Manufacturing method of N type all-aluminum back emitter solar cell and solar cell prepared by the same

A technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve the problems of small effective area of PN junction, easy damage of PN junction, lower battery efficiency, etc., so as to reduce the loss of open-circuit voltage and short-circuit current, and increase the PN junction. Area, composite center reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

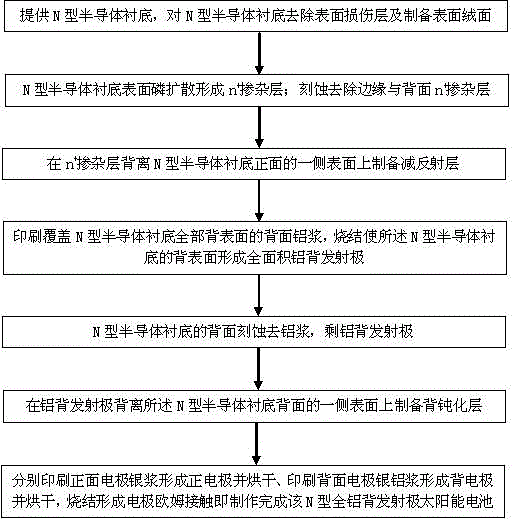

[0053] This embodiment provides a manufacturing method of an N-type aluminum back solar cell, the process flow of the manufacturing method is as follows image 3 As shown, the steps of the production method are as follows:

[0054] (1) Provide a single crystal silicon wafer or a polycrystalline silicon wafer as an N-type semiconductor substrate; remove the surface damage layer and prepare a surface suede on the N-type semiconductor substrate.

[0055] (2) Phosphorus is diffused on the surface of the N-type semiconductor substrate to form n + doped layer, and etch to remove the n on the edge and back + doped layer.

[0056] Usually with POCl 3 Diffusion to form n + doped layer. no + The doped layer is not only formed on the front (front surface) of the N-type semiconductor substrate, but also on the edge and the back; so the edge and back of the N-type semiconductor substrate are de-PSG and etched to remove the n + doped layer.

[0057] It should be noted that the "fr...

Embodiment 2

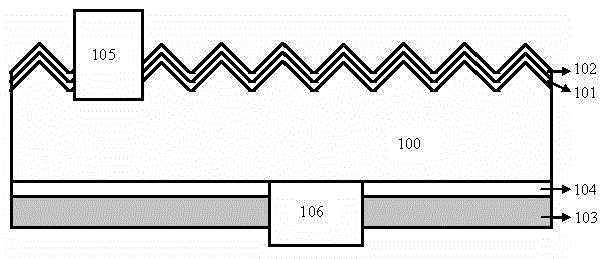

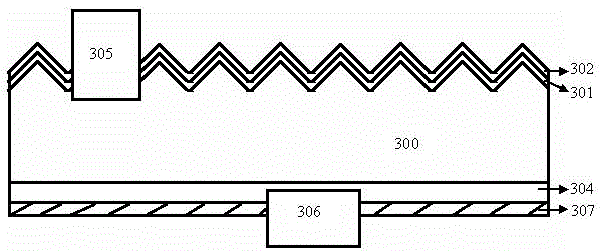

[0077] Based on the first embodiment, this embodiment provides an N-type all-aluminum back-emitter solar cell, such as figure 2As shown, the N-type all-aluminum back-emitter solar cell includes:

[0078] N-type semiconductor substrate 300;

[0079] Covering the n on the front side of the N-type semiconductor substrate 300 + doped layer 301;

[0080] covered in the n + An anti-reflection layer 302 on the surface of the doped layer 301 away from the front side of the N-type semiconductor substrate 300;

[0081] An aluminum back emitter 304 located on the back of the N-type semiconductor substrate 300 and covering the entire back of the N-type semiconductor substrate 300;

[0082] A back passivation layer 307 covering the surface of the aluminum back emitter 304 away from the back side of the N-type semiconductor substrate 300, wherein the back passivation layer 307 has a thickness of 1 nm to 100 nm and is made of aluminum oxide and nitrogen a double-layer structure of a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com