Patents

Literature

59 results about "Aluminium electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound corrosion inhibitor of alkaline electrolyte of alkaline aluminium battery, electrolyte and preparation method of compound corrosion inhibitor

ActiveCN102088115AExtended service lifeImprove work efficiencyAlkaline accumulatorsIndiumAluminium electrode

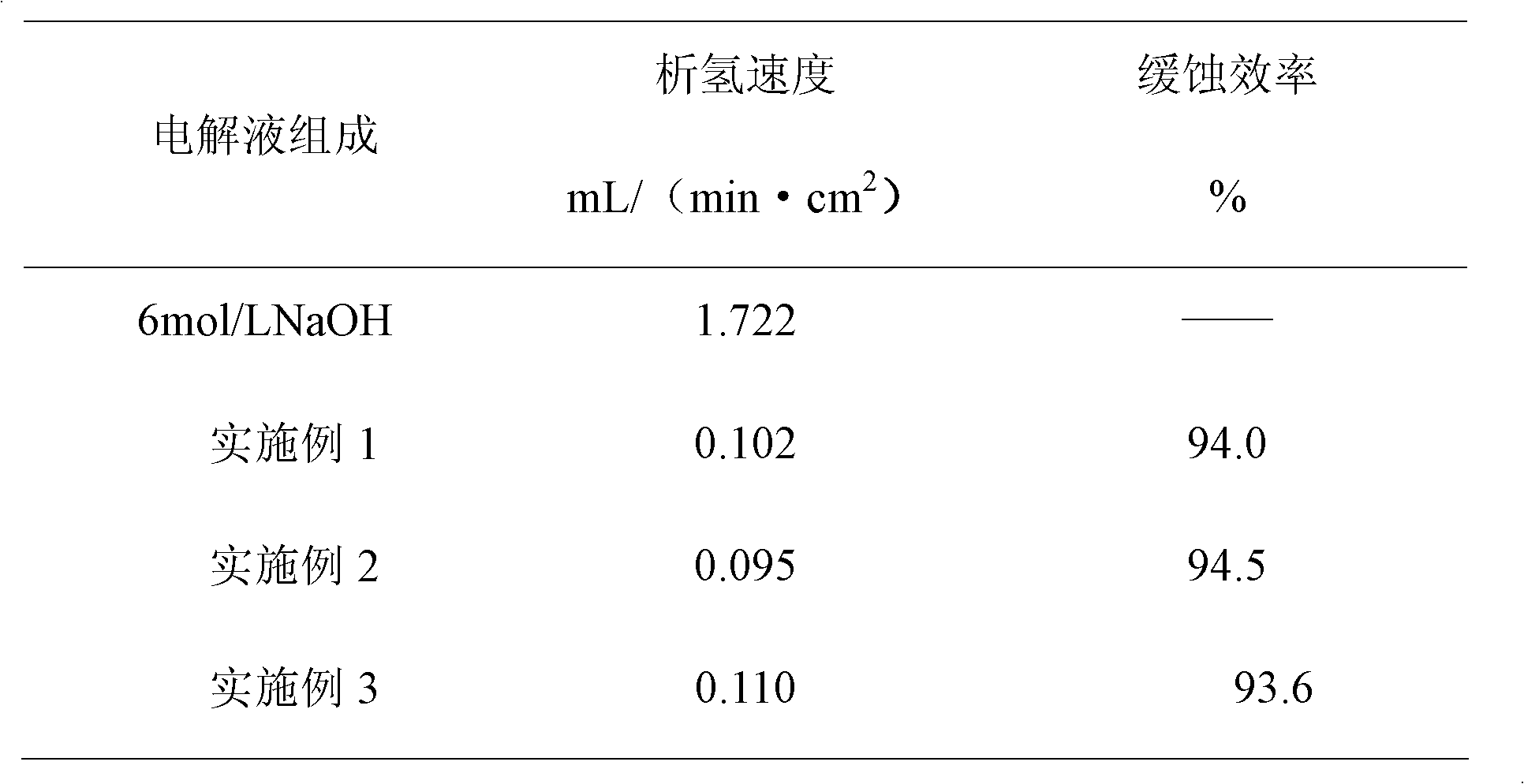

The invention discloses a compound corrosion inhibitor of an alkaline electrolyte of an alkaline aluminium battery, an electrolyte and a preparation method thereof. The compound corrosion inhibitor of the alkaline electrolyte of an alkaline aluminium battery is compounded by an inorganic corrosion inhibitor and an organic corrosion inhibitor, wherein the inorganic corrosion inhibitor comprises the following components based on the concentration: 0.015-0.1mol / L sodium stannate, 0.005-0.05mol / L of indium hydroxide, 0.03-0.1mol / L sodium citrate, 0.003-0.05mol / L calcium oxide and 0.02-0.1mol / L zinc oxide; the organic corrosion inhibitor comprises the following components by weight percent: 0.01-0.1wt% of chitosan derivant and 0.05-0.5wt% of organic surface active agent. The compound corrosioninhibitor can effectively prevent an aluminium electrode from corroding in an alkaline solution, and the electrochemistry performance of an aluminium anode is not affected.

Owner:CENT SOUTH UNIV

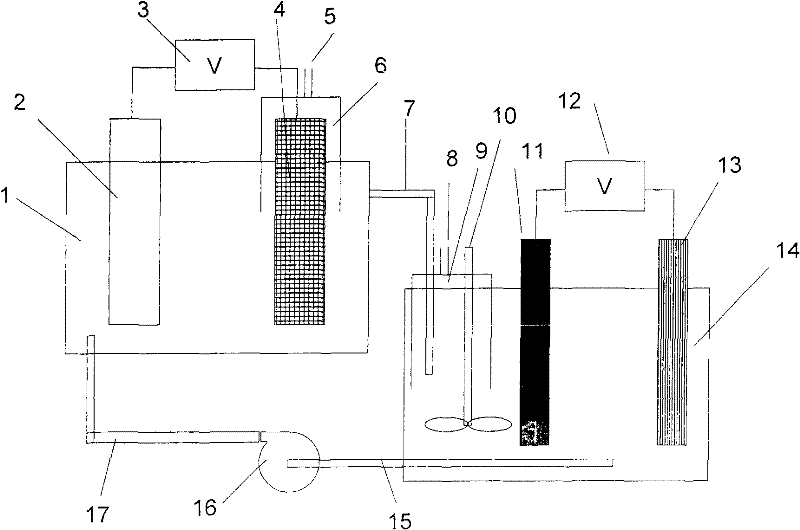

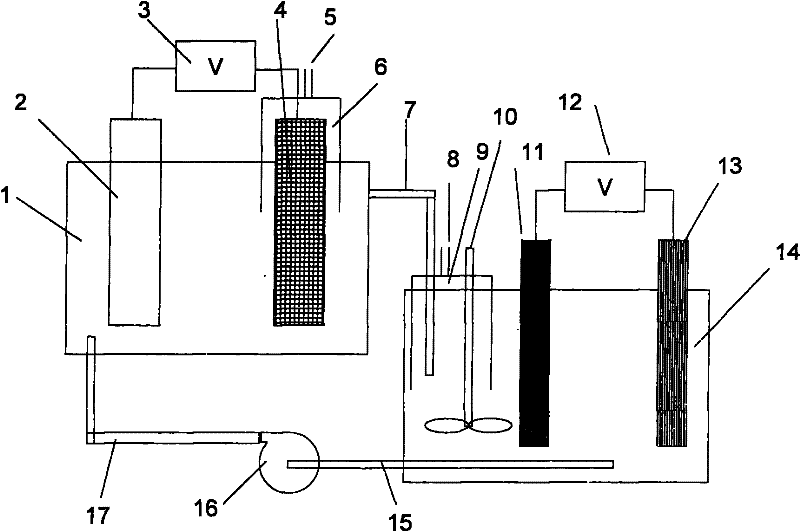

Electrochemical reactor for simultaneously removing arsenic and fluorine pollutant in water and method

ActiveCN101386433AEfficient removalAvoid passivationWater/sewage treatmentElectrochemical responseElectricity

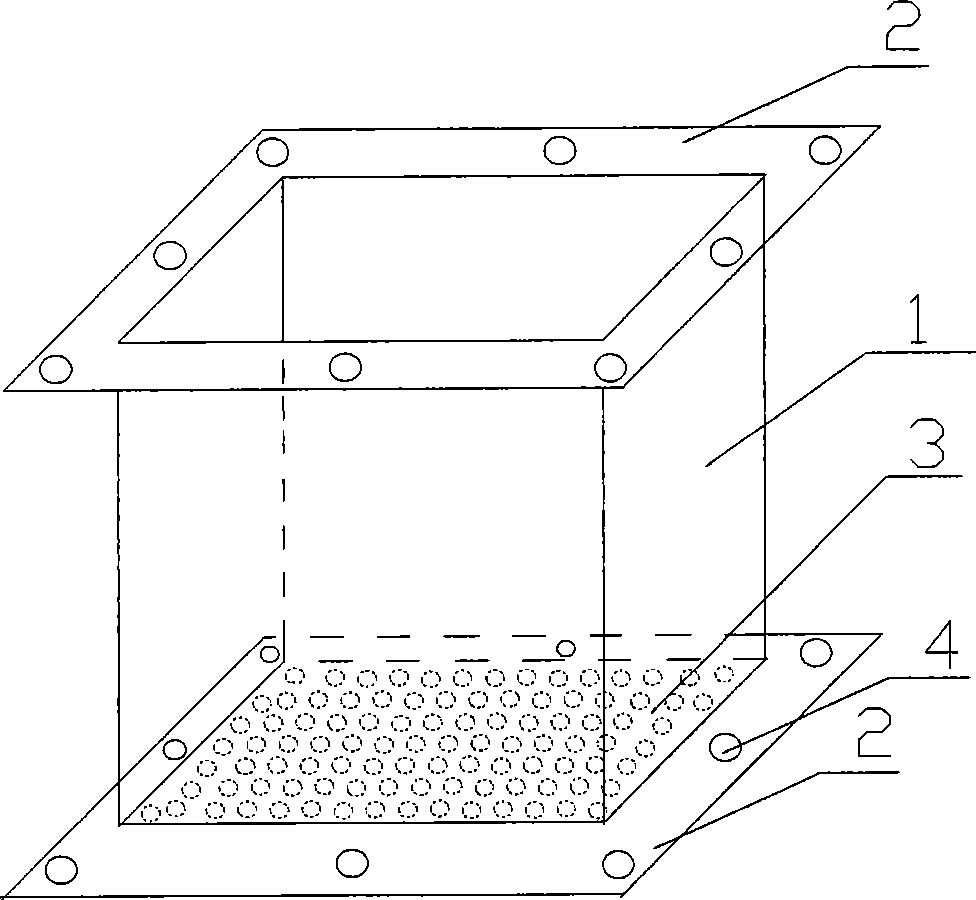

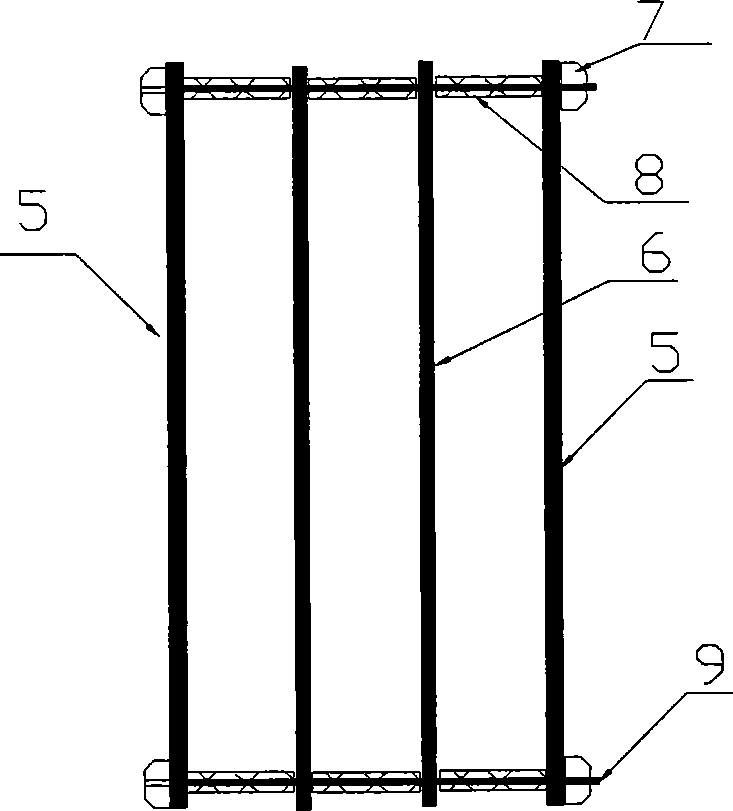

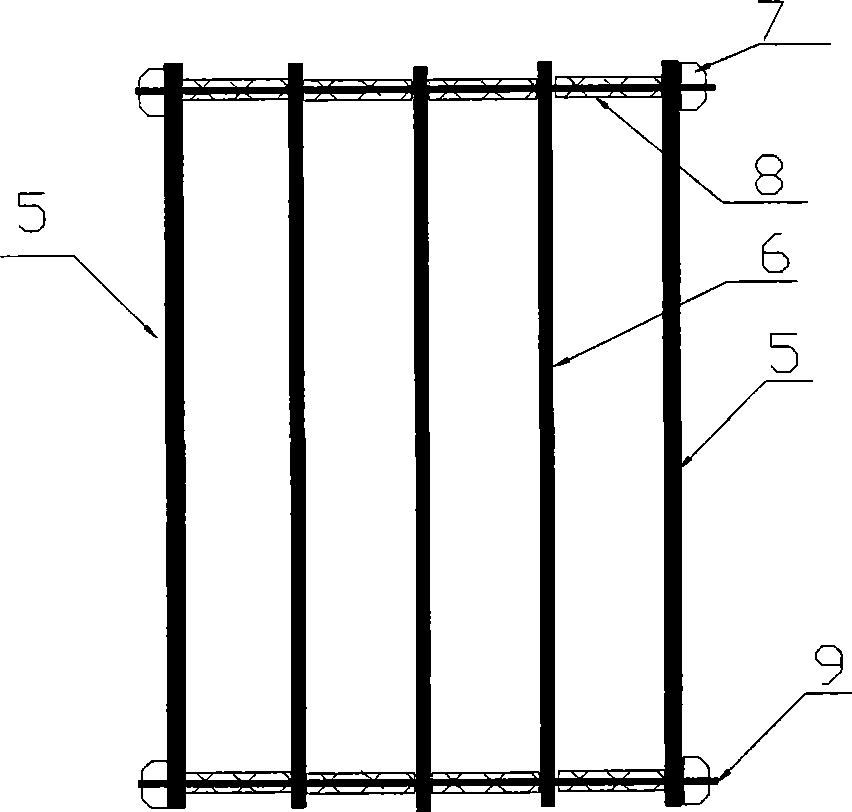

The invention relates to an electrochemical reactor and a method which can remove arsenic and fluorin pollutants in water at the same time. Ferrum and aluminium electrodes are coupled, ferrum and aluminium ions are generated by electric induction and trivalent arsenic is converted into pentavalent arsenic by electrooxidation at the same time. Ferrum and aluminium ions generated through electrolysis further form ferrum and aluminium flocs, which respectively react with arsenic and fluorin pollutants in water to remove arsenic and fluorin pollutants in water at the same time. The bottom of an electric coagulation reactor of the invention is provided with a water distribution plate, the upper part of which is provided with dimensionally stable electrodes, ferrum plate electrodes and aluminium plate electrodes that are fixed to an insulating bar through an insulation spacer and nuts; the dimensionally stable electrodes, the ferrum plate electrodes and the aluminium plate electrodes alternate at intervals as an anode and a cathode, or as a cathode and an anode, and are arranged in the reactor in a parallel manner; wherein, the adjacent dimensionally stable electrodes are respectively connected with the anode and the cathode of a direct current power source and timed anode and cathode switch is carried out so as to improve the reaction efficiency of the electrode and inhibit passivation of the electrode. The method can be applied to remove arsenic and fluorin pollutants in drinking water respectively or at the same time.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Piezoelectric ceramic element of metal aluminium electrode and preparation method thereof

InactiveCN101714607AReduce manufacturing costImprove adhesion strengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionSlurryAluminium electrode

The invention discloses a piezoelectric ceramic element of a metal aluminum electrode and a preparation method thereof. The piezoelectric ceramic element of the metal aluminum electrode comprises PZT ceramic and a metal electrode sintered on the upper and lower surfaces of the PZT ceramic; the metal electrode at least has an aluminum electrode surface which is sintered on the PZT ceramic by using aluminum electrode slurry. Based on mass percentage, the prescription of raw materials of the aluminum electrode comprises 55-60% of metal aluminum powder, 12-15% of unleaded glass powder with low melting point, 14-18% of ethylcellulose bond, 1.0% of antioxidant assistant and the balance of organic solvent. The preparation method comprises the steps of preparing the aluminum electrode slurry, printing, sintering the aluminum electrode slurry on the surfaces of the PZT ceramic and polarizing the electric field. In the invention, the bonding strength between the aluminum electrode surface and the PZT piezo ceramic is improved through adjusting chemical components and the proportion of the organic bond in the aluminum electrode slurry, and by replacing the silver electrode with the aluminum electrode, the manufacturing cost of the piezoelectric ceramic element can be reduced greatly.

Owner:SOUTH CHINA UNIV OF TECH +1

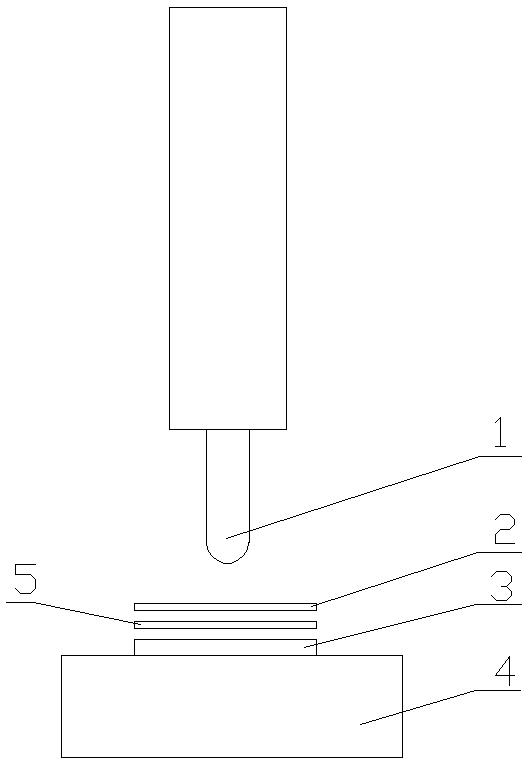

Resistance welding method

InactiveCN102133682AWon't stickExtended service lifeElectrode featuresElectrical resistance and conductanceAluminium electrode

The invention discloses a resistance welding method. When aluminum is spot-welded on a spot welding machine, the aluminum to be spot-welded is placed on a spot welding platform and is covered by a thin aluminum foil, the thin aluminum foil is covered by a thin copper foil, and welding parameters are adjusted to control a spot welding head to perform resistance spot welding. When a thin aluminum electrode is welded, the spot welding head is separated from the electrode by a thin copper sheet, and the part in contact with the spot welding head is the copper foil during welding, so that the welding head of the spot welding machine does not stick the thin aluminum electrode when the copper foil is used as a sacrificial layer. Therefore, after the copper foil is used as the sacrificial layer, the spot welding head does not stick the aluminum foil, so that the service life of the spot welding head is prolonged and the production efficiency is improved.

