Patents

Literature

203 results about "Aluminium paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Back surface field aluminium paste for solar cells

ActiveCN102097154AReduce warpageNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

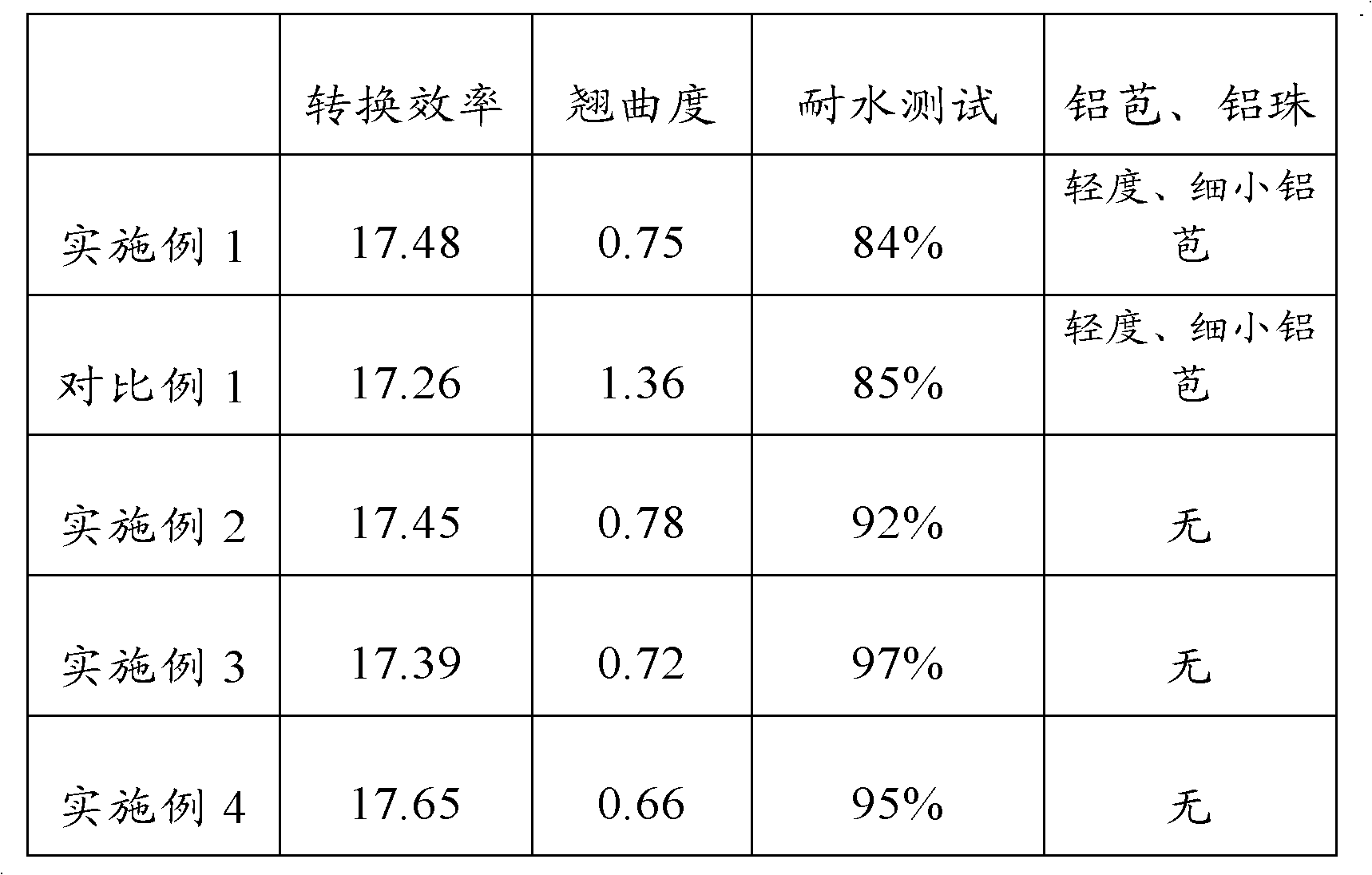

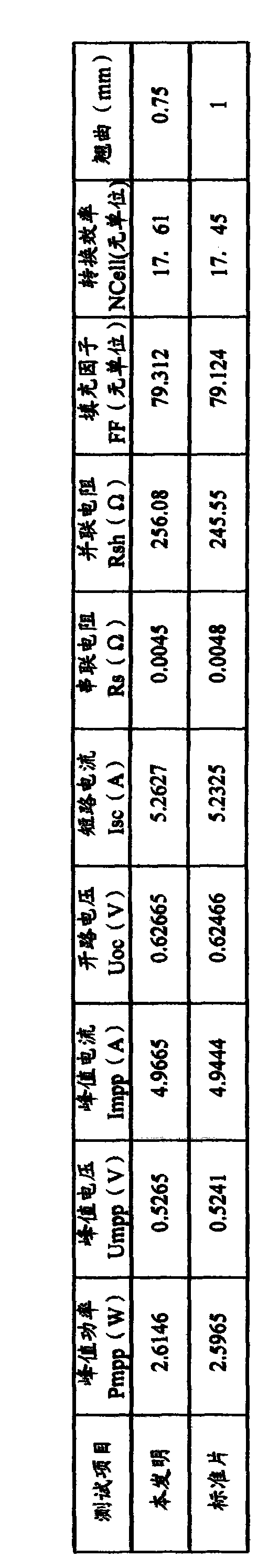

The invention relates to a back surface field aluminium paste for solar cells. The aluminium paste comprises the following components in parts by weight: 65-80 parts of aluminium powder, 1-5 parts of inorganic adhesive, 10-30 parts of organic carrier and 1-2 parts of modifier. Sintered films with lower warpage can be obtained through the back surface field aluminium paste.

Owner:长沙族兴新材料股份有限公司

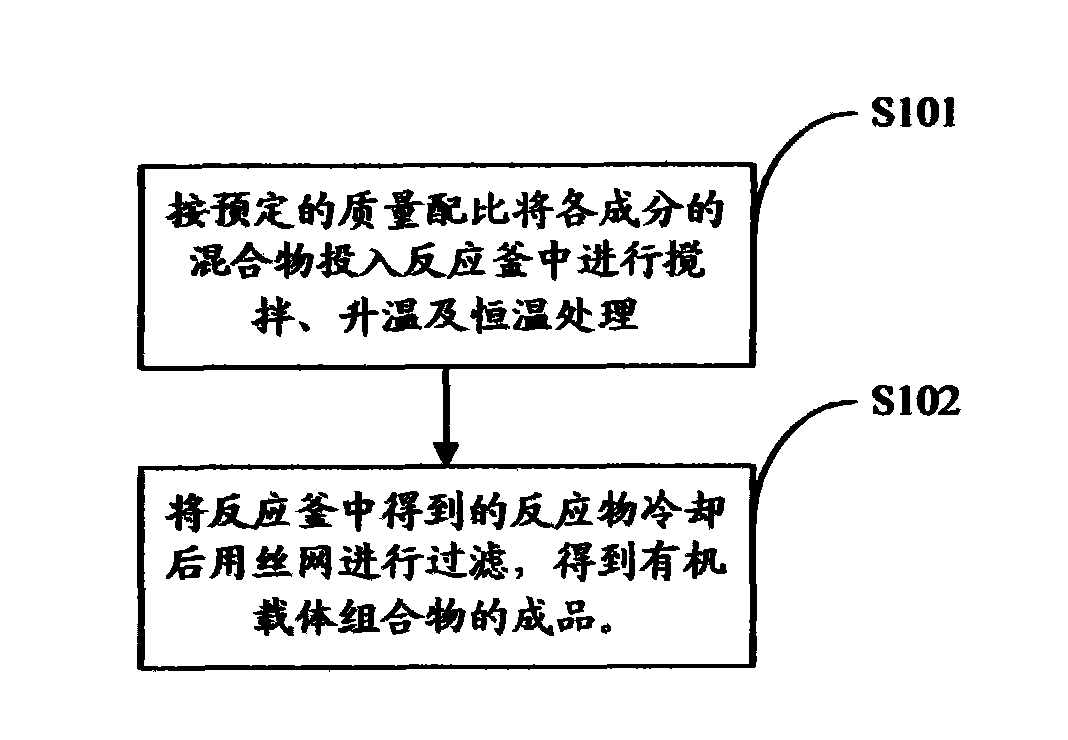

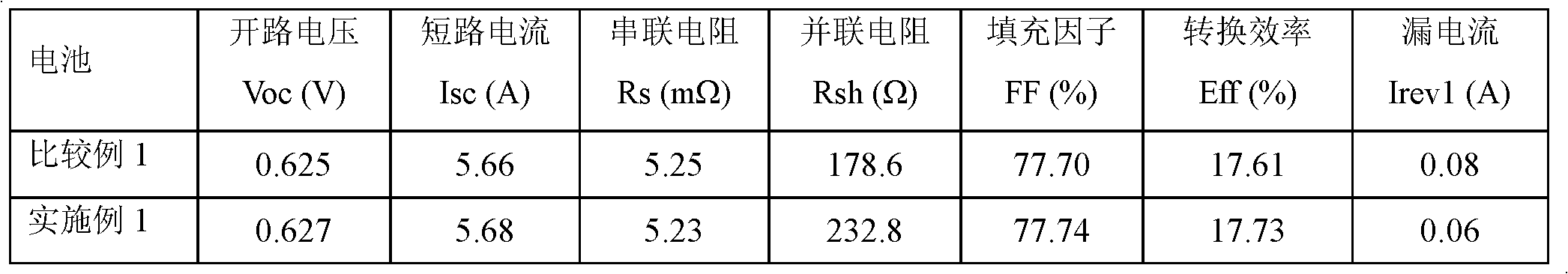

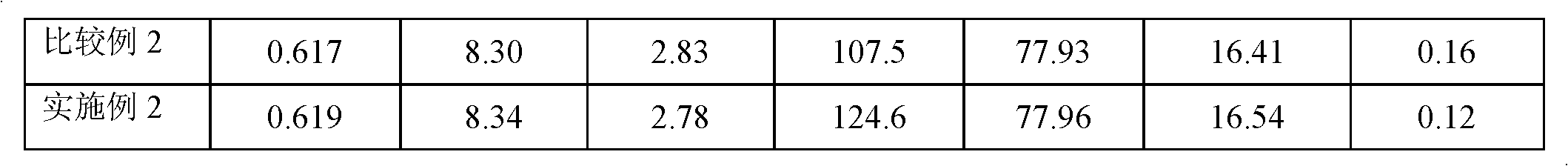

Organic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555394AReduce stressReduce Fragmentation RateFinal product manufactureCellulose adhesivesAluminum Oxide PasteChemistry

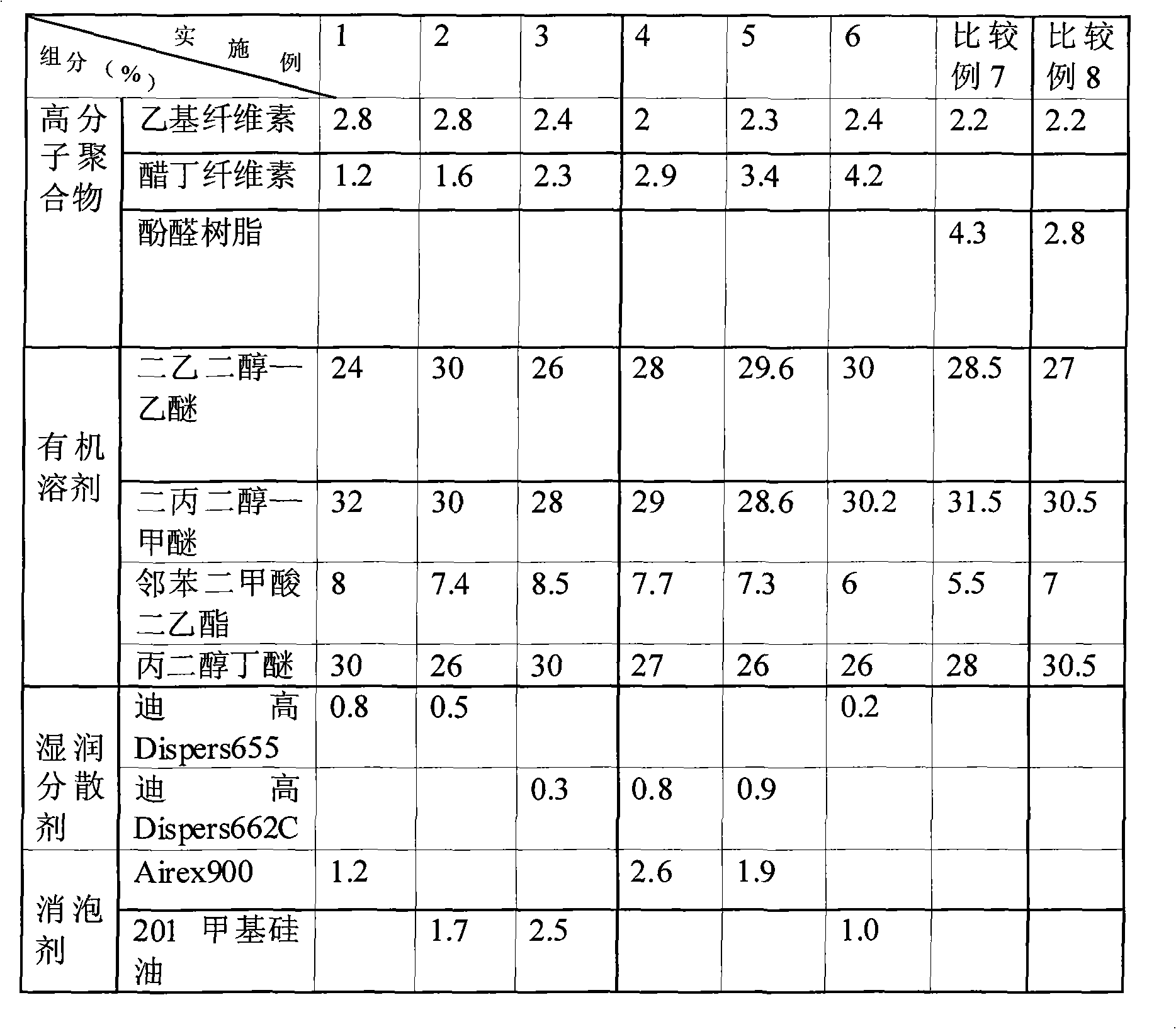

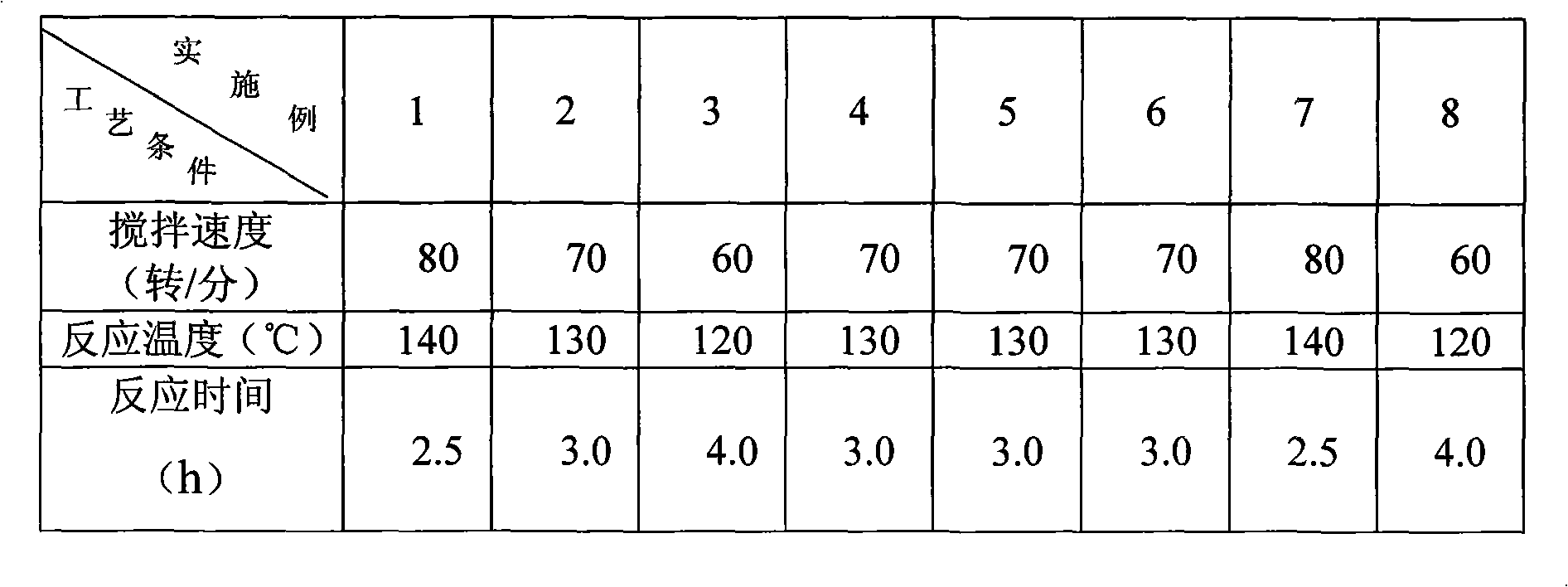

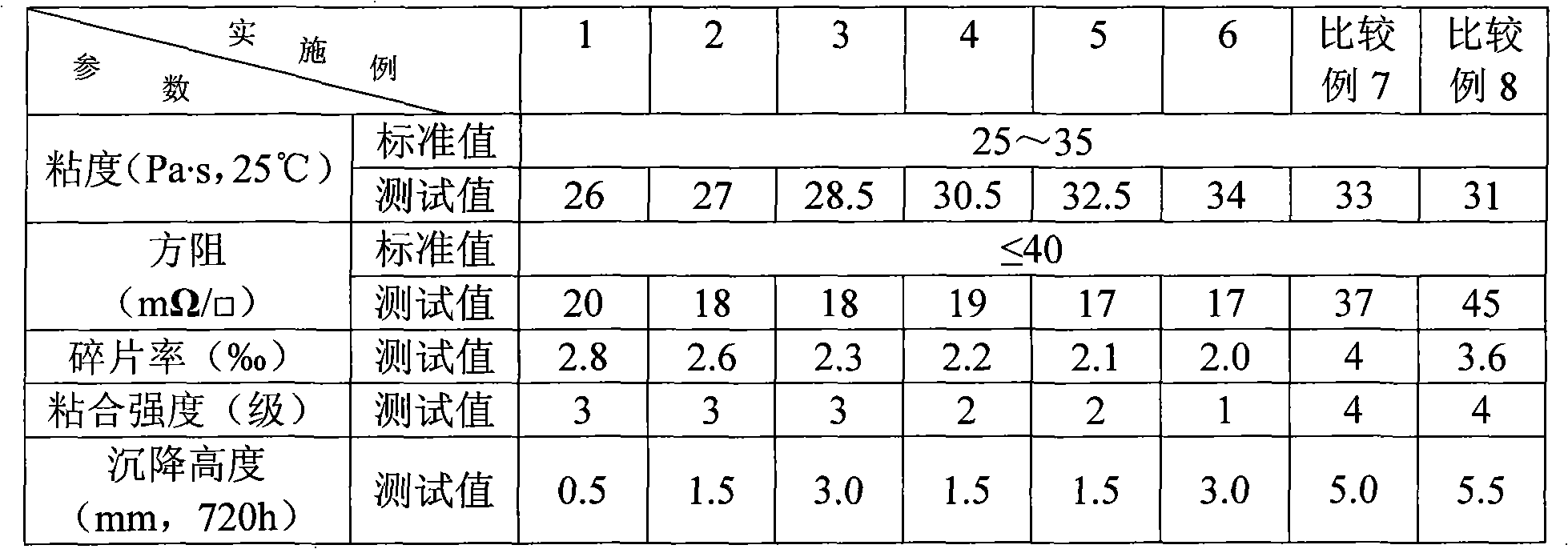

The invention provides organic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The organic adhesive comprises the following components by the weight part: 23% of ethyl cellulose, 1% to 5% of cellulose acetate butyrate, 88% to 94% of organic solvent, 0.2% to 1% of wetting dispersant and 1% to 3% of defoamer with the total amount being 100%. The preparation method comprises the following steps: putting the components into a reaction kettle; heating the components up to the temperature of 120 to 140 DEG C while stirring at the speed of 60 to 80 RPM and holding at a constant temperature for 2 to 4 hours to ensure that the components in the reaction kettle can be evenly stirred and subjected to complete reaction; and cooling the reactant and filtering the reactant with mesh to obtain the final product of the organic adhesive. The aluminum paste prepared from the organic adhesive has the advantages that the dispersibility or the suspensibility thereof is high, the aluminum paste does not laminate or precipitate after long-time storage and the aluminum paste can be uniformly coated so that the solid powder in the dried aluminum powder has the advantages of high adhesive strength and low stress generated on silicon chips.

Owner:WUXI RUXING TECH DEV +1

Solar cell capable of saving silver paste and preparation process thereof

InactiveCN102569438AImprove conductivityReduced series resistanceFinal product manufactureOther printing apparatusSilver pasteSilver plate

The invention belongs to the technical field of solar cells, and particularly discloses a solar cell capable of saving silver paste and a preparation process of the solar cell. The solar cell comprises a silicon chip, a full-aluminium paste layer is coated on the back of the silicon chip, a back silver-plated copper band is arranged on the surface of the full-aluminium paste layer on the back of the silicon chip, a pattern of auxiliary grid lines is arranged on the front of the silicon chip, a plurality of front silver-plated copper bands with bottoms coated with silver paste are arranged on the surface of the auxiliary grid lines; the front silver-plated copper bands are arranged at intervals, and are extended out from the side surface of the silicon chip towards the back of the silicon chip; the front silver-plated copper bands comprise main grid lines and an outward welding band, wherein the main grid lines are arranged on the front of the silicon chip at intervals and form a front electrode, and the welding band is bent and extends towards the back of the silicon chip and is provided with a soldering tin material welded with the silver-plated copper band at the bottom of the adjacent silicon chip. With adoption of the solar cell capable of saving silver paste and the preparation process of the solar cell, the use of silver paste can be reduced, the shading area is reduced, the efficiency of the solar cell is improved, and simultaneously, the silver-pated copper bands can be directly used as the welding band between cell plates, thereby simplifying the welding process, effectively reducing the production cost and being suitable for large-scale industrial production.

Owner:LESHAN VOCATIONAL & TECHN COLLEGE

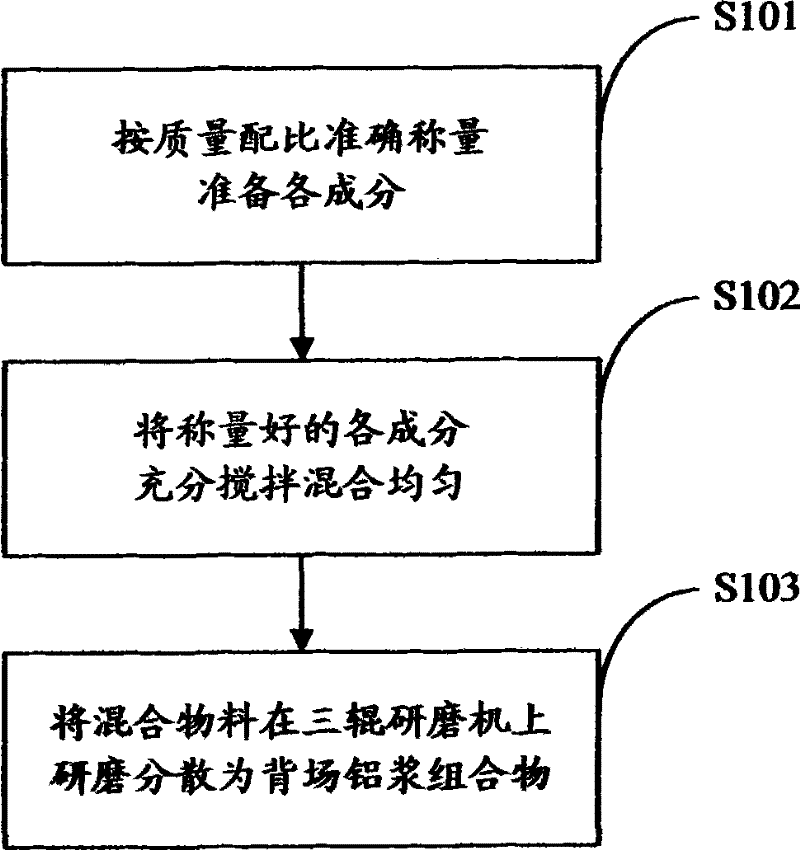

Aluminium paste for preparing crystal silicon solar cell aluminium back surface field and manufacture method thereof

InactiveCN102347094AReduce manufacturing costImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh cellSilicon alloy

The invention relates to an aluminium paste for preparing a crystal silicon solar cell aluminium back surface field and a manufacture method thereof. The paste comprises the following components in percentage by weight: 40-80wt% of aluminium powder, 3-45wt% of aluminium-silicon alloy powder, 0.5-10wt% of lead-free glass powder, 10-26wt% of organic solvent, 2-12wt% of thickening agent and 0.3-6wt% of organic addition agent. The manufacture method for the aluminium paste comprises the following steps: preparing the aluminium-silicon alloy powder; preparing the lead-free glass powder; preparing an organic carrier; proportioning all components; and synthetizing slurry. The aluminium paste has the advantages of reasonable component proportion, simple preparation technology, good adhesive force between the prepared aluminium paste and a solar cell silicon substrate, low slurry production cost, high peeling strength of the aluminium back surface field prepared by sintering, good formation of the aluminium back surface field, small cell sheet flexibility and high cell photoelectric conversion rate, and is suitable for industrial production, and the solar cell photoelectric conversion efficiency can be effectively improved.

Owner:湖南威能新材料科技有限公司

Photosensitive conductive aluminium paste and preparation method

ActiveCN102768464AReduce dosageLow costPhotosensitive materials for photomechanical apparatusMetallurgyAluminium powder

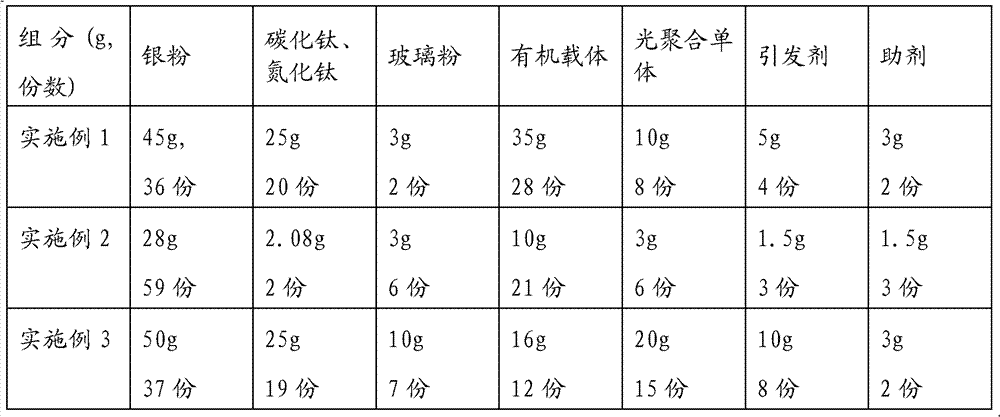

The invention discloses a photosensitive aluminium paste for plasma display site-selection electrodes. The aluminium paste includes the following components: by a weight ratio, 36-59 parts of aluminium powder, 2-20 parts of conductive oxygen-free ceramic powder, 2-7 parts of an inorganic binder, 12-28 parts of an organic carrier, 6-15 parts of a photopolymerization monomer, 3-8 parts of a photoinitiator, and 2-3 parts of an additive. The photosensitive aluminium paste of the invention is added with the conductive oxygen-free ceramic powder, reducing the amount of used aluminium powder and the cost.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD +1

Environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and preparation method thereof

InactiveCN102024856AConducive to import and exportFinal product manufactureSemiconductor devicesAdhesiveHazardous substance

The invention discloses an environment-friendly crystalline silicon solar-cell back surface field silver-aluminium paste and a preparation method thereof. The silver-aluminium paste comprises the following components in percentage by weight: 15-35% of silver powder, 30-70% of aluminium powder, 10-15% of organic carrier, 1-5% of adhesive, 3.5-13% of solvent and 0.5-2% of dispersant. The organic carrier is prepared by dissolving 10-30% of ethyl cellulose resin in 70-90% of organic solvent. In the paste, environment-friendly glass powder without harmful substances is used as the adhesive, and an environment-friendly organic reagent is used as a solvent and a diluter; and thus, the prepared silver-aluminium paste does not contain six substances (Pb, Cd, Hg, Cr(VI), polybrominated diphenyl PBB and polybrominated diphenyl ether PBDE) inhibited by European Union RoHS Instruction, completely conforms to the Instruction 2005 / 84 / EC on phthalic ester in European Union RoHS, realizes environment friendliness in deed, and is beneficial to the import and export of solar cells made in China and raw materials of the cells.

Owner:IRICO

Aluminium paste special for local aluminium back surface field crystalline silicon solar cells and preparation method of aluminium paste

ActiveCN103545013AImprove liquidityAvoid damageFinal product manufactureNon-conductive material with dispersed conductive materialAl powderBack surface field

The invention discloses aluminium paste special for local aluminium back surface field crystalline silicon solar cells. The paste is prepared from, by mass, 70-80 parts of aluminium powder, 0.05-3 parts of inorganic bond, 17-27 parts of organic bond and 1-5 parts of additives in proportion. The invention further discloses a preparation method of the aluminium paste special for the local aluminium back surface field crystalline silicon solar cells. Compared with traditional aluminium paste, the aluminium paste specially applied to the local aluminium back surface field crystalline silicon solar cells has the advantages of good fluidity, small damage to passivating films, good contact with a window, density and uniformity in aluminium coatings, and the like. Average conversion efficiency of mass production of the aluminium paste applied to the local aluminium back surface field crystalline silicon solar cells is more than or equal to 20.0%, and tested aluminium back surface field adhesion tension is more than or equal to 10N via EVA tearing test after the cells are laminated and encapsulated.

Owner:GUANGZHOU RUXING TECH DEV +1

Solar cell back electric field aluminium paste and preparation method thereof

ActiveCN102142467AAvoid cleaningNot blockedFinal product manufactureNon-conductive material with dispersed conductive materialWaxScreen printing

The invention provides a solar cell back electric field aluminium paste comprising the following components in percentage by weight based on the total mass of a conductive paste: 70-85% of aluminite powder, 0.2-10% of glass powder and 10-30% of organic carrier. The solar cell back electric field aluminium paste is characterized in that the organic carrier comprises a thickening agent, micro powder wax, tributyl phosphate and an organic solvent; and micro powder wax accounts for 0.5-3.0wt% and tributyl phosphate accounts for 0.2-5wt% by taking the total mass of the organic carrier as a reference. By utilizing the solar cell back electric field aluminium paste and the preparation method thereof, the technical problems of screen leakage and blockage in the screen printing process can be solved. In addition, the photoelectric conversion rate of a crystalline silicon solar cell can be improved.

Owner:BYD CO LTD

Preparation method of back-contact electrode structure of crystal silicon solar cell

InactiveCN101533875ALow costSolve the "warping" problemFinal product manufactureSemiconductor devicesScreen printingFrit

The invention discloses a preparation method of a back-contact electrode structure of a crystal silicon solar cell. The method comprises the steps of performing silk-screen printing of aluminium paste containing frit on a SiNx film passivation layer on a crystal silicon chip formed with the SiNx film passivation layer by deposition, and then performing the silk-screen printing of complete aluminium paste, and finally sintering at high temperature to prepare the back-contact electrode structure. The method of the invention has simple working procedures and low cost, and is suitable for mass production and for preparing the crystal silicon solar cell with high transformation efficiency in the condition that the silicon chip is continuously thinned.

Owner:SUN YAT SEN UNIV

Aluminium paste for silicon solar battery

InactiveCN102244112AImprove electrical performanceAvoid warpingNon-conductive material with dispersed conductive materialSemiconductor devicesSilicon solar cell5052 aluminium alloy

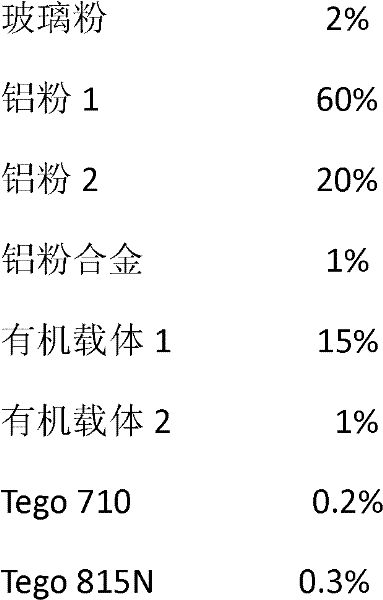

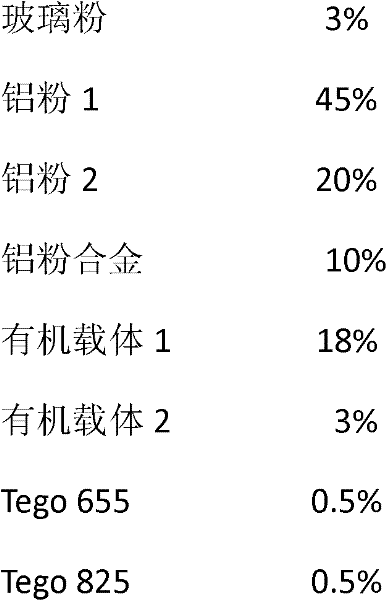

The invention provides aluminium paste for a silicon solar battery, which comprises the following materials: 1-3% of glass powder, 45-60% of first powered aluminum, 20-45% of second powered aluminium, 1-10% of powered aluminium alloy, 15-20% of first organic carrier, 21-5% of second organic carrier, 0.1-0.5% of dispersing agent, 0.1-0.5% of deforming agent and 0-1% of metallic oxide. The aluminium paste for the silicon solar battery, provided by the invention, has the advantages of being capable of preventing silicon slices from warping and alumina beads from forming after baking and having strong adhesive force.

Owner:IRICO

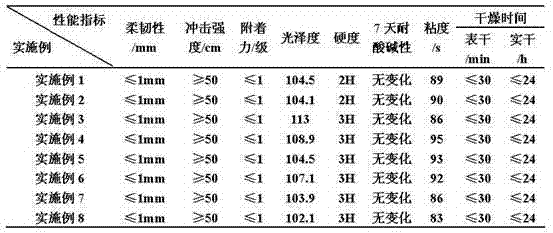

Silver priming paint of 1K silver powder containing automobile refinishing coating and preparation method thereof

The invention discloses a silver priming paint of a 1K silver powder containing automobile refinishing coating and a preparation method thereof. The silver priming paint is composed of a base material and a pigment, wherein the base material contains low hydroxy acrylic resin, polyester resin, cellulose acetate butyrate, a levelling agent, an anti-settling agent and a solvent; and the pigment contains a coated aluminium paste, a wetting dispersant and n-butyl acetate. The preparation method comprises the following steps of: adding the coated aluminium paste into n-butyl acetate with the wetting dispersant dissolved in it so as to obtain the pigment; mixing the low hydroxy acrylic resin, cellulose acetate butyrate, polyester resin, the levelling agent and the anti-settling agent, dispersing at a high speed, and adding the solvent to obtain the base material; adding the pigment into the base material, dispersing at a low speed, discharging, and filtering to obtain the priming paint. The refinishing coating prepared by the complex formulation of the priming paint has advantages of high glossiness, excellent adhesion, good flexibility, high hardness, high scratch resistance, good acid and alkali resistance, high viscosity, rapid surface drying and short flash evaporation time. In addition, no curing agent is added during the preparation process. The priming paint volatilizes and dries itself and is convenient to use. by the adoption of the priming paint, comprehensive performance of the automobile refinishing coating is raised.

Owner:SOUTH CHINA UNIV OF TECH

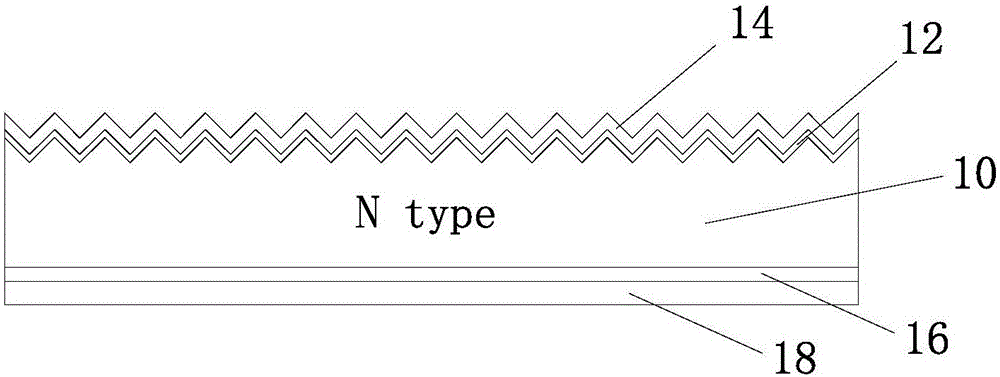

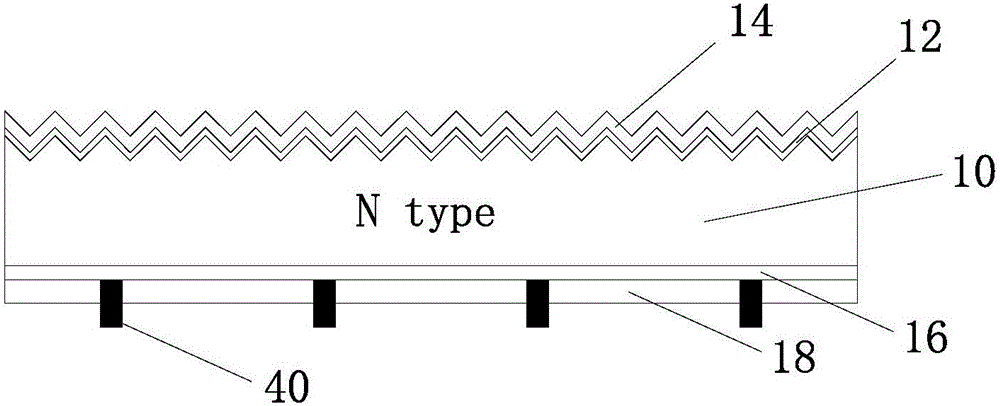

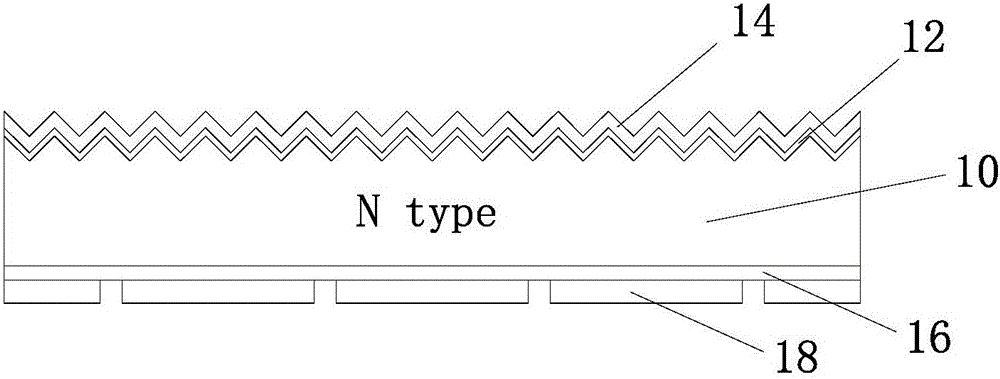

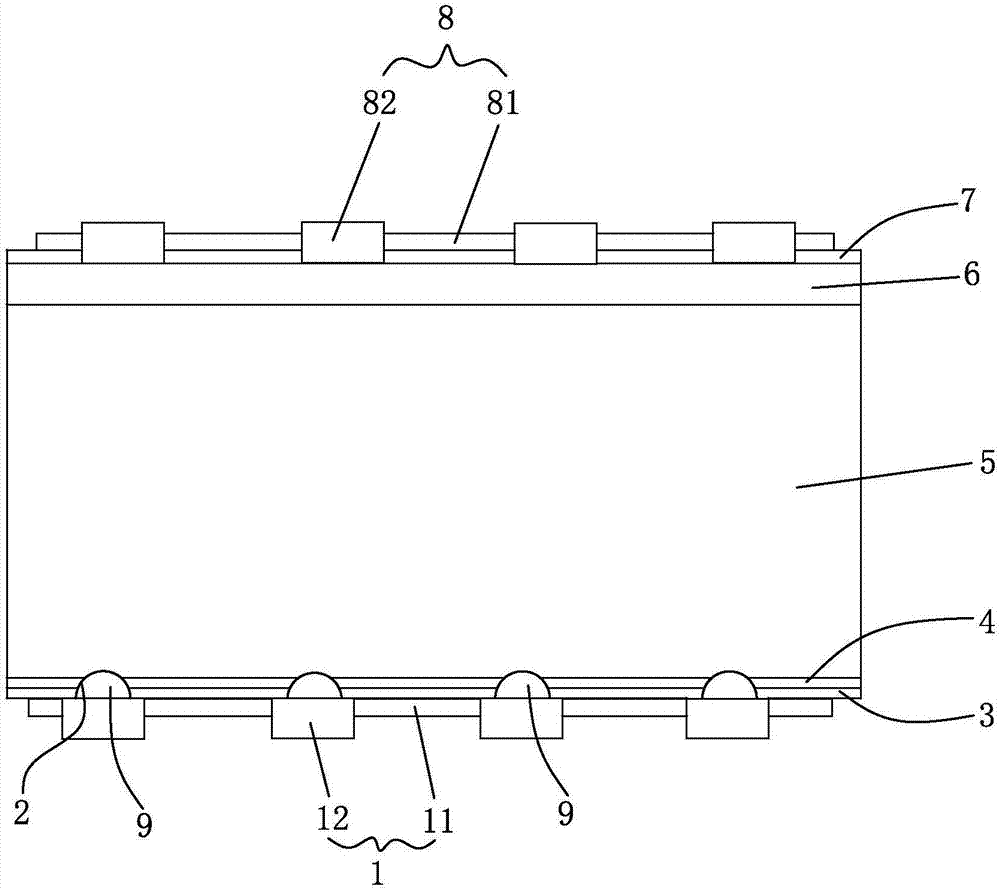

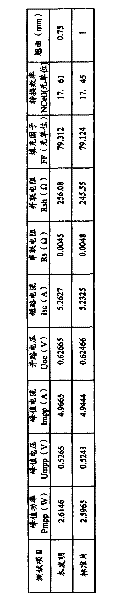

Preparation method of back junction N type solar battery, back junction N type solar battery, back junction N type solar battery assembly and back junction N type solar battery system

InactiveCN105702758AIncrease the open circuit voltageReduce consumptionFinal product manufacturePhotovoltaic energy generationSilver pasteAluminium electrode

The invention discloses a preparation method of a back junction N type solar battery, a back junction N type solar battery, a back junction N type solar battery assembly and a back junction N type solar battery system. According to the preparation method of the back junction N type solar battery, an N type crystalline silicon substrate is processed; a slotted structure penetrating a passivation film is formed on the back surface of the N type crystalline silicon substrate; aluminium paste is printed on the back surface of the N type crystalline silicon substrate, thus forming a back aluminium electrode; silver paste is printed on the back surface of the N type crystalline silicon substrate, thus forming a back silver master gate electrode; the silver paste is printed on the front surface of the N type crystalline silicon substrate, thus forming a front electrode; and sintering is carried out, thus forming the back junction N type solar battery. The method, the battery, the assembly and the system provided by the invention has the advantages that the passivation film on the back surface is slotted; the aluminium paste is printed; the aluminium paste forms partial contact with the p+ doped layer on the back surface, only at the location of the slotted pattern; compared with the method of printing the electrode by aluminium doped silver paste, the method provided by the invention has the advantages of improving the open-circuit voltage of the battery, greatly reducing silver paste consumption of the battery sheet and reducing the preparation cost of the battery sheet.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Method for preparing polycrystalline silicon solar cell by RIE texturing

ActiveCN104362221AReduce mechanical impact damageReduce usageFinal product manufactureSemiconductor devicesChemical treatmentSilicon chip

The invention discloses a method for preparing a polycrystalline silicon solar cell by RIE texturing. The method comprises the following steps that (1) plasma dry etching is used for removing a front surface damage layer of a polycrystalline silicon chip, and then RIE texturing is conducted; (2) a chained wet chemical processing method is used for sequentially conducting back face etching polishing, RIE damage layer removing and post cleaning processing on the silicon chip; (3) the texturing surface of the silicon chip is subjected to phosphorus source diffusion in a back-to-back chip inserting mode; (4) the diffused silicon chip is subjected to wet etching, surface PSG is removed, and then a passivation antireflection film is deposited on the front surface of the silicon chip; (5) back silver and aluminium paste are printed on the back face of the silicon chip and then are dried; then front silver is printed on the front surface of the silicon chip and then is sintered, and accordingly the polycrystalline silicon solar cell can be obtained. According to the method, the technology steps can be reduced, the using amount of chemicals is also reduced simultaneously, and the operation cost of an enterprise is greatly lowered.

Owner:CSI CELLS CO LTD +1

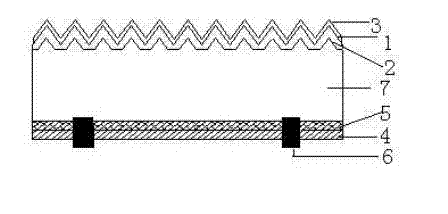

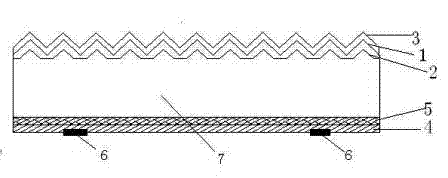

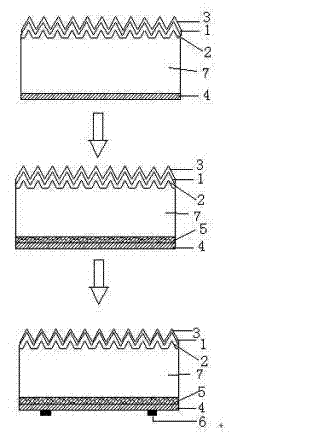

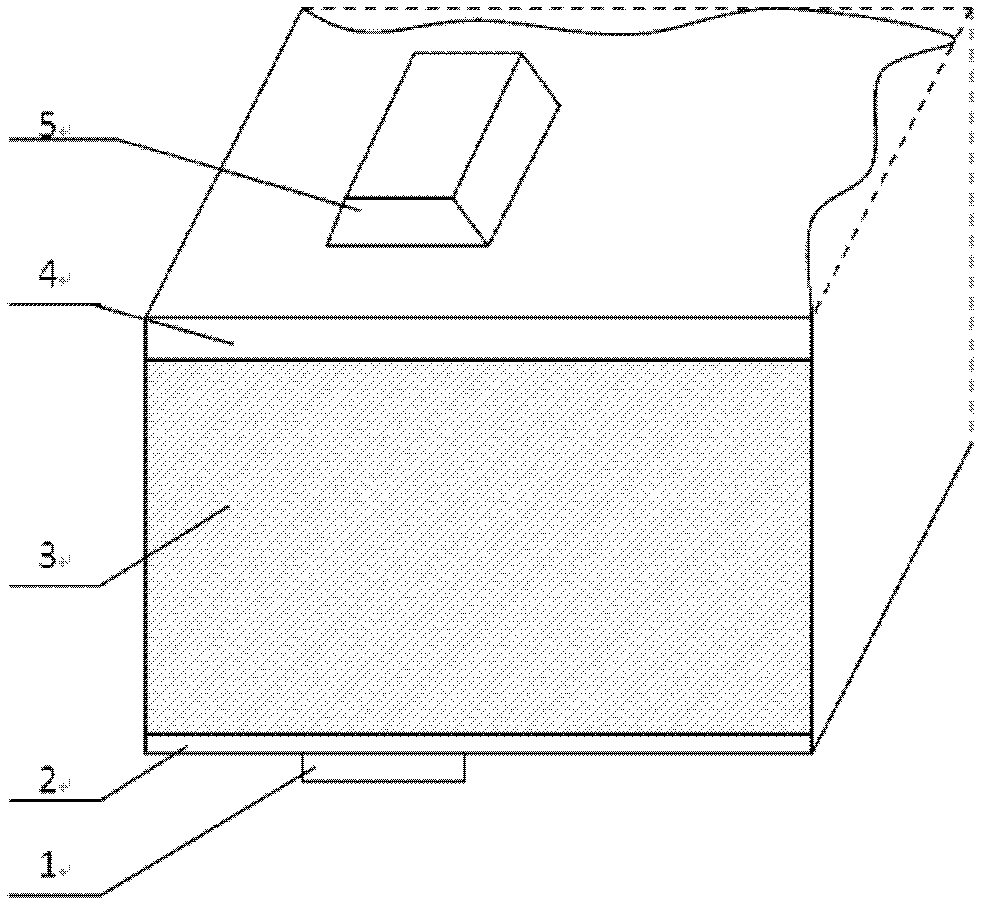

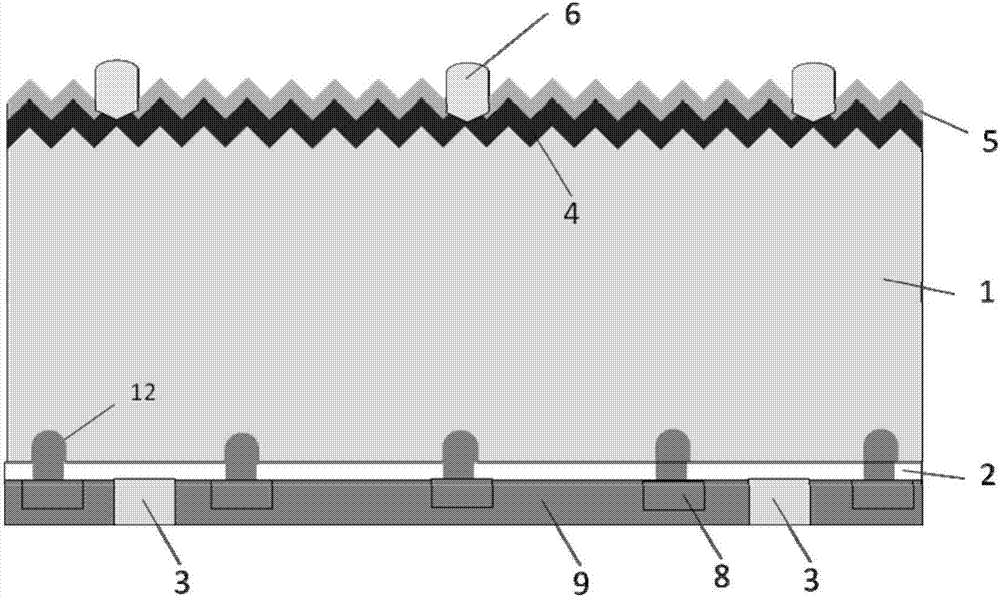

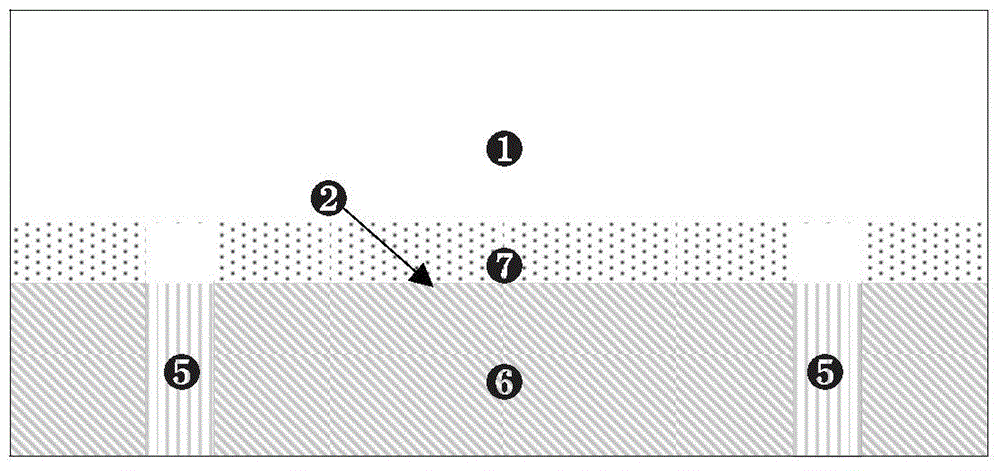

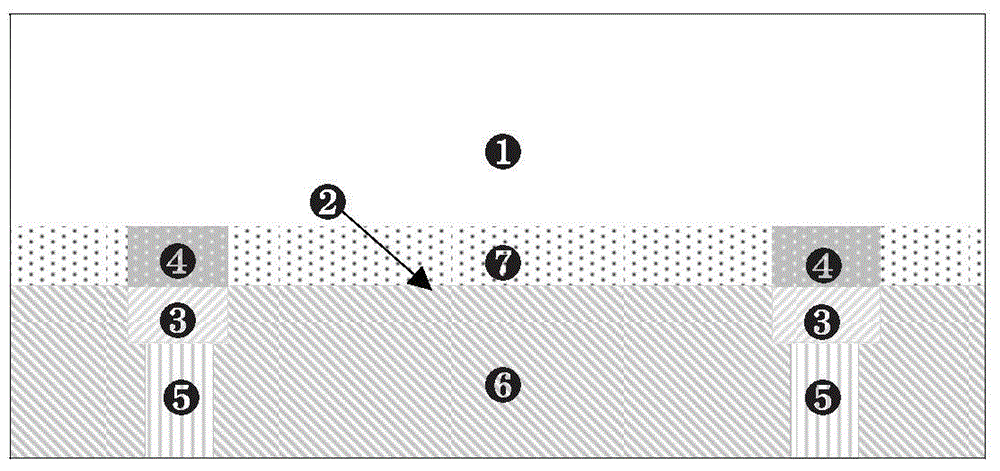

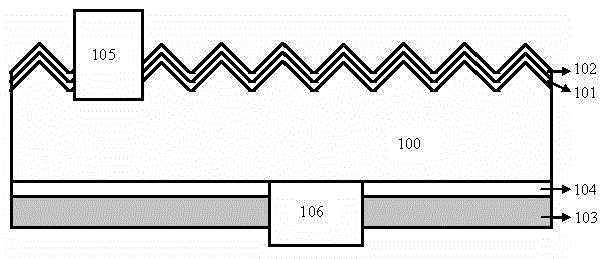

All Al-BSF crystal silicon cell and preparation method thereof

InactiveCN102903765ANo additional equipmentNo process addedFinal product manufactureSemiconductor devicesEngineeringCrystalline silicon

The invention discloses an all Al-BSF crystal silicon cell and a preparation method thereof. The all Al-BSF crystal silicon cell comprises a silicon wafer layer (7), wherein a P+ passivation layer (5) and an Al-BSF conducting layer (4) are sequentially bonded on a back face of the silicon wafer layer (7); and a back electrode (6) is arranged on the Al-BSF conducting layer (4). The method comprises the following steps of: printing one layer of aluminium paste on all positions of a back face of a solar cell expect for edges; printing the back electrode; and forming the P+ passivation layer on an electrode area through sintering. Due to the structure of the cell, direct contact of silver and a silicon wafer is avoided, so that the complex defects of a back electrode area is greatly reduced; the photoelectric conversion efficiency of the crystal silicon cell can be greatly improved; and compared with a preparation manner of a general cell, an overlapping area of the back electrode and BSF can be neglected, and the width of the electrode can be reduced, so that the production cost is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Organic carrier composition for solar cell back surface field aluminium paste and preparation method thereof

InactiveCN101914221AEliminate hazardsGood dry film adhesionFinal product manufactureNon-conductive material with dispersed conductive materialDiethylene glycol monobutyl etherCellulose

The invention relates to an organic carrier composition for solar cell back surface field aluminium paste, comprising a main carrier; wherein the main carrier comprises the following components by mass: 3-5% of methylcellulose, 30-45% of terpinol, 20-40% of diethylene glycol monobutyl ether, 10-20% of diethylene glycol monobutyl ether acetate and 0.2-1% of lecithin. The invention also relates to a method for preparing the organic carrier composition used for solar cell back surface field aluminium paste. In the organic carrier composition for solar cell back surface field aluminium paste and preparation method thereof which are provided by the invention, diethylene glycol monobutyl ether acetate is adopted to substitute the traditional o-benzene compound and is taken as solvent and plasticizer, thus eliminating environmental harm of organic carrier.

Owner:CHANGZHOU YINGDE ENERGY TECH

A back field back electrode of a crystalline silicon battery and its printing process

ActiveCN102280525AIncrease passivation areaReduce compoundingFinal product manufactureSemiconductor devicesElectricitySlurry

The invention relates to a crystal silicon cell back field back pole and a printing technology thereof. Aluminium paste is printed on the back surface of a crystal silicon sheet and is dried at certain temperature to form an aluminium back field; and back electrode slurry is printed on the dried aluminium paste surface to form a back electrode pattern. According to the printing technology, the area of the crystal silicon cell aluminium back field can be increased, crystal silicon back surface compound is reduced, and the gettering effect of the aluminium back field is increased, and the electric performance of the crystal silicon cell is effectively improved.

Owner:REALFORCE POWER

Local aluminium surface-back-field solar cell and preparation method of the same

PendingCN107068777AReduce formation rateImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectricityBlack point

The invention discloses a local aluminium surface-back-field solar cell. The local aluminium surface-back-field solar cell includes a crystalline silicon wafer, wherein the back surface of the crystalline silicon wafer is provided with a passivation layer and a back electrode; and the front surface of the crystalline silicon wafer is provided with an emitting electrode, an anti-reflection layer and a front electrode. The local aluminium surface-back-field solar cell is characterized in that a laser open hole or open groove is formed in the passivation layer on the back surface of the crystalline silicon wafer; the laser open hole or open groove is provided with a first layer of local back surface aluminium paste covering the laser open hole or open groove; the first layer of local back surface aluminium paste, the front electrode and the back electrode are formed together through sintering; and a second layer of back surface aluminium paste which processed through high temperature is arranged on the first layer of local back surface aluminium paste. The local aluminium surface-back-field solar cell can greatly reduce the voidage of the local aluminium surface-back-field cell through optimization of aluminium paste printing and the sintering technology so as to solve the problem that black points and black lines appear during the electroluminescent process and improve the photoelectric conversion efficiency of the cell. The invention also discloses a preparation method of the local aluminium surface-back-field solar cell.

Owner:JA SOLAR TECH YANGZHOU +1

P-type PERC double-faced solar cell employing laser marking alignment and preparation method thereof

ActiveCN106972065AReduce defective rateSimple structureFinal product manufacturePhotovoltaic energy generationSilver electrodeP type silicon

The invention discloses a P-type PERC double-faced solar cell employing laser marking alignment and a preparation method thereof. The P-type PERC double-faced solar cell comprises back electrodes, a back side silicon nitride film, an alumina film, P-type silicon, an N-type emitter electrode, a front side silicon nitride film and positive silver electrodes which are sequentially arranged from bottom to top. Each back electrode is formed by a back electrode main grid and a back aluminum grid line which are vertically crossed and are connected with each other, the back side silicon nitride film is provided with several grooves traversing the back side silicon nitride film and the alumina film to form laser grooving zones, the P-type silicon is exposed in the grooves, the parts, of the back aluminum grid lines, arranged in the grooves are connected with the P-type silicon, the back side silicon nitride film is provided with laser marks, relative positions of the laser marks and the laser grooving zones are preset, by positioning the laser marks and in dependence on the distance between the laser grooving zones and the laser marks, the printing back aluminum grid lines are aligned. According to the invention, aluminium paste on the back side of each silicon chip can accurately cover the laser grooving zones, and the fraction defective of the double-faced PERC solar cells can be effectively reduced.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD

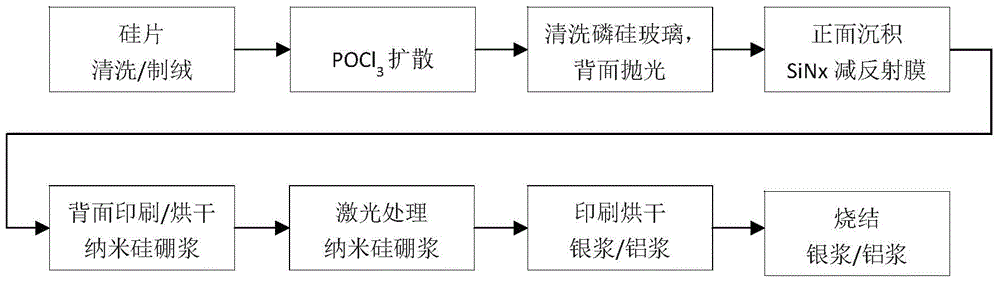

Nano silicon boron slurry and method for preparing solar cell with the same

InactiveCN104617164AImprove efficiencyReduce contact resistanceFinal product manufacturePhotovoltaic energy generationNano siliconGrating

The invention discloses nano silicon boron slurry and a method for preparing N type composite emitter and an improved P type solar cell with the nano silicon boron slurry. The nano silicon boron slurry is used as a carrier, and local boron adulteration of the grating line coverage area of the solar cell back through laser or high-temperature treatment can be realized. The method is combined with the aluminum paste sintering process to prepare an N-type composite emitter cell when an N type cell is produced so that the problems that the ordinary aluminum paste sintering process only forms emitters in the aluminum paste coverage area and the emitters in the silver grating line coverage area are not continuous can be solved, and the photovoltaic conversion efficiency of the N type aluminum emitter cell is improved. The method is combined with the original aluminum paste sintering process to prepare the improved P type cell when the P type cell is produced so that the problems that the original P type cell only forms a back surface field in the aluminum slurry coverage area and the back surface field in the silver grating line coverage area is not continuous can be solved.

Owner:苏州金瑞晨科技有限公司

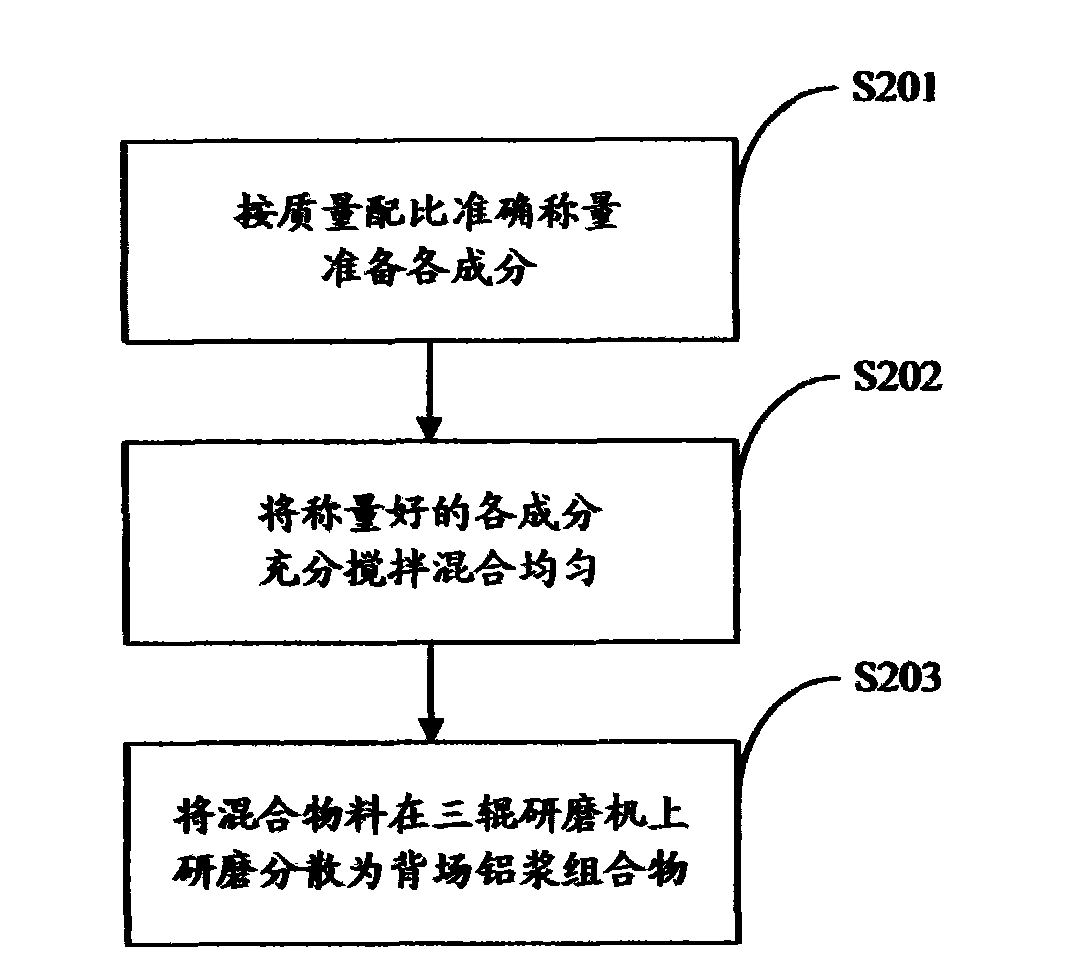

Crystalline silicon solar cell back surface field aluminum paste and preparation method thereof

ActiveCN103208321AUniform fluidityBalanced thixotropyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldWater boil

The invention relates to crystalline silicon solar cell back surface field aluminum paste and a preparation method thereof. The crystalline silicon solar cell back surface field aluminum paste comprises, by weight, 74 parts of aluminum powder, 20-25 parts of organic bonds, 1-4 parts of lead-free glass powder and 0.1-2 parts of additives, wherein the organic bond comprises, by weight, 40-70 parts of terpineol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of dibutyl phthalate and one part of sorbitol anhydride stearate; the lead-free powder comprises, by weight, 30-60 parts of Bi2O3, 5-15 parts of B2O3, 3 parts of BiF3, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 1-3 parts of P2O5; and the additive is spherical copper powder with the purity larger than 99% and the fineness being 20000 meshes. The aluminum powder, the organic bonds, the lead-free glass powder and the additives are evenly mixed and then rolled by a three-roll grinder until the fineness is smaller than or equal to 10 mum and the viscosity is 30-60Pa*s. The crystalline silicon solar cell back surface field aluminum paste is high in photoelectric conversion efficiency and adhesive force, the adhesive force conversion efficiency after high temperature aging declines, and the water-boiling resistance is good.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Non-floating type silicon dioxide coated waterborne aluminium paste and preparation method thereof

InactiveCN102061114ARich varietyLow tinting strengthInorganic pigment treatmentPigment pastesElectricityIndustrial smog

The invention provides non-floating type silicon dioxide coated waterborne aluminium paste and a preparation method thereof. The non-floating type silicon dioxide coated waterborne aluminium paste is characterized in that the aluminium paste is self-assembled silicon dioxide colloidal particles; SiO2 colloids with negative electricity are evenly and compactly absorbed on the front surface of aluminium powder with positive electricity; the particle size of the aluminium powder with positive electricity is 5-50nm; and the thickness of the silicon dioxide film coated on the aluminium powder surface is 1-10nm. The non-floating type aluminium paste has various types, the tinting strength of the non-floating type aluminium paste is increased from low to high, the grain size of the non-floating type aluminium paste is reduced from thick to thin, and the appearance of the non-floating type aluminium paste is from white, bright to darker and is more and more finer; and in addition, a series of acid-resisting products can reduce influences of industrial smog, acid rain and other adverse environments on paints.

Owner:柴中南

Aluminium paste anode electrophoresis tank liquid and aluminium paste anode electrophoresis technology

InactiveCN105153782ALow solidsImprove stabilityElectrophoretic coatingsPaints for electrolytic applicationsElectrophoresisHardness

A provided aluminium paste anode electrophoresis tank liquid is composed of anode electrophoresis paint, aluminium paste, an aluminium paste auxiliary agent, a solvent and deionized water. A provided aluminium paste anode electrophoresis technology comprises the following steps: (1) pretreating a base material; (2) putting the pretreated base material in the aluminium paste anode electrophoresis tank liquid for electrophoresis, and controlling all technological parameters; (3) washing by using pure water; and (4) solidifying and drying. Various technological problems in the prior art are broken through, the developed liquid and technology are suitable for aluminium paste anode electrophoresis, an electrophoresis film with the thickness of 15-30 mu m is obtained, and the film is uniform in thickness, high in hardness, good in adhesive force, good in wear resistance, flat in appearance, slivery white and strong in metal texture, and possesses both corrosion resistance and decorative property.

Owner:东莞市霖辉金属表面处理材料有限公司

Back field aluminum paste composition of solar battery and preparation method thereof

InactiveCN101916610BReduce stressReduce warpageNon-conductive material with dispersed conductive materialCable/conductor manufactureMass ratioDiameter ratio

The invention relates to a back field aluminum paste composition of a solar battery, wherein the back field aluminum paste composition of the solar battery comprises the following components in percentage by weight: 70-76 percent of aluminum powder, 1-3 percent of glass binder phase and 20-30 percent of organic carrier, wherein the aluminum powder is formed by mixing fine aluminum powder with grain diameter of 3-5mum and coarse aluminum powder with grain diameter of 6-8mum in a predetermined mass ratio, and the grain diameter ratio of the fine aluminum powder to the coarse aluminum powder is greater than 0.414. In the back field aluminum paste composition of the solar battery and the preparation method thereof provided by the technical scheme of the invention, by reasonably designing the grain diameter ratio of the fine aluminum powder to the coarse aluminum powder, the stress generated in process of sintering is minimum, therefore, the purpose of reducing warping is realized.

Owner:CHANGZHOU YINGDE ENERGY TECH

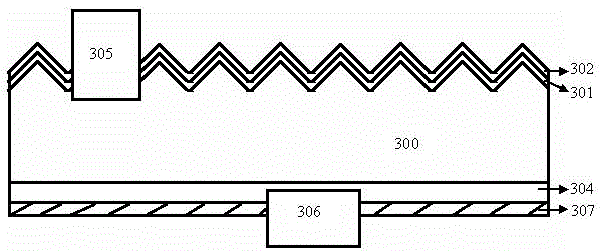

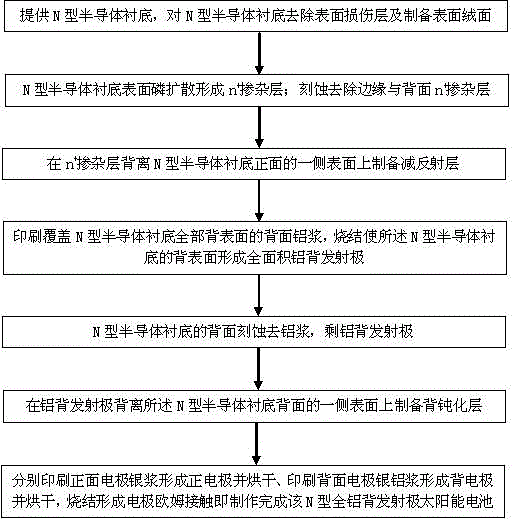

Manufacturing method of N type all-aluminum back emitter solar cell and solar cell prepared by the same

InactiveCN104868011AAvoid leakage currentImprove energy conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a manufacturing method of an N type all-aluminum back emitter solar cell and a solar cell prepared by the same. The manufacturing method comprises: providing an N type semiconductor substrate, removing a surface damage layer, and preparing a surface pile face; carrying out phosphorus diffusion to form an n<+> doping layer and etching and removing the parts, formed at the edge and the back, of the n<+> doping layer; preparing an antireflection layer at the front side; printing a back aluminium paste and carrying out sintering to form a full-area aluminum back emitter; carrying out etching at the back and removing the aluminium paste and keeping the aluminum back emitter; preparing a back passivation layer at the back; printing a front electrode silver paste and carrying out drying, printing a back electrode silver-aluminium paste and carrying out drying, and carrying out sintering to form electrode ohmic contact. According to the invention, a problem of leak current existence at the boundary of the local back aluminium emitter and the back silver electrode can be solved; the solar cell quality is improved; and the conversion efficiency is improved by increasing the effective area of the PN node. With the back passivation layer, the open-circuit voltage and short-circuit current of the cell are increased. Moreover, the dual-face solar cell can be manufactured, so that the cell energy output is enhanced and the conversion efficiency is improved.

Owner:DK ELECTRONICS MATERIALS INC

Special high temperature-resistant coating on outer wall of tobacco-curing furnace and preparation method thereof

InactiveCN102153947AMeet the needs of useHigh temperature resistance hasCoatingsMicrosphereTemperature resistance

The invention discloses a special high temperature-resistant coating on an outer wall of a tobacco-curing furnace, which consists of the following components according to parts by weight: 30-40 parts of organic silicon resin, 5-10 parts of aluminium paste, 8-12 parts of titanium white, 30-40 parts of mixed stuffing, 0.5-1.5 parts of organic bentonite, 2-4 parts of PM, 1-3 parts of PMA (Propylene Glycol Monomethyl Acetate), and 4-6 parts of absolute ethyl alcohol, wherein the mixed stuffing consists of the following components according to parts by weight: 35-45 parts of low-melting point glass powder, 10-20 parts of hollow ceramic microspheres, 10-20 parts of zinc phosphate, 5-15 parts of aluminum tripolyphosphate and 18-22 parts of talcum powder. The special high temperature-resistant coating on the outer wall of the tobacco-curing furnace mainly has the advantages that a viscosity number reaches 85s, the percentage of solid reaches 65%, surface dry only needs 16 minutes, hard dry only needs 6 hours, the thermal endurance is strong, and the coating is not stripped for 6h at 500 DEG C. The coating has the advantages of high temperature resistance, rust prevention, quick drying, heat insulation, environmental protection and the like, can satisfy the use requirements on the outer wall of the tobacco-curing furnace, and is especially applicable for the tobacco-curing furnace.

Owner:无锡市南雅化工有限公司

Lead-free glass powder for aluminium paste of solar cell

The invention relates to a lead-free glass powder for the aluminium paste of a solar cell and a preparation method for the same. The lead-free glass powder comprises the following components in percentage by weight: 20-29% of bismuth oxide, 5-15% of boron oxide, 21-39% of silicon oxide, 5-30% of zinc oxide, 1-10% of calcium oxide, 1-10% of antimony oxide and 0.5-5% of tin oxide, wherein the total of the percentages by weight of the raw material components is 100%; the median particle diameter of the glass powder is 2 mum, and the maximum particle diameter of the glass powder is 5 mum; and the softening temperature of the glass powder is 400-550 DEG C. Compared with the prior art, the lead-free glass powder for the aluminium paste of a solar cell disclosed by the invention is low in the content of the bismuth oxide component, high in the contents of the silicon oxide component and the boron oxide component, good in wettability with a silicon substrate, and capable of forming good bonding with the silicon substrate; and moreover, the glass powder is capable of avoiding damages on the substrate due to the over-reaction of the glass powder and the silicon substrate during sintering, beneficial to the epitaxial growth of the silicon substrate to form a P+ layer, and capable of increasing the electric performance of the cell slice.

Owner:JIANGSU RUIDE NEW ENERGY TECH

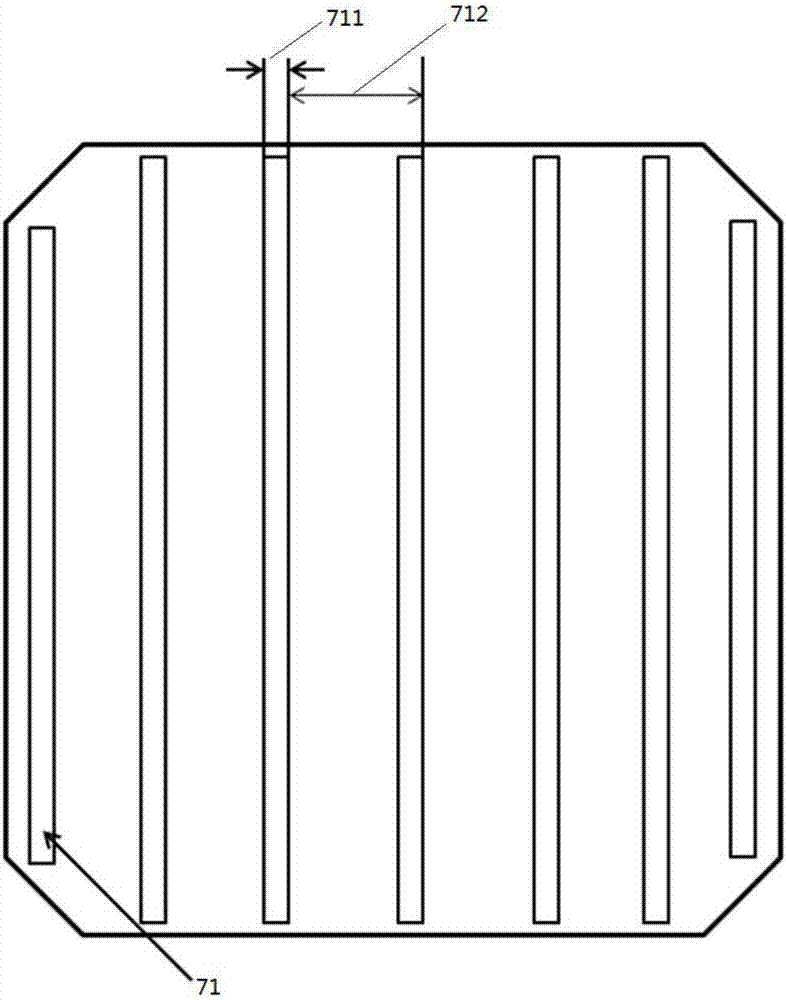

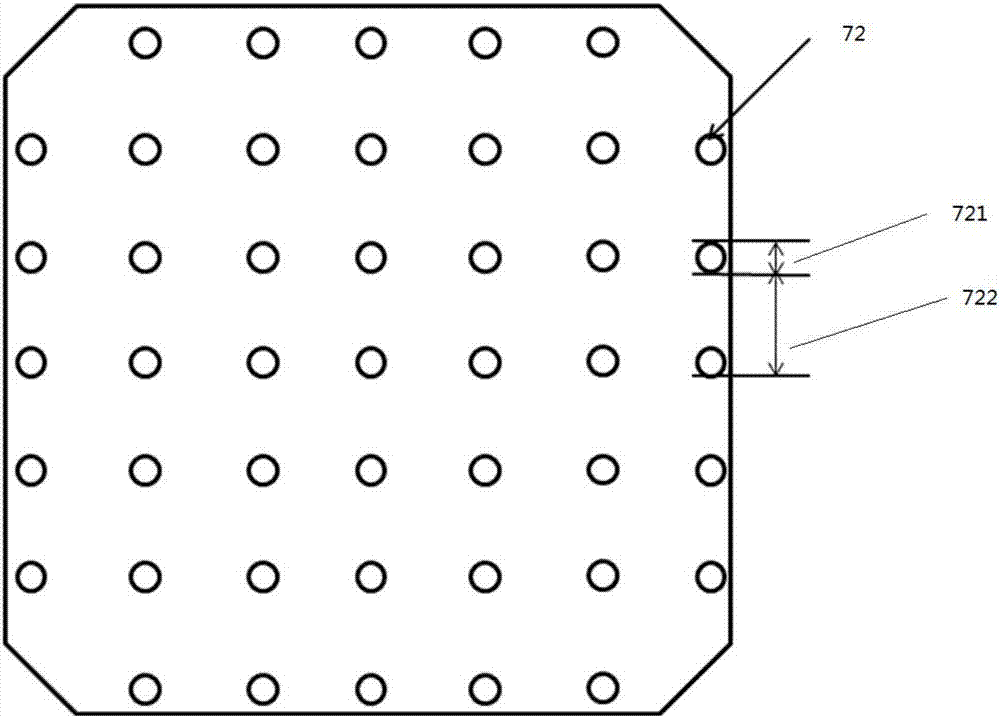

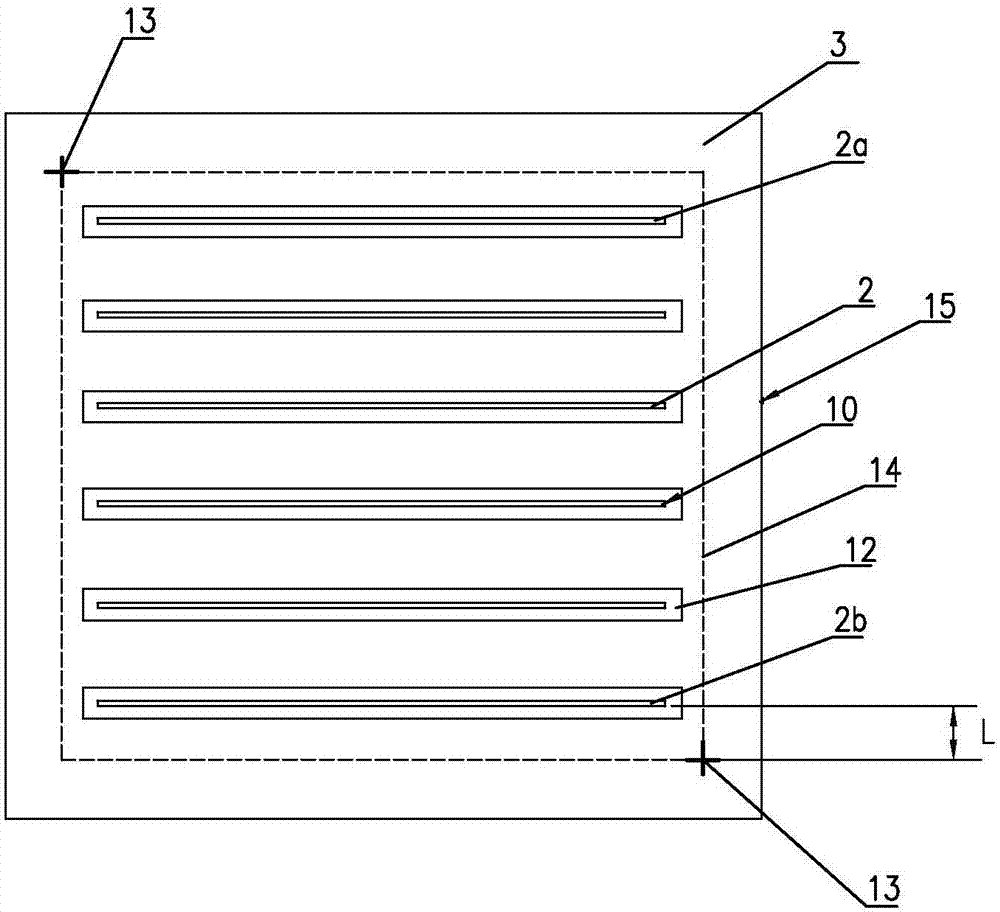

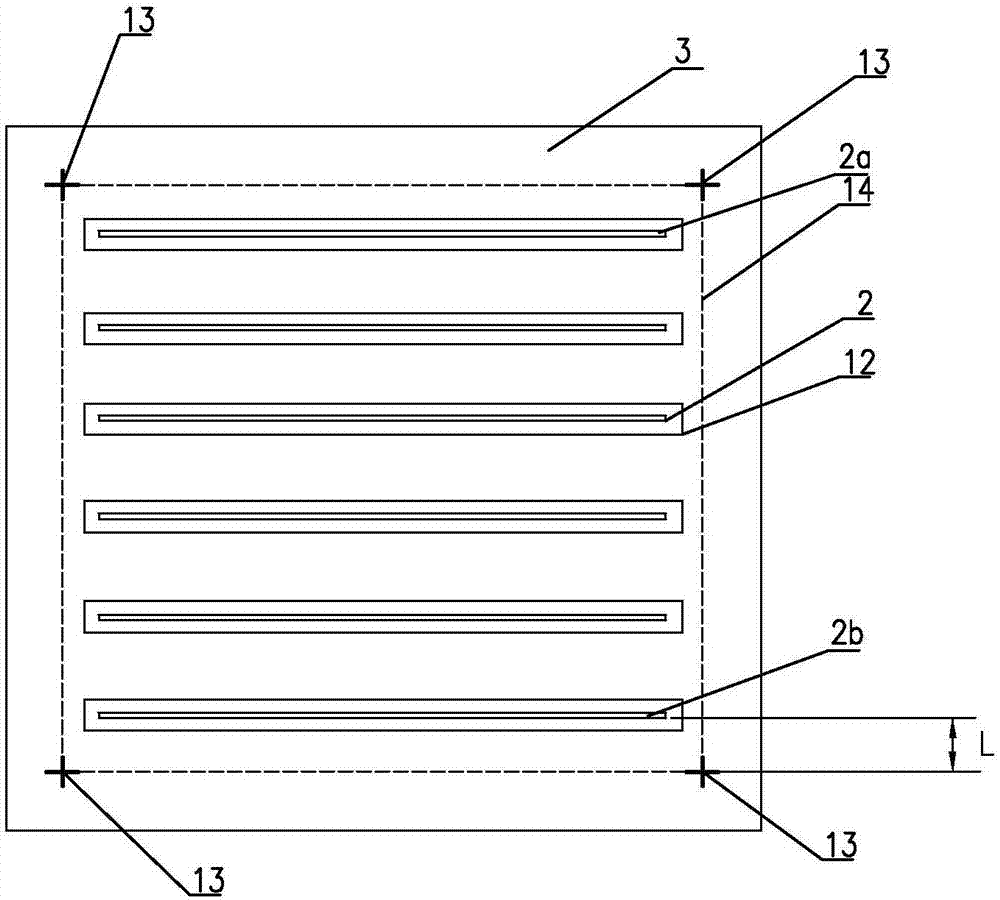

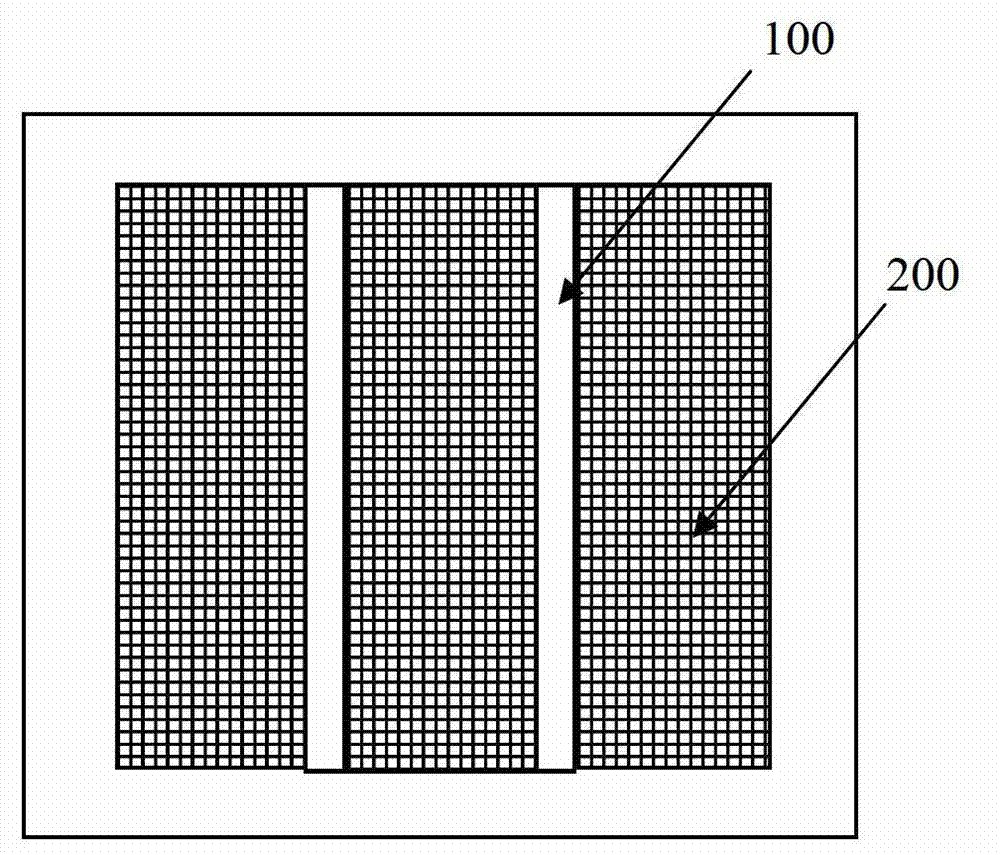

Solar cell wafer and printing screen thereof

ActiveCN103029423AImprove conversion efficiencyUniform thicknessScreen printersSemiconductor devicesEngineeringAluminium paste

The invention discloses a solar cell wafer and a printing screen thereof. The number of the meshes of the two edge engraved areas of the printing screen parallel with the printing direction is less than the number of the meshes of the other engraved area. By changing the parameter of part of the edge engraved areas of the printing screen, the thickness of aluminium paste printed on the whole silicon wafer is enabled to be uniform, the surface of the edge area with thin aluminium is prevented from becoming rough or producing aluminium balls due to temperature fluctuation when sintering temperature is high, the sintering temperature regulation range is broadened, consequently, the surface electric contact capability between the front electrode, the back electrode and the back electric field of the solar cell wafer can be enhanced by increasing the sintering temperature, and thereby the conversion efficiency of a solar cell can be increased ultimately.

Owner:YINGLI ENERGY CHINA

Manufacturing process of local back surface field

InactiveCN102983225ARealize self-drillingReduce production processFinal product manufactureSemiconductor devicesSilver pasteAmorphous silicon

The invention discloses a manufacturing process of a local back surface field, which comprises the following steps of a, washing and conducting texture surface making on a silicon wafer, b, diffusing the washed silicon wafer, c, removing back surface junctions of the diffused silicon wafer and polishing the back surface; d, depositing a silicon nitride anti-reflection film on the front surface of the silicon wafer with the polished back surface, depositing an amorphous silicon film, an aluminum oxide film or a silicon oxide film on the bottom layer of the back surface, and depositing a silicon nitride film on the upper layer, e, printing aluminum paste on the back surface and silver paste on the front surface, and f, forming the local back surface field by sintering. With the adoption of the manufacturing process of the local back surface field, self-opening of a passive film of the back surface field can be realized, production procedures are reduced, and the production cost is lowered.

Owner:泰州德通电气有限公司

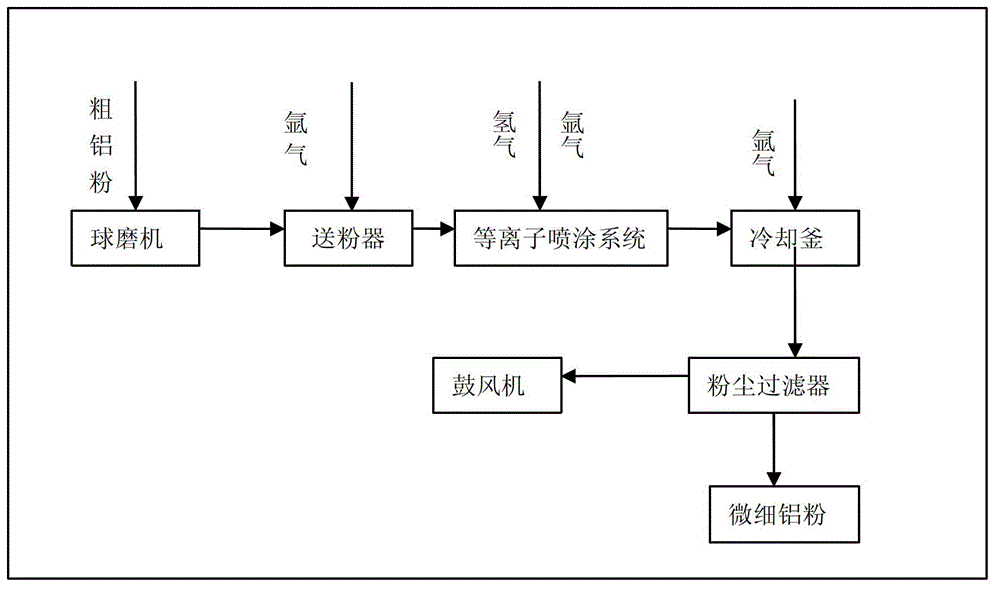

Production method of superfine spherical aluminium powder

The invention discloses a production method of superfine spherical aluminium powder, which comprises the steps of ball-milling coarse aluminium powder in a ball mill under the shielding of nitrogen, crushing the coarse aluminium powder to fine flake aluminum powder, placing the flake aluminum powder into a powder feeder, replacing gas in a plasma spraying system with inert gas to form an oxygen-free atmosphere, then starting the plasma spraying system, adjusting the power of a plasma spray gun to reach a setting value, starting the powder feeder, allowing the aluminium powder to pass through a plasma arc of the plasma spray gun under gas delivery, allowing the fine flake aluminum powder heated by the plasma arc of the plasma spray gun to be melt into small liquid drops, and rapidly cooling the small liquid drops to the superfine spherical aluminium powder in a cooling kettle. The production method has the advantages that the produced aluminium powder is spherical, good in dispersity, high in activity, uniform in size distribution and narrow in particle size distribution, is 1-5 micrometers in particle size, and can be completely applied to aluminium paste for back surface fields of silicon solar cells, raw materials are used fully, the production efficiency is high, and the materials are not wasted.

Owner:JIANGSU BOQIAN NEW MATERIALS

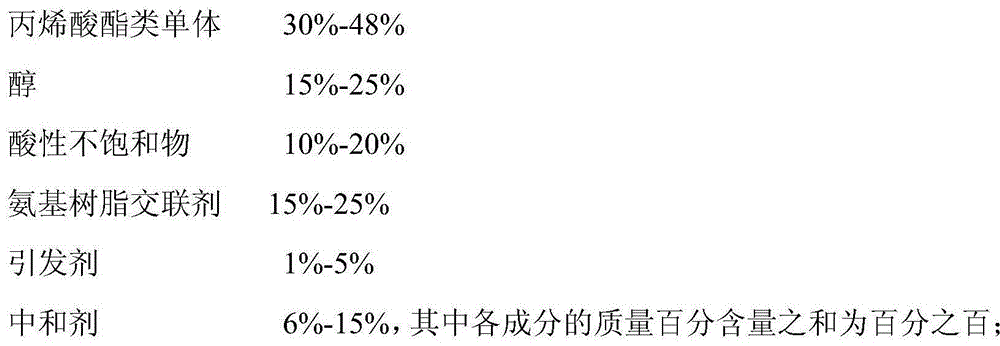

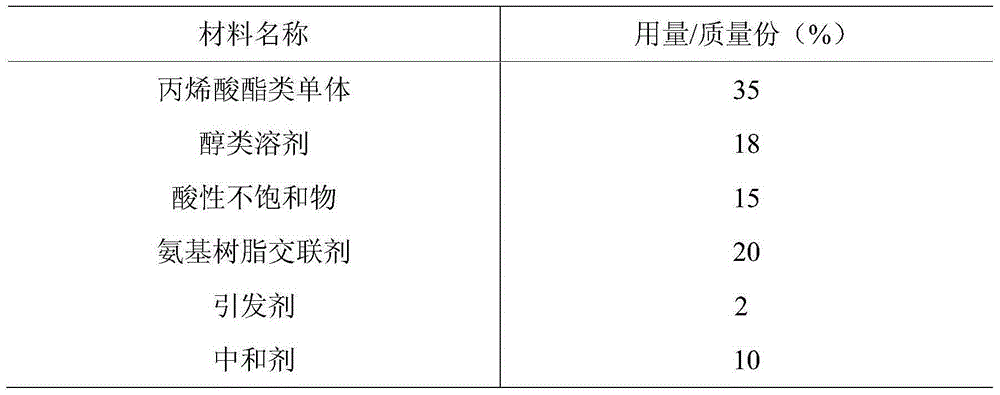

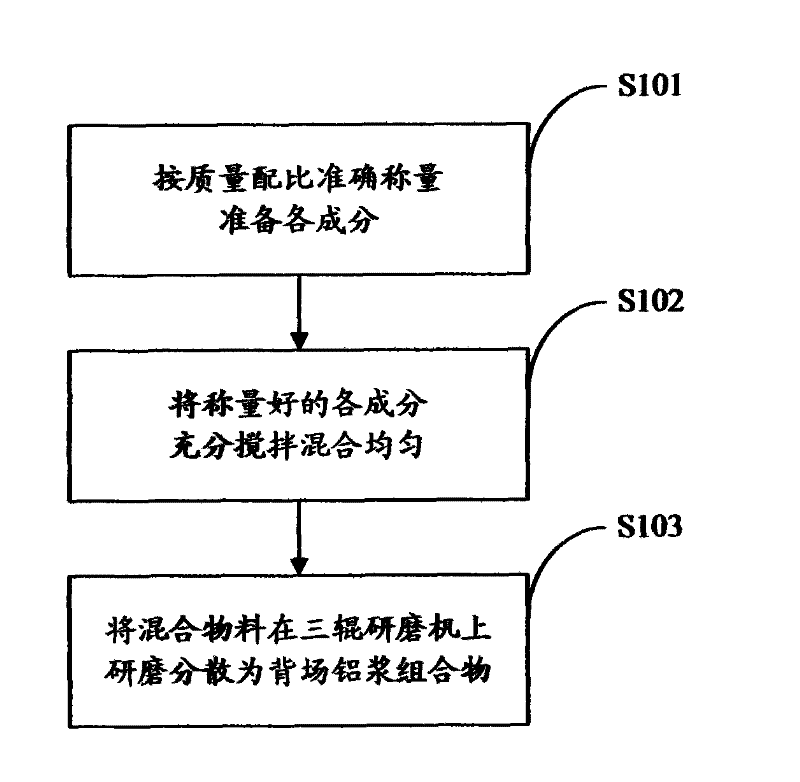

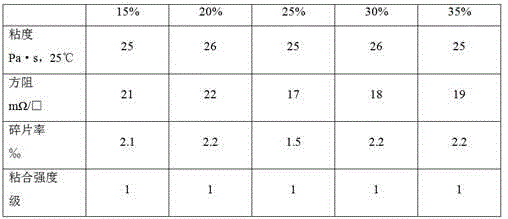

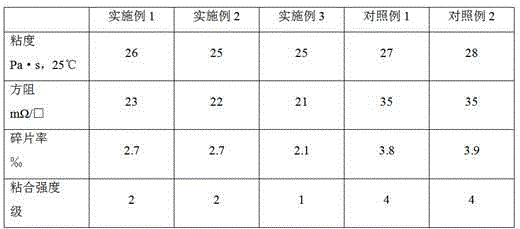

Preparation method of organic binding agent for silicon solar cell aluminum paste

InactiveCN104387714AHigh bonding strengthLow resistivityNon-conductive material with dispersed conductive materialSemiconductor devicesCelluloseActive agent

The invention relates to a preparation method of an organic binding agent for silicon solar cell aluminum paste, belonging to the technical field of solar cells. The preparation method comprises the following steps: dissolving polyalcohol in water, adding cellulose, polylactic acid, 2-ethylhexyl acrylate, acrylamide and surfactant, and stirring uniformly to obtain a mixture I; heating the mixture I, dropwisely adding acrylic acid and initiator, and keeping the temperature to obtain a mixture II; cooling the mixture II, and regulating the pH value to 6.0-8.0 to obtain a mixture III; and adding diethanolamine and aluminum sol into the mixture III, and stirring uniformly. When being applied to solar cell aluminum paste, the organic binding agent prepared by the method can enhance the binding strength and lower the resistivity, and has low fragment rate especially when the solid content of the aluminum sol is controlled at 20%.

Owner:WUXI SUNOCEAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com