Silver priming paint of 1K silver powder containing automobile refinishing coating and preparation method thereof

A technology of automotive refinishing paint and silver color, which is applied in the field of automotive refinishing paint. Focus on the effect of excellent strength and short flash time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

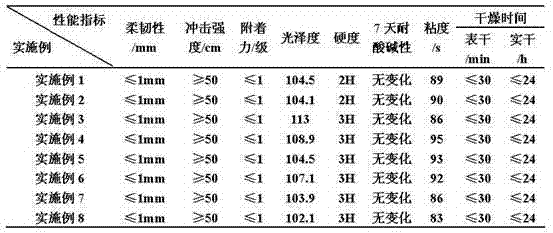

Examples

Embodiment 1

[0038] Prepare the silver primer of 1K silver powder automotive refinish paint according to the following components:

[0039] Base composition:

[0040] 50% low hydroxyl value acrylic resin 50,

[0041] CAB-381-0.5 25,

[0042] CAB-381-0.5 5.2,

[0043] 50% polyester resin 2,

[0044] Fluorine-modified acrylic 0.35,

[0046] 20% polyethylene wax 6,

[0047] Butyl acetate 5,

[0048] Propylene Glycol Methyl Ether Butyl Acetate 3,

[0049] Xylene 2,

[0050] Pigment composition:

[0051] 19μm coated aluminum paste 7,

[0052] Silicone-modified acrylic resin 0.2,

[0053] Butyl acetate 6.

[0054] Follow the steps below to prepare a silver primer for 1K silver powder automotive refinish paint:

[0055] (1) Add 7 parts of coated aluminum paste to 3 parts of butyl acetate dissolved with 0.2 parts of wetting and dispersing agent for wetting and stirring until there are no particles, then add the remaining 3 parts of butyl acetate to soak t...

Embodiment 2

[0068] Prepare the silver primer of 1K silver powder automotive refinish paint according to the following components:

[0069] Base composition:

[0070] 60% low hydroxyl value acrylic resin 50,

[0071] CAB-381-0.2 5.2,

[0072] CAB-381-2 20,

[0073] CAB-381-0.5 5,

[0074] 50% polyester resin 5,

[0075] Silicone modified acrylic 0.5,

[0077] 20% polyethylene wax 4.5,

[0078] Butyl acetate 4.5,

[0079] Propylene Glycol Methyl Ether Butyl Acetate 2.7,

[0080] Xylene 1.8,

[0081] Pigment composition:

[0082] 19μm coated aluminum paste 7,

[0083] Silicone-modified acrylic resin 0.6,

[0084] Butyl acetate 6.

[0085] The preparation steps and testing steps are the same as in Example 1.

Embodiment 3

[0087] Prepare the silver primer of 1K silver powder automotive refinish paint according to the following components:

[0088] Base composition:

[0089] 60% low hydroxyl value acrylic resin 50,

[0090] CAB-381-0.2 5.2,

[0091] CAB-381-2 20,

[0092] CAB-381-0.5 5,

[0093] 50% polyester resin 2,

[0094] Fluorine-modified acrylic acid 0.2

[0095] 20% polyamide wax 2.89,

[0096] 20% polyethylene wax 6,

[0097] Butyl acetate 5.5,

[0098] Propylene Glycol Methyl Ether Butyl Acetate 3.3,

[0099] Xylene 2.2,

[0100] Pigment composition:

[0101] 30μm coated aluminum paste 4,

[0102] 12μm coated aluminum paste 6,

[0103] Silicone-modified acrylic resin 0.8,

[0104] Butyl acetate 10.

[0105] The preparation steps and testing steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com