A kind of preparation method of the photoelectrode of photoelectrochemical cell

A photoelectrochemical cell and photoelectrode technology, applied in electrodes, electrolytic coatings, electrolysis processes, etc., can solve the problems of limited specific surface area of photoelectrodes, limited electrolyte contact area, low photolysis water efficiency, etc. Efficiency, beneficial to large-scale production, and the effect of huge application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

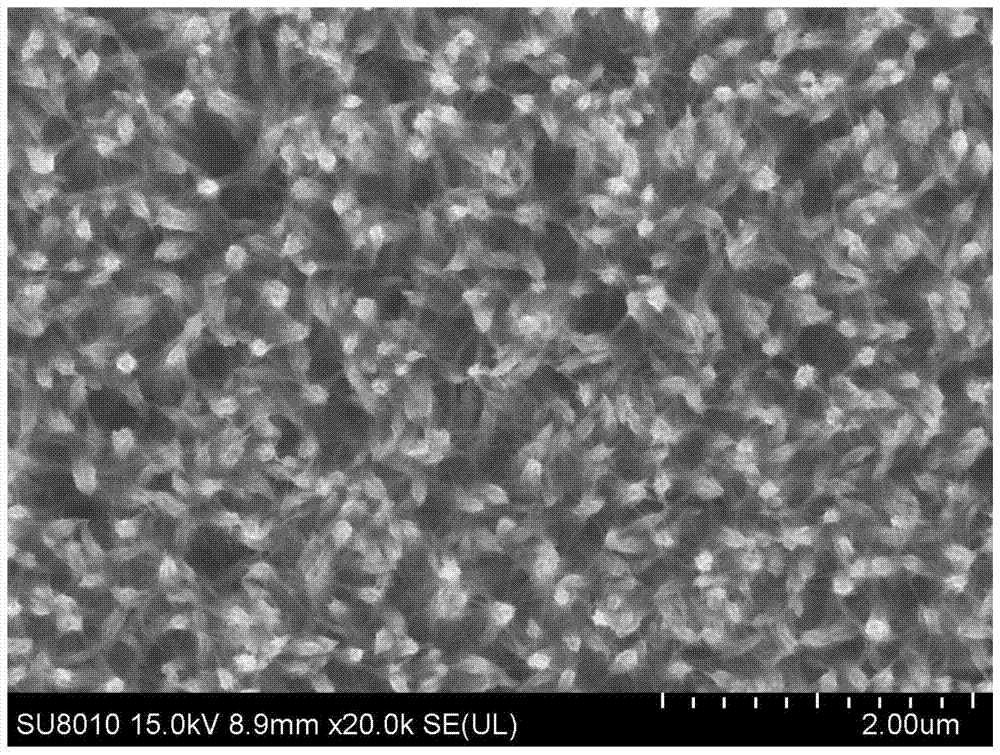

[0028] Implementation case 1: FTO (fluorine-doped tin oxide) conductive glass was ultrasonically cleaned in the order of acetone, alcohol and deionized water for 20 minutes; 1mL of tetrabutyl titanate and 0.269g of anhydrous citric acid were added to 30mL of deionized water. And 30mL hydrochloric acid (mass ratio 36-38%) mixed solvent, continue to stir until uniformly mixed; use a pipette to measure 10mL of the newly prepared solution and transfer to a volume of 20mL PTFE-lined stainless steel high pressure In the kettle, place the cleaned FTO conductive glass with the conductive surface facing down in the inner lining of the autoclave, then seal the autoclave and place it in an oven, raise the temperature to 150°C in 20 minutes, and keep it at this temperature for 6 hours. After the reaction is over, after the reaction is naturally cooled to room temperature, take out the sample from the autoclave and wash it with deionized water and alcohol, and then dry the cleaned sample in ...

