Hole selective MoO<x>/SiO<x>(Mo)/n-Si heterojunction, solar cell device and fabrication method of solar cell device

A solar cell and heterojunction technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of reduced recombination, narrow process window, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

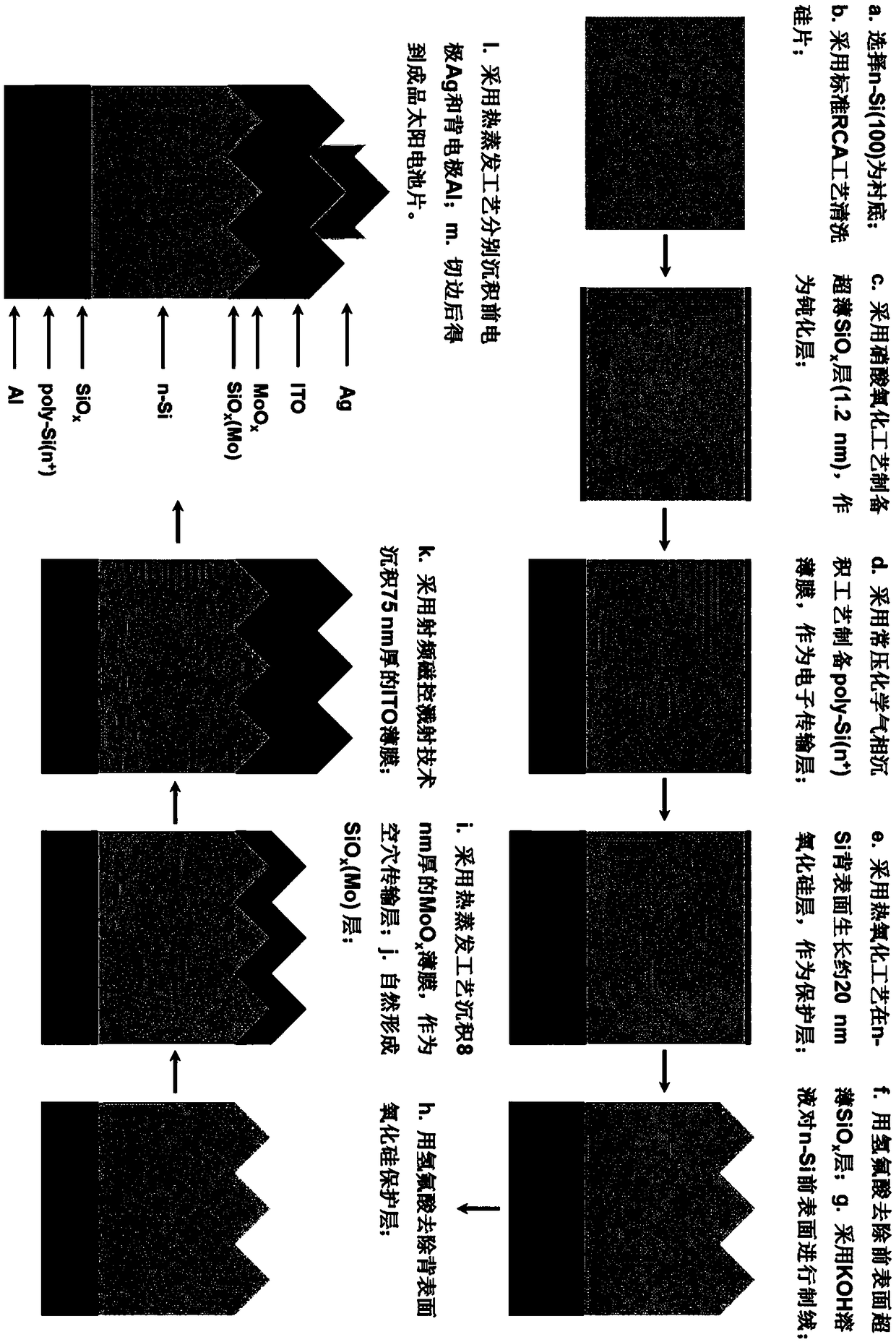

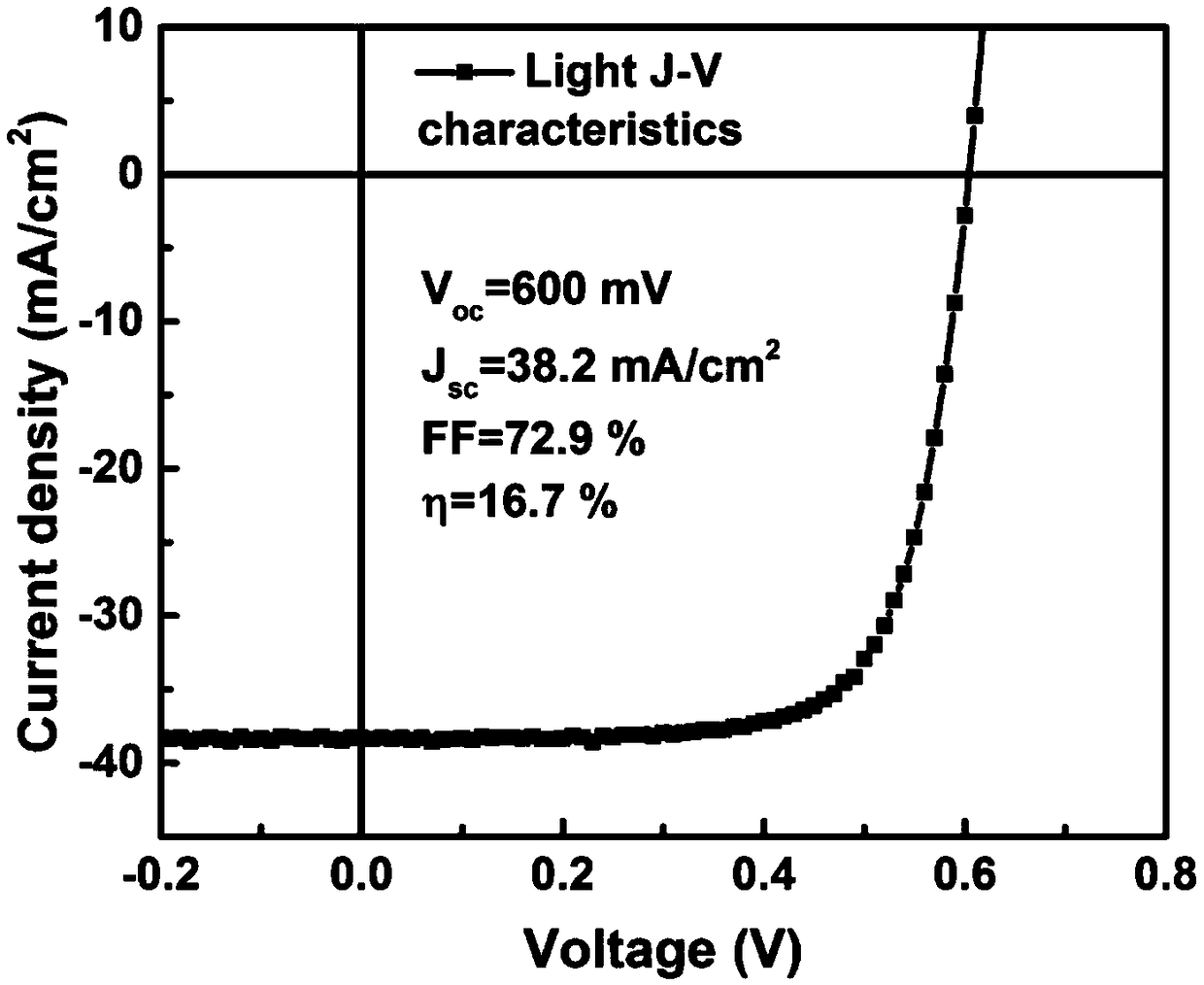

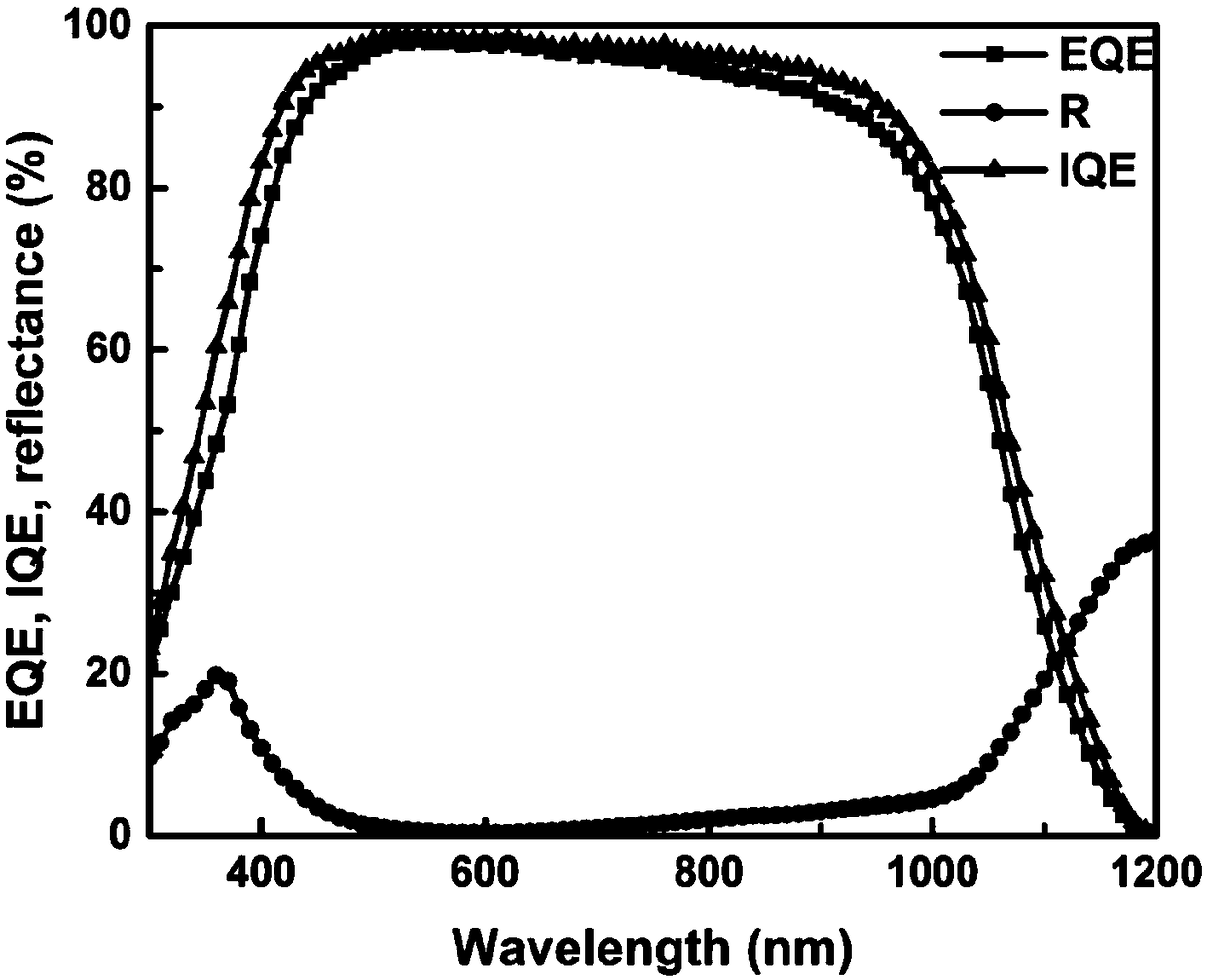

[0046] In this example, see Figure 1 to Figure 7 , a hole-selective MoO x / SiO x (Mo) / n-Si heterojunction using MoO x / SiO x (Mo) stacked composite thin film material is matched with the n-Si material layer to form a hole-selective passivation contact heterojunction to obtain MoO x / SiO x (Mo) / n-Si heterojunction; wherein, the MoO x / SiO x Ultrathin SiO in (Mo)Laminated Composite Thin Film Materials x (Mo) film is in MoO x Ultrathin SiO containing Mo element formed between film and n-Si substrate x Thin films, MoO during thermal evaporation 3 Molecular groups, Mo, and O atoms move to the front surface of the single crystal silicon wafer, and react with the shallow silicon atoms of the single crystal silicon wafer to form ultra-thin SiO x (Mo) thin film layer, ultra-thin SiO x (Mo) The mass percentage of Mo in the thin film layer is 30%.

