Method for preparing high efficiency solar cell with stereostructure

A solar cell and three-dimensional structure technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low conversion efficiency, high price, and limited capacity, and achieve high conversion efficiency, large short-circuit current, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

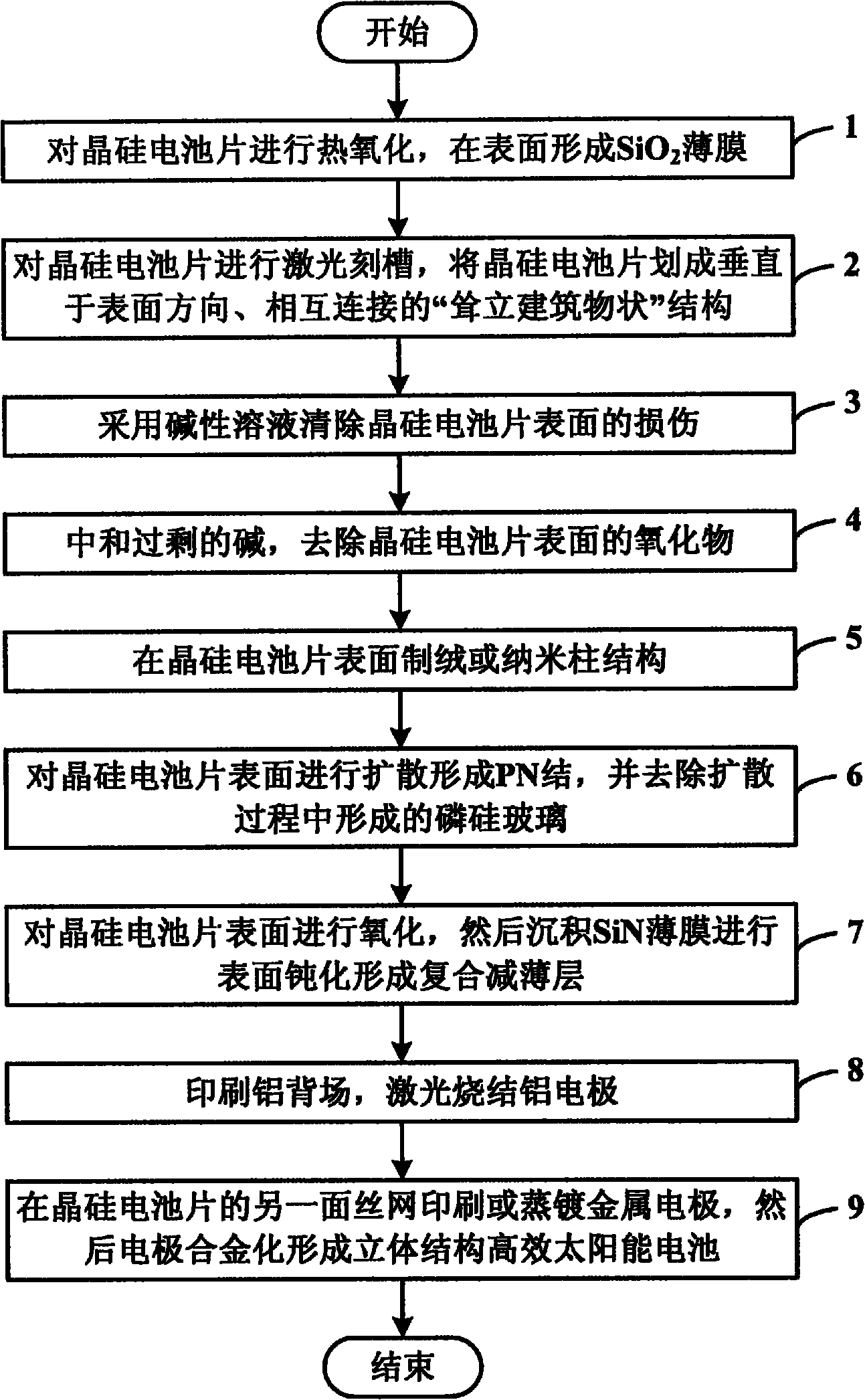

[0044] Such as figure 1 as shown, figure 1 A flow chart of the method for preparing a three-dimensional structure high-efficiency solar cell provided by the present invention, the method includes the following steps:

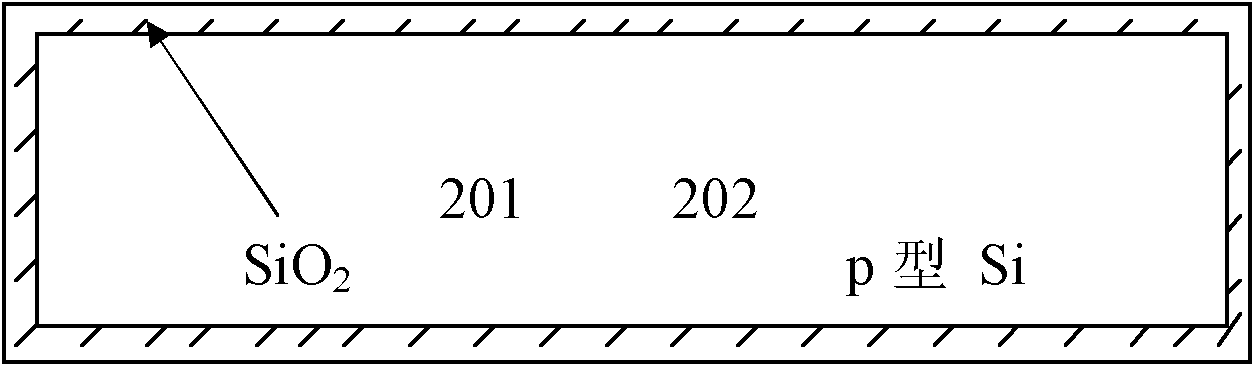

[0045] Step 1: Thermal oxidation of crystalline silicon cells to form SiO on the surface 2 film;

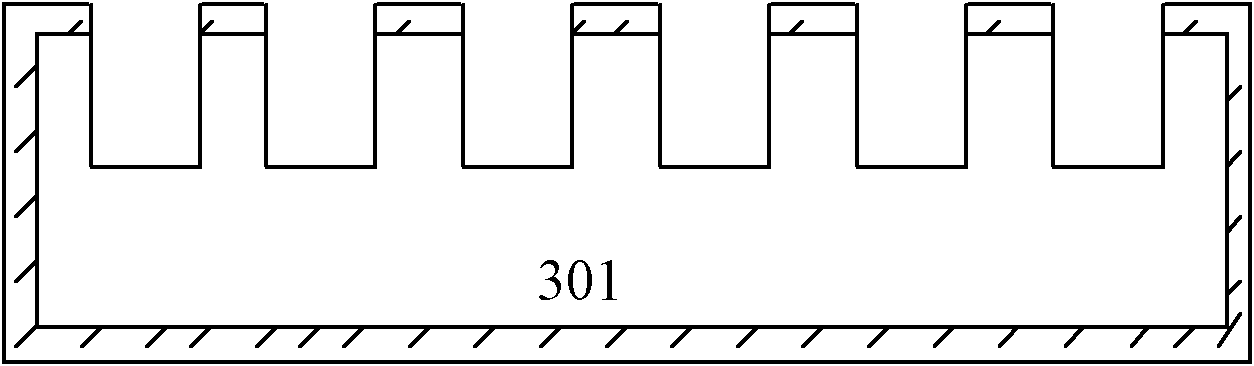

[0046] Step 2: Cover SiO 2 Thin-film crystalline silicon cells are laser-grooved, and the crystalline silicon cells are divided into vertical and interconnected "tower-like" structures;

[0047] Step 3: Use an alkaline solution to remove the damage on the surface of the crystalline silicon cell;

[0048] Step 4: Use an acidic solution to neutralize excess alkali to remove oxides on the surface of crystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com