Embodiment example 2

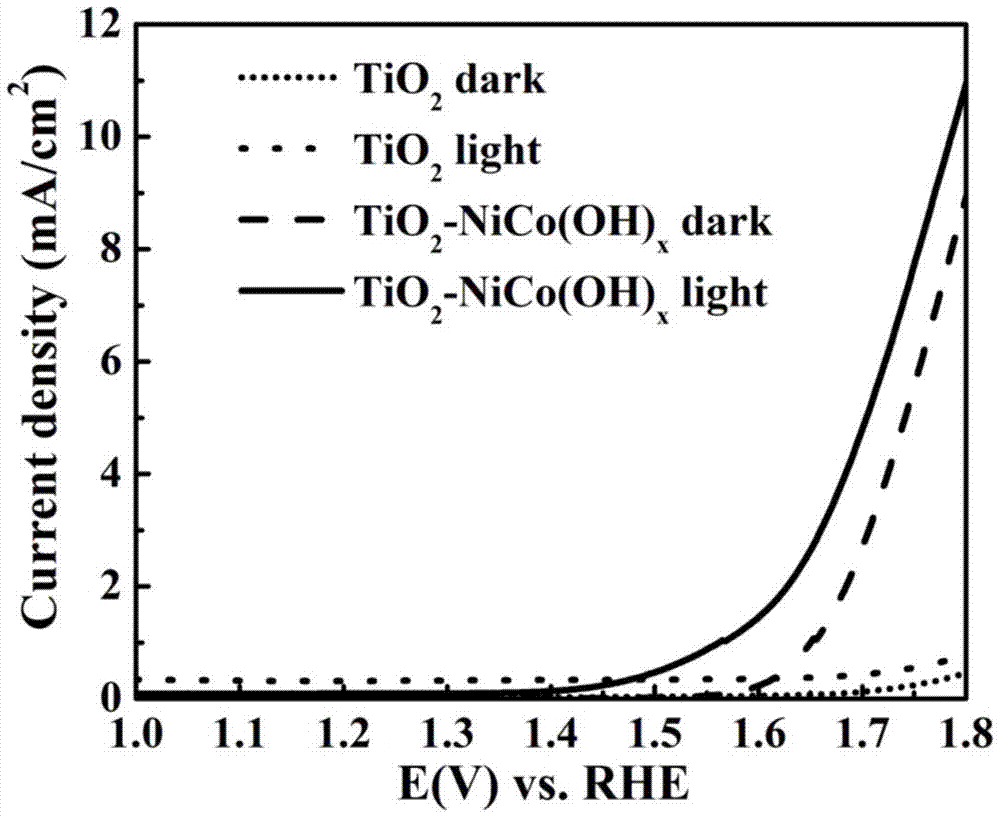

[0029] Implementation case 2: FTO (fluorine-doped tin oxide) conductive glass was ultrasonically cleaned in the order of acetone, alcohol and deionized water for 20 minutes; 1mL of tetrabutyl titanate and 0.269g of anhydrous citric acid were added to 30mL of deionized water And 30mL hydrochloric acid (mass ratio 36-38%) mixed solvent, continue to stir until uniformly mixed; use a pipette to measure 10mL of the newly prepared solution and transfer to a volume of 20mL PTFE-lined stainless steel high pressure In the kettle, place the cleaned FTO conductive glass with the conductive surface facing down in the inner lining of the autoclave, then seal the autoclave and place it in an oven, raise the temperature to 150°C in 20 minutes, and keep it at this temperature for 6 hours. After the reaction is over, after the reaction is naturally cooled to room temperature, take out the sample from the autoclave and wash it with deionized water and alcohol, and then dry the cleaned sample in t...

Embodiment example 3

[0030] Implementation case 3: FTO (fluorine-doped tin oxide) conductive glass was ultrasonically cleaned in the order of acetone, alcohol and deionized water for 20 minutes; 1mL of tetrabutyl titanate and 0.269g of anhydrous citric acid were added to 30mL of deionized water And 30mL hydrochloric acid (mass ratio 36-38%) mixed solvent, continue to stir until uniformly mixed; use a pipette to measure 10mL of the newly prepared solution and transfer to a volume of 20mL PTFE-lined stainless steel autoclave Place the cleaned FTO conductive glass with the conductive surface facing down in the inner lining of the autoclave, then seal the autoclave and place it in an oven, raise the temperature to 150°C in 20 minutes, and keep it at this temperature for 6 hours. After cooling to room temperature, take out the sample from the autoclave and clean it with deionized water and alcohol. Then dry the cleaned sample in the air at 60°C for 2 hours. In order to improve the crystallinity of titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com