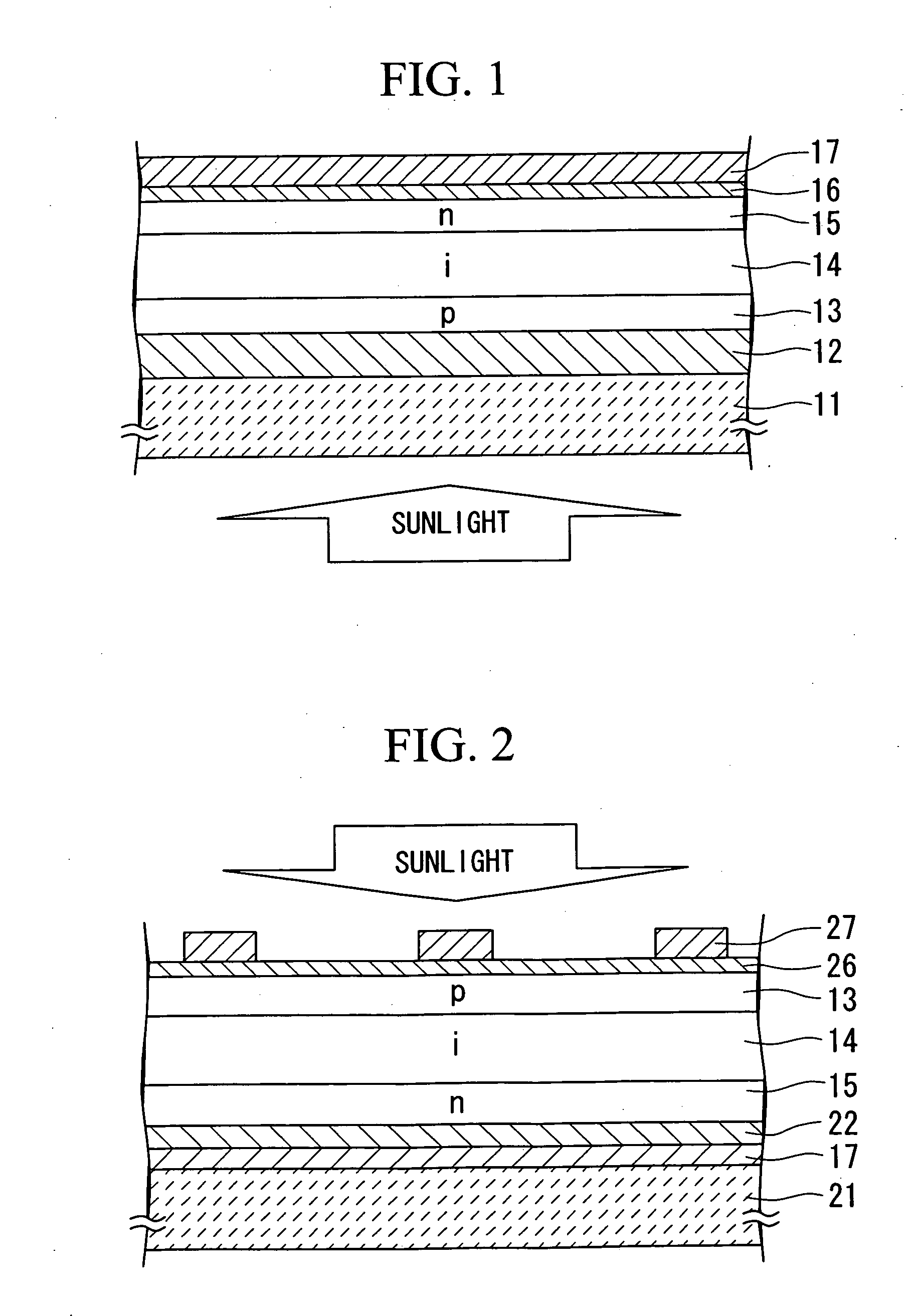

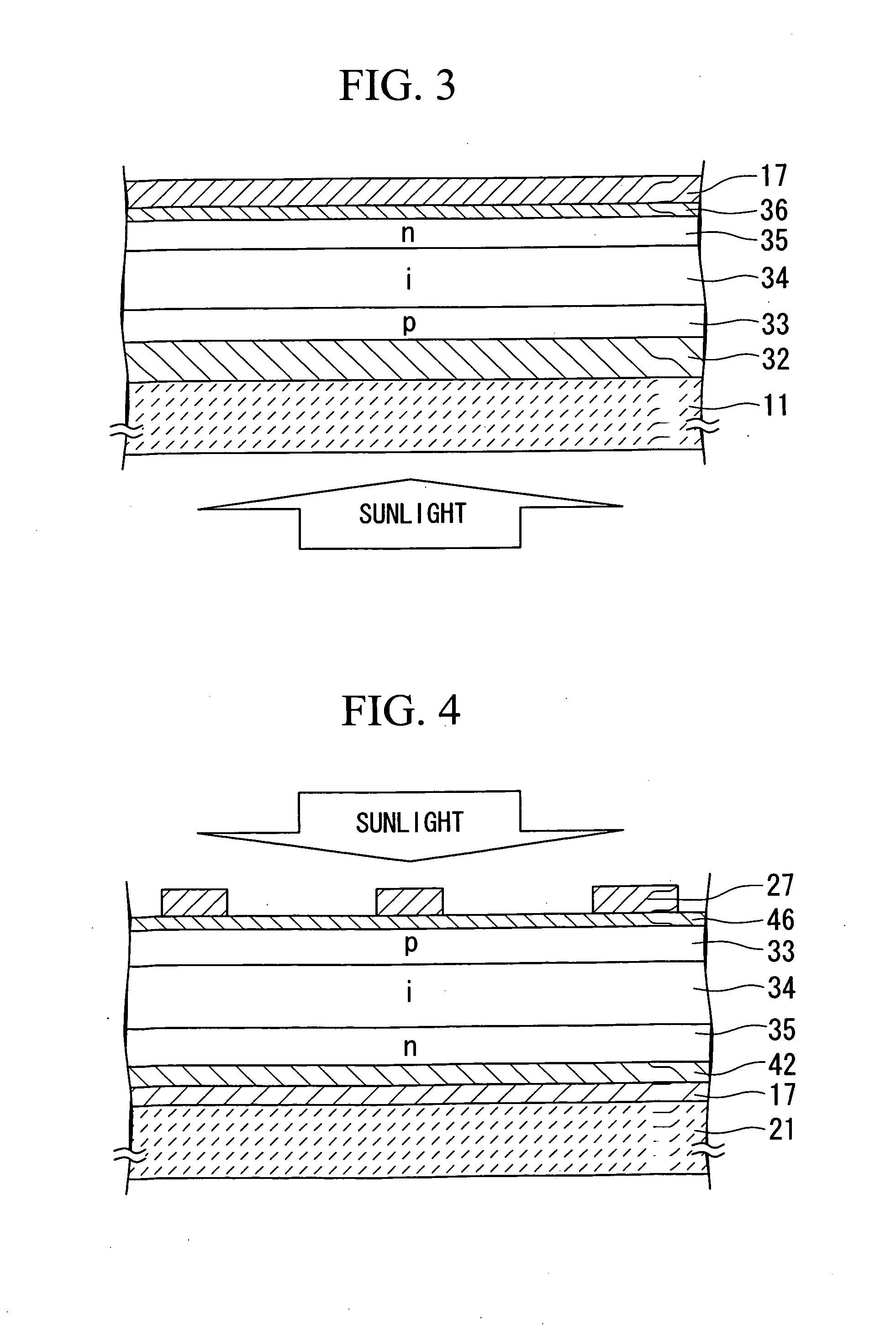

A process for producing a solar cell is provided which can enhance the photovoltaic conversion efficiency by enlarging the grain sizes in the direction of the thickness of an i-layer to reduce grain boundaries, thereby avoiding recombination of carriers and activating the dopant at the same time. A process for producing a solar cell includes depositing at least a first transparent electrode, polycrystalline silicon layers in a PIN structure, and a second electrode in sequence on an electrically insulating substrate, the polycrystalline silicon layers in a PIN structure including a p-type silicon layer, an i-type silicon layer, and an n-type silicon layer, wherein the polycrystalline silicon layers in a PIN structure are formed by: forming a p-type, which is then subjected to thermal annealing; depositing an i-type silicon layer on the p-type silicon layer; and depositing an n-type silicon layer on the i-type silicon layer.

Owner:MITSUBISHI HEAVY IND LTD

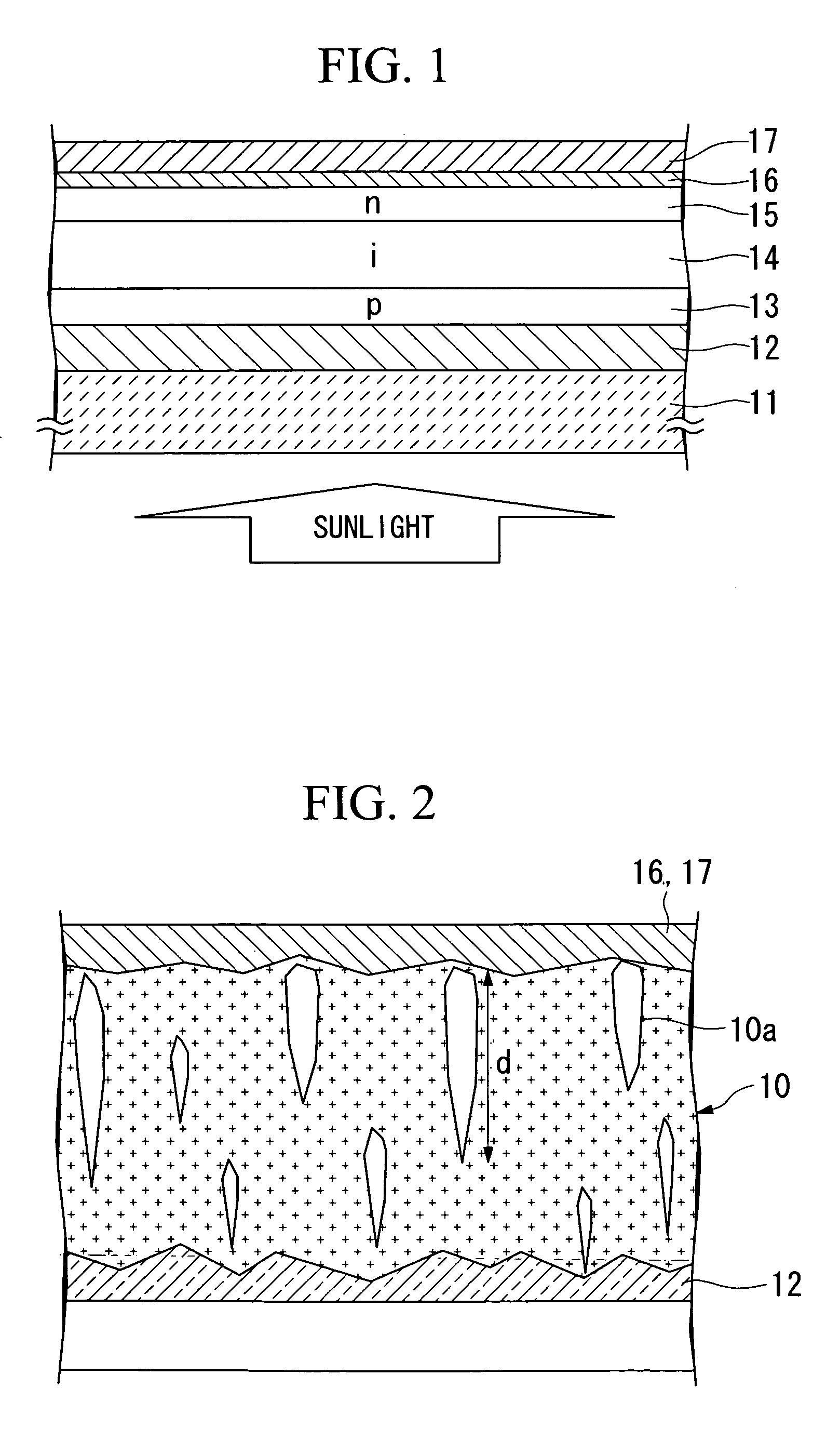

Photovoltaic device

InactiveUS20050205127A1High light transmittanceReduce harmPV power plantsPhotovoltaic energy generationMicrocrystalline siliconP type silicon

A photovoltaic device is formed by depositing at least a first transparent electrode, PIN-structured or NIP-structured microcrystalline silicon layers, a second transparent electrode, and a back electrode in sequence on an electrically insulating transparent substrate. The PIN-structured or NIP-structured microcrystalline silicon layers include a p-type silicon layer, an i-type silicon layer, and an n-type silicon layer. At least one of the first transparent electrode and the second transparent electrode is a ZnO layer doped with Ga, and the Ga concentration is 15 atomic percent or less with respect to Zn.

Owner:MITSUBISHI HEAVY IND LTD

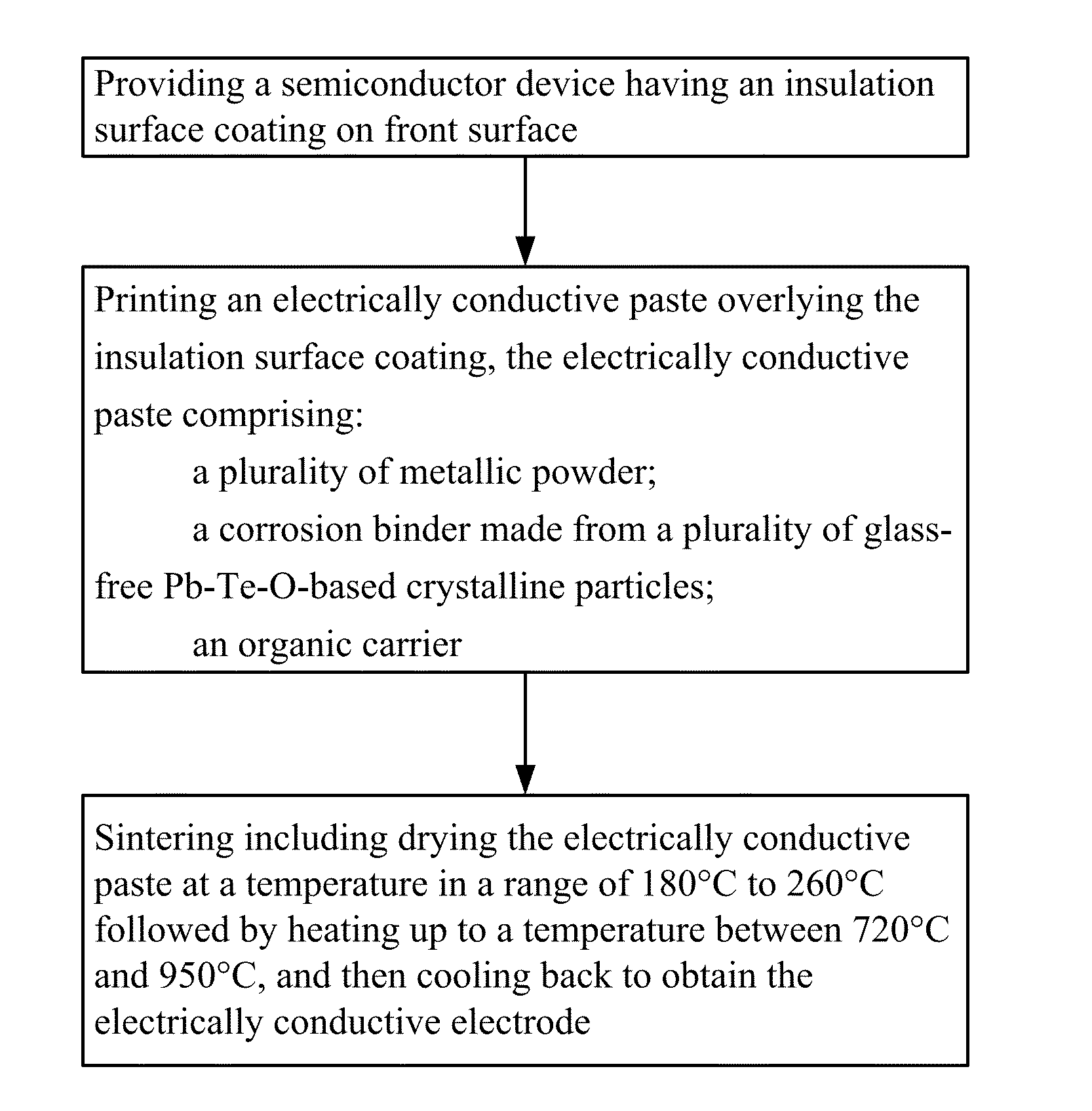

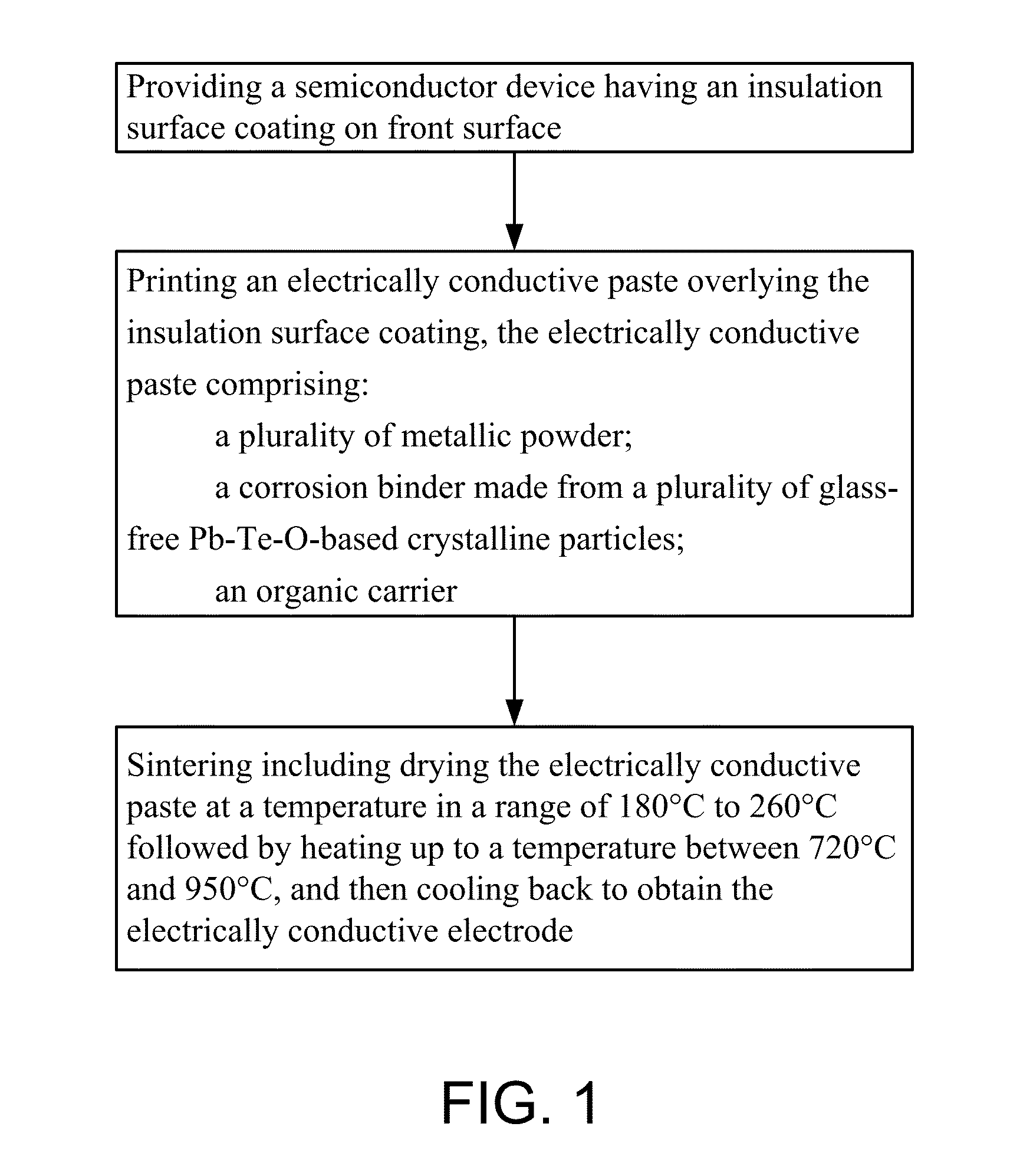

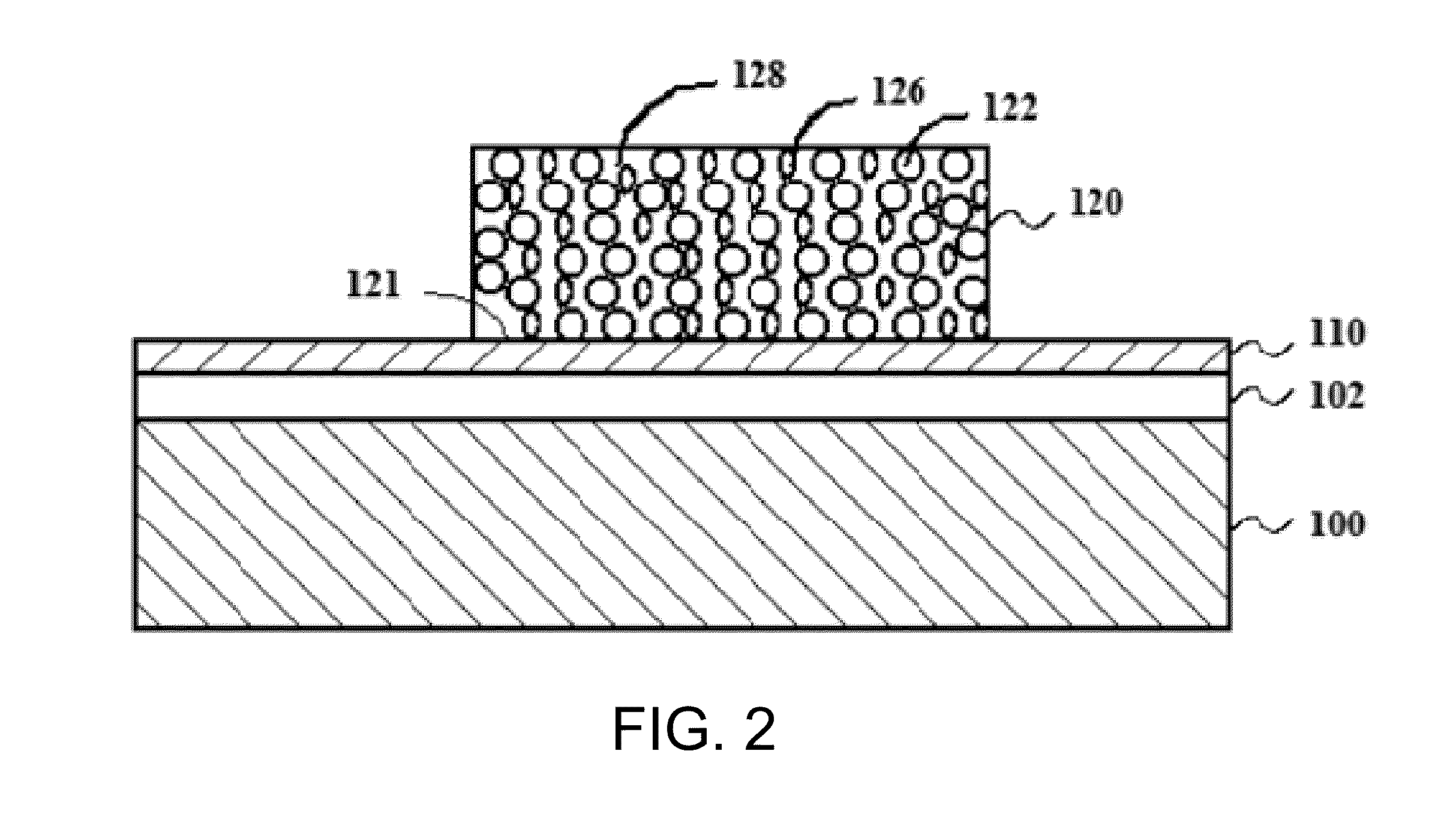

Electrically conductive paste for front electrode of solar cell and preparation method thereof

InactiveUS20140287583A1Reduced series resistanceImprove photovoltaic conversion efficiencyConductive materialSemiconductor/solid-state device manufacturingOhmic contactSilicon solar cell

The present invention provides an electrically conductive paste for a front electrode of a solar cell and a preparation method thereof. The electrically conductive paste is composed of a corrosion binder, a metallic powder and an organic carrier. The corrosion binder is one or more glass-free Pb—Te based crystalline compounds having a fixed melting temperature in a range of 440° C. to 760° C. During a sintering process of the electrically conductive paste for forming an electrode, the corrosion binder is converted into a liquid for easily corroding and penetrating an antireflective insulating layer on a front side of the solar cell, so that a good ohmic contact is formed. At the same time, the electrically conductive metallic powder is wetted, and the combination of the metallic powder is promoted. As a result, a high-conductivity front electrode of a crystalline silicon solar cell is formed.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

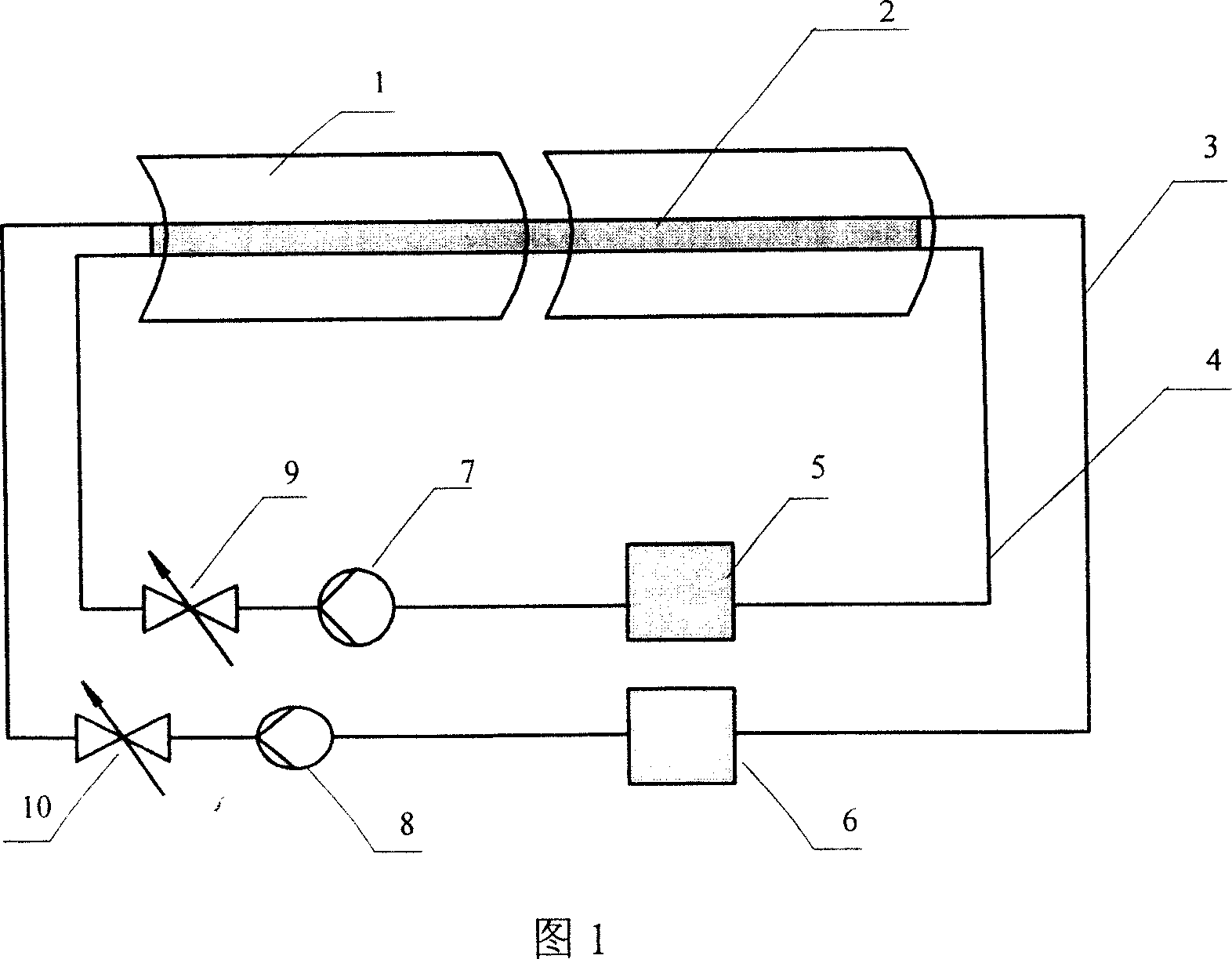

Solar energy light gathering thermo-electric union system

InactiveCN1975282AEfficient use ofReduce lossesSolar heating energySolar heat devicesElectricityPlate heat exchanger

The invention discloses solar united system of concentrate light and pyroelectricity. It has condenser plate and the pyroelectric united device set on condenser zone on the condenser plate. The pyroelectric united device is set with an outer insulating layer of glass, solar cell plate were set under the glass, with cooling conduit which links nano cooling fluid set under the cell plate, the cooling conduit of pyroelectric united device are connected with the cryogenic circulating conduit sequentially installed with cryogenic heat exchanger,cryogenic circulating pump and cryogenic governor valve; the cavity of pyroelectric united device is connected with the high-temperature circulating conduit sequentially installed with high-temperature heat exchanger,high-temperature circulating pump and high-temperature governor valve. The invention complex utilizes the photo electricity and photo-thermal; improve photovoltaic conversion efficiency when the heat is used. The condenser technology reduces the utilization area of photovoltaic battery panels; great reduce the system investment, with a very broad market prospect.