Owner:HUATING HEFEI POWER TECH

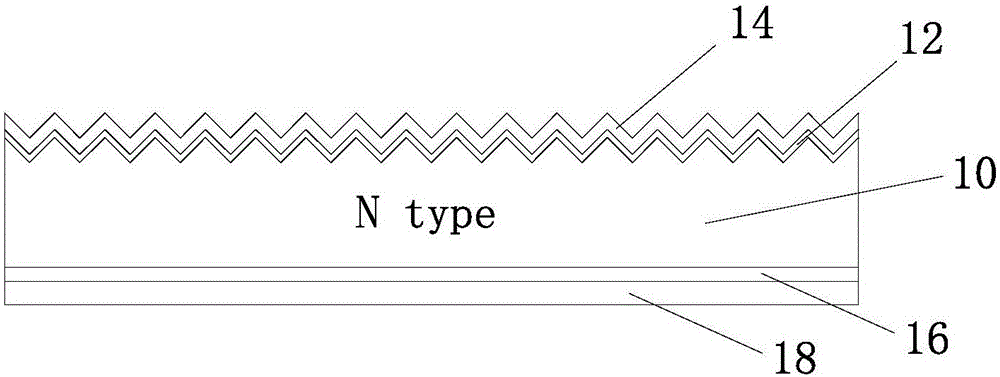

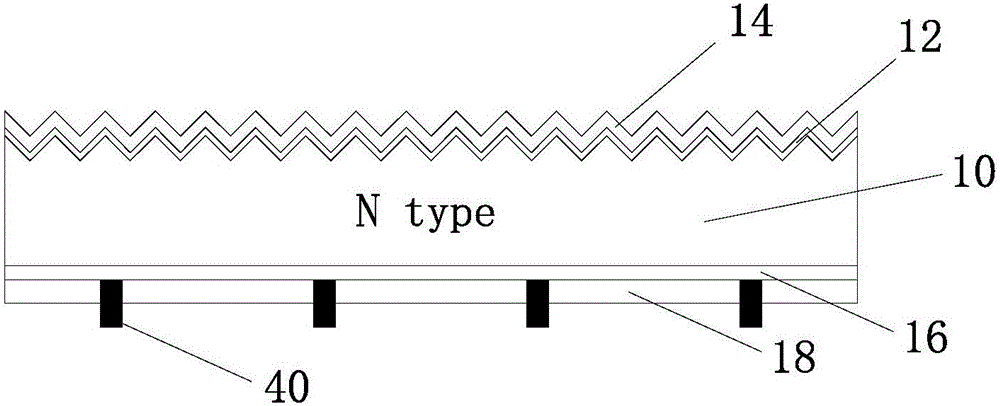

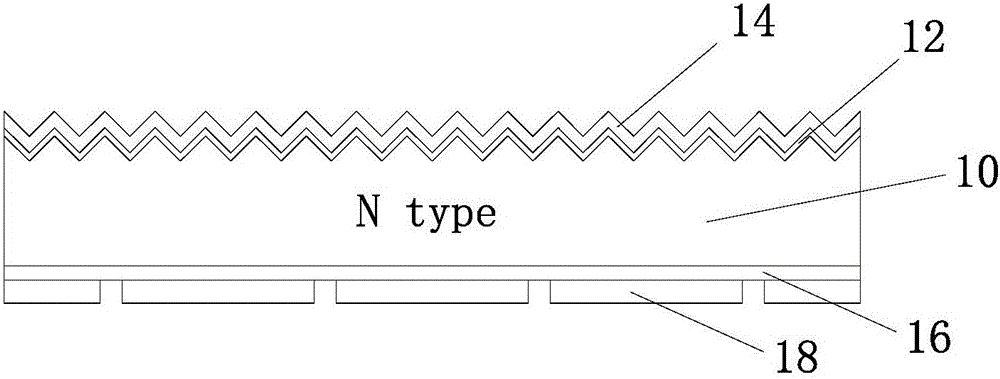

Preparation method of back junction N type solar battery, back junction N type solar battery, back junction N type solar battery assembly and back junction N type solar battery system

InactiveCN105702758AIncrease the open circuit voltageReduce consumptionFinal product manufacturePhotovoltaic energy generationSilver pasteAluminium electrode

The invention discloses a preparation method of a back junction N type solar battery, a back junction N type solar battery, a back junction N type solar battery assembly and a back junction N type solar battery system. According to the preparation method of the back junction N type solar battery, an N type crystalline silicon substrate is processed; a slotted structure penetrating a passivation film is formed on the back surface of the N type crystalline silicon substrate; aluminium paste is printed on the back surface of the N type crystalline silicon substrate, thus forming a back aluminium electrode; silver paste is printed on the back surface of the N type crystalline silicon substrate, thus forming a back silver master gate electrode; the silver paste is printed on the front surface of the N type crystalline silicon substrate, thus forming a front electrode; and sintering is carried out, thus forming the back junction N type solar battery. The method, the battery, the assembly and the system provided by the invention has the advantages that the passivation film on the back surface is slotted; the aluminium paste is printed; the aluminium paste forms partial contact with the p+ doped layer on the back surface, only at the location of the slotted pattern; compared with the method of printing the electrode by aluminium doped silver paste, the method provided by the invention has the advantages of improving the open-circuit voltage of the battery, greatly reducing silver paste consumption of the battery sheet and reducing the preparation cost of the battery sheet.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

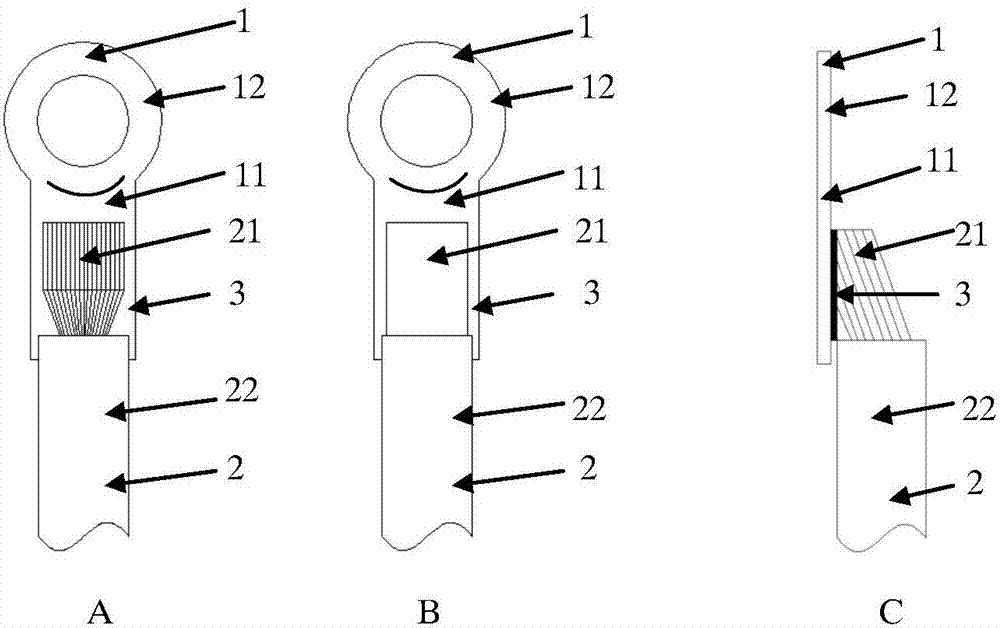

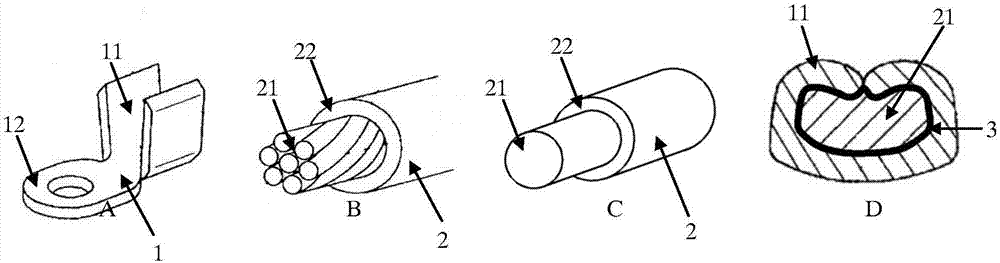

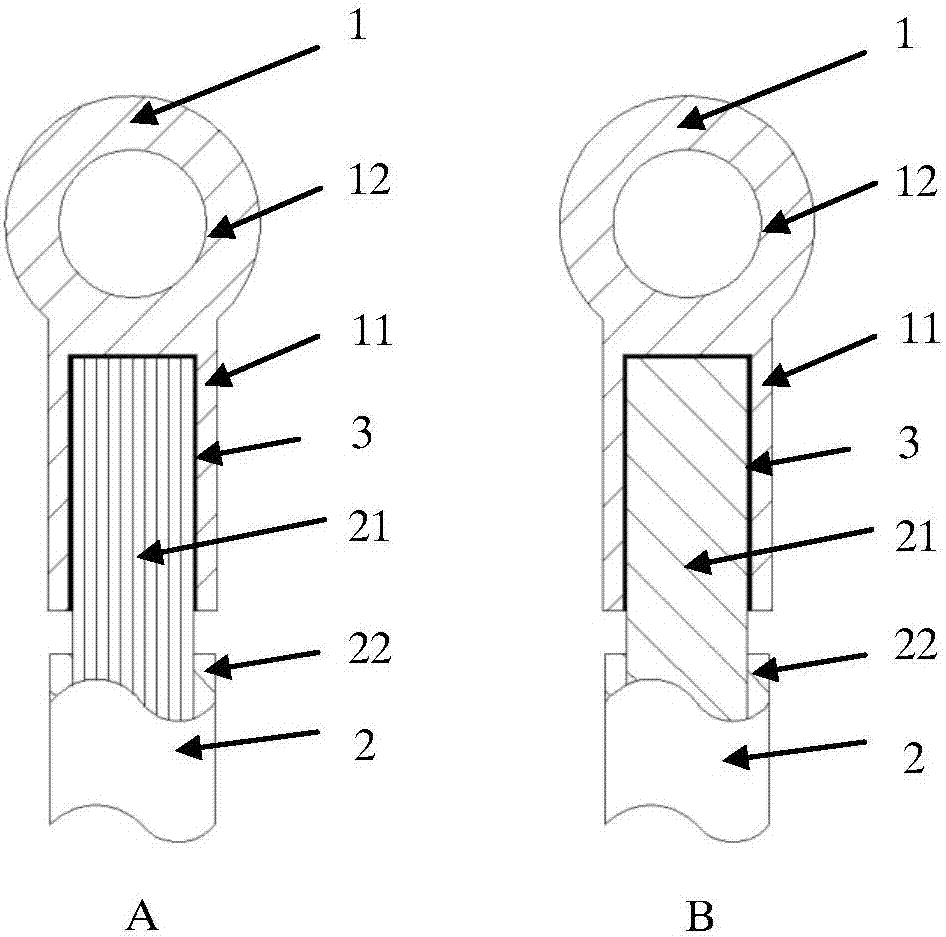

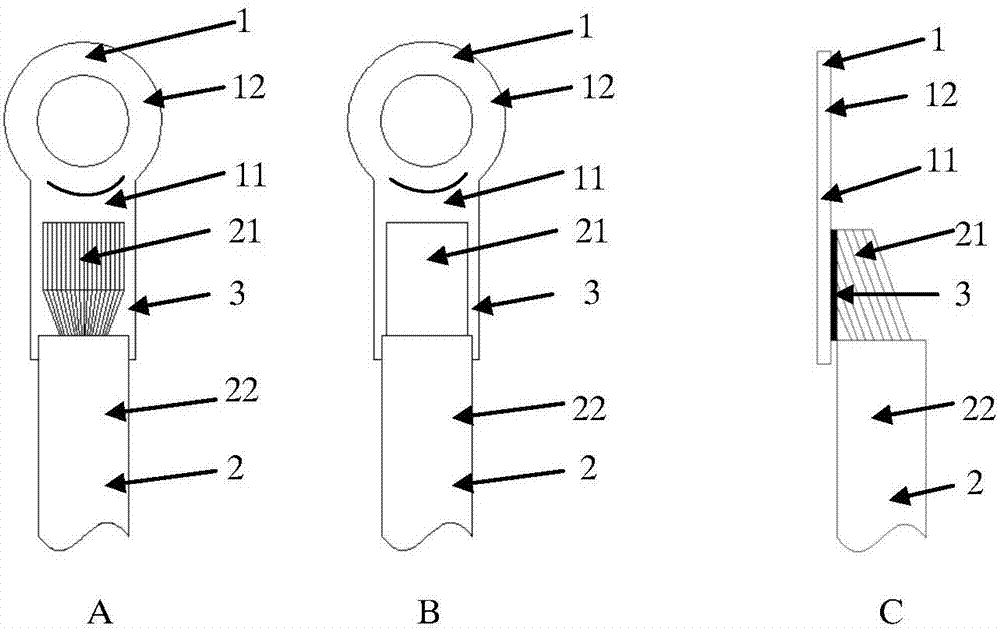

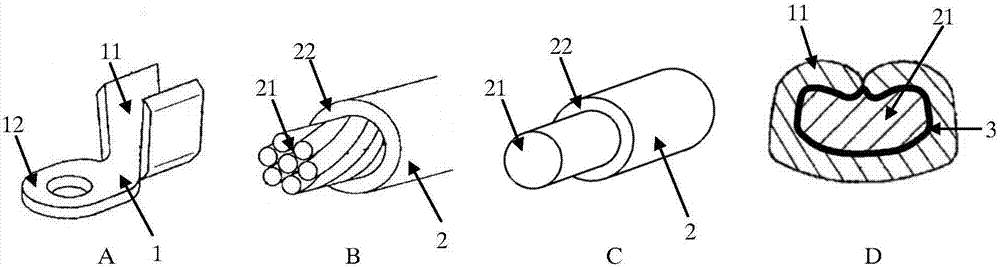

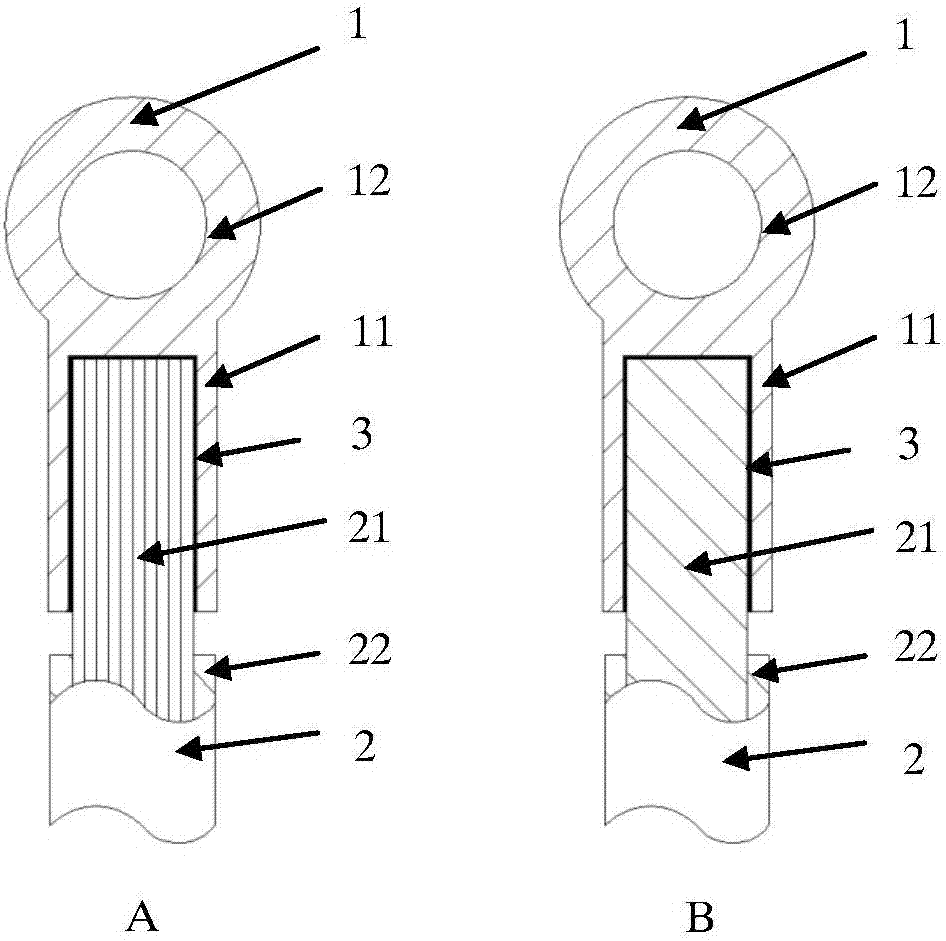

Junction for copper terminal and aluminium conductor and ultrasonic welding method thereof

ActiveCN107342466AGuaranteed mechanical propertiesGuaranteed electrical performanceCoupling contact membersSoldered/welded connectionsPotential differenceUltrasonic welding

The invention belongs to the field of a wiring hardness and specifically relates to a junction for a copper terminal and an aluminium conductor and an ultrasonic welding method thereof. In order to solve the problem that in the prior art, the electrochemical corrosion exists in the welding between the copper terminal and the aluminium conductor and the mechanical property of a welding junction is low, according to the junction and the method, a spacing metal layer is added between the copper terminal and the aluminium conductor. The spacing metal layer is fixed at a welding end of a base material in modes such as electroplating, pressure welding, electric arc spray welding or electromagnetic welding, and then the three parts: the spacing metal layer, the copper terminal and the aluminium conductor are welded together. The ultrasonic welding method provided by the invention is applicable to the welding of the copper terminal and the aluminium conductor and also applicable to the welding of various junctions. The electrochemical corrosion resulting from the potential difference of copper and an aluminium electrode can be effectively reduced. The mechanical property of the junction is improved.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

