Texturing method of polysilicon solar cell

A solar cell, polysilicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor light trapping effect, high cost of precious metals, and difficult to remove precious metal impurities, and achieves efficiency improvement, improved light trapping effect, and convenience. Fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

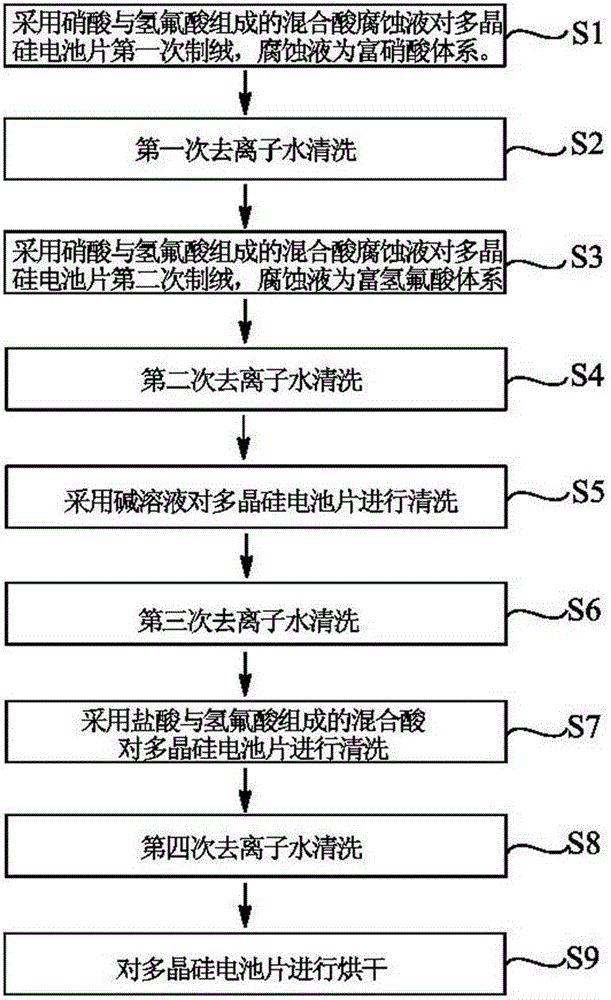

[0027] A method for making texture of polycrystalline silicon solar cells, using a specific ratio of mixed acid etching solution, according to the following steps to carry out two times of texturing, the mixed acid etching solution is composed of HNO3, HF and H2O:

[0028] A. Use the mixed acid etching solution of rich nitric acid system to carry out the first texture making to polycrystalline silicon solar cells, the mass concentration of nitric acid in the described mixed acid etching solution is greater than the mass concentration of hydrofluoric acid;

[0029] B. Use deionized water to clean the polycrystalline silicon solar cells after the A step of texturing;

[0030] C. Using a mixed acid etching solution rich in hydrofluoric acid to perform second texturing on the polycrystalline silicon solar cells, the mass concentration of hydrofluoric acid in the mixed acid etching solution is greater than that of nitric acid.

[0031] Further, in the step A, the mass concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com