Owner:ZHEJIANG UNIV

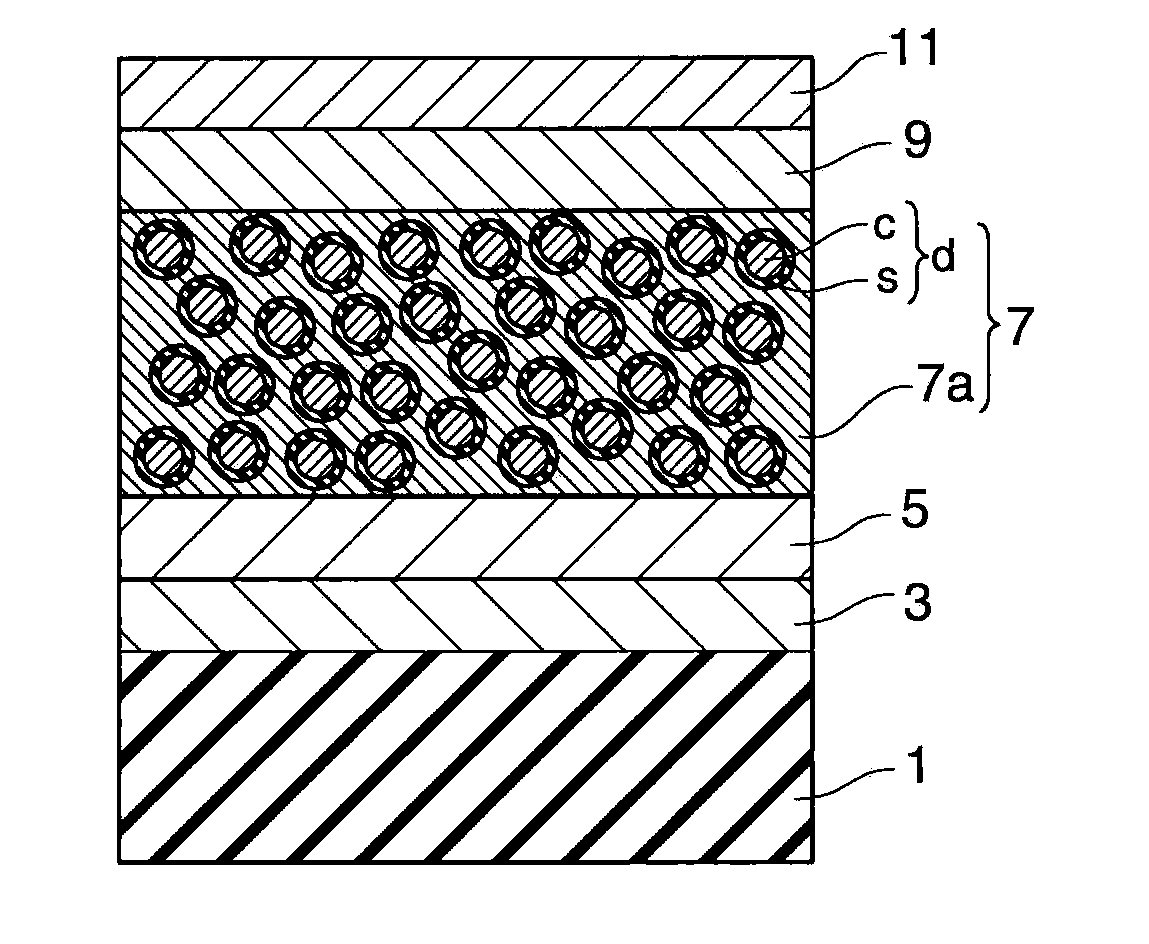

Photovoltaic converter device and electronic device

ActiveUS20100224244A1Improve featuresImprove efficiencyMaterial nanotechnologyNanoinformaticsNanoparticleNanometre

A photovoltaic converter device includes a photovoltaic conversion layer containing a plurality of nanoparticles in a first material in a dispersed state, wherein the nanoparticles include a second material in particles and a third material that coats the second material, the third material having a band gap E3 that is greater than a band gap E1 of the first material, and greater than a band gap E2 of the second material.

Owner:SEIKO EPSON CORP

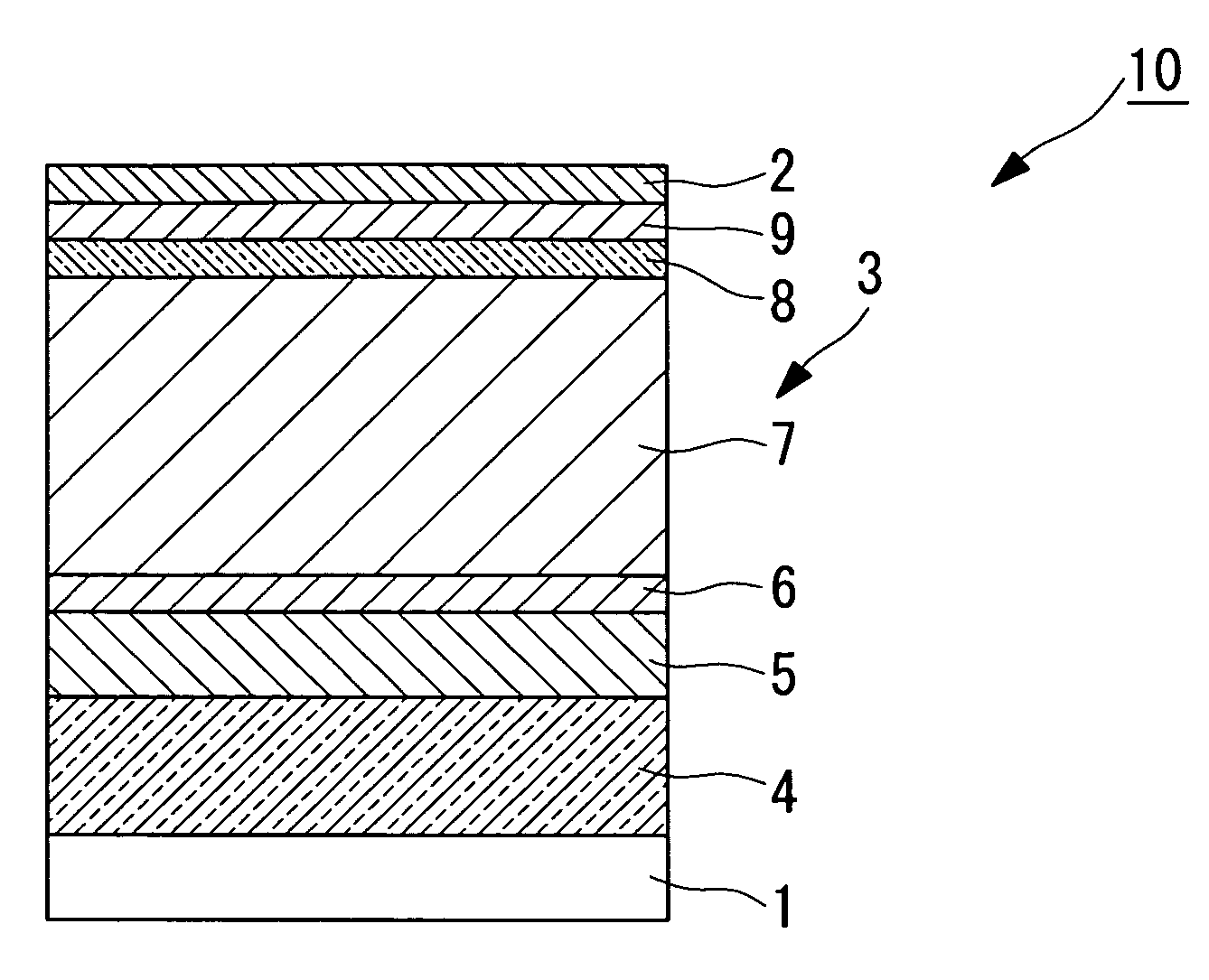

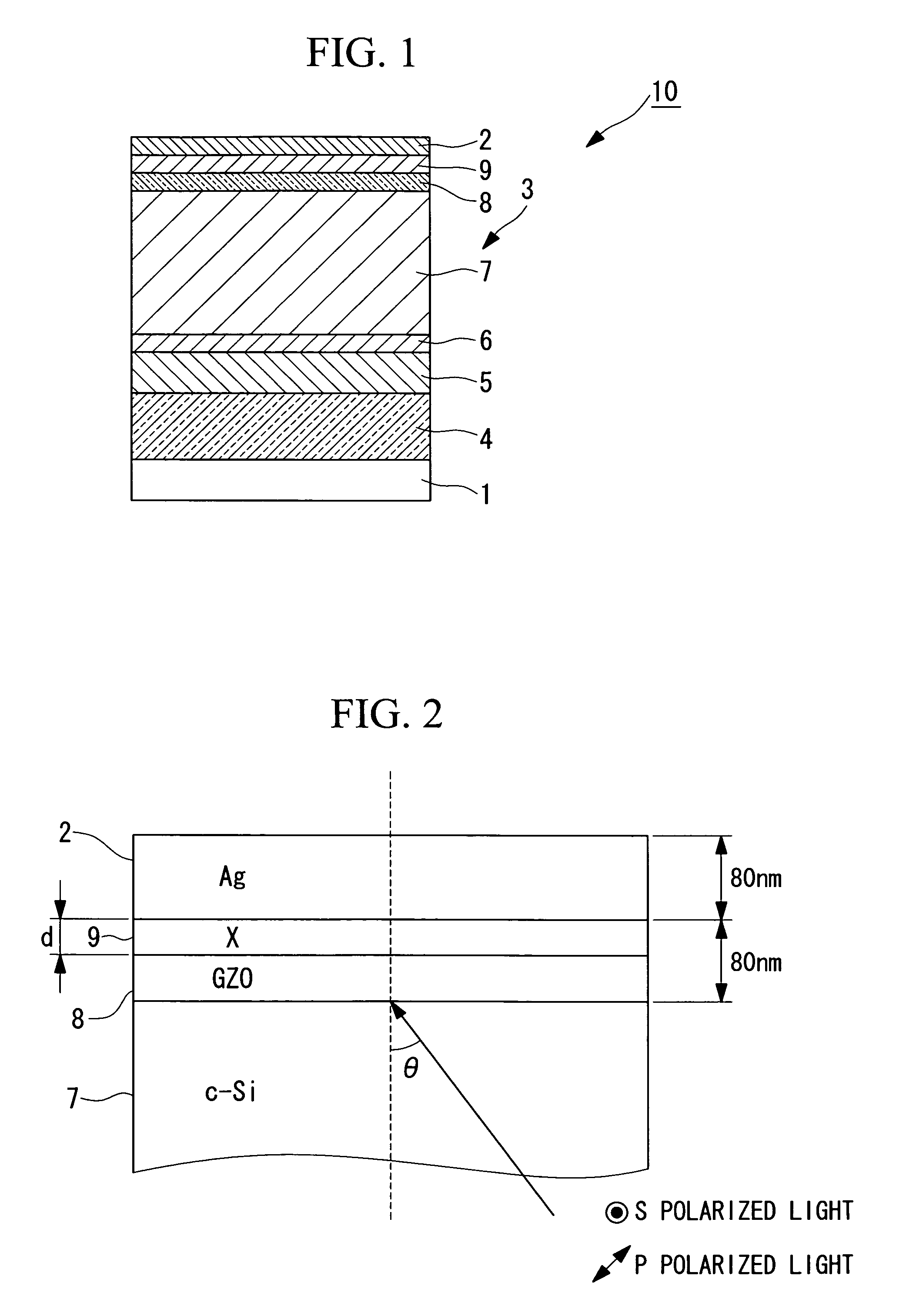

Photovoltaic conversion cell, photovoltaic conversion module, photovoltaic conversion panel, and photovoltaic conversion system

InactiveUS20070221269A1Improve photovoltaic conversion efficiencyPhotovoltaic energy generationSemiconductor devicesRefractive indexTransparent conducting film

The efficiency of a thin film Si solar battery is improved. Between a back face electrode and a transparent conductive film provided on a front face side of the back face electrode, a refractive index adjustment layer is interposed made from a material that has a lower refractive index than that of the transparent conductive film. For example when the transparent conductive film is GZO, SiO2 is interposed between the transparent conductive film and the back face electrode made from Ag. As a result light that penetrates into and is absorbed at the back face electrode is reduced, and the reflectivity of light at the back face electrode is improved.

Owner:MITSUBISHI HEAVY IND LTD

Method for annealing photovoltaic cells

ActiveUS20080075840A1Improve photovoltaic conversion efficiencyImprove carrier lifetimeFinal product manufactureSemiconductor/solid-state device manufacturingHydrogenElectrical battery

Method for annealing at least one photovoltaic cell comprising a substrate based on silicon with a first type of conductivity, a layer doped with a second type of conductivity produced in the substrate and forming a front face of the substrate, an antireflection layer produced on the front face of the substrate and forming a front face of the photovoltaic cell, at least one metallization on the front face of the cell and at least on metallization on a rear face of the substrate. This method comprises at least the steps of:a) a first annealing of the photovoltaic cell at a temperature between around 700° C. and 900° C.,b) a second annealing of the photovoltaic cell at a temperature between around 200° C. and 500° C., at ambient pressure and in ambient air,with hydrogen being diffused in the substrate during the process.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Silicon solar cell module using conductive npaste as electrode and method for manufacturing same

InactiveUS20150004740A1Reduce the required powerDecrease in electric currentPV power plantsSemiconductor/solid-state device manufacturingSilver pasteConductive paste

The present invention relates to a silicon solar cell module comprising electrodes formed from conductive paste. In the invention, front electrode finger lines and front electrode bus bars are separately formed. The front electrode finger lines are formed by printing a silver paste and calcining the printed silver paste at high temperature, and rear electrode bus bars and front electrode bus bars are formed from an inexpensive lower-temperature conductive paste including a buffer and a curing agent having reducing power, whereby the expensive silver paste is replaced with the inexpensive low-temperature conductive paste, thereby reducing the production cost. Because the front electrode bus bars formed from the conductive paste do not come into contact with the silicon substrate, the area of contact between the silicon substrate and the front electrode is reduced, and thus the decrease in electric current caused by the recombination of electrons and holes resulting from this contact is inhibited, thereby increasing the photovoltaic conversion efficiency of the cell. Also, when the conductive paste is used, the rear electrode and front electrode bus bars are calcined at low temperature, and thus the occurrence of cracks in the silicon substrate is reduced, thereby preventing a decrease in the photovoltaic conversion efficiency of the silicon solar cell and increasing the yield of the cell.

Owner:GENS ENG

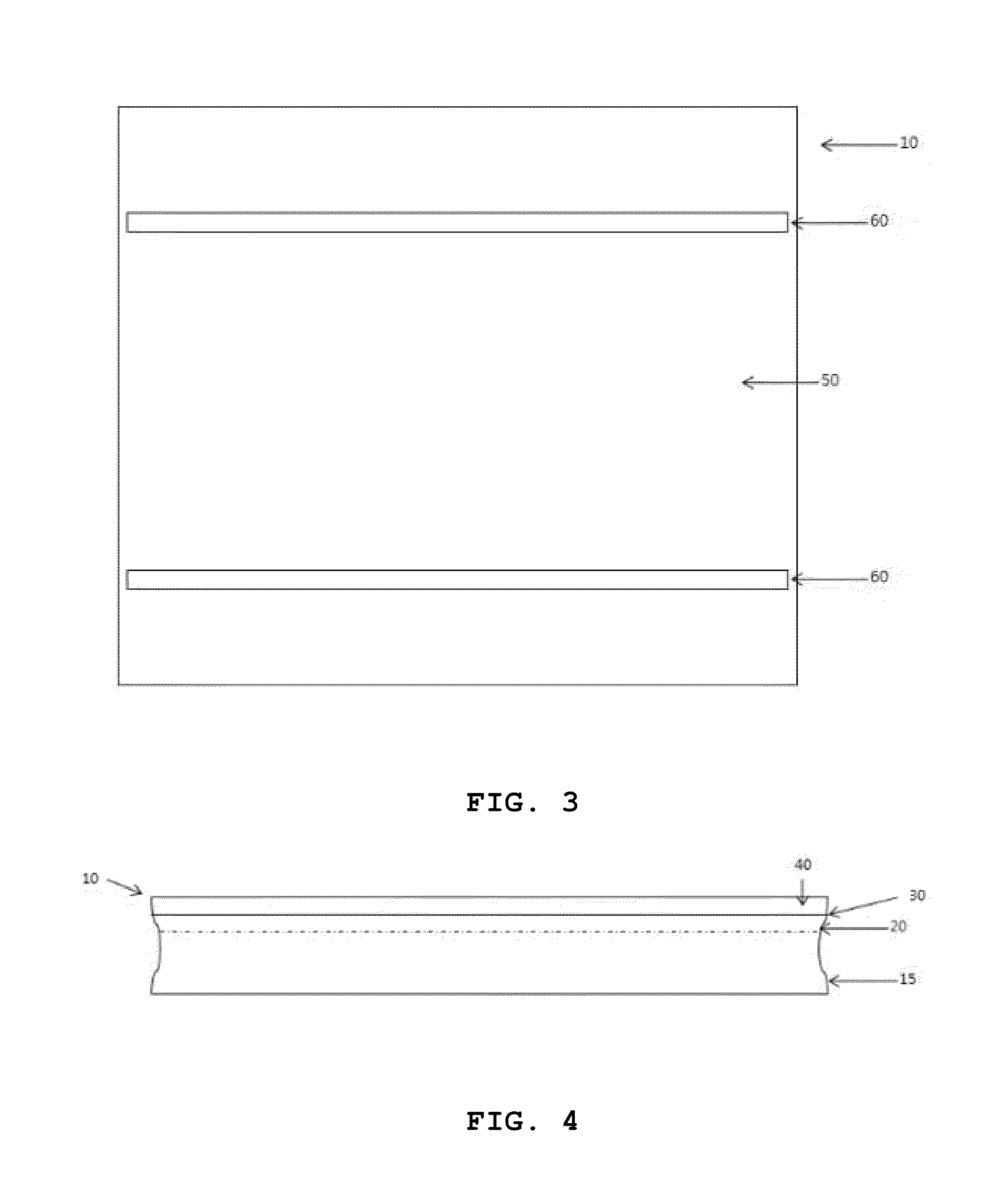

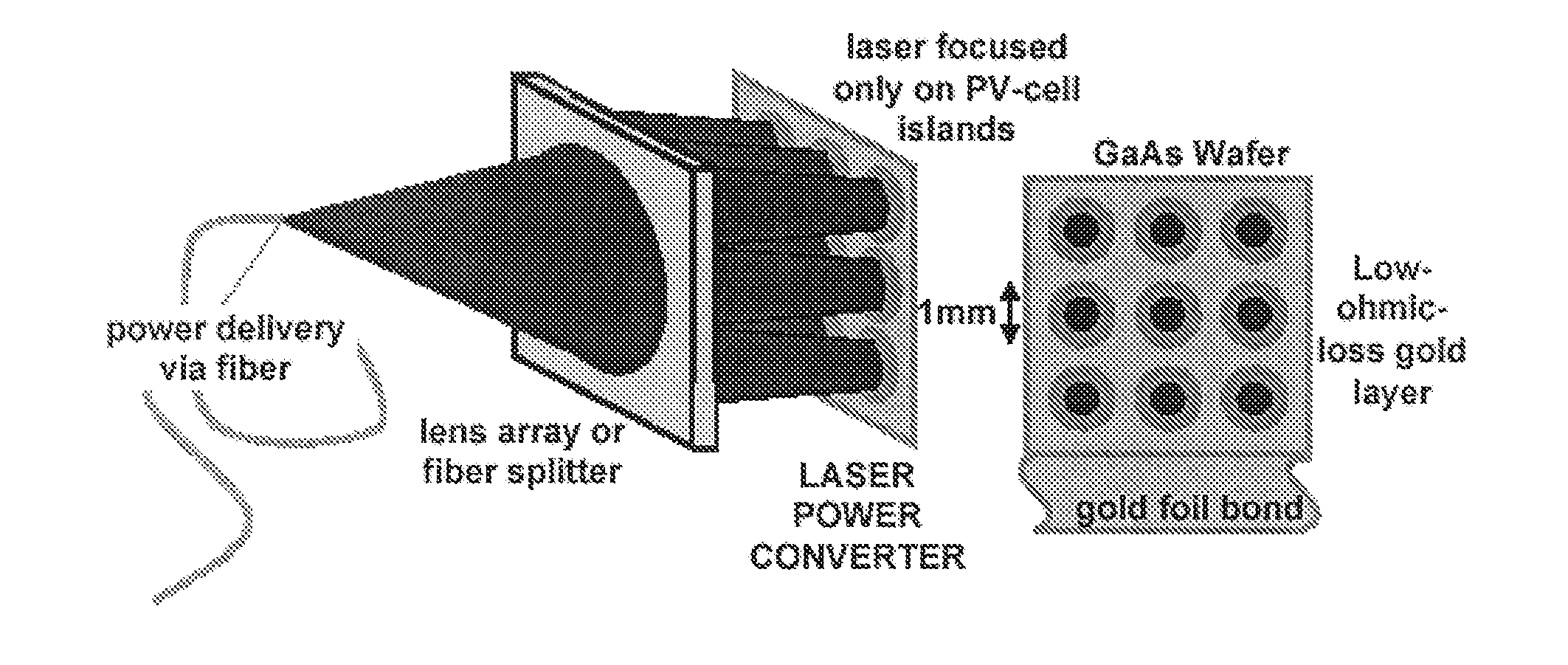

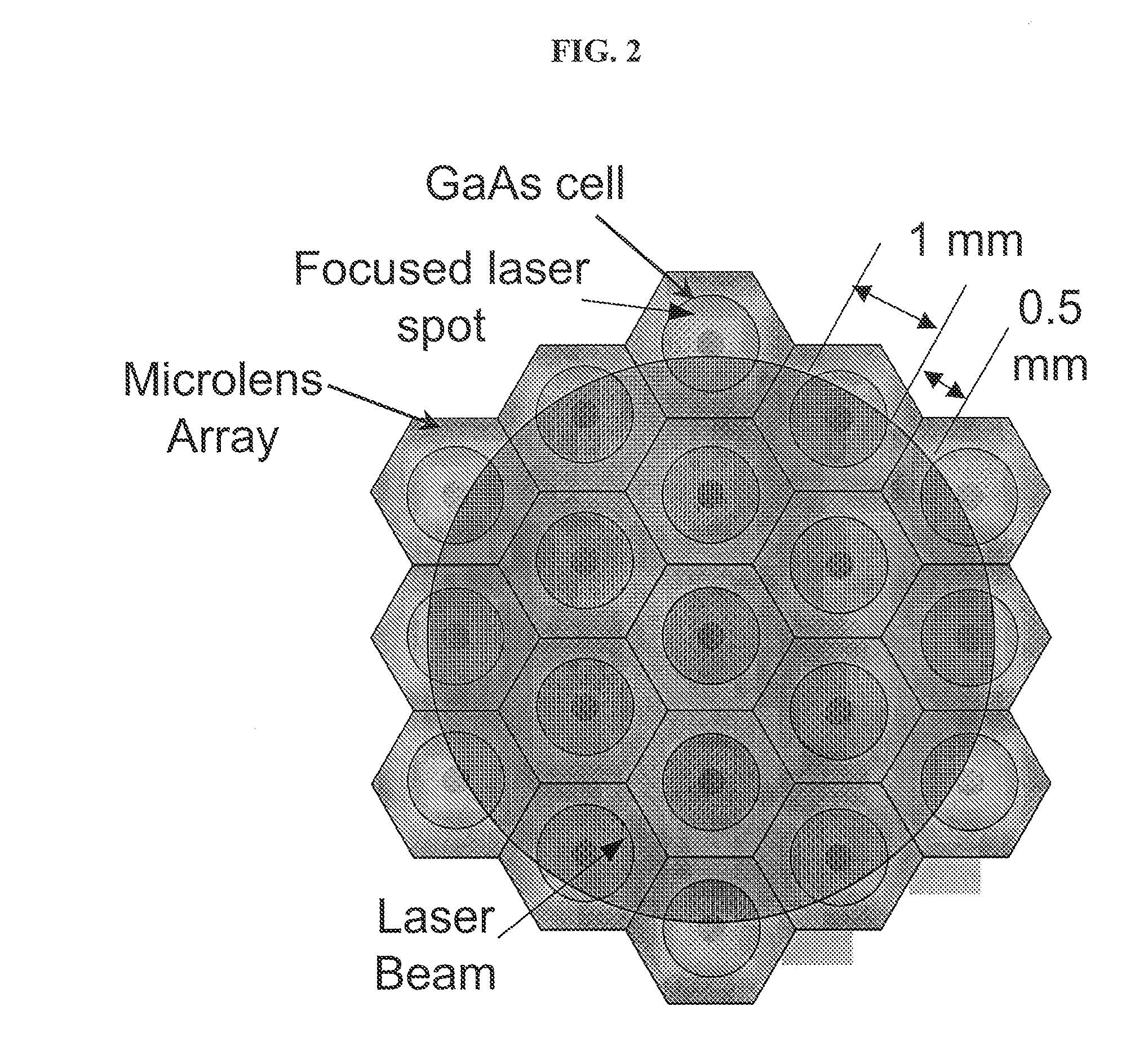

Pixelated photovoltaic array method and apparatus

InactiveUS20100116318A1Improve device efficiencyImprove photovoltaic conversion efficiencyPV power plantsPhotovoltaic energy generationOptical powerLight beam

The present invention comprises a method and apparatus to increase the efficiency of photovoltaic conversion of light into electrical power and to achieve operation at higher optical power and therefore higher electrical power. Preferred embodiments increase the efficiency of photovoltaic power conversion of any source of a beam of photons by spatially dividing the beams into a plurality of individual beamlets, each beamlet focusing on an active photovoltaic region. The preferred architecture of the apparatus of the invention comprises spatially separated photovoltaic cells to substantially match the pattern of the spatially separated plurality of beamlets. Preferred embodiments result in a significant reduction in ohmic losses and current shunting, thereby increasing photovoltaic conversion efficiencies.

Owner:HRL LAB

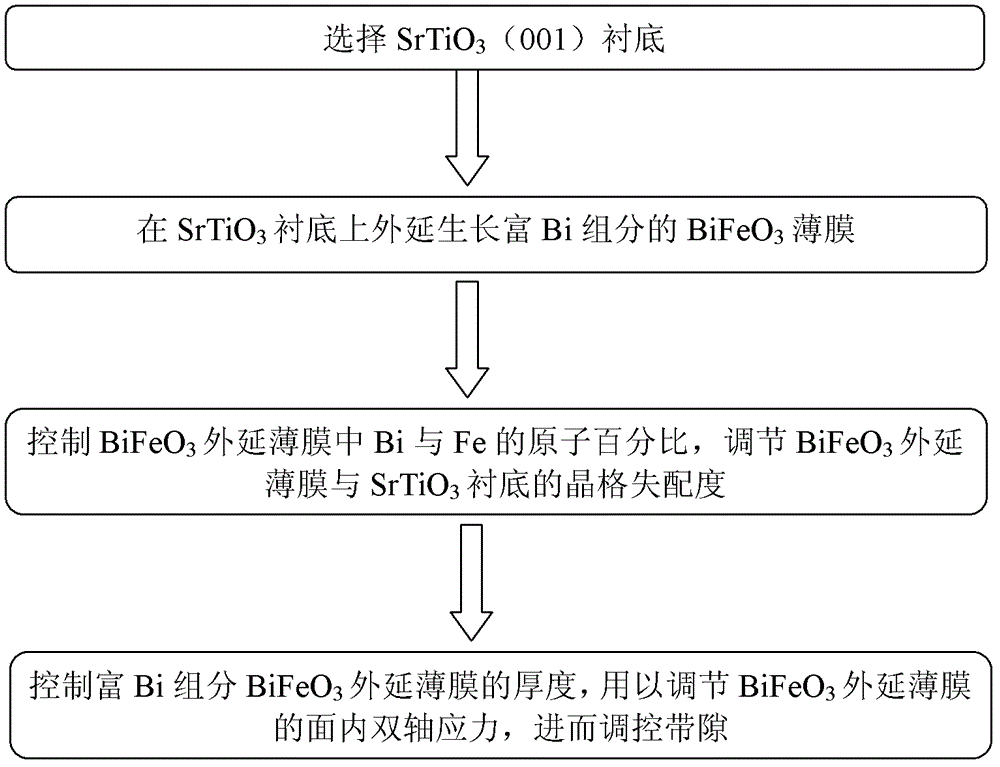

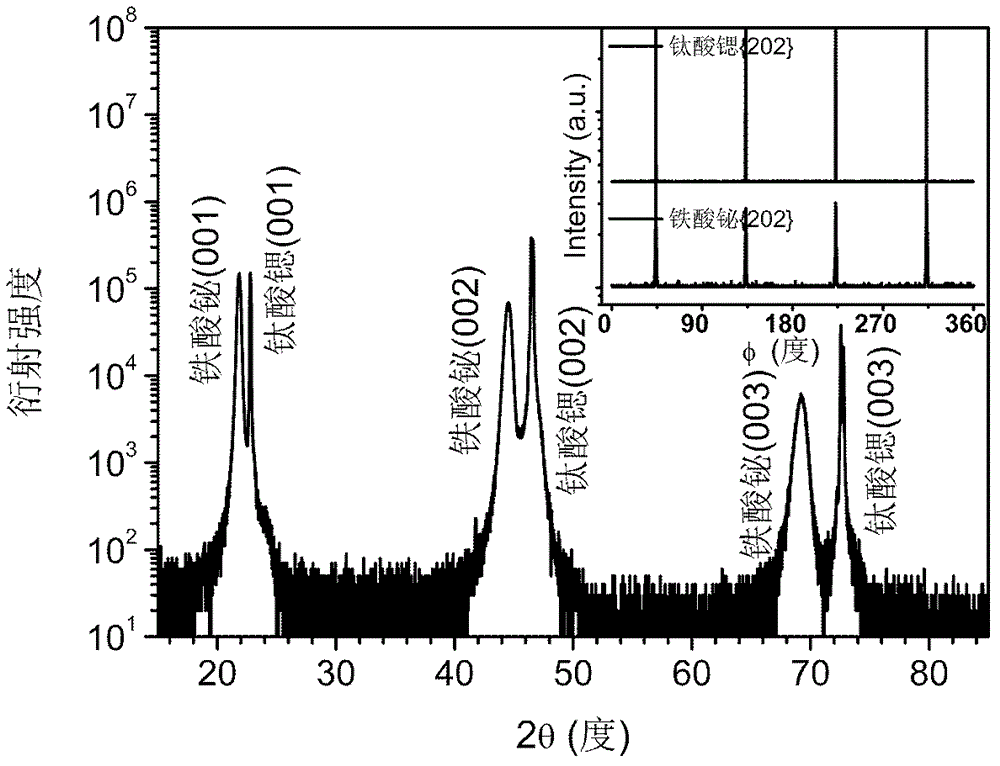

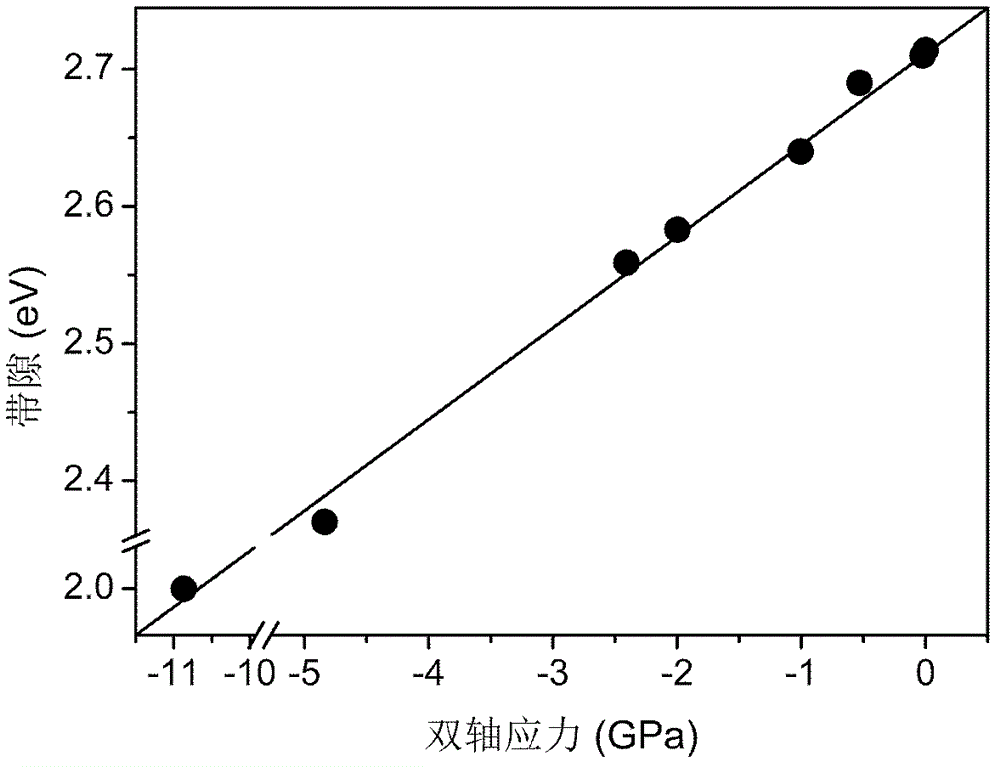

Method for regulating and controlling multiferroic BiFeO3 epitaxial film band gap on SrTiO3 substrate