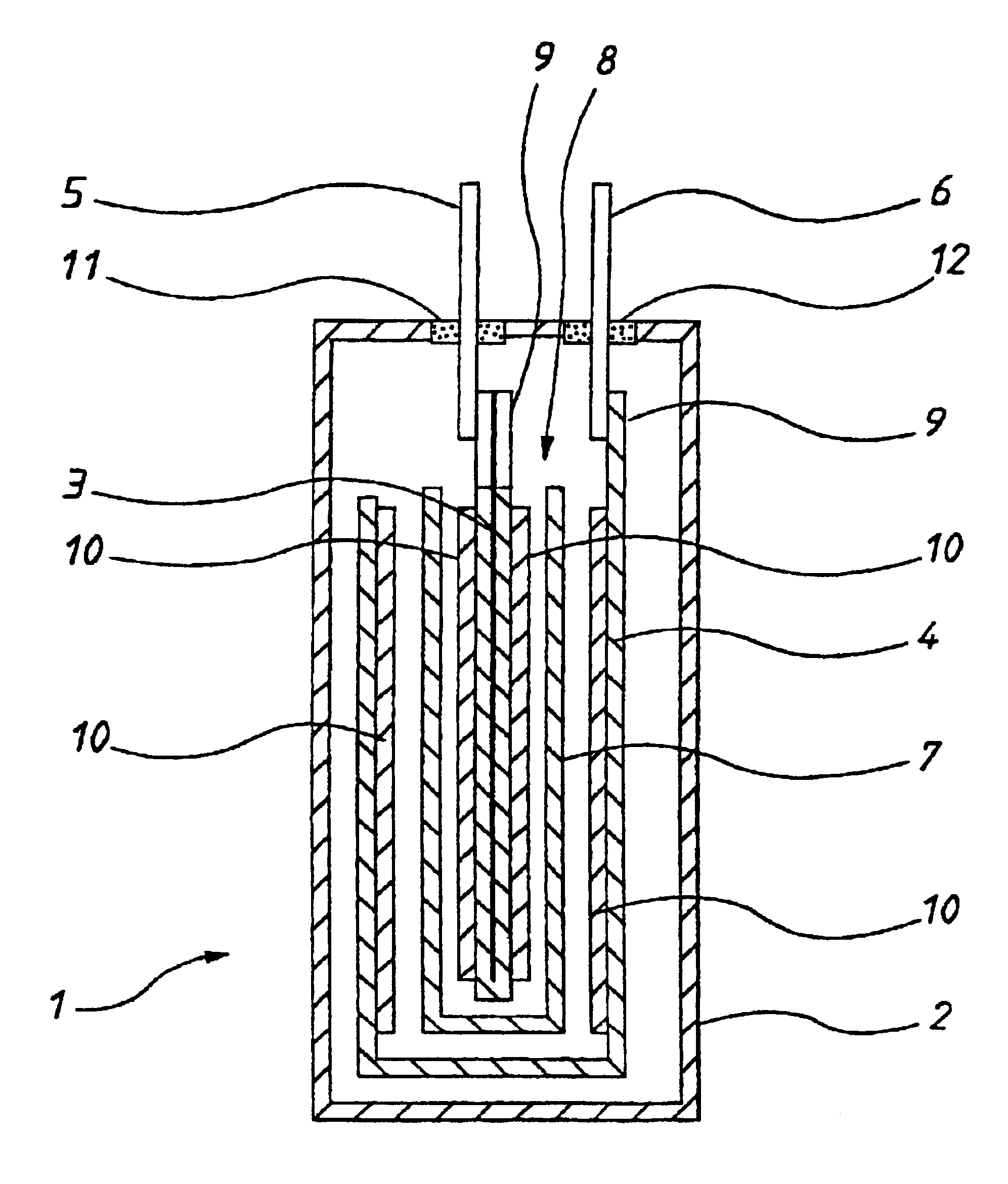

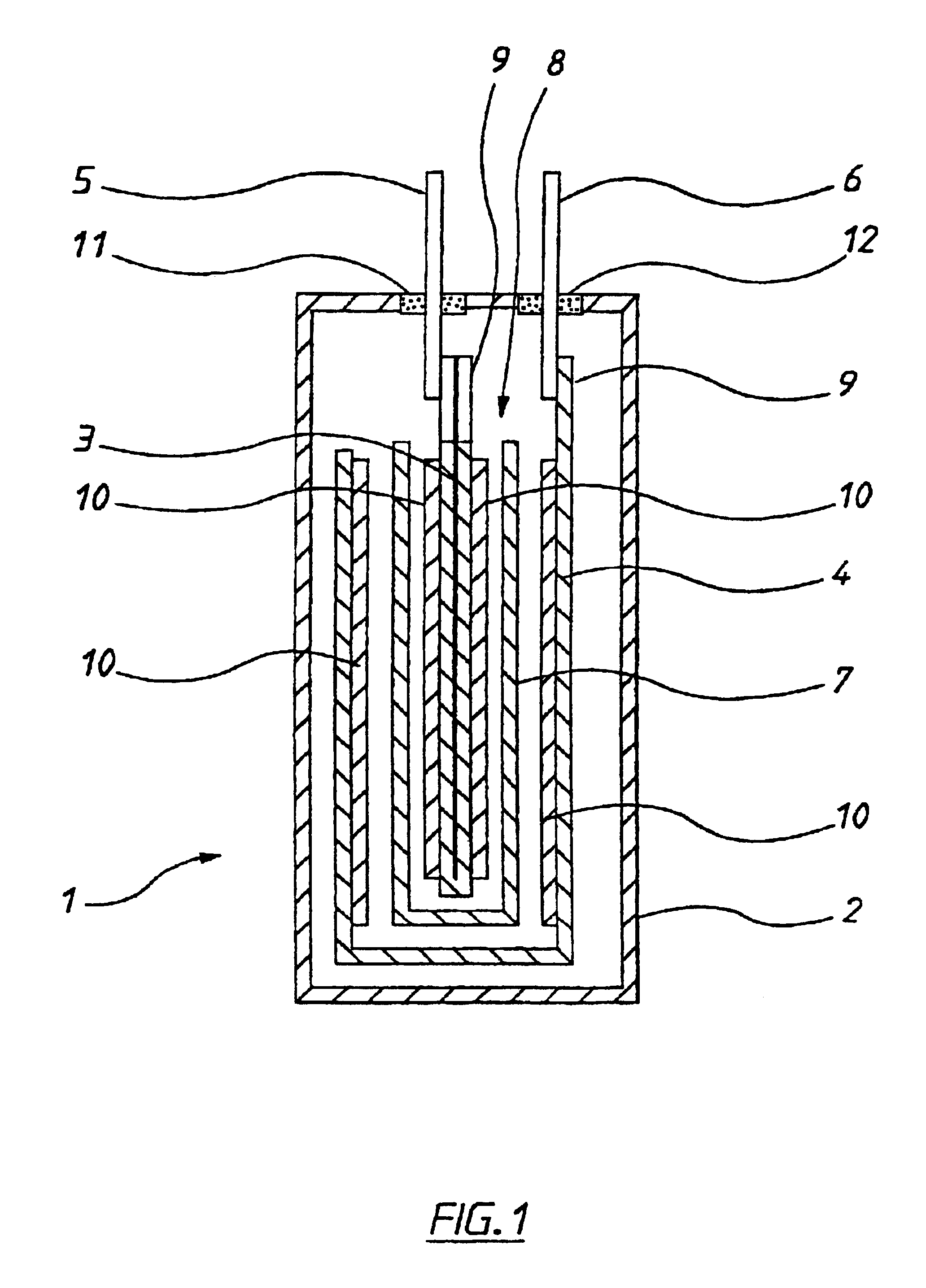

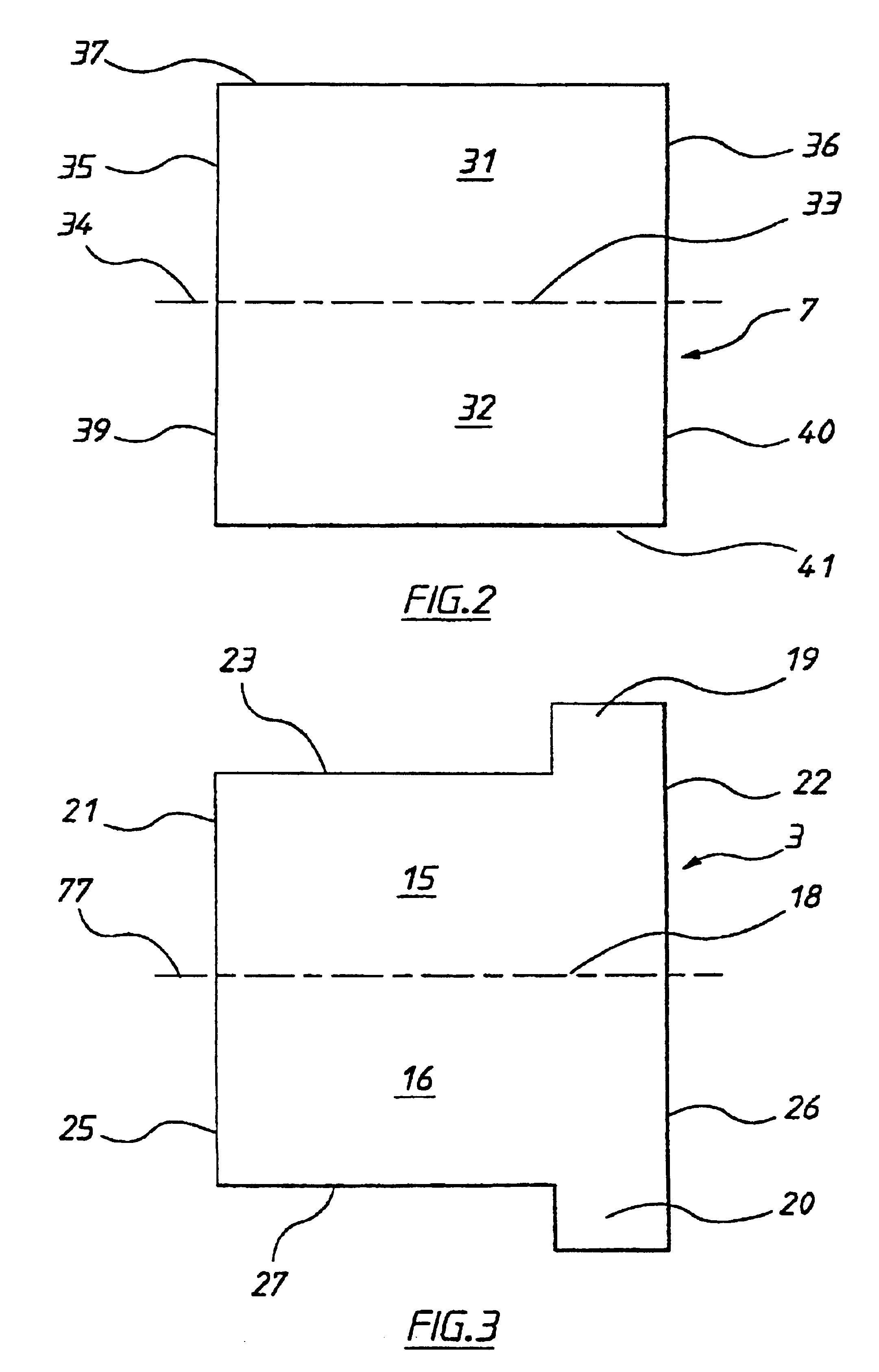

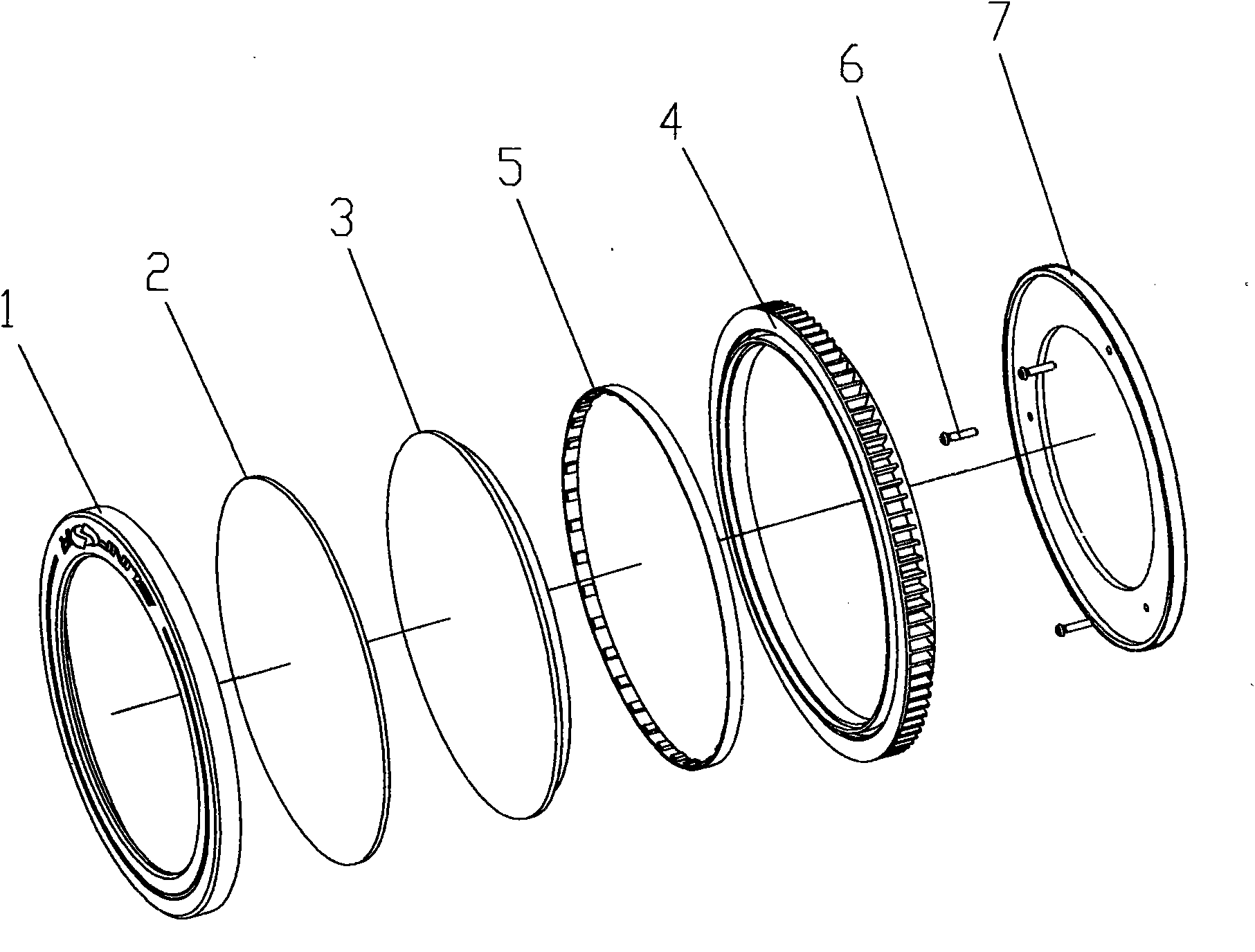

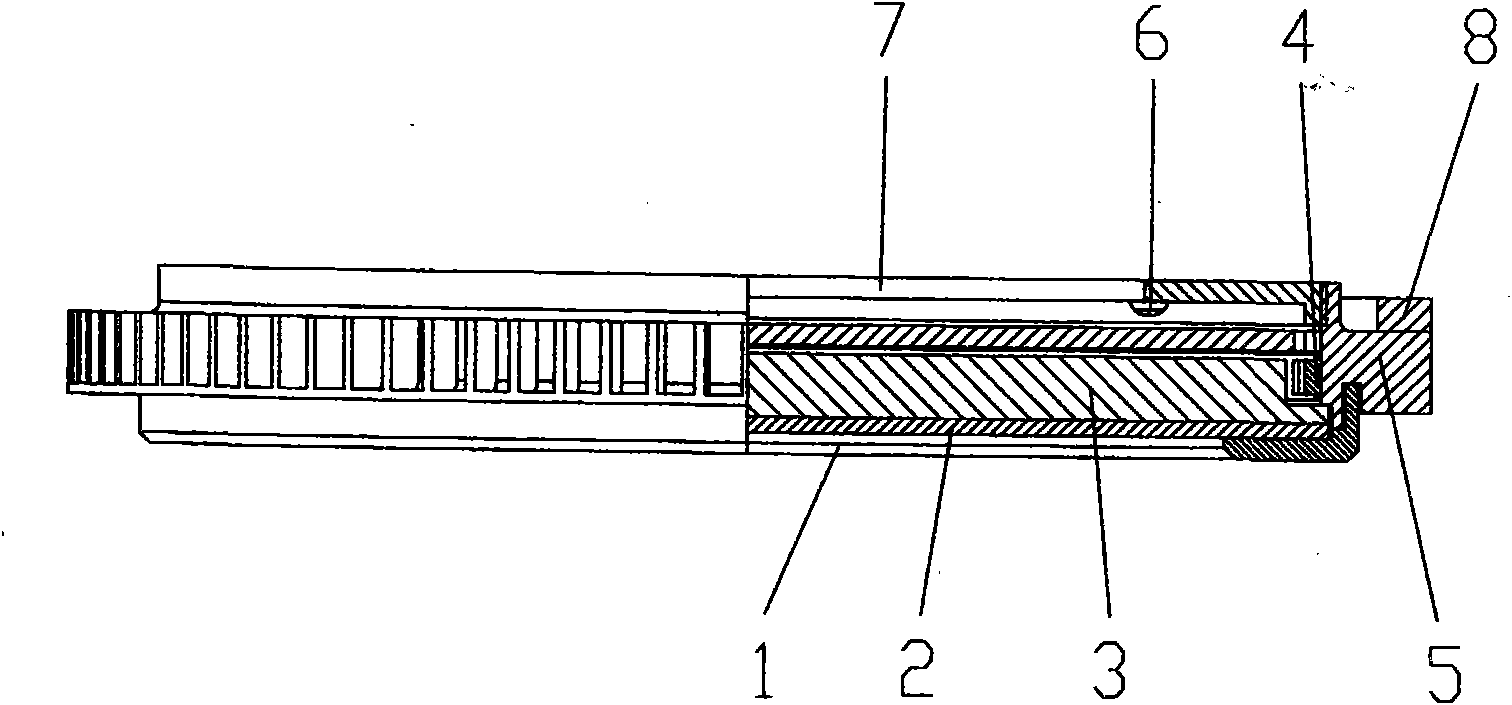

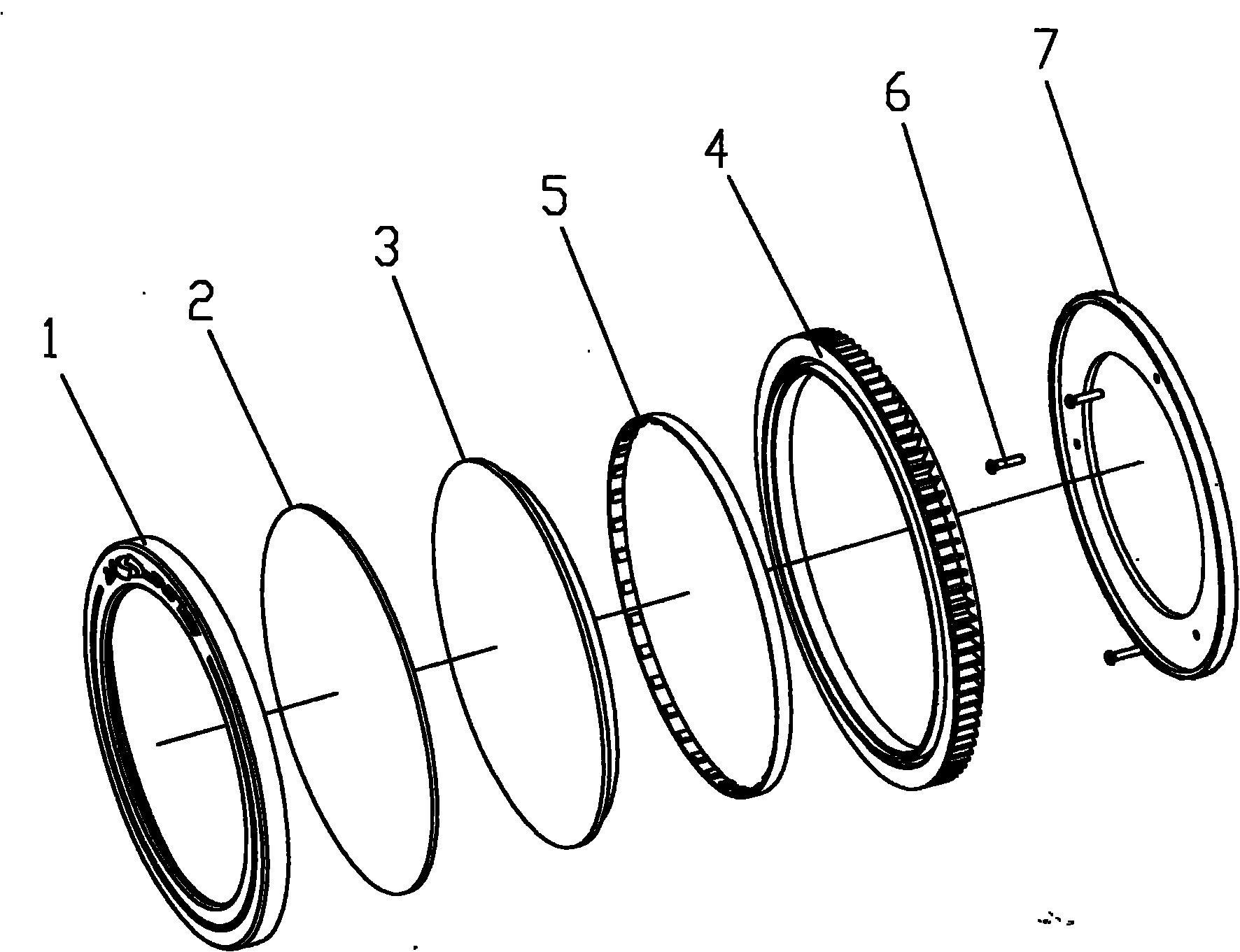

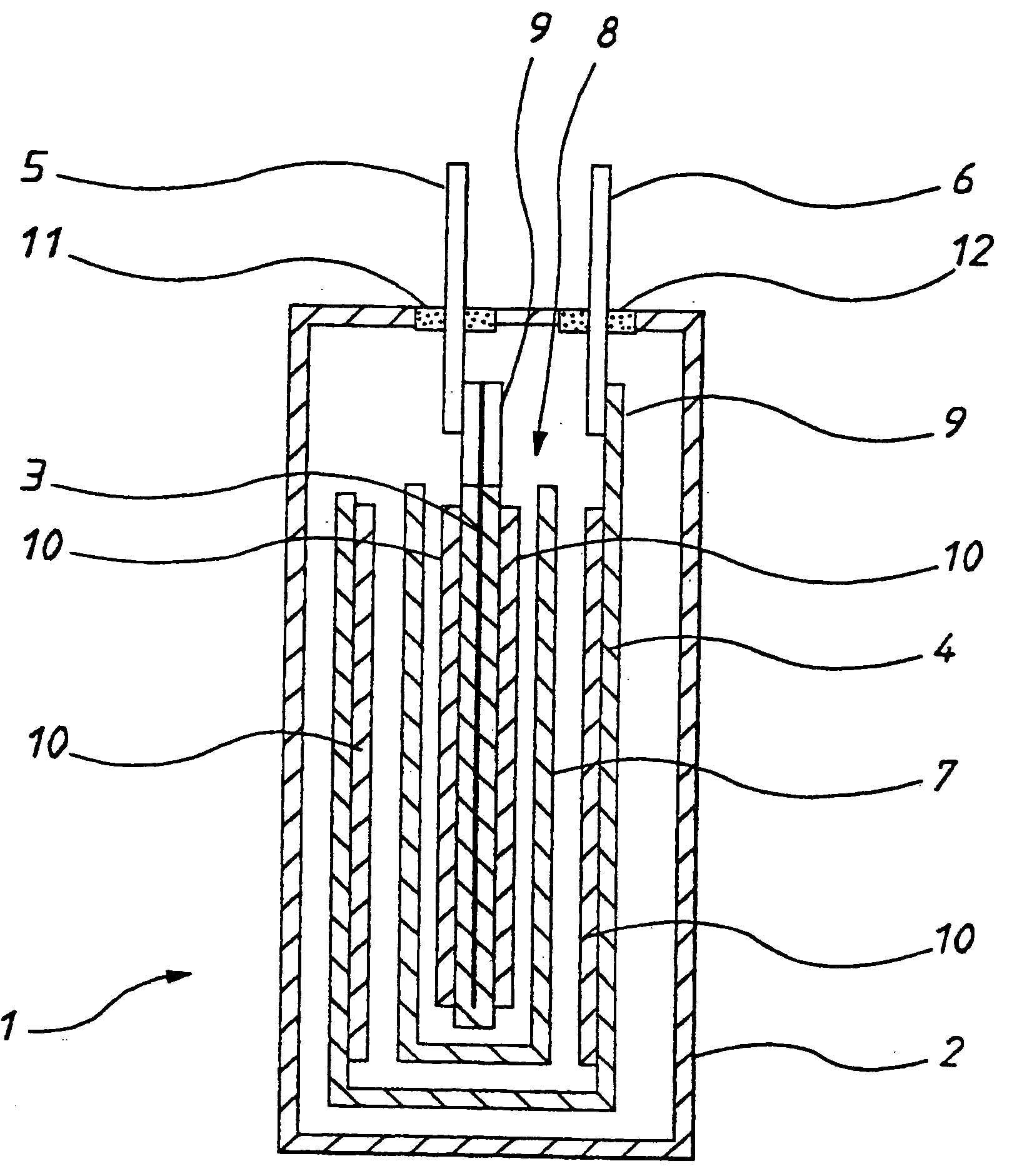

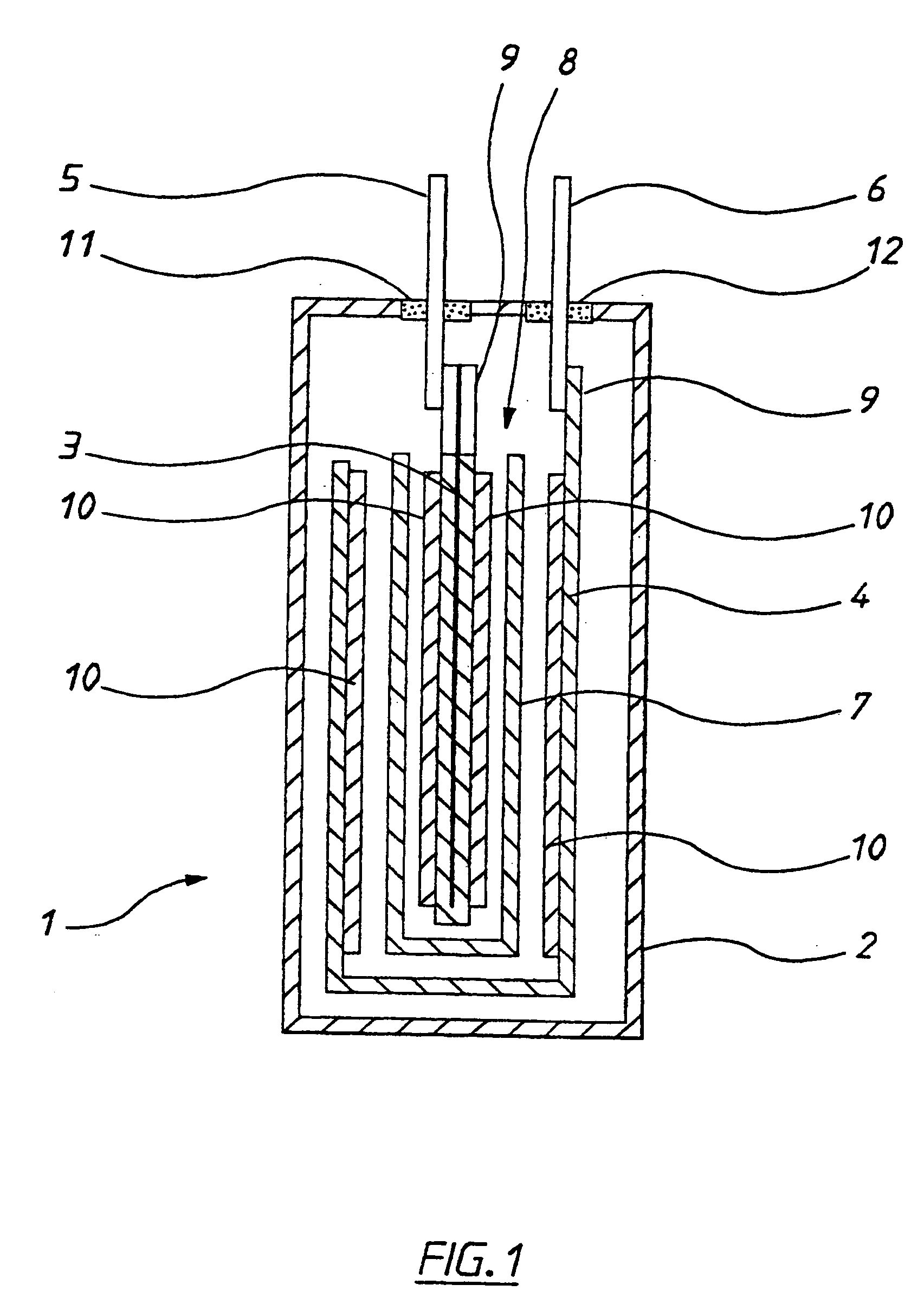

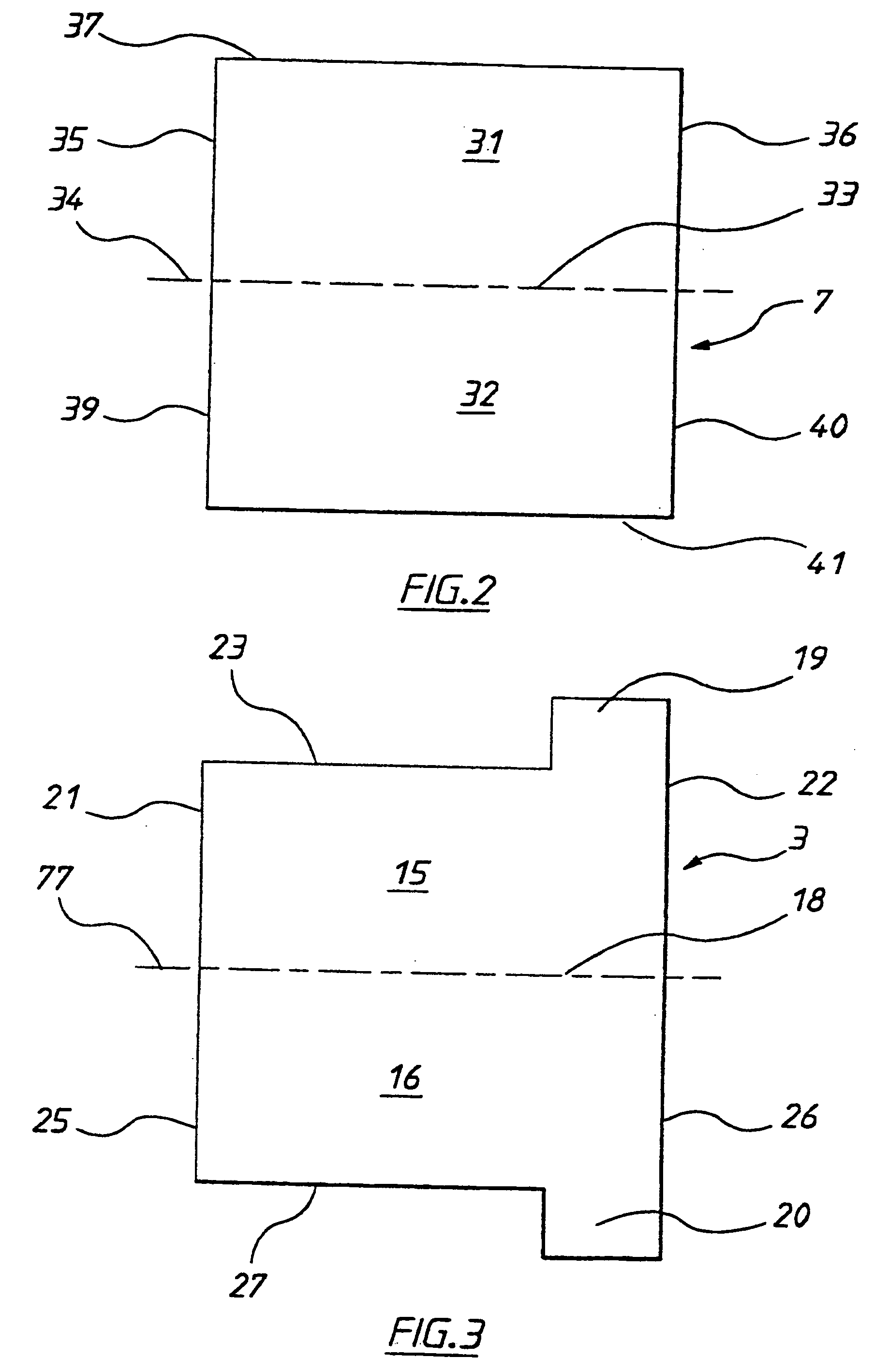

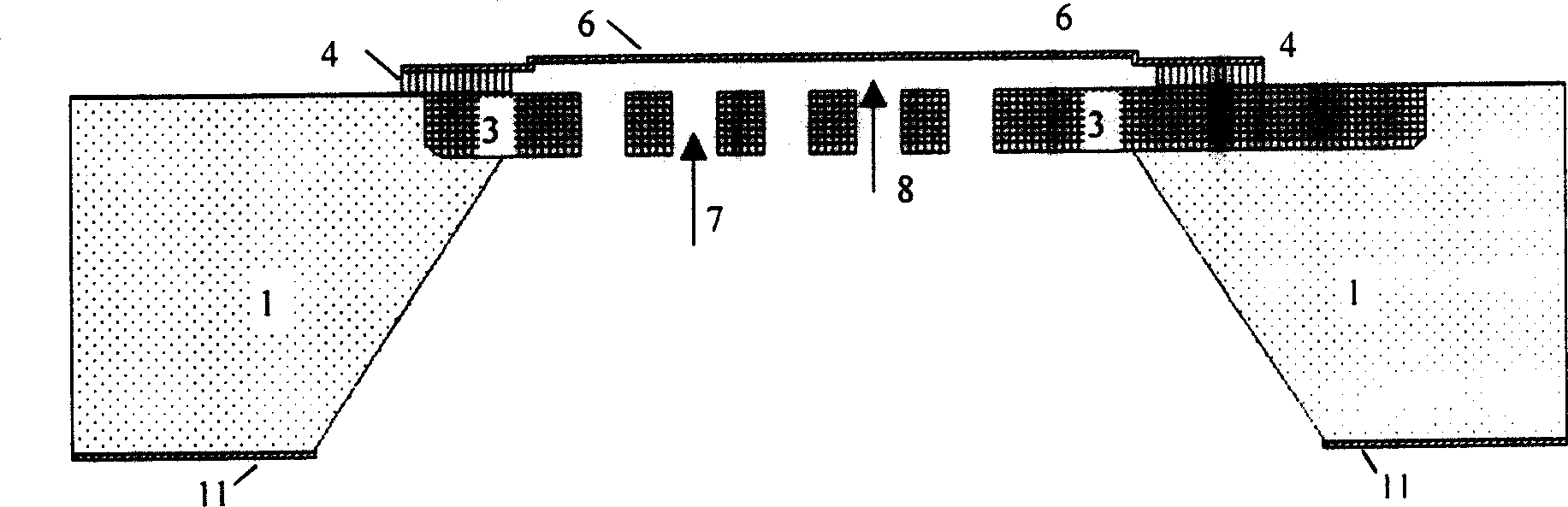

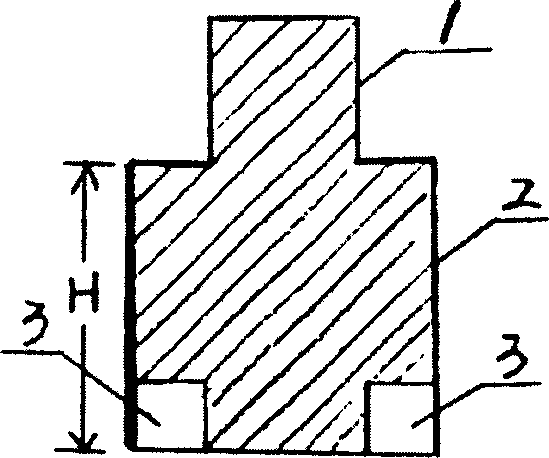

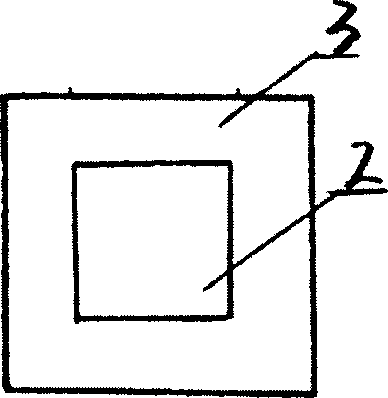

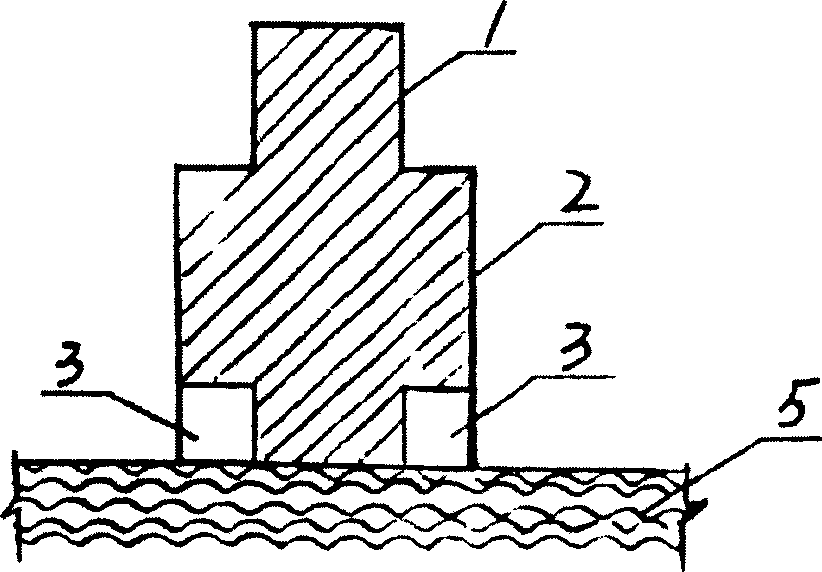

Charge storage device

InactiveUS6944010B1Overcome disadvantagesImprove disadvantagesHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersElectrical connectionAluminium electrode

A charge storage device (1) includes a sealed prismatic housing (2). Two opposed folded rectangular aluminium electrodes (3, 4) are disposed within housing (2) and connected to respective metal terminals (5, 6) for allowing external electrical connection to the electrodes. A porous, electronically insulating separator material, e.g. Solupor™, sheet separator (7) is disposed intermediate electrodes (3, 4) for maintaining those electrodes in a fixed spaced apart configuration. An electrolyte (not shown) is also disposed intermediate the electrodes. Collecting means in the form of a scavenging agent is grafted to separator (7) for sequestering one or more predetermined contaminants from the housing.

Owner:CAP XX LTD

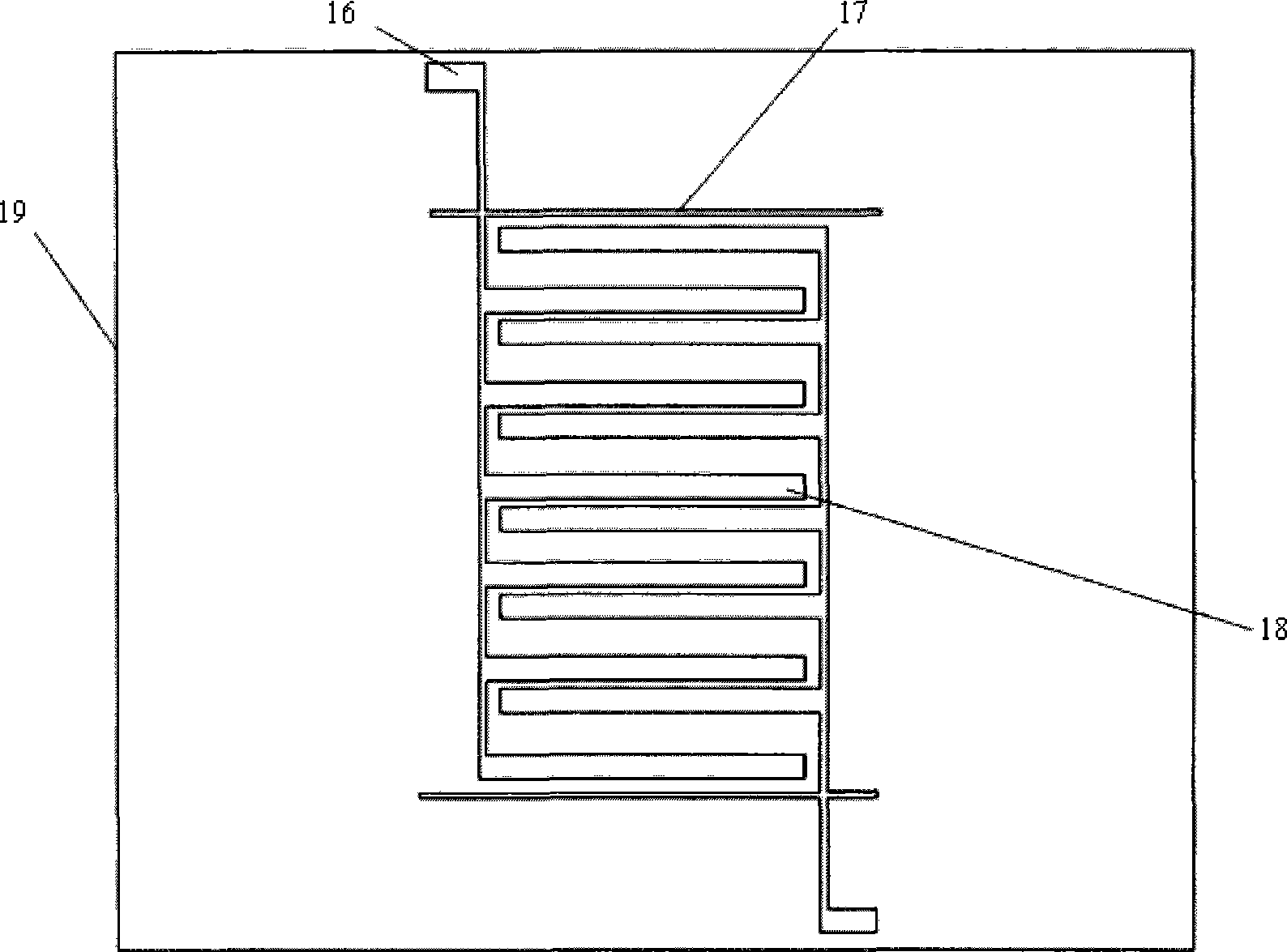

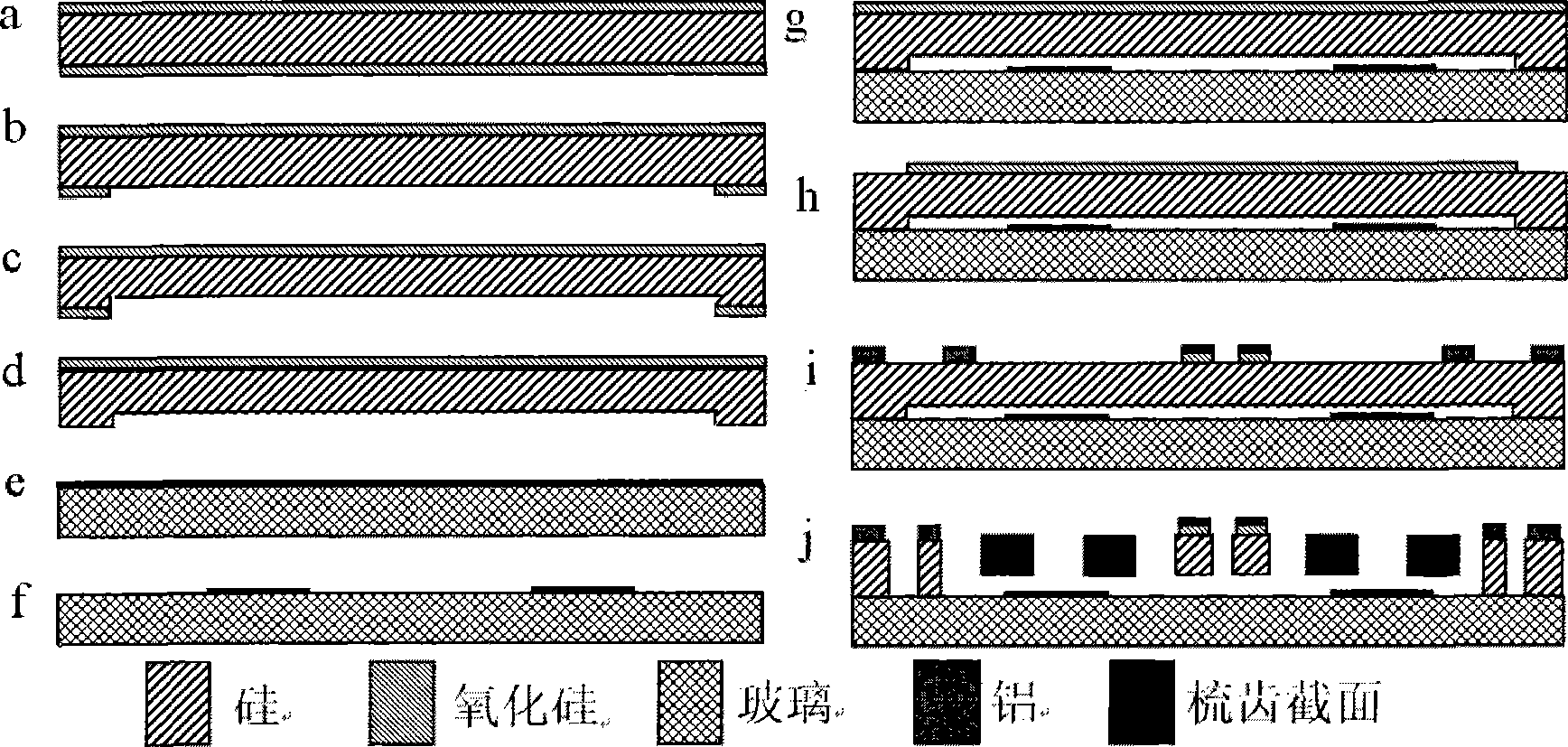

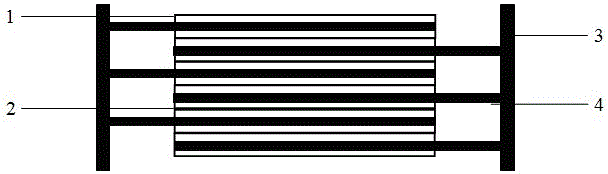

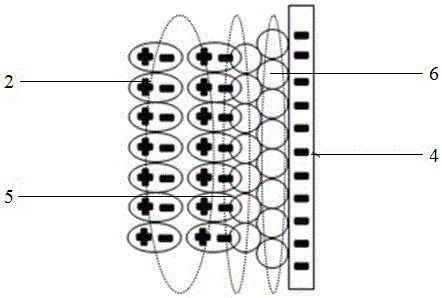

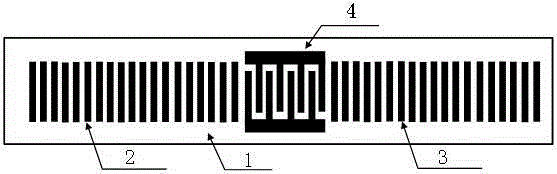

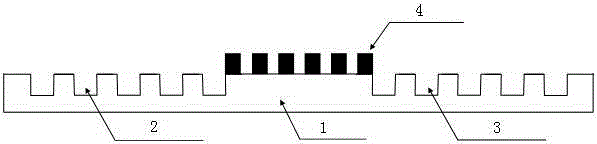

Magnetic drive micro-inertial sensor for increasing detection capacitance and preparation method

InactiveCN101531334AReduce air dampingChange rangeTelevision system detailsSemi-permeable membranesCapacitanceAluminium electrode

The invention discloses a magnetic drive micro-inertial sensor for increasing the detection capacitance and its preparation method. The mass increase of the sensor oscillator and the decrease of the pole plate distance are limited in the prior art. In the invention, the mass block of the sensor is the rectangle silicon chip with the grid-like strips, both ends are connected with the anchor point by the silicon support girder, both sides are respectively provided with