Patents

Literature

91results about How to "Improve light trapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

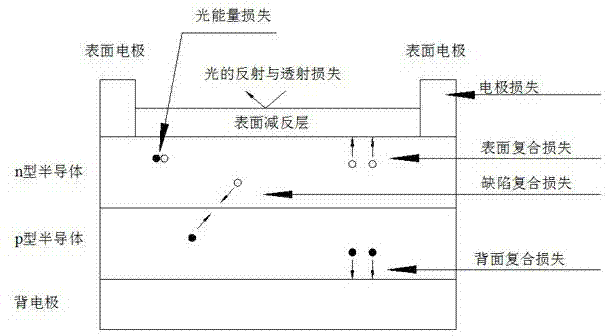

Encapsulant material, crystalline silicon photovoltaic module and thin film photovoltaic module

ActiveUS20100147363A1High light reflectivityImprove light trappingPV power plantsSynthetic resin layered productsHeat resistanceMicrometer

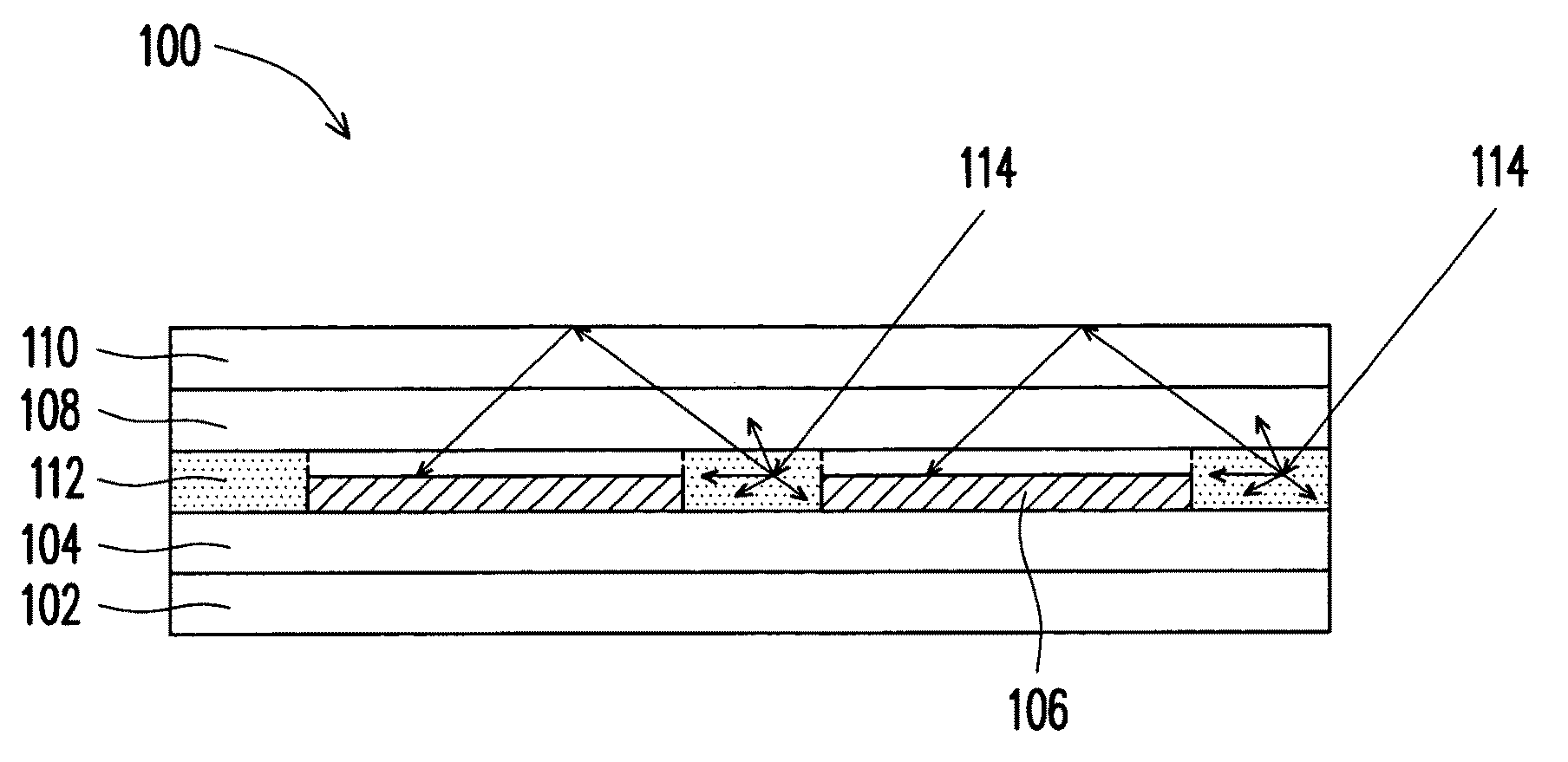

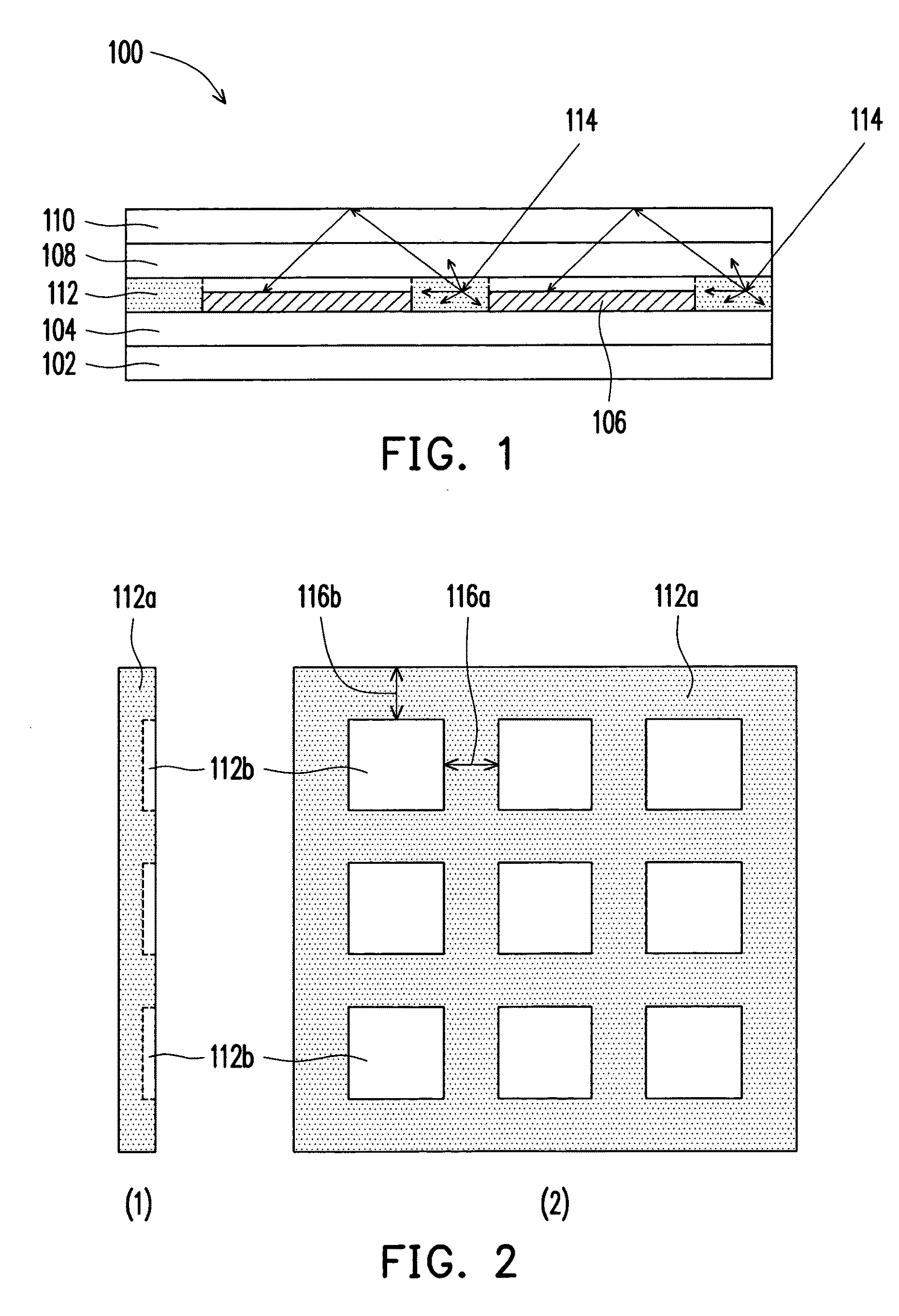

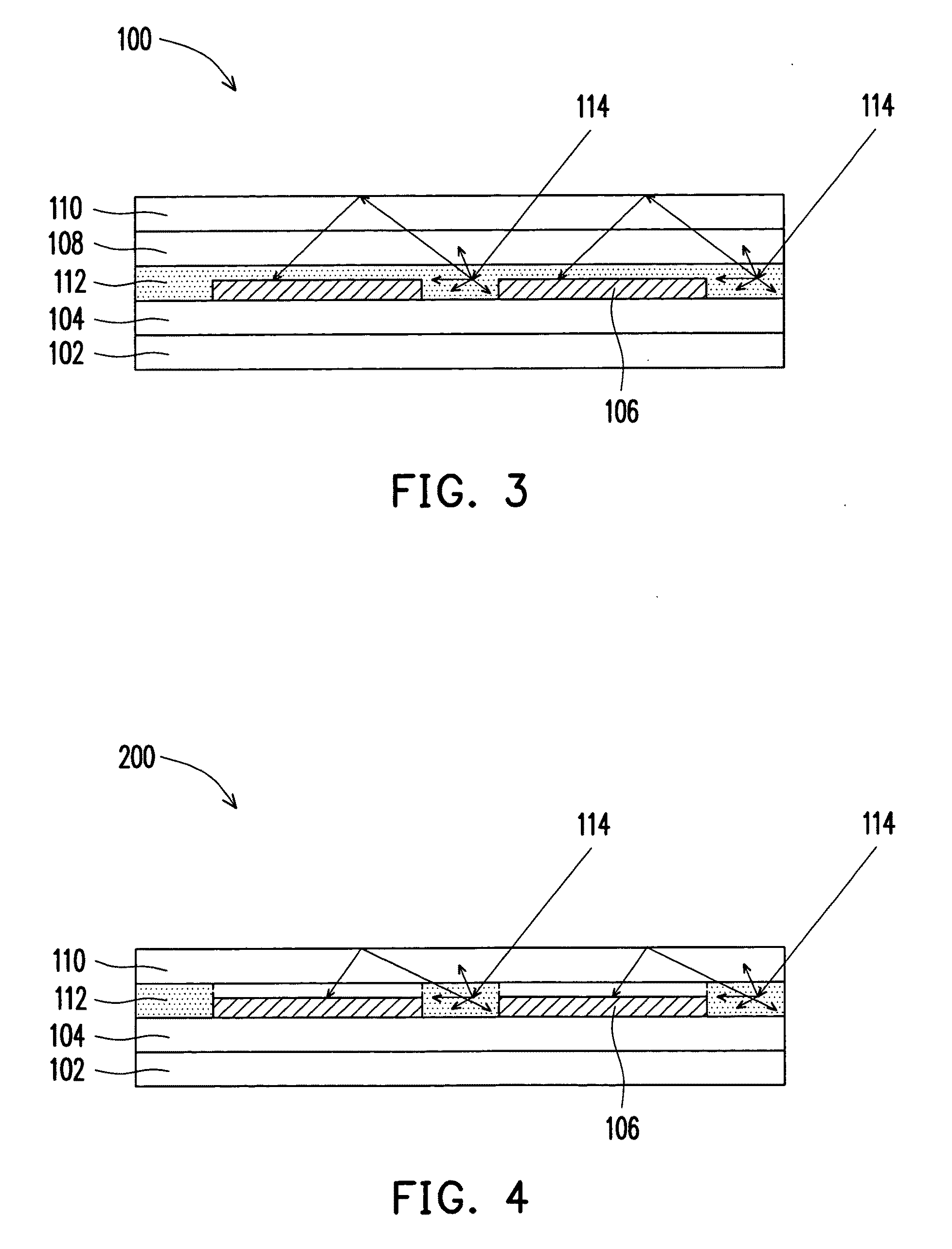

An encapsulant material with enhanced light reflectivity, a crystalline silicon photovoltaic module and a thin film photovoltaic module are provided. The encapsulant material has a porous structure therein, and an average pore diameter of the porous structure is between several hundreds of nanometers and several hundreds of micrometers, so that the light reflectance of the encapsulant material is improved. Moreover, the encapsulant material is crosslinked by a physical or chemical crosslinking method, so heat resistance thereof is improved. Therefore, the encapsulant material is suitable for the crystalline silicon photovoltaic module and the thin film photovoltaic module, so as to increase power conversion efficiency of these modules.

Owner:IND TECH RES INST

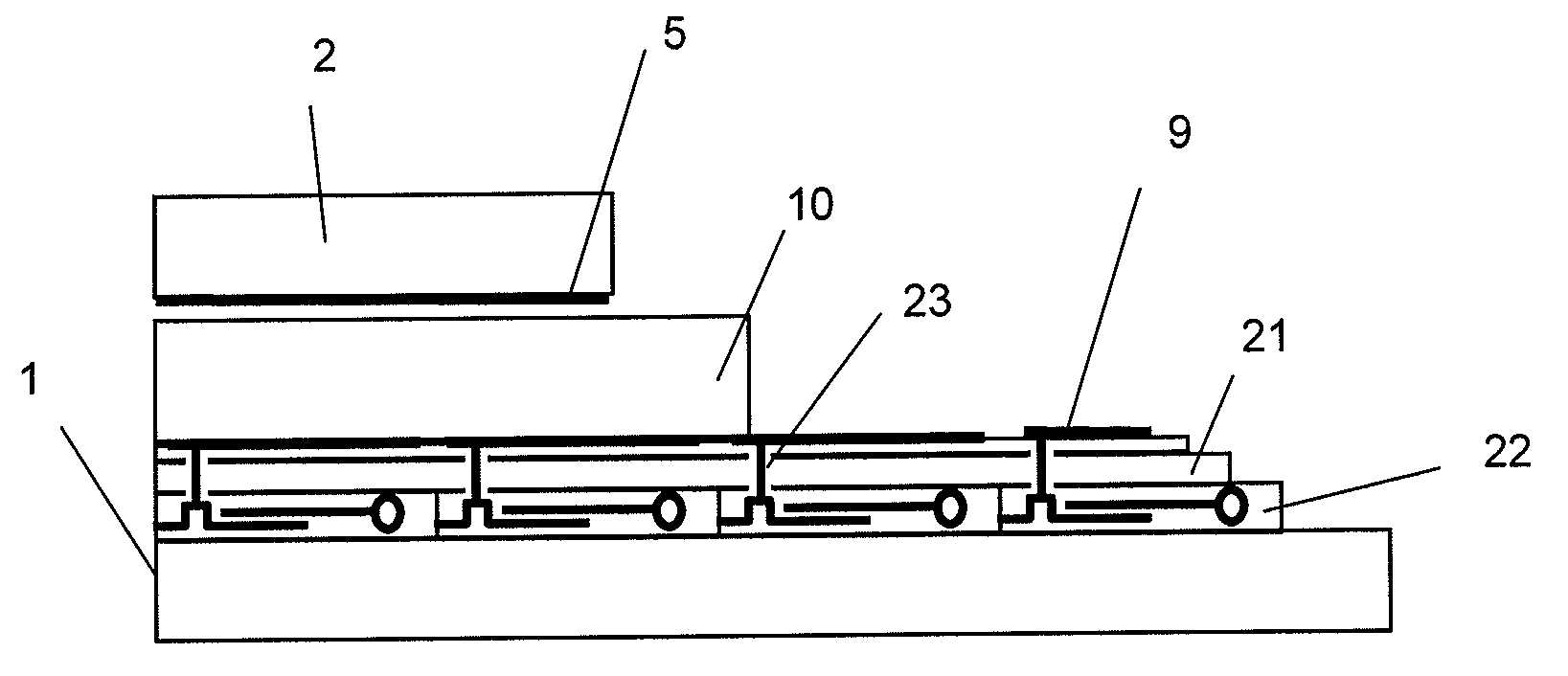

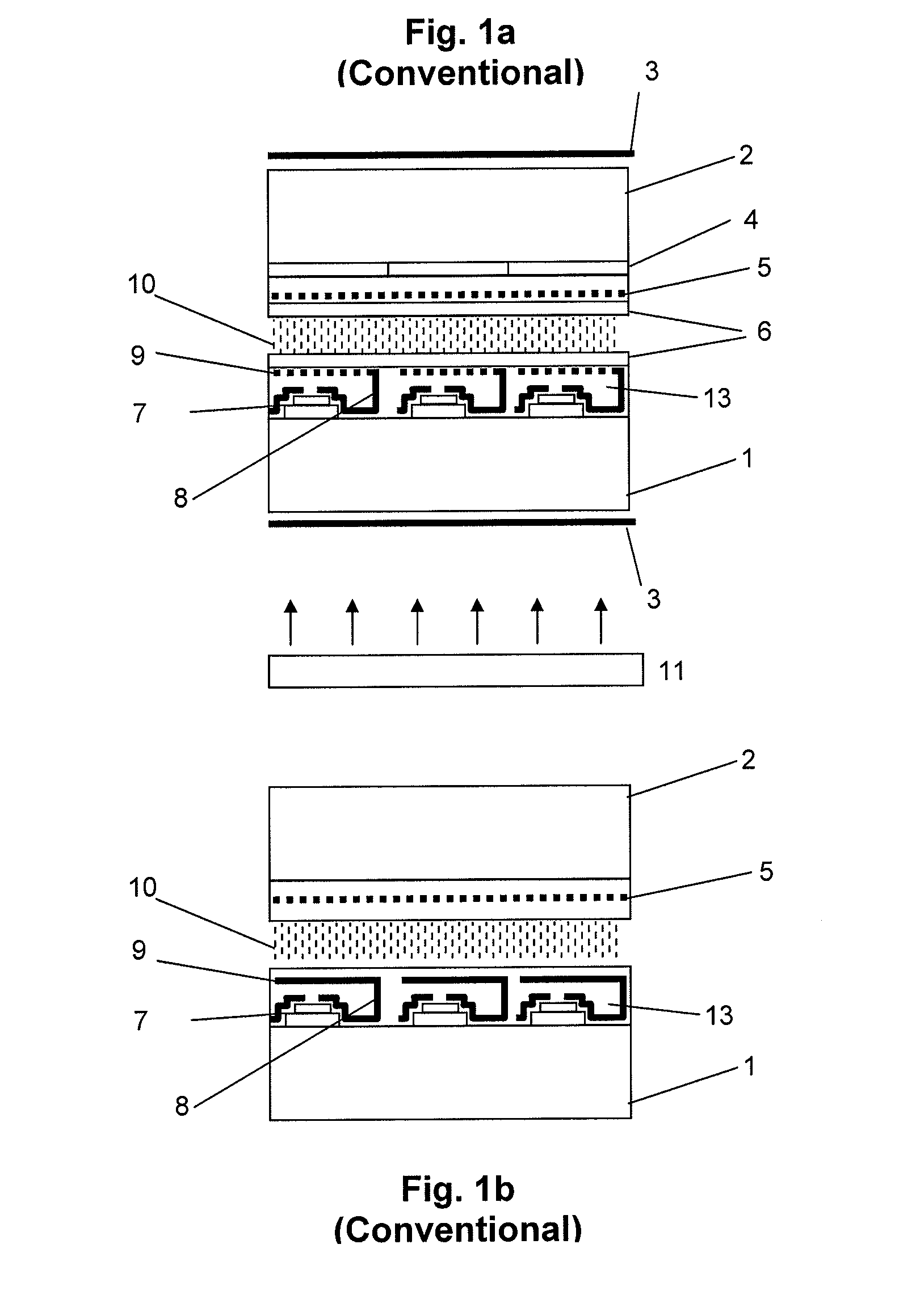

Integrated display and photovoltaic element

InactiveUS20110249219A1Increase display brightnessEfficient power generationVessels or leading-in conductors manufactureNon-linear opticsDisplay deviceEngineering

A display device includes a first layer having an optically active display portion, a second layer including a photovoltaic element, and a third layer including electronics operatively coupled to the first layer, wherein the electronics are configured to drive the optically active display portion. Further, the second layer is arranged between the first and third layers.