InactiveCN102723400APrecisely control the magnitude of biaxial compressive stressFlexible and adjustable bandgapFinal product manufactureSemiconductor devicesStrontium titanium oxideIn plane

A method for regulating and controlling a multiferroic BiFeO3 epitaxial film band gap on a SrTiO3 substrate comprises the following steps: 1) Selecting a strontium titanate substrate; 2) Making a BiFeO3 epitaxial film rich in Bi component grow on the SrTiO3 substrate; 3) Controlling an atomic percent of the Bi and Fe in the BiFeO3 epitaxial film and regulating crystal lattice mismatching of the BiFeO3 epitaxial film and the SrTiO3 substrate; 4) Controlling thickness of the grown BiFeO3 epitaxial film rich in Bi component and regulating an in-plane bi-axis stress of the BiFeO3 epitaxial film.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

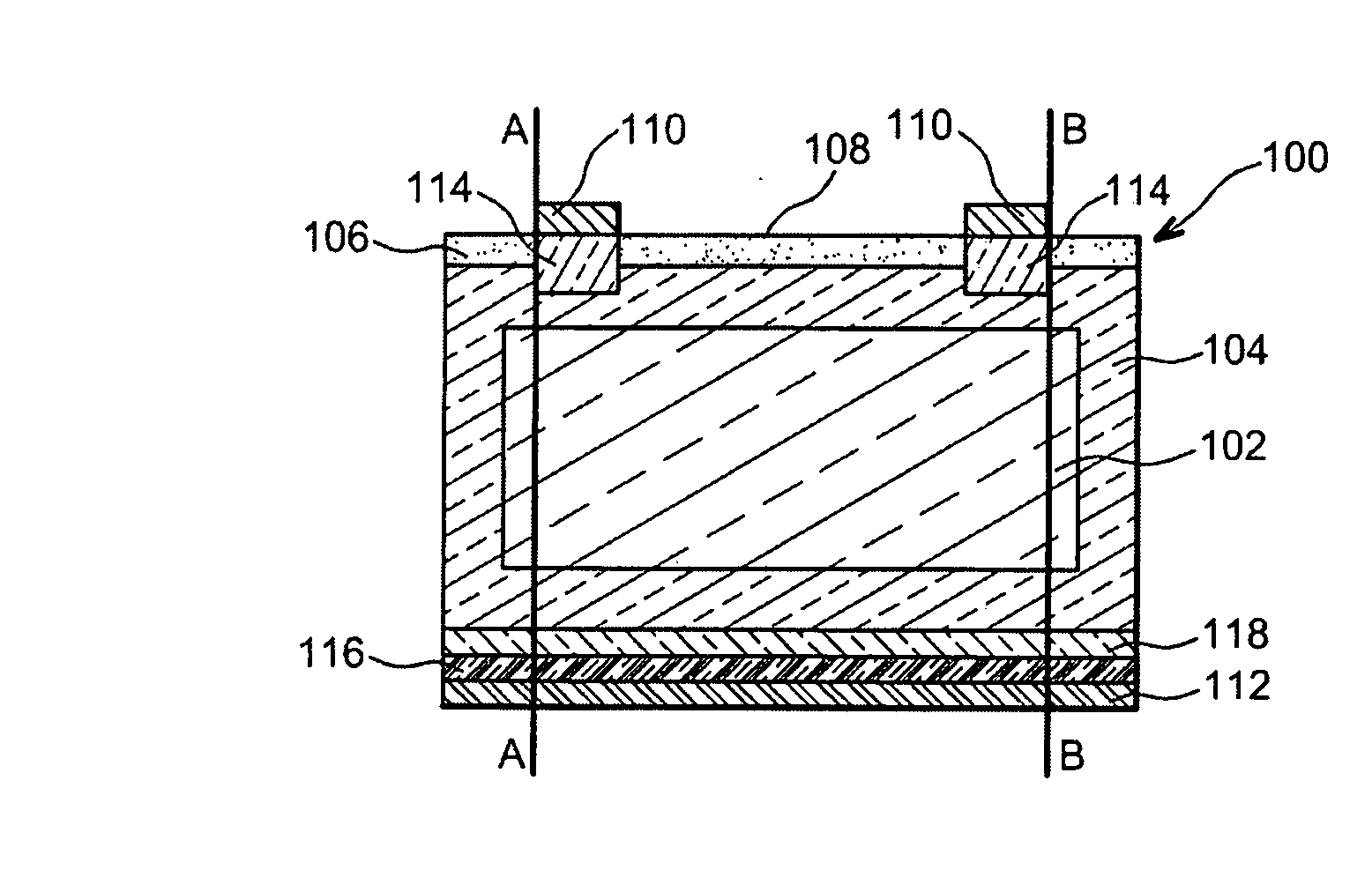

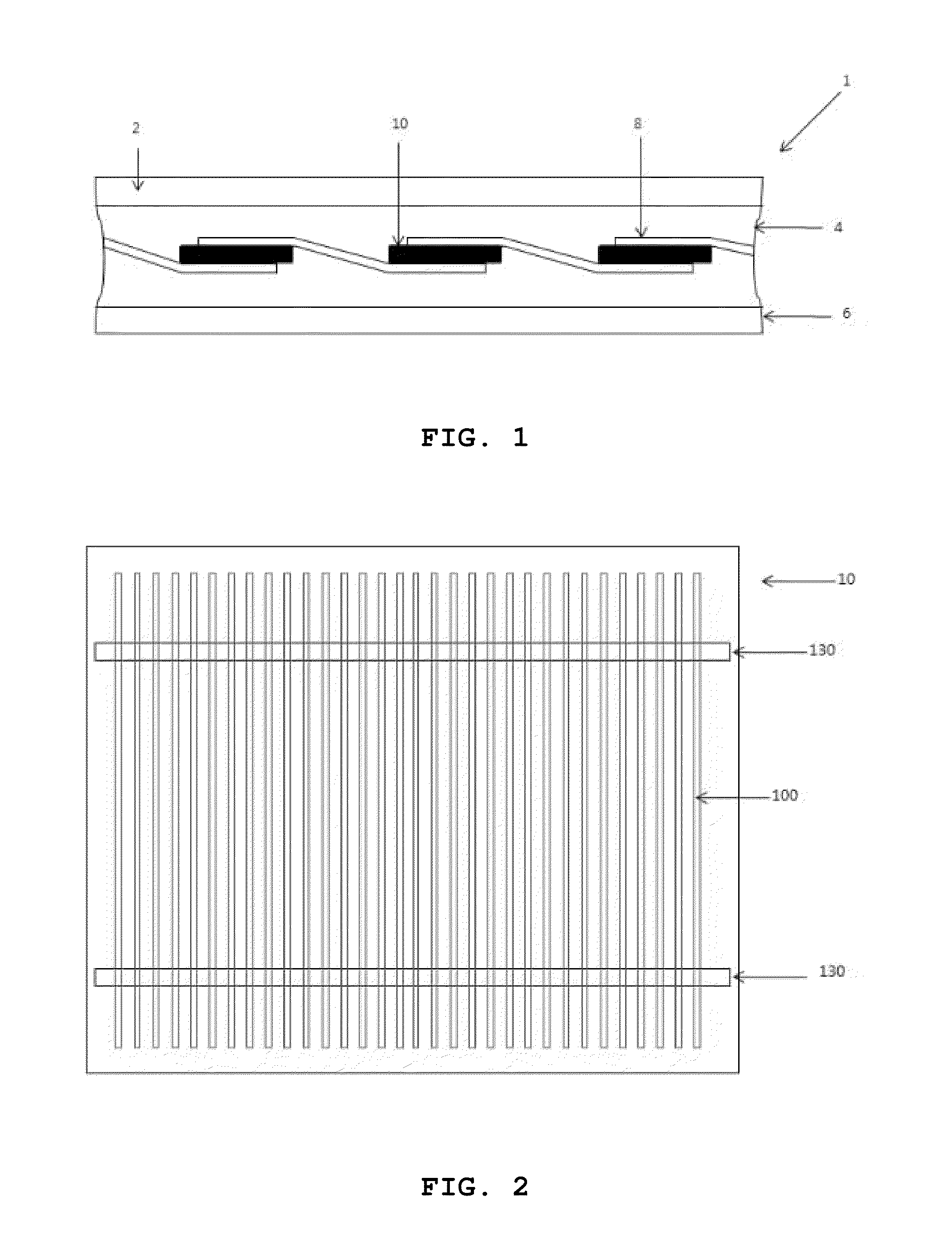

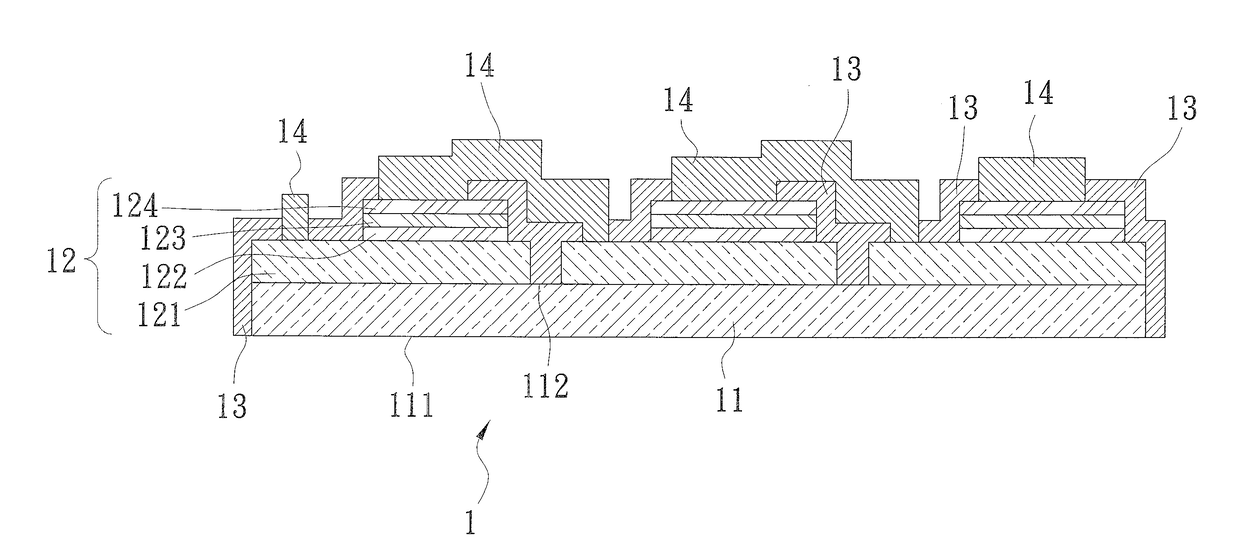

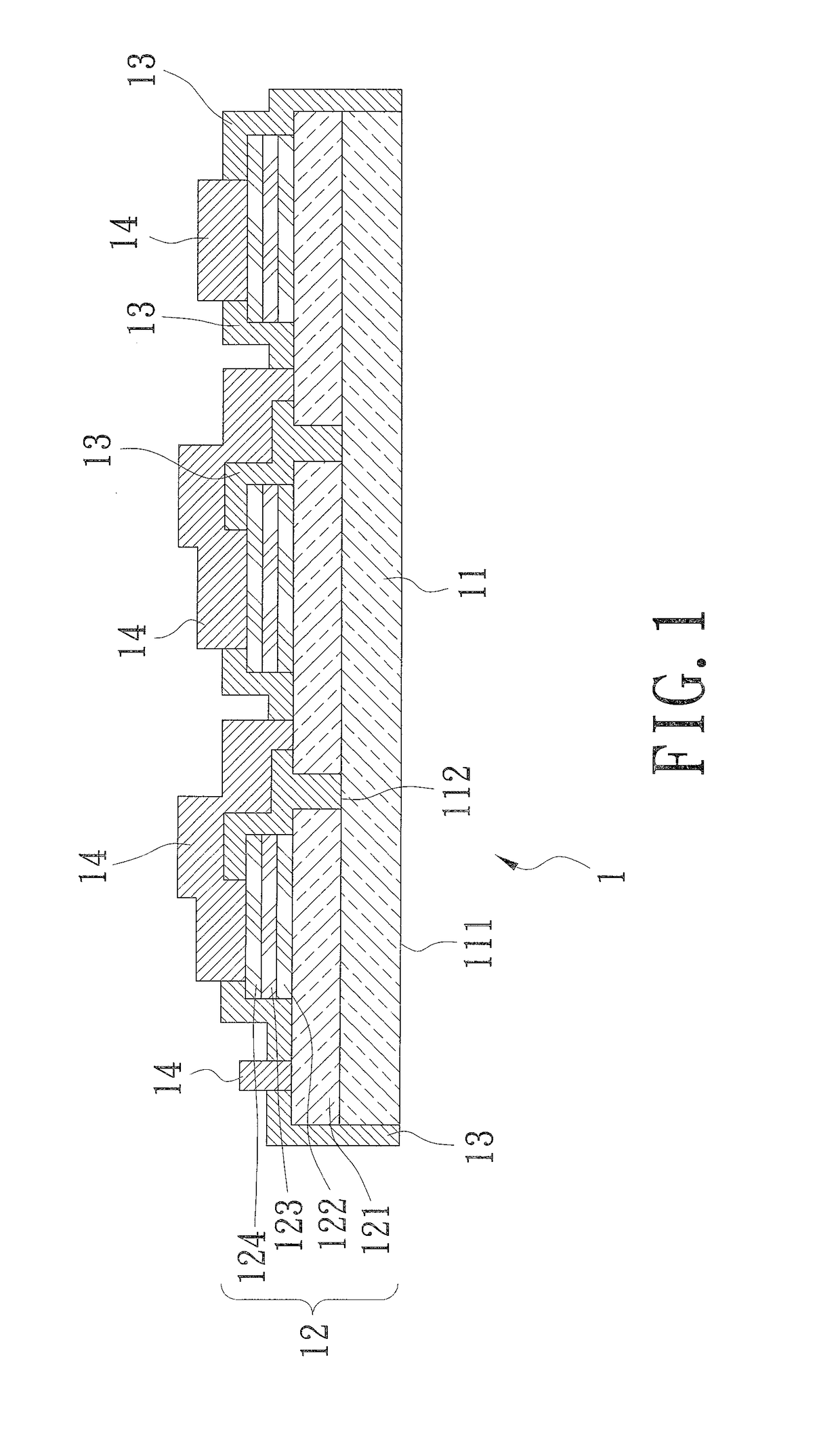

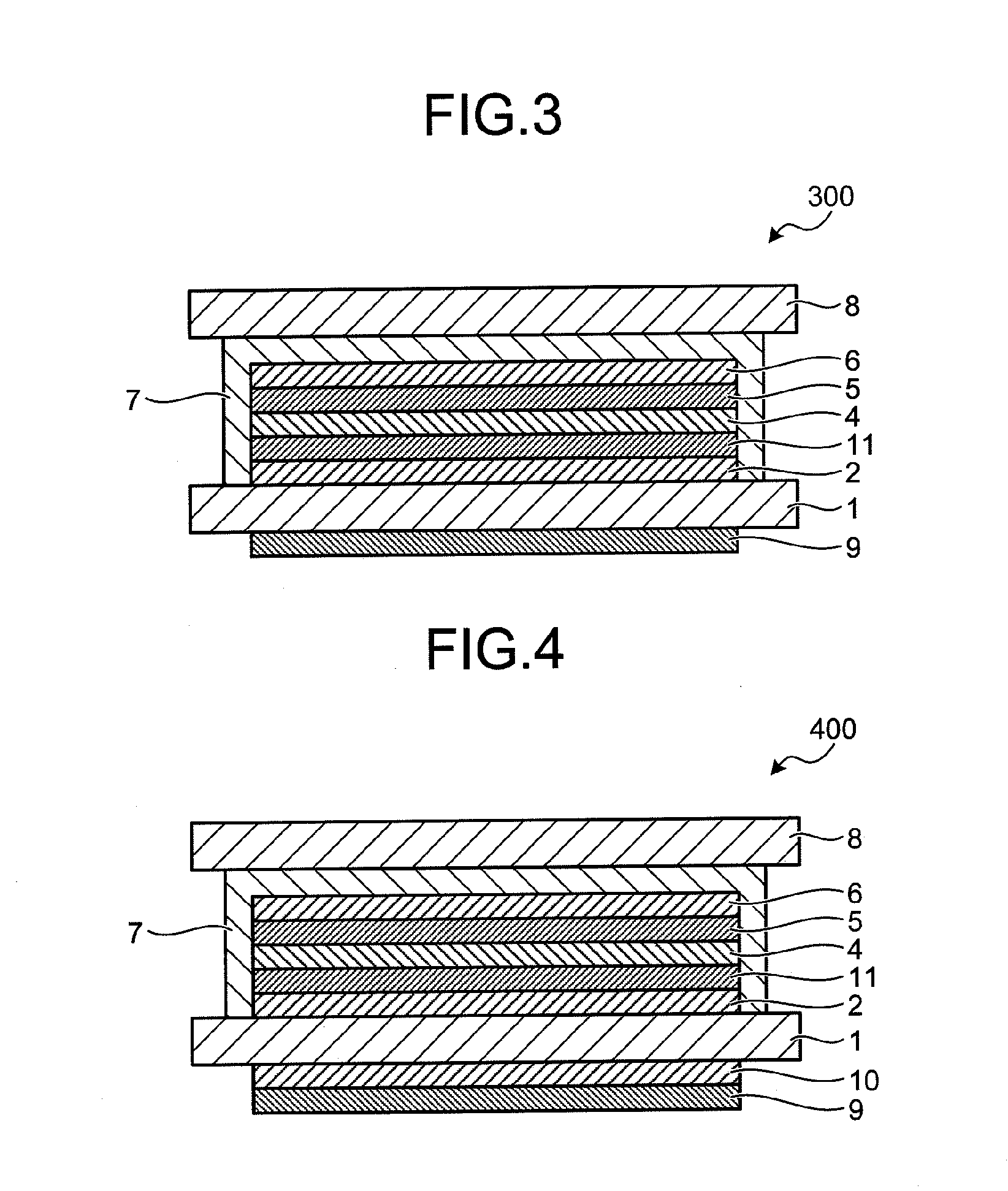

Solar cell module with perovskite layer

InactiveUS20170194102A1Avoid decompositionImprove instabilityLight-sensitive devicesSolid-state devicesElectrical conductorTransport layer

A solar cell module with a perovskite layer is revealed. The solar cell module includes a transparent substrate with a light incident surface and a surface opposite to the light incident surface. A plurality of solar cell units is disposed on the surface and each solar cell includes a transparent conductive layer, a first carrier transport layer, a perovskite layer and a second carrier transport layer. An insulation layer is not only located between the adjacent solar cell units but also covered over the solar cell units. A plurality of conductors is used for electrical connection of the plurality of solar cell units in series. Thus the solar cell module has better open circuit voltage and higher stability owing to connection way of the solar cell units in series and the insulation layer.

Owner:CPC CORPORATION

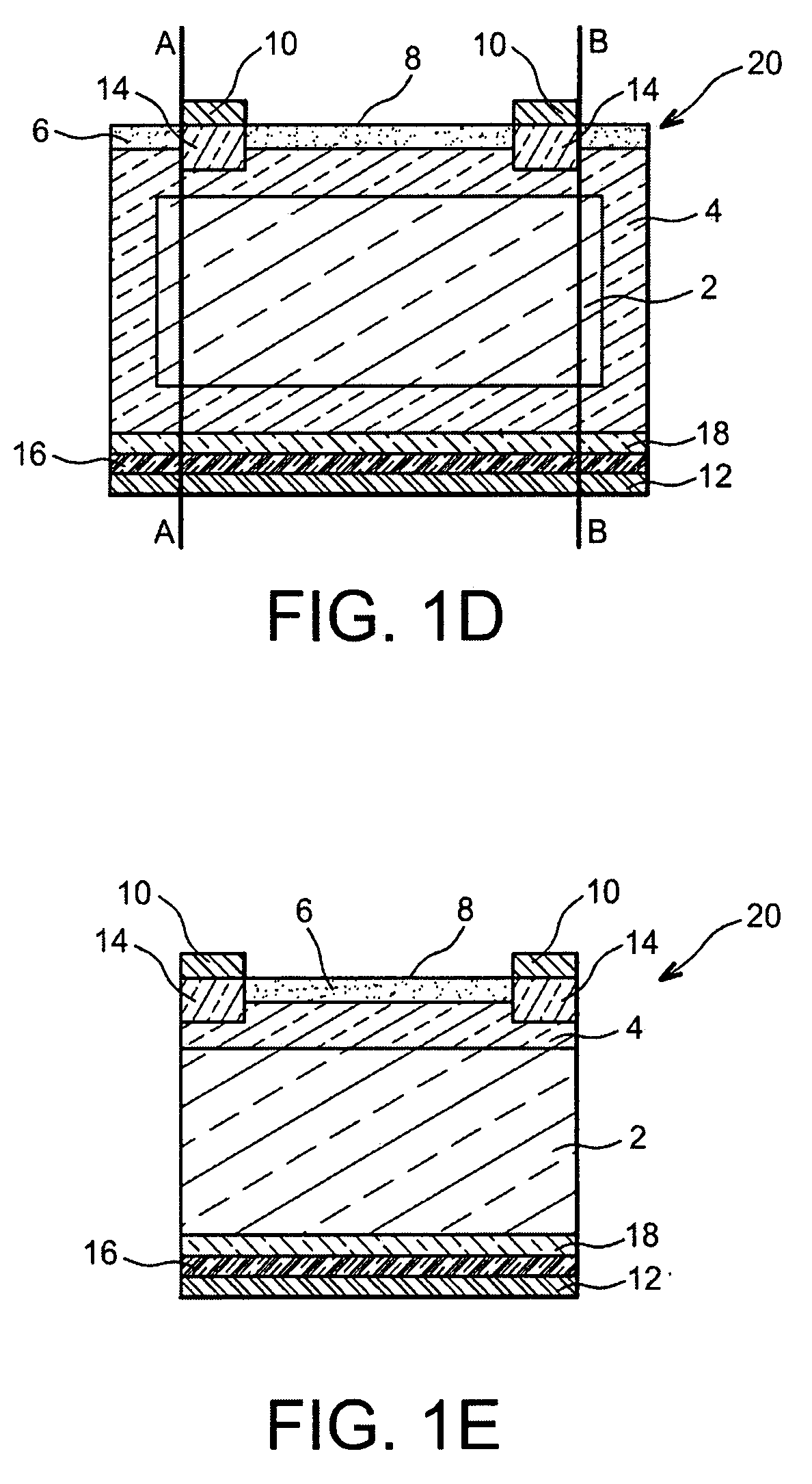

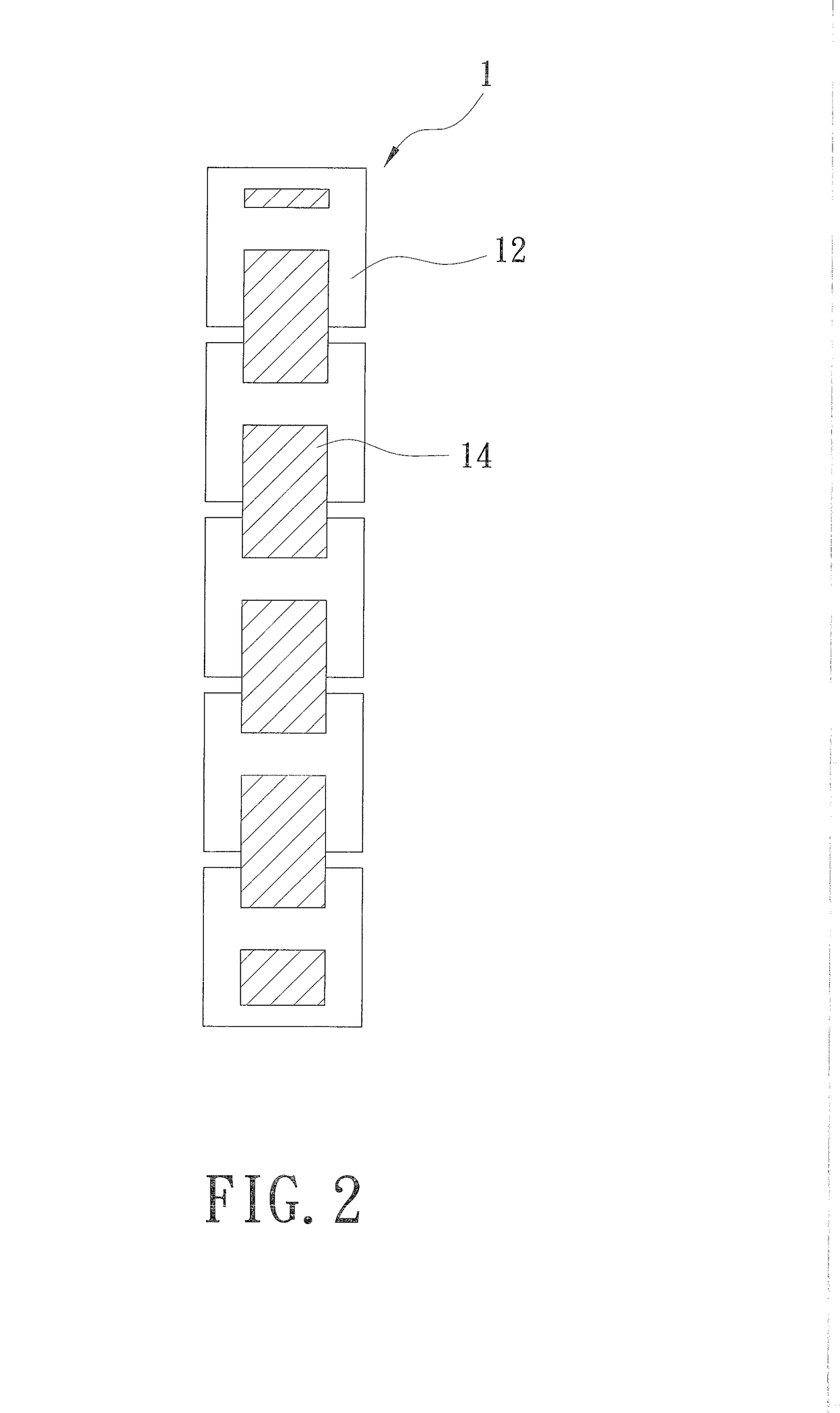

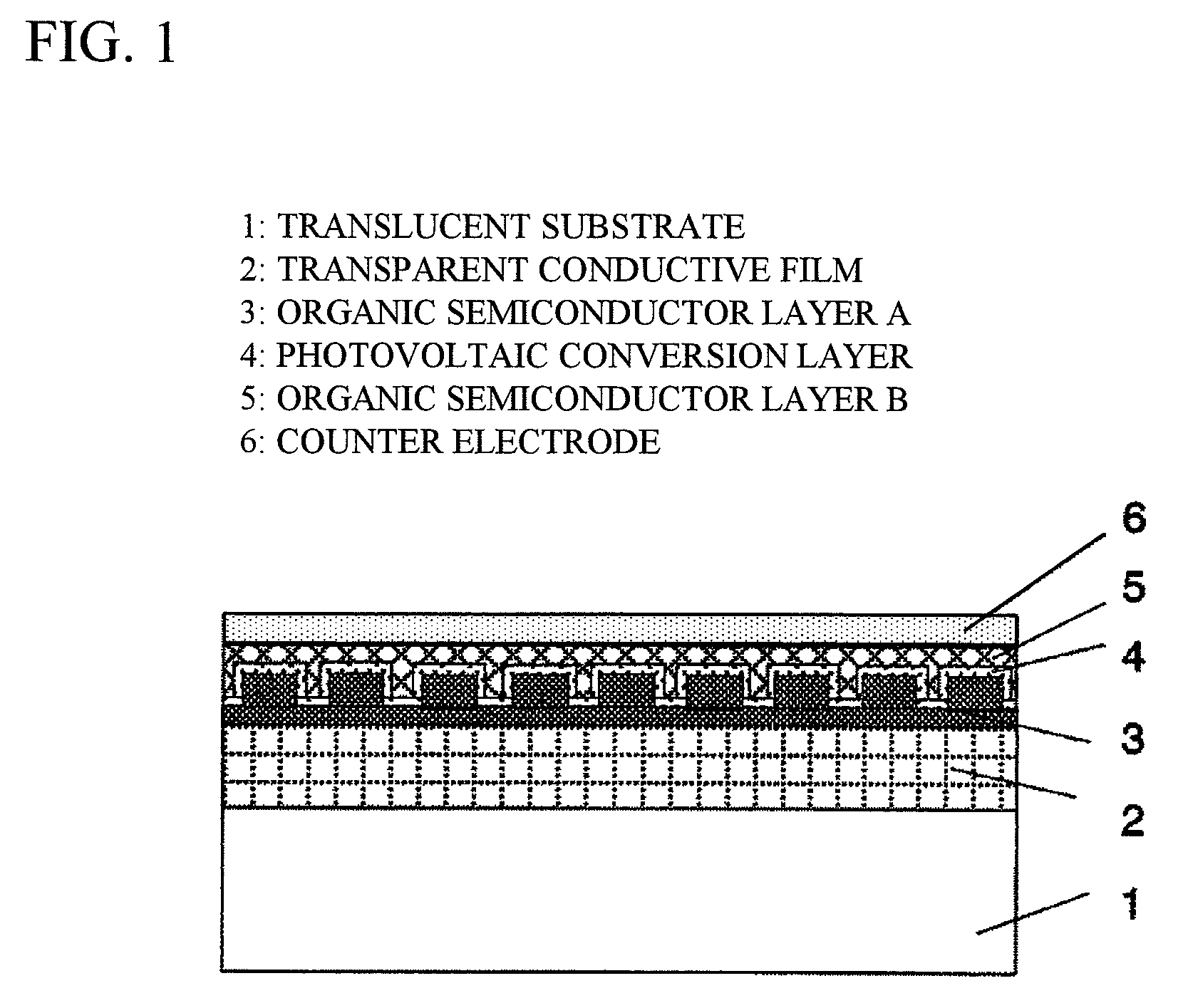

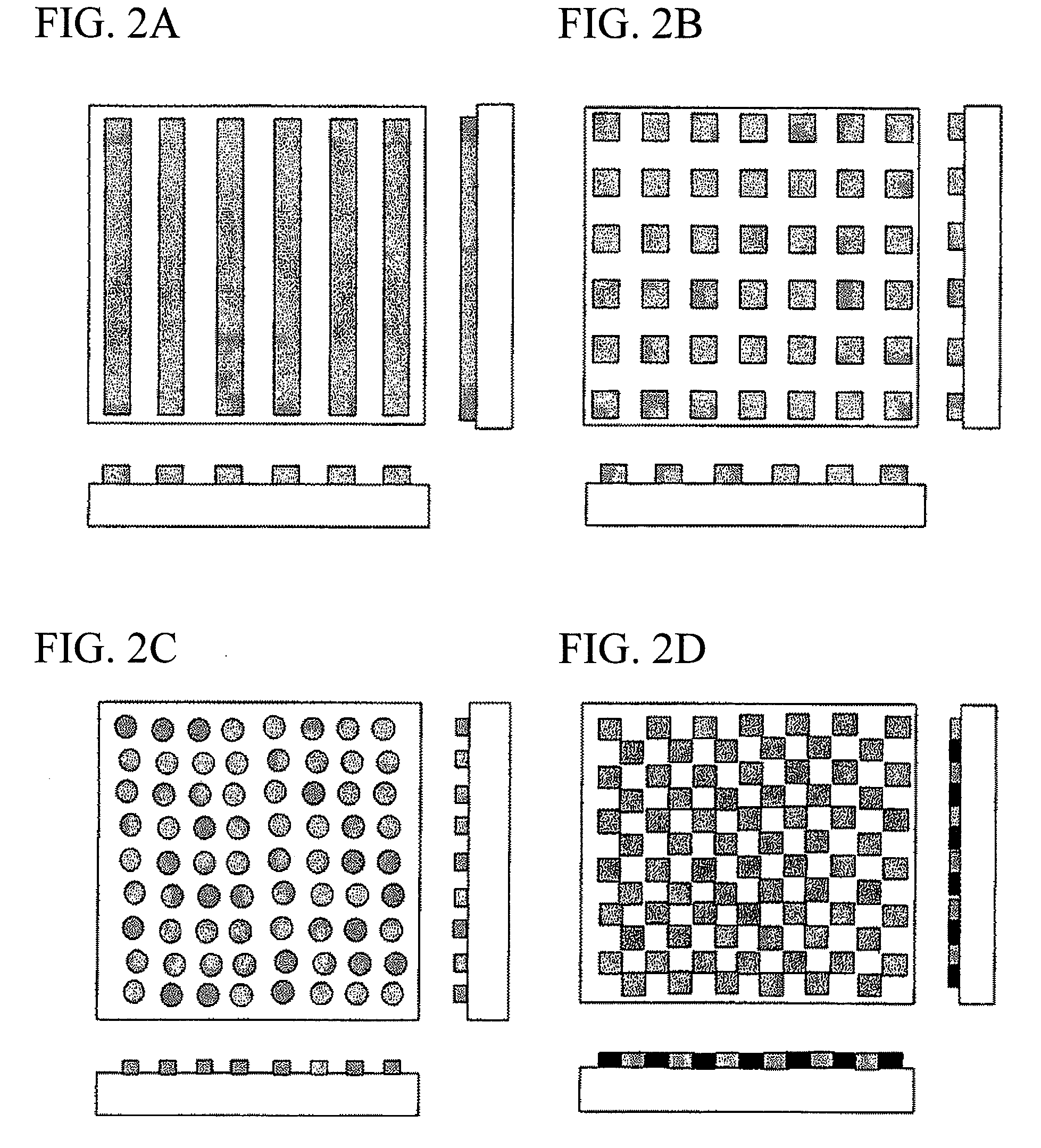

Photovoltaic Cells and Manufacture Method

InactiveUS20090084442A1Improve photovoltaic conversion efficiencyInhibit currentFinal product manufactureNanoinformaticsLight CellEngineering

The present invention provides photovoltaic cells that stably increase photovoltaic conversion efficiency while restraining current leakage. The photovoltaic cells of the present invention include a transparent conductive layer formed on a light-permeable substrate, an organic semiconductor layer A covering the surface of the transparent conductive layer, a photovoltaic conversion layer in contact with the organic semiconductor layer, an organic semiconductor layer B in contact with the photovoltaic conversion layer, and a counter electrode in contact with the organic semiconductor layer B. In the photovoltaic cells, a patterned indented interlayer is formed at the interface between the organic semiconductor layer A and the photovoltaic conversion layer. With the patterned indented interlayer at the interface between the organic semiconductor layer A and the photovoltaic conversion layer, the interface between the organic semiconductor layer A and the photovoltaic conversion layer has a specific surface area 1.5 to 10 times as large as the interface between the transparent conductive layer and the organic semiconductor layer A.

