Nano silicon boron slurry and method for preparing solar cell with the same

A nano-silicon-boron paste and solar cell technology, applied in the field of nano-materials, can solve the problems of discontinuity and affecting the photoelectric conversion efficiency of the battery, and achieve the effects of reducing contact loss, improving photoelectric conversion efficiency, and optimizing the process path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

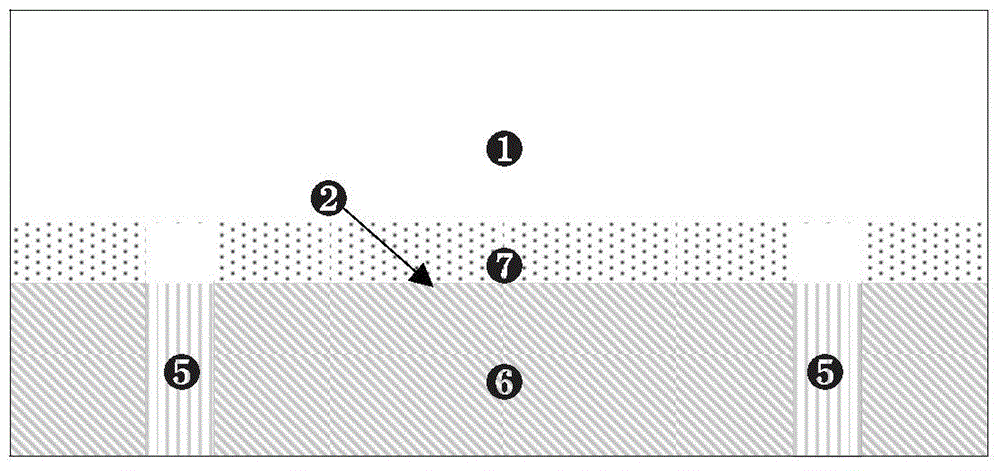

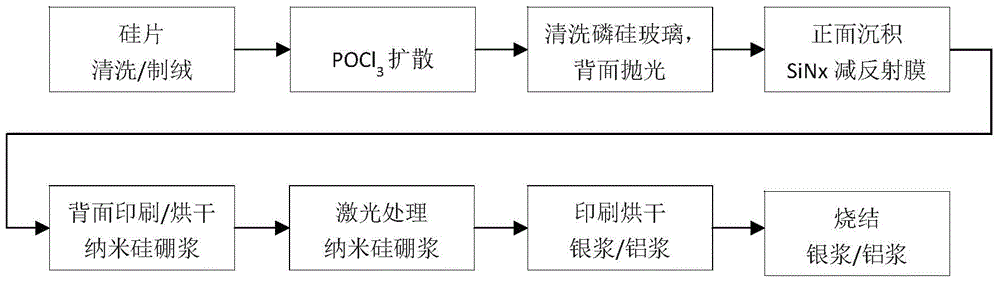

[0049] Example 1: Preparation of N-type composite emitter solar cells by laser treatment process image 3 The process route shown is carried out, and concrete steps are as follows:

[0050] (1) Use a 125*125mm N-type CZ single crystal silicon wafer with a thickness of 160um and a silicon wafer substrate with a phosphorus doping concentration of 6x10 16 atm / cm 3 . Complete the following process according to the usual battery preparation process: 1. Silicon wafer cleaning and flocking; 2. POCl 3 Diffusion; 3. Clean the phosphosilicate glass and polish the back; 4. Deposit SiNx emission reduction film on the front;

[0051] (2) Print the nano-silicon boron paste on the back of the silicon wafer after (1) using the silver grid wire screen on the back of the conventional P-type battery and a conventional screen printing machine. The boron paste pattern is the same as the silver grid wire, and the printing thickness is 3.5 um. Nano silicon boron slurry is composed of 75 parts o...

Embodiment 2

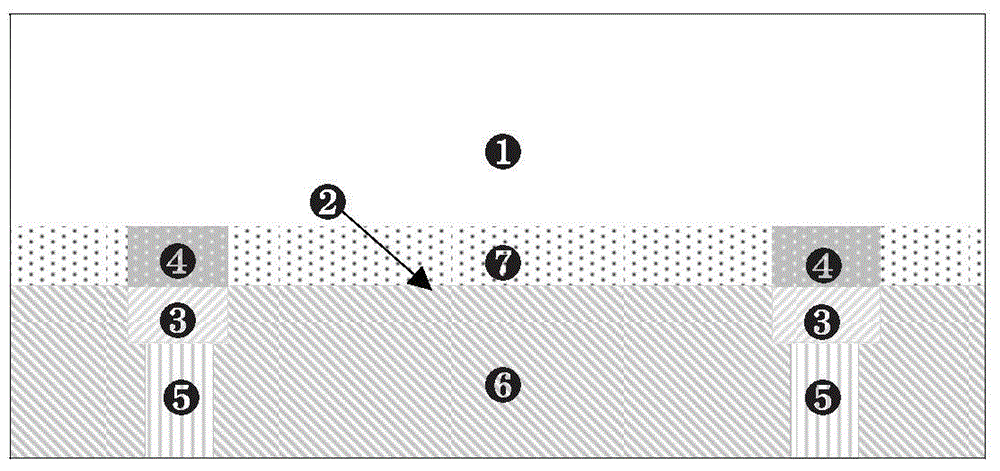

[0058] Embodiment 2: Utilize high-temperature treatment process to prepare N-type composite emitter solar cell, such as Figure 4 Shown:

[0059] (1) Use a 125*125mm N-type CZ single crystal silicon wafer with a thickness of 165um and a silicon wafer substrate with a phosphorus doping concentration of 6x10 16 atm / cc. According to the normal battery preparation process, complete the texturing of the front side of the silicon wafer and the polishing of the back side;

[0060] (2) Print the nano-silicon boron paste on the back of the silicon wafer after the process (1) using the silver grid wire screen on the back of the conventional P-type battery and a conventional screen printing machine. The boron paste pattern is the same as the silver grid wire, and the printing thickness is 2um . The nano-silicon boron slurry is composed of 80 parts of sandalwood and 20 parts of nano-silicon, the average particle diameter of the nano-silicon is 60nm, and the boron content is 8%.

[006...

Embodiment 3

[0067] Example 3: Preparation of improved P-type solar cells by laser treatment process image 3 The process route shown is carried out,

[0068] Specific steps are as follows:

[0069] (1) Use a 125*125mm P-type CZ monocrystalline silicon wafer with a thickness of 180um and a silicon wafer substrate with a boron doping concentration of 8x10 15 atm / cc. According to the normal battery preparation process, complete the production process of the front of the cell: 1. Silicon wafer cleaning and flocking; 2. POCl 3 Diffusion; 3. Clean and remove phosphorus silicon glass; 4. Deposit SiNx emission reduction film on the front side;

[0070] (2) Print the nano-silicon boron paste on the back of the silicon wafer after the process (1) using the silver grid screen and screen printing machine on the back of the conventional P-type battery. The pattern of the boron paste is the same as that of the silver grid, and the printing thickness is 2um. The nano-silicon boron slurry is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com