Owner:SHARP KK

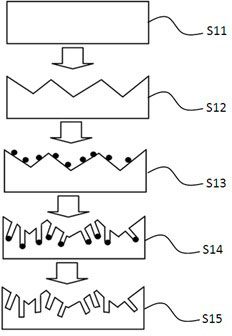

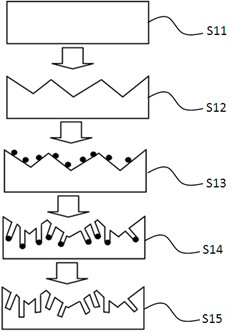

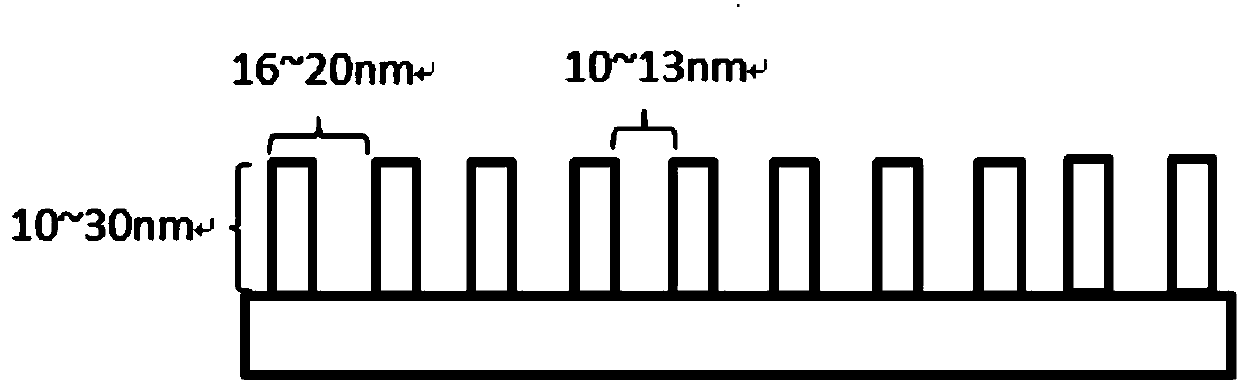

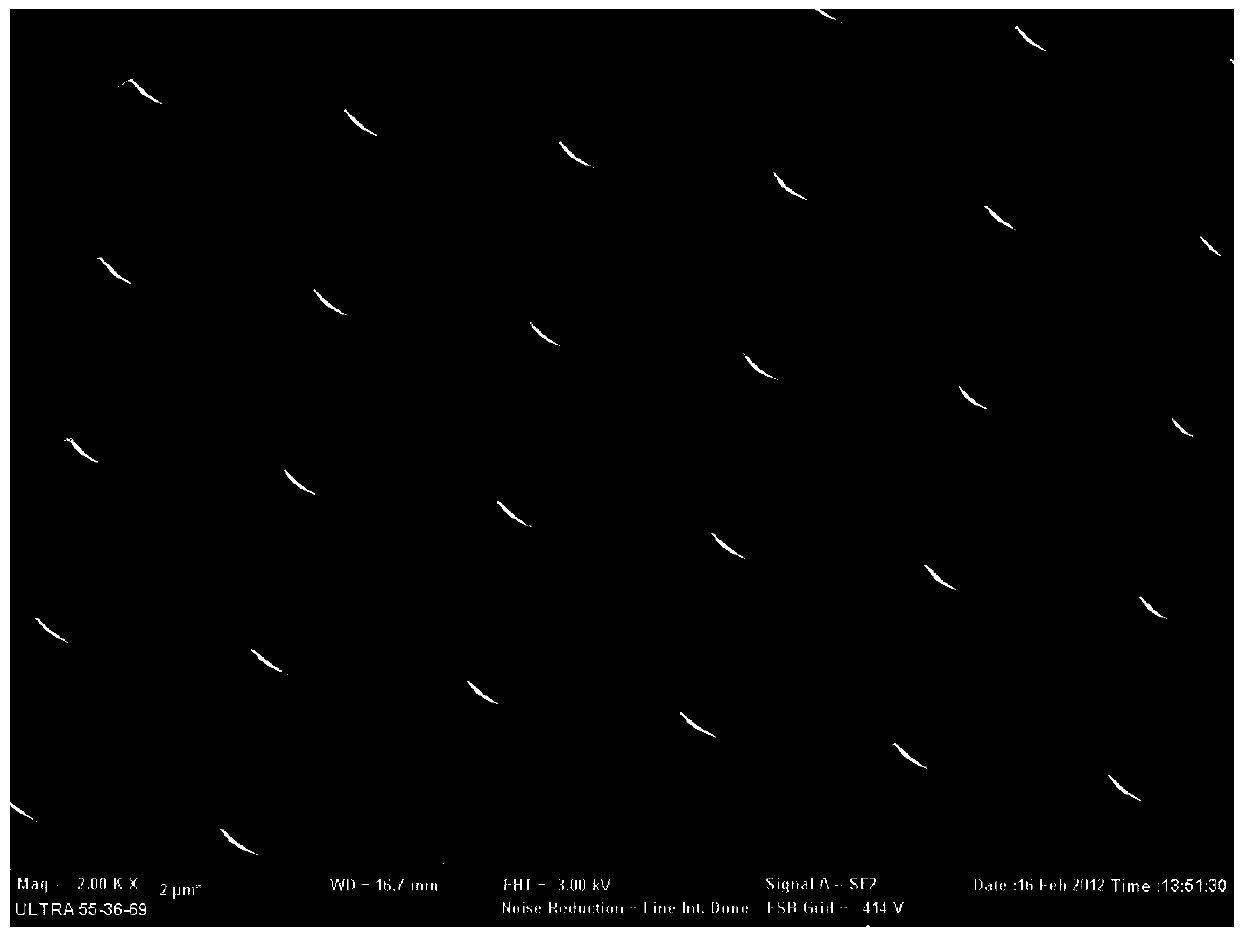

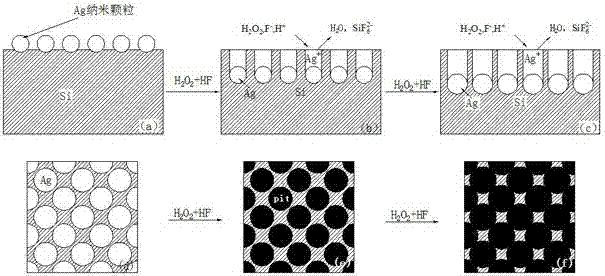

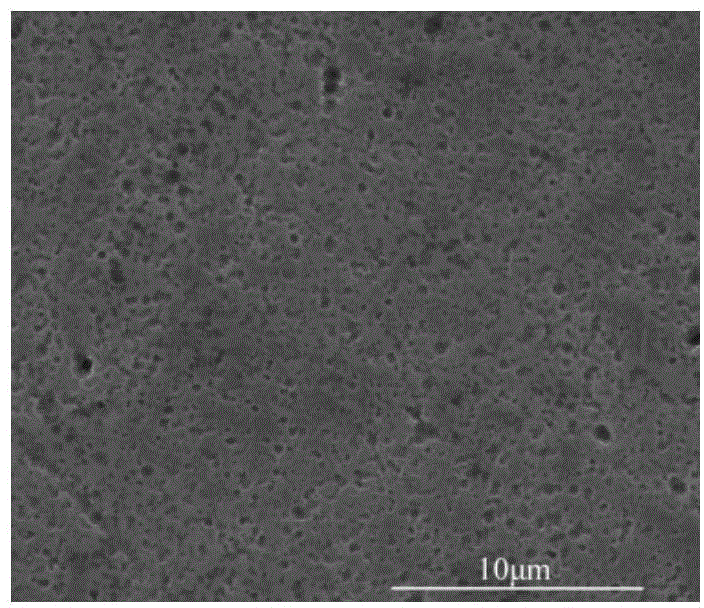

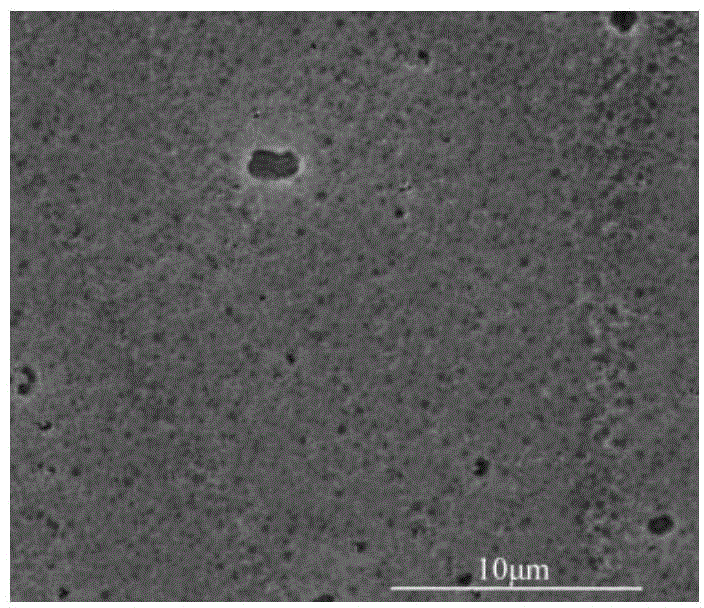

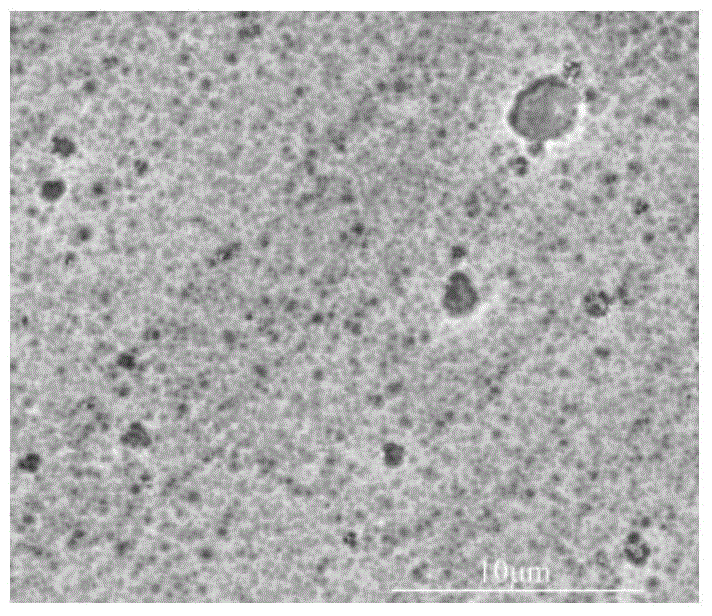

Method for preparing crystalline silicon nanometer and micrometer composite texture surface

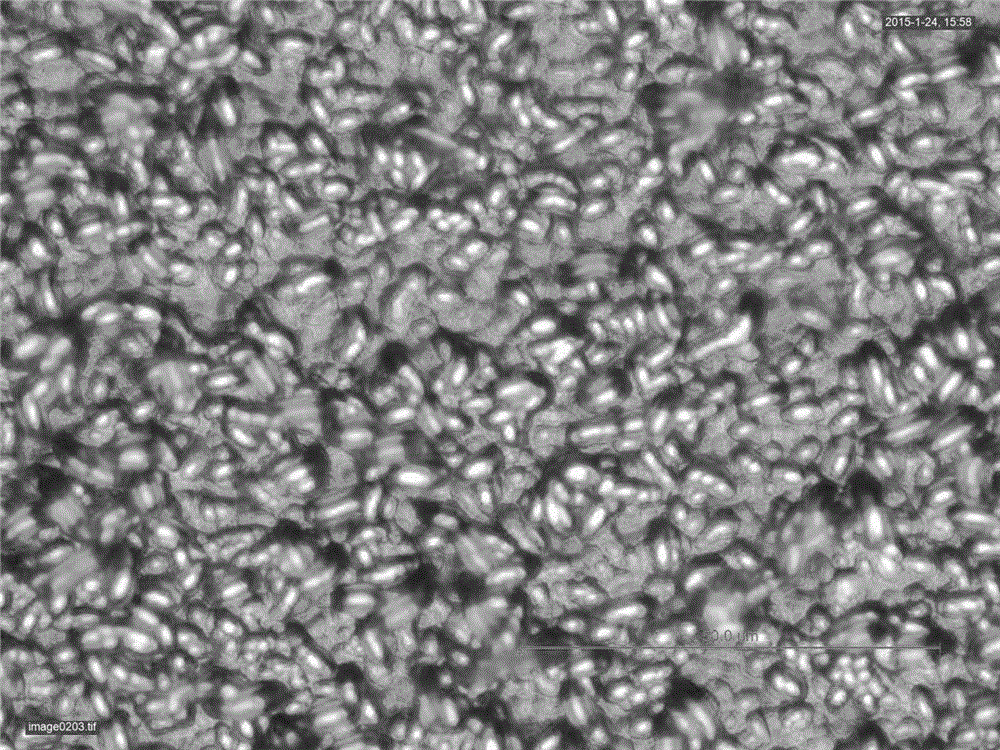

InactiveCN102610692AImprove light trappingPromote absorptionFinal product manufactureSemiconductor devicesSelective leachingScale structure

The invention relates to a method for preparing a crystalline silicon nanometer and micrometer composite texture surface. The method is technically characterized by comprising carrying out cleaning and texture surface making for a crystalline silicon wafer and forming a micrometer-scale texture surface; then uniformly covering a layer of discontinuous nanometer-scale precious metal particles on the surface of the silicon wafer; selectively corroding the surface of the silicon wafer by the aid of chemical corrosive liquid, and forming a nanometer-scale texture surface; and finally cleaning and removing the precious metal particles by the aid of chemical liquor. The composite texture surface prepared by the method has a micrometer-scale structure and a nanometer-scale structure, the structure of the texture surface is finer, a light trapping effect of the surface of the silicon wafer is greatly improved, short-circuit current of a battery can be effectively increased, and accordingly photoelectric conversion efficiency of the battery is enhanced.

Owner:REALFORCE POWER

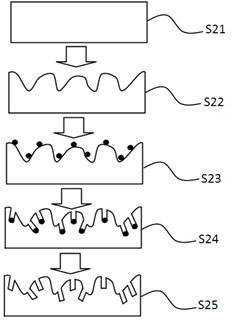

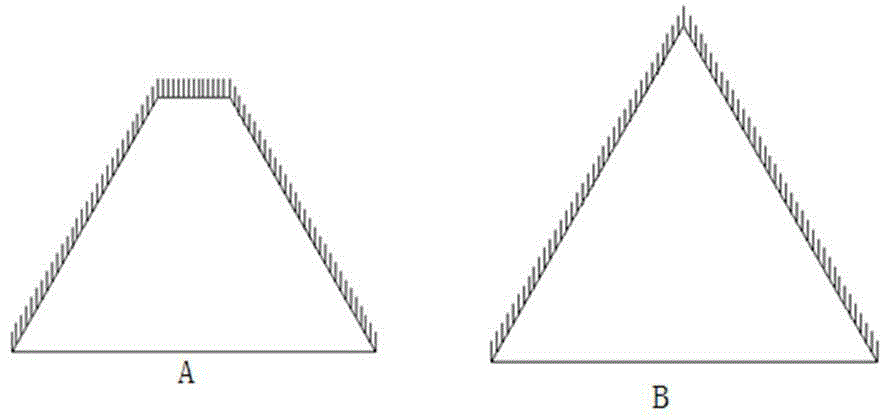

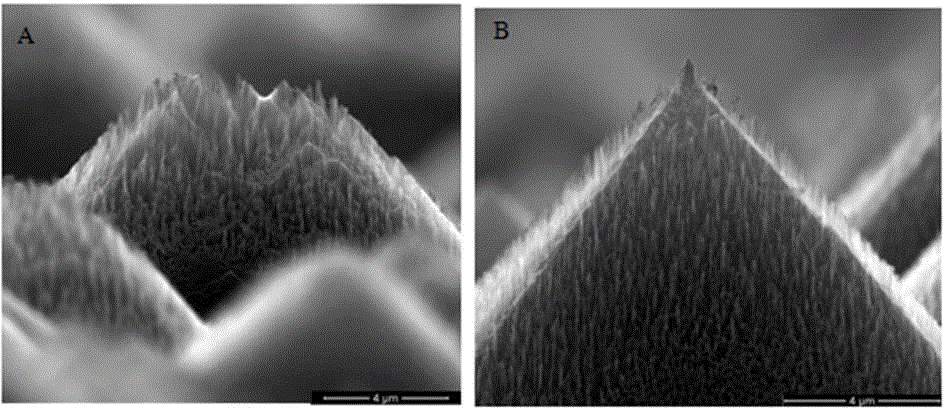

Preparation method of three-dimensional silicon nano structure for solar cell

ActiveCN103337560ALarge specific surface areaEnhance light trappingAfter-treatment detailsFinal product manufactureIonEtching

The invention discloses a preparation method of a three-dimensional silicon nano structure for a solar cell. The preparation method aims at obtaining a silicon wafer with a large specific surface area, so that a light trapping effect of the silicon wafer on sunlight is improved. The preparation method comprises the steps that after the silicon wafer is cleaned, a pyramid-shaped suede structure is formed on the surface of the silicon wafer by utilizing the surface anisotropy corrosion of aqueous alkali on monocrystalline silicon, and a silicon nanowire is further etched on the pyramid suede structure by utilizing a metal ion-assisted chemical etching method, so that the novel silicon nanowire-pyramid three-dimensional silicon nano structure is formed. According to the preparation method, the novel three-dimensional silicon nano structure can provide the silicon wafer with the larger specific surface area, so that the light trapping effect of the surface of the silicon wafer on the sunlight is improved; the reflectivity of a short-wave band is less than 5%; the preparation method is low in cost, mild in condition and shorter in time; a technological process is controllable; and industrial operation is facilitated.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

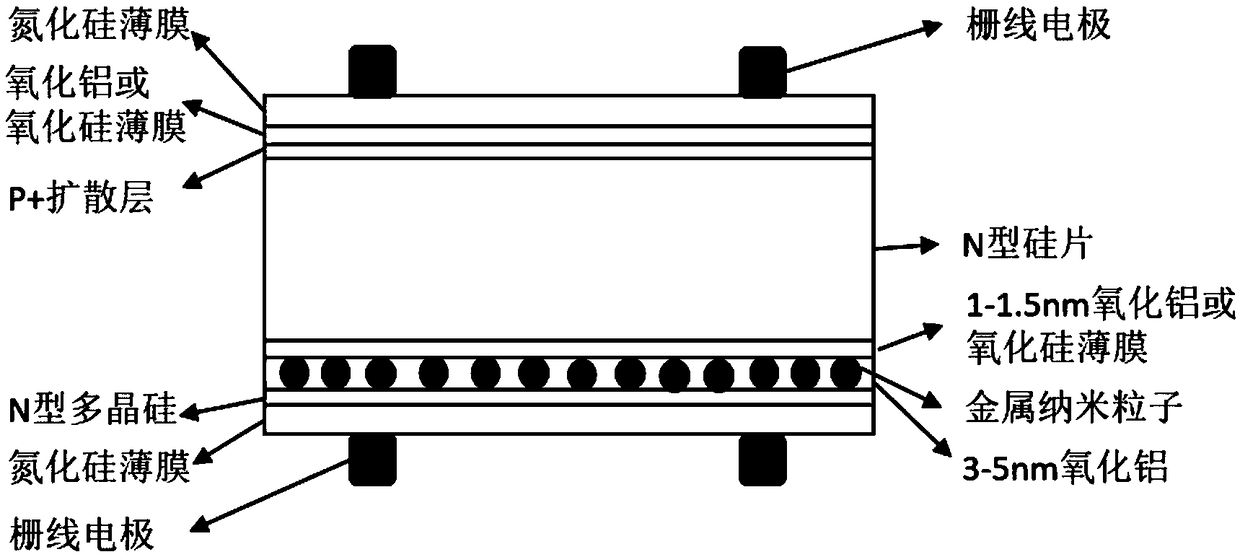

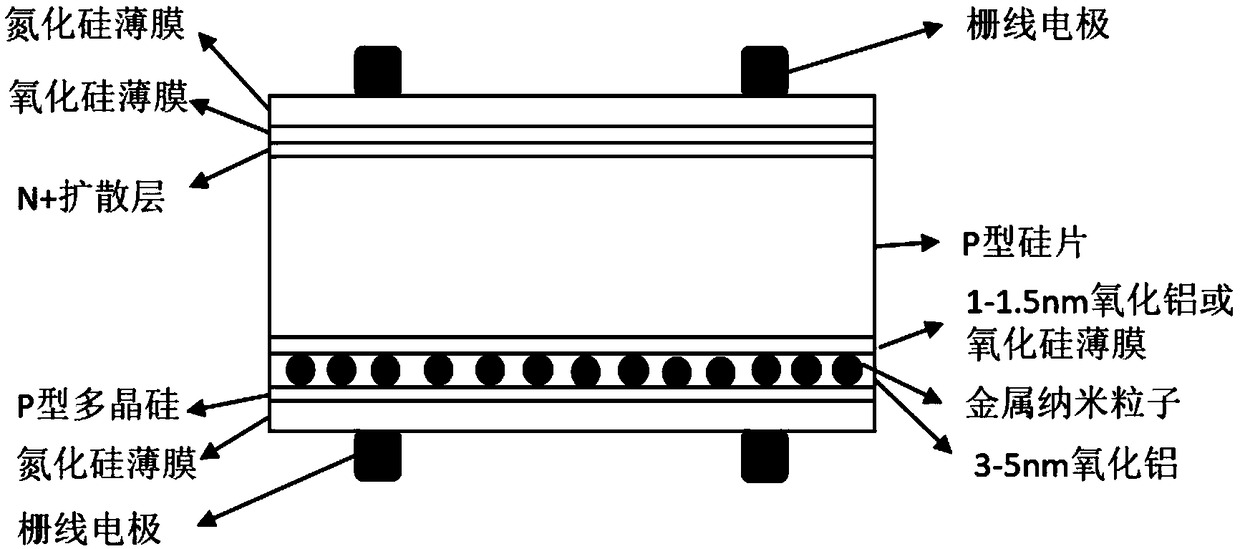

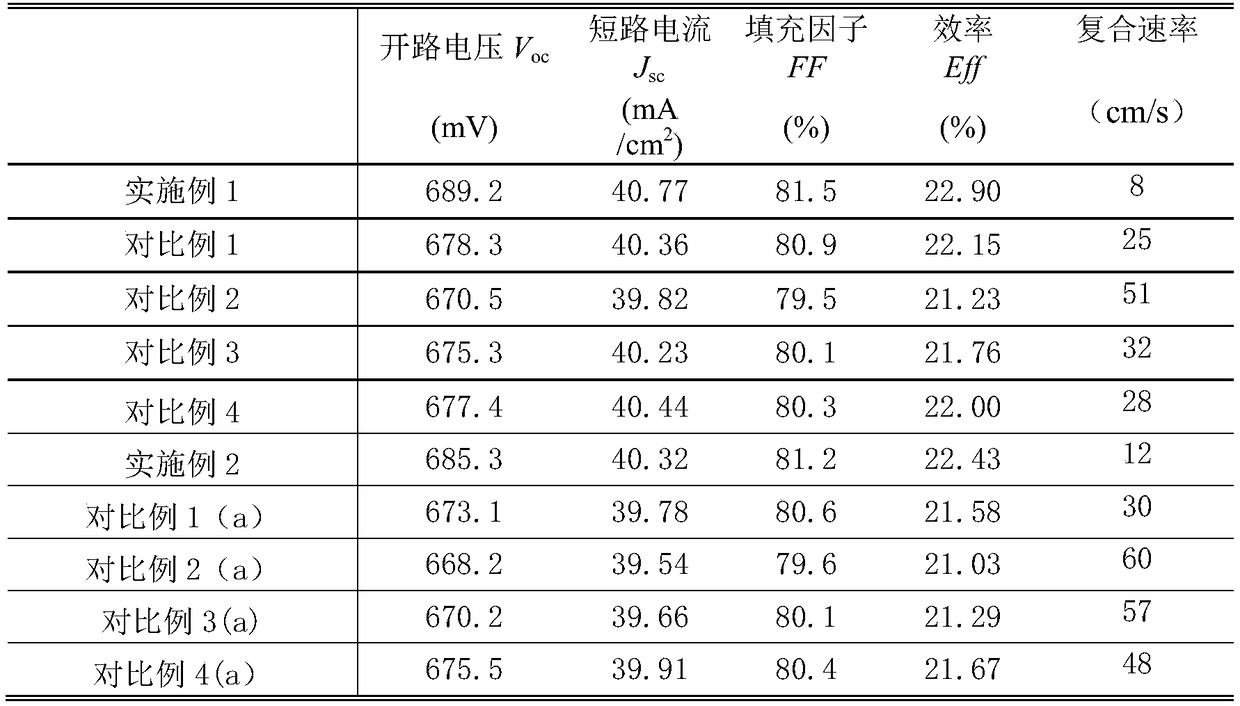

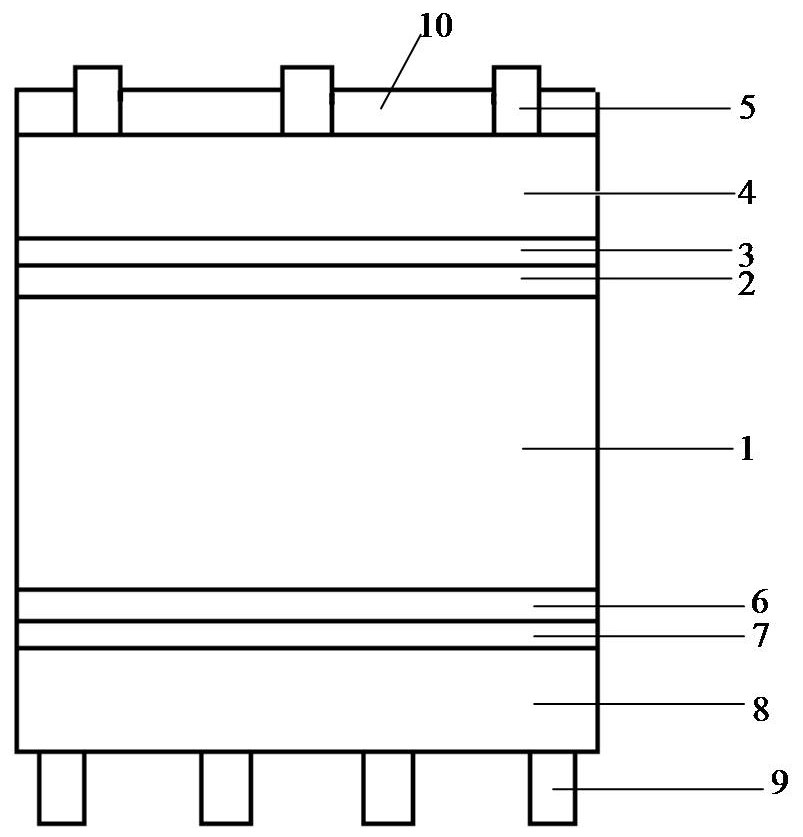

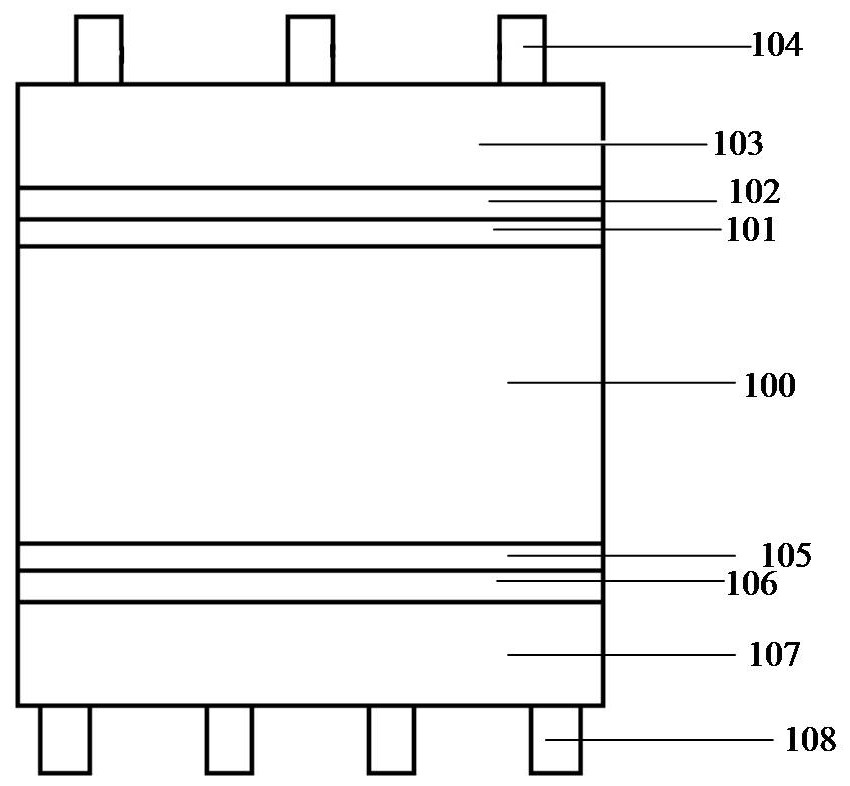

Contact-passivation crystalline silicon solar cell structure and preparation method

ActiveCN109346536AEvenly distributedImprove passivation effectFinal product manufacturePhotovoltaic energy generationElectrical batterySilicon solar cell

The invention discloses a contact-passivation crystalline silicon solar cell structure and a preparation method thereof and belongs to the technical field of a solar cell. An N-type silicon wafer or aP-type silicon wafer is used as a substrate of the solar cell; a structure of an illuminated surface of the N-type silicon wafer substrate sequentially includes a P+ diffusion layer, a silicon oxideor aluminum oxide, silicon nitride film and a grid line electrode from bottom to top; a structure of a back surface of the N-type silicon wafer substrate sequentially includes silicon oxide or aluminum oxide, an metal nanoparticle coated aluminum oxide film, an N-type polycrystalline silicon, the silicon nitride film and the grid line electrode from top to bottom; a structure of an illuminated surface of the P-type silicon wafer substrate sequentially includes an N+ diffusion layer, the silicon oxide film, the silicon nitride film and the grid line electrode from bottom to top; a structure ofa back surface of the P-type silicon wafer substrate sequentially includes silicon oxide or aluminum oxide, the metal nanoparticle coated aluminum oxide film, a P-type polycrystalline silicon, the silicon nitride film and the grid line electrode from top to bottom; the mutual synergistic effect exists between stacked layers; and the obtained solar cell is capable of remarkably improving the cellefficiency.