[0047] In this example, in MoO x / SiO x (Mo) / n-Si laminated composite film, MoO x The thickness of the film layer is 8nm and...

Embodiment 2

[0074] This embodiment is basically the same as Embodiment 1, especially in that:

[0075] In this example, a hole-selective MoO x / SiO x (Mo) / n-Si heterojunction using MoO x / SiO x (Mo) stacked composite thin film material is matched with the n-Si material layer to form a hole-selective passivation contact heterojunction to obtain MoO x / SiO x (Mo) / n-Si heterojunction; wherein, the MoO x / SiO x Ultrathin SiO in (Mo)Laminated Composite Thin Film Materials x (Mo) film is in MoO x Ultrathin SiO containing Mo element formed between film and n-Si substrate x Thin films, MoO during thermal evaporation 3 Molecular groups, Mo, and O atoms move to the front surface of the single crystal silicon wafer, and react with the shallow silicon atoms of the single crystal silicon wafer to form ultra-thin SiO x (Mo) thin film layer, ultra-thin SiO x (Mo) The mass percentage of Mo in the thin film layer is 30%.

[0076] In this example, in MoO x / SiO x (Mo) / n-Si laminated composite...

Embodiment 3

[0098] This embodiment is basically the same as the previous embodiment, and the special features are:

[0099] In this example, a hole-selective MoO x / SiO x (Mo) / n-Si heterojunction using MoO x / SiO x (Mo) stacked composite thin film material is matched with the n-Si material layer to form a hole-selective passivation contact heterojunction to obtain MoO x / SiO x (Mo) / n-Si heterojunction; wherein, the MoO x / SiO x Ultrathin SiO in (Mo)Laminated Composite Thin Film Materials x (Mo) film is in MoO x Ultrathin SiO containing Mo element formed between film and n-Si substrate x Thin films, MoO during thermal evaporation 3 Molecular groups, Mo, and O atoms move to the front surface of the single crystal silicon wafer, and react with the shallow silicon atoms of the single crystal silicon wafer to form ultra-thin SiO x (Mo) thin film layer, ultra-thin SiO x (Mo) The mass percentage of Mo in the thin film layer is 30%.

[0100] In this example, in MoO x / SiO x (Mo) / n-S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com