Owner:HITACHI LTD

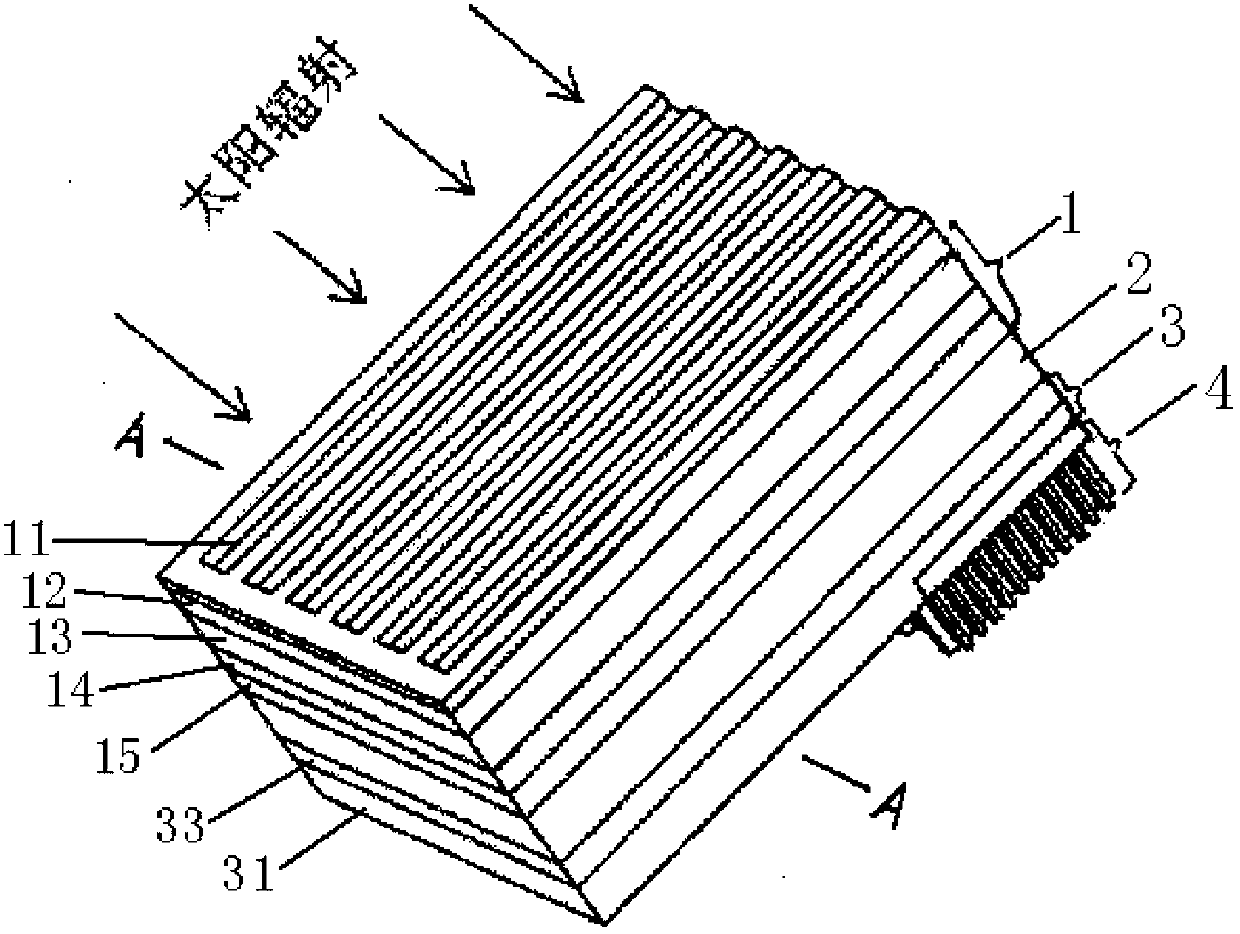

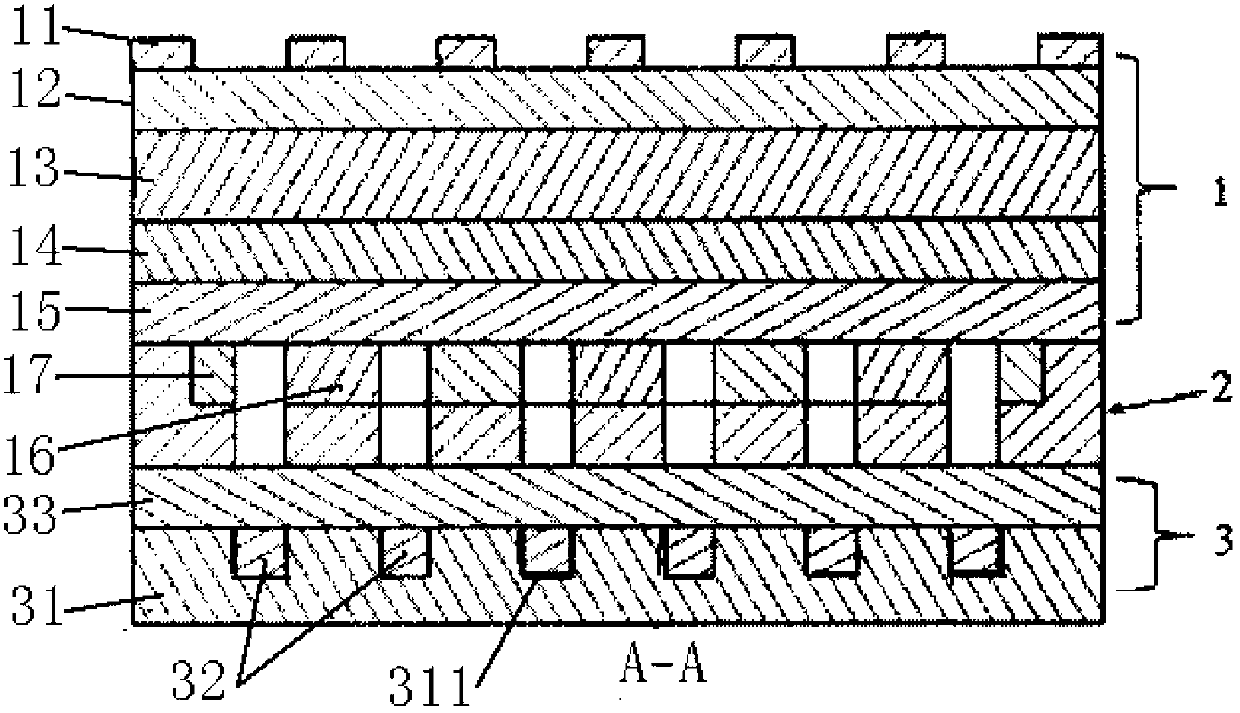

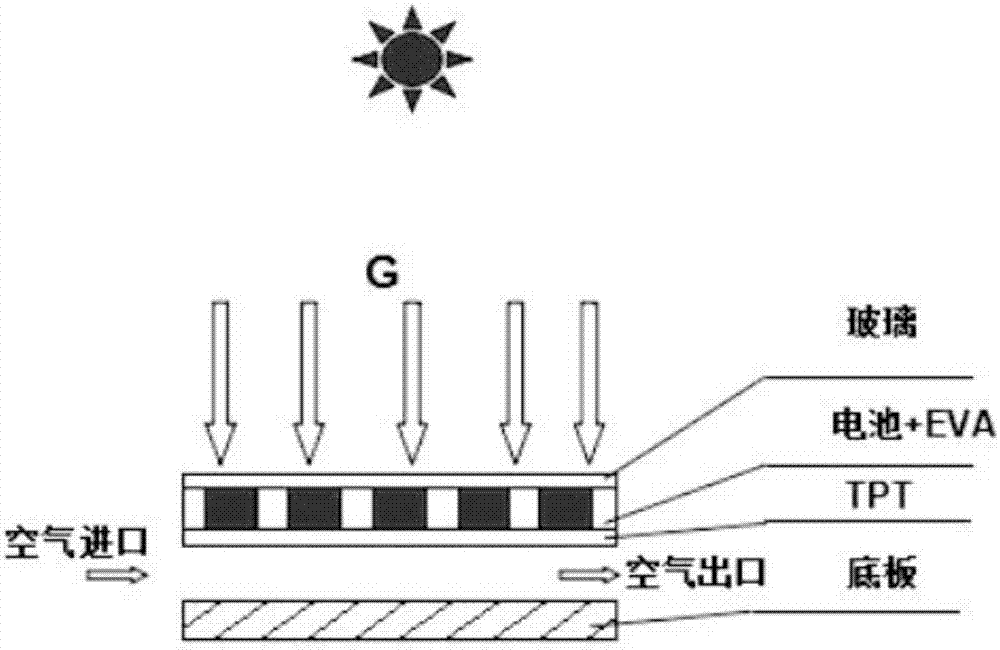

Solar photovoltaic and optothermal coupling type solar battery and coupling power generation method thereof

InactiveCN103000737AImprove photovoltaic conversion efficiencyImprove photovoltaic efficiencyIndirect heat exchangersPhotovoltaic energy generationHeat sinkBoiling point

The invention belongs to the technical field of solar power generation and discloses a solar photovoltaic and optothermal coupling type solar battery and a coupling power generation method thereof. The battery is composed of a phototropic face photovoltaic power generation module, a silicon channel, a silica-based back plate processed with permanent magnetic film arrays and cooling fins. On one side of a system facing the sun, electric potentials are generated in the photovoltaic power generation module for photovoltaic effects when sunlight illuminates; on a shady face, a vacuum pumping liquid injection port on the silica-based back plate faces an S-shaped micro-channel on a micro-channel plate, the micro-channel is filled with high-boiling-point conductive working media A and low-boiling-point insulation working media B alternatively, and then the micro-channel is sealed, so that a snake loop forms a pulsating heat pipe loop with two working media. The solar photovoltaic and optothermal coupling type solar battery has the advantages that a shady face pulsating heat pipe power generation loop absorbs heat released by the phototropic face for power generation, so that the work temperature of a photovoltaic panel is low, the conversion efficiency of the photovoltaic panel is improved, and the service life is increased, and a wide application prospect is provided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

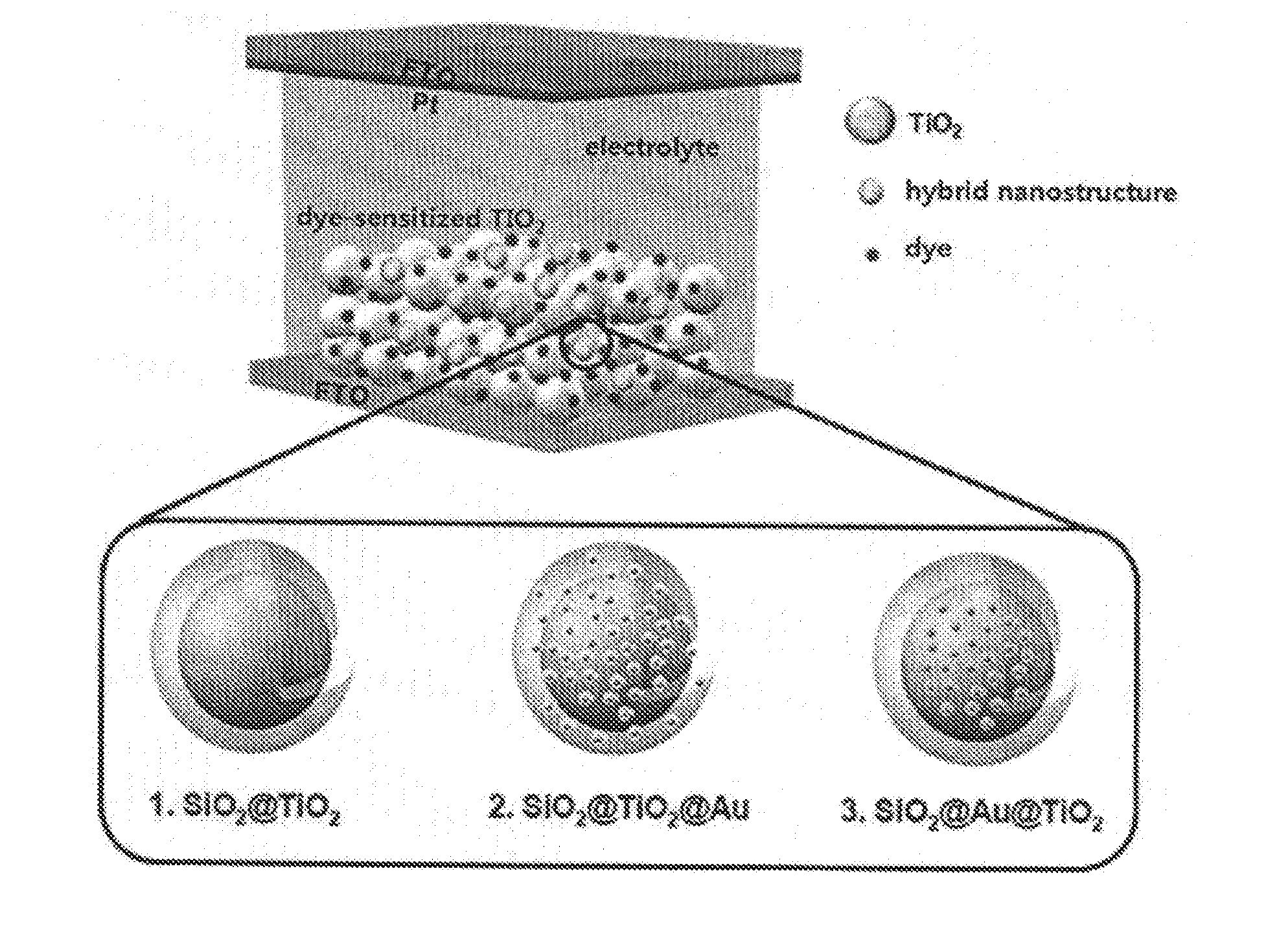

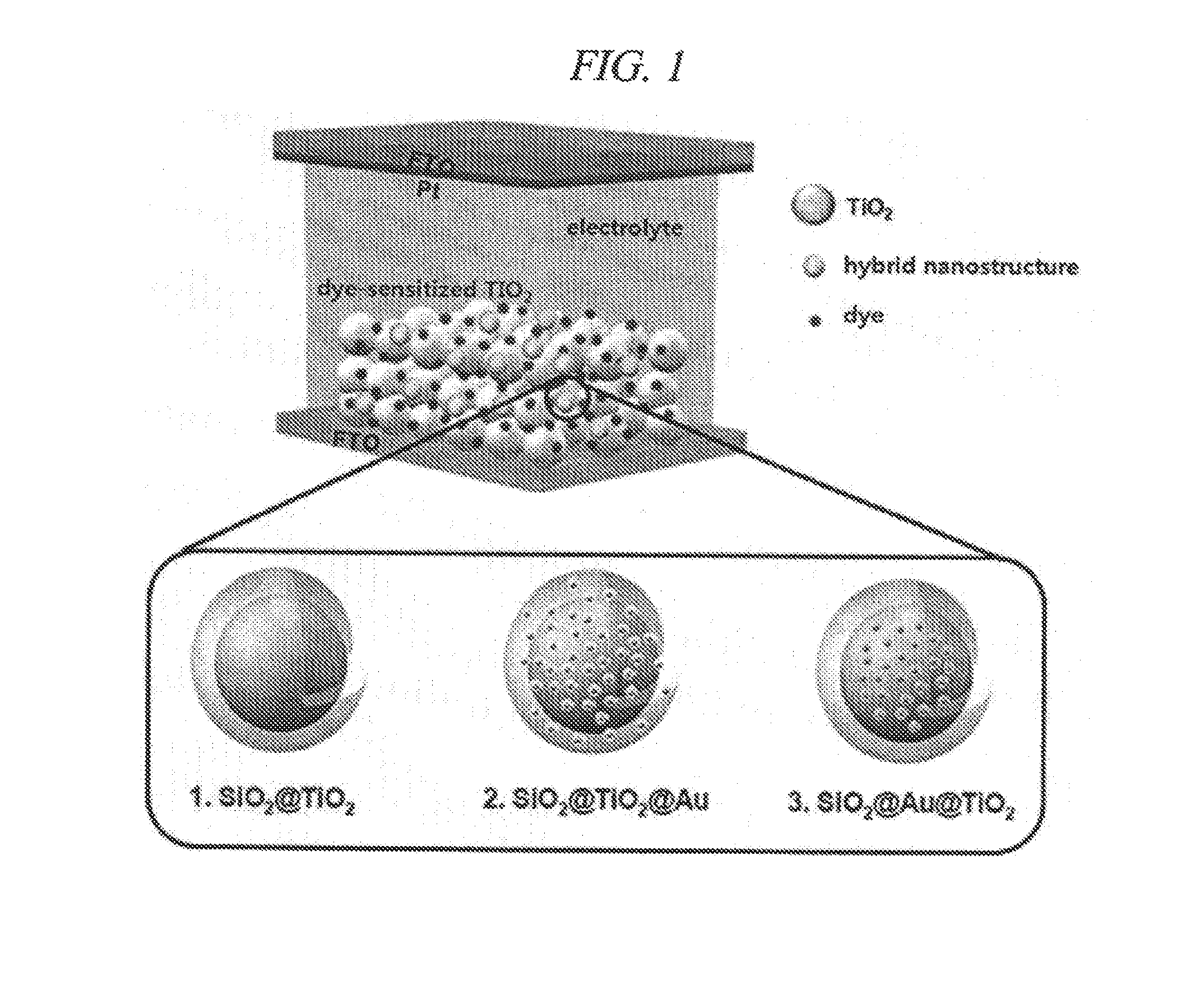

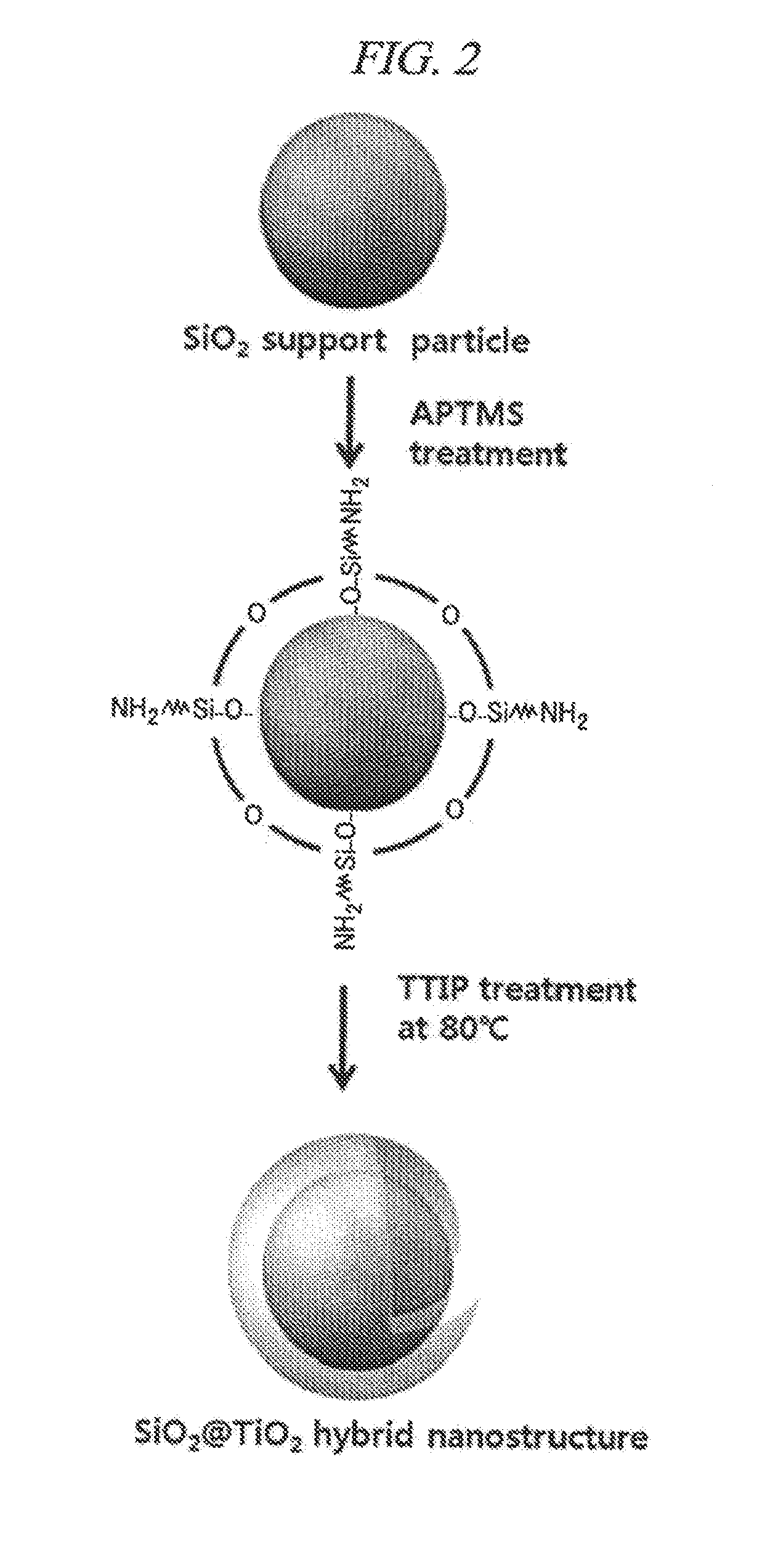

Hybrid nanostructure including gold nanoparticles and photoelectrode for solar cell having the same

ActiveUS20130319513A1Improve photovoltaic conversion efficiencyLow costLight-sensitive devicesSemiconductor/solid-state device manufacturingNanoparticleSolar cell

There is provided a hybrid nanostructure including Au nanoparticles, a photoelectrode for a solar cell having the hybrid nanostructure, and a solar cell including the photoelectrode.