silicon trips, a ring groove is arranged in the middle of the driver mass block, a detecting silicon strip is arranged at one side of the driver mass block corresponding to the sensor block, a driver welding point is arranged at the anchor position at the outer side of the driver mass block near the U-shaped girder, the driver welding point is connected with the driver anchor point, an external current driven welding points are arranged at two anchor points relative to the driver, a metal driven lead is arranged among the external current driven welding points. An interdigital aluminium electrode is arranged on the glass substrate surface, each grid-like strip of the sensor mass block is corresponding to each pair of fork finger in the interdigital aluminium electrode. The invention has simple technology, is beneficial for reducing the cost and the improving the yield rate.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

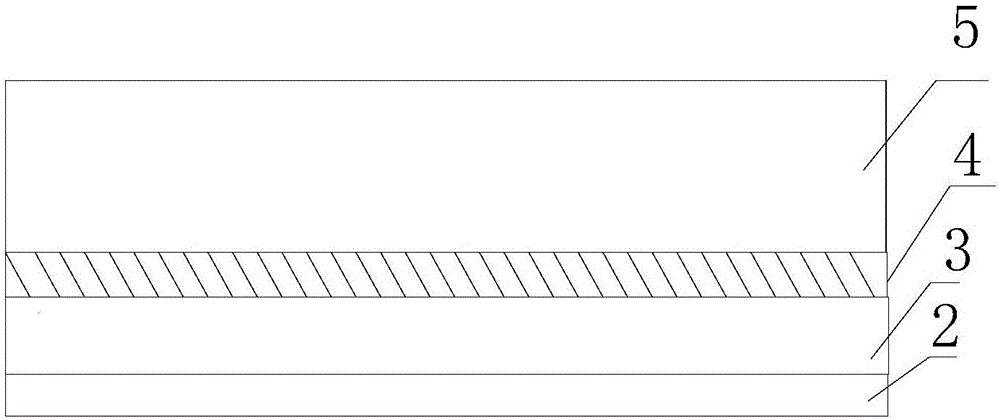

Al/Al2O3/BaTiO3 composite film super capacitor and preparation method thereof

ActiveCN105006373ATightly boundExcellent dielectric propertiesHybrid capacitor electrodesElectrolytic capacitorsComposite filmBarium titanate

The invention discloses an Al / Al2O3 / BaTiO3 composite film super capacitor and a preparation method thereof. An aluminium sheet is adopted to serve as an electrode material, triethanolamine is selected as a treatment fluid and will gradually disassociate, the surface of the aluminium electrode is dissolved in an alkali manner under the effect of the triethanolamine, and a reaction quickly occurs in a micropore of the aluminium electrode to produce a hydrated Boehmite AlO (OH) deposited film. The content of alumina in the film is increased, and the structure and the form generating alumina are changed by controlling the degree of oxidation treatment. A thin insulating layer is arranged between the electrode and barium titanate, so the dielectric loss of a dielectric layer is reduced, and then the capacity performance of the capacitor is improved. Moreover, the insulating layer can be closely combined with the barium titanate, so the density of the whole dielectric layer is increased, and thus leakage currents of the capacitor are minimized. Furthermore, the voltage-resistant Al / Al2O3 / BaTiO3 composite film super capacitor with high capacity is prepared through multilayer lamination.

Owner:OCEAN UNIV OF CHINA

Aluminium paste for laser pore-forming partial back contact-passivating emitter crystalline silicon solar cell and preparation method and application thereof

InactiveCN105405488AStrong adhesionDo not lose powderNon-conductive material with dispersed conductive materialPhotovoltaic energy generationScreen printingAluminium powder

The invention discloses an aluminium paste for a laser pore-forming partial back contact-passivating emitter crystalline silicon solar cell and a preparation method and an application thereof. The aluminium paste comprises the following components in percentage by weight: 50.00-75.00% of micro-size aluminium powder, 0.50-2.00% of glass powder, 15.00-30.00% of organic intermediate, 0.02-1.00% of inorganic additive and 1.00-2.50% of organic additive, and the sum of the components of the aluminium paste is 100% in percentage by weight. The required aluminium paste is prepared by steps of dosing, dual-planetary stirring, three-roller machine grinding, screening and filtering. When the aluminium paste is applied, the aluminium paste is printed on a monocrystalline wafer by a 325-mesh silk screen, and then the monocrystalline wafer is dried and sintered. An aluminium back field is formed in the pore-forming place in the back surface of the battery piece by the aluminium paste; the aluminium paste is relatively strong in adhesion with the passivating layer in the non-pore-forming places; and in addition, pill of aluminium or aluminium protruding parts are not formed on the surface of an aluminium film, so that the formed aluminium electrode is excellent in the electrical performance.

Owner:DK ELECTRONICS MATERIALS INC

Method for obtaining high-purity zinc by electrolyzing zinc chloride

InactiveCN102453926AAchieve recyclingSolve Post-Processing IssuesPhotography auxillary processesElectrolysisOver potential

The invention discloses a method for obtaining recyclable chlorine and high-purity metallic zinc by electrolyzing zinc chloride in an aqueous solution system; in the method, an anode is an RuTi coated electrode with low chlorine over-potential; a cathode is a polished aluminium electrode or a pure zinc sheet; electrolyte is a zinc chloride aqueous solution system added with proper sodium chloride and ammonium chloride as conductive salt; and deposition zinc, the Zn content of which is over 99.99%, can be obtained by controlling a proper electrolytic condition. The method disclosed by the invention is applied to the processes for recycling zinc-containing waste zinc, and the cyclic utilization of zinc and chlorine is realized in the technology process of directly generating zinc chloride waste.

Owner:ORISI SILICON +1

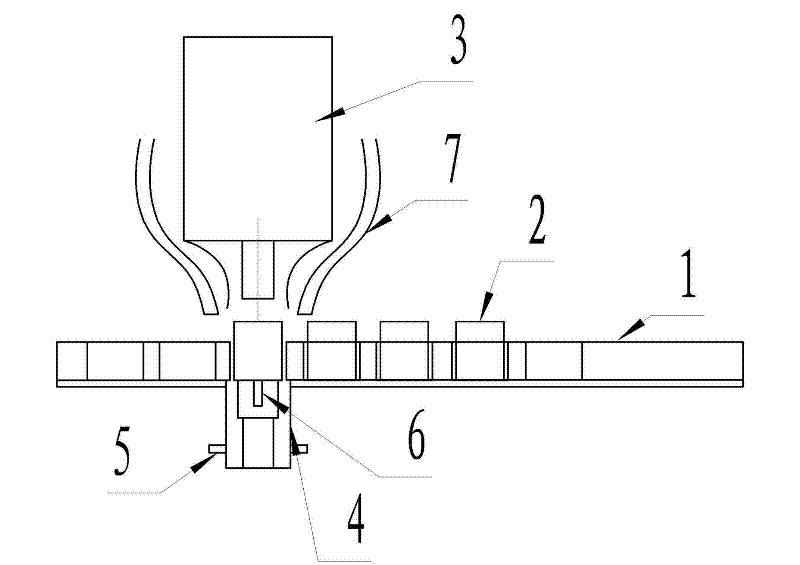

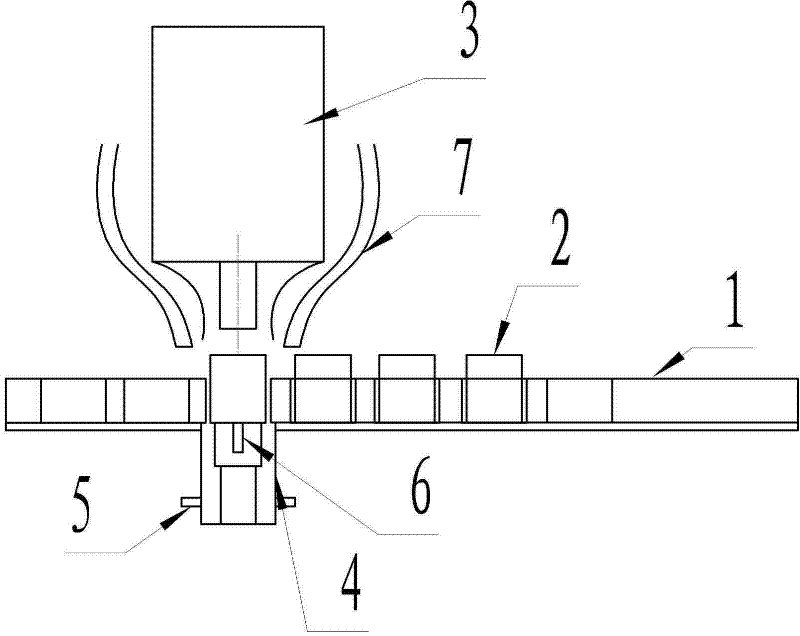

Zinc oxide resistor aluminium spraying device and aluminium spray process thereof

InactiveCN102568726ALow costImprove spraying work efficiencyResistor manufactureRubber ringAluminium electrode

The invention discloses a zinc oxide resistor aluminium spraying device, and the aluminium spray process thereof. An aluminium electrode spraying device includes a spray gun, a conveyor belt, a blowing table and an exhaust gas collection pipe; the conveyor belt is used for conveying a zinc oxide resistor to the blowing table under the spray gun, and after a sensor in the blowing tables senses the resistor, a spray switch of the spray gun and a gas valve of the blowing table under the spray gun are opened at the same time, and aluminium electrode spraying is started; the spray gun and the blowing table are closed at the same time after the blowing and spraying time is reached; and then the conveyer belt is used for conveying the next resistor to the blowing table under the spray gun for next resistor spraying. Through adopting the aluminium electrode spraying process for the resistors, the spraying work efficiency is high, only 2 workers are required for operation, and the operation is simple. The zinc oxide resistors are not needed to be sleeved with rubber rings, the labor force is reduced, and the cost for purchasing the rubber rings is eliminated, so that the cost is lowered. At the same time, the aluminium electrode covering range on an end surface of each resistor is enlarged to improve the product through-current capability.

Owner:NANYANG JINNIU ELECTRIC +1

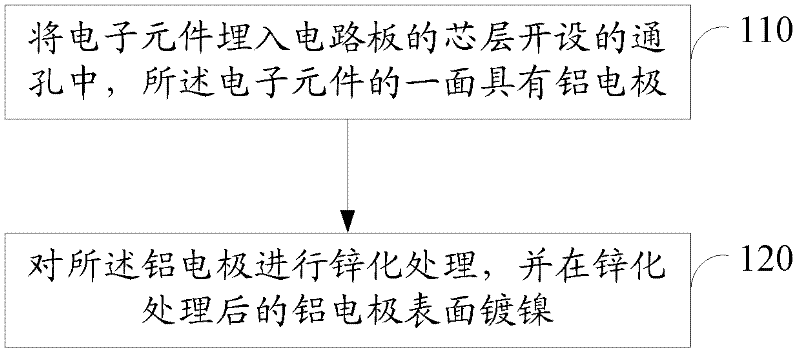

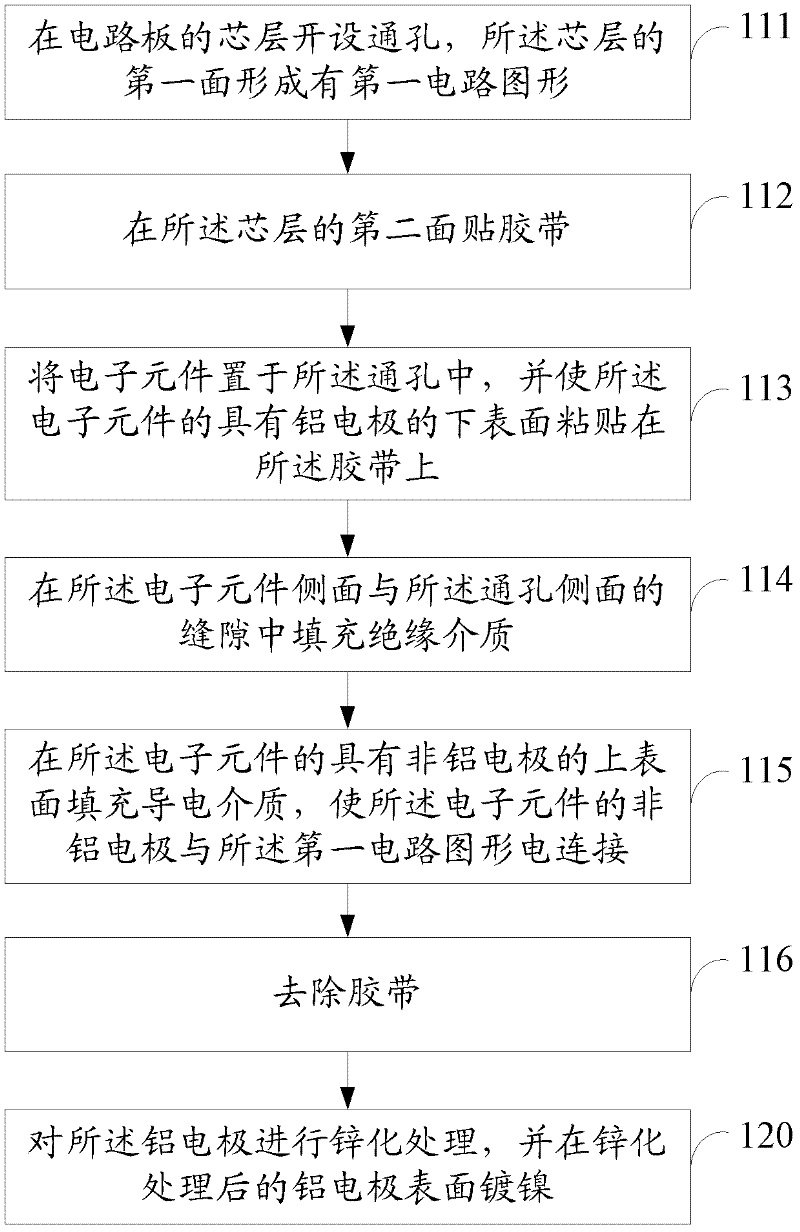

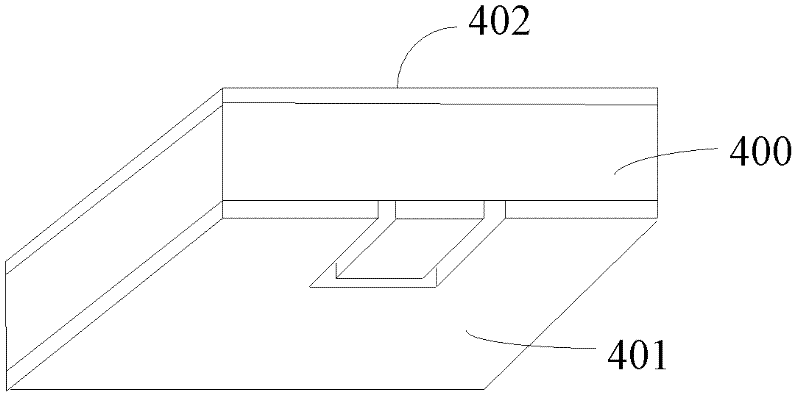

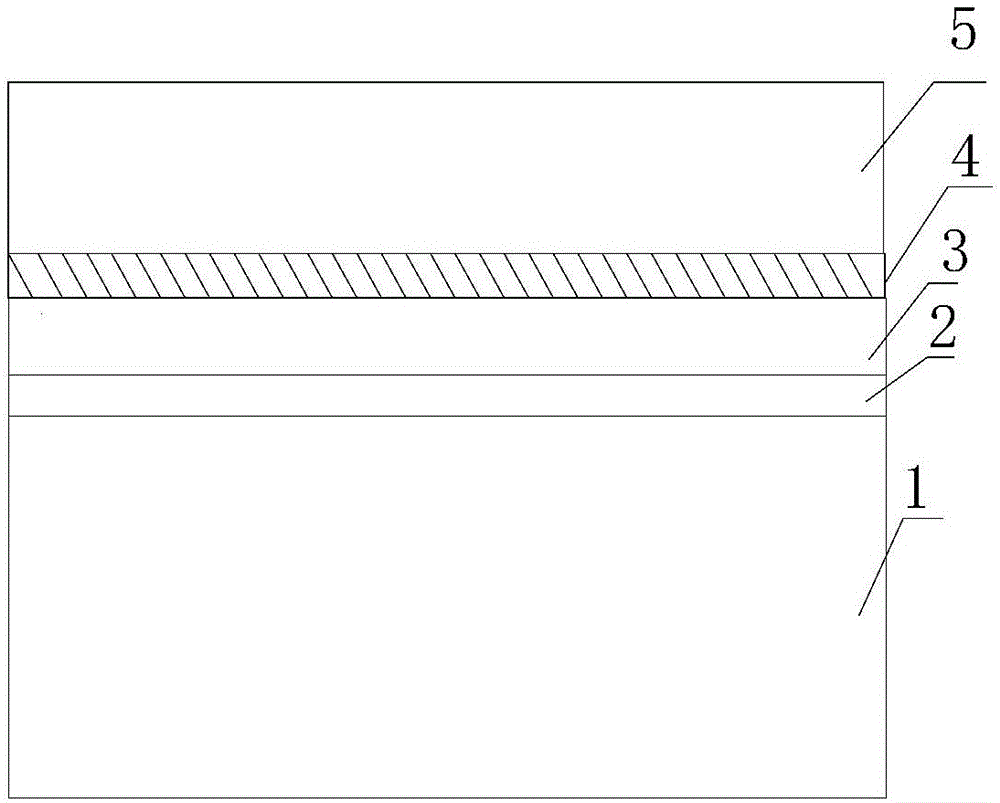

Electronic component embedded circuit board and manufacturing method thereof

ActiveCN102300417ASo as not to damagePrinted circuit assemblingSemiconductor/solid-state device detailsChemical solutionAluminium electrode

The invention discloses a manufacture method of an electronic component embedded type circuit board. The method comprises the following steps: embedding an electronic component into a through hole provided in a core layer of a circuit board, wherein one side of the electronic component is provided with an aluminium electrode; carrying out zinc processing on the aluminium electrode, and plating nickel on a surface of the aluminium electrode after the zinc processing. An embodiment of the invention also provides a corresponding electronic component embedded type circuit board. According to a technical scheme of the invention, the zinc processing and the nickel plating processing are adopted to form a zinc nickel protection layer on the surface of the aluminium electrode. In subsequent circuit board manufacture flows, the aluminium electrode is not damaged by laser, various acidic or alkaline chemical solutions.

Owner:SHENNAN CIRCUITS

Method for preparing flexible Cu-In-Ga-Se thin film solar cell

ActiveCN106784151AImprove crystal qualityExcellent photoelectric propertiesFinal product manufacturePhotovoltaic energy generationWater bathsIndium

The invention discloses a method for preparing a flexible Cu-In-Ga-Se (CIGS) thin film solar cell. The method is characterized by comprising the following steps: step 1, preparing a CIGS light absorption layer on a soda glass substrate by adoption of a high-temperature coevaporation process; step 2, pasting a temporary supporting layer; step 3, removing the soda glass substrate; step 4, bonding a flexible substrate; step 5, removing the temporary supporting layer, wherein the step 5 particularly comprises the following steps: firstly, adopting limonene to dissolve paraffin on the surface of the CIGS light absorption layer, removing the temporary supporting substrate and paraffin, cleaning with deionized water and blow-drying with nitrogen; after that, preparing a CdS buffer layer with the deposition thickness of 50-80 nm by adoption of a chemical water bath method; adopting a magnetron sputtering process on the buffer layer to obtain an intrinsic zinc oxide thin film with the deposition thickness of 50 nm and an ITO thin film with the deposition thickness of 300-800 nm, and preparing a 3 [mu]m aluminium electrode on the ITO thin film by adoption of an electron beam evaporation process to finish preparation of a cell device.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Joint of copper terminal and aluminium conductor and resistance welding method thereof

InactiveCN107104292AGuaranteed mechanical propertiesGuaranteed electrical performanceLine/current collector detailsElectric connection structural associationsState of artPotential difference

The invention belongs to the field of a wire harness, and particularly relates to a resistance welding structure and method between a copper terminal and an aluminium conductor. In order to solve the problems of electrochemical corrosion of welding between the copper terminal and the aluminium conductor and poor mechanical property of a welding joint in the prior art, according to the resistance welding structure and method disclosed by the invention, a separation metal layer is added between the copper terminal and the aluminium conductor; firstly, the separation metal layer is fixed at a welding end of one base metal in a mode of electroplating, pressure welding, arc spray welding or electromagnetic welding and the like; and then the separation metal layer, the copper terminal and the aluminium conductor are welded together. The resistance welding method disclosed by the invention not only is suitable for welding the copper terminal and the aluminium conductor, but also is suitable for welding of various types of joints, electrochemical corrosion caused by a potential difference of copper and aluminium electrodes can be effectively reduced, and the mechanical property of the joint is improved.

Owner:JILIN ZHONG YING HIGH TECH CO LTD

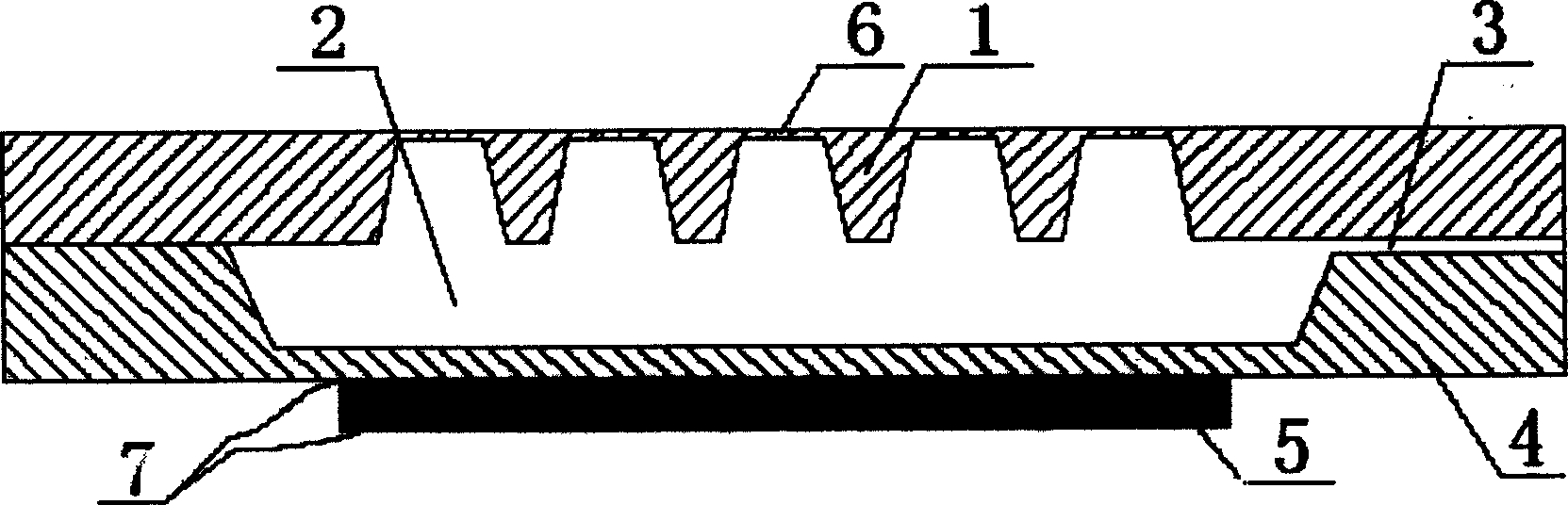

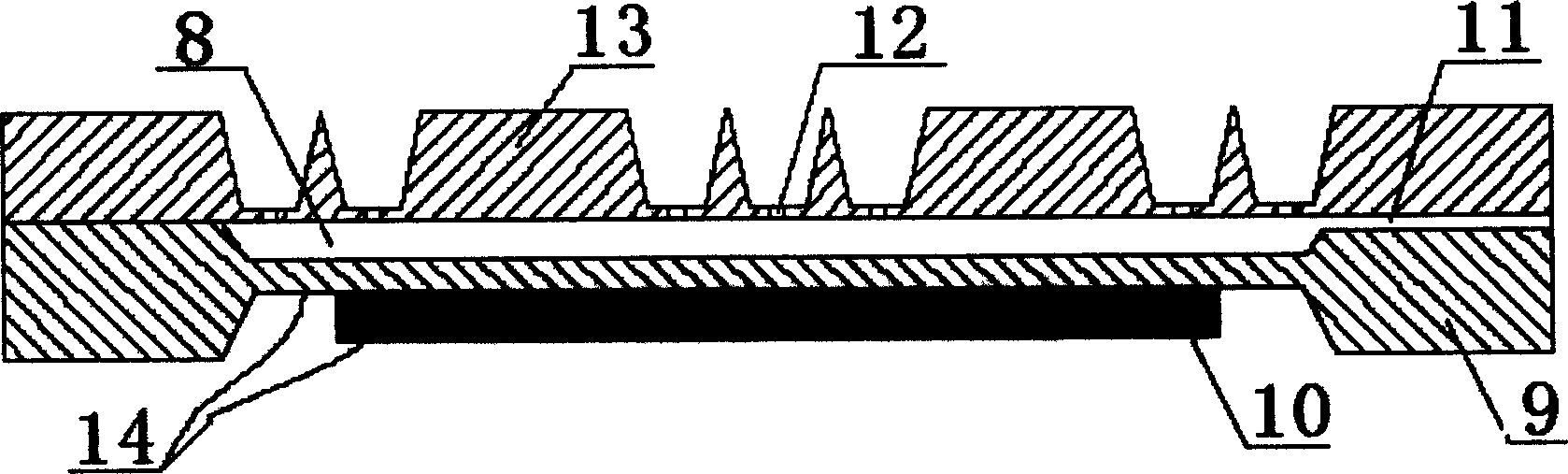

Optimized piezo driven micro spraying device and fabricating method

InactiveCN1562398AEven spray distributionAvoid water film problemsMedical atomisersTransducerAluminium electrode

An optimized microsprayer driven piezoelectrically is composed of a membrane with spray orifices, an elastic cavity membrane and piezoelecric sheet on whose both surfaces the aluminium electrodes are plated. said elastic cavity membrane is combined with said piezoelectric sheet to form a piezoelectric transducer. said orifice membrane is adhered with said electric cavity membrane to form a closed liquid cavity. Its advantages are no water membrane, and increased flow.

Owner:TSINGHUA UNIV +1

Method for processing stibium containing industrial wastewater by aluminium electrode-electric flocculence

InactiveCN101544416ASolve the problem of serious exceeding the standardQuality improvementWater contaminantsWater/sewage treatment by flotationEnvironmental qualityAluminium electrode

The invention discloses a method for processing stibium containing industrial wastewater by aluminium electrode-electric flocculence, and relates to wastewater or sewage treatment. The method comprises the following steps: adopting an aluminium material as electrodes, electrolyzing the containing industrial wastewater of which the pH value is adjusted in advance by direct current in an electrolytic cell, and flocculating stibium ions in the wastewater by floc generated by the electrodes; and then standing, and discharging the wastewater after the wastewater passes detection. The method for processing the stibium containing industrial wastewater by the aluminium electrode-electric flocculence can solve the problem of severe superstandard of the stibium ions in the stibium containing industrial wastewater, remove the stibium in the stibium containing industrial wastewater by over 90 percent to make the concentration of the stibium ions in the treated water less than 3mg / L, realize qualified discharge and improve environmental quality. The method has the advantages of low cost, simple devices and easy operation, and is suitable for antimony ore concentration plants and metallurgical and chemical engineering enterprises related with the stibium.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

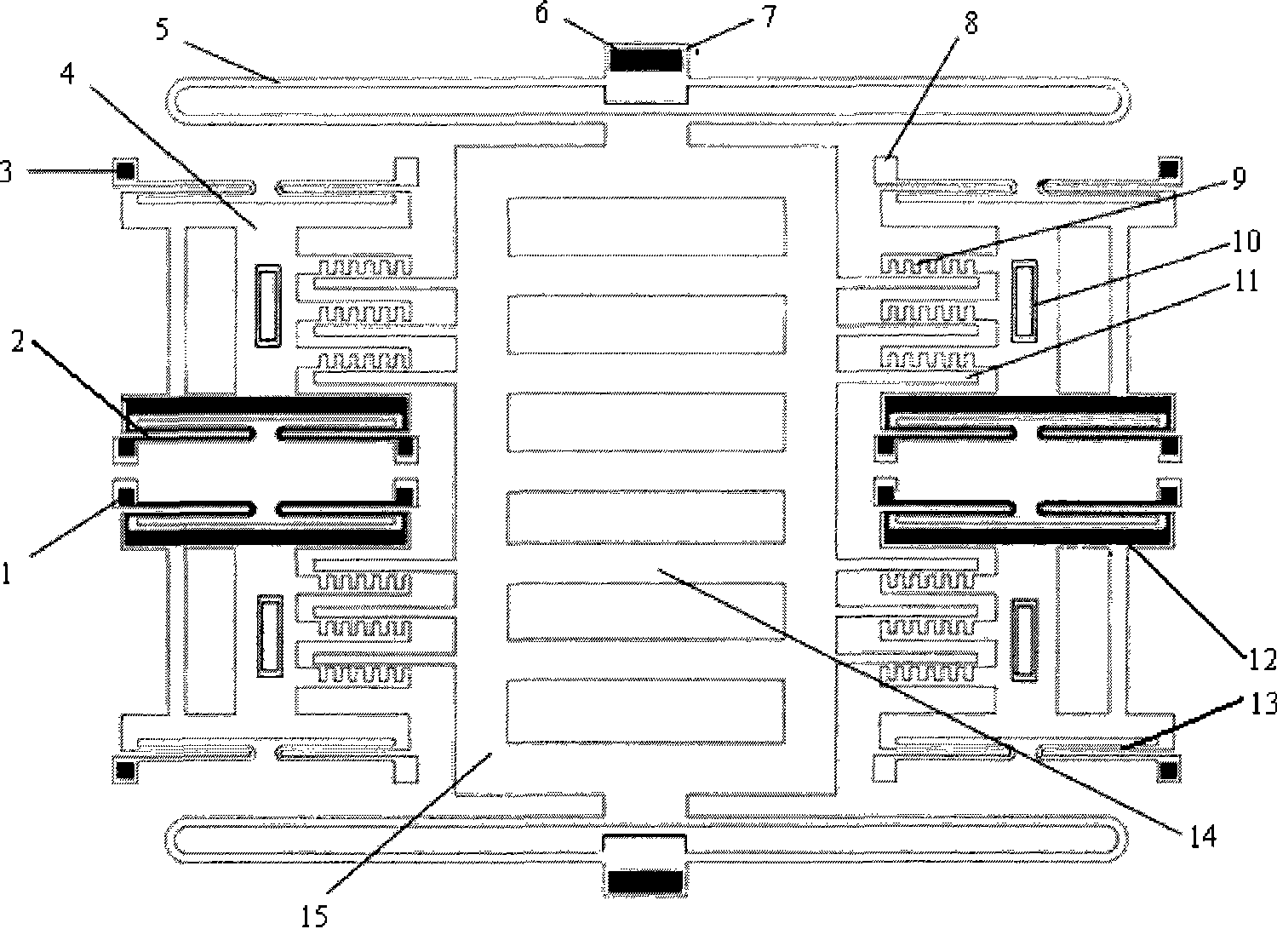

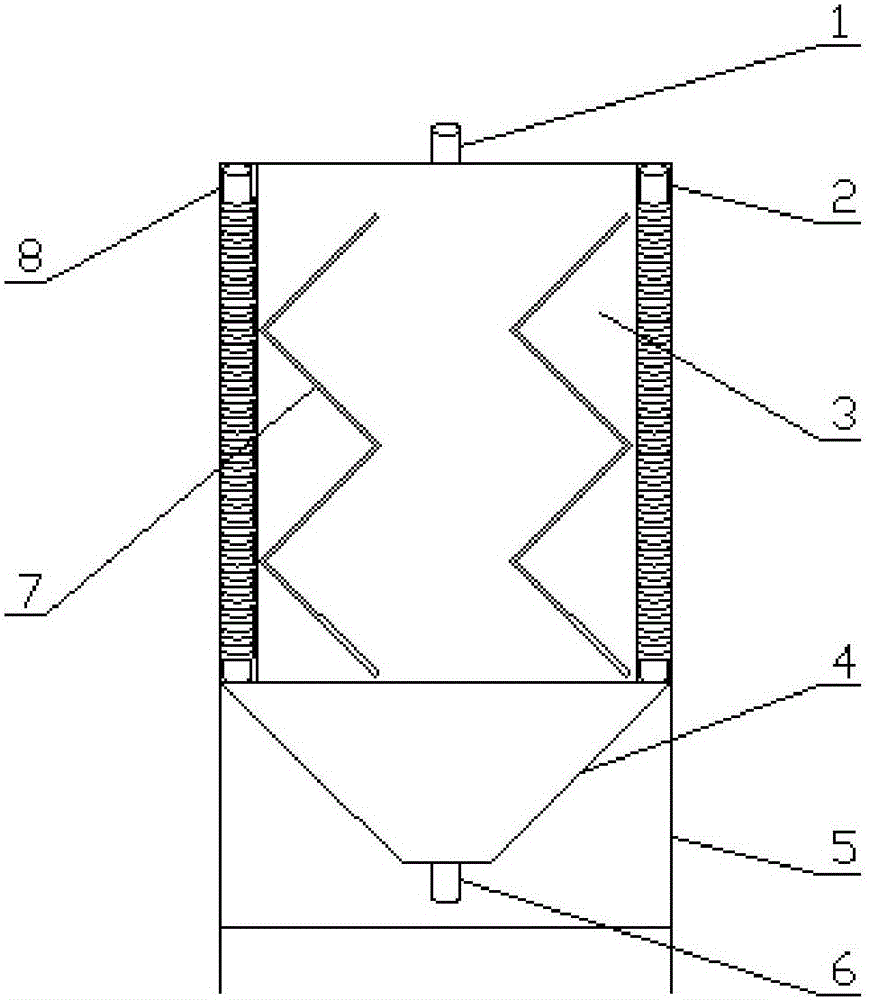

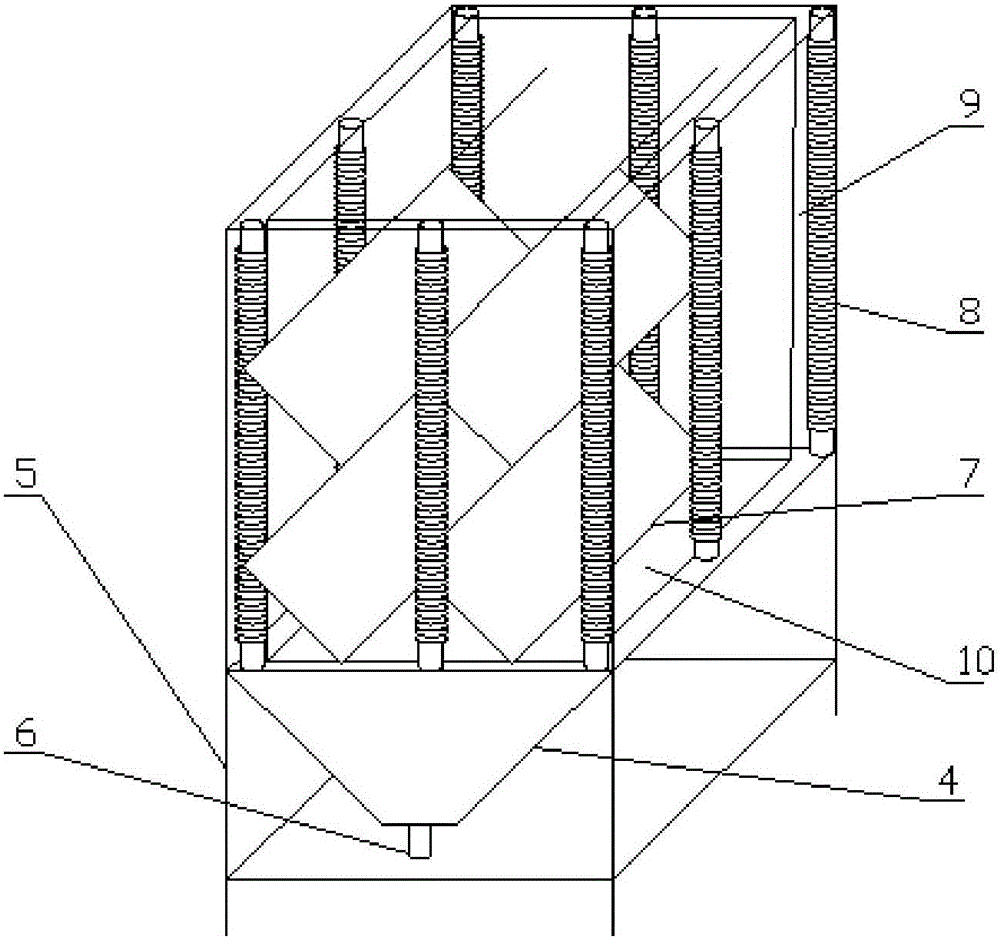

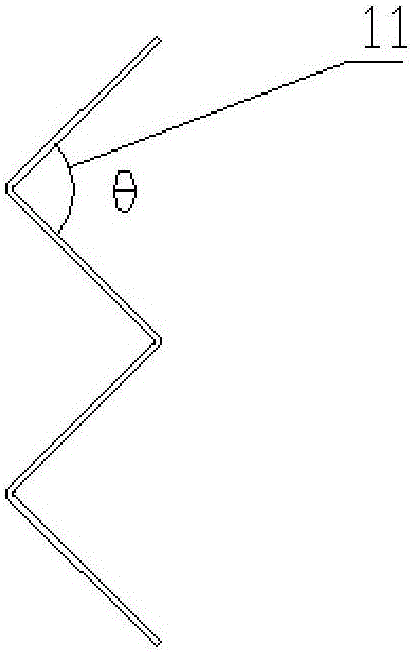

Electromagnetic coupling inclined plate electric flocculation reactor

InactiveCN105967428AReduce volumeShort flocculation timeWater/sewage treatmentMultistage water/sewage treatmentSludgeEngineering

The invention provides an electromagnetic coupling inclined plate electric flocculation reactor. A casing of the reactor is made by adopting PPR or PVDF and other corrosion-resistant and high-temperature-resistant materials; the interior of the reactor is divided into an electromagnetic zone and an inclined plate electric flocculation zone which are mutually insulated, wherein the electromagnetic zone comprises a plurality of groups of electromagnets, the inclined plate electric flocculation zone comprises a set of inclined plate zigzag electrodes, and iron electrode or aluminium electrodes are adopted as the electrodes. The plurality of groups of electromagnets and the electrodes are connected in series; when direct current passes, the electromagnets generate a magnetic field with certain intensity, the electrodes generate ferrous or aluminous hydroxide flocculating agents under the action of the current, a certain amount of the magnetic powder is added into the reactor and is mixed with the ferrous or aluminous hydroxide flocculating agents to form magnetic floccule, and the magnetic floccule under the action of electromagnetic force and the inclined plate electrodes settle rapidly in a frustum-shaped sludge-collecting hopper at the bottom of the reactor. Compared with a traditional electric flocculation device, the reactor has the advantages of small size, short flocculation time, large treatment amount, and the like.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Light-guiding plane lighting lamp with external power supply

InactiveCN101865399AIncrease the light areaIncrease illuminationMechanical apparatusPoint-like light sourceIlluminanceHigh energy

The invention relates to a light-guiding plane lighting lamp with an external power supply; an LED point light source is arranged on an aluminium electrode plate so as to form a lamp ring; the front end in the lamp ring is sheathed with a light-guiding plate; the front end of the light-guiding plate is sheathed with a ground glass sheet; the periphery of the lamp ring is sheathed with a radiator; and finally, the lamp ring is fixed on an installing seat. The light-guiding plane lighting lamp is an ultra-thin product, the thickness thereof is less than 2cm, the external power supply is adopted to be connected with the LED point light source arranged on the lamp ring, the point light source is converted into the light-guiding plane lighting lamp, therefore, the light-guiding plane lighting lamp increases the lighting area and illumination, has the advantages of reasonable structure, convenient installation, high energy-saving efficiency, strong illumination, long service life and small installation occupying space and is suitable for being used as various different lamps for indoor decoration and advertising lighting.

Owner:蓝智华

Germanium-silicon schottky diode and its production method

InactiveCN100372128CReduce contact areaReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesHydrofluoric acidOhmic contact

The Schottky diode consists of: ohmic contact electrode stacked in sequence from bottom to top; silicon substrate and silicon nitride layer on which a window is opened, in the window there are germanium silicon layer and nisiloy layer. The nisiloy layer is above the germanium silicon layer. The aluminium electrode touching the nisiloy compound covers the window of silicon nitride. The making method includes following steps: first a silicon layer is developed on the silicon substrate; deposits a silicon dioxide layer on silicon nitride and photoetches a window; develops germanium silicon layer; with dilute hydrofluoric acid, strips silicon dioxide layer; metallic nickel is coated by vaporization on germanium silicon layer; anneal to form germanium silicon compound layer; coats by vaporization aluminium electrode and ohmic contact electrode.

Owner:ZHEJIANG UNIV

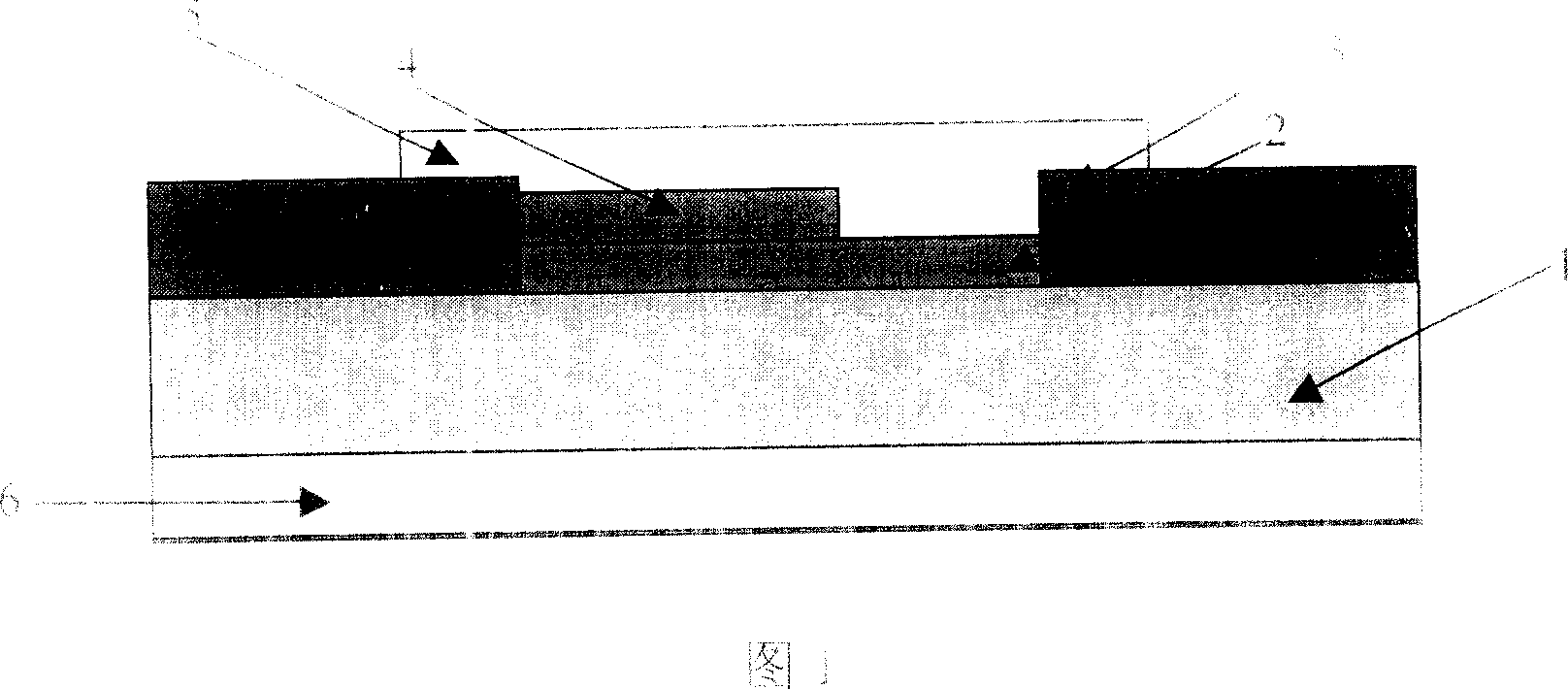

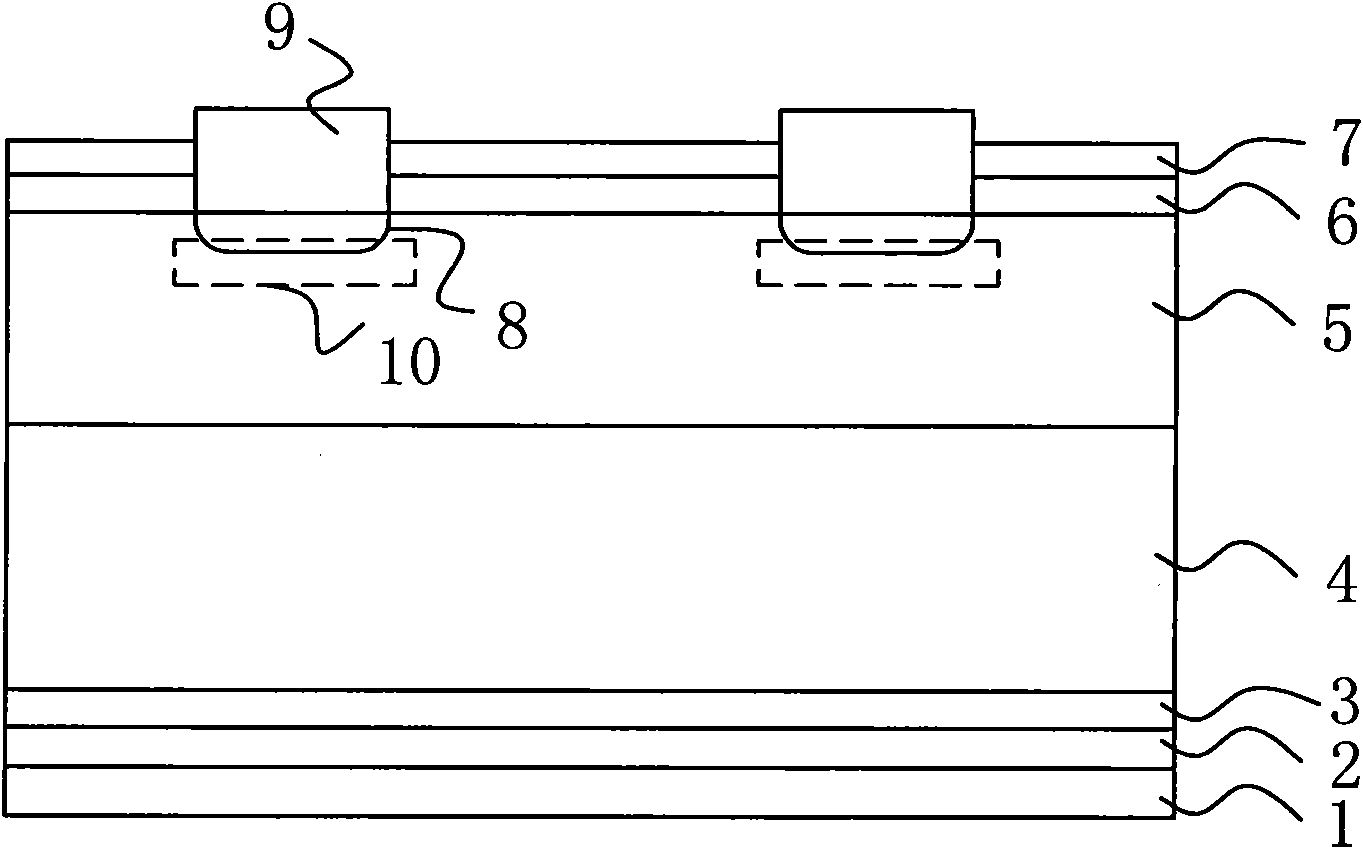

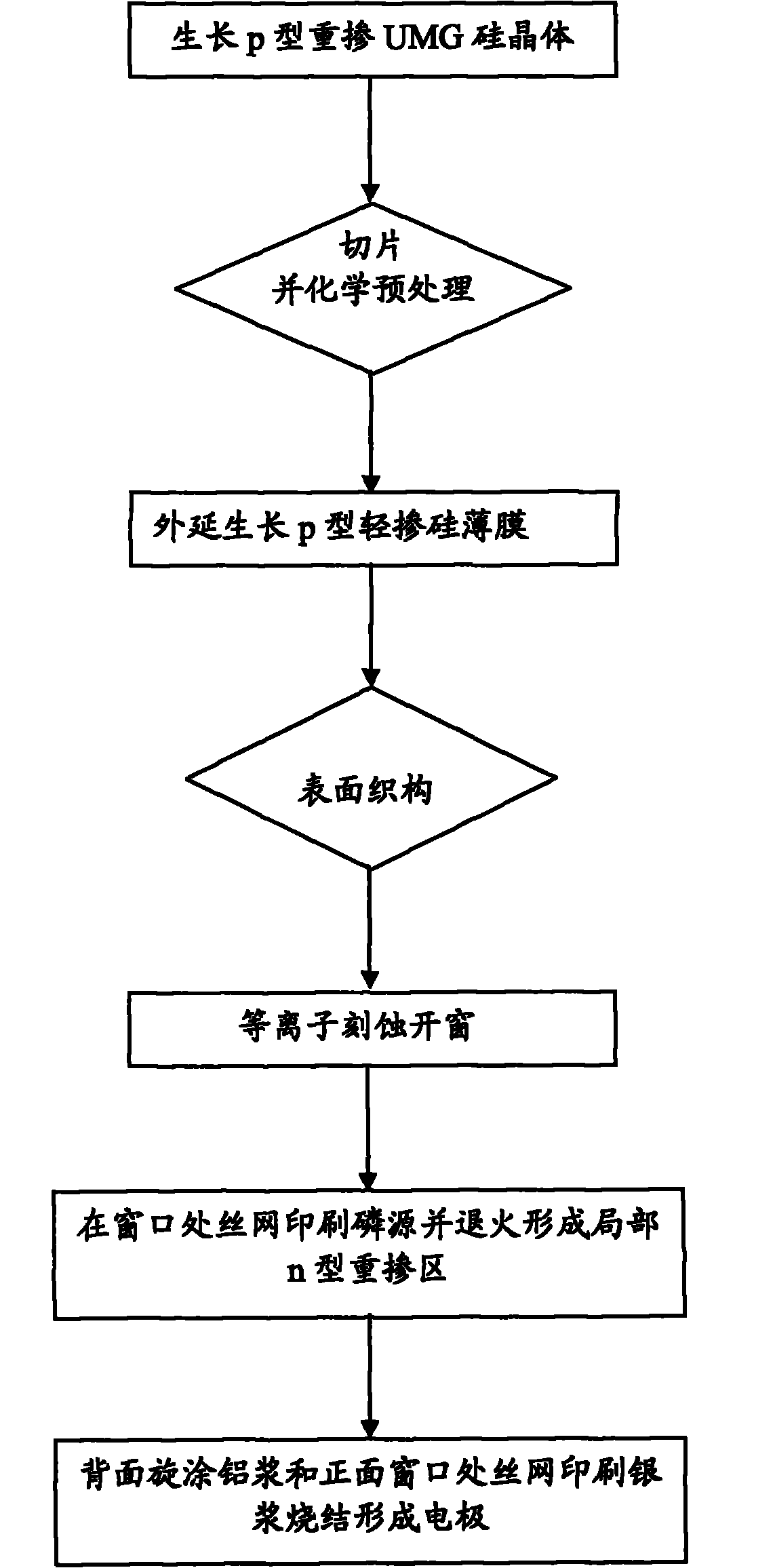

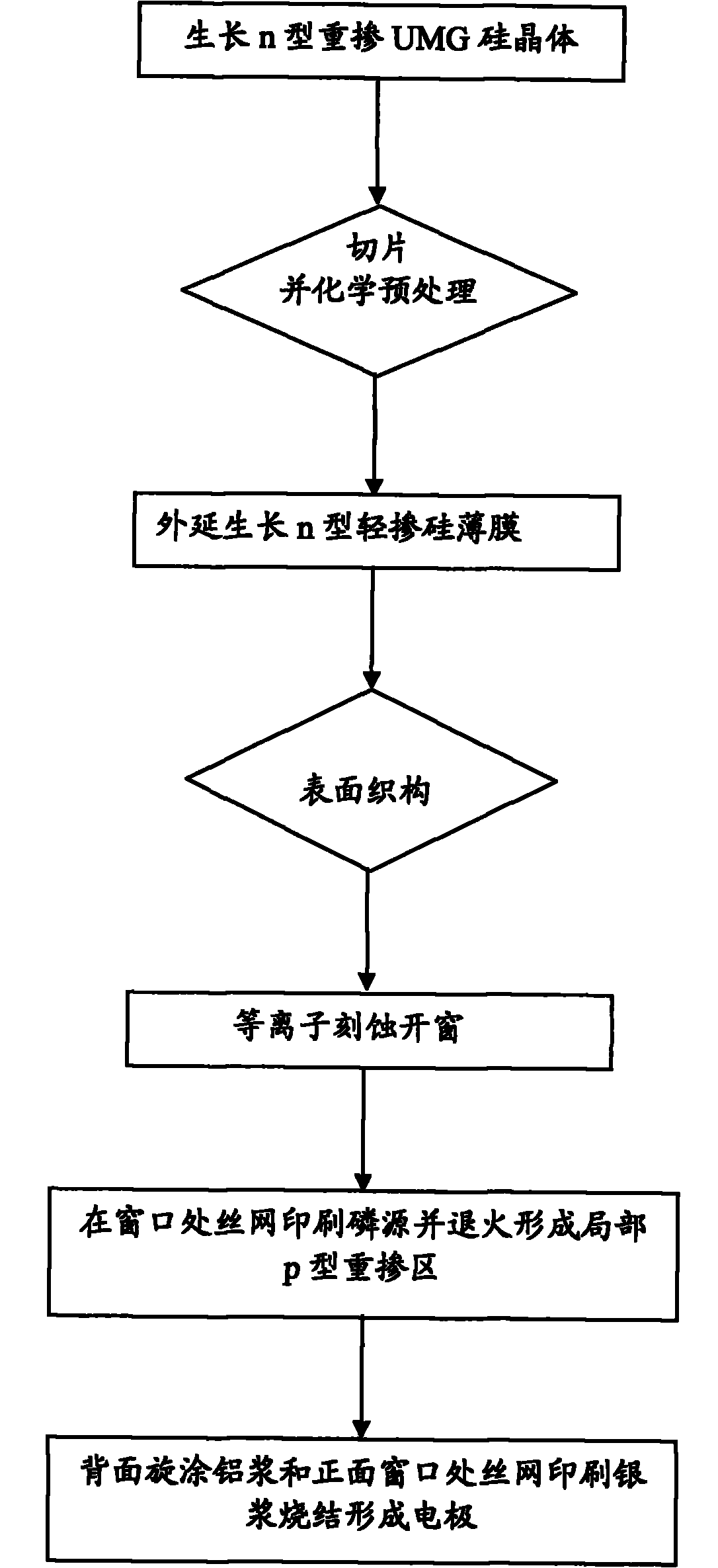

Heavily-doped UMG silicon epitaxially generated high-low junction-based solar cell and preparation method

InactiveCN101777592AImprove photoelectric conversion efficiencyLow costFinal product manufacturePhotovoltaic energy generationSilver electrodeAluminium electrode

The invention discloses a heavily-doped UMG silicon epitaxially generated high-low junction-based solar cell, which comprises a plurality of cells; and each cell is provided with an aluminium electrode layer, a first silicon nitride layer, a first silicon dioxide layer, a heavily-doped UMG silicon layer, a lightly-doped silicon epitaxy layer, a second silicon dioxide layer, a second silicon nitride layer and a plurality of heavily-doped areas from bottom to top in turn, wherein the conduction type of the lightly-doped silicon epitaxy layer is the same as that of the heavily-doped UMG silicon layer; the conduction type of the heavily-doped areas is opposite to that of the heavily-doped UMG silicon layer; and the upper surfaces of the heavily-doped areas and the upper surface of the second silicon nitride layer are provided with silver electrodes. The invention also provides a preparation method for the solar cell. A low-cost UMG silicon material is utilized, heavily-doped UMG silicon crystals are grown by the heavy doping technology, and the heavily-doped UMG silicon crystals are epitaxially grown to form a high-quality silicon film so as to prepare the solar cell, so the cost of the solar cell is much lower than that of a solar cell prepared from a high-quality silicon material directly, and the photoelectric conversion efficiency is much higher than that of a solar cell prepared from a lightly-doped UMG silicon material directly.

Owner:ZHEJIANG UNIV

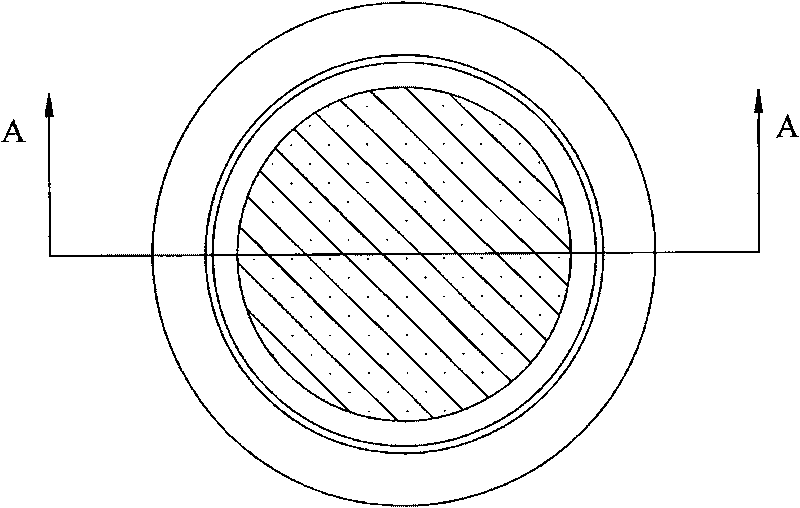

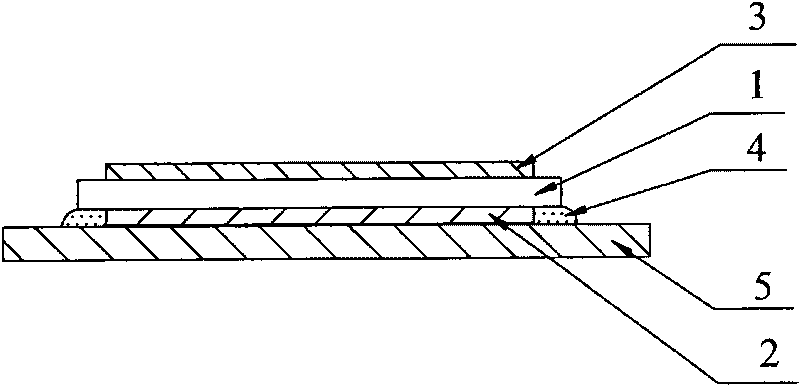

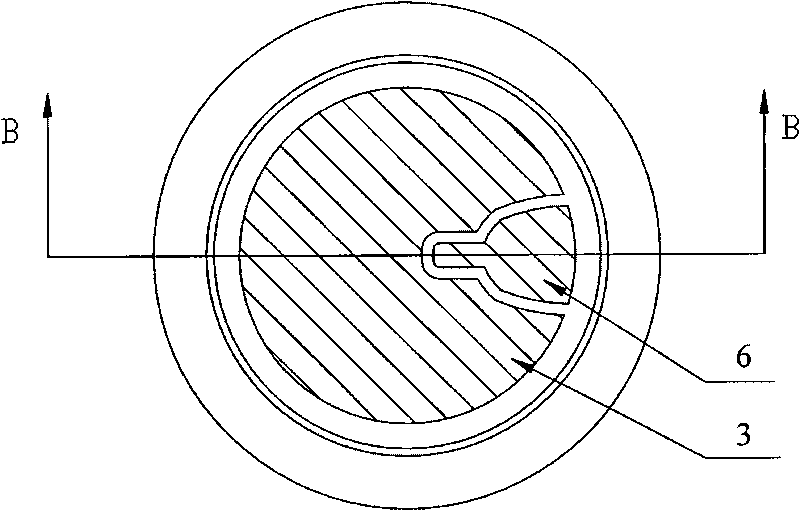

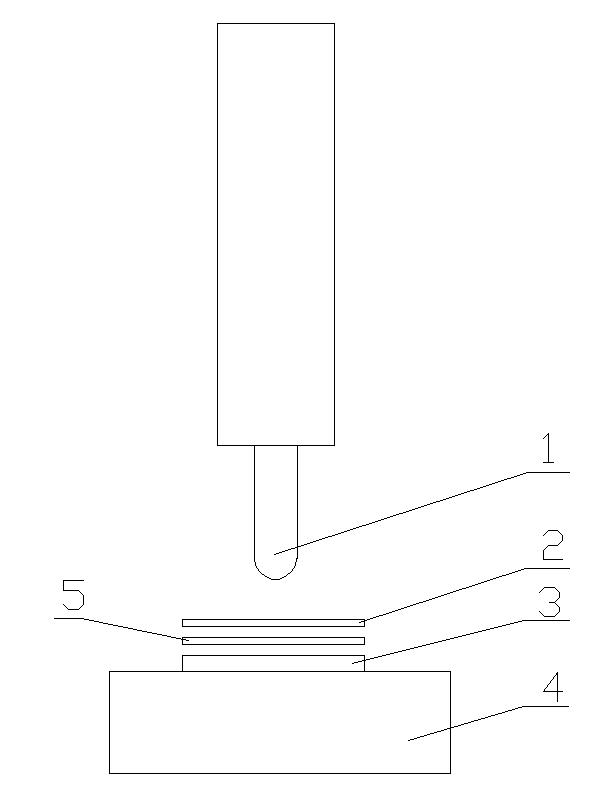

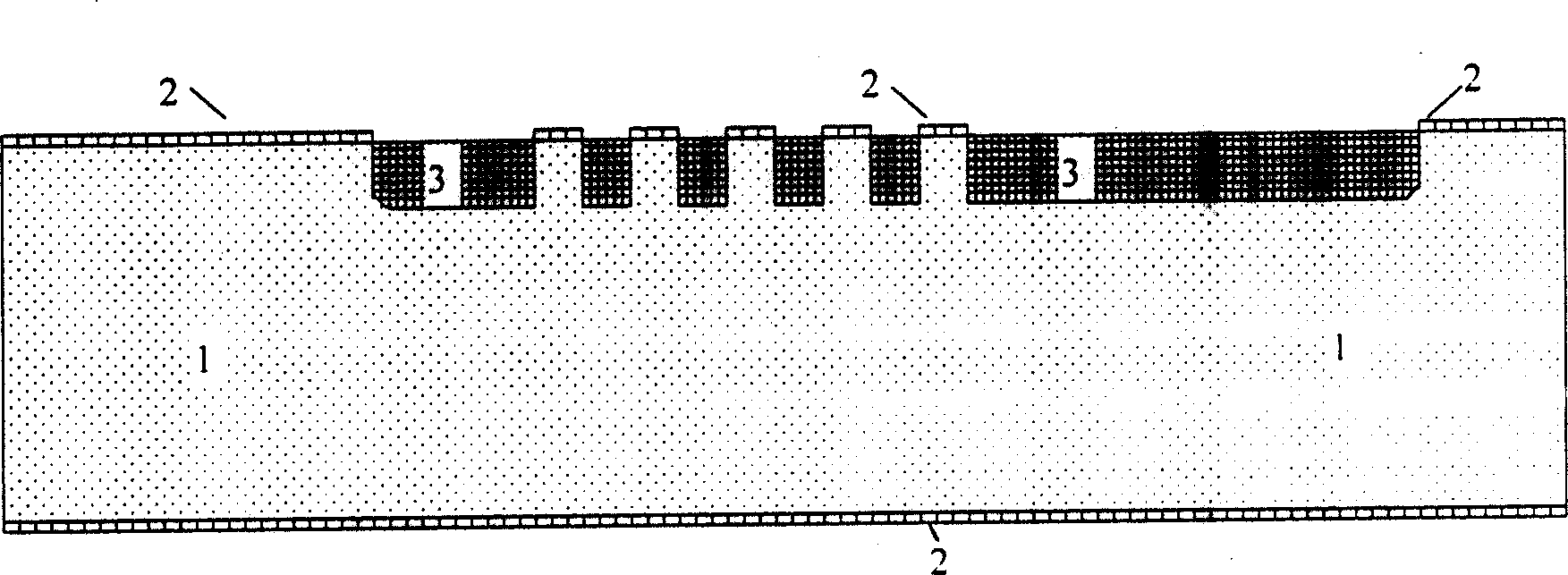

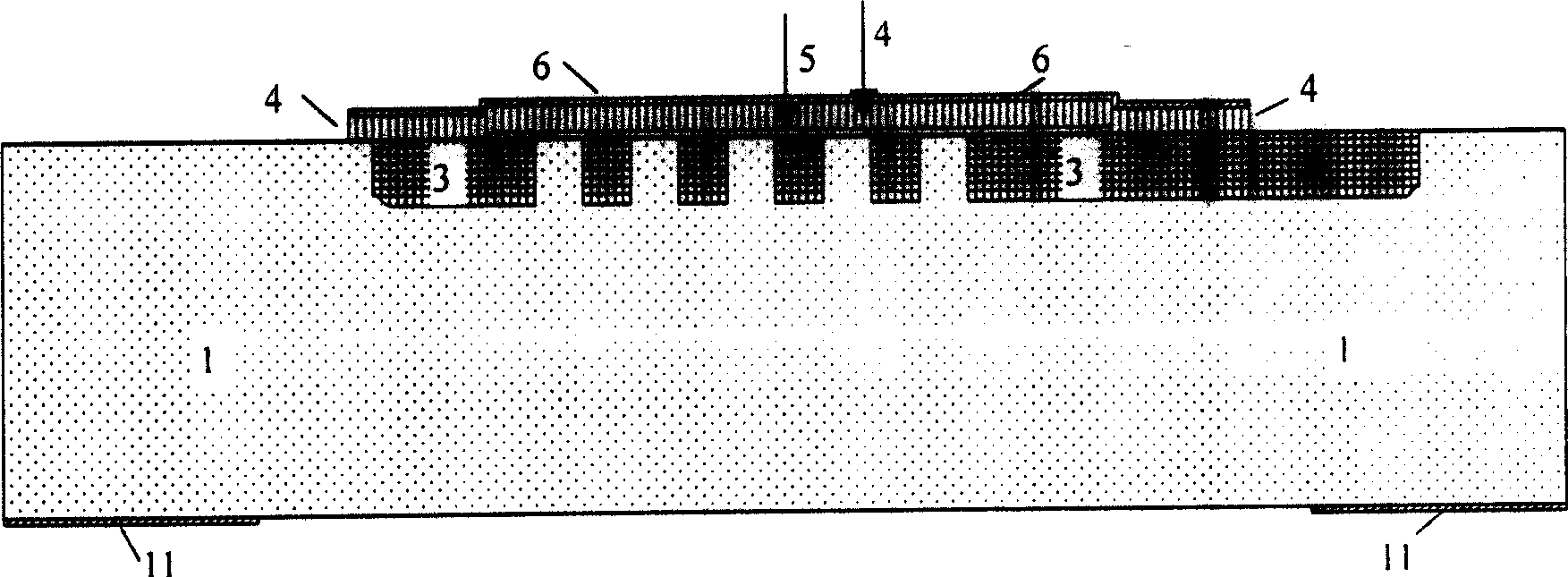

Charge storage device

InactiveUS20050219799A1Improve overcharge performanceHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersAluminium electrodeEngineering

A charge storage device (1) includes a sealed prismatic housing (2). Two opposed folded rectangular aluminium electrodes (3, 4) are disposed within housing (2) and connected to the electrodes. A porous, electronically insulating separator material, e.g. Solupor™, sheet separator (7) is disposed intermediate electrodes (3, 4) for maintaining those electrodes in a fixed spaced apart configuration. An electrolyte (not shown) is also disposed intermediate the electrodes. Collecting means in the form of a scavenging agent is grafted to separator (7) for sequestering one or more predetermined contaminants from the housing.

Owner:PAUL GEORGE LANGE +3

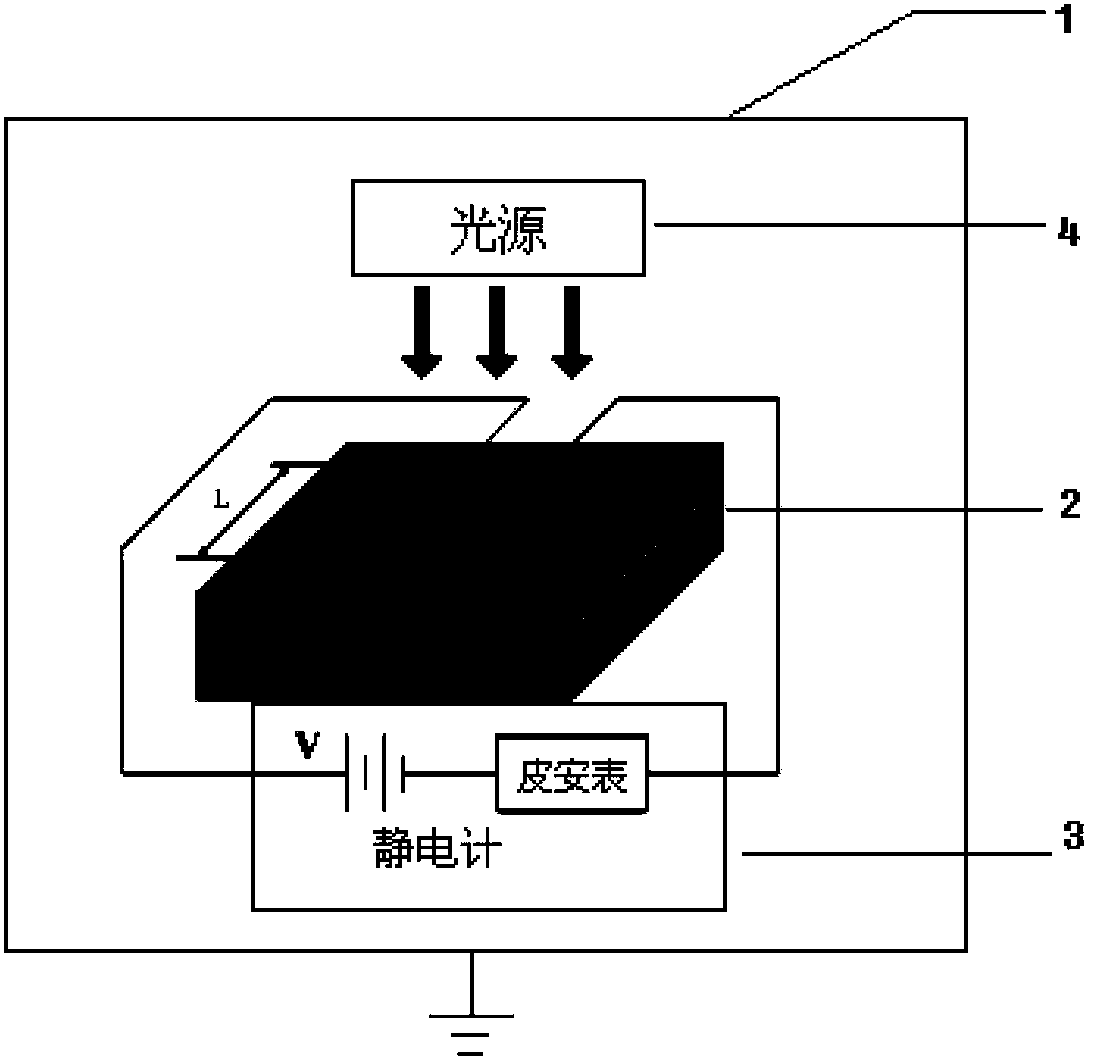

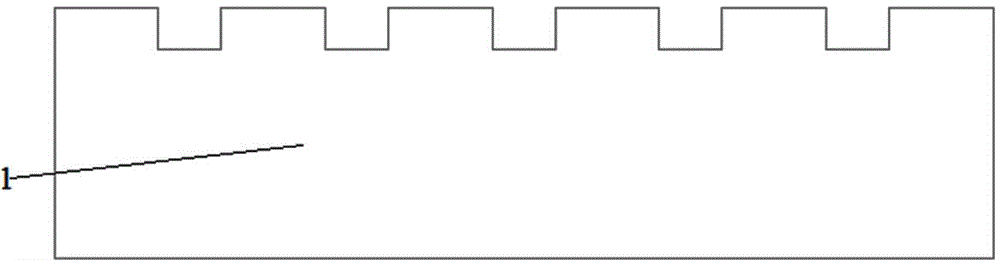

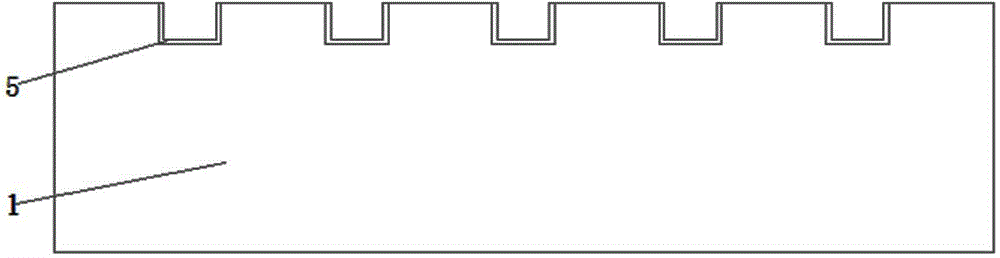

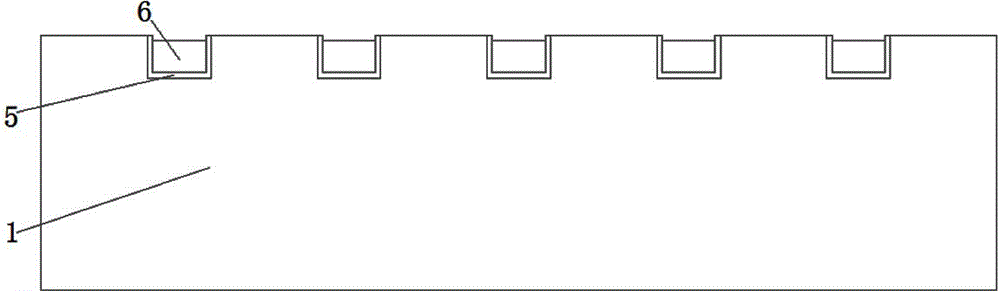

Testing device and testing method for light dark conductivity of HIT exclusive single-layer membrane

The invention relates to a testing device and testing method for light dark conductivity of an exclusive single-layer membrane for a high-efficiency heterojunction with intrinsic thin layer (HIT). The testing device comprises a lead, a probe, a sample platform, a dark box, an electrometer, a light source and a shielding case. According to the testing method, two coplanar aluminium electrodes are formed at the surface of a sample by evaporation, wherein the material between the two electrodes is used as the tested sample; the sample is placed at the sealed sampling platform; the programmable electrometer and the light source are connected; and the conductivity of the thin film is calculated based on the current obtained by testing. According to the invention, the testing device and the testing method are simple; the cost is low; and the photoelectric property of the material can be reflected accurately.

Owner:上海太阳能工程技术研究中心有限公司

Relative humidity sensor of monolithic integrated porous silicon and preparation method of humidity sensor

ActiveCN104089990ACompact structureSimple structureMaterial capacitanceIsolation layerAluminium electrode

The invention aims at solving the defect of the structure of an existing humidity sensor and provides a relative humidity sensor of monolithic integrated porous silicon and a preparation method of the humidity sensor. The humidity sensor comprises a substrate, wherein a pair of comb-shaped and staggered aluminium electrodes are arranged on the substrate; the bottom surfaces and the side walls of the aluminium electrodes are uniformly coated with oxidation isolation layers; passivation layers covers the tops of the aluminium electrodes; the top surface of the substrate at areas among combs of the aluminium electrodes is coated with a porous silicon layer; the top surface of the porous silicon layer is coated with an oxide layer; a polycrystalline silicon heating layer is arranged at the top of the oxide layer. The preparation method of the humidity sensor comprises the following eight steps: scribing, preparing an electrode tank, preparing the oxidation isolation layers, preparing the aluminium electrodes, preparing the porous silicon layer, preparing the oxide layer, preparing the passivation layers and preparing the polycrystalline silicon heating layer. The relative humidity sensor has the beneficial effects of being compact in structure and high in sensitivity; the method is compatible with an MEMS (Micro-electromechanical Systems) process; extra devices or severe working conditions are not required to be added; the method is high in yield of finished products.

Owner:HEFEI UNIV OF TECH

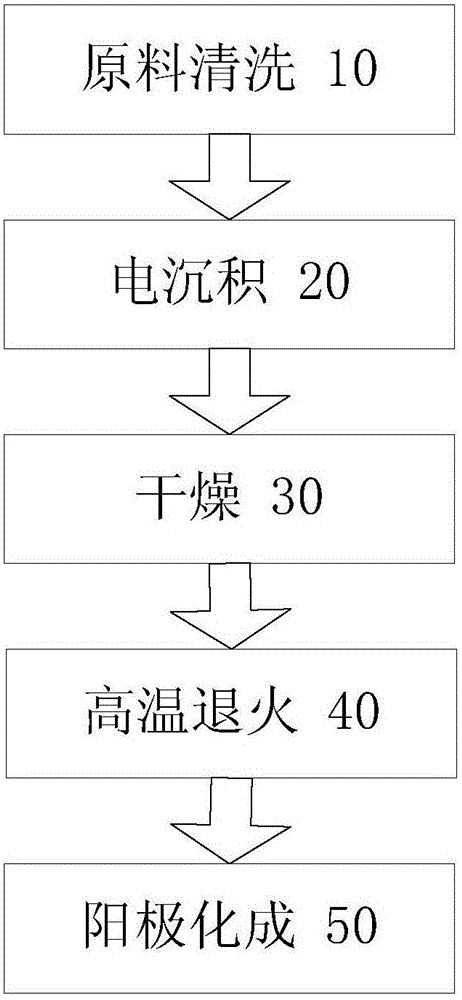

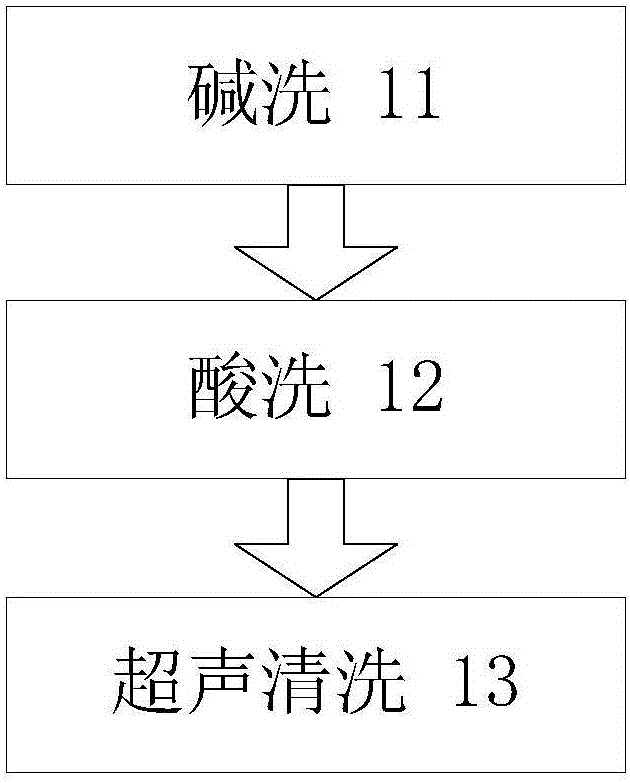

Preparation method for high-dielectric-constant formed aluminum foil

ActiveCN105702466AGood capacity increaseImprove the situation with small dielectric constantAnodisationElectrolytic inorganic material coatingDielectricAcid washing

The invention discloses a preparation method for a high-dielectric-constant formed aluminum foil. The preparation method comprises the following steps of (10): raw material cleaning: performing alkali washing, acid washing and ultrasonic washing on a to-be-processed corroded foil to obtain corroded foil with the clean surface; (20) electrodeposition: immersing the corroded foil with the clean surface into a deposition solution to be subjected to electrochemical deposition; (30) drying: drying the corroded foil after the corroded foil is subjected to electrochemical deposition; (40) high-temperature annealing: performing high-temperature annealing on the dried corroded foil; and (50) positive electrode formation: performing positive electrode formation processing by putting the high-temperature-annealed corroded foil in a formation solution to obtain the formed aluminum foil. The preparation method for the formed aluminum foil has a controllable production process, high aluminium electrode foil dielectric constant and high specific capacity.

Owner:YANGZHOU UNIV

Chip having high sensitivity for silicon micro-capacitor microphone and preparation method thereof

This invention refers to a chip used in silicon micro capacitance microphone and preparation method thereof, said chip contains a N negative type silicon substrate, P positive type doped layer formed by boron diffusion on positive surface of silicon substrate, silicon dioxide deposited on it, etching isolation layer adhered with a vibration membrane layer deposited with metal aluminium membrane layer then photo etching and corroding to form round aluminium membrane and rectangle aluminium electrode, a silicon nitride protective film on back surface of silicon substrate, corroding a trapeze notch with depth to P positive doped layer and corroding acoustics hole in vertical direction to form perforation back board which and silicon nitride vibration membrane form air gap. Said invention reduces vibration membrane stress and greatly raises the sensitivity of vibration membrane and avoids aging crack.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Novel refined aluminium electrode and its using method

InactiveCN1800449AQuality improvementCompact and reasonable structureElectrolysisAluminium electrode

The invention relates to a new type of refined aluminum electrode and it's using method. The new type of refined aluminum electrode has an electrode ring with fire resistant, cold and hot resistance and refined aluminum solution non-polluted on the external side of the electrode bottom, wherein the electrode ring is integer with the electrode. The bottom of the refined aluminum electrode immerges in the refined aluminum liquid 0-5 centimeters of the three layer refined aluminum electrolysis bath.

Owner:XINJIANG JOINWORLD CO LTD

Method for manufacturing zinc oxide nonlinear resistance slice used for lightning arrester

ActiveCN101154487AReduce typesThe preparation process is simple and environmentally friendlyResistor manufactureVaristor coresNonlinear resistorAluminium electrode

The invention discloses a method for preparing a praseodymium series zinc oxide curve resistance, comprising the following procedures: additives are added according to the mol percentage: Co2O3is from 0.9 to 1.1 percent; Cr2O3 is from 0.4 to 0.6 percent; Pr6O11 is from 0.5 to 1.0mol percent; K2CO3 is from 0.5 to 1.0mol percent; Al(NO3)3.9H2O is from 0.025 to 0.032 percent; the remainder is the main ingredient of zinc oxide which is matched with ingredients and calculated and weighted, the additives are mixed to be calcined and then mixed with the zinc oxide to be comminuted by the wet method; the whole is kept at the temperature of 1200 to 1250 degrees for three to four hours to calcine a ceramic water after spray pelleting and moulding as well as binder removal, the ceramic water is cleaned and dried after polished dressing; finally, the two end surfaces of the ceramic water are sprayed with aluminium electrodes, the circle surface of the ceramic water is applied with an insulating barrier, and a resistance card is manufactured. The invention has a small variety of additives, is capable of increasing the effective area of grain boundary layer and increasing the discharge current capability, which contributes to improving the potential gradient of products and decreasing the leakage current; in addition, the addition of Al(NO3)3.9H2O introduces an aluminium ion and zinc ion to form a substitution type flaw, increases the thickness of conductive ions, decreases grain of zinc oxide, and obviously improves the residual voltage ratio of the praseodymium series zinc oxide curve resistance.

Owner:CHINA XD ELECTRIC CO LTD

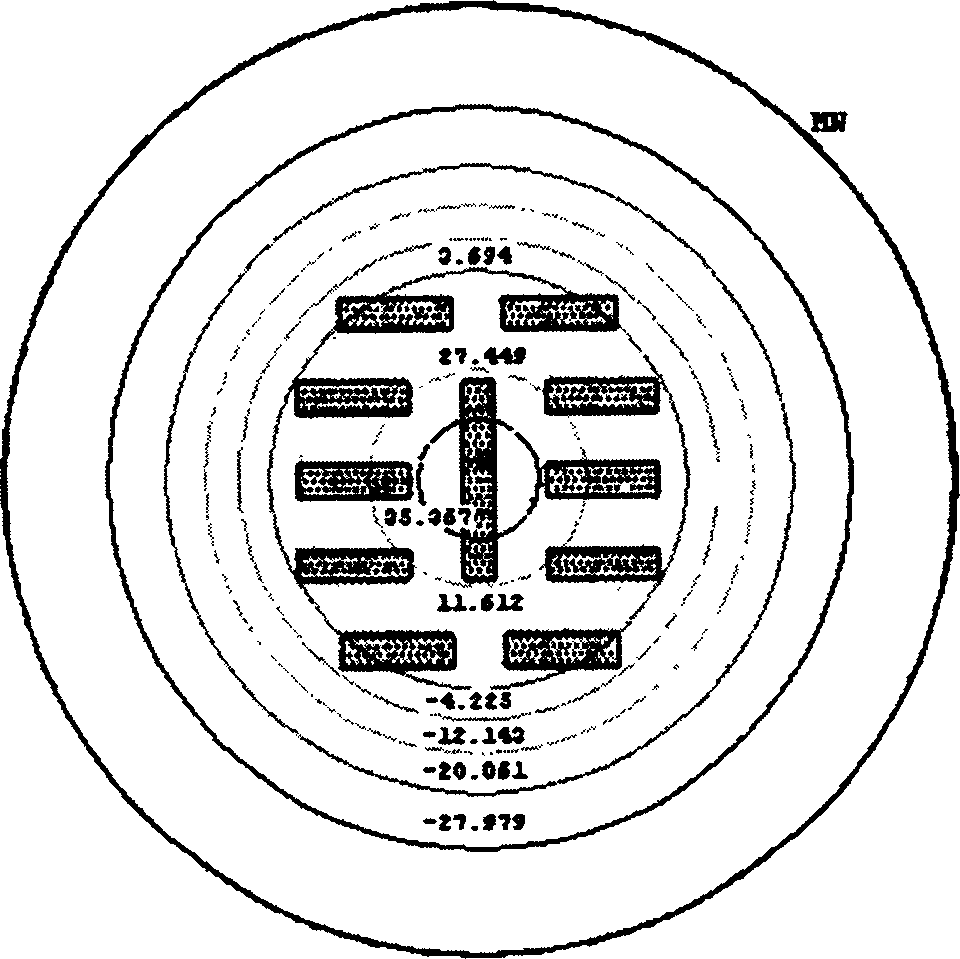

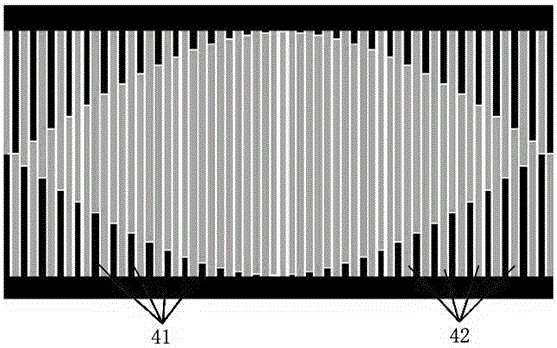

Acoustic surface wave resonator having high Q value and one port applied to wireless temperature sensor

The invention discloses an acoustic surface wave resonator having high Q value and one port applied to a wireless temperature sensor. The acoustic surface wave resonator comprises an interdigital transducer, two reflectors and a piezoelectric substrate, wherein the two reflectors are respectively distributed at two sides of the interdigital transducer; the interdigital transducer is arranged on the piezoelectric substrate in a manner of withdrawing and weighting a cosine function; and the two reflectors are arranged on the piezoelectric substrate in the form of a groove. The piezoelectric substrate is a quartz crystal, which is rotatably cut in 0-30-degree around a Y axis and transmitted along the X direction; the interdigital transducer is an aluminium electrode, the duty ratio of which is 1.3-1.5; the performances of small volume, high Q value, low loss, low parasitism and the like can be realized; the Q value is increased; loss of devices is reduced; and the acoustic surface wave resonator has high practicability.

Owner:SALISENSE TECH

Lead-free glass powder used for back passivation point contact solar cell aluminium paste, and preparation method thereof

The invention discloses lead-free glass powder used for a back passivation point contact solar cell aluminium paste, and a preparation method thereof. The lead-free glass powder is prepared from the following ingredients in parts by weight: 20-50% of ZnO, 5-25% of V2O5, 13-30% of B2O3, 10-25% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-10% of Bi2Se3 and 1-10% of MoTe2. All components are mixed after being stirred and rotated for 1 h in a blender mixer; mixed materials are smelted in a resistance furnace at the temperature of 1110-1250 DEG C, and nitrogen is introduced to keep the temperature for 30-60 min; molten fused glass is rolled into a thin sheet; the thin sheet is smashed to granularity for 1-3 mum, and then, glass powder is subjected to airflow grading sieving to obtain the lead-free glass powder of which the median particle diameter is 1.5-2.5 mu m and the softening temperature is 480-510 DEG C. The lead-free glass powder does not contain lead oxide and has a low softening point, an aluminium electrode and a silicon substrate form good ohmic contact, and the conversion efficiency of the prepared solar cell is high.

Owner:GUIZHOU BYBOARD NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com