Owner:CHANGZHOU UNIV +1

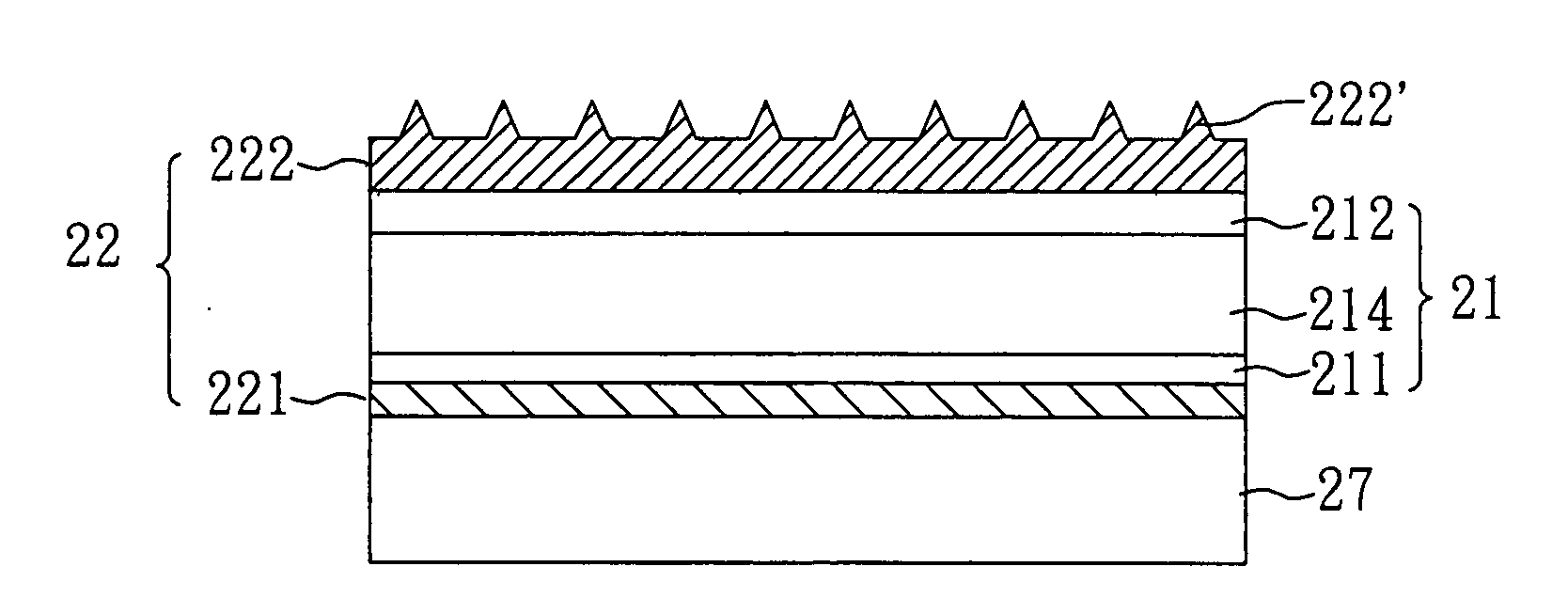

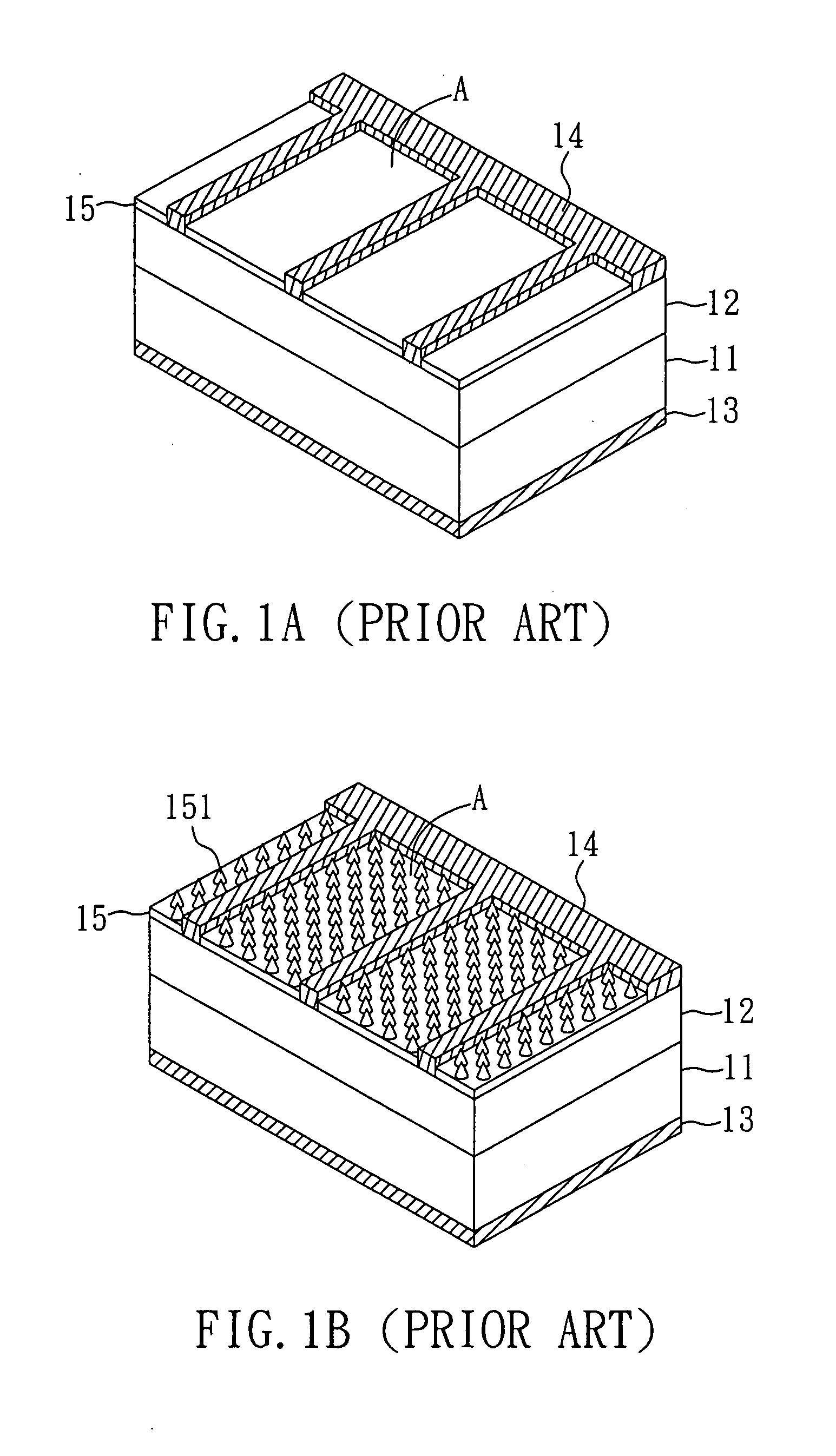

Sub-wavelength structure layer, method for fabricating the same and photoelectric conversion device applying the same

InactiveUS20110146779A1Simple and low cost technologyGood effectSolid-state devicesSemiconductor/solid-state device manufacturingPhotoelectric conversionWavelength

The present invention relates to a method for fabricating a sub-wavelength structure layer, including: forming a metal film on a passivation layer, an n-GaN layer or a transparent conductive oxide layer; performing thermal treatment to form self assembled metal nano particles; using the metal nano particles as a mask to remove a partial area of the passivation layer, the n-GaN layer or the transparent conductive oxide layer to form a sub-wavelength structure of which the cross-sectional area increases along the thickness direction of the passivation layer, the n-GaN layer or the transparent conductive oxide layer; and removing the metal nano particles. In addition, the present invention further provides the obtained sub-wavelength structure layer and a photoelectric conversion device using the same.

Owner:NAT CHIAO TUNG UNIV

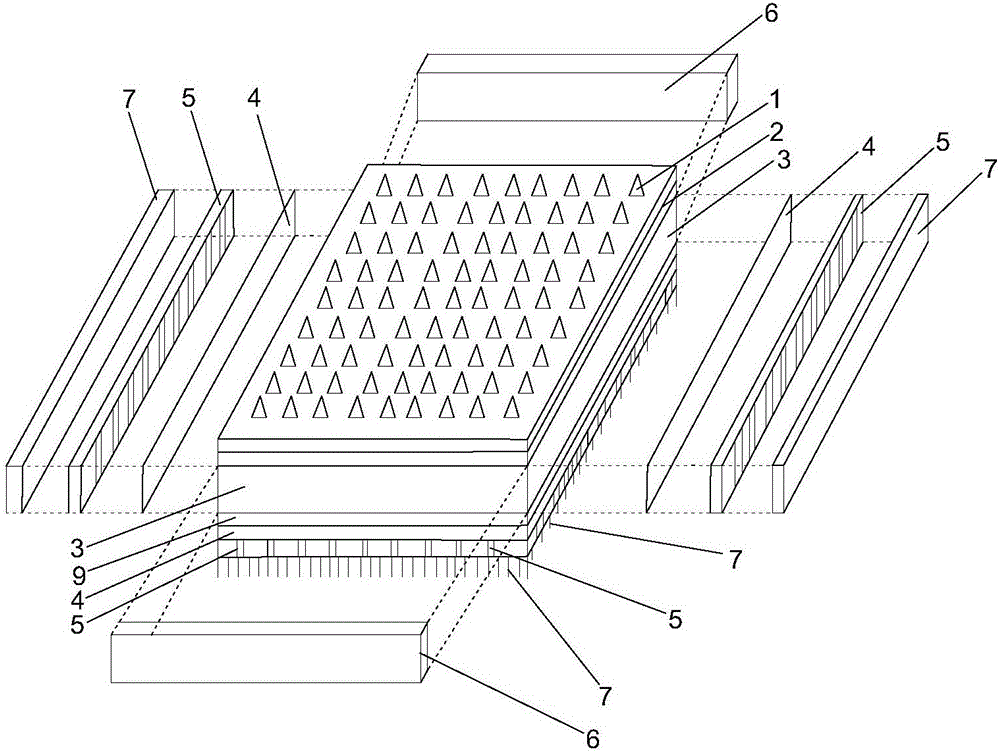

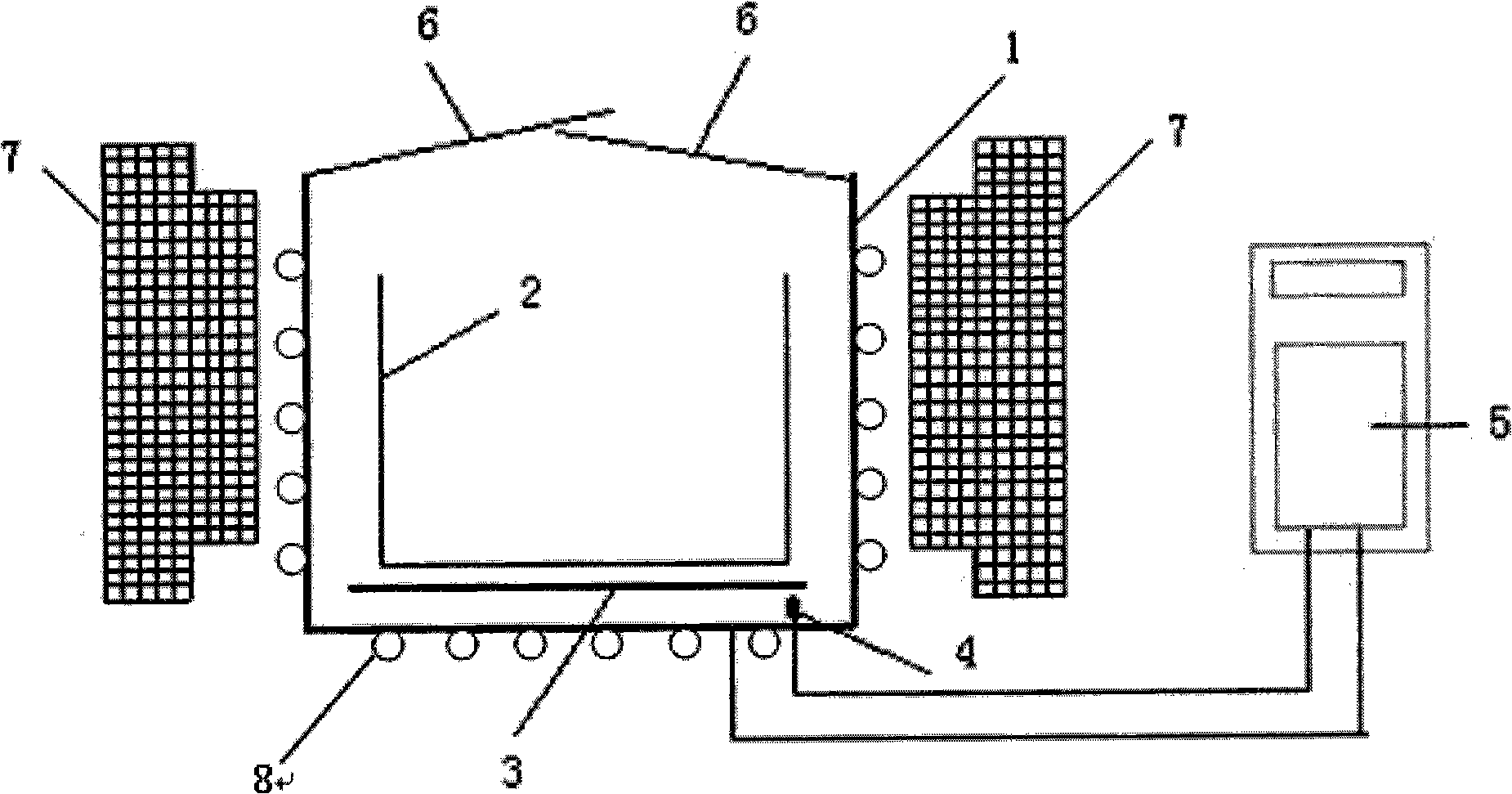

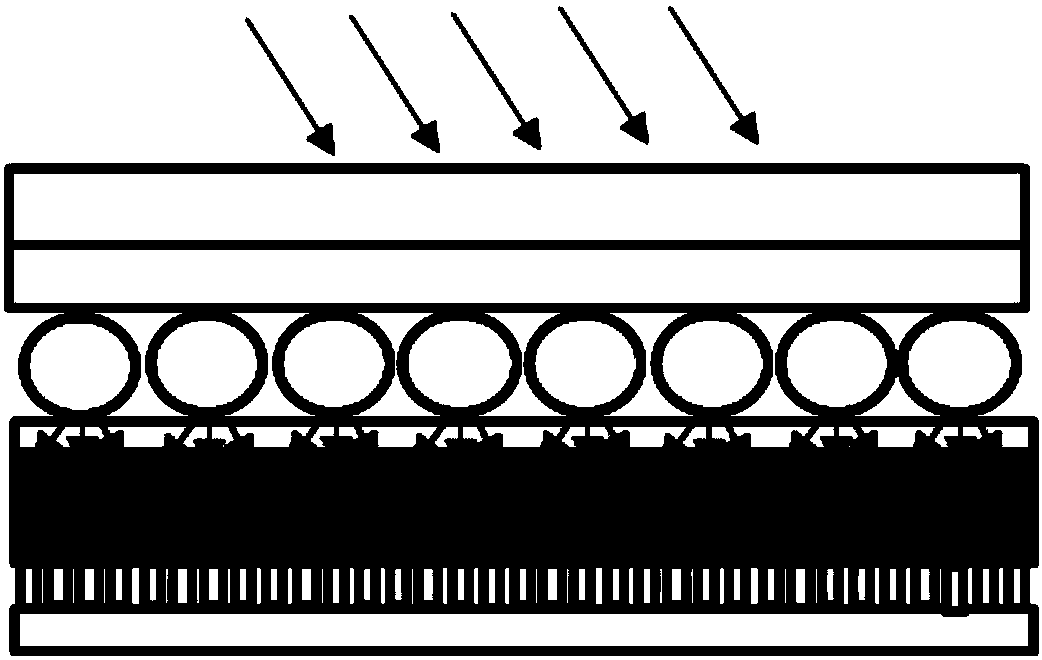

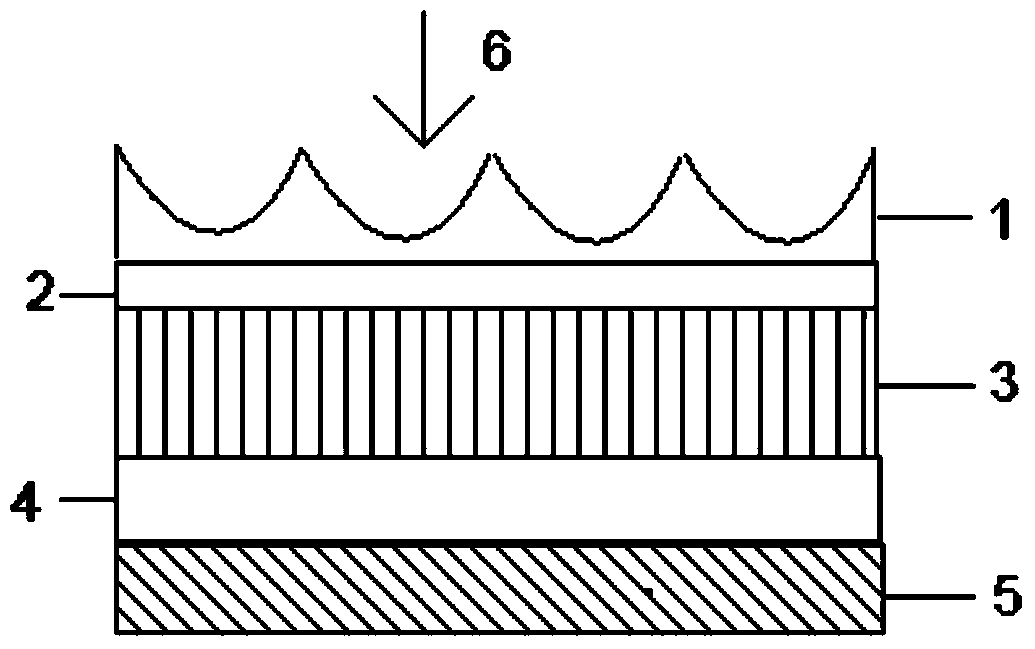

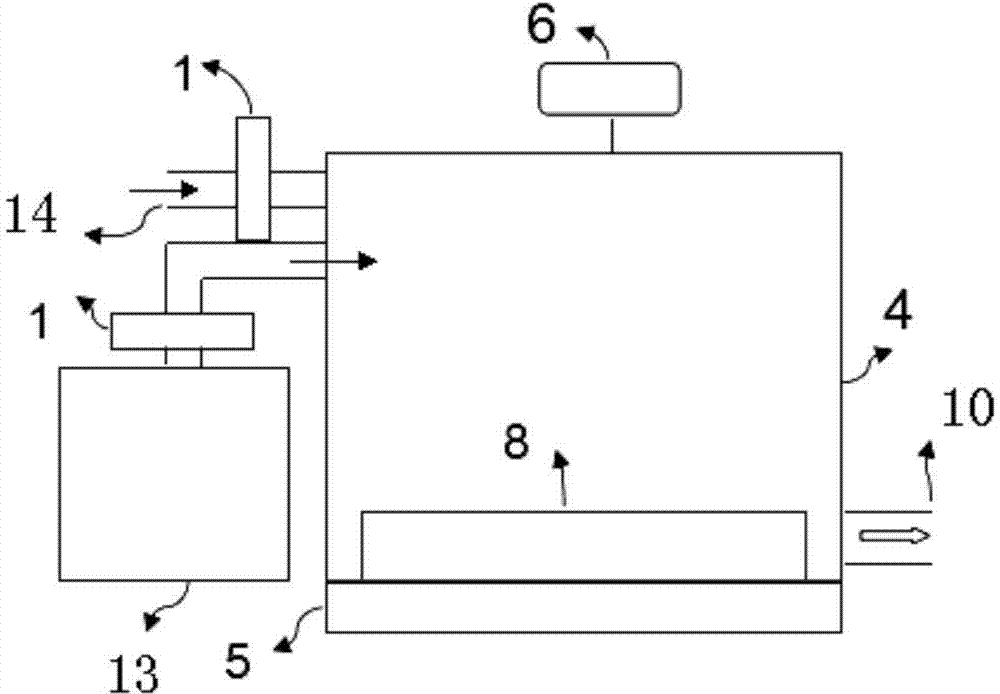

Fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation device

InactiveCN106788213ALower working temperatureImprove photoelectric conversion efficiencyPV power plantsGenerators/motorsMicro nanoWaveguide

The invention relates to a fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation device. The device comprises a laser type fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation device and a solar-energy type fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation device; both the two types of the fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation devices comprise micro-nano light trap layers, light transmitting heat conduction layers and fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation layers; each fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation layer comprises a fluorescent waveguide light-harvesting device, a heat conduction layer, a thermoelectric temperature difference power generation device, a photovoltaic power generation device and a radiator; the two types of the devices are capable of producing a photovoltaic power generation effect and a photothermal power generation effect respectively under irradiation of laser, or sunlight, or solar concentrating light, and are capable of outputting externally electricity generated through photovoltaic-photothermal combined power generation. The fluorescent waveguide light-harvesting type photovoltaic-photothermal combined power generation device is capable of being widely applied in the fields of aerospace vehicles, unmanned aerial vehicles, unmanned ships and warships, unmanned vehicles, robots, engineering equipment and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing silicon solar battery pile face in magnetic field

InactiveCN101409313AControl the direction of motionUniform movementFinal product manufactureSemiconductor/solid-state device manufacturingPhosphoric acidSilicon solar cell

The invention discloses a method for preparing a texture of a silicon solar cell under a magnetic field. The method comprises the following technological steps: firstly, a polysilicon wafer is put into a texture preparation reactor with prepared acid reaction solution for reaction, and the texture preparation reactor is put in the magnetic field, wherein, the reaction solution is made from 0.05%-15% of nitric acid or chromic acid by mass, 1%-30% of hydrofluoric acid by mass and 1%-30% of phosphoric acid or acetic acid by mass; the temperature of the reaction solution is kept at 0-30 DEG C, and the polysilicon wafer is washed in 0.5%-3% sodium hydroxide solution for 1-5 minutes after reaction in the acid solution; secondly, the magnetic field is applied in the whole course of preparing the texture of the silicon solar cell, the magnetic field strength is kept at 0-10T, and the texture preparation time is 1-45 minutes. A compact and even texture can be grown on the surface of the polysilicon wafer by the method, thus realizing the high-efficiency and even production of the silicon solar cell texture by acid oxidants under the magnetic field.

Owner:张根发

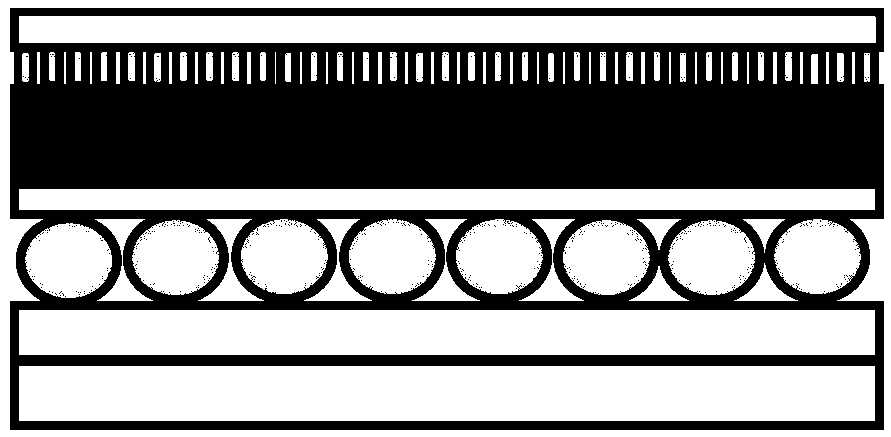

Perovskite solar cell with mixed light trapping structure and preparation method thereof

InactiveCN107591483AIncrease the optical pathPromote absorptionSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoGrating

The invention relates to a perovskite solar cell with a mixed light trapping structure and a preparation method thereof, and belongs to the technical field of perovskite solar cells. The perovskite solar cell comprises a substrate, a conductive electrode, a micro-nano particle light trapping layer, an electron transport layer, a perovskite light absorbing layer, a hole transport layer, a nano Ag optical grating and a metal electrode, wherein the conductive electrode, the micro-nano particle light trapping layer, the electron transport layer, the perovskite light absorbing layer, the hole transport layer, the nano Ag optical grating and the metal electrode are sequentially formed on the substrate, and the micro-nano particle light trapping layer is TiO2 micro-nano particles. The micro-nanostructure is introduced into the perovskite solar cell with the mixed light trapping structure, so that the light trapping capacity of the solar cell can be significantly improved, and the light absorption of the solar cell is enhanced through increasing scattering of the incident light and prolonging the light path of the incident light in the solar cell, so that the light current of the cell isincreased, and the conversion efficiency of the solar cell is effectively improved. Meanwhile, the nano Ag optical grating is introduced to a back electrode of the solar cell, so that a back reflection effect for the transmission light can be effectively increased by combining back reflection of a silver electrode, and thus the absorption of the cell for the incident light is further enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