Owner:EWHA UNIV IND COLLABORATION FOUND

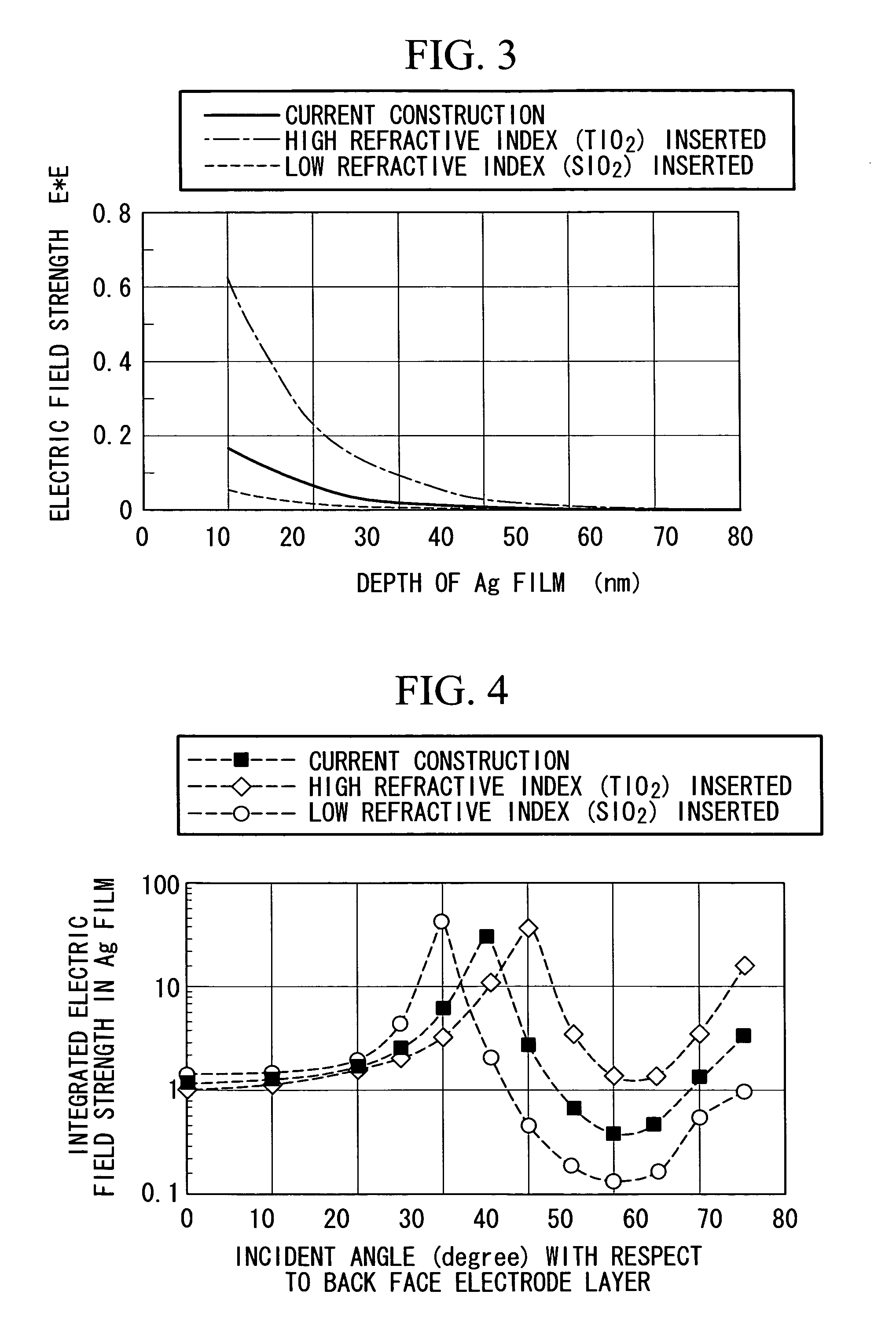

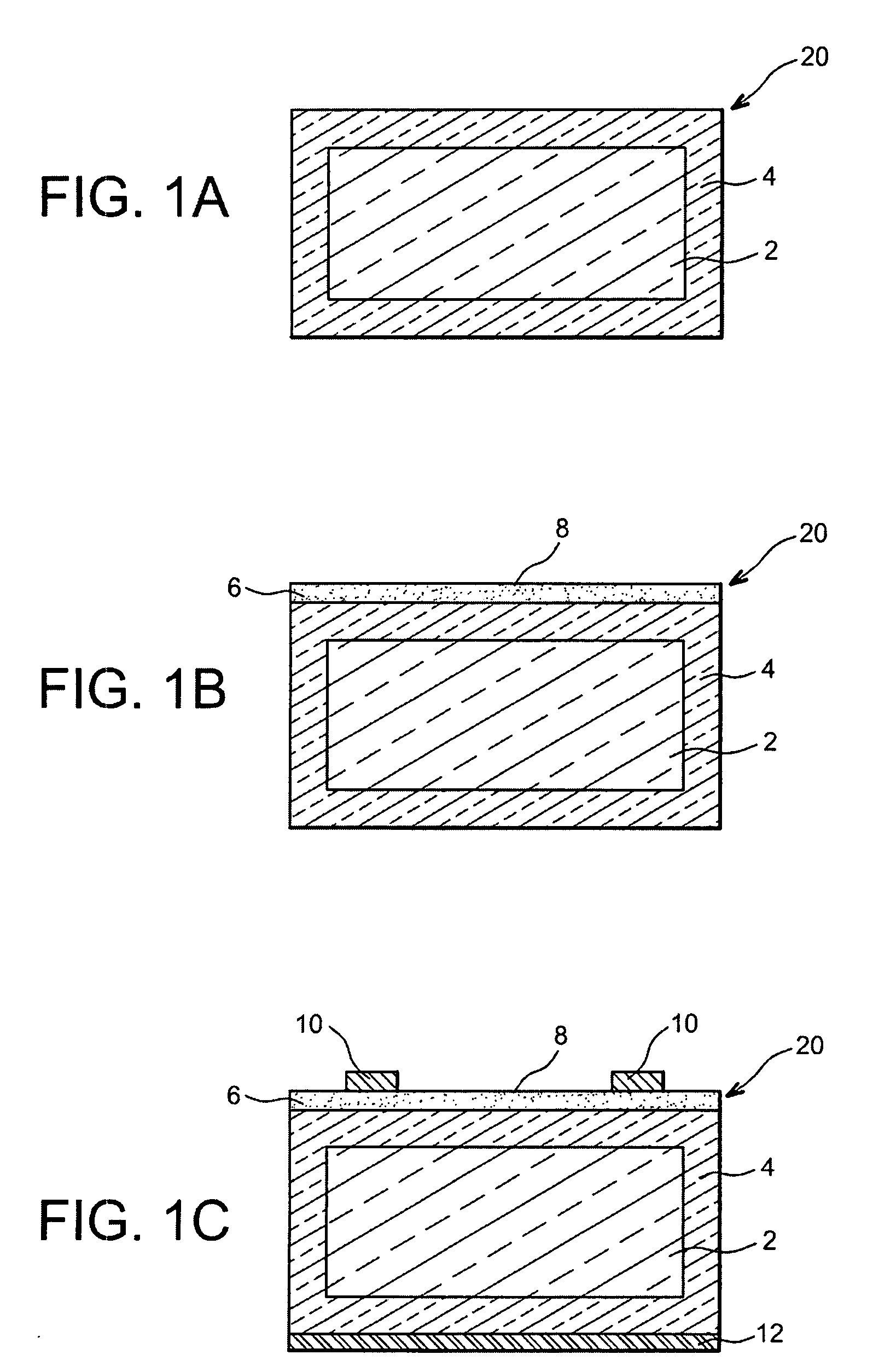

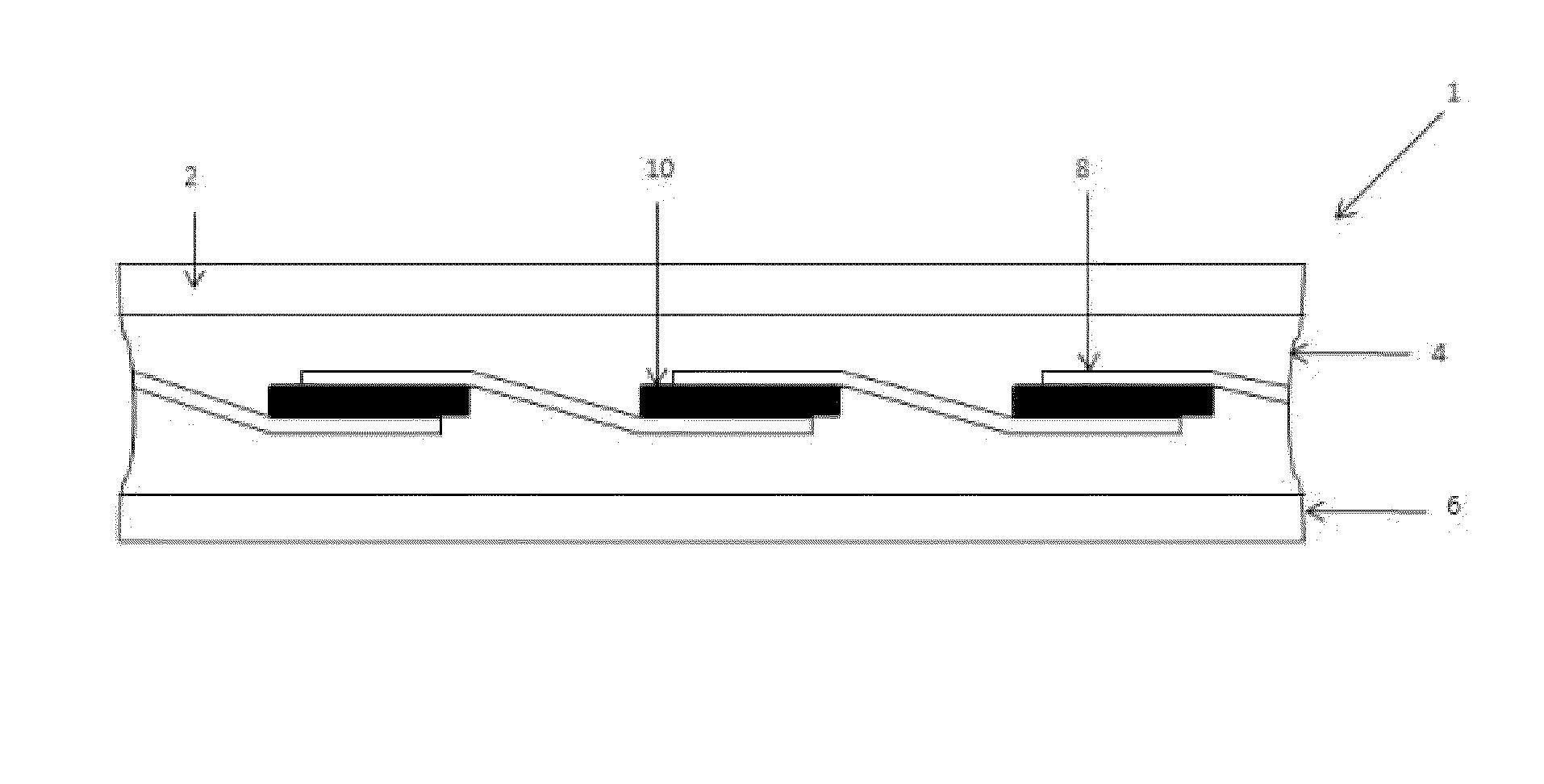

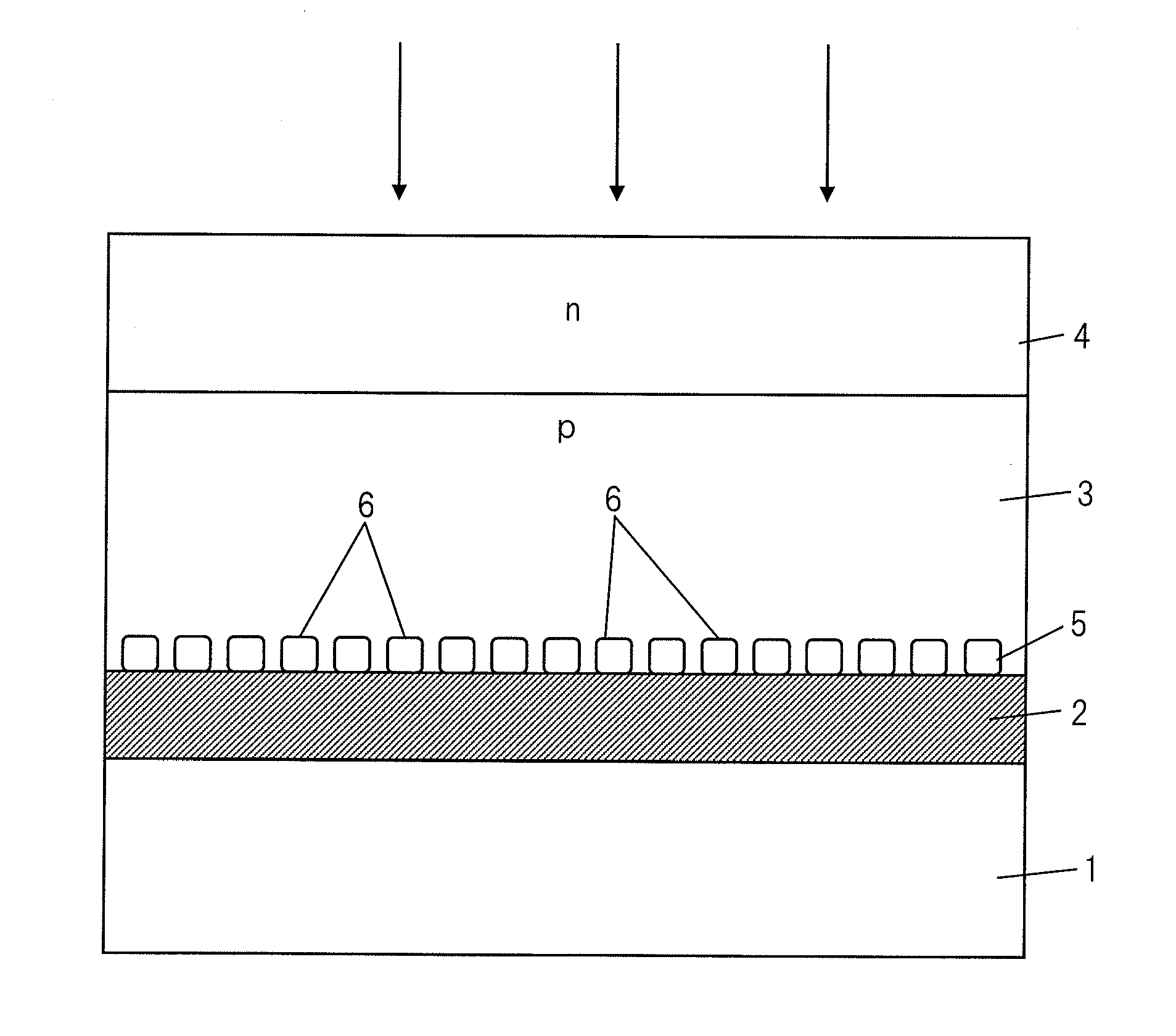

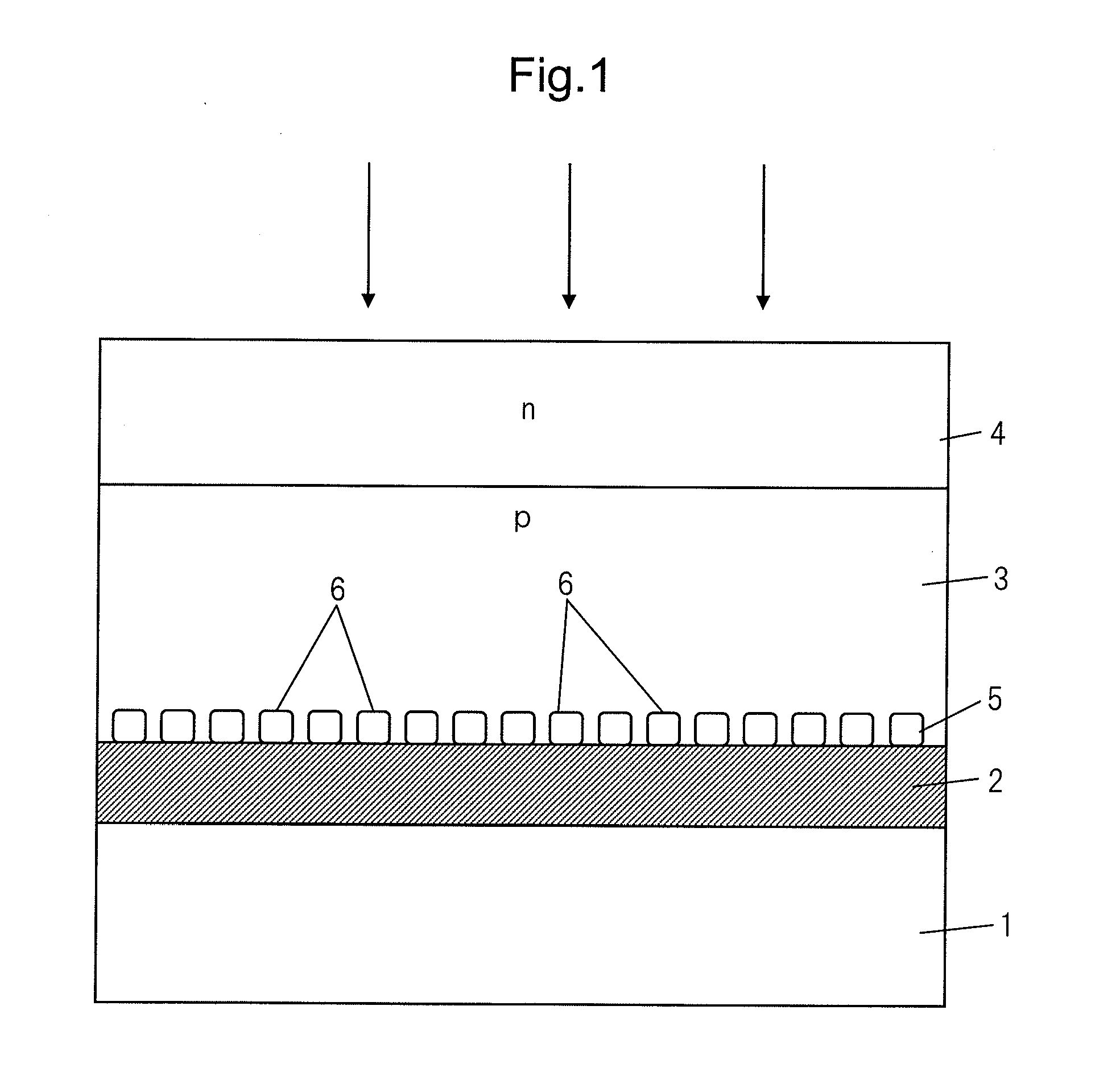

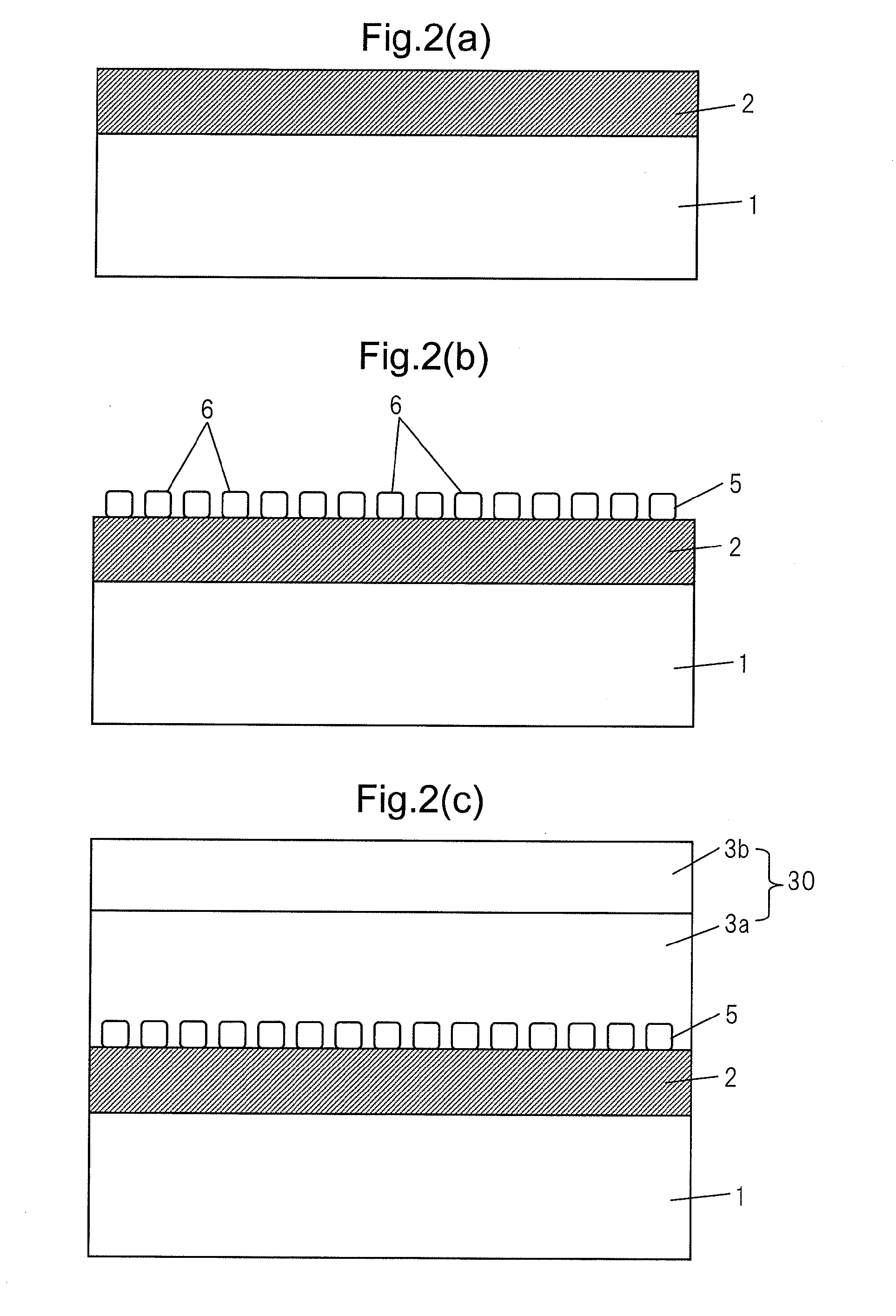

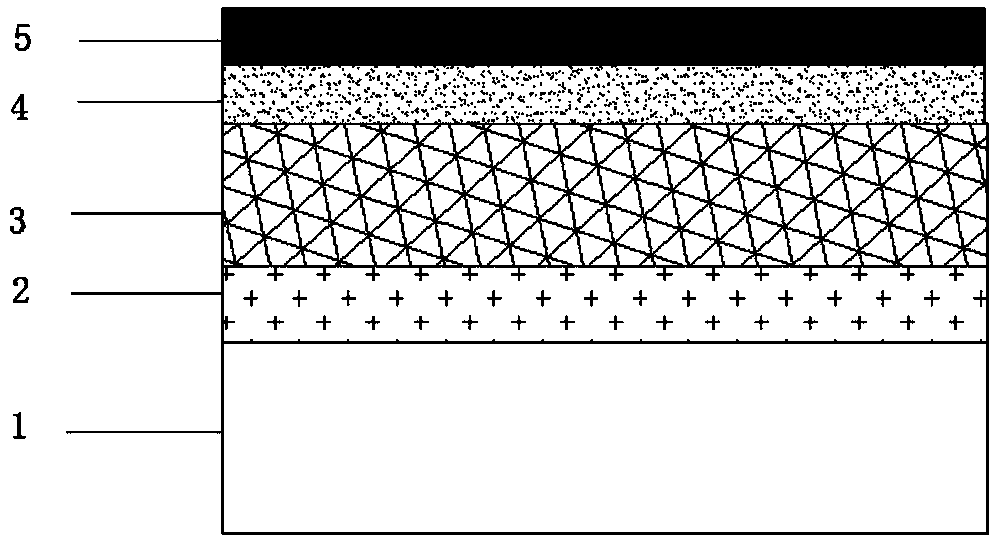

Thin film solar cell and manufacturing method therefor

ActiveUS20140216543A1Improve photovoltaic conversion efficiencyWell formedFinal product manufactureSemiconductor/solid-state device manufacturingTransparent conducting filmMetal electrodes

In the present invention, in order to achieve a point contact, a thin film solar cell has a thin film light absorbing layer (3) disposed between a transparent conducive film (4) and a back-side metal electrode layer (2), and at the interface between the back-side metal electrode layer (2) and the light absorbing layer (3), the thin film solar cell is provided with a nanoparticle dispersion layer (5) including nanoparticles (6, 6 . . . ), where at least the surface of the nanoparticles is an insulator.

Owner:SOLAR FRONTIER

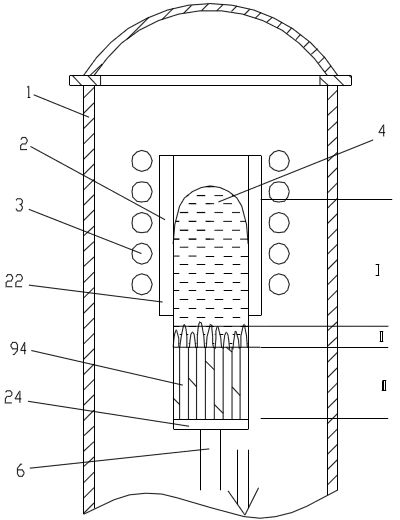

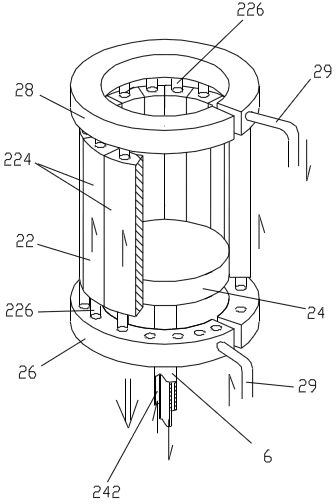

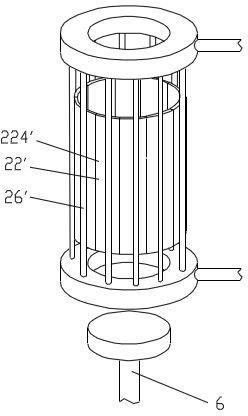

Equipment and method for preparing high-purity directionally crystallized polysilicon

ActiveCN102191542AImprove efficiencyImprove photovoltaic conversion efficiencyPolycrystalline material growthSilicon compoundsCrucibleInductor

The invention relates to equipment for preparing high-purity directionally crystallized polysilicon. The equipment comprises a vacuum chamber, a cold crucible, a main inductor, a crystallizing device and a cooler, wherein the cold crucible is arranged in the vacuum chamber and made of red copper; the cold crucible comprises a cylindrical crucible wall and a crucible bottom separated from the crucible wall; the crucible wall is partitioned into a plurality of crucible blades; each crucible blade is provided with a cooling water path; a water inlet sleeve and a water returning sleeve are arranged on the lower surface and the upper surface of the cold crucible respectively; the crucible bottom can move below the crucible wall; the main inductor is encircled outside the cold crucible; the crystallizing device is an auxiliary inductor arranged below the main inductor or the crystallizing device comprises a ceramic tube and a temperature preservation layer; the ceramic tube is arranged at the lower end of the crucible wall of the cold crucible; the temperature preservation layer is wrapped or encircled on the ceramic tube; and the cooler is arranged below the crystallizing device. The equipment is free of pollution and high in production efficiency. The invention also provides a method for preparing the high-purity directionally crystallized polysilicon by using the equipment.

