Local aluminium surface-back-field solar cell and preparation method of the same

A solar cell and aluminum back field technology, applied in the field of solar cells, can solve the problem of reducing the void rate of local aluminum back field cells, and achieve the effects of improving photoelectric conversion efficiency and solving the problem of black spots and black lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

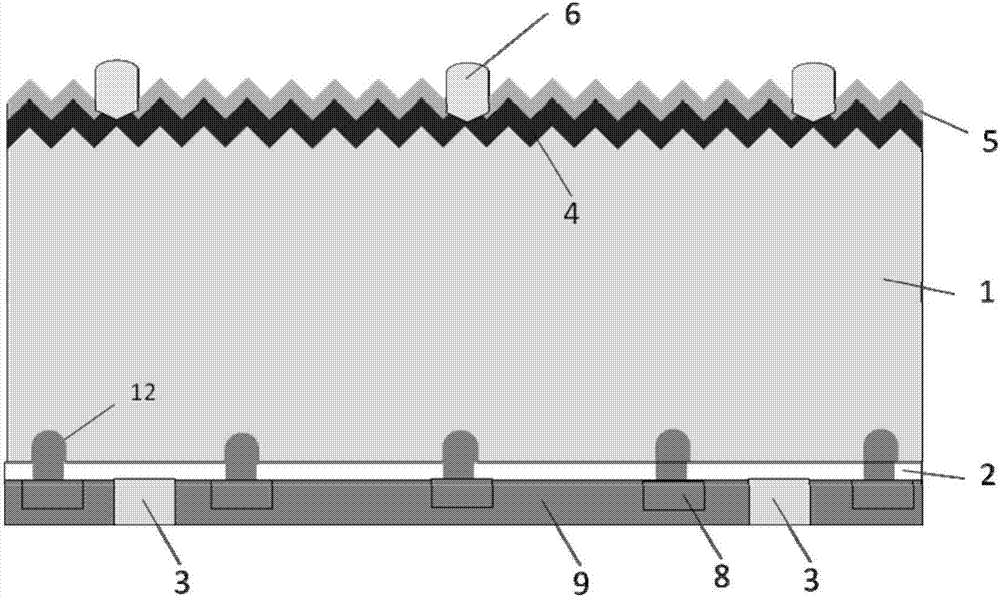

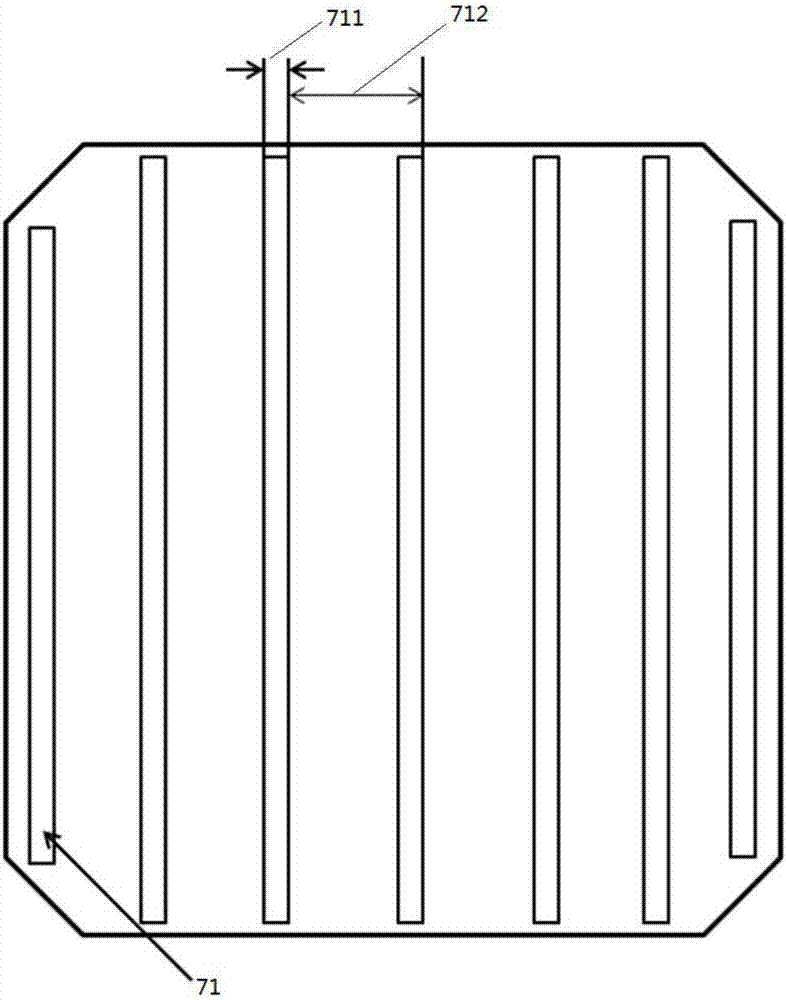

[0036] Such as figure 1 As shown, the local aluminum back field solar cell provided in this embodiment comprises a crystalline silicon wafer 1, a passivation layer 2 and a back electrode 3 are provided on the back side of the crystalline silicon wafer, an emitter 4, an anti-reflection layer 5 and the front electrode 6, the passivation layer 2 on the back of the crystalline silicon wafer is provided with a laser slot 71, and the laser slot 71 is provided with a first layer of partial back aluminum paste 8 covering the slot 71, wherein the first layer The partial back aluminum paste 8 is formed by co-sintering with the front electrode 6 and the back electrode 3 , and the second layer of high temperature treated back aluminum paste 9 is provided on the first layer of partial back aluminum paste 8 .

[0037] The second layer of back aluminum paste 9 is directly or indirectly electrically connected to the back electrode 3 and the first partial back aluminum paste 8 .

[0038] The ...

Embodiment 2

[0059] The difference from Example 1 is that the aluminum paste on the back of the second layer adopts hollow printed patterns, and the area of the aluminum paste accounts for 30% of the total area of the battery.

Embodiment 3

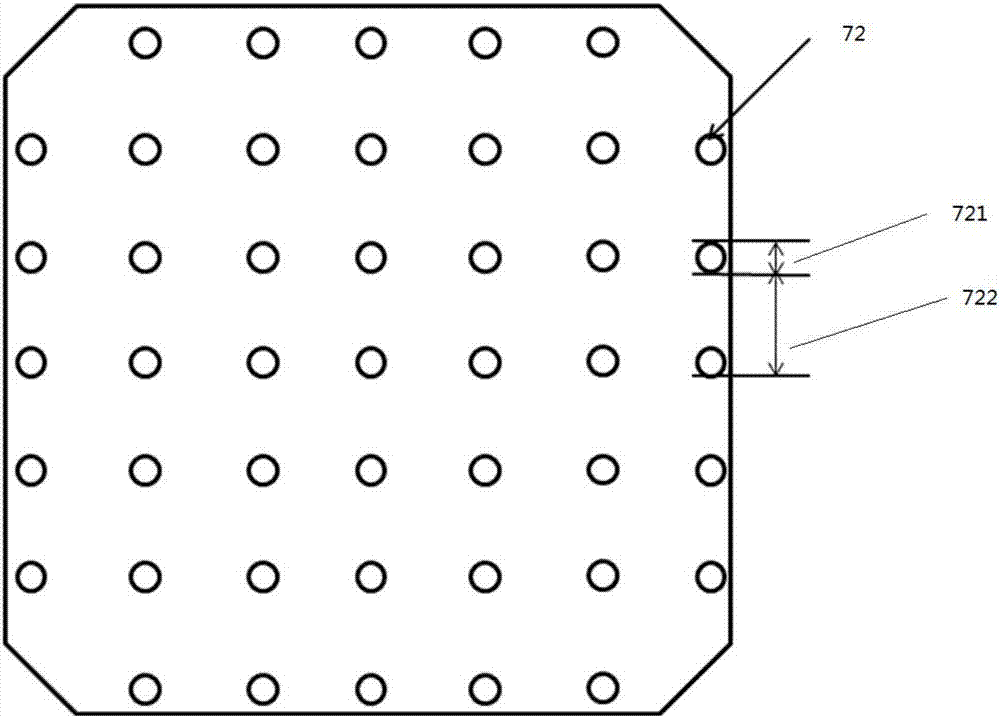

[0061] The difference from Example 1 is that here the laser adopts the method of opening holes, such as image 3 , the opening diameter 721 is 200 μm, and the hole spacing 722 is 700 μm. The first layer of aluminum paste is also arranged in the same way as the laser holes, and the diameter is slightly larger than the opening diameter, which is 300 μm. The second layer of aluminum paste is printed on the whole surface. The place of the back electrode is not printed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com