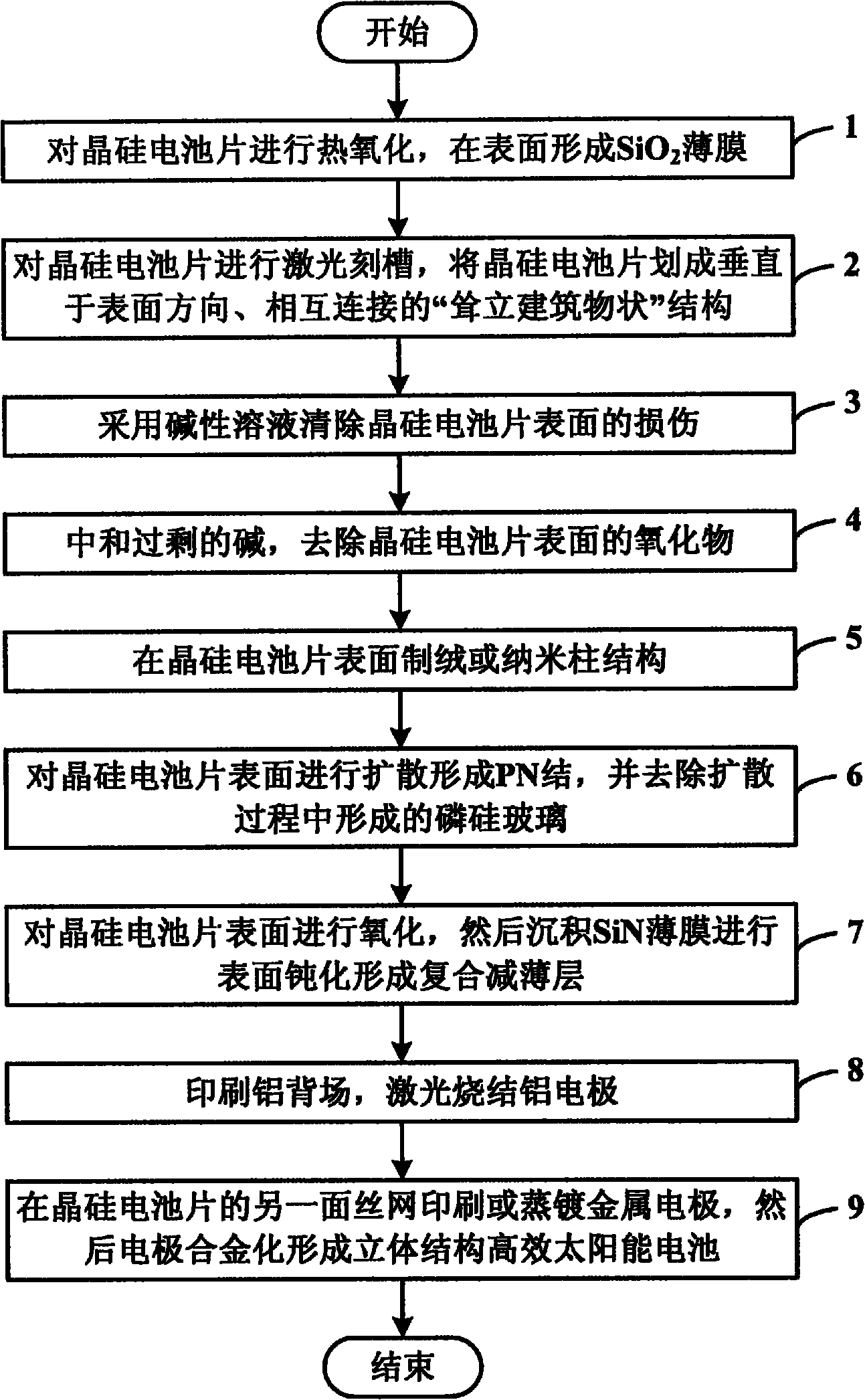

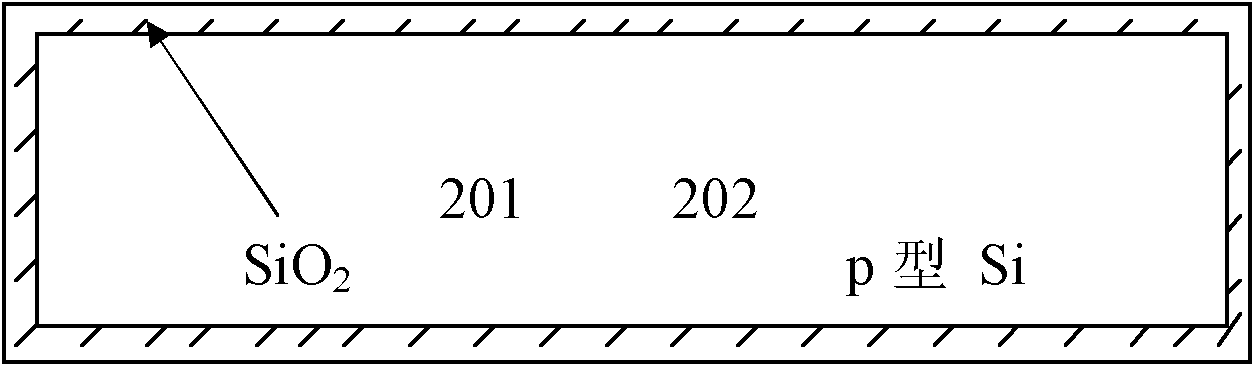

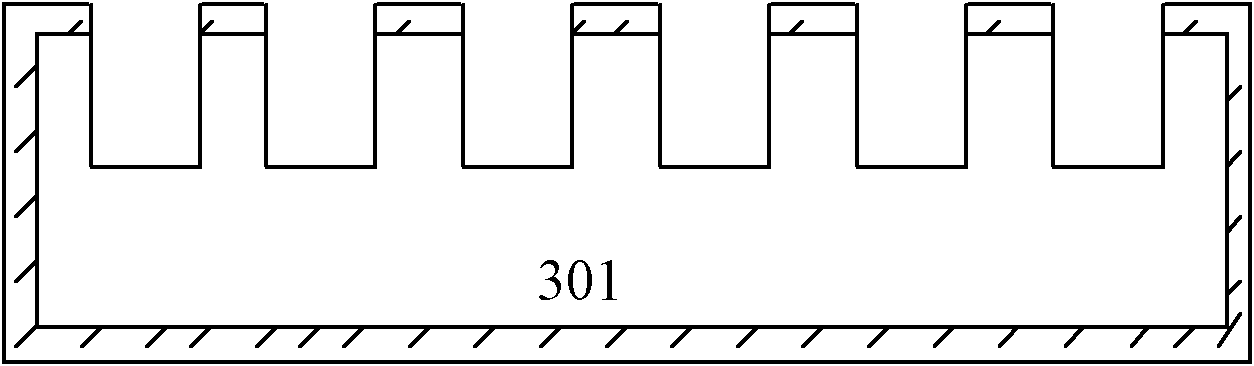

Method for preparing high efficiency solar cell with stereostructure

InactiveCN102487105AImprove light trappingIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationCrystalline siliconPhosphosilicate glass

The invention discloses a method for preparing a high efficiency solar cell with a stereostructure. The method comprises the followings steps that: thermal oxidation is carried out on a crystalline silicon cell so as to form a SiO2 film; laser grooving is carried out on the crystalline silicon cell and thus the crystalline silicon cell is etched into a structure with a ''towering building shape'', wherein the structure is formed in a direction vertical to the surface and the towering buildings are mutually connected; an alkaline solution is employed to remove damages on the surface of the crystalline silicon cell; an acid solution is employed to neutralize surplus alkali so as to remove oxide on the surface of the crystalline silicon cell; texturing is carried out on the surface of the crystalline silicon cell to form a nanopillar structure; diffusion is carried out on the surface of the crystalline silicon cell to form a PN node as well as phosphosilicate glass that is formed during the diffusion process is removed; oxidation is carried out on the surface of the crystalline silicon cell and then a SiN film is deposed and surface passivation is carried out to form a composite attenuated layer; an aluminium back field is printed and laser sintering is carried out on an aluminium electrode; and screen printing or evaporation is carried out on a metal electrode at the other surface of the crystalline silicon cell and then electrode alloying is carried out to form a high efficiency solar cell with a stereostructure. According to the invention, conversion efficiency of a solar cell is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

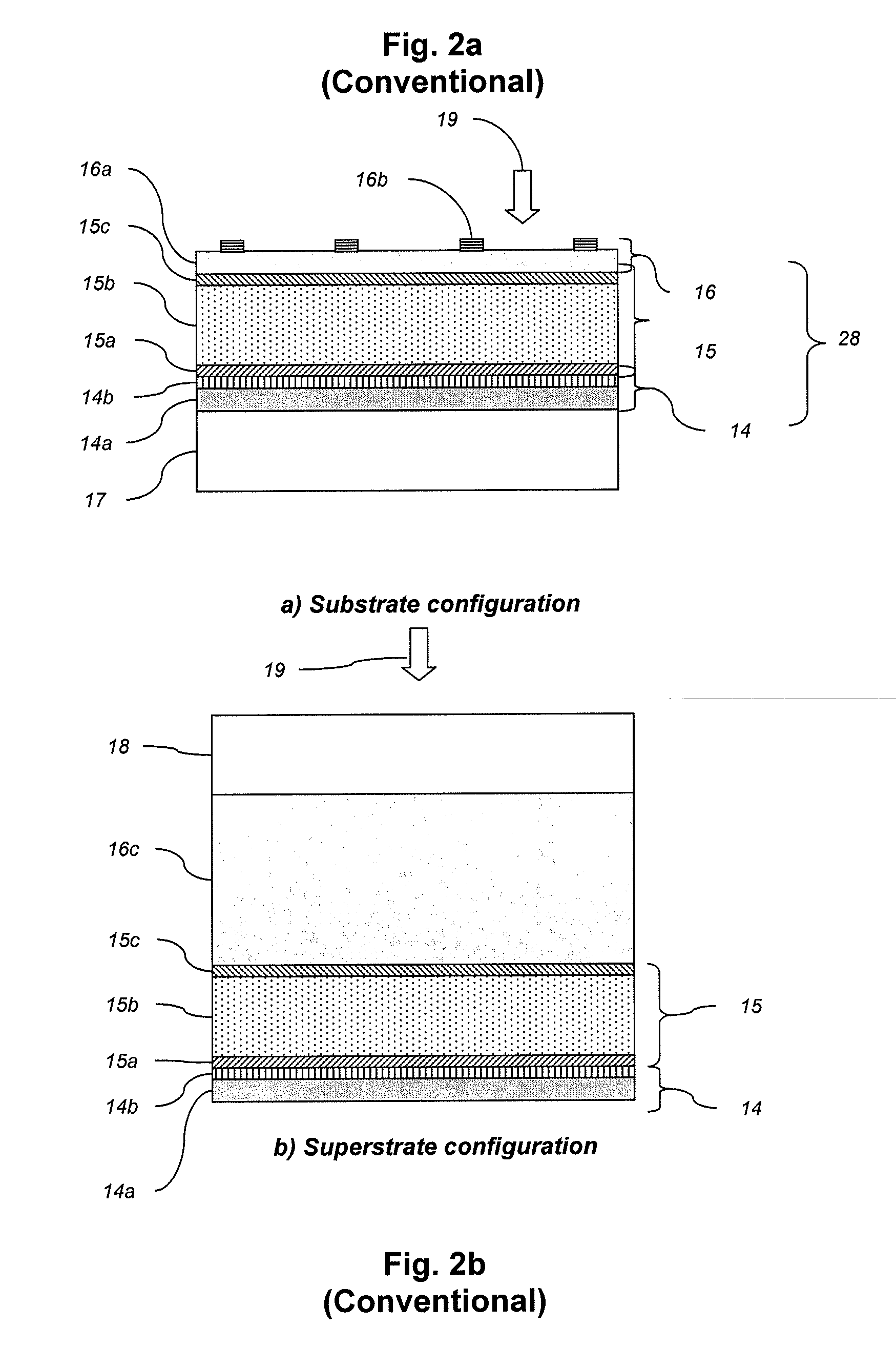

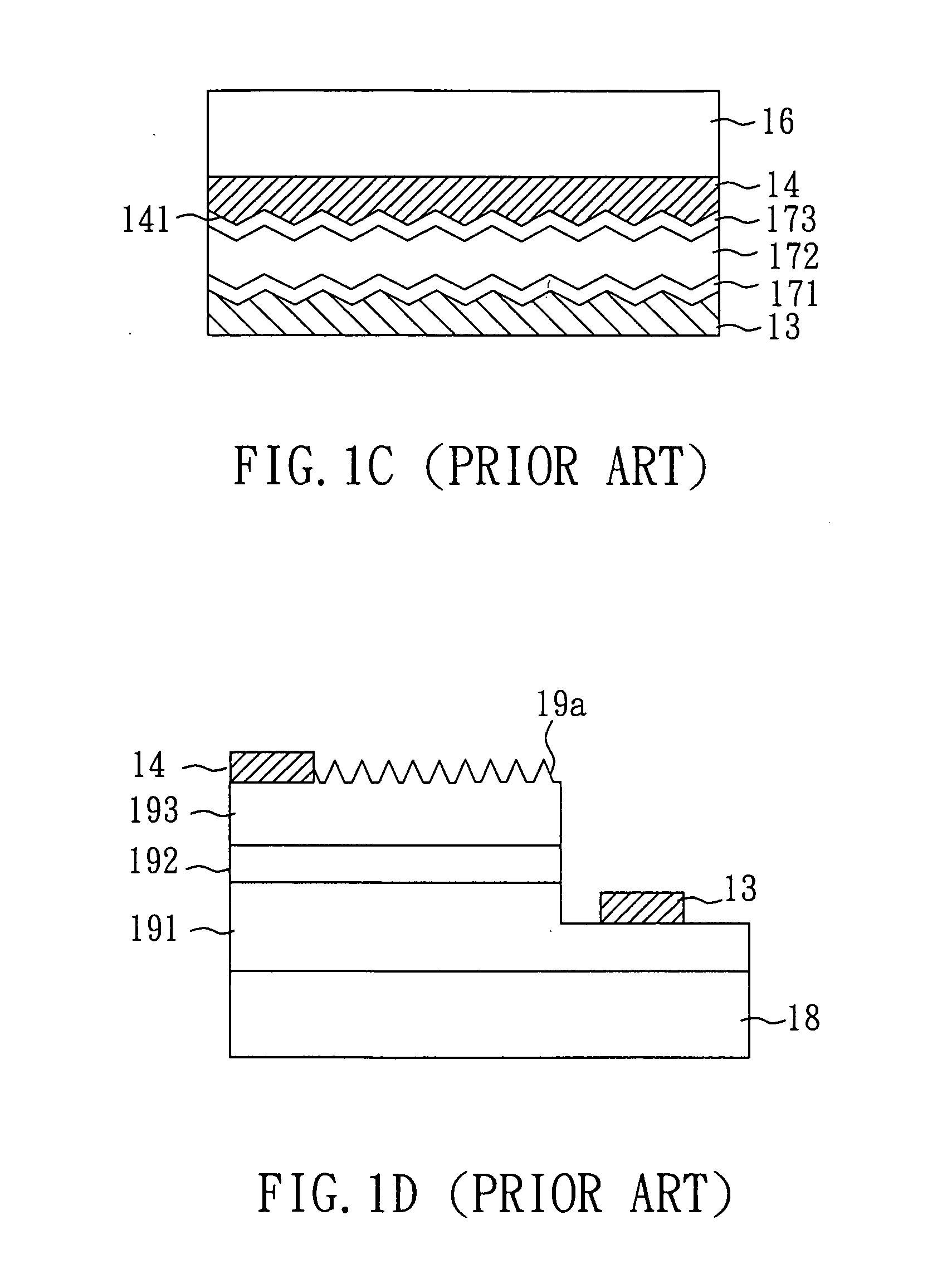

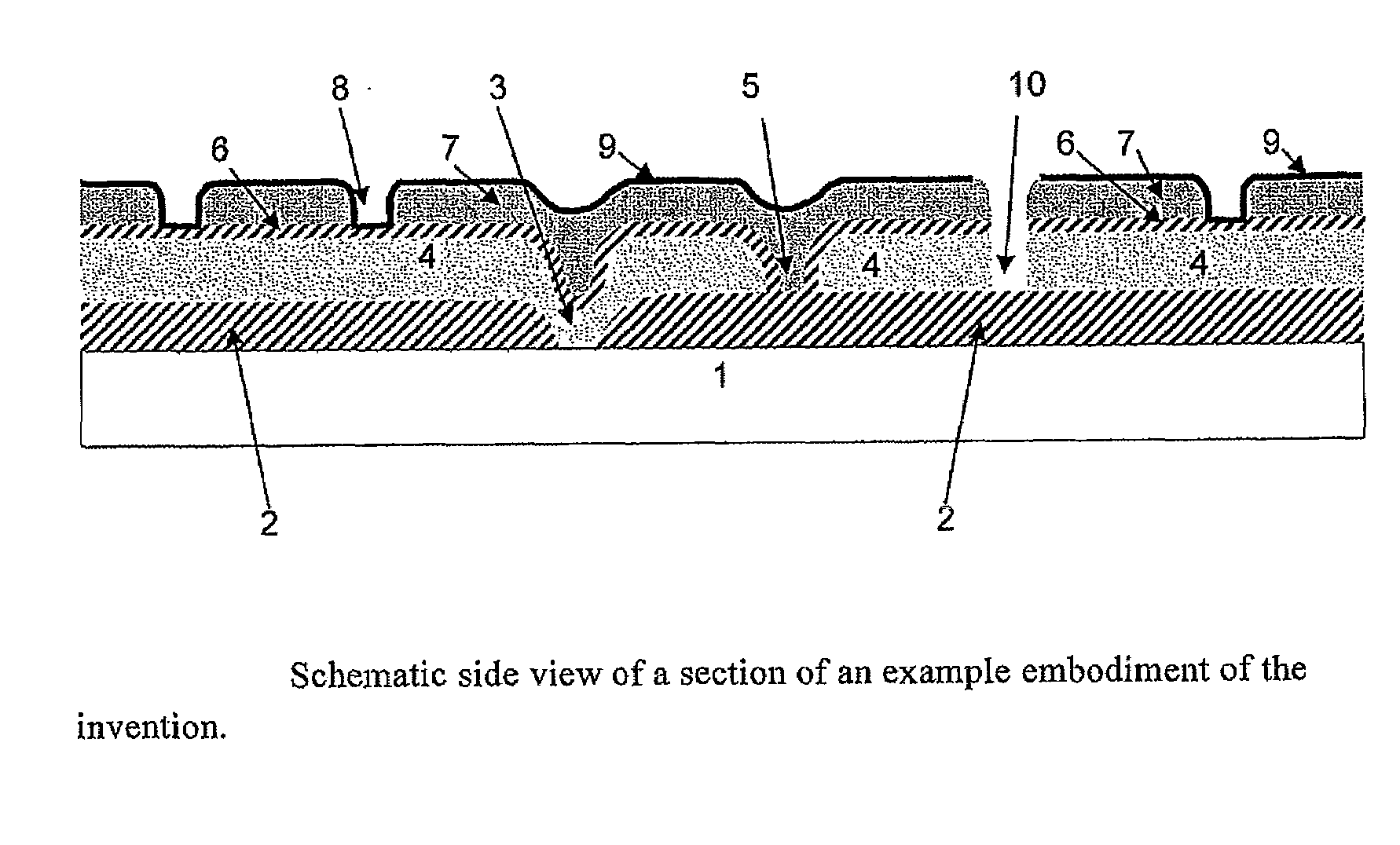

Coating for thin-film solar cells

InactiveUS20090314338A1Improve efficiencyImprove light trappingFinal product manufactureSemiconductor/solid-state device manufacturingPlanar substrateAlloy

This invention relates to a method for producing thin film solar cells with a back-side reflective layer, wherein the solar module is a silicon thin film device placed in-between a back side planar substrate and a front side planar glass superstrate placed in parallel and a distance from the back side planar substrate, wherein the silicon thin film device comprises in successive order from the front side: a front side transparent conductive (TCO) layer, a multi junction thin-film solar conversion layer comprising amorphous and microcrystalline silicon or alloys thereof, a back side TCO-layer, a diffuse reflective layer with one or more local through-going apertures, and a metal layer covering the reflective layer and which is in contact with the back side TCO-layer through the one or more apertures in the reflective layer. The invention also relates to a method for forming the solar cell.

Owner:RENEWABLE ENERGY CORP LTD

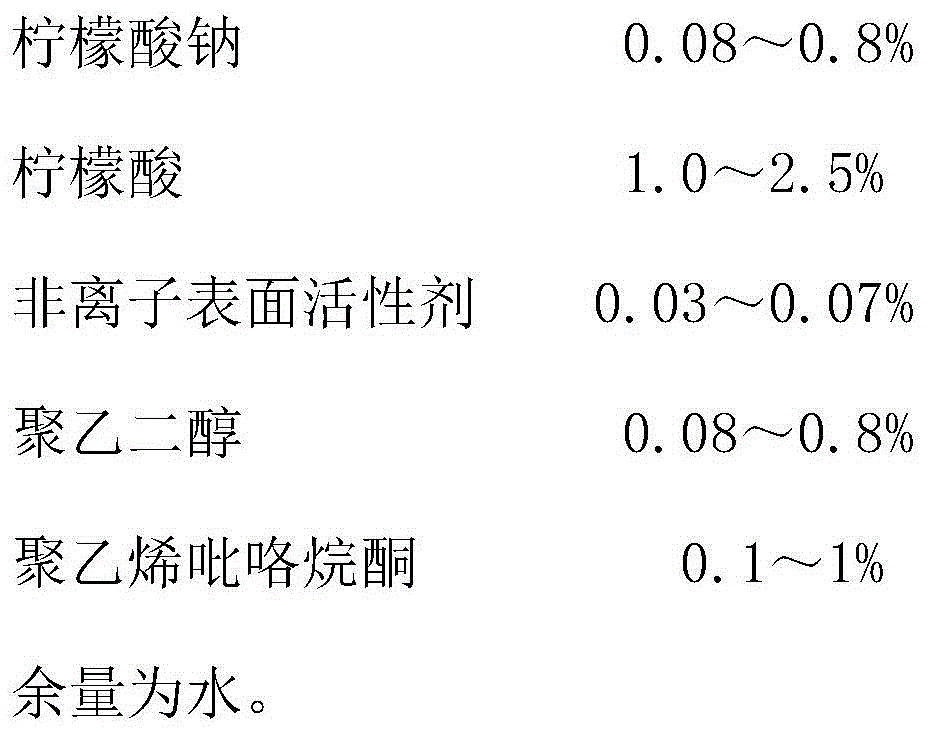

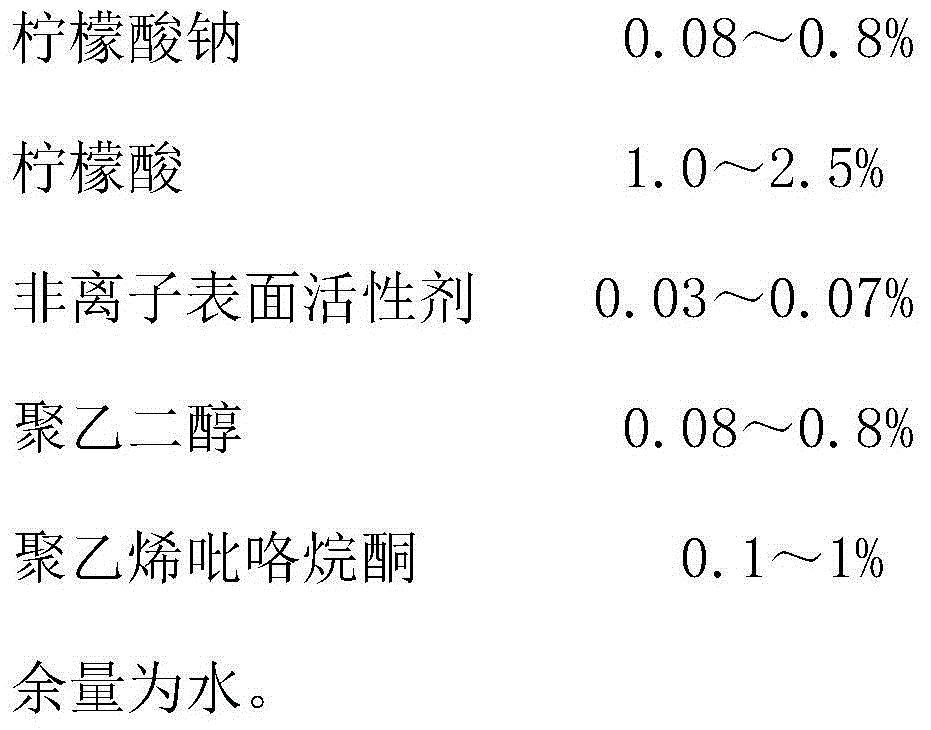

Multi-crystalline silicon wafer texturization additive

ActiveCN104651949AImprove wettabilityImprove the environment of acid textureAfter-treatment detailsFinal product manufacturePolyethylene glycolOptoelectronics

The invention discloses a multi-crystalline silicon wafer texturization additive, which comprises the following components in percentage by mass: 0.08-0.8% of sodium citrate, 1.0-2.5% of citric acid, 0.03-0.07% of non-ionic surfactant, 0.08-0.8% of polyethylene glycol, 0.1-1% of polyvinylpyrrolidone and the balance of water. After being texturized through using the prepared multi-crystalline silicon wafer texturization additive, the multi-crystalline silicon wafer has an even surface, the reflective rate is reduced by 3-5%, and a battery conversion rate is promoted by 0.1-0.2%.