Owner:SHENZHEN SUMMIT LEVITATION METALLURGICAL SCI & TECHN

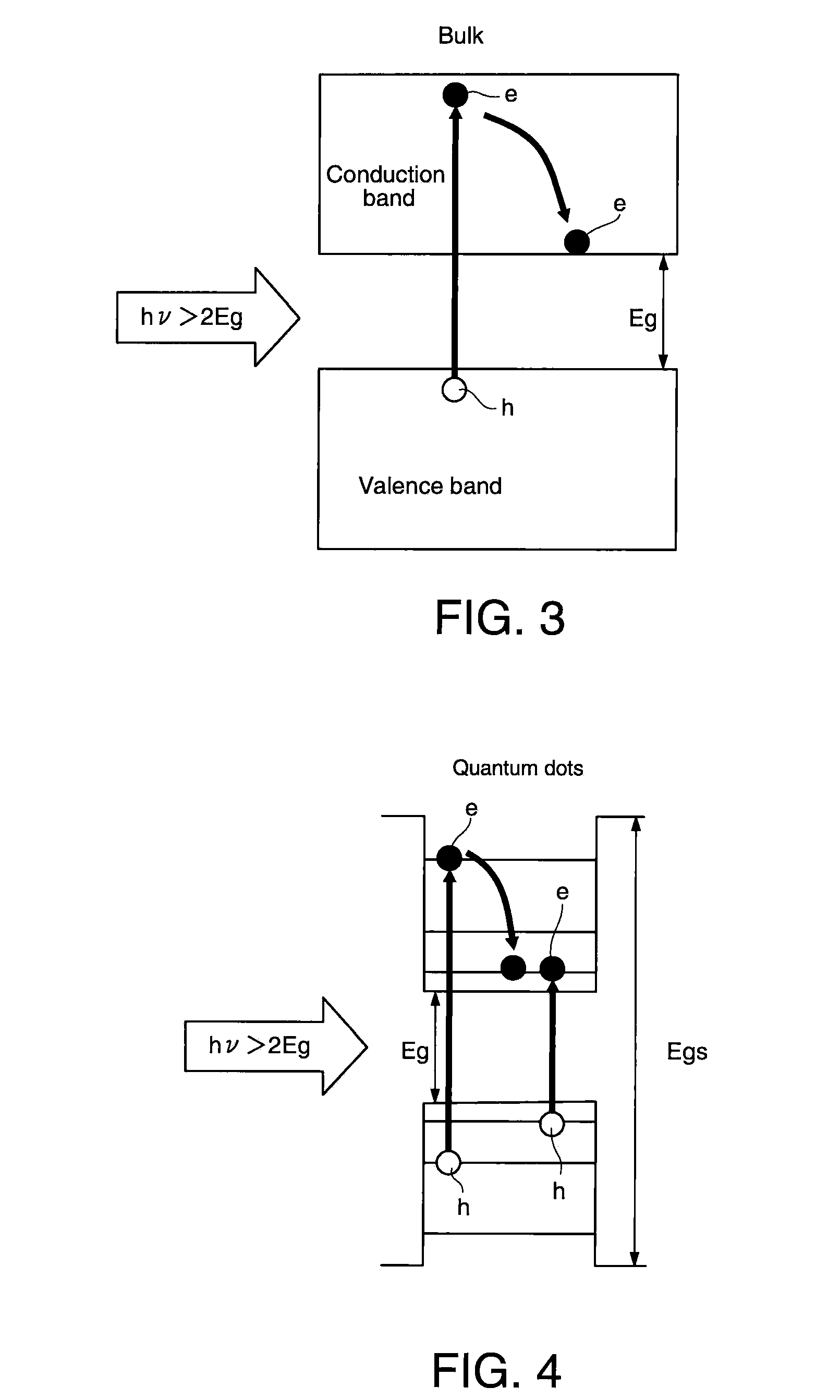

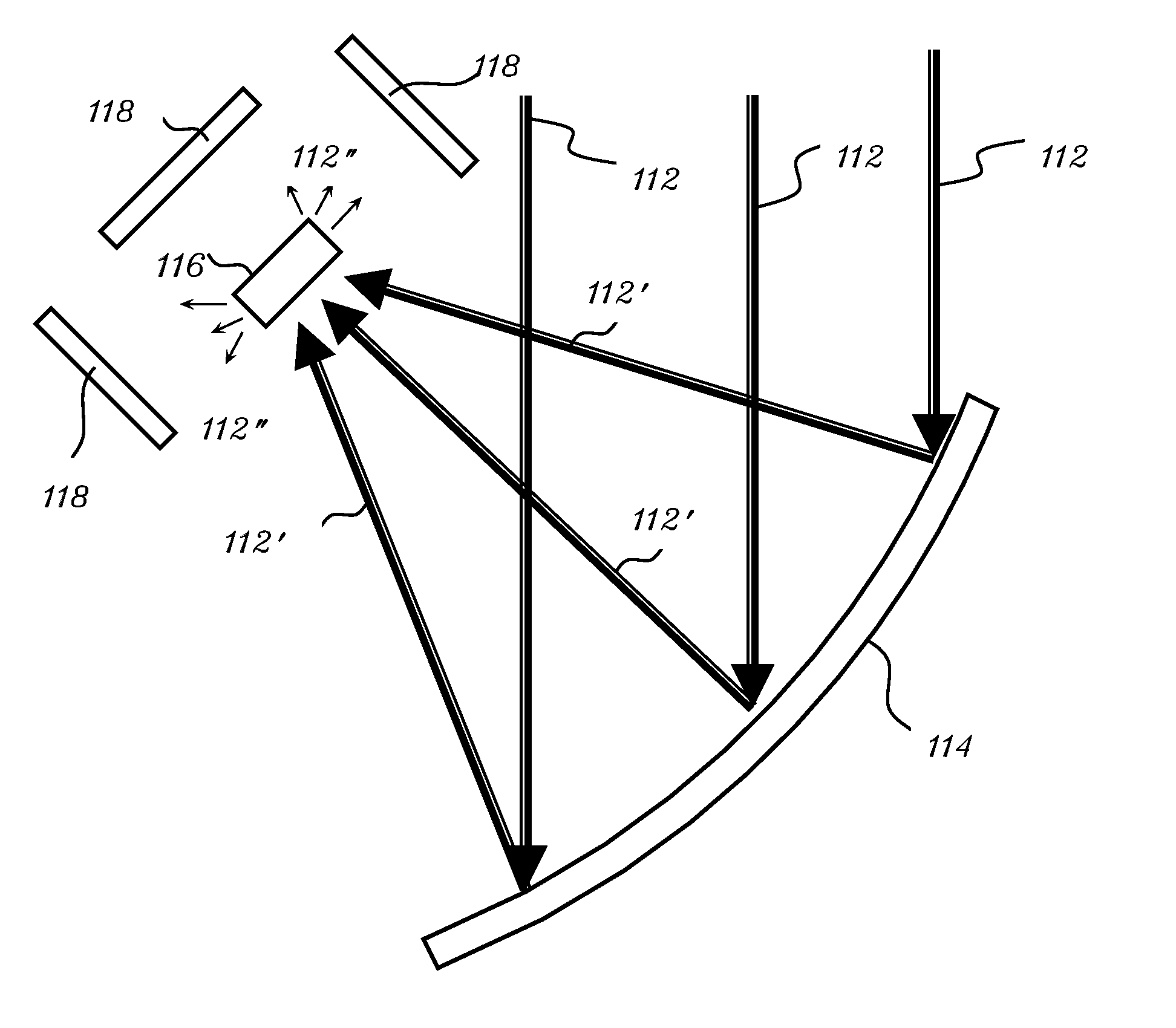

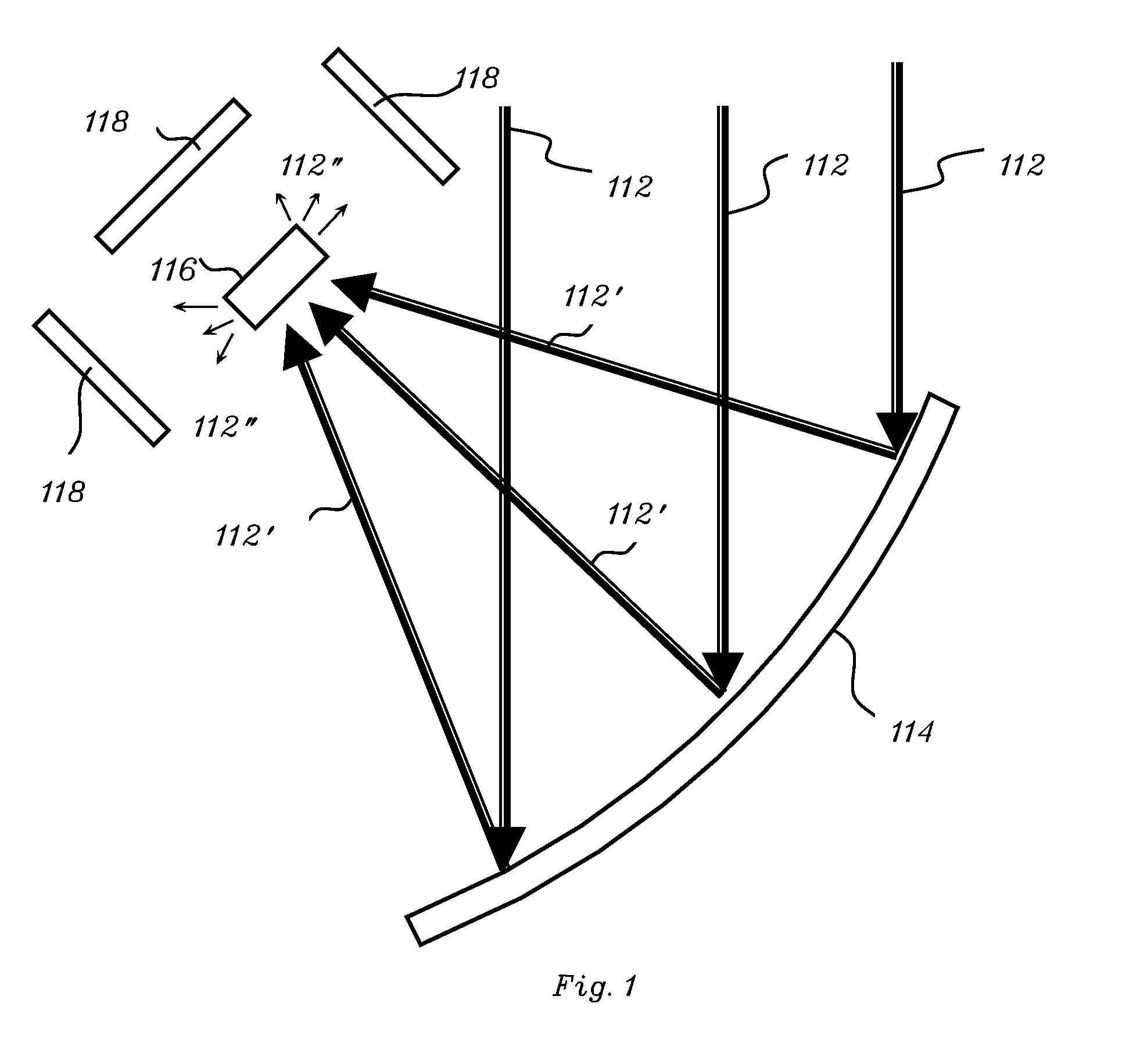

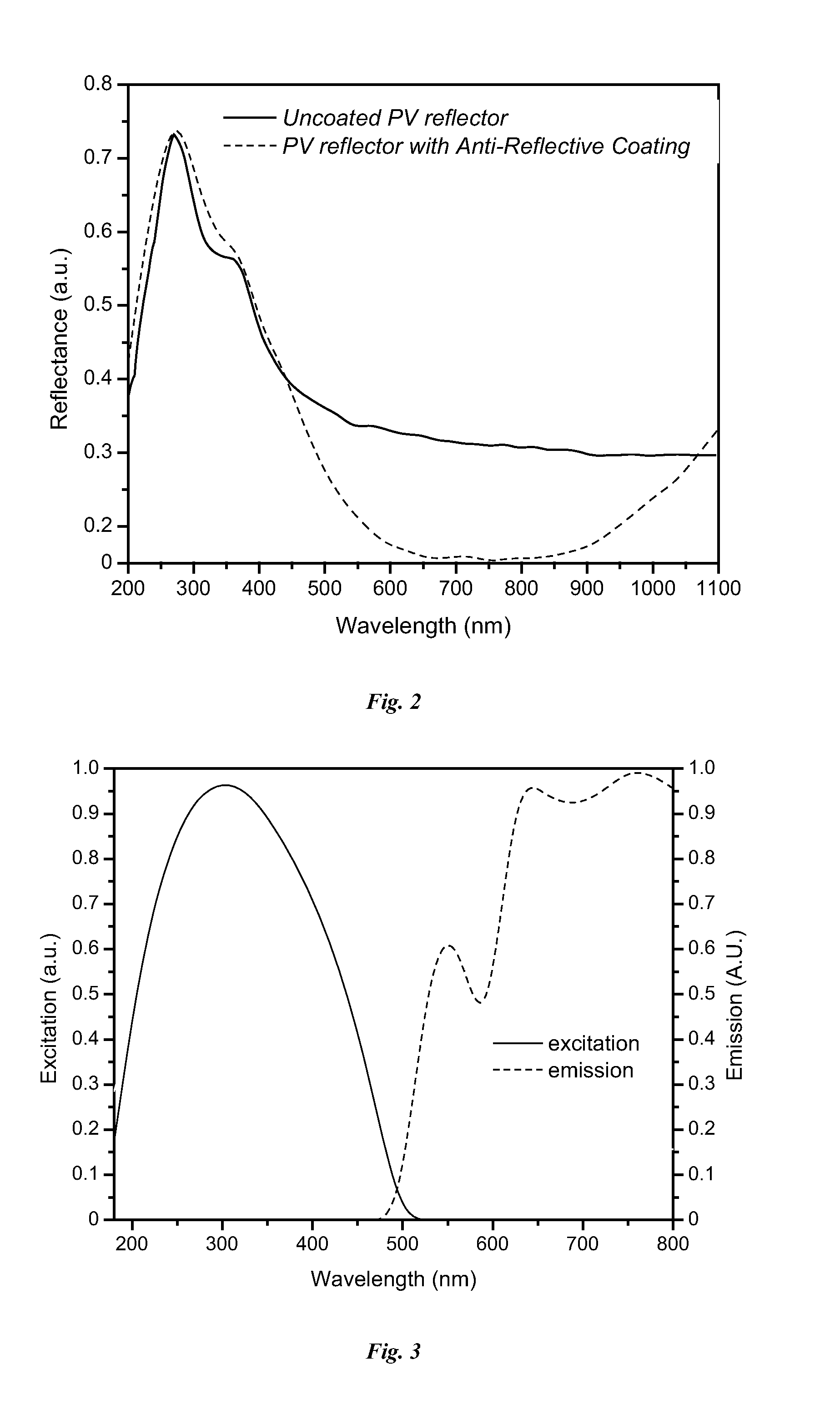

Spectrum-splitting and wavelength-shifting photovoltaic energy converting system suitable for direct and diffuse solar irradiation

InactiveUS20110079271A1Low bandgap energyHigh bandgap energyPV power plantsPhotovoltaic energy generationFluorescenceElectricity

A photovoltaic energy converting system includes: (a) a first photovoltaic converter operable to receive incident solar radiation and convert to electricity those photons of the incident solar radiation having energies less than a predetermined bandgap energy; (b) a fluorescing member positioned for receiving reflected photons having reflected from the first photovoltaic converter, the fluorescing member being operable to produce, in response to the reflected photons, wavelength-shifted photons having energies less than the predetermined bandgap energy; and (c) a second photovoltaic converter operable to convert into electricity the wavelength-shifted photons. The system is thereby advantageously suitable for operation under either direct or diffuse solar irradiation.

Owner:DETAB SERGIY

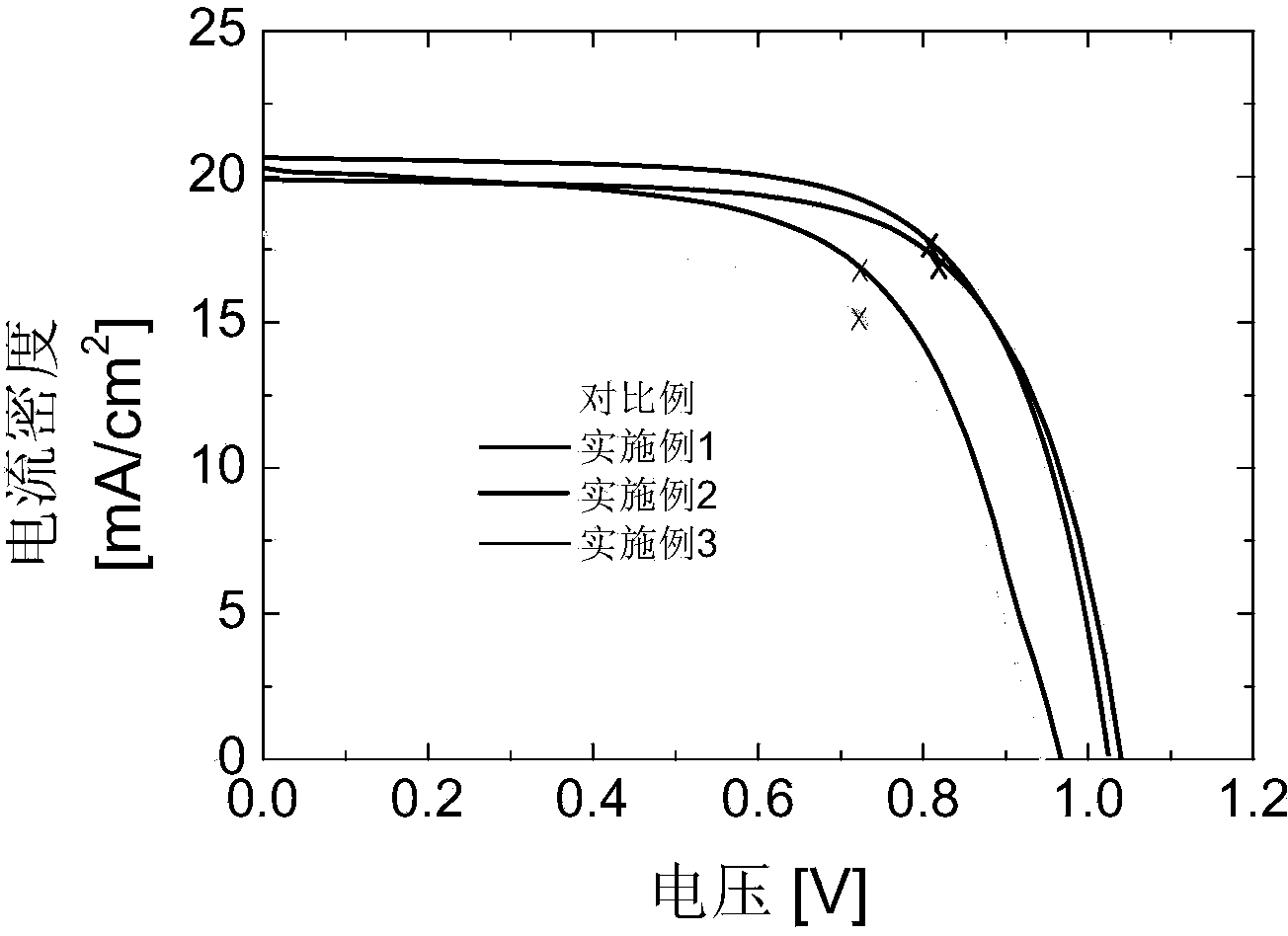

Perovskite phase organic metal halide-based solar cell and manufacturing method thereof

ActiveCN104393177AReduce contact areaReduce surface recombination rateSolid-state devicesSemiconductor/solid-state device manufacturingSynthesis methodsElectron transfer

The invention discloses a perovskite phase organic metal halide-based solar cell and a manufacturing method thereof. The solar cell uses a dense titanium dioxide nano film as an electron transfer layer, the surface recombination speed between the electron transfer layer and a semiconductor layer can be reduced, and a photovoltaic conversion rate of a photovoltaic device is improved; the solar cell with the structure can use a normal temperature and pressure full liquid phase synthesis method to manufacture the semiconductor layer of a perovskite phase organic metal halide, thereby saving energy consumption needed by manufacturing and reducing the cost of the solar cell. A two-step synthesis method is adopted during the process of manufacturing the semiconductor layer of the perovskite phase organic metal halide, a PbX2 layer formed in the first step is soaked in a 2-propanol solution between the two steps, the second-step synthesis is carried out, and thus, a chlorine and iodine mixed preparation method can be adopted, the halogen ion concentration and the annealing temperature are controlled, crystal growth during a liquid phase precipitation process is optimized, and the photovoltaic conversion efficiency of the solar cell is improved.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

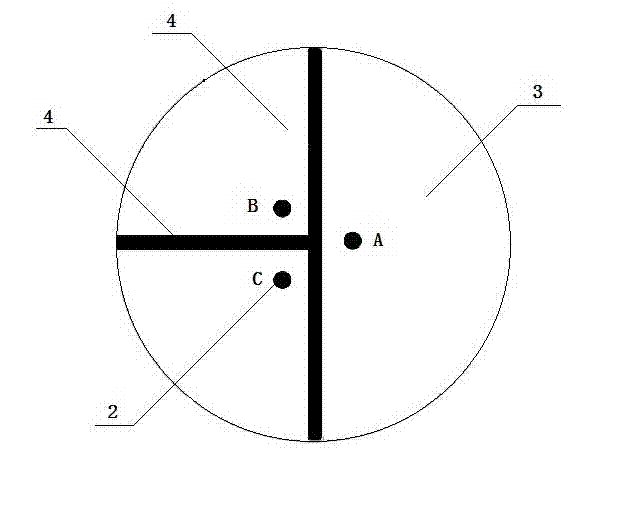

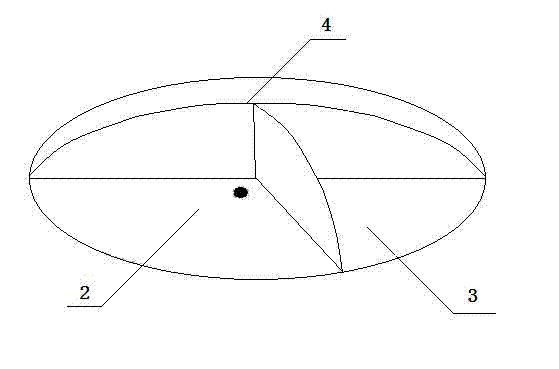

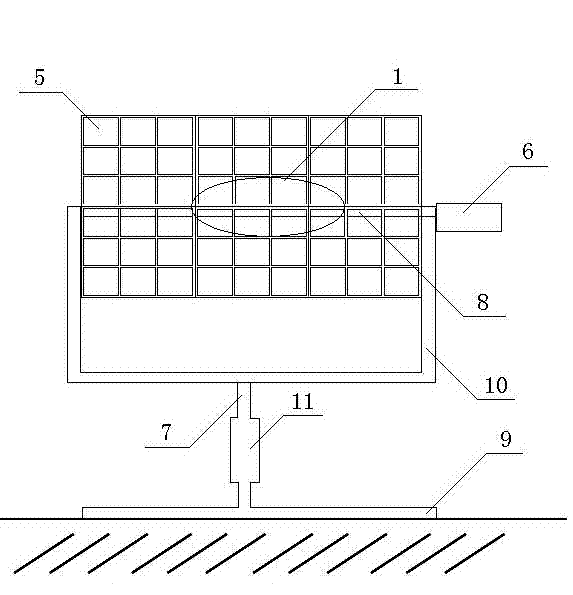

Solar automatic tracking system

InactiveCN103076814AImprove power generation efficiencyLow costControl using feedbackEngineeringSolar altitude

The invention relates to the field of solar photovoltaic power generation, in particular to a solar automatic tracking system which is realized by utilizing automatic real-time tracking and database track simulation methods. A light and shadow capture device comprises a photoreceptor and a photo-chopper, wherein photosensitive diodes are arranged on three faces separated by the photo-chopper on the light and shadow capture device; a light offset inductive sensor is arranged at a central position of a solar cell component; the solar cell component is arranged on a solar altitude transmission shaft; one end of the solar altitude transmission shaft is connected with a high altitude direct current motor; and an azimuth direct current motor is connected with a pedestal. According to the solar automatic tracking system, and the efficiency can be greatly increased, and the cost of the solar cell component and a storage battery can be greatly reduced on the premise of high-efficiency stable operation. The solar automatic tracking system has the advantages of simple structure, low cost, reliable operation and capability of effectively improving the power generation efficiency of the solar component.

Owner:郝勇

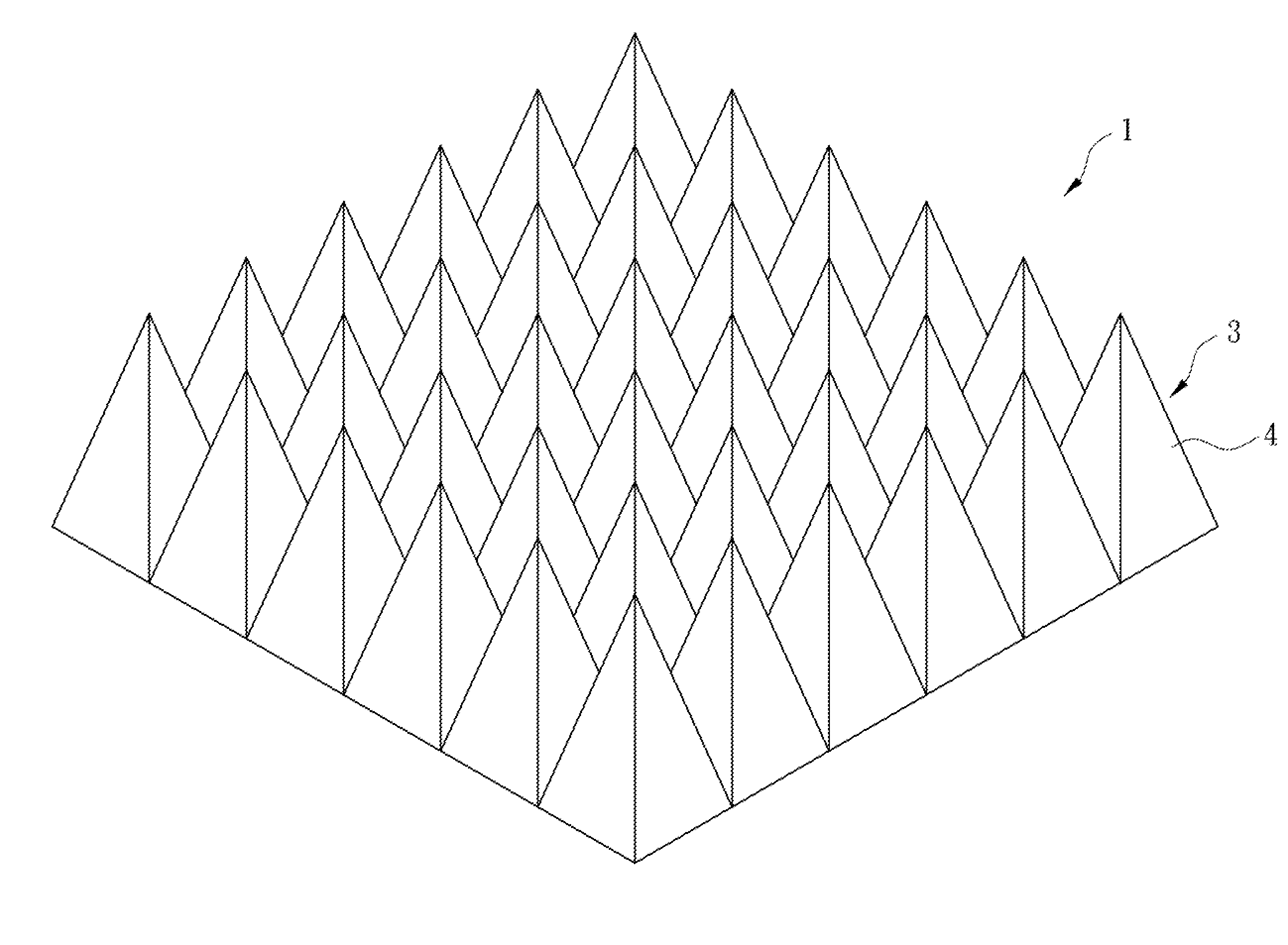

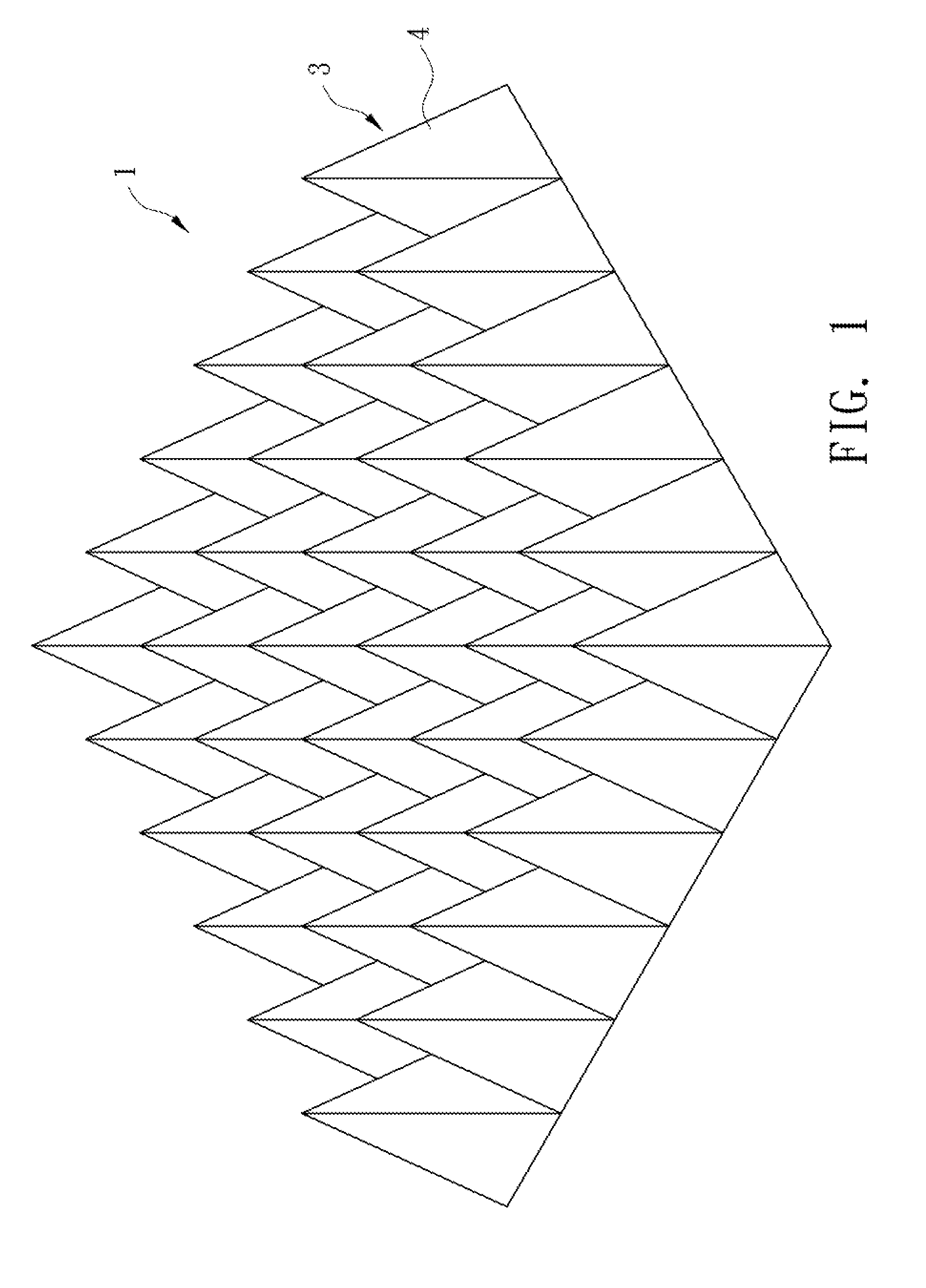

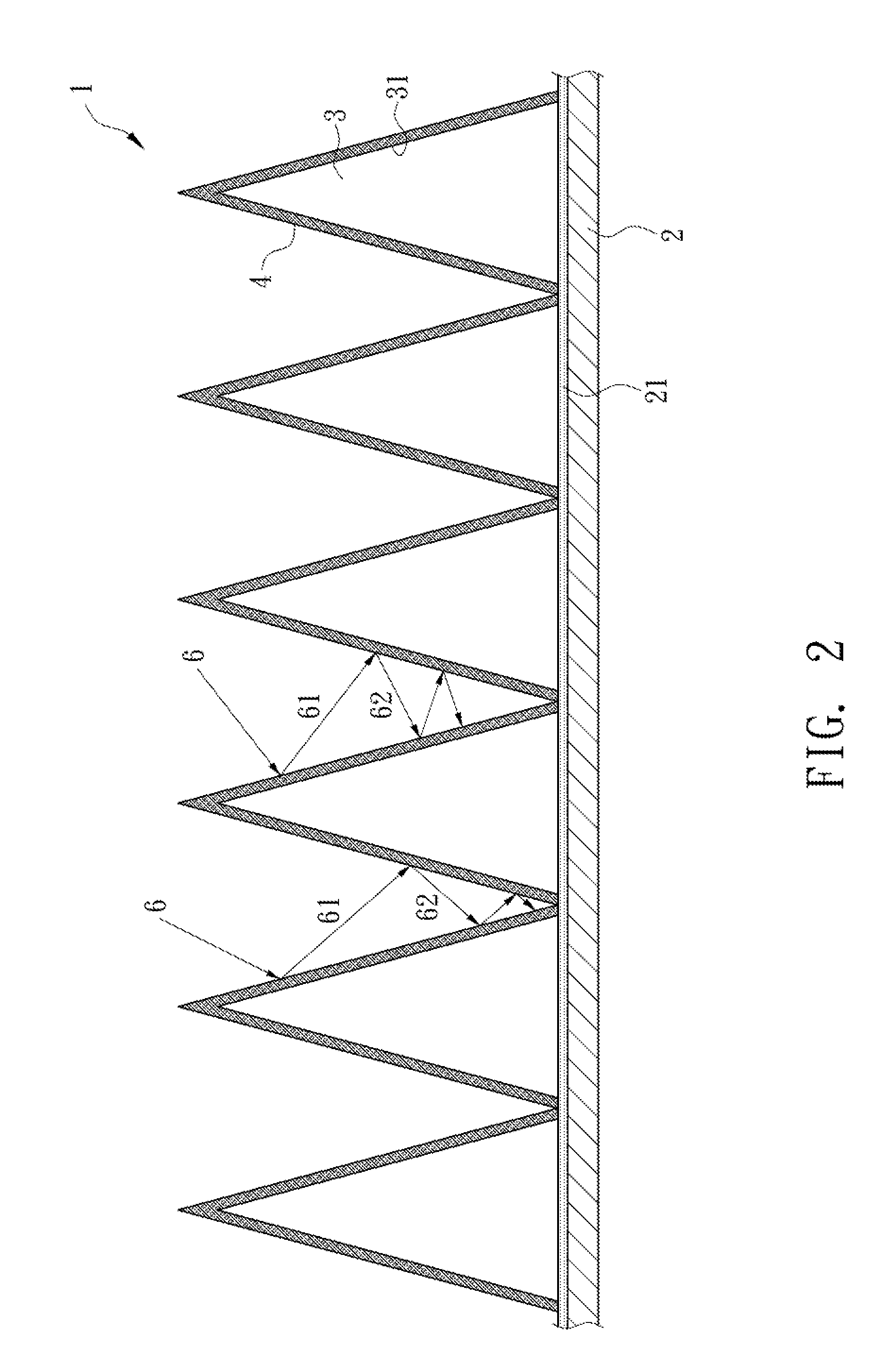

Solar power generation system with cone -shaped protrusions array

InactiveUS20120017966A1Increase the effective areaEfficient collectionSolar heating energySolar heat devicesLight energyPhotoelectric conversion

A solar power generation system includes multiple cones connected to a base in an array fashion and each cone includes multiple solar panels connected to the boards thereof so that the incoming light is fully absorbed and most of the spectrum of light energy will convert into electric energy by the different solar panels on any board of the cones. The cone-shaped array solar power generation system includes larger absorbing area to absorb light from different angles and the efficiency of photoelectric conversion of the solar power generation system increases. The cone-shaped array increases mechanical strength of the solar panels, and is easily to be cleaned up and also lowers the temperature of the solar panels.

Owner:CHIENKUO TECHNOLOGY UNIVERSITY

Photovoltaic photo-thermal energy storage device

InactiveCN102290476AImprove photovoltaic conversion efficiencyCompact structurePhotovoltaicsPhotovoltaic energy generationBusiness efficiencyMiniaturization

The invention discloses a photovoltaic photo-thermal energy storage device, which comprises a photovoltaic cell, an upper conduction plate, a lower conduction plate, a phase change heat storage material and a channel pipe, wherein the upper conduction plate is arranged on the back of the photovoltaic cell; the lower conduction plate is arranged below the upper conduction plate; the channel pipe is arranged between the upper conduction plate and the lower conduction plate; a cyclic medium is arranged in the channel pipe; and the phase change heat storage material is arranged out of the channel pipe and is filled between the upper conduction plate and the lower conduction plate. According to the photovoltaic photo-thermal energy storage device, the total use ratio of the solar energy is above 70%, the photovoltaic conversion efficiency is improved by above 15%, and the energy efficiency ratio of a heat pump system is above 3.0; solar energy photovoltaic utilization, photo-thermal utilization and the heat pump system are integral, the integral structure is compact, and a unit is minimized; and electric energy output provided by the photovoltaic cell can satisfy the requirements for the heat pump system to operate.

Owner:NANJING UNIV

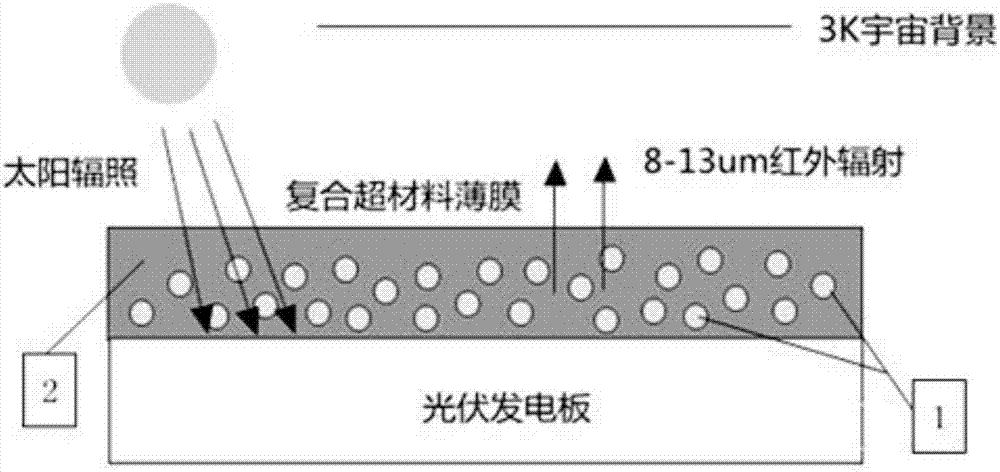

Method for improving photovoltaic conversion efficiency of solar energy photovoltaic power generating panel

InactiveCN106972068AImprove photovoltaic conversion efficiencyIncrease cooling powerPhotovoltaic energy generationSemiconductor devicesMicrosphereUltrasonic vibration

The invention provides a method for improving the photovoltaic conversion efficiency of a solar photovoltaic power generation panel, comprising: using an EVA adhesive film to bond a composite metamaterial film to the light-receiving surface of a solar photovoltaic power generation panel; the composite metamaterial film is prepared by the following method : Micron-sized SiO 2 The microspheres are dispersed in the dispersant and ultrasonically oscillated to obtain SiO 2 microsphere dispersion; make SiO 2 The microsphere dispersion is evenly distributed on the polymethylpentene film, so that the SiO 2 The microsphere dispersion is volatilized, and the distribution of SiO 2 Polymethylpentene thin film of microspheres; using rolling machine to distribute SiO 2 The polymethylpentene film of the microspheres was rolled to obtain the composite metamaterial film. The invention utilizes the principle of radiation cooling to significantly reduce the surface temperature of the solar photovoltaic power generation panel, thereby improving the photovoltaic conversion efficiency of the solar photovoltaic power generation panel, and also has the advantages of low energy consumption, high efficiency and simple structure.

