Microstructure light trapping method for silicon-based thin film solar cell

A technology of solar cells and silicon-based thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced production efficiency and easy puncture of thin film layers, so as to improve efficiency, improve light trapping ability, and increase photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

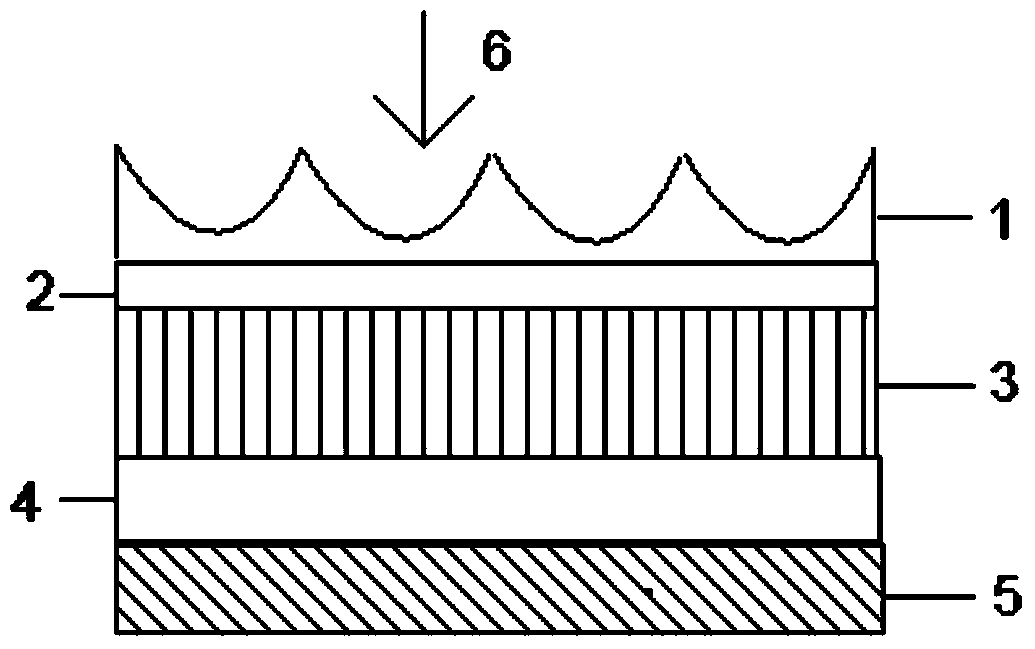

[0028] Example 1 (single-junction battery preparation)