Owner:CHANGZHOU JUNHE TECH

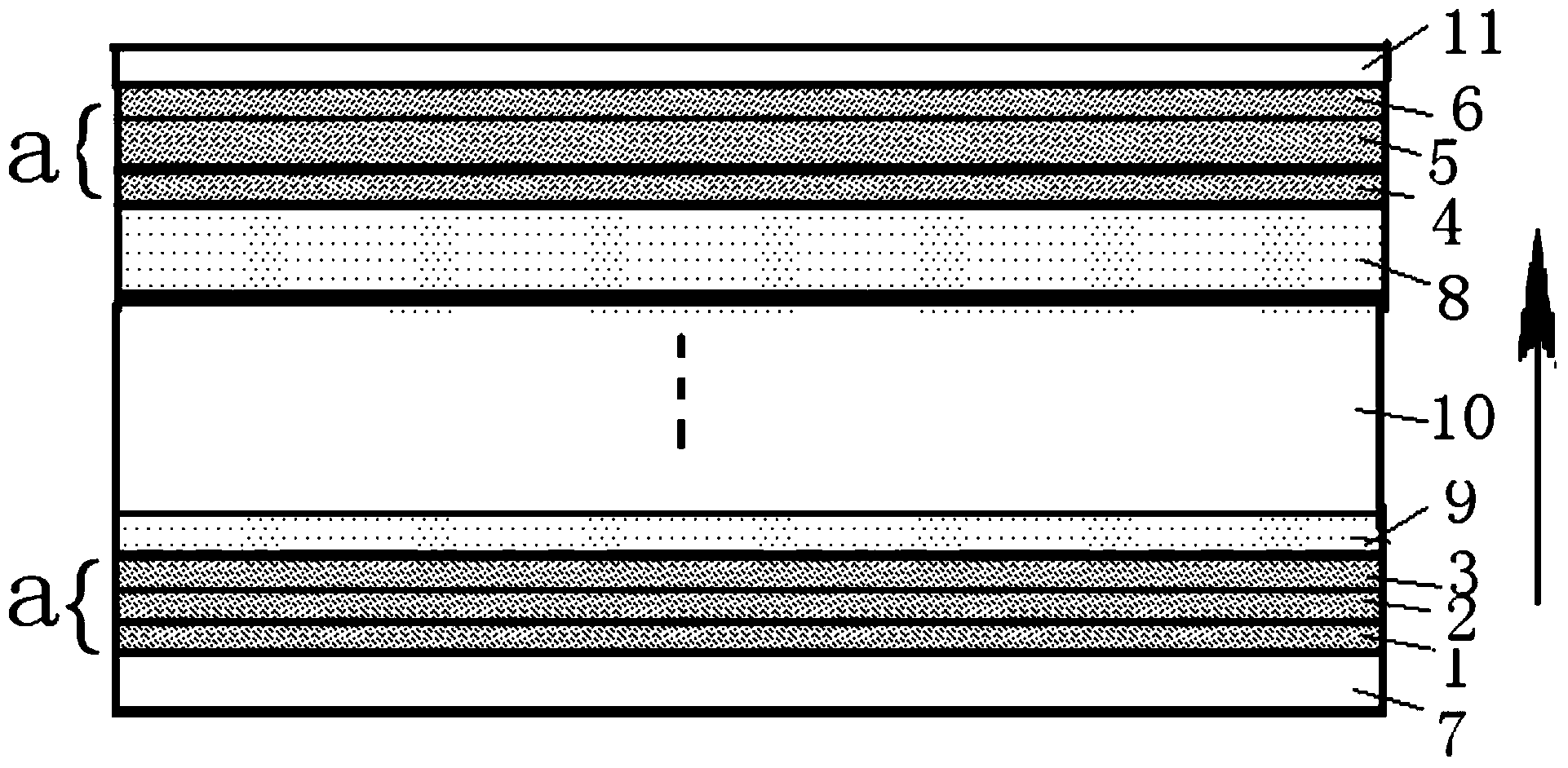

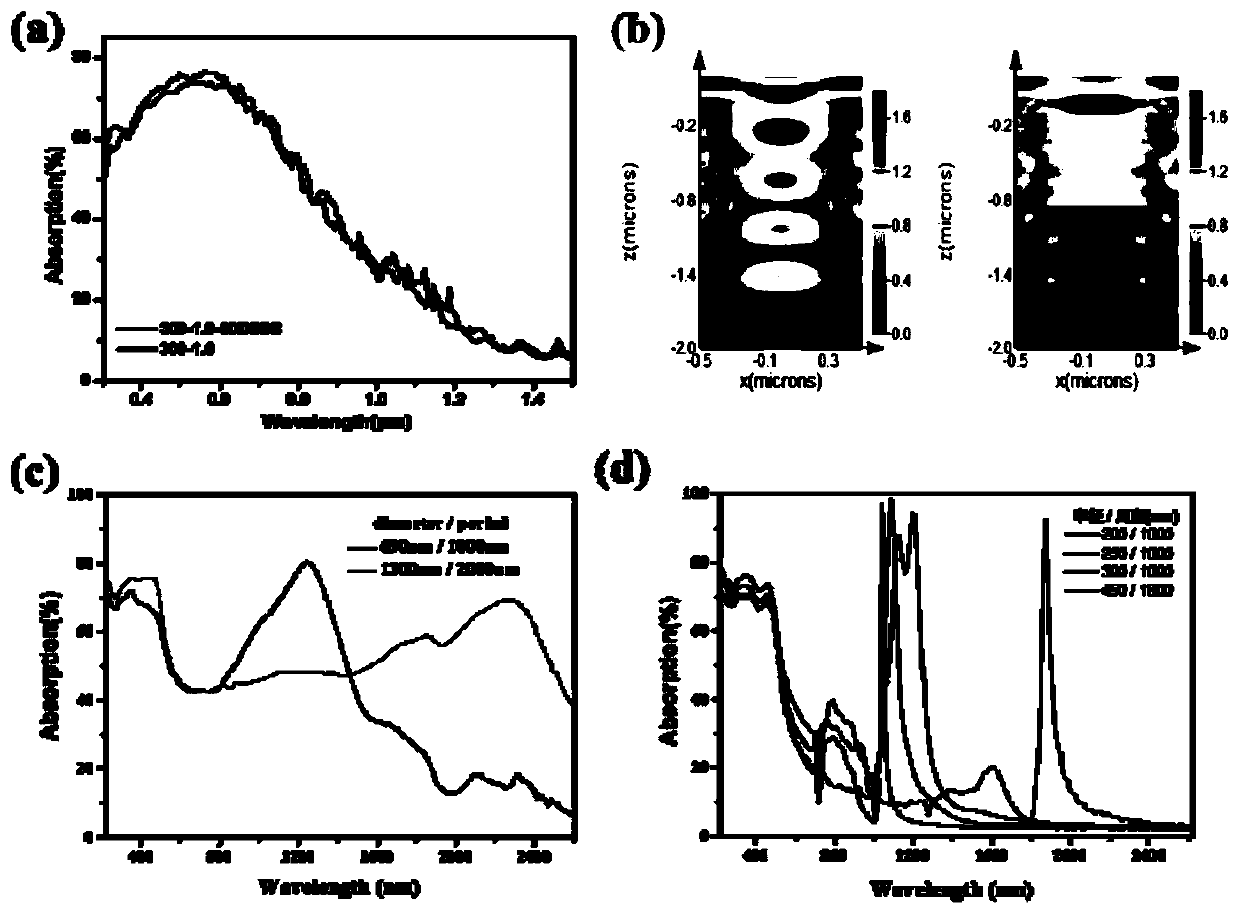

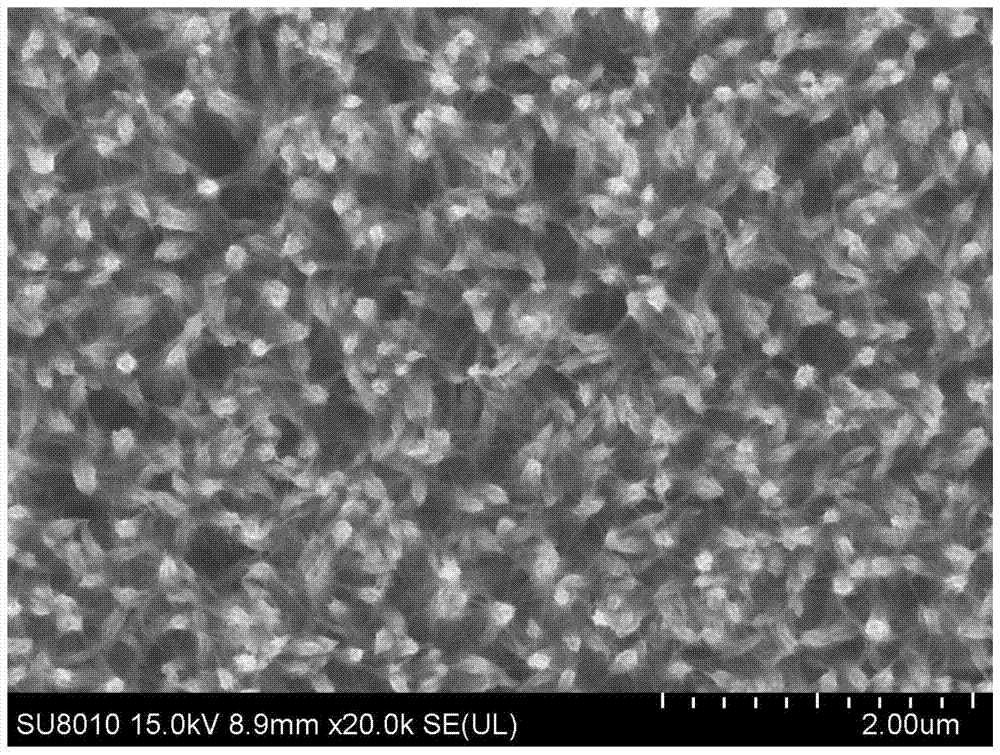

TCO thin film and preparation method thereof

ActiveCN103646972AChange surface topographyIncreased interface conductivityFinal product manufactureChemical vapor deposition coatingElectrical batteryMaterials science

The invention discloses a TCO (transparent conducting oxide) thin film and a preparation method thereof. The TCO thin film comprises three zinc oxide thin film layers containing dopants from top to bottom, wherein the atom ratios of dopants in the zinc oxide thin film layer are different in zinc oxide. In the preparation method, dopant gas flows are adjusted in the thin film growing process to form a multiple-layer structure and modulate a surface microstructure and the optical performance of the TCO thin film, wherein the middle and an interface of the multiple-layer structure are different in dosage concentration. The light trapping effect of the film and the optical transmittance of a near-infrared light region can be greatly improved while good electrical conductivity of the TCO film and the interface of the film are maintained, a haze average value of a 400-1100nm waveband is improved from 27.3% to 34.9 %, the transmittance of a 700-2000nm near-infrared waveband is improved from 76% to 77.7%, and the photoelectric conversion efficiency of batteries is improved.

Owner:湖南共创光伏科技有限公司

Method for preparing polysilicon solar battery suede in magnetic field

InactiveCN101369613AControl the direction of motionAccelerated disengagementFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidPotassium hydroxide

The invention discloses a preparation method of high efficient textures of a polycrystalline silicon solar cell in a magnetic field. The preparation method comprises the following processing steps: firstly, putting a polycrystalline silicon chip into a texture preparation reactor with prepared reaction liquids to react, placing the texture preparation reactor in the magnetic field, wherein, the mixture ratio of the reaction liquids is that: sodium hydroxide or potassium hydroxide is 0.05 to 15 weight percent, ethanol or isopropyl alcohol is 5 to 25 weight percent, and sodium silicate is 0.05 to 3 weight percent, the temperature of the reaction liquids is kept at 65 to 90 DEG C; secondarily, after the polycrystalline silicon chip finishes reacting in the alkali solution, washing for 5 to 10 minutes in the 0.5 to 5 percent of hydrofluoric acid solution at the normal temperature; finally, in the whole step of preparing the polycrystalline silicon solar cell texture in the magnetic field, the magnetic field strength is kept at 0 to 10T, and the texture preparation time is 10 to 45 minutes.

Owner:张根发

GaAs nano optical resonance structure photoelectric negative electrode electron source and preparation method thereof

ActiveCN108766857AImprove light absorptionShorten the transportation distancePhoto-emissive cathodesPhoto-emissive cathodes manufacturePhotocathodeScanning electron microscope

The invention discloses a GaAs nano optical resonance structure photoelectric negative electrode electron source, and belongs to the technical field of photoelectric negative electrodes; the structureof the photoelectric negative electrode electron source comprises a P-type semiconductor substrate, a nano optical resonance emission layer active region and a surface activation layer from bottom totop in sequence. An optical resonance effect is generated by virtue of the nano optical resonance structure and the incident light effect, and a light field and charges are limited in the active region, so that the absorption rate of the incident light is greatly improved, the photoelectron conveying distance is shortened, and the influence of harmful photoelectric emission caused by surface light reflection on the quality of the electron beams can be reduced, thereby effectively improving the quantum efficiency and the quality of the electron beams. The GaAs nano optical resonance structurephotoelectric negative electrode electron source can be prepared by adopting nano-imprinting etching, self-assembled nanosphere etching, electron beam photoetching, focusing ion beam etching and the like, the technology is mature and the stability is high; and therefore, the photoelectric negative electrode electron source can be applied to the fields of large-scale electron accelerators, low-light-level night vision, scanning electron microscope and the like.

Owner:EAST CHINA UNIV OF TECH

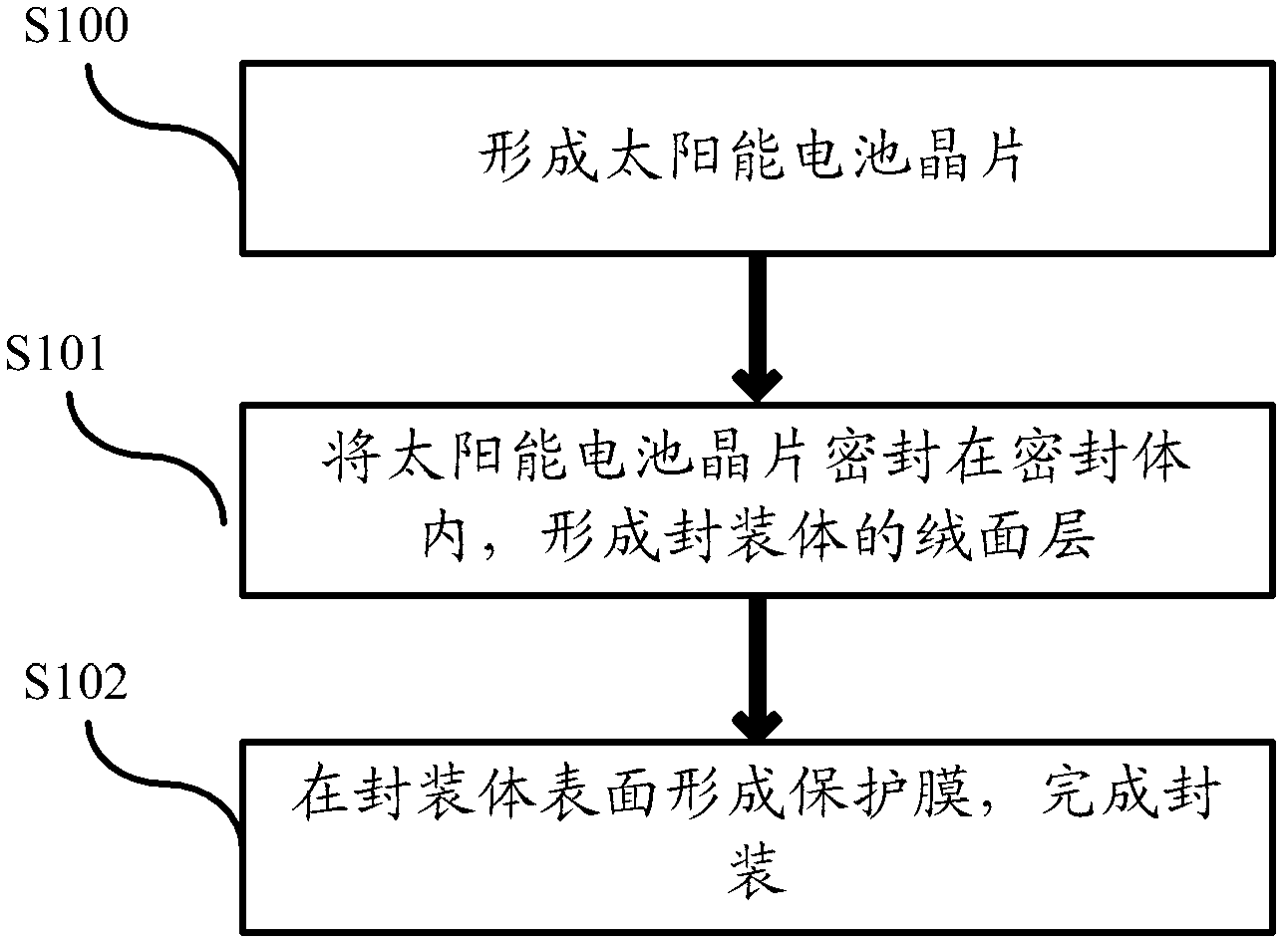

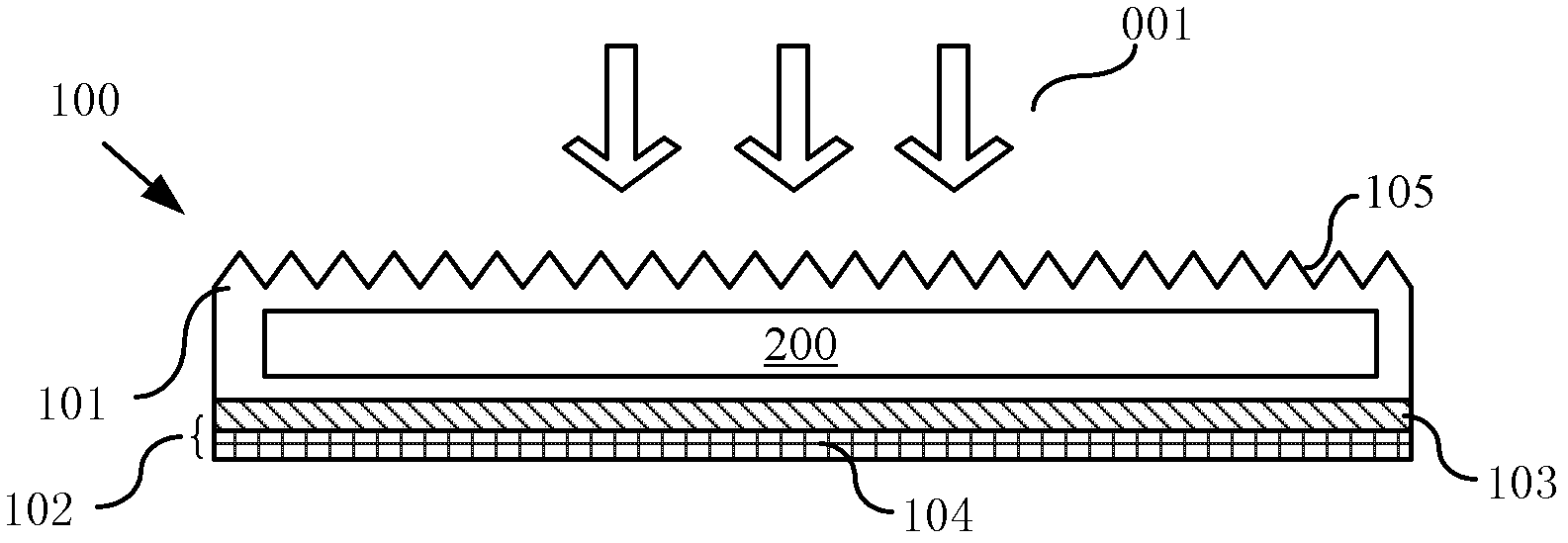

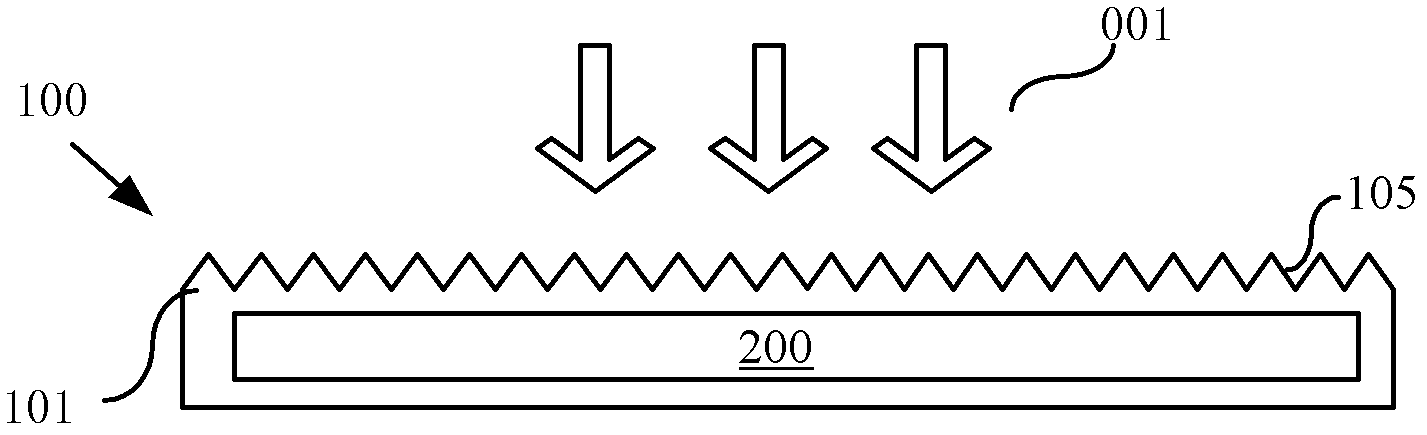

Packaged solar cell wafer and manufacturing method thereof

InactiveCN103107206AThe production process is simpleImproved anti-reflection and light trappingFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

The invention provides a packaged solar cell wafer which comprises a packaging body and the solar cell wafer sealed in the packaging body, and the solar cell wafer is provided with a light inlet face and a shady face. The packaged solar cell wafer is characterized in that the packaging body comprises a packaging inner layer and a packaging outer layer, the packaging inner layer is made from transparent material, and a suede layer is arranged on the surface of the packaging inner layer. Due to the fact that the suede layer is arranged on the surface of the packaging inner layer, the flame light effect of the solar cell wafer can be improved, and therefore the efficiency of a solar cell is improved. Correspondingly, the invention further provides a method for packaging the solar cell wafer. The surface of the packaging body is imprinted through the utilization of a suede mould, or the surface of the packaging body is etched so as to form the suede layer of the packaging body. The manufacturing technology is simple, and meanwhile the antireflection effect and the flame light effect are improved, and the conversion efficiency of the solar cell is enhanced.

Owner:SUNOVEL SUZHOU TECH

Double-sided crystalline silicon solar battery sheet

PendingCN109300998AImprove conversion efficiencyIncrease short circuit currentPhotovoltaic energy generationSemiconductor devicesSilver electrodeEngineering

The invention discloses a double-sided crystalline silicon solar battery sheet. The double-sided crystalline silicon solar battery sheet comprises a silicon substrate, a back passivation film and a back surface electrode; the back passivation film is stacked on the back surface of the silicon substrate; and the back passivation film is a blue film of which the thickness ranges from 60 and 90 nm; the back surface electrode includes a back silver electrode contacting the silicon substrate, a back aluminum main gate formed on the back passivation film, and a plurality of back aluminum auxiliary gates, wherein the back aluminum auxiliary gates intersect with the back aluminum main gate, and the back silver electrode is nested in the back aluminum main gate; and therefore, the short-circuit current and conversion efficiency of the back surface of the battery sheet can be improved.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