Owner:WUHAN UNIV

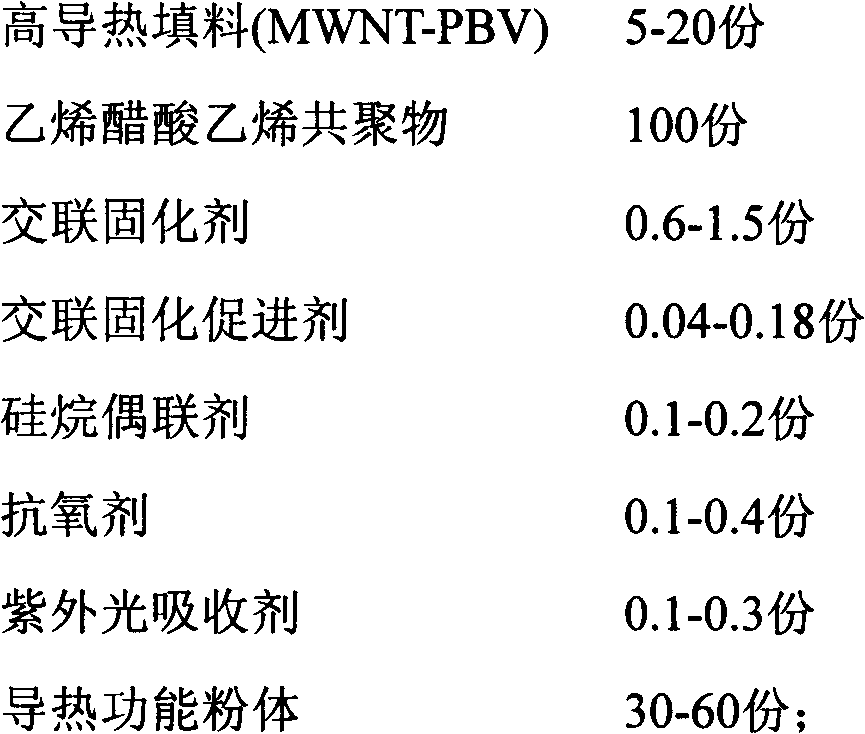

Novel high-thermal-conductive packaging material for solar module

ActiveCN103360986AImprove adhesionIncrease crosslink densityNon-macromolecular adhesive additivesFilm/foil adhesivesElectrical batteryAntioxidant

The invention provides a novel high-thermal-conductive packaging material for a solar module. The novel high-thermal-conductive packaging material is characterized in that fillers which have outstanding thermal conductive performance and can be dispersed uniformly in an EVA (Ethylene Vinyl Acetate) adhesive film are prepared; and the PV (Photovoltaic) packaging material is composed of the following raw materials in parts by mass: 5 to 20 parts of high-performance carbon multi-walled nano-tube thermal-conductive filler (MWNT-PBV), 100 parts of ethylene vinyl acetate copolymer, 0.6 to 1.5 parts of crosslinking curing agent, 0.04 to 0.18 part of crosslinking curing accelerant, 0.1 to 0.2 part of silane coupling agent, 0.1 to 0.4 part of antioxidant, 0.1 to 0.3 part of ultraviolet absorber, and 30 to 60 parts of thermal-conductive functional powder. The prepared heat-conductive solar packaging material has outstanding adhering performance and high crosslinking density, can resist outdoor ultraviolet light aging, thermal oxidation and moisture erosion for a long time; and the heat resistance and heat dissipation properties are effectively improved, the temperature on the surface of a silicon cell can be effectively reduced, and the photovoltaic conversion efficiency is remarkably improved.

Owner:JIANGNAN UNIV

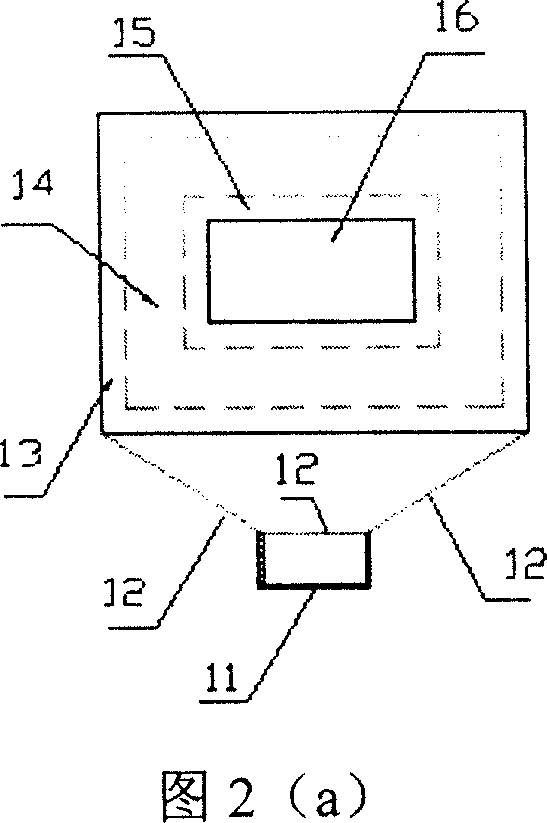

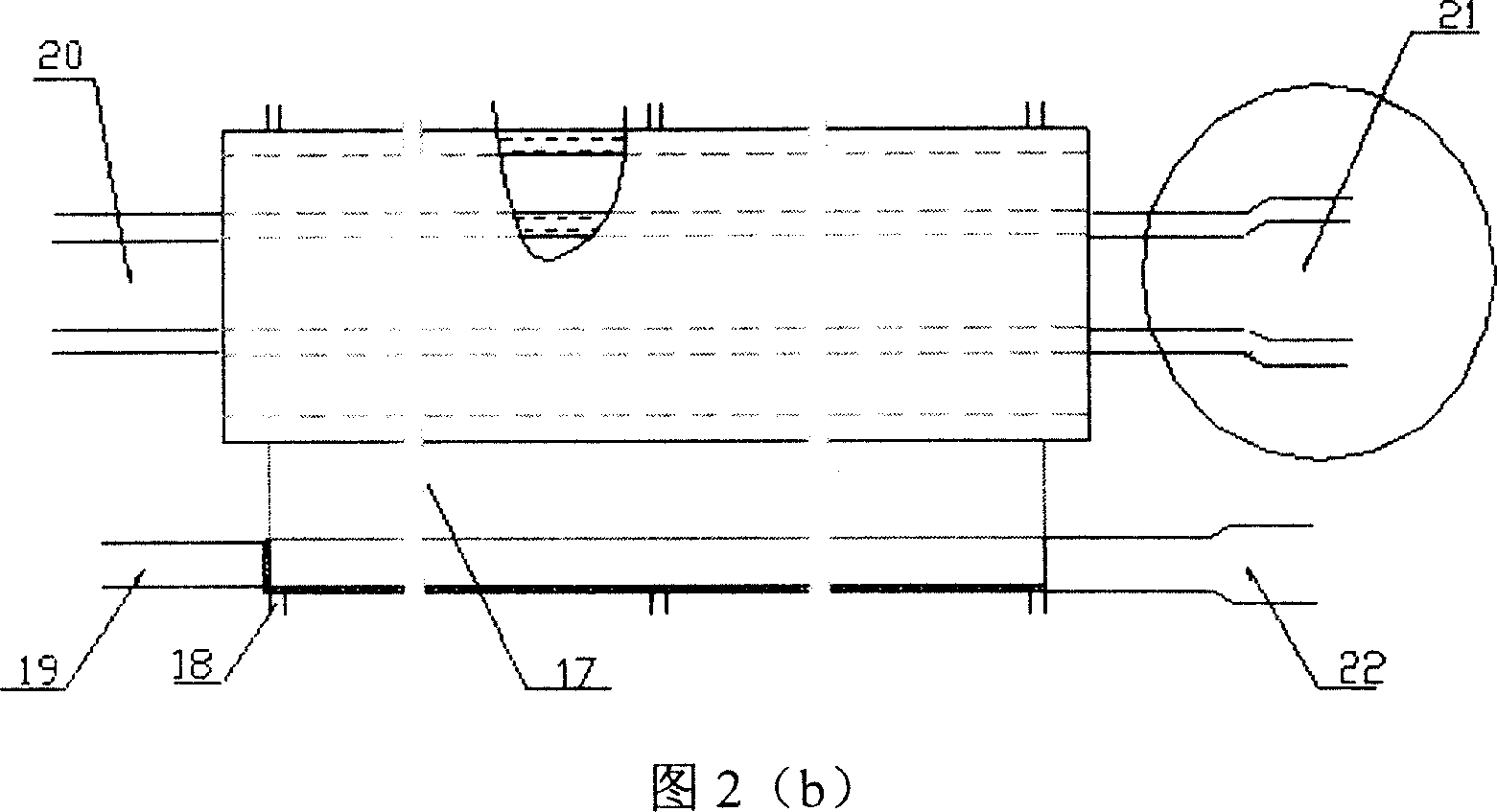

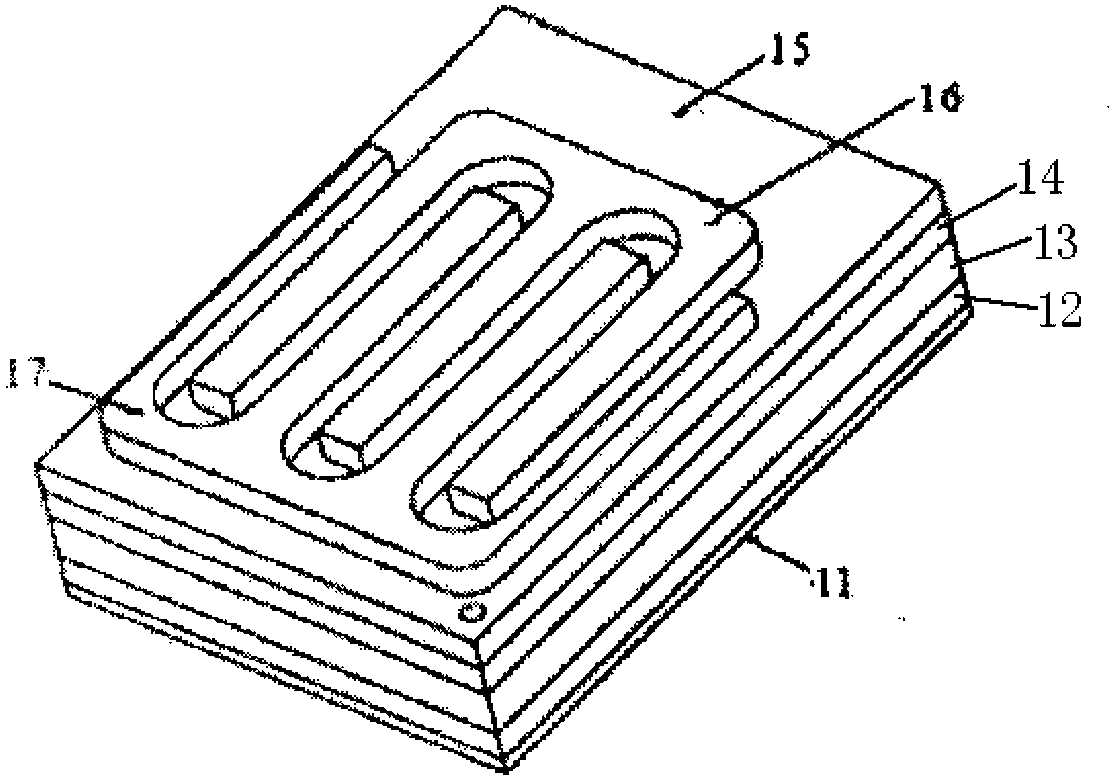

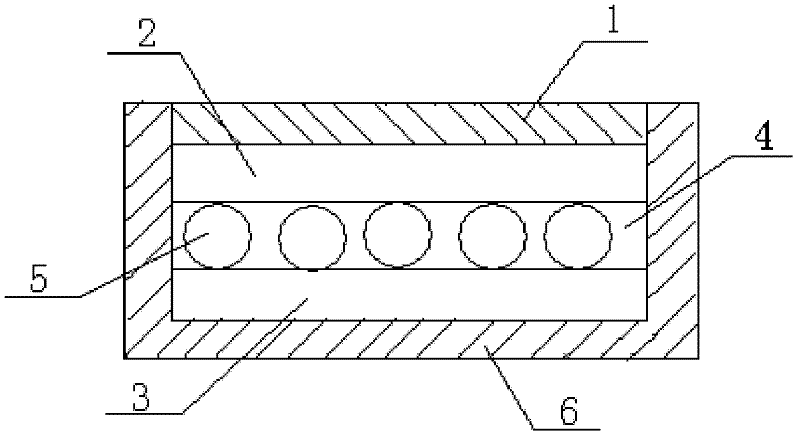

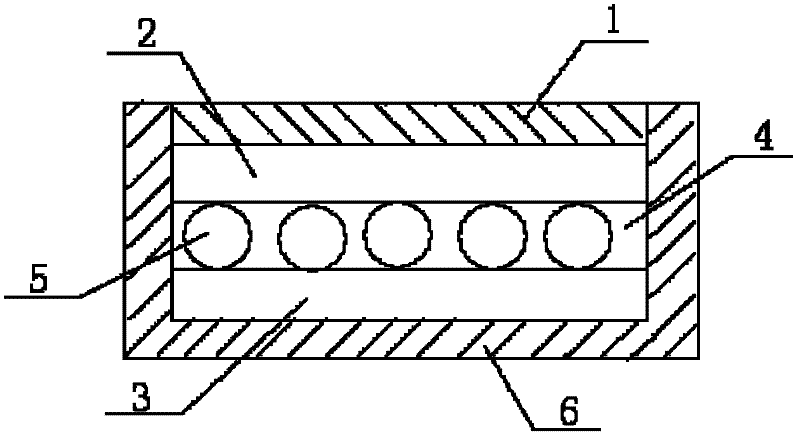

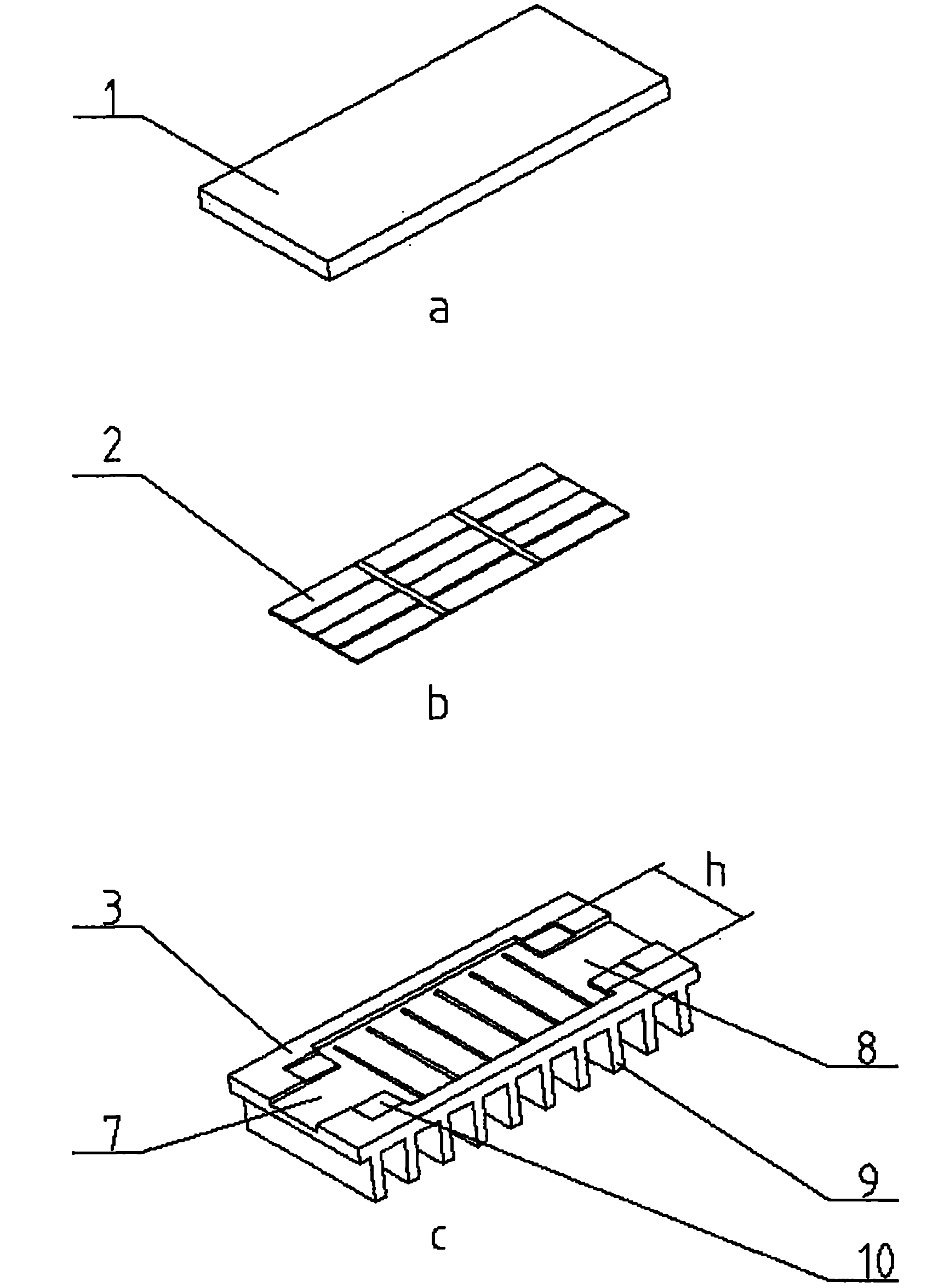

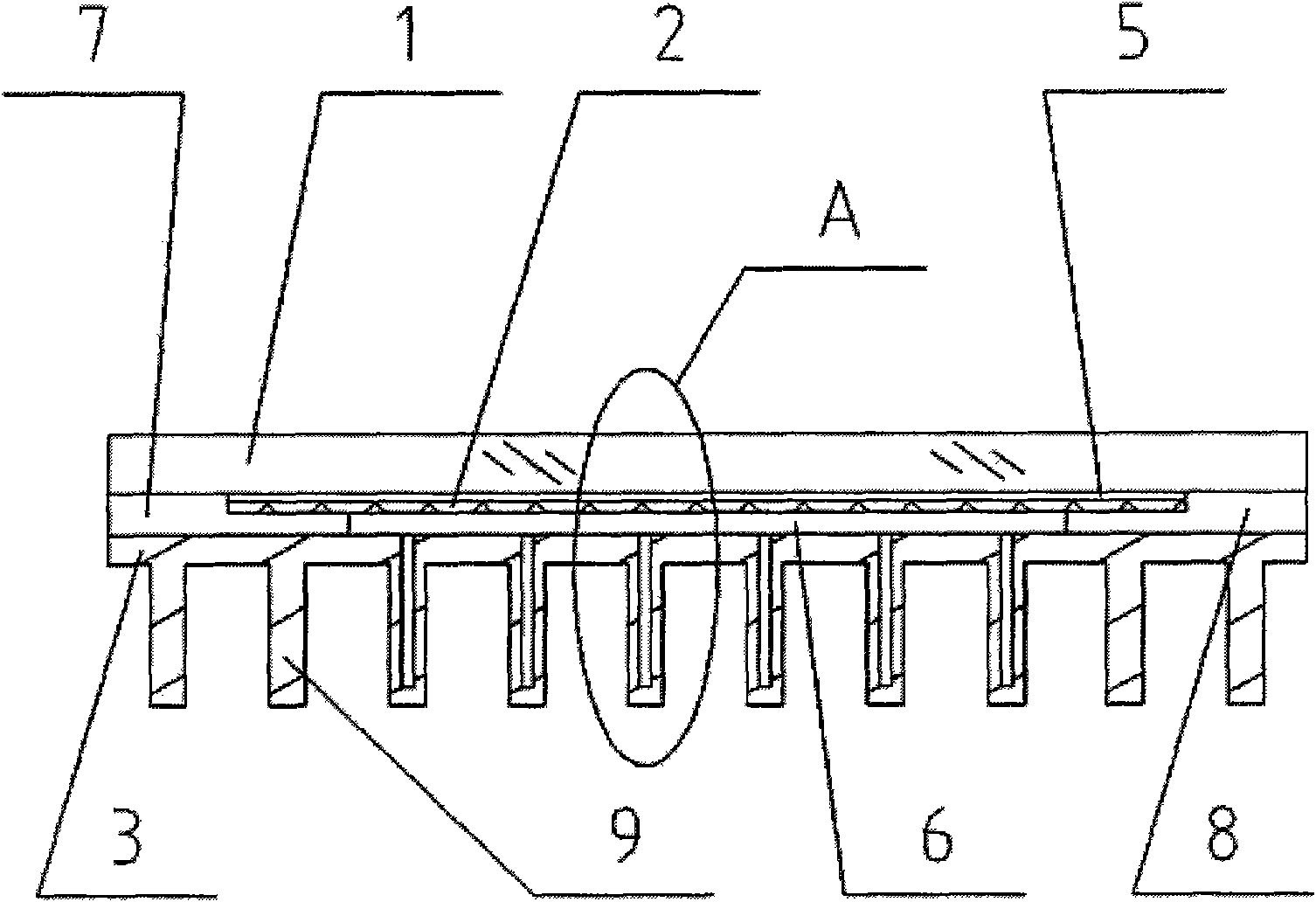

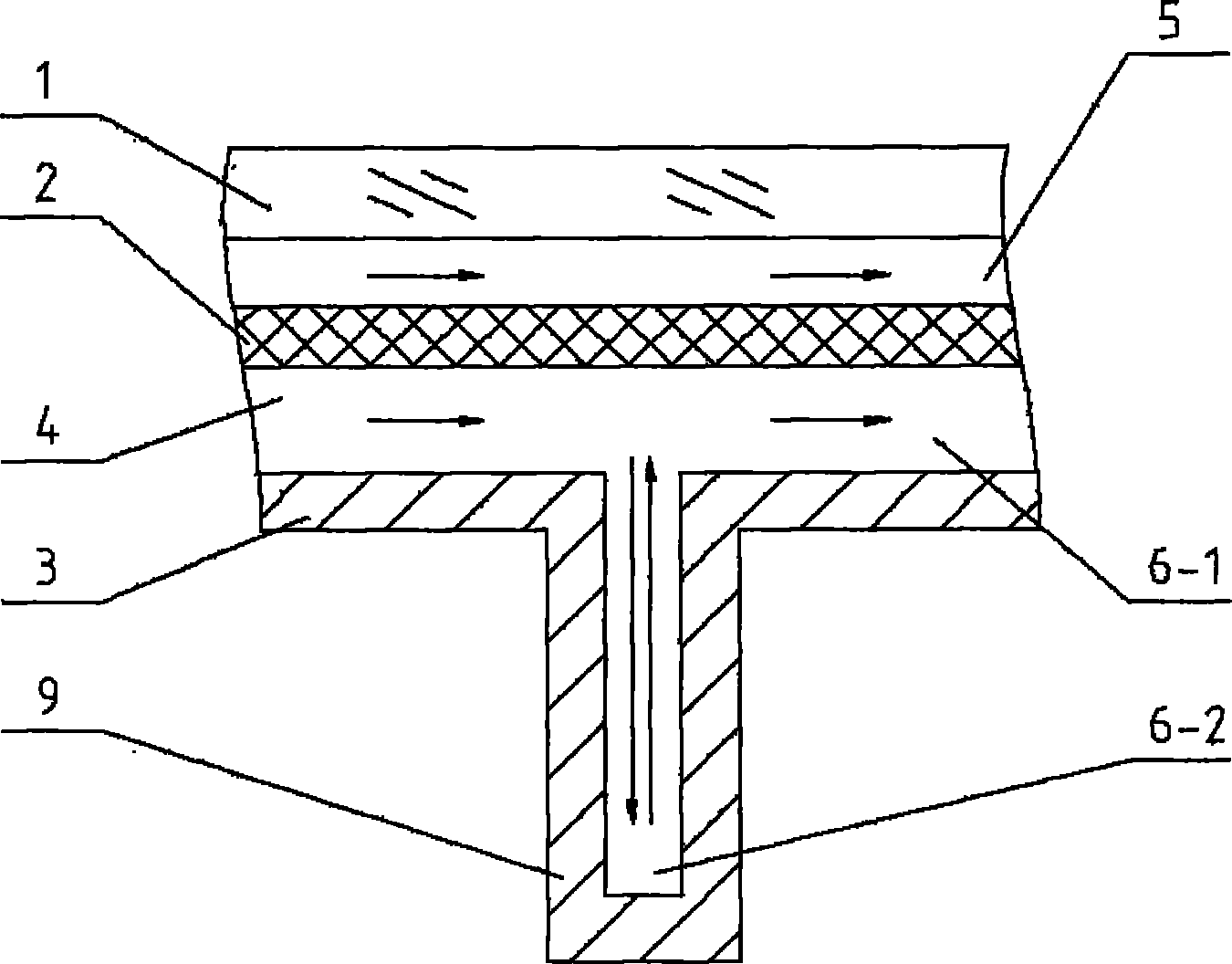

Solar photovoltaic cell with micro-fluidic structure

InactiveCN101840948AImprove photovoltaic conversion efficiencyReduce the angle of incidencePhotovoltaic energy generationSemiconductor devicesMicrofluidicsAdhesive

The invention discloses a solar photovoltaic cell with a micro-fluidic structure, aiming at overcoming the problem that the prior solar photovoltaic cell has no better radiating effect. The solar photovoltaic cell comprises an upper cover plate, a solar cell panel, a lower cover plate and a working medium. The solar cell panel is arranged in the lower cover plate; the upper cover plate covers the lower cover plate; the upper cover plate and the lower cover plate are adhered by adhesive in a sealing way; an upper fluid channel is formed between the lower surface of the upper cover plate and the upper surface of the solar cell panel; a main lower fluid channel is formed between the lower surface of the solar cell panel and the bottom surface of the slot of the lower cover plate; branched lower fluid channels are arranged in the radiating fins at the bottom of the lower cover plate; the main lower fluid channel is communicated with the lower fluid channels; the upper fluid channel is communicated with the main lower fluid channel; the left end of the solar photovoltaic cell is provided with a working medium inlet, and the right end is provided with a working medium outlet; both the working medium inlet and the working medium outlet are communicated with the main lower fluid channel and the upper fluid channel; and the working medium is filled between the upper cover plate and the lower cover plate which are adhered in a sealing way.

Owner:JILIN UNIV

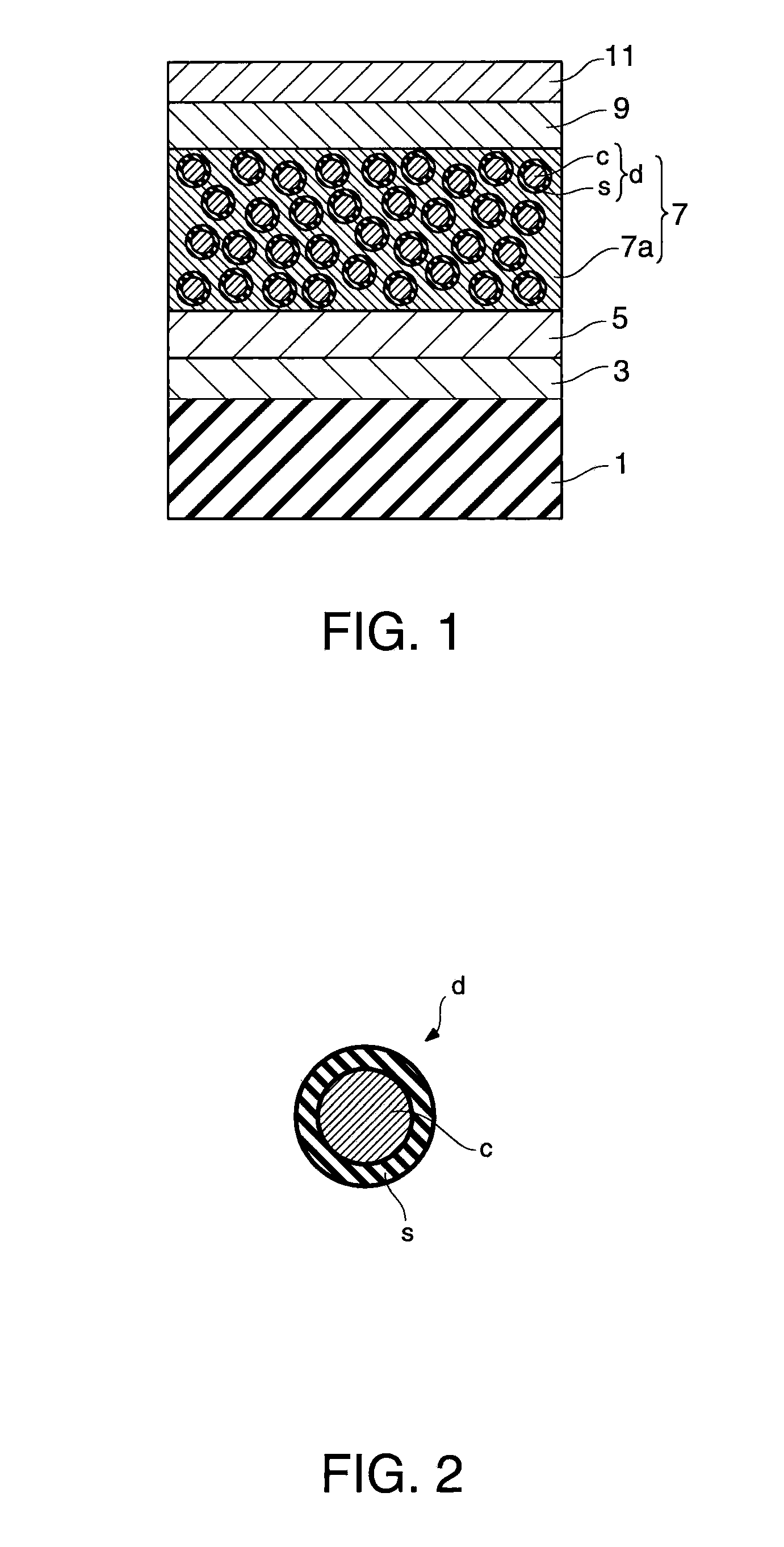

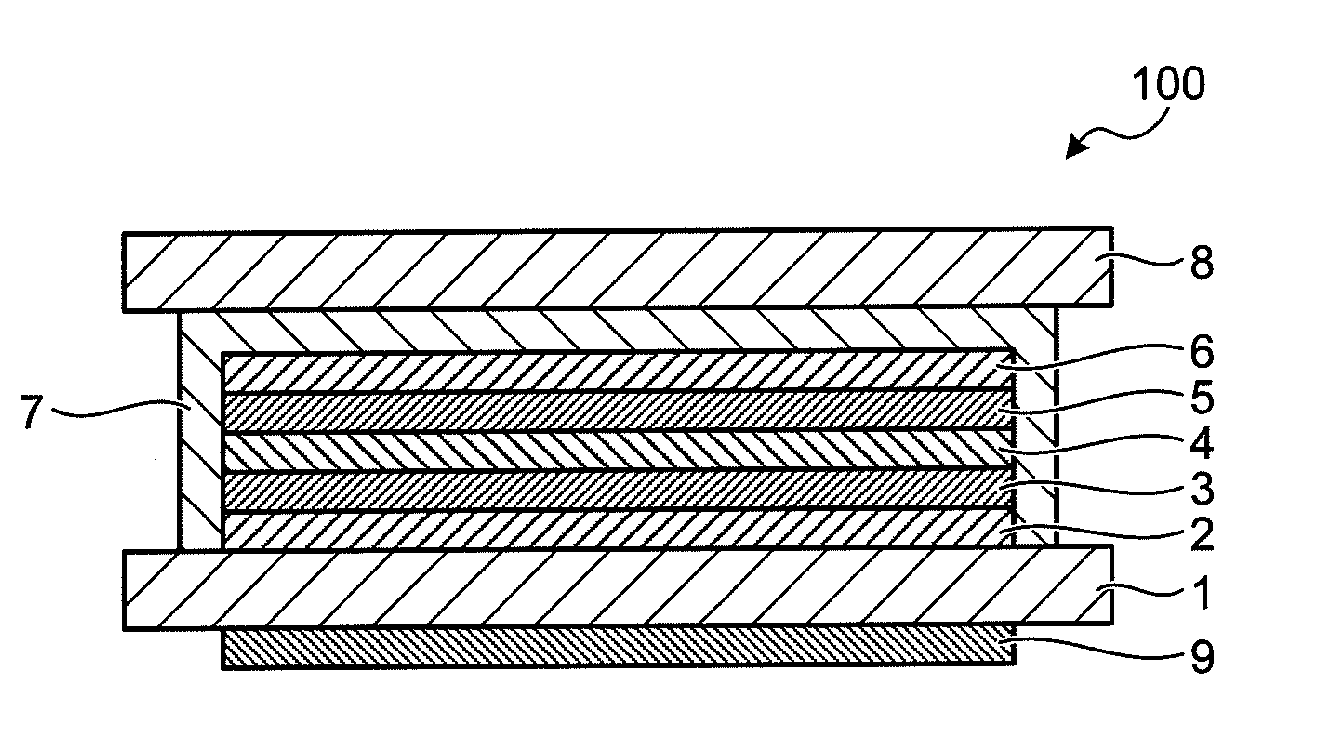

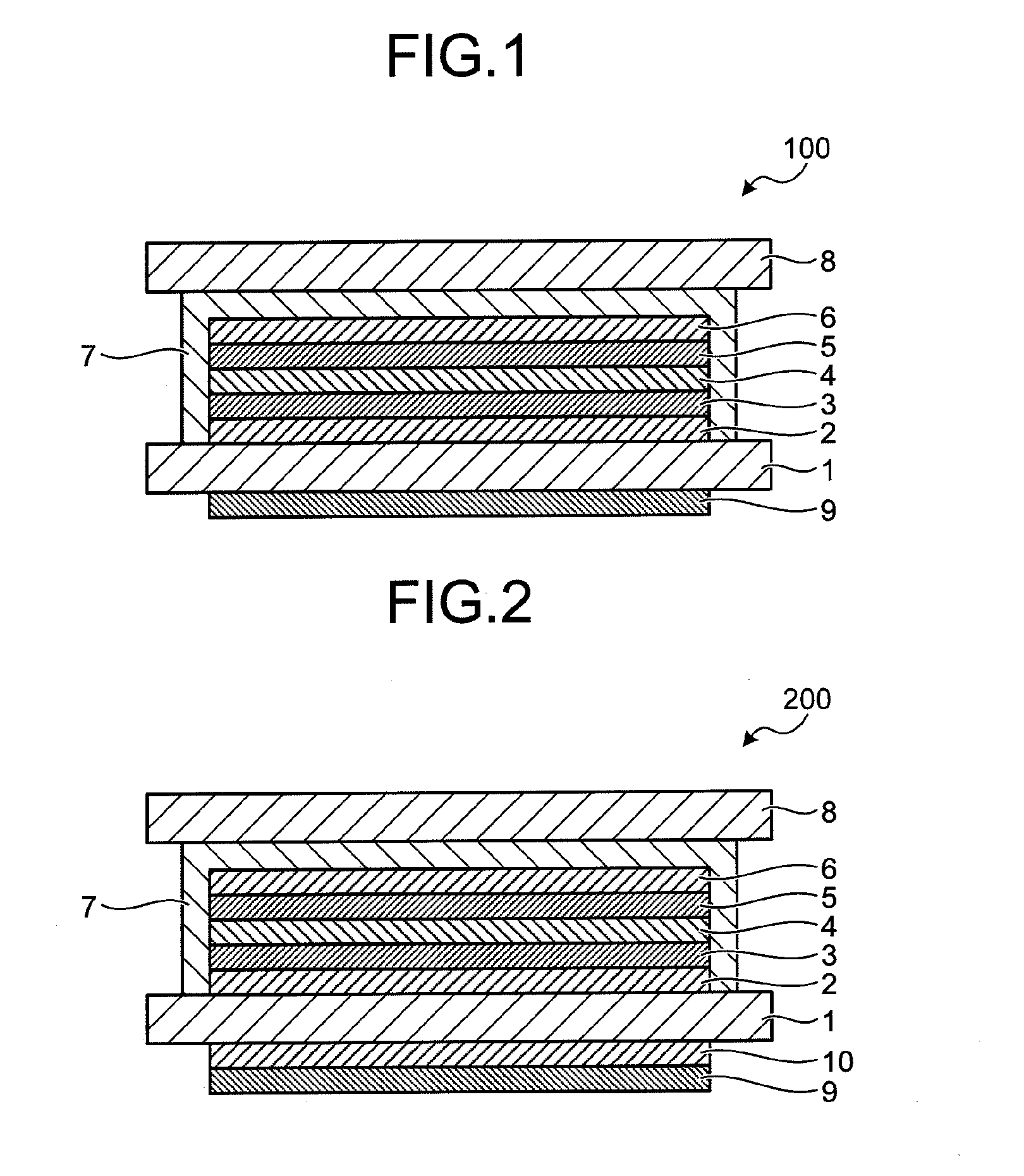

Organic photovoltaic cell

InactiveUS20120227807A1Conversion efficiency be improveInhibit deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingLong wavelengthUltraviolet

Provided is an organic photovoltaic cell having excellent photovoltaic conversion efficiency. An organic photovoltaic cell 100 comprises a first electrode 6, an active layer 4 capable of generating charges by incident light, a second electrode 2, and a wavelength conversion layer 9 capable of wavelength conversion of incident ultraviolet light into light having longer wavelength than that of the ultraviolet light and outputting the resulting light, in this order.

Owner:SUMITOMO CHEM CO LTD

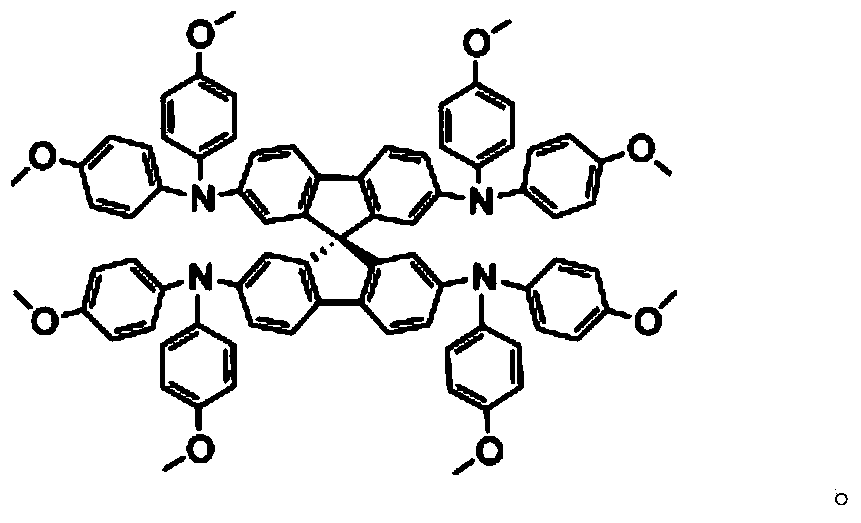

Perovskite photoelectric functional material modified with amphipathic molecule, and methods for preparing and using the same

ActiveUS20160137915A1Material is facilitatedHigh crystallinityTin compoundsSolid-state devicesOrganic chemistryPerovskite

A perovskite-based photoelectric functional material having a general formula MzAyBXz+y+2. The matrix of the photoelectric functional material is a perovskite material ABX3, M is an organic amphipathic molecule used as a modification component of the matrix, 0<z≦0.5, 0<y≦1, and y+z≧1.

Owner:HUBEI WONDER SOLAR LLC

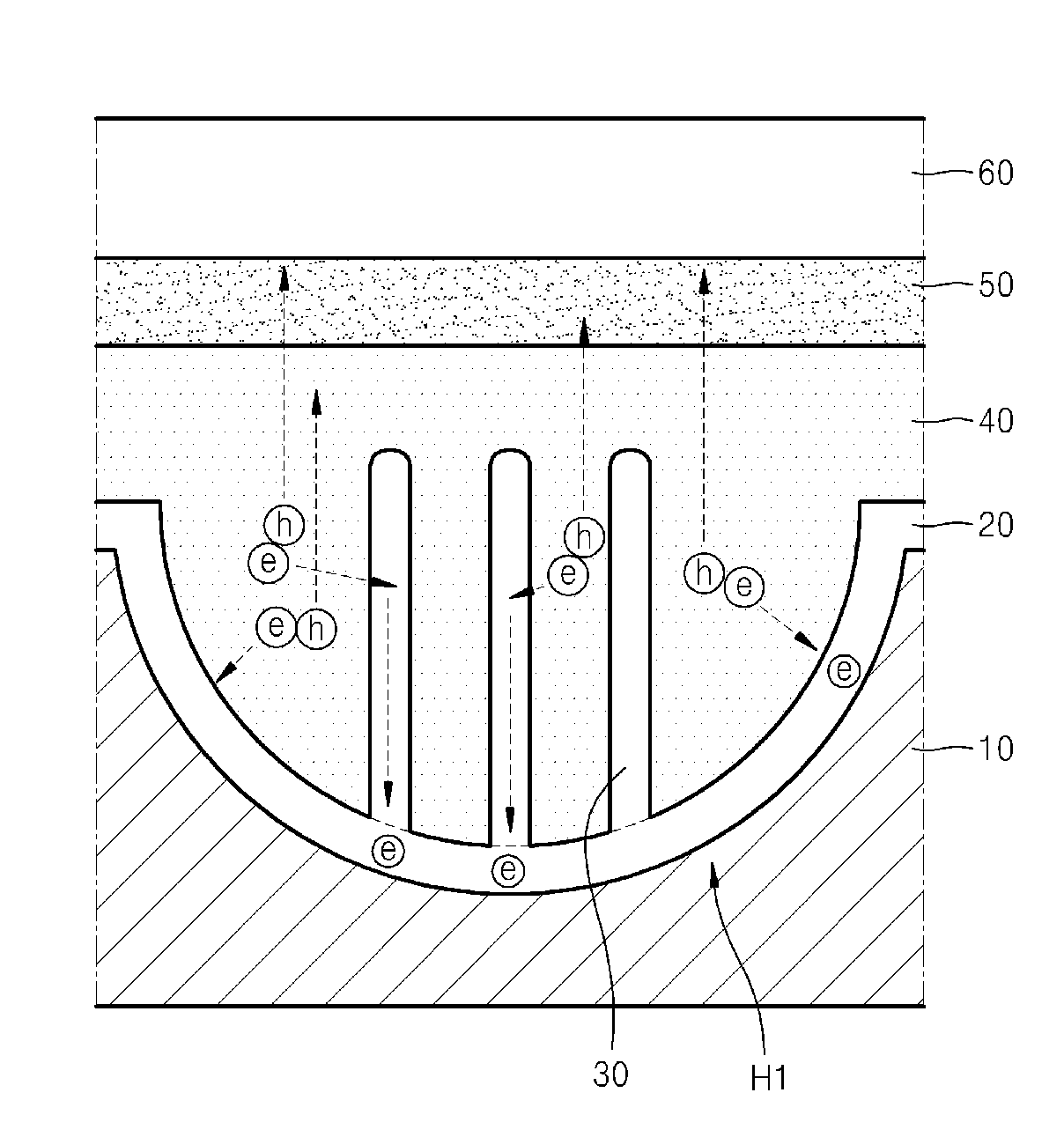

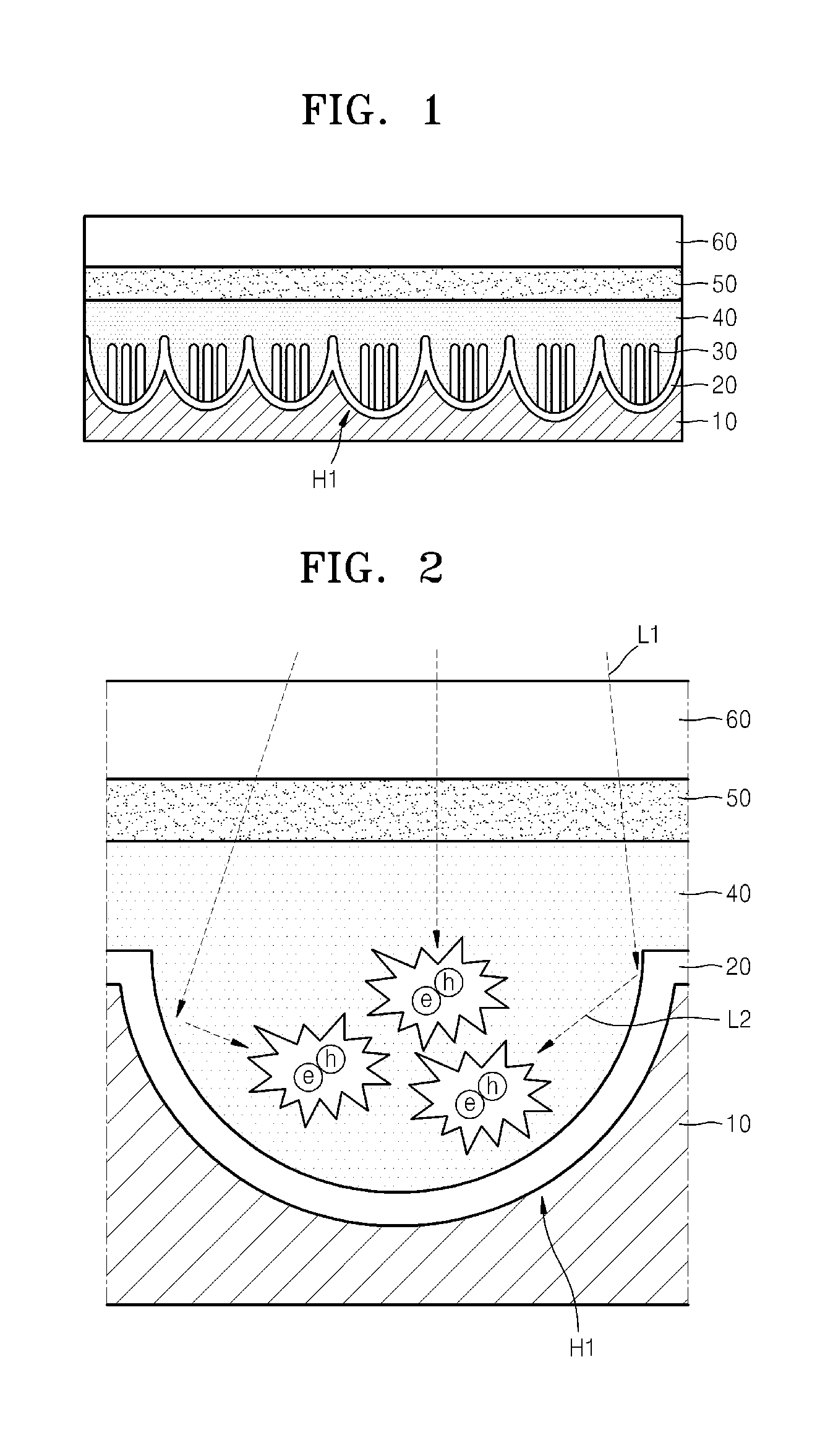

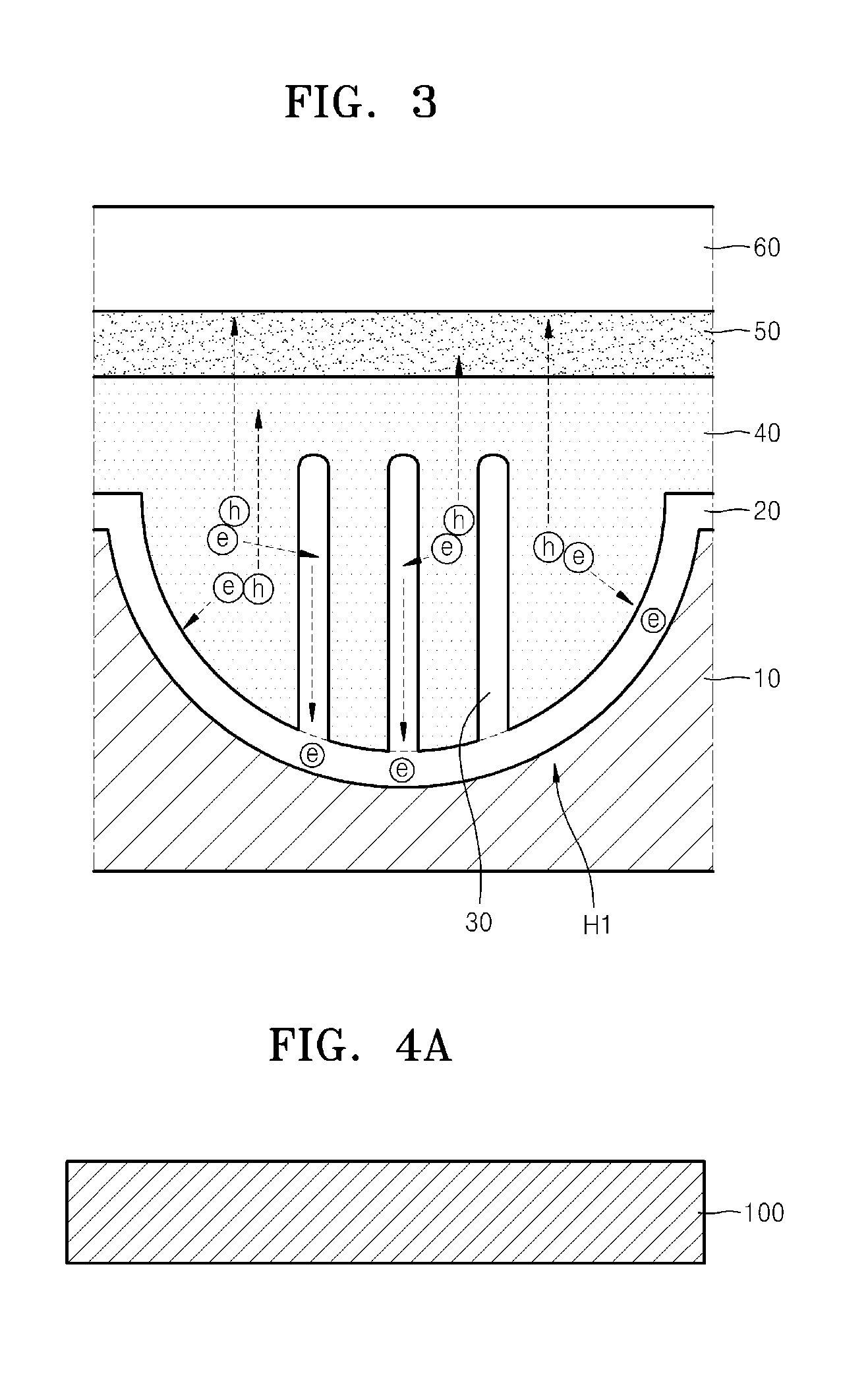

Solar cells and methods of manufacturing the same

ActiveUS20120125413A1Improve photovoltaic conversion efficiencyMaterial nanotechnologyFinal product manufactureEngineeringSolar cell

Solar cells and methods of manufacturing the solar cells are provided. The solar cell may be formed on a substrate having a plurality of concave portions. A plurality of nanostructures may be formed on a surface of the substrate, in which the plurality of concave portions are formed. A photoactive layer may be formed to cover the plurality of nanostructures. The nanostructures may include an inorganic material, and the photoactive layer may include an organic material.

Owner:SAMSUNG ELECTRONICS CO LTD

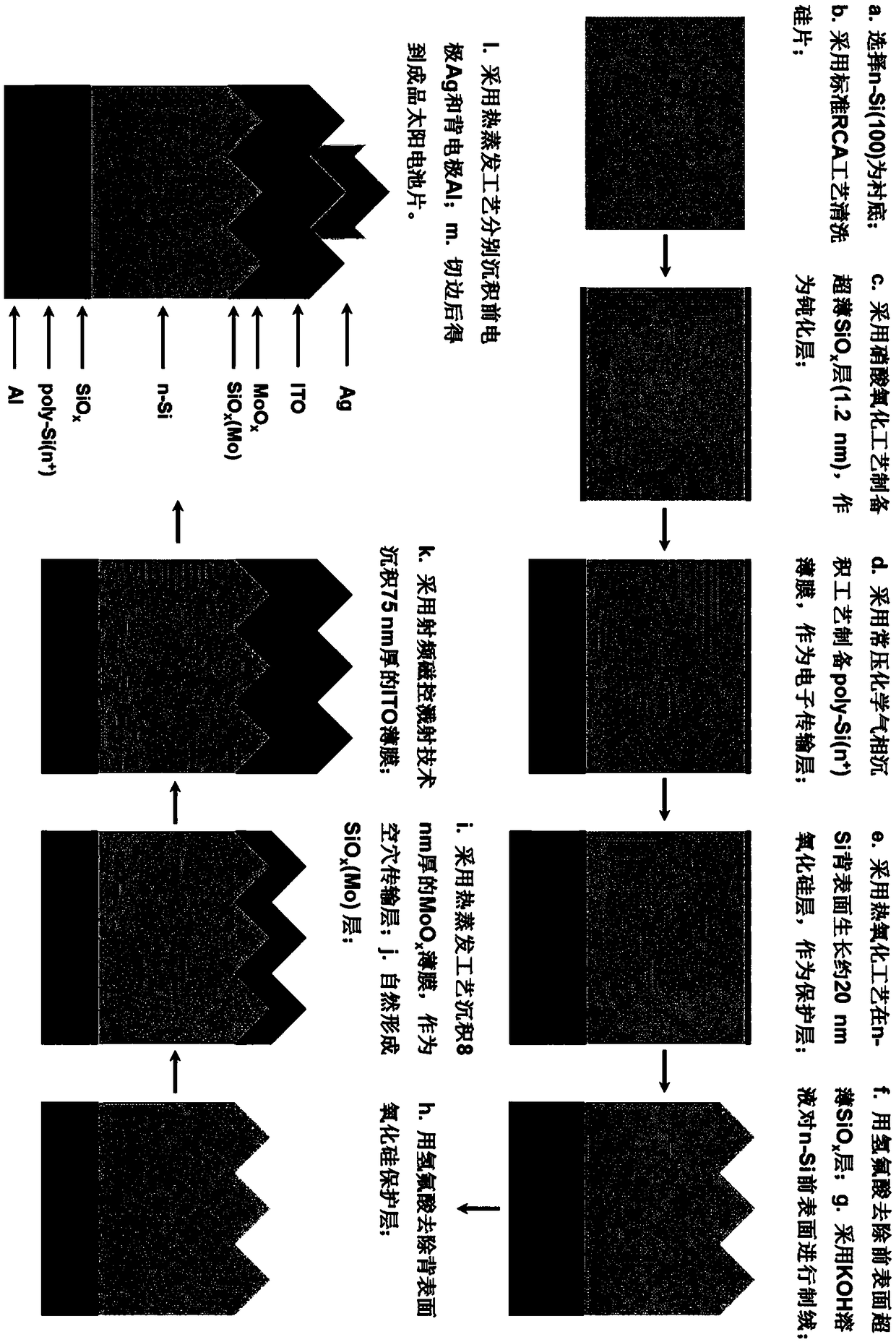

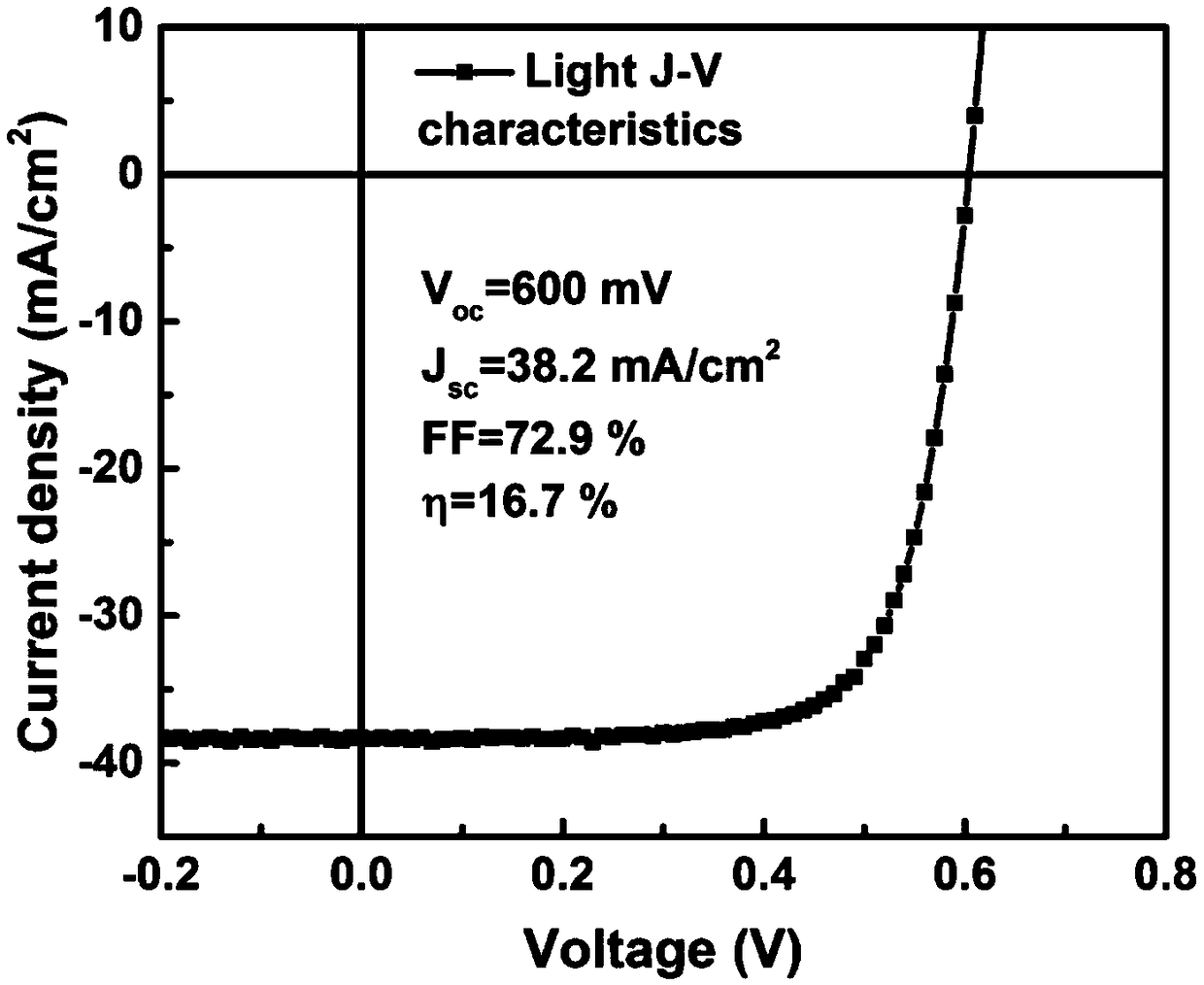

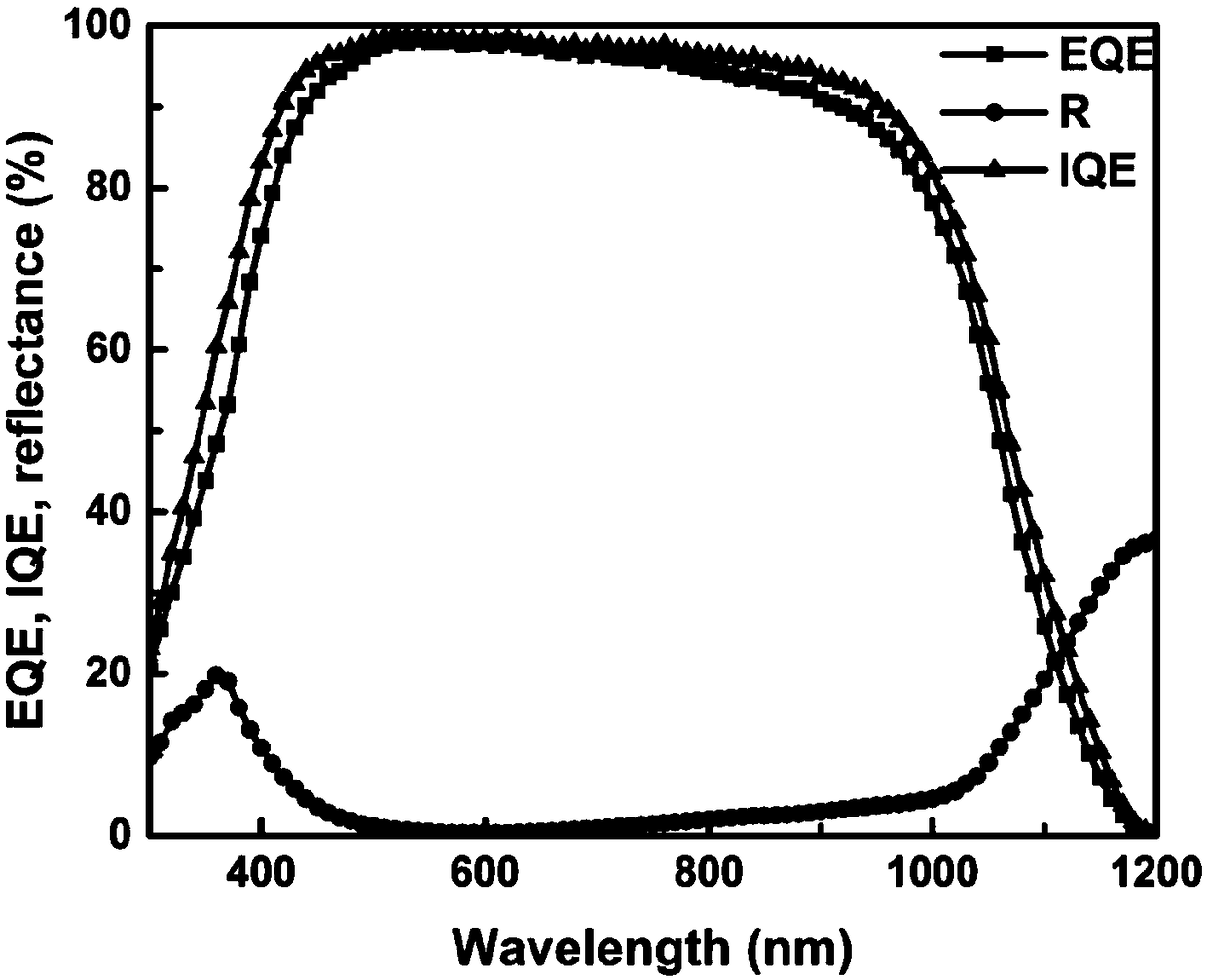

Hole selective MoO<x>/SiO<x>(Mo)/n-Si heterojunction, solar cell device and fabrication method of solar cell device

ActiveCN108878570AImprove stabilityImprove photovoltaic conversion efficiencyFinal product manufacturePhotovoltaic energy generationHeterojunctionSurface cleaning

The invention discloses a hole selective MoO<x> / SiO<x>(Mo) / n-Si heterojunction, a solar cell device and a fabrication method of the solar cell device. The fabrication method comprises the steps of depositing a MoO<x> thin film by taking a single-crystal silicon wafer as a substrate, and enabling MoO3 molecular groups in vapor steam, Mo, O atoms and silicon atoms in a shallow layer of the single-crystal silicon wafer to generate solid-phase reaction to form an ultrathin SiO<x>(Mo) layer by hot evaporation; and forming a functional layer structure body of an interface composite solar cell device, and fabricating an IOT thin film and an electrode to obtain a solar cell piece. The MoO<x> / SiO<x>(Mo) / n-Si heterojunction solar cell is fabricated by combining a crystal silicon surface cleaning process, a MnO<x> thin film deposition process by hot evaporation, a low-energy vapor steam solid-phase reaction method, a ITO thin film deposition process by radio-frequency magnetron sputtering, a nitric acid oxidization process, a normal-pressure chemical vapor deposition thin film process and a hot evaporation metal electrode process, and has relatively good stability and relatively high photoelectric conversion efficiency.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com