Patents

Literature

154results about How to "Uniform fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

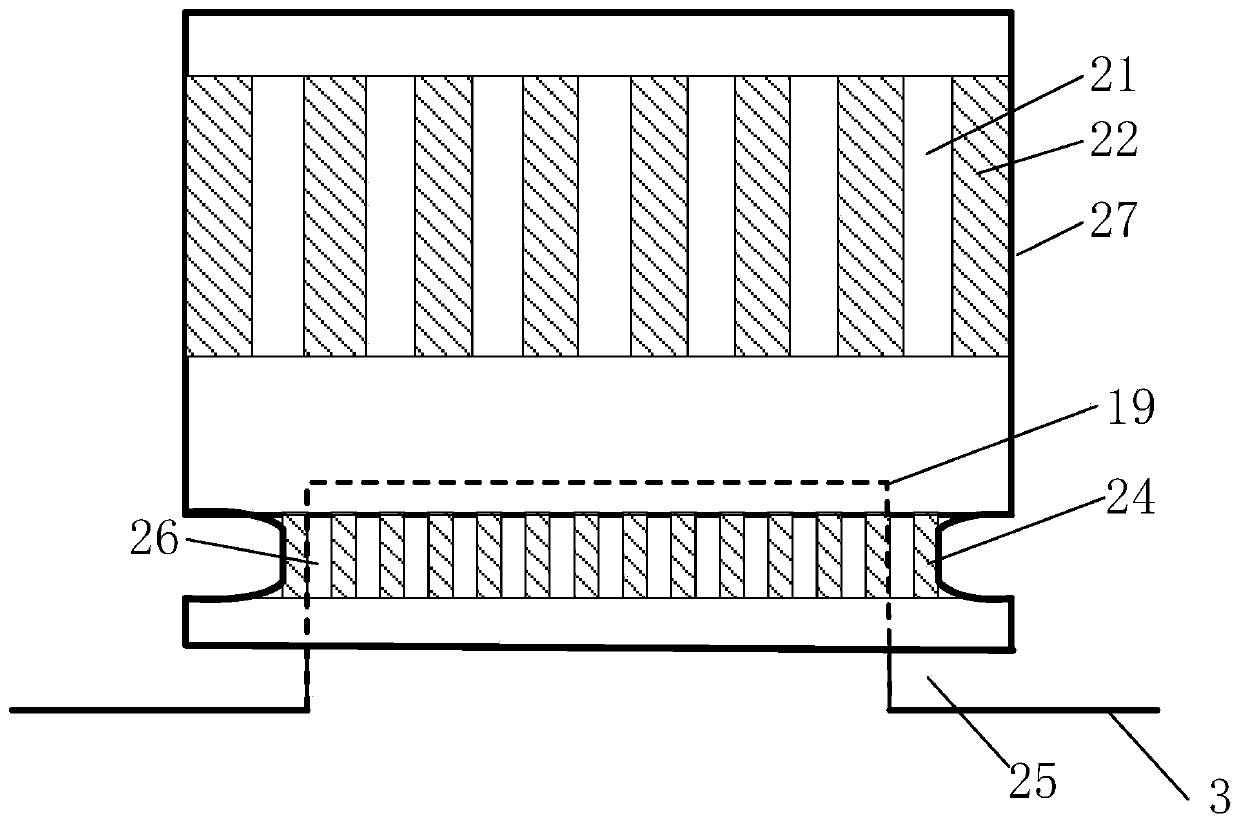

Screen printing device for solar batteries

InactiveCN102336051ASimple structural designLittle impact on deformabilityFinal product manufactureScreen printersScreen printingSlurry

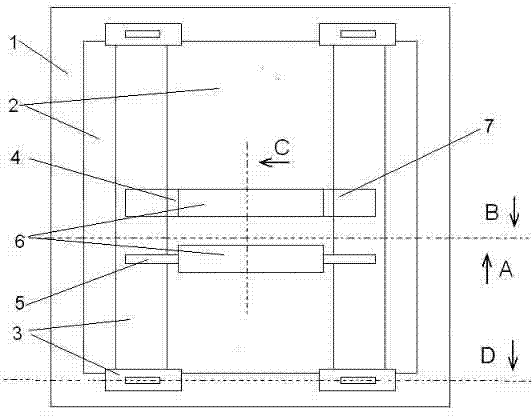

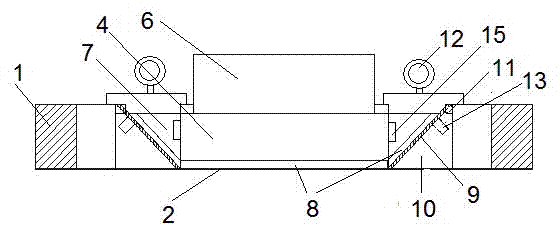

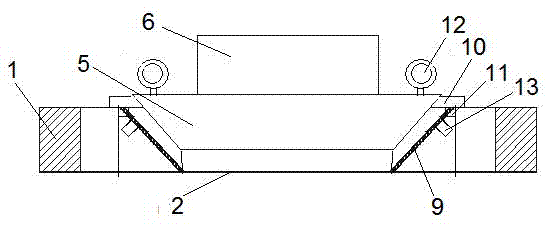

The invention discloses a screen printing device for solar batteries. The screen printing device comprises a printing scraper, an auxiliary scraper, a feed back knife and a printing screen. The device is characterized in that two baffle structures are mounted on the printing screen, at two sides close to the ends of the printing scraper, wherein each baffle structure is mainly composed of a baffle surface, a baffle frame and an installation rack; the bottom of the baffle surface is in split type contact with a screen surface, or adhered to the screen surface through a flexible material; edges of the feed back knife, the printing scraper and the auxiliary scraper are in seamless contact with the baffle surface; a printing head drives the scrapers and the feed back knife to contact the baffle surface in a sliding manner, so that the paste moves in a range defined by the baffle surfaces at the two sides, the scraper and the feed back knife, and slurry is prevented from flowing to the two sides; and the device can ensure uniform fluidity, viscosity and thixotropy of the slurry and avoid the local drying and waste of the slurry, thereby improving electrode printing efficiency and printing quality.

Owner:NANCHANG UNIV

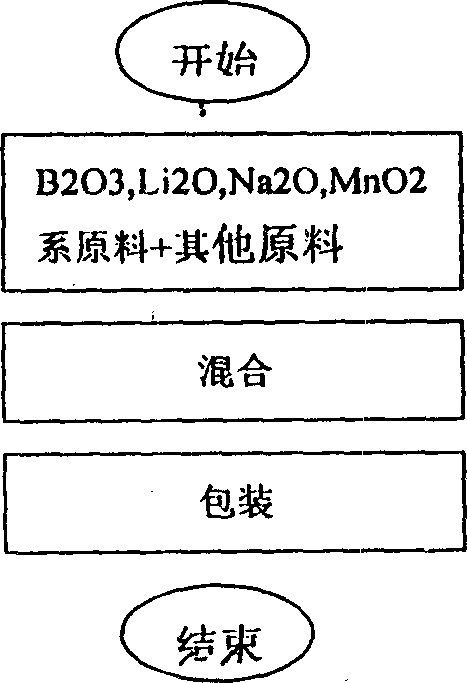

Fluorine free protecting slag for steelmaking and continuous casting and method for manufacturing same

A fruorine-free mold flux for the continuous casting of steel and method for producing the same relates to a mold flux for the continuous casting of new steel grade, which accord with the requirement of protecting natural environment. The characteristic is in that the mold flux contains the fellowing compositions and performance range: 23-40% SiO2, 20-4-% CaO, 0.5-10% MgO, 0.5-10% Al2O3, 0.5-10% MnO2, 2-15% Na2O, 5-15% B2O3, and 0.5-10% C; the melting point is 800-1200 DEG C, the viscosity is 0.2-5 pt, and the crystallizer rate is 0.1-30%. The advantages of the invention are in that the fruorine-free mold flux can alternatively act the role of the fluorine component, according with the continuous casting conditions (steel grade, casting speed, and the like). In this way, uniform fusing characteristic, fluidity and viscosity are improved or promoted, and the mold flux is contributed to the improvement of the operational stability and the product quality with the smooth workability in the continuous casting process by singly or in combination use.

Owner:SANYI METALLURGICAL MATERIAL