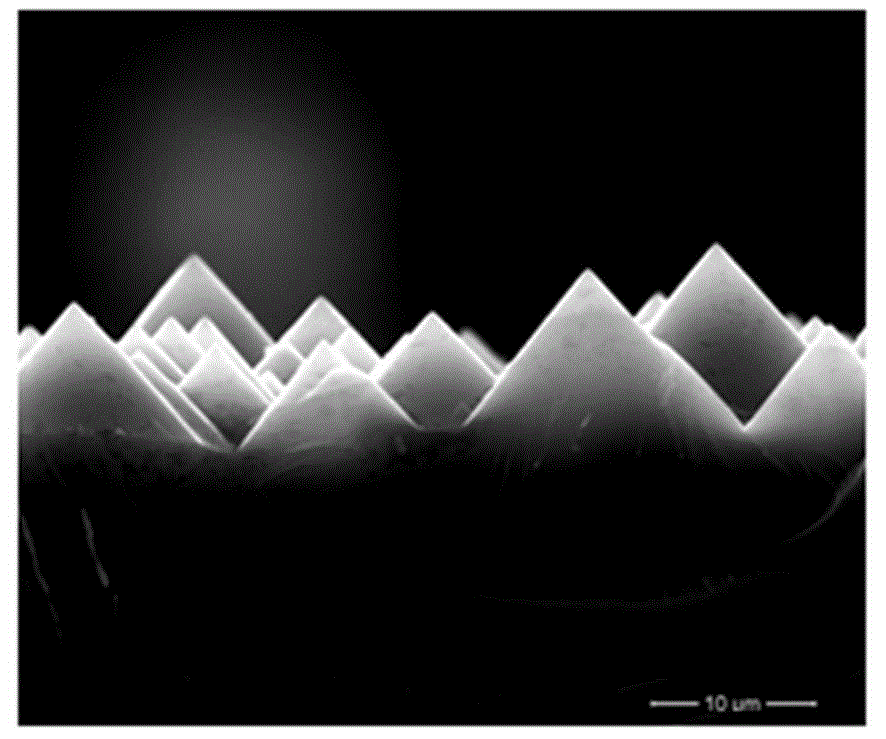

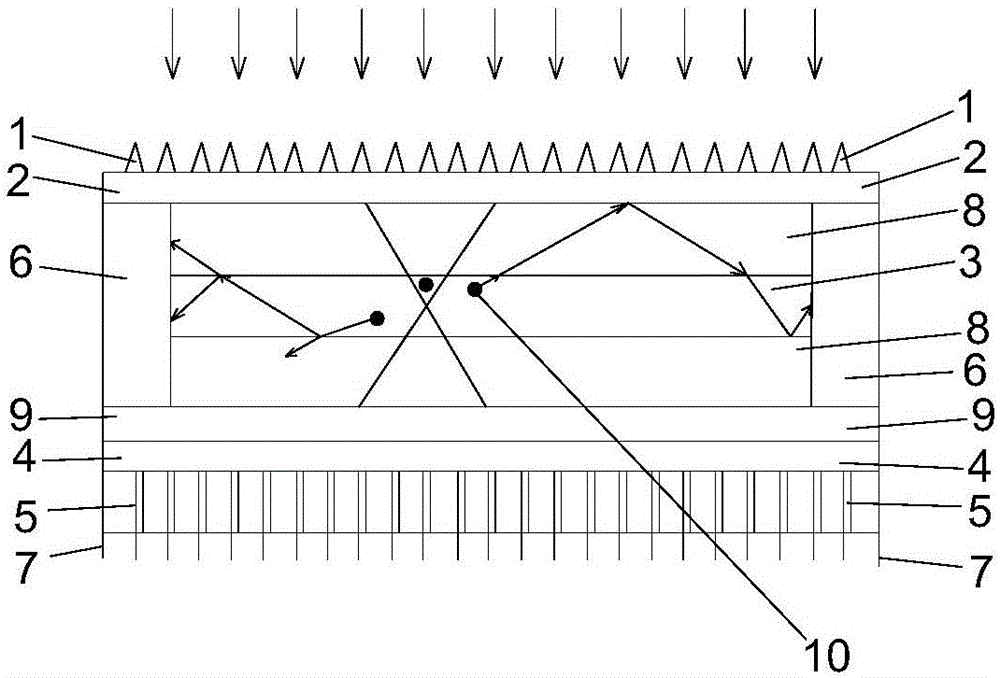

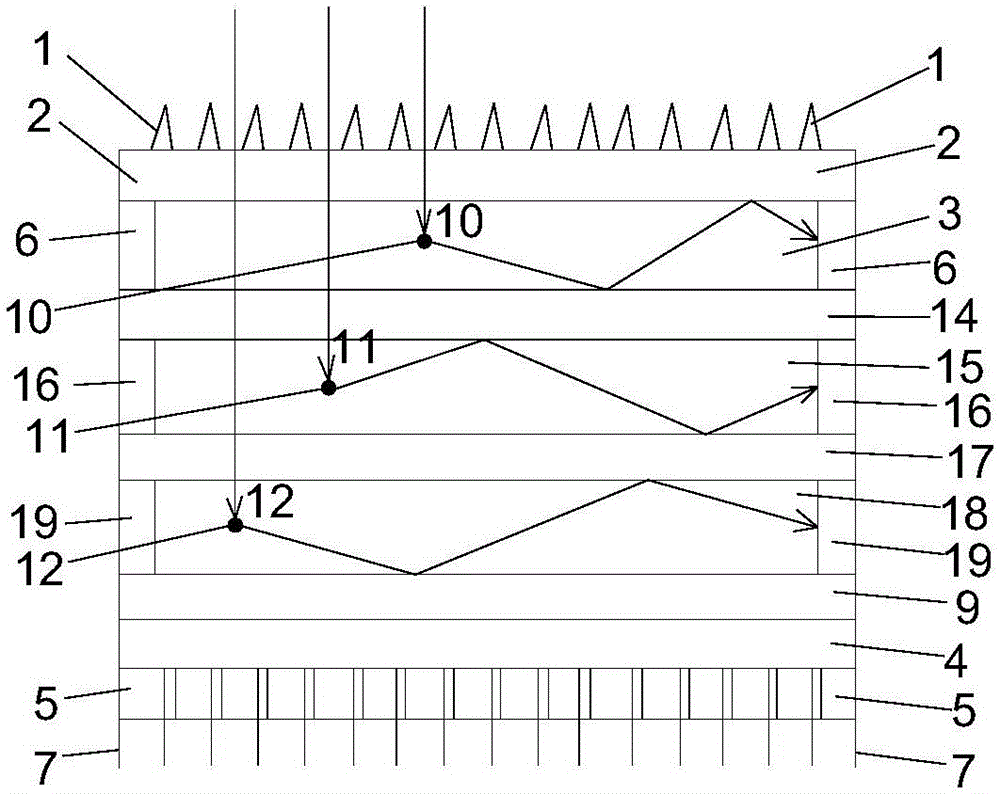

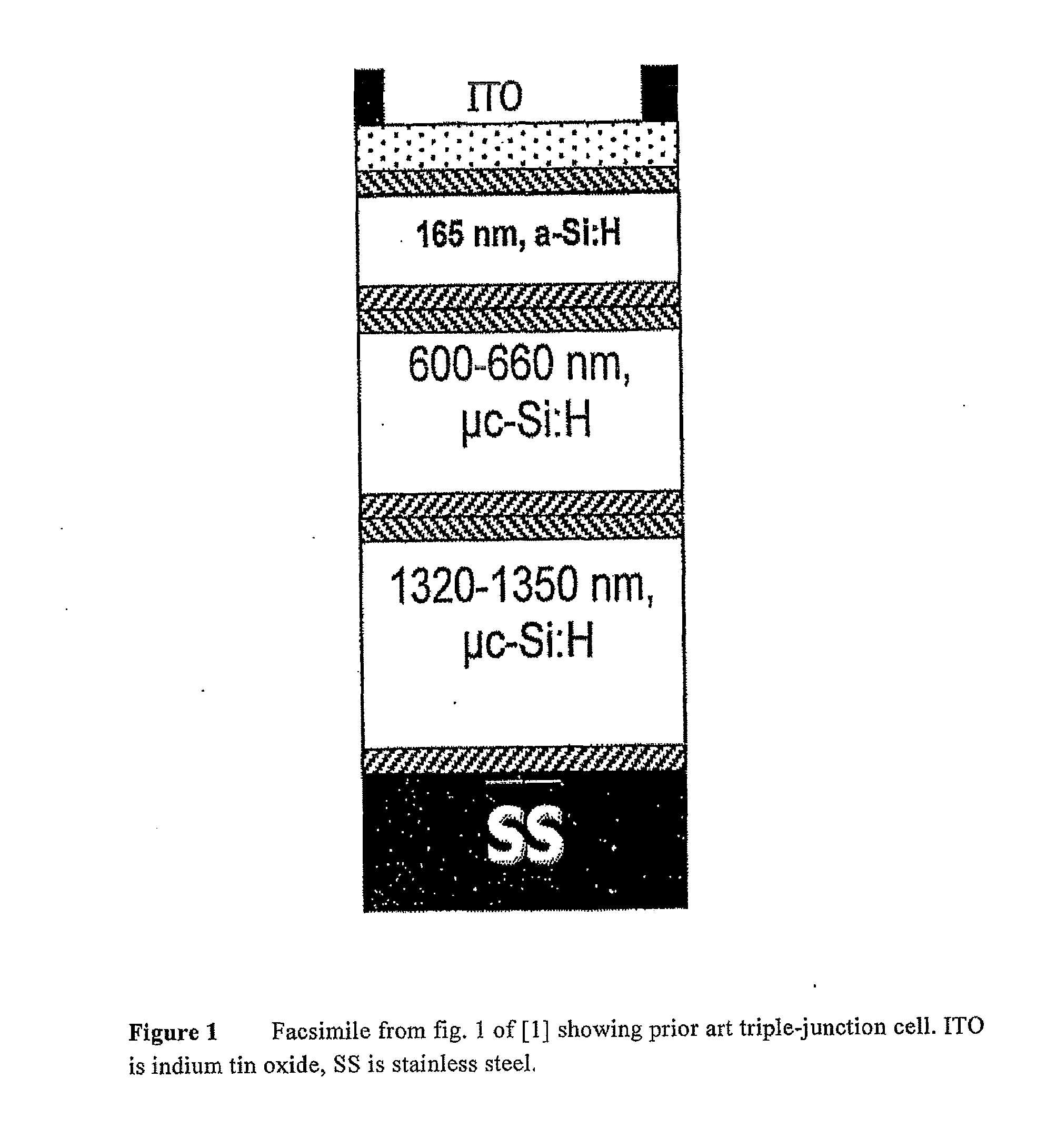

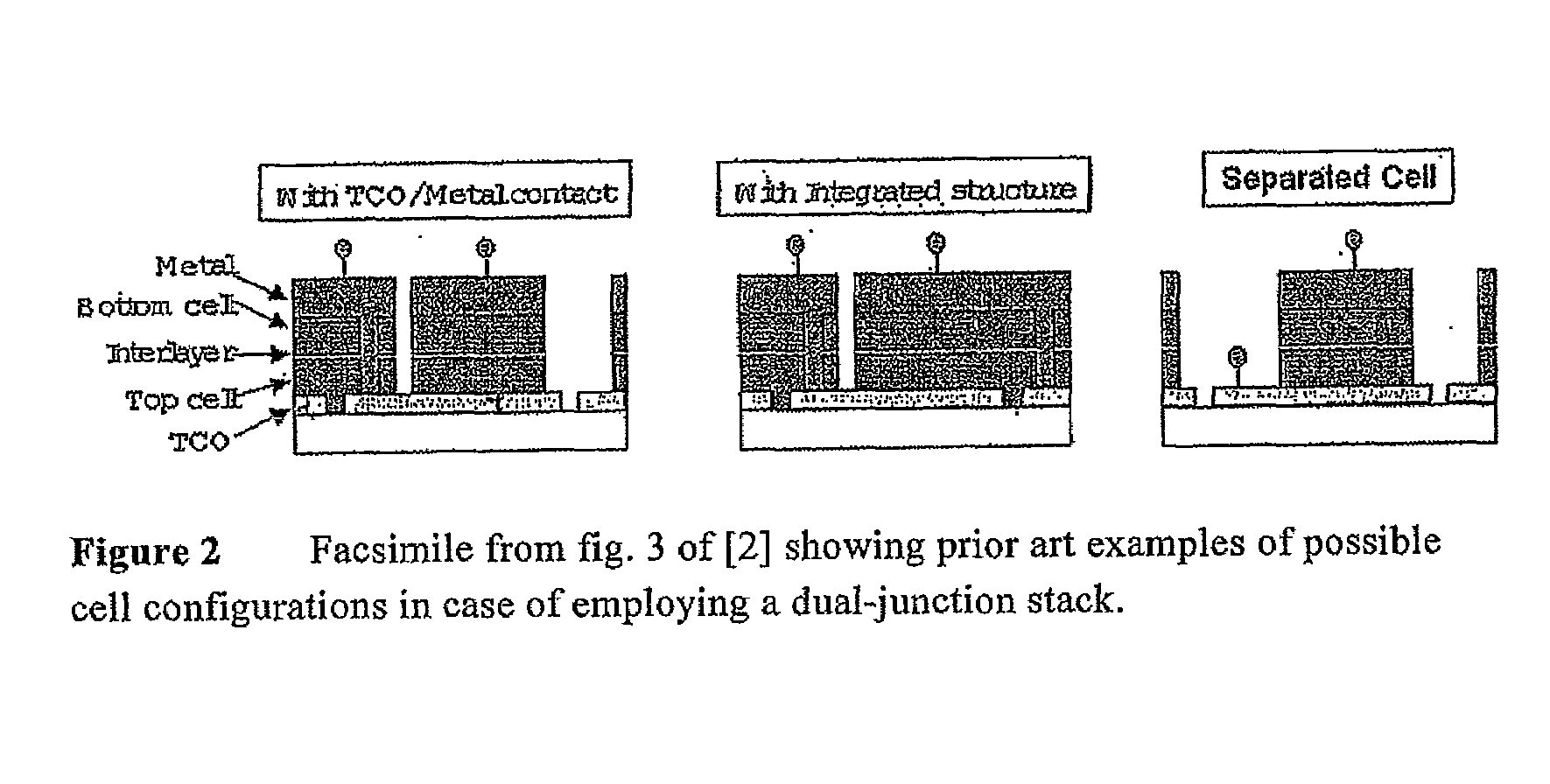

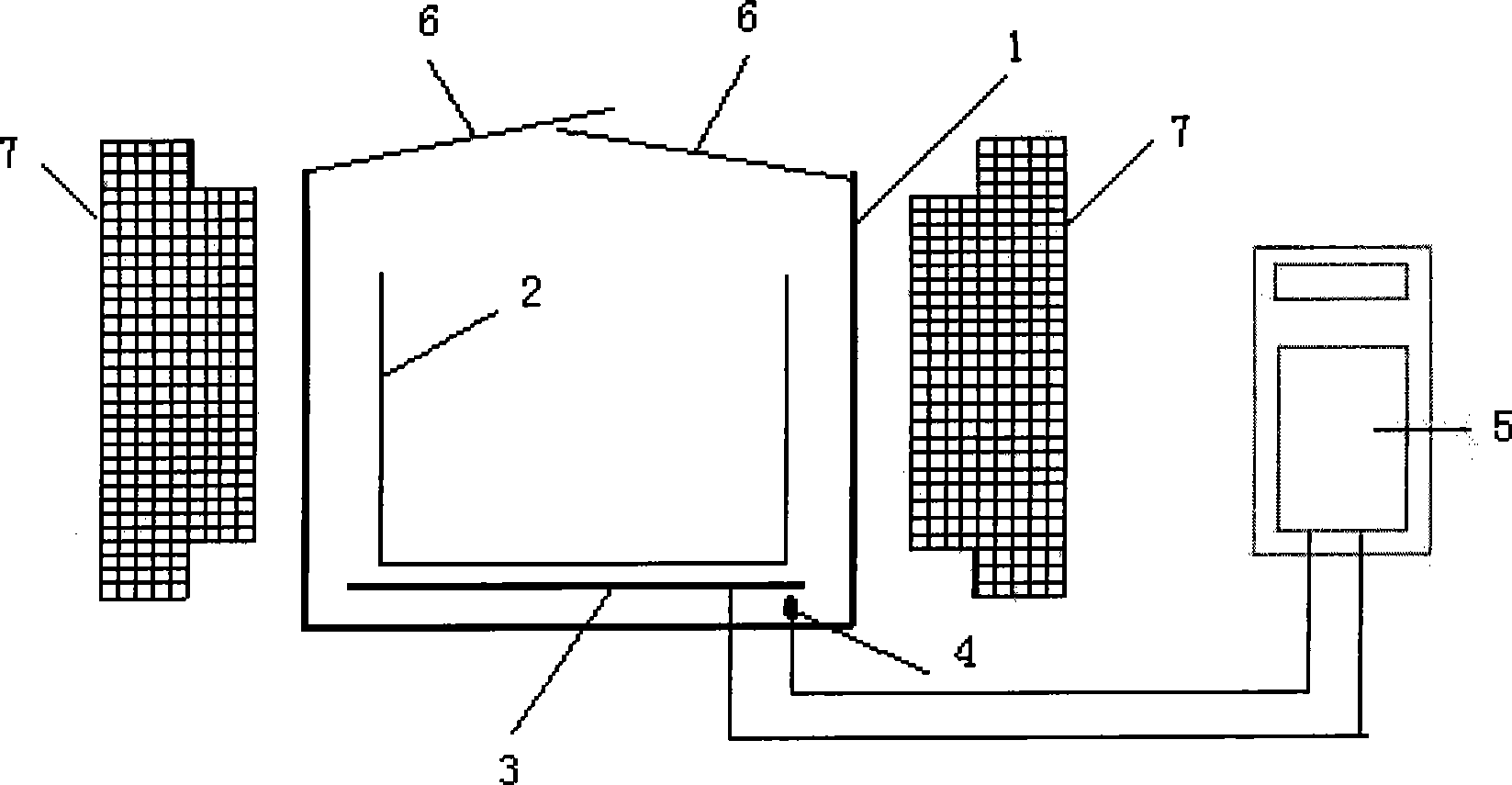

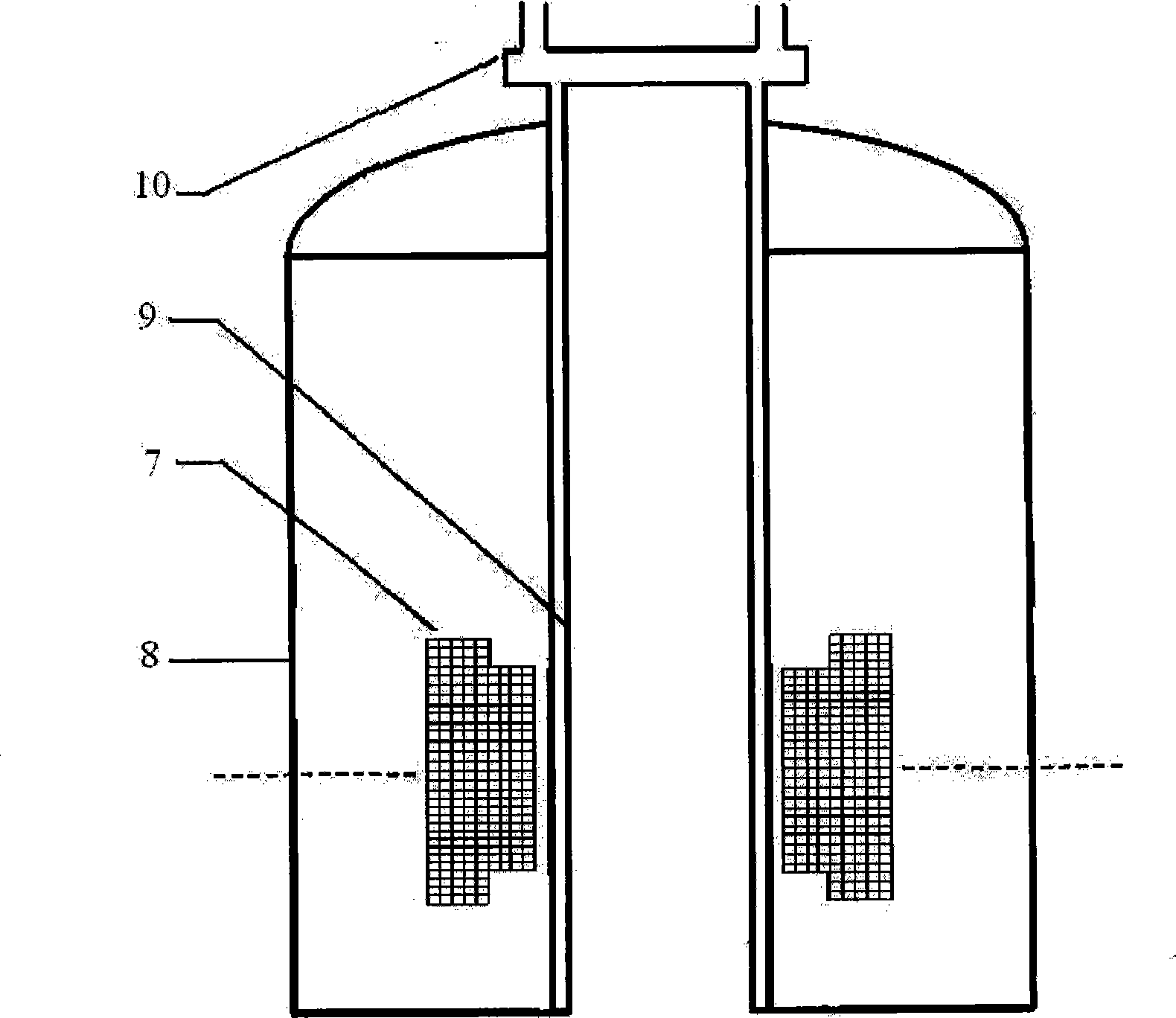

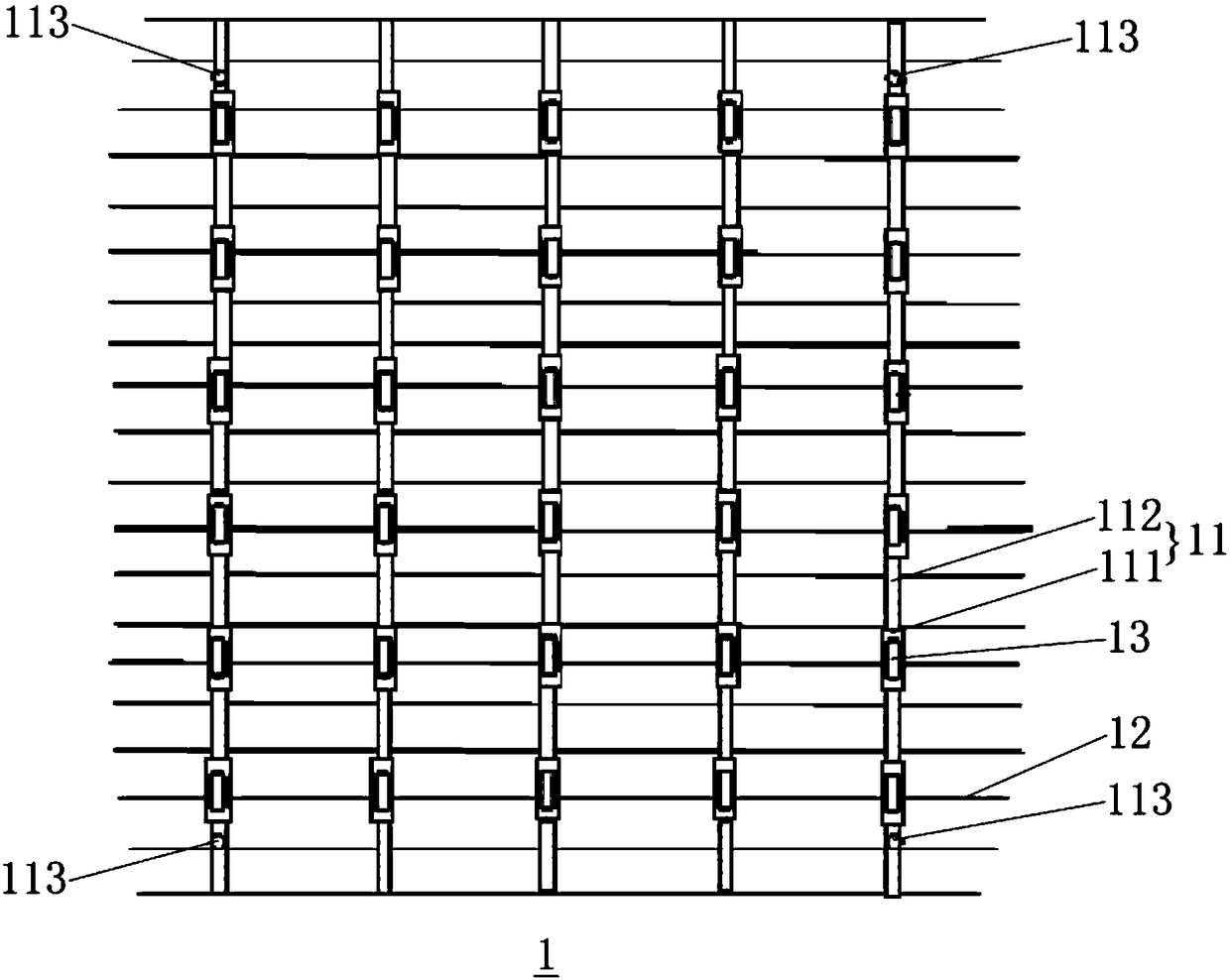

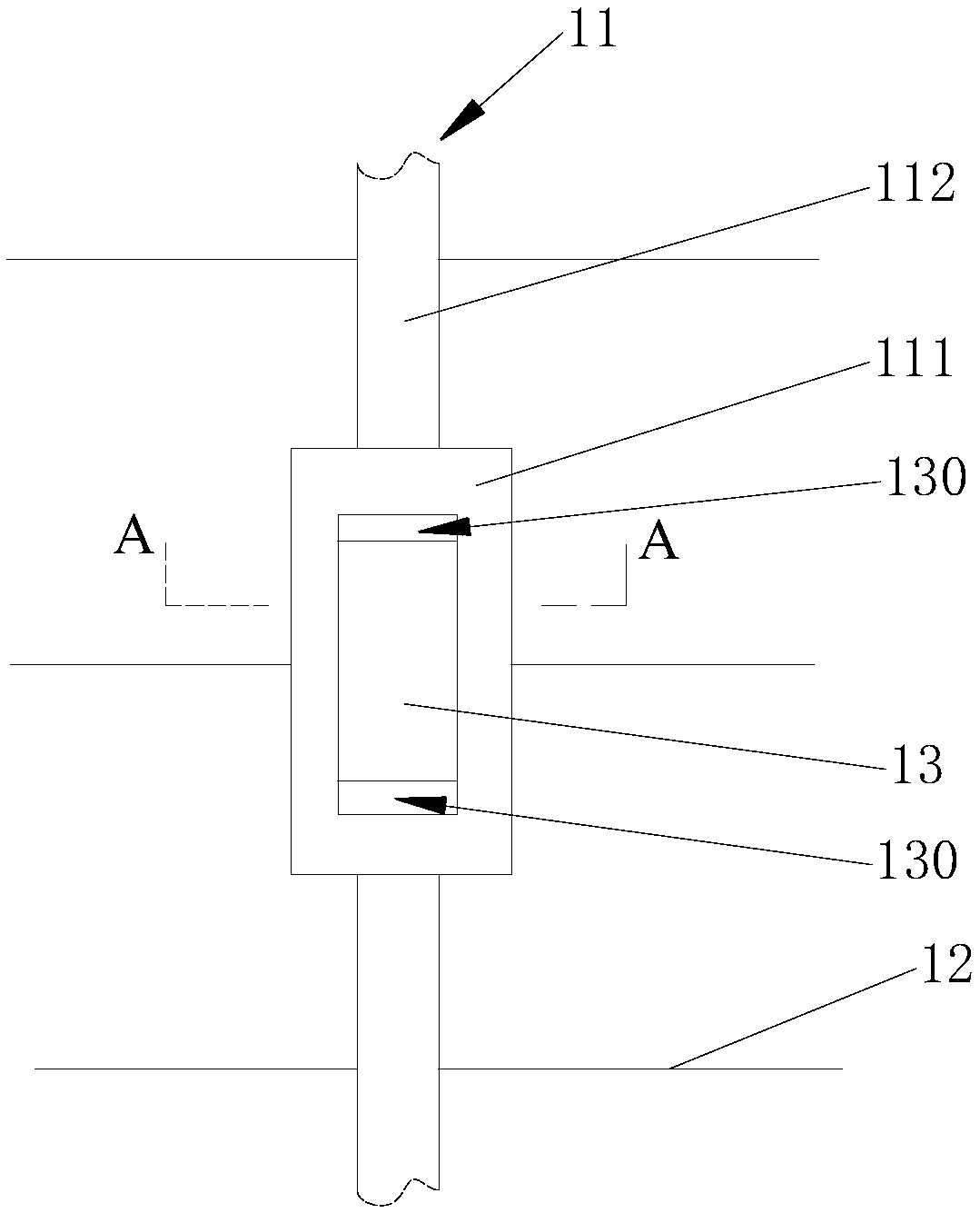

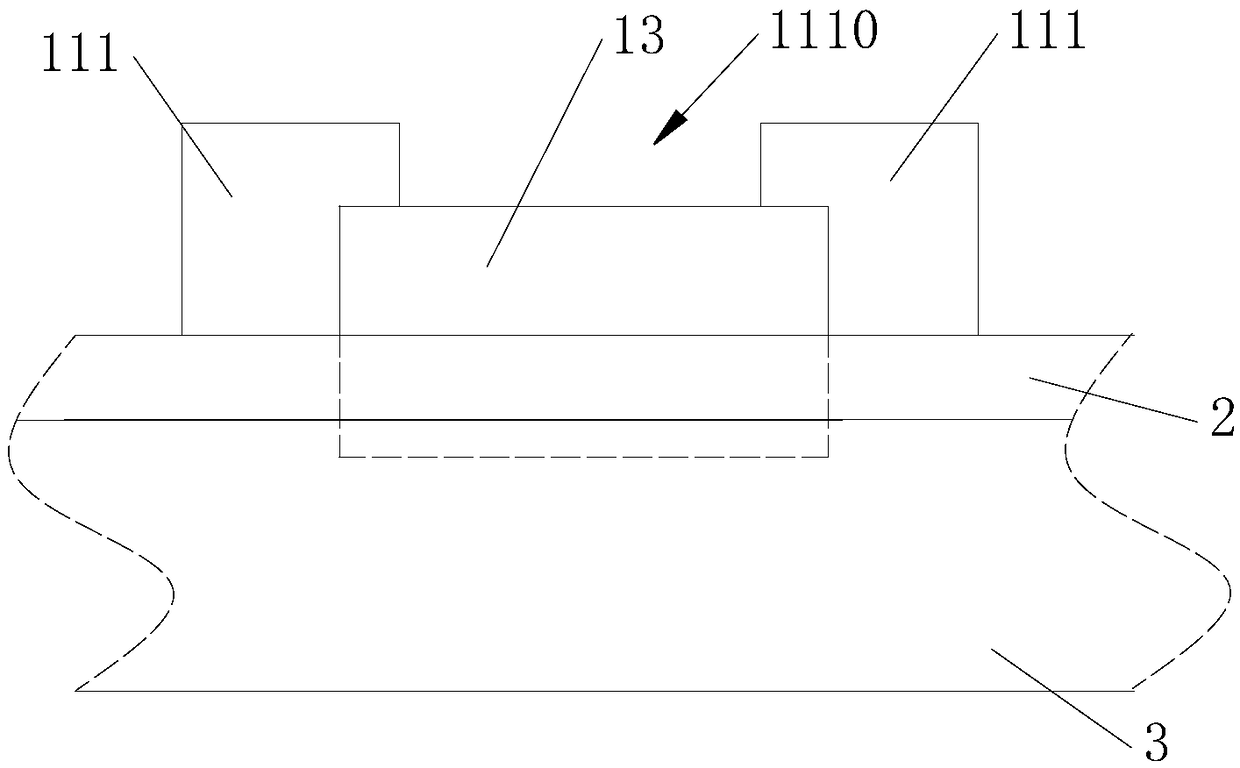

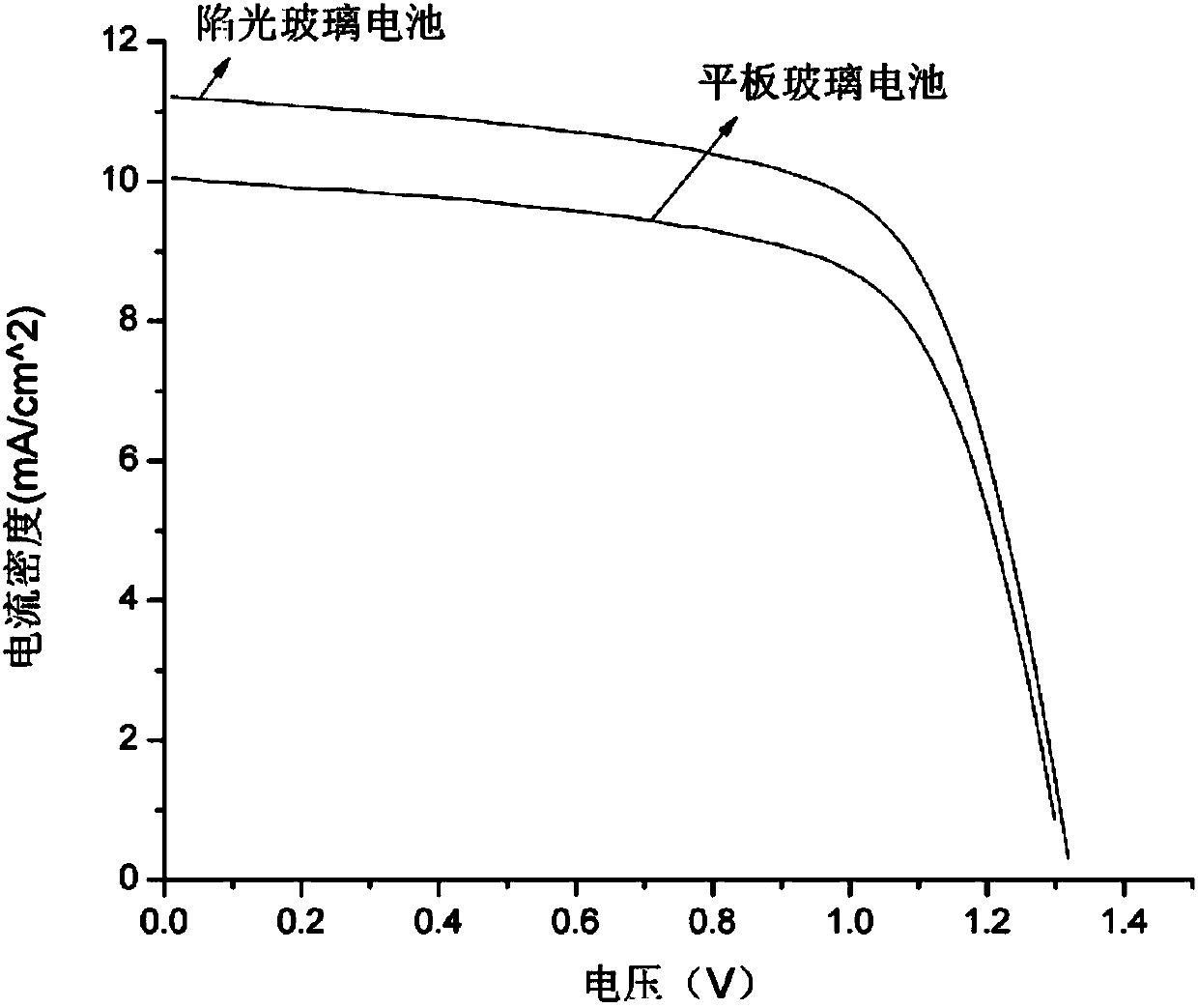

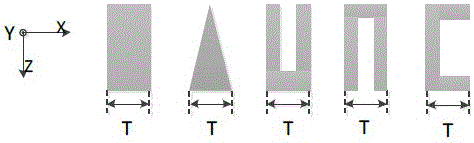

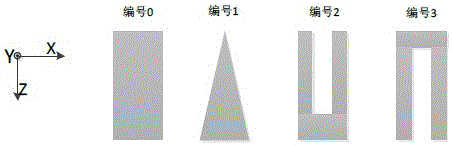

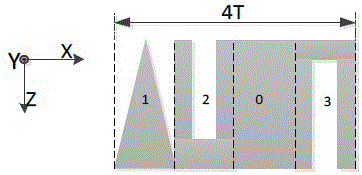

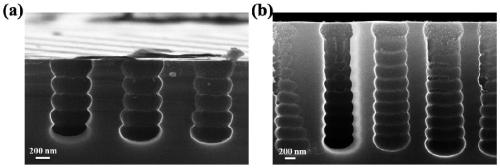

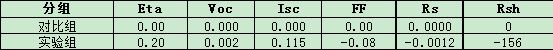

Microstructure light trapping method for silicon-based thin film solar cell

InactiveCN103633193AImprove light trappingImprove efficiencyFinal product manufacturePhotovoltaic energy generationTrappingMicrocrystalline silicon

The invention relates to a microstructure light trapping method for a silicon-based thin film solar cell. A micrometer-scale periodic structure is used as a light trapping part of the cell, or the micrometer-scale periodic structure and a textured structure form the light trapping part of the cell. The light trapping structure is prepared on a substrate material, and the thin film solar cell can be directly deposited on the light trapping substrate, and can be covered by light trapping sheet glass, so that the light trapping capability of the cell can be effectively improved, the photo absorption can be improved, and the photoelectric conversion efficiency of the thin film solar cell can be improved. Photoelectric efficiency tests show that the relative efficiency of a double-junction amorphous silicon / microcrystalline silicone cell can be improved by 9.95 percent by the light trapping technology. The microstructure light trapping method is compatible with a conventional thin film cell preparation technology, and is suitable for large-area batch production, and the efficiency of the thin film solar cell can be effectively improved under the condition of no changes in process parameters.

Owner:SHANGHAI JIAO TONG UNIV

Wet etching-based preparation method for light trapping structure with Ag nanowires embedded into silicon surface

InactiveCN107302040AImprove light trappingIncrease contact areaFinal product manufacturePhotovoltaic energy generationEtchingNanowire

The invention relates to a wet etching-based preparation method for a light trapping structure with Ag nanowires embedded into a silicon surface. The preparation method comprises the following steps of effectively dispersing the Ag nanowires in an ethanol solution by a low-power ultrasonic dispersion means; uniformly coating the dispersed Ag nanowires on a surface of a silicon wafer by a spin-coating mode; and improving contact between the Ag nanowires and the silicon wafer by an annealing mode. By etching of an etching liquid, the Ag nanowires are embedded into the silicon surface to prepare a novel light trapping, resistance reduction and efficiency improving structure. By the structure, the contact area between the Ag nanowires and the silicon surface is remarkably expanded, and meanwhile, the light trapping capability of the Ag nanowires in silicon is greatly improved within a visible light spectral range. The design and the preparation process provide a novel technical means for improving the efficiency of a device such as a silicon thin film solar cell and an LED.

Owner:YANTAI NANSHAN UNIV

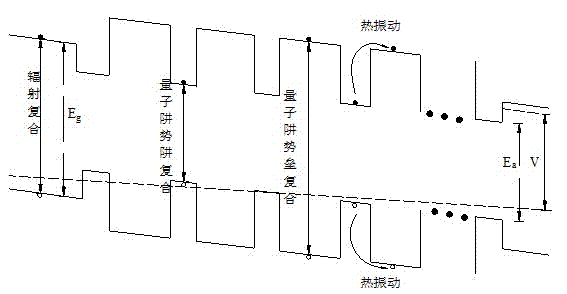

Silicon nano wire quantum well solar cell and preparation method thereof

InactiveCN103594535AImprove light trappingImprove efficiencyFinal product manufacturePhotovoltaic energy generationAluminum doped zinc oxideOhmic contact

The invention discloses a silicon nano wire quantum well solar cell. A Ti / Pd / Ag grid electrode, a transparent aluminum-doped zinc oxide (AZO) conductive layer film, an n<+> ohmic contact layer, an n layer, an nc-Si:H / SiNx superlattice quantum well, a p<+> ohmic contact layer and an AL back electrode are sequentially arranged along an incident sunshine direction, a solar cell employs a p-type silicon nano wire array to support the nc-Si:H / SiNx superlattice quantum well. The solar cell preparation method is further disclosed. The solar cell has advantages of high light tripping, high efficiency, low cost and long service life. A gradual change type quantum well material is formed at a surface of the silicon nano wire array, so a light tripping effect of the solar cell is greatly improved, a light absorption spectrum of the solar cell is further widened, and the approximate full-spectrum nc-Si:H / SiNx superlattice quantum well solar cell is formed.

Owner:JIANGSU UNIV

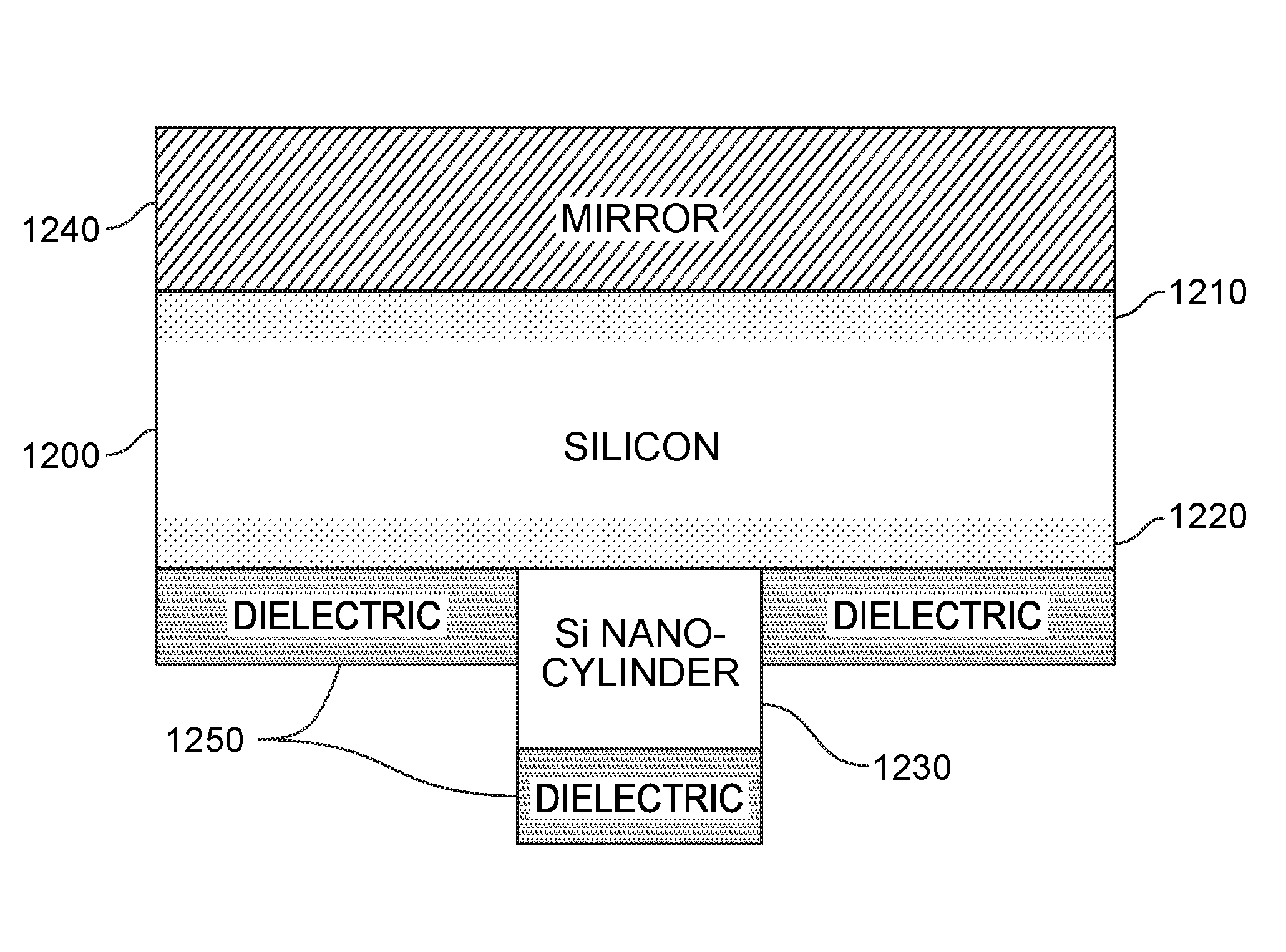

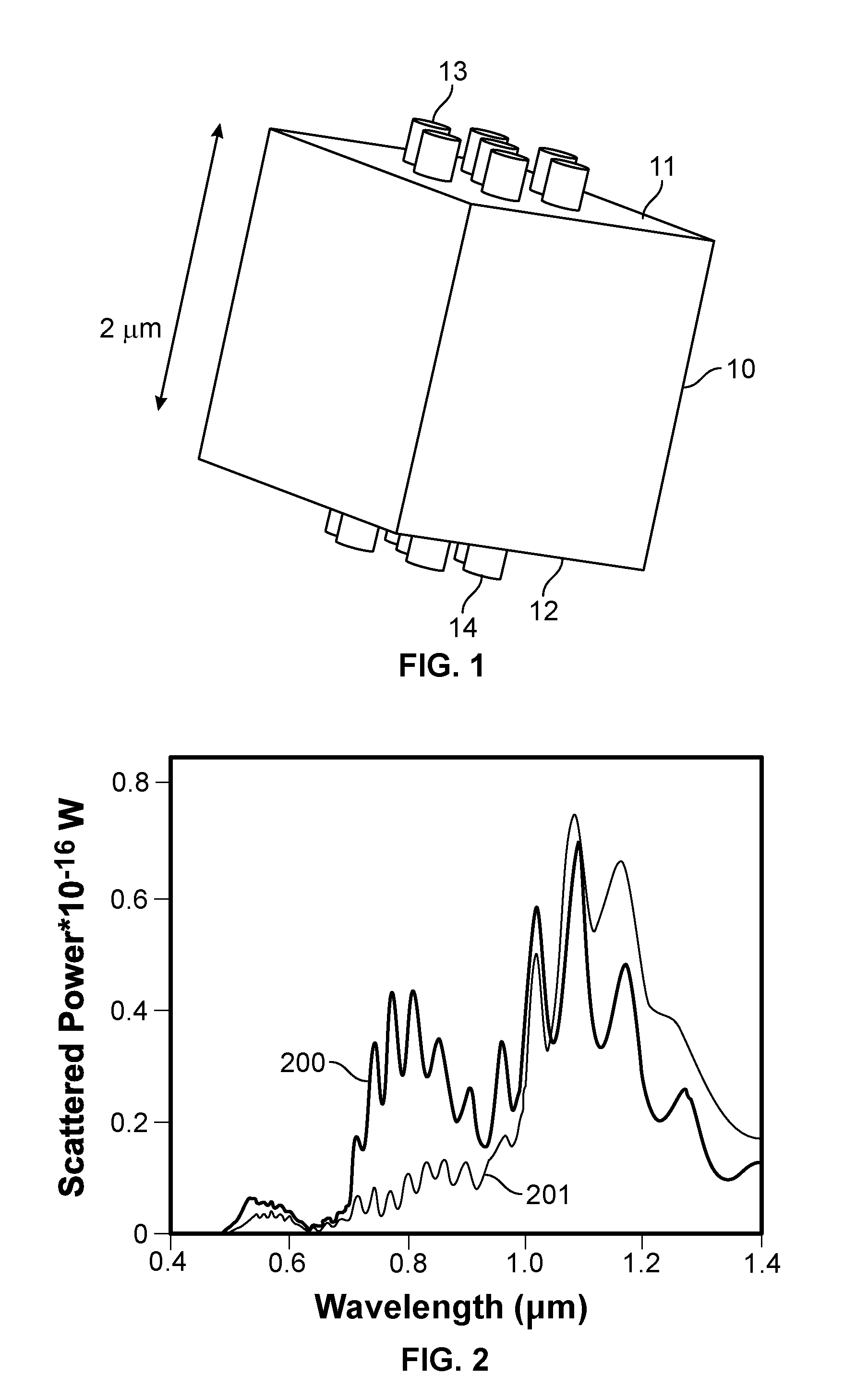

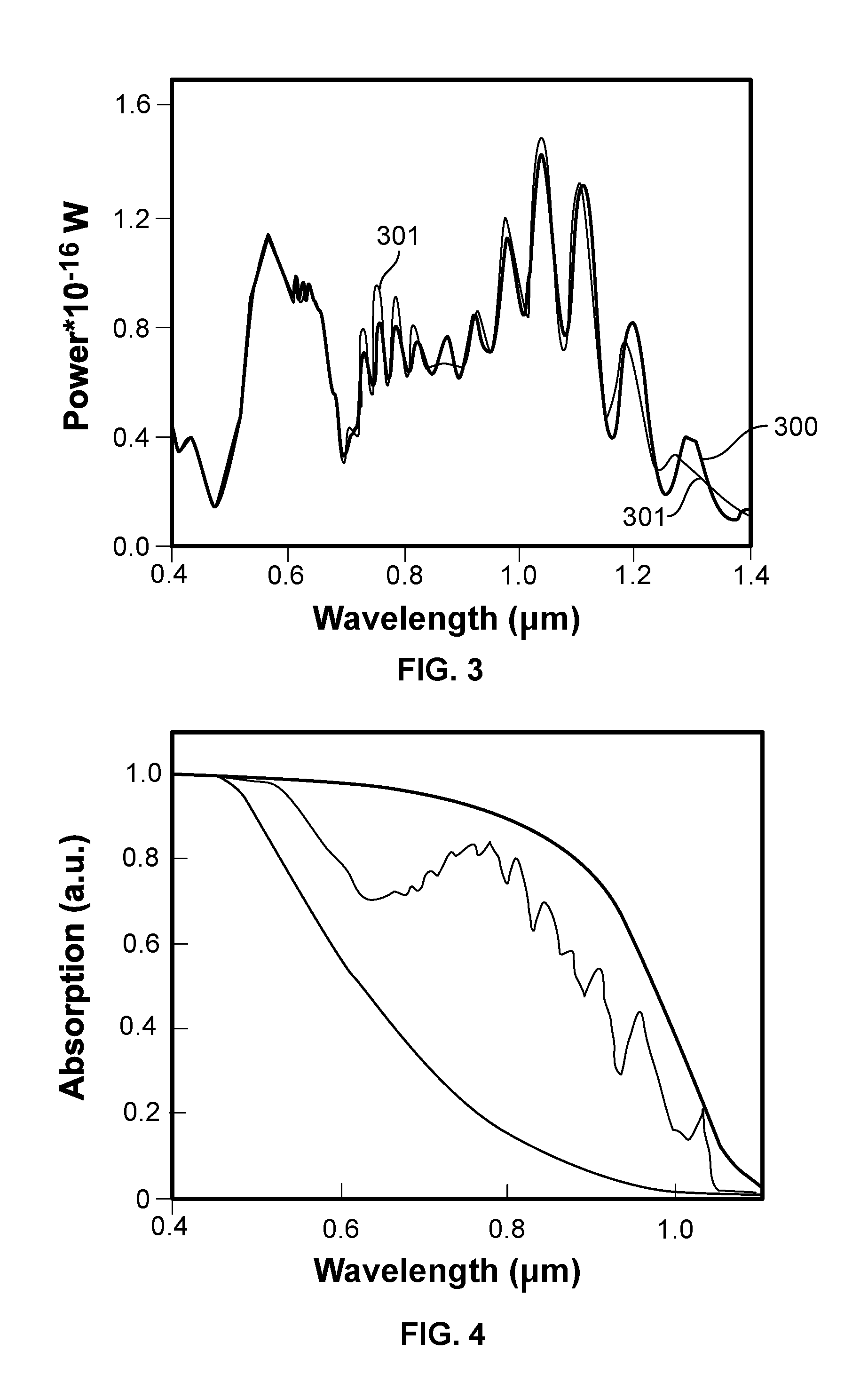

Photovoltaic cell with light trapping for enhanced efficiency

ActiveUS9190542B1Improve photovoltaic conversion efficiencyImprove permeabilityPhotovoltaic energy generationSemiconductor devicesForward scatterNanopillar

The efficiency of a photovoltaic cell is enhanced by light trapping using Mie-scattering nanostructures. In one embodiment, an array of nanocylinders is formed on the front surface of a silicon film to enhance forward scattering into the film, and an array of nanocylinders is formed on the back surface to enhance backscattering so that more light is absorbed within the silicon film. In an alternate embodiment, a mirror layer is formed on the back surface of the silicon film to reflect light within the film back toward the front-surface nanocylinder array.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Out-of-order sub-structure grating and method for designing optical grating through secondary random function

ActiveCN106066501AStrong handlingImprove light trappingDiffraction gratingsOrder structureEngineering

The invention discloses a disordered sub-structure and long-period grating, which comprises a plurality of one-dimensional disordered sub-structure and long-period gratings. The one-dimensional disordered sub-structure and long-period gratings are composed of periodic units periodically arranged along the X-axis. The periodic units are composed of several different sub-structures arranged along the X-axis. All periodic units in each single one-dimensional disordered sub-structure and long-period grating are the same in structure and all one-dimensional disordered sub-structure and long-period gratings are arranged along the Y-axis to form a two-dimensional disordered sub-structure and long-period grating. The invention further discloses a method for designing the grating through a secondary random function. According to the technical scheme of the invention, an ordered structure and a disordered structure are integrated together. In this way, the advantages of the ordered structure can be maintained, and the disordered structure is better in control capability in terms of bandwidth, angle and the like. When the large bandwidth range of the optical wavelength is 300-1000 nm, the light tripping effect is improved by nearly 90% compared with other disordered structures.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

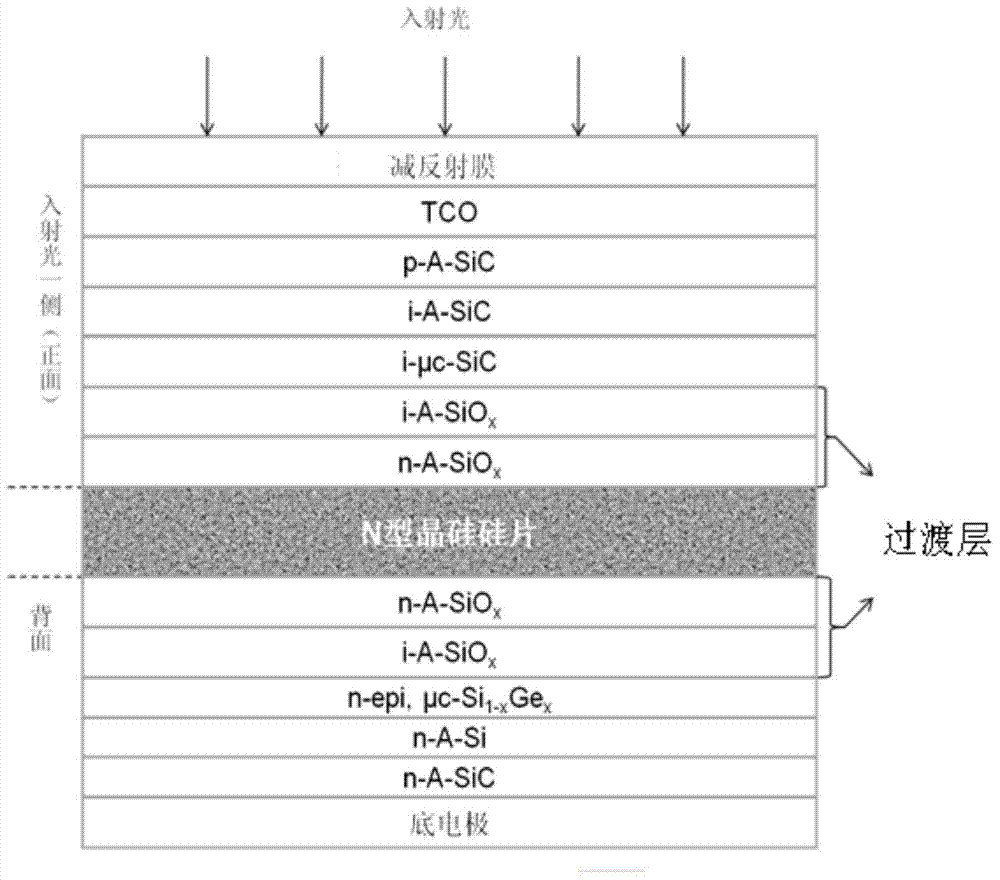

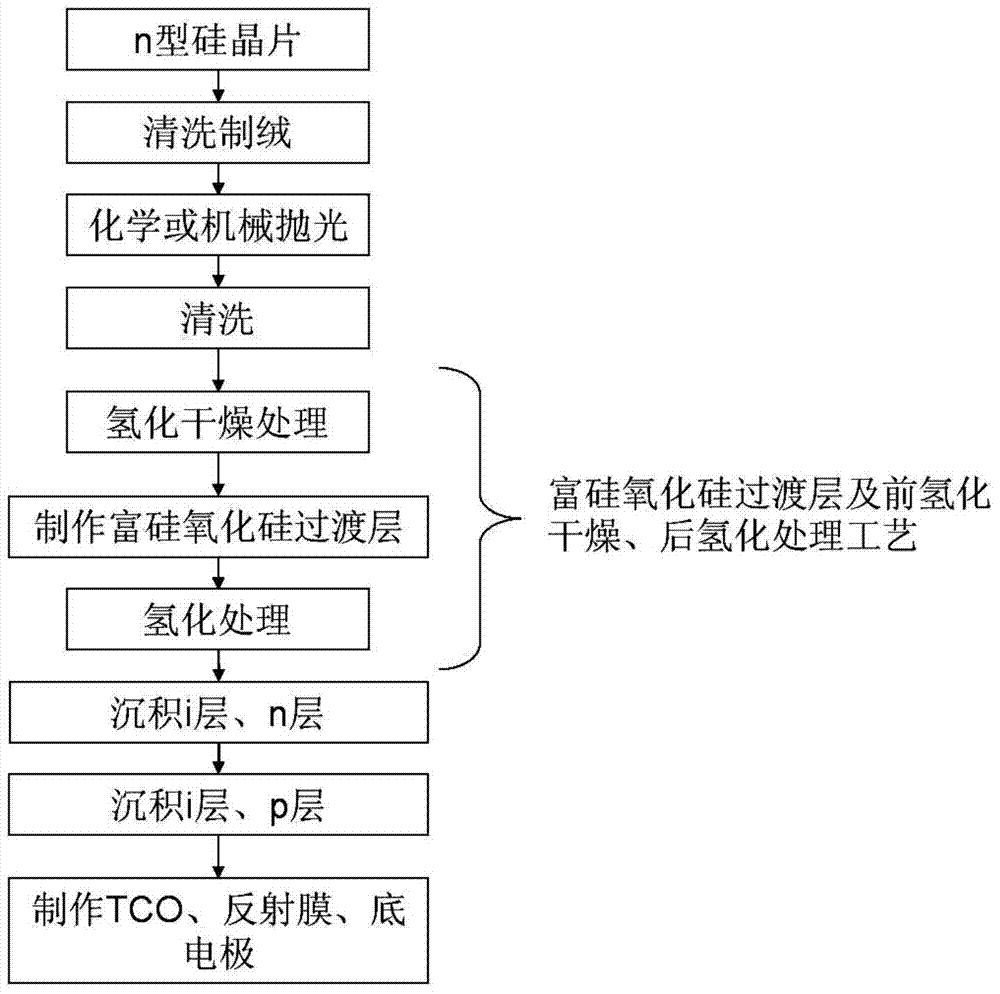

Crystal silicon and silicon carbide film compound unijunction PIN solar battery with transition layer, and preparation method thereof

ActiveCN104505419AReduce defect statesImprove passivation effectFinal product manufacturePhotovoltaic energy generationOxygenSolar battery

The invention provides a crystal silicon and silicon carbide film compound unijunction PIN solar battery with a transition layer, and a preparation method thereof. According to the solar battery, the front surface of an n-type silicon wafer or the back surface of the n-type silicon wafer or both the front surface and the back surface of the n-type silicon wafer are simultaneously provided with the transition layer, the transition layer has one layer or multiple layers, and one layer of the transition layer is a silicon-enriched oxygen ambient silica layer. The preparation method involves adding a pre-hydrogenation drying processing after the silicon wafer is textured, polished and cleaned and at the same time, adding a post-hydrogenation processing mode after the process of the transition layer is finished. The two methods are used for improving the interface quality and the structure stability. By using the transition layer and using the crystal silicon and silicon carbide film compound battery which is subjected to the pre-hydrogenation drying processing and post-hydrogenation processing and is provided with the transition layer, the battery conversion efficiency can be improved by more than 10% on the basis of the prior arts.

Owner:湖南共创光伏科技有限公司

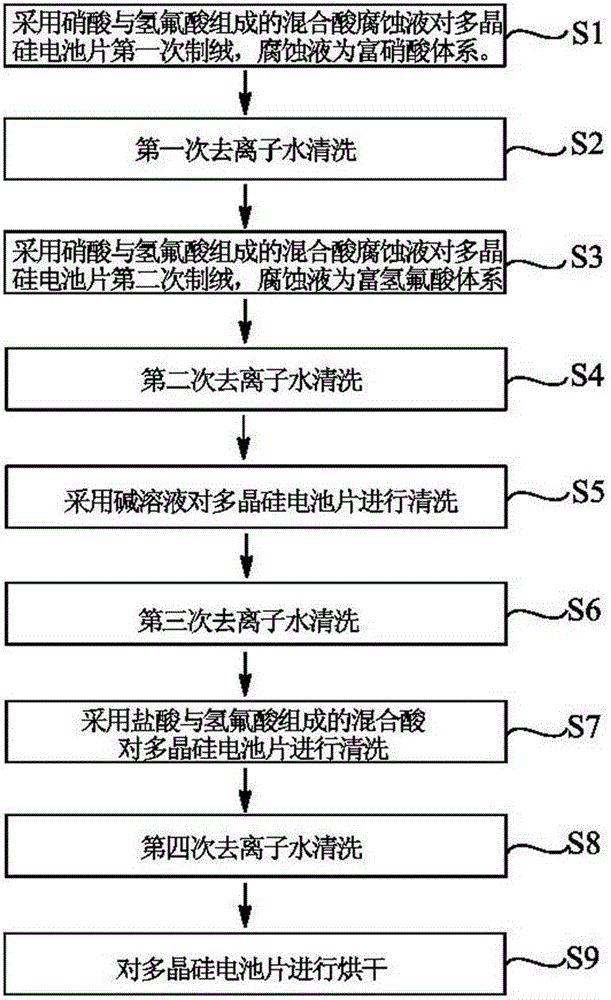

Texturing method of polysilicon solar cell

InactiveCN104835879AReduce oxidation densityImprove light trappingFinal product manufacturePhotovoltaic energy generationProduction lineHydrofluoric acid

The invention relates to a texturing method of a polysilicon solar cell. Twice texturing is included, and a combined acid corrosion solution is by formed mixing HNO3, HF and H2O. The texturing method comprises the following steps that A) first texturing is carried out on the polysilicon solar cell by using the mixed acid corrosion solution, in which the mass concentration of HNO3 is greater than that of HF, of the rich HNO3 system; B) the polysilicon solar cell after texturing in step A is cleaned by deionized water; and C) secondary texturing is carried out on the polysilicon solar cell by using the mixed acid corrosion solution, in which the mass concentration of HNO3 is greater than that of HF, of the rich HNO3 system. The solutions used in twice texturing need neither a texturing additive nor other chemicals, the texturing reflectivity of twice texturing is 9% or more lower than that of once texturing traditionally, the light tripping effect of the textured surface is improved, the short circuit current is improved by 200mA or more, and the efficiency is improved by 0.35%; and the texturing method can be combined with a present production line conveniently to reduce the cost and provide convenience for large-scale production.

Owner:REALFORCE POWER

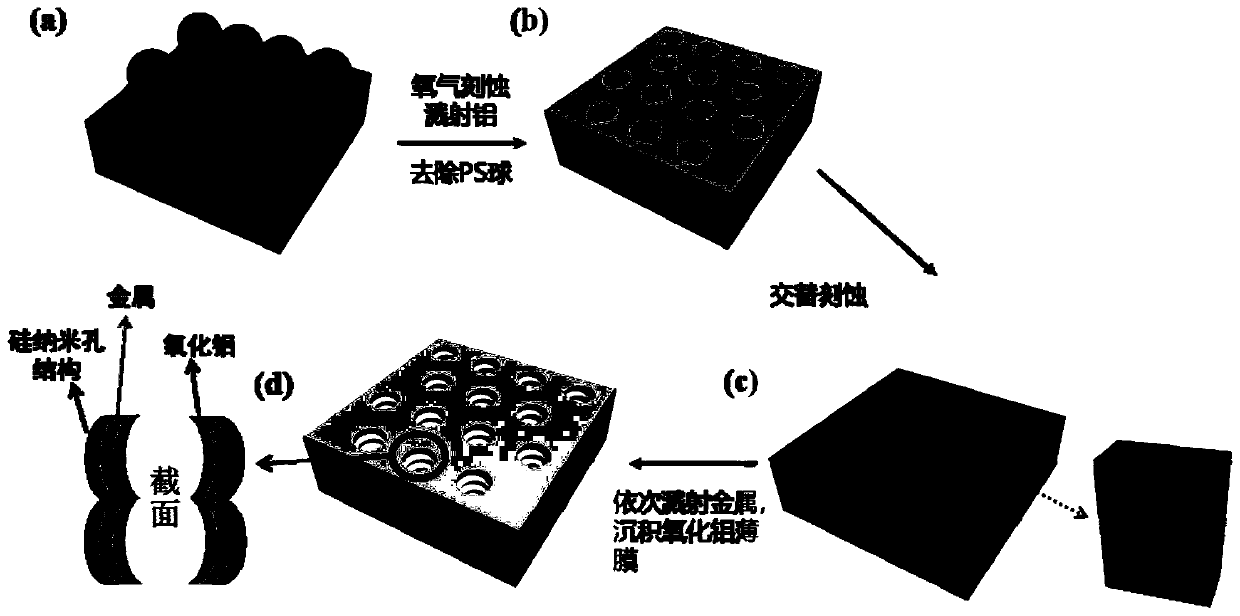

Silicon-based single-sided integrated absorption emitter for solar thermal photovoltaic cell and preparation method of silicon-based single-sided integrated absorption emitter

ActiveCN111244219AImprove solar conversion efficiencyImprove light trappingFinal product manufacturePhotovoltaic energy generationSolar energy conversion efficiencyPhysical chemistry

The invention discloses a silicon-based single-sided integrated absorption emitter for a solar thermal photovoltaic cell. The silicon-based single-sided integrated absorption emitter comprises a top-layer solar concentrating system, a selective absorption emitter at the bottom, a narrow-band-gap photovoltaic cell surrounding the selective absorption emitter and a heat storage layer at the lower part of the selective absorption emitter; and the selective absorption emitter comprises a silicon wafer substrate and a plurality of fan-shaped side wall nanopore arrays which are arranged on the silicon wafer substrate and have different depth levels. The silicon-based semiconductor metal composite structure easy to prepare without photoetching provided by the invention can be applied to a single-sided integrated absorption emitter of a solar thermal photovoltaic system by utilizing the unique optical characteristics of the silicon-based semiconductor metal composite structure, and higher solar conversion efficiency is obtained.

Owner:NANJING UNIV

Processing technology for preparing battery sheet by cutting silicon wafer with diamond wire

ActiveCN111599892AQuality improvementReduce lossesFinal product manufacturePhotovoltaic energy generationElectrical batterySolar battery

The invention discloses a processing technology for preparing a battery sheet by cutting a silicon wafer through a diamond wire. The processing technology comprises the following steps of: selecting apolycrystalline silicon wafer obtained by diamond wire cutting as a substrate, sequentially putting the substrate into nitric acid and hydrofluoric acid for cleaning and polishing, and removing the damaged layer on the surface of the substrate; preparing a photoetching mask layer on the front surface of the substrate, texturing through a steam texturing method, and preparing a P-N junction on thefront surface of the substrate through a POCL3 liquid diffusion source thermal diffusion method; and finally performing wet etching, antireflection film plating, printing and sintering on the front surface of the substrate to obtain a finished product. The invention discloses a processing technology for preparing a battery sheet by cutting a silicon wafer through a diamond wire, wherein the method is reasonable in process design and simple and controllable in operation, selects the silicon wafer cut by the diamond wire as the substrate for processing, and prepares the battery sheet with excellent electrical performance, so that the open-circuit voltage, short-circuit current and fill factor of the solar cell are improved, the conversion efficiency is improved, the purposes of reducing thecost and improving the efficiency are achieved, and high practicality is achieved.

Owner:ECONESS ENERGY

Current-aided aluminum-doped zinc oxide film chemical texturing method

InactiveCN104952947AEnhanced Light Scattering PropertiesIncrease roughnessPhotovoltaic energy generationSemiconductor devicesAluminum doped zinc oxideTrapping

The invention discloses a current-aided aluminum-doped zinc oxide film chemical texturing method. According to the method, assistant current is added while conventional chemical texturing of an aluminum-doped zinc oxide film, roughness of the textured surface of the aluminum-doped zinc oxide film is improved highly, light-scattering property of the aluminum-doped zinc oxide film is enhanced, the aluminum-doped zinc oxide film is suitable for making thin-film solar cells, and light trapping capacity and photoelectric conversion efficiency of the solar cells can be improved. The method is simple and easy to implement and suitable for large-area production.

Owner:SHAANXI NORMAL UNIV

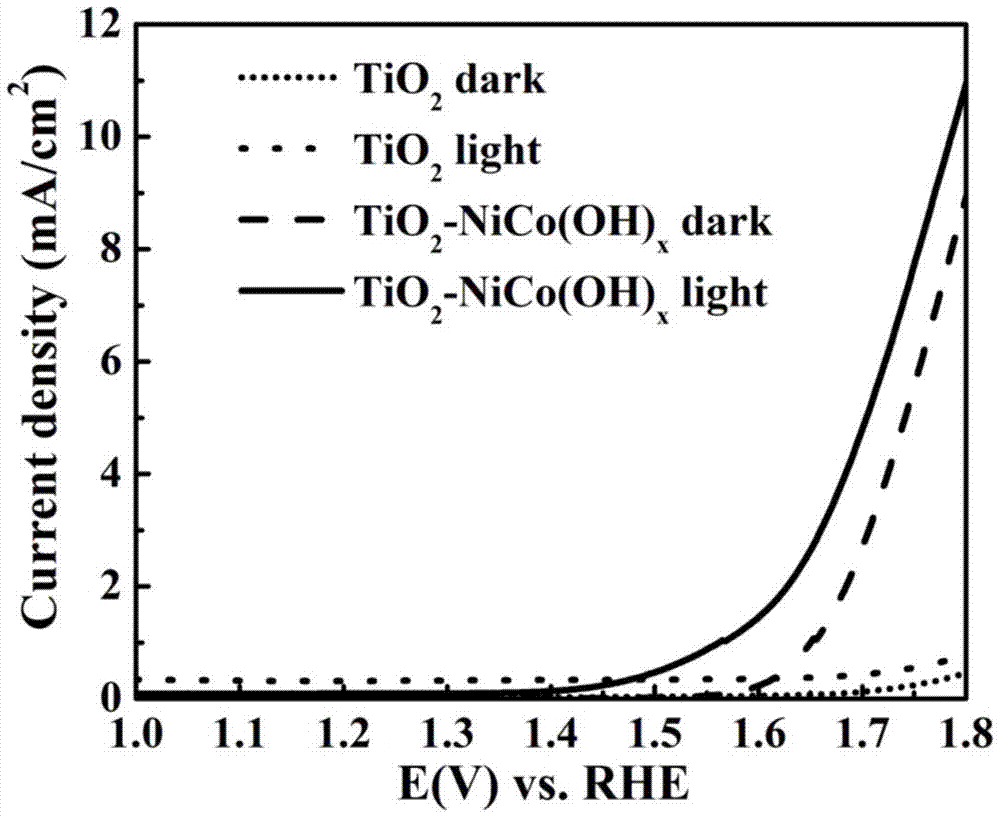

A kind of preparation method of the photoelectrode of photoelectrochemical cell

ActiveCN105568309BLarge specific surface areaRapid responseSurface reaction electrolytic coatingEnergy inputSemiconductor electrodeCobalt

Owner:SUZHOU UNIV

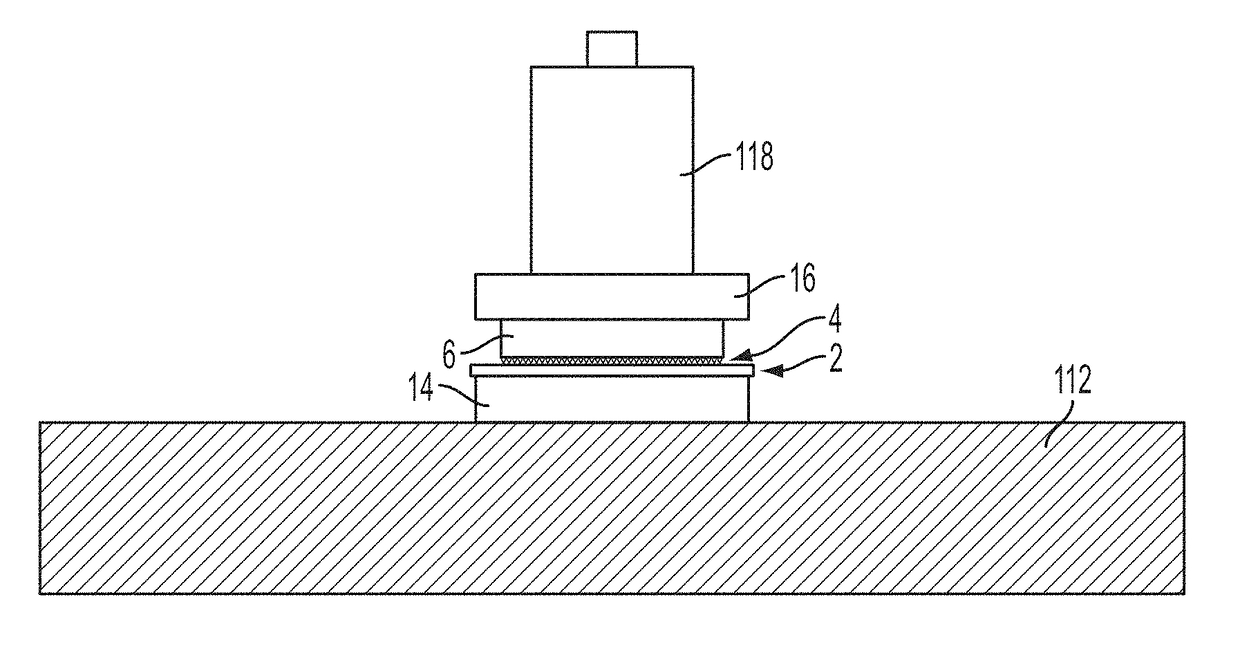

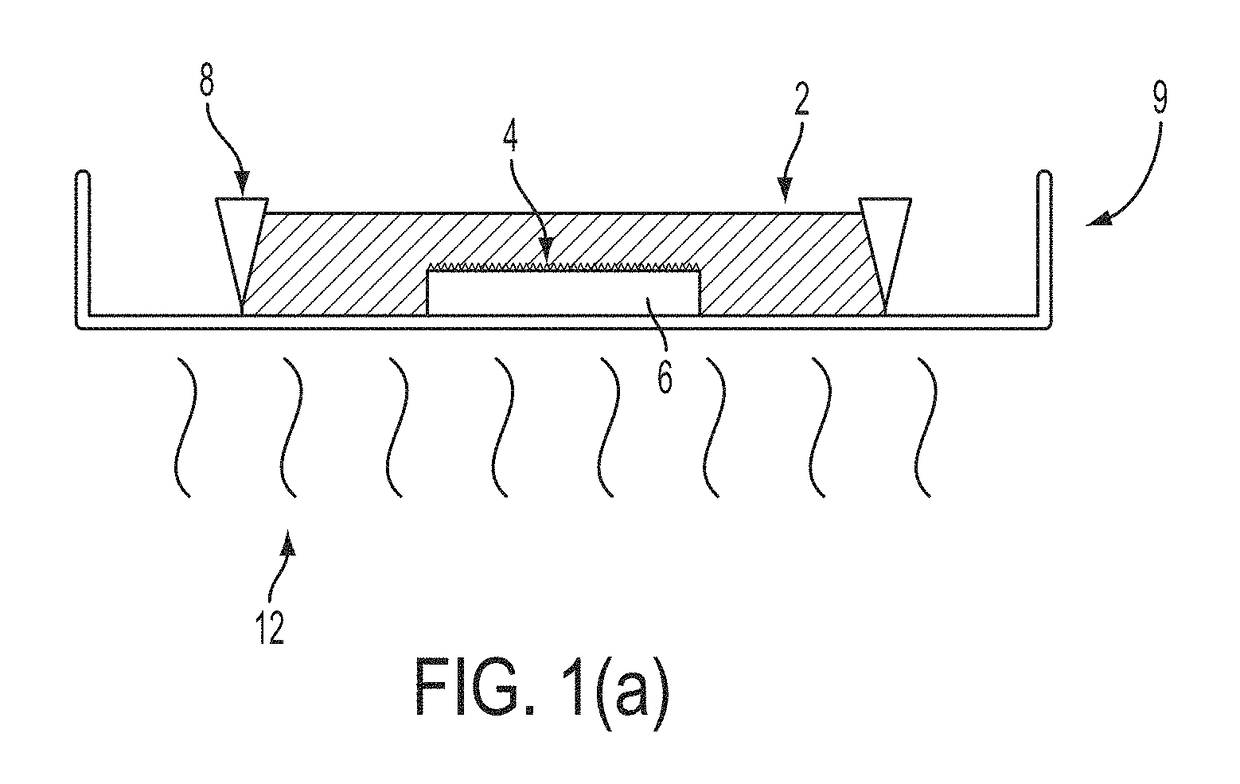

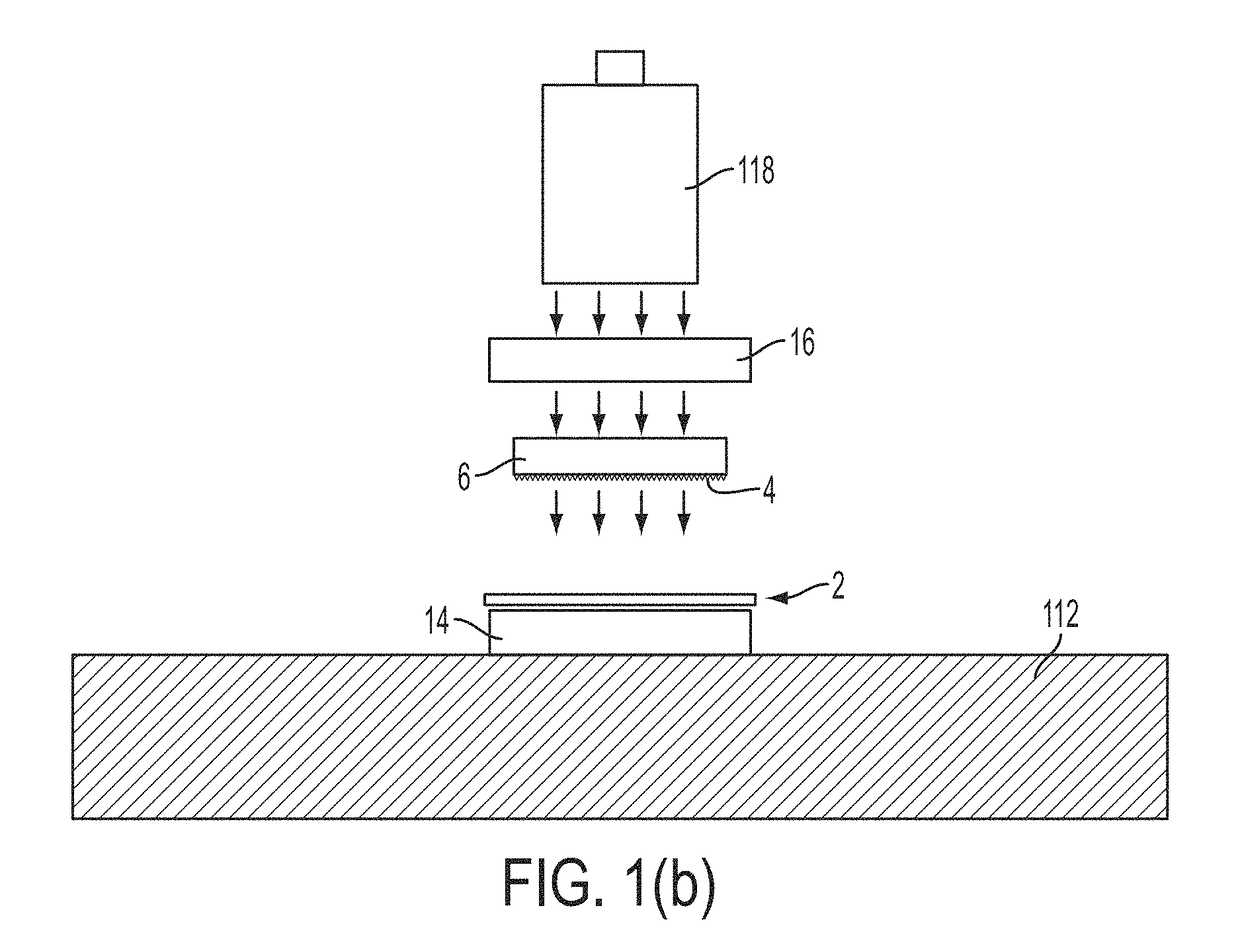

Micro-structure and nano-structure replication methods and article of manufacture

ActiveUS10131086B2Reduce processing stepsEliminating additional processing step for photovoltaicOptical articlesRecord information storageMicro structureMicron scale

A method for the replication of a textured surface of a master is disclosed, in which the textured surface of the master is comprised of micron-scale cones having nano- or micro-scale surface features. Alternatively, the master may be comprised of micron-scale structures, nano-scale structures, and micron scale structures having nano-scale surface features. Replication can be achieved through a molding or embossing technique. Using these technique, the textured surface of the master is faithfully replicated onto the surface of the replica. A number of representative materials and additional processing steps are also disclosed. The replicated texture exhibits many useful properties, including enhanced hydrophobicity and reduced light reflection properties, making the disclosed method a simple and attractive alternative to existing texturing techniques.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Heterojunction solar cell and preparation method thereof

InactiveCN114582983AImprove conversion efficiencyReduce damage effectPhotovoltaic energy generationSemiconductor devicesHeterojunctionSpectral response

The invention relates to a heterojunction solar cell and a preparation method thereof, and belongs to the technical field of solar cell manufacturing. Comprising a crystalline silicon substrate, and a front intrinsic amorphous silicon layer, an N-type doped layer, a front TCO layer and a front metal electrode are sequentially deposited on the front surface of the crystalline silicon substrate; a back intrinsic amorphous silicon layer, a P-type doped layer, a back TCO layer and a back metal electrode are sequentially deposited on the back of the crystalline silicon substrate, and a functional film containing a down-conversion fluorescent material covers a fine gate electrode in the front metal electrode and the front TCO layer which is not shielded by the metal electrode. By introducing the functional film containing the down-conversion fluorescent material, photons in a short-wave region which cannot be utilized by a solar cell can be converted into photon energy matched with spectral response of the photons, namely photons below 400nm are absorbed and converted into low-energy photons of 400-1100nm, so that absorption and utilization of the cell to sunlight are promoted, and the conversion efficiency of the solar cell is improved. The conversion efficiency of the heterojunction solar cell is improved, and the damage effect of part of ultraviolet light on the cell is weakened.

Owner:晋能光伏技术有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com