Preparation method of back junction N type solar battery, back junction N type solar battery, back junction N type solar battery assembly and back junction N type solar battery system

A solar cell, N-type technology, applied in the field of solar cells, can solve the problems of loss of open circuit voltage, high proportion of silver-containing paste, serious metal recombination, etc., to improve open circuit voltage, reduce silver paste consumption, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

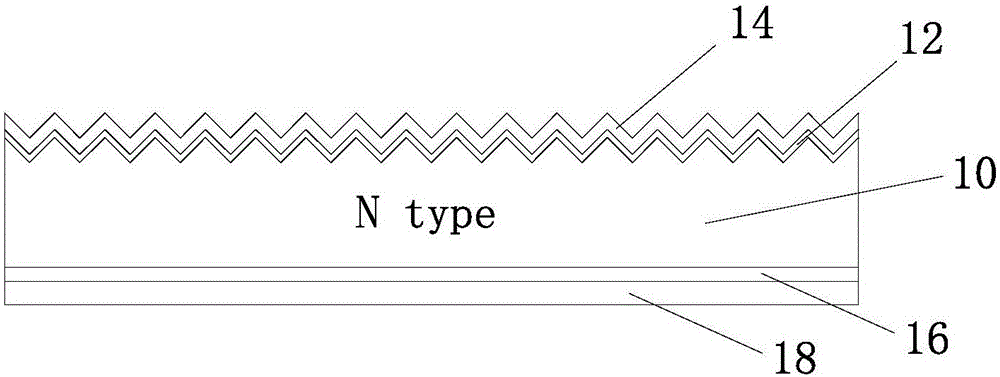

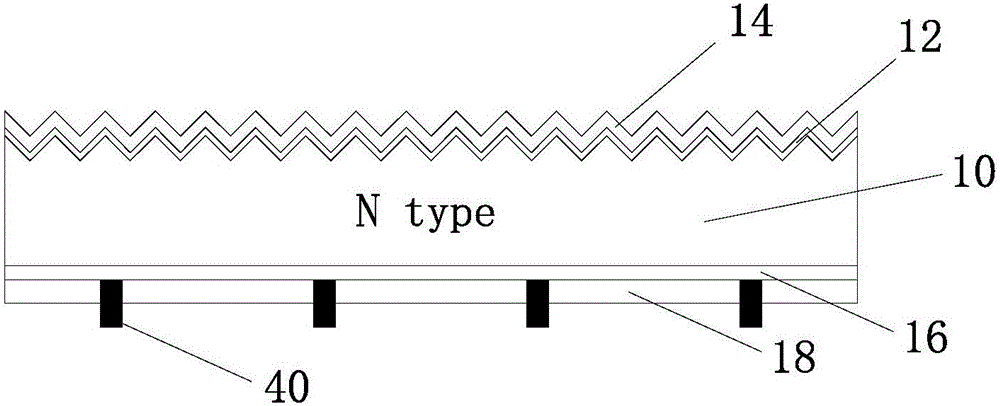

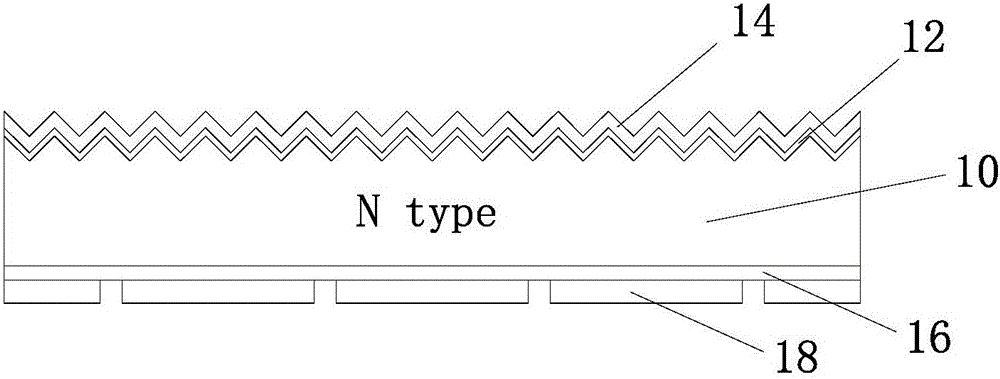

[0031] see figure 1 , Figure 3 to Figure 9 As shown, the preparation method of the back-junction N-type solar cell in this embodiment includes the following steps:

[0032] (1), prepare the back-junction N-type solar cell before metallization, comprise N-type crystalline silicon substrate 10, the front surface of N-type crystalline silicon substrate 10 comprises the n+ doped region 12 and front surface passivation reduction successively from inside to outside The reverse film 14 ; the back surface of the N-type crystalline silicon substrate 10 includes a p+ doped region 16 and a passivation film 18 on the back surface sequentially from inside to outside. Wherein the passivation anti-reflection film 14 on the front surface is SiO 2 and SiN x A composite dielectric film composed of a dielectric film, the passivation film 18 on the back surface is SiO 2 、SiN x and Al 2 o 3 One or more of the dielectric films. The thickness of the N-type crystalline silicon substrate 10 i...

Embodiment 2

[0038] see Figure 1 to Figure 9 As shown, the preparation method of the back-junction N-type solar cell in this embodiment includes the following steps:

[0039] (1), prepare the back-junction N-type solar cell before metallization, comprise N-type crystalline silicon substrate 10, the front surface of N-type crystalline silicon substrate 10 comprises the n+ doped region 12 and front surface passivation reduction successively from inside to outside The reverse film 14 ; the back surface of the N-type crystalline silicon substrate 10 includes a p+ doped region 16 and a passivation film 18 on the back surface sequentially from inside to outside. Wherein the passivation anti-reflection film 14 on the front surface is SiO 2 and SiN x A composite dielectric film composed of a dielectric film, the passivation film 18 on the back surface is SiO 2 、SiN x and Al 2 o 3 One or more of the dielectric films. The thickness of the N-type crystalline silicon substrate 10 is 50-300 μm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com