Preparation method of organic binding agent for silicon solar cell aluminum paste

A technology of silicon solar cells and organic adhesives, which is applied in the field of solar cells, can solve the problems of low bonding strength and high square resistance, and achieve the effects of reducing resistivity, improving bonding strength, and small fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

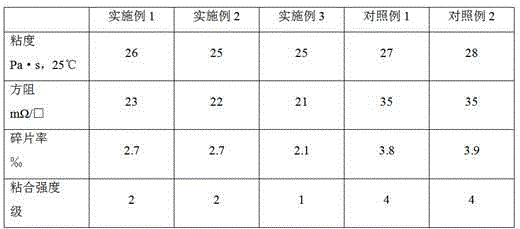

Embodiment 1

[0032] The preparation method of organic binder for silicon solar cell aluminum paste, the steps are as follows:

[0033] Step 1, dissolve 40g of polyol in water, then add 5g of cellulose, 4g of polylactic acid, 3g of isooctyl acrylate, 5g of acrylamide, and 3g of surfactant, stir evenly, and the stirring speed is 700 rpm. The cellulose is hydroxyethyl cellulose, the surfactant is sodium lauryl sulfate, and the polyhydric alcohol is Polyethylene Glycol to obtain the mixture I;

[0034] Step 2, heat up the mixture I, the temperature is 70 ° C, dropwise add 10 g of acrylic acid, 3 g of initiator, keep warm, keep warm time is 2 hours, the initiator is hydrogen peroxide, to obtain the mixture II;

[0035] Step 3, the temperature of the mixture II is lowered, the cooling temperature is 30°C, and then the pH is adjusted to 6.0 to obtain the mixture III, and the pH is adjusted by using a pH regulator, and the pH regulator is selected from hydrochloric acid and ammonia. one or a mixt...

Embodiment 2

[0039] The preparation method of organic binder for silicon solar cell aluminum paste, the steps are as follows:

[0040] Step 1: Dissolve 60g of polyol in water, then add 10g of cellulose, 7g of polylactic acid, 6g of isooctyl acrylate, 10g of acrylamide, and 5g of surfactant, and stir evenly. The stirring speed is 1000 rpm. The cellulose is hydroxyethyl cellulose, the surfactant is sodium lauryl sulfate, and the polyhydric alcohol is Polyethylene Glycol to obtain the mixture I;

[0041] Step 2. Heat up the mixture I, the temperature is 90°C, add 30g of acrylic acid and 6g of initiator dropwise, keep the temperature for 4 hours, the initiator is hydrogen peroxide, and obtain the mixture II;

[0042] Step 3, the temperature of the mixture II is lowered, the cooling temperature is 50°C, and then the pH is adjusted to 8.0 to obtain the mixture III, and the pH is adjusted by a pH regulator, and the pH regulator is selected from hydrochloric acid and ammonia water one or a mixtur...

Embodiment 3

[0046] The preparation method of organic binder for silicon solar cell aluminum paste, the steps are as follows:

[0047] Step 1: Dissolve 50g of polyol in water, then add 7g of cellulose, 6g of polylactic acid, 5g of isooctyl acrylate, 7g of acrylamide, and 4g of surfactant, stir evenly, and the stirring speed is 800 rpm. The cellulose is hydroxyethyl cellulose, the surfactant is sodium lauryl sulfate, and the polyhydric alcohol is Polyethylene Glycol to obtain the mixture I;

[0048] Step 2, heat up the mixture I, the temperature is 80°C, dropwise add 20g of acrylic acid, 5g of the initiator, keep warm, the keep time is 3 hours, the initiator is hydrogen peroxide, to obtain the mixture II;

[0049] Step 3, the temperature of the mixture II is lowered, the cooling temperature is 40°C, and then the pH is adjusted to 7.0 to obtain the mixture III, and the pH is adjusted by using a pH regulator, and the pH regulator is selected from hydrochloric acid and ammonia. one or a mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com