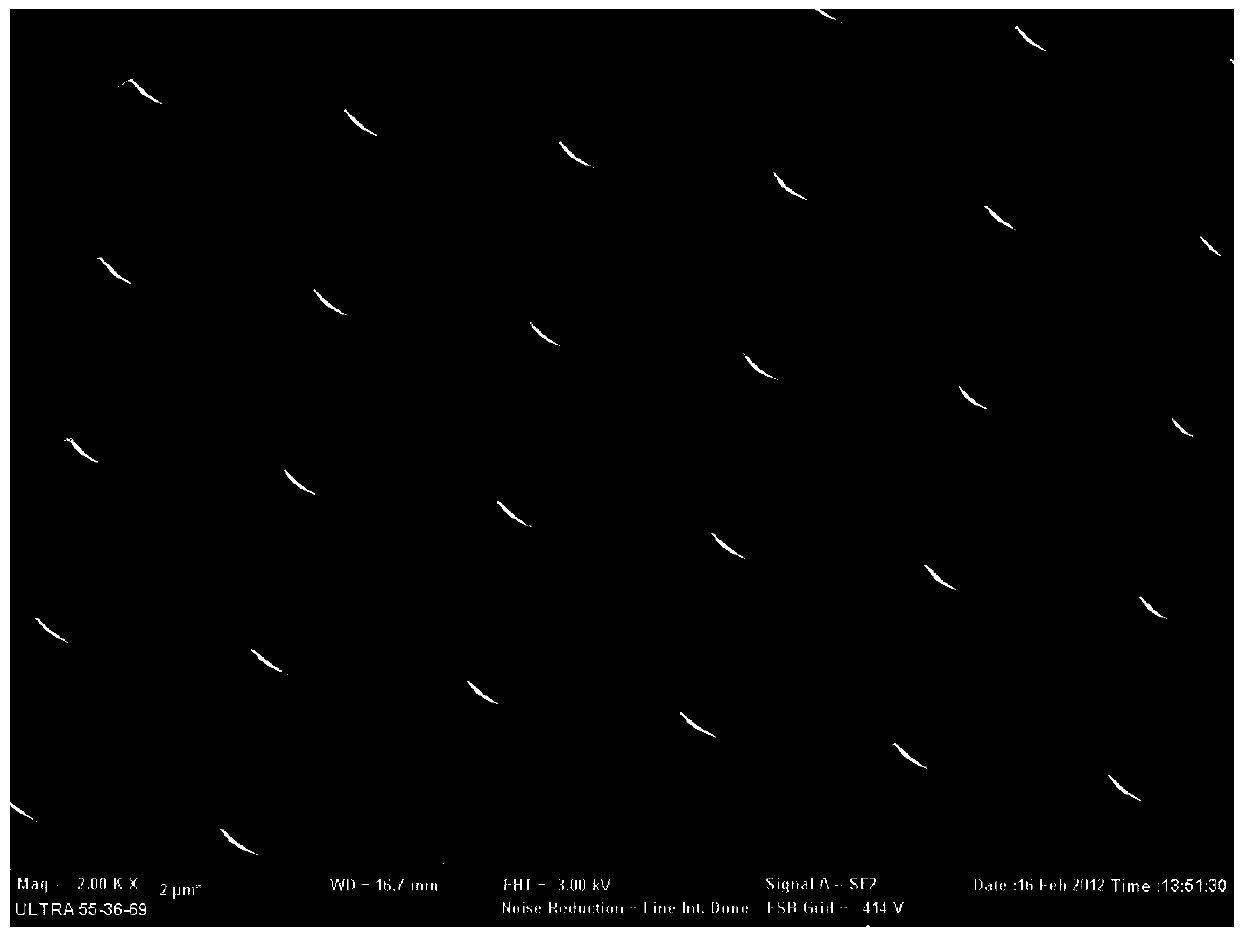

[0029]1. Through photolithography, development and etching, etc., prepare a hemispherical pit structure with a size of 10 μm and periodically arranged on the flat glass suitable for solar cells, as a light-trapping structure for thin-film solar cells.

[0030] 2. Use the light-trapping structural glass prepared in step 1 as the substrate, and deposit 0.3 μm TCO on it as the front electrode.

[0031] 3. Deposit 0.3μm a-Si as the p-i-n structure of the battery.

[0032] 4. Deposit 0.1 μm AZO as the back electrode and transition layer.

[0033] 5. Finally, 0.3 μm Ag is used as the back reflection layer to obtain a single-junction high-efficiency light-trapping thin-film solar cell. The schematic diagram is as follows figure 1 shown.

Embodiment 2

[0034] Example 2 (Double-junction battery preparation)

[0035] 1. On the basis of steps 1-4 of Example 1, deposit 2 μm microcrystalline silicon as the p-i-n structure of the bottom cell.

[0036] 2. Deposit 0.1μm AZO as the back electrode and transition layer.

[0037] 3. Finally, 0.3 μm Ag is used as the back reflection layer to obtain a double-junction high-efficiency light-trapping thin film solar cell.

Embodiment 3

[0038] Example 3 (light-trapping structure covered thin-film battery)

[0039] 1. According to the method shown in Step 1 of Example 1, prepare a light-trapping glass sheet with a size of 10 μm and a size of 2 μm.

[0040] 2. Prepare a thin-film battery according to steps 1-3 of Example 1.

[0041] 3. The 10μm light-trapping glass covers the surface of the battery for anti-reflection, and the 2μm light-trapping glass covers the bottom of the battery, which can effectively improve the absorption rate of infrared and near-infrared photons.

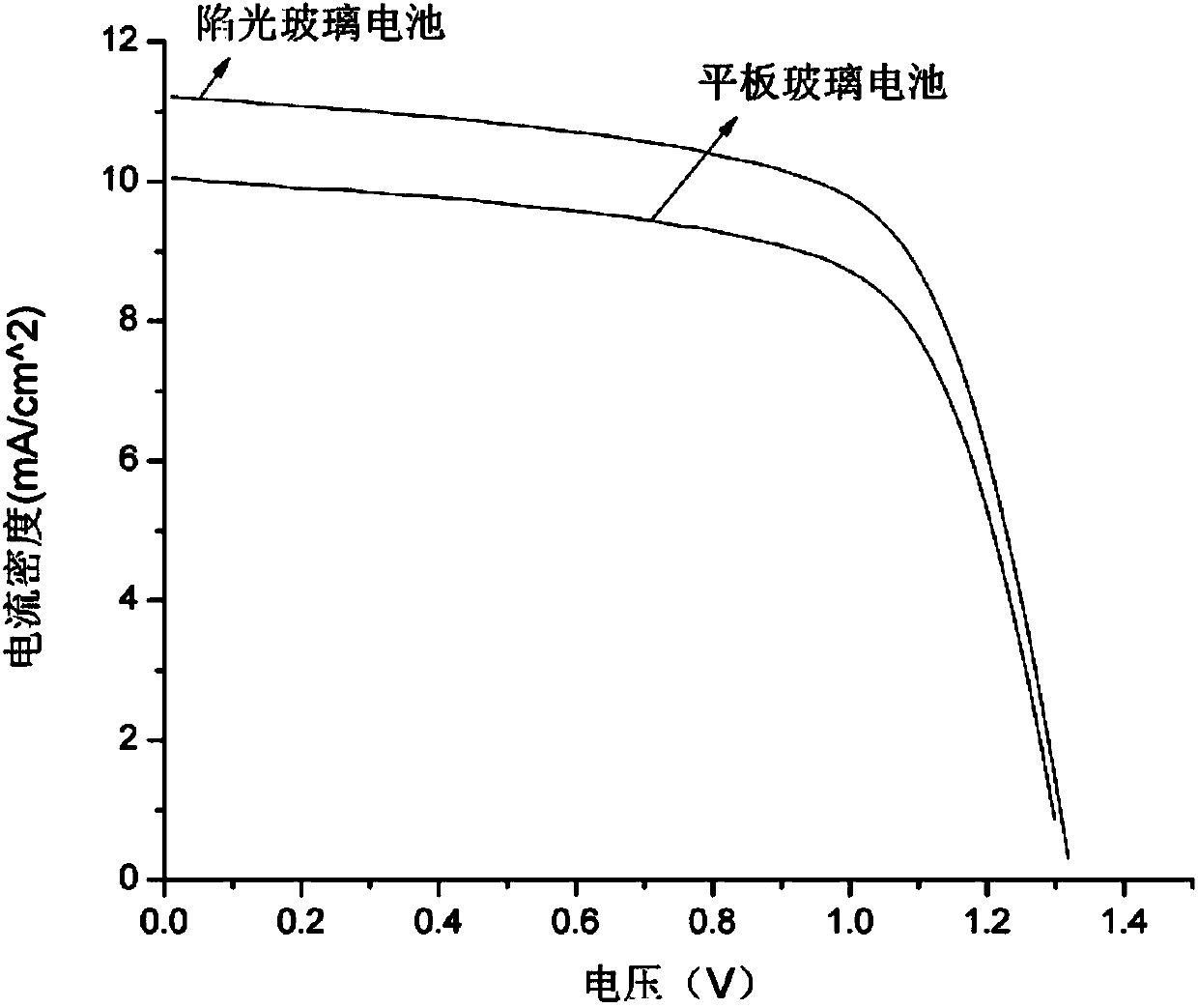

[0042] In the above implementation, first prepare a micron-scale light-trapping glass sheet, and then use the light-trapping glass sheet as a substrate to deposit a thin-film battery, or cover the light-trapping glass sheet on the thin-film battery, which can effectively improve the light absorption of the thin-film battery. Thereby improving battery efficiency. The light-trapping glass sheet is used as the substrate of the thin-film batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com