Production method of superfine spherical aluminium powder

A technology of spherical aluminum powder and production method, which is applied in the production field of fine spherical aluminum powder, can solve the problems of waste of high-purity aluminum powder, wide particle size distribution, poor dispersibility, etc., and achieves high production efficiency, narrow particle size distribution and dispersibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

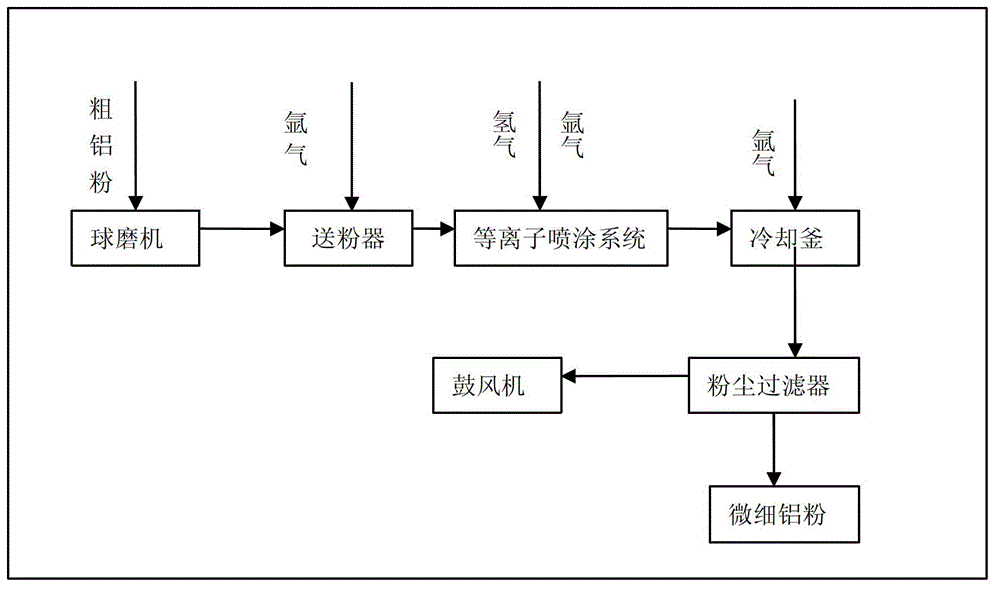

Method used

Image

Examples

Embodiment 1

[0020] Put the aluminum powder with a particle size of 100 microns into a planetary ball mill, and ball mill it for 3 hours under a nitrogen atmosphere to obtain a fine flake-shaped aluminum powder with a thickness of about 0.5 microns and a diameter of about 4 microns. Put the aluminum flakes into the powder feeder, Replace the air in the plasma spraying system with argon to make the system in an oxygen-free state, start the plasma spraying system, adjust the power of the plasma spraying gun in the plasma spraying system to 60KW, and start the powder feeding after the plasma arc of the plasma spraying gun is stable The powder feeding rate is 25Kg / h. The fine flake aluminum powder enters the plasma torch through a pipe connecting the powder feeder and the plasma torch under the conveyance of argon, and passes through the plasma arc. The gas that generates the plasma is Argon and hydrogen; the thin flakes of aluminum powder are heated and melted into small droplets when they pas...

Embodiment 2

[0022] Put 50-micron aluminum powder into a planetary ball mill and ball mill for 2.5 hours under a nitrogen atmosphere to obtain a fine flaky aluminum powder with a thickness of about 0.2 microns and a diameter of about 3.5 microns. Put the aluminum flakes into a powder feeder and spray the plasma Replace the gas in the system to make the system in an oxygen-free state, start the plasma spraying system, adjust the power of the plasma spray gun to 60KW, and after the plasma arc of the plasma spray gun is stable, start the powder feeder, and the rate of the powder feeder is 30Kg / h, follow-up procedure is the same as embodiment 1. The produced aluminum powder is a spherical powder with an average particle size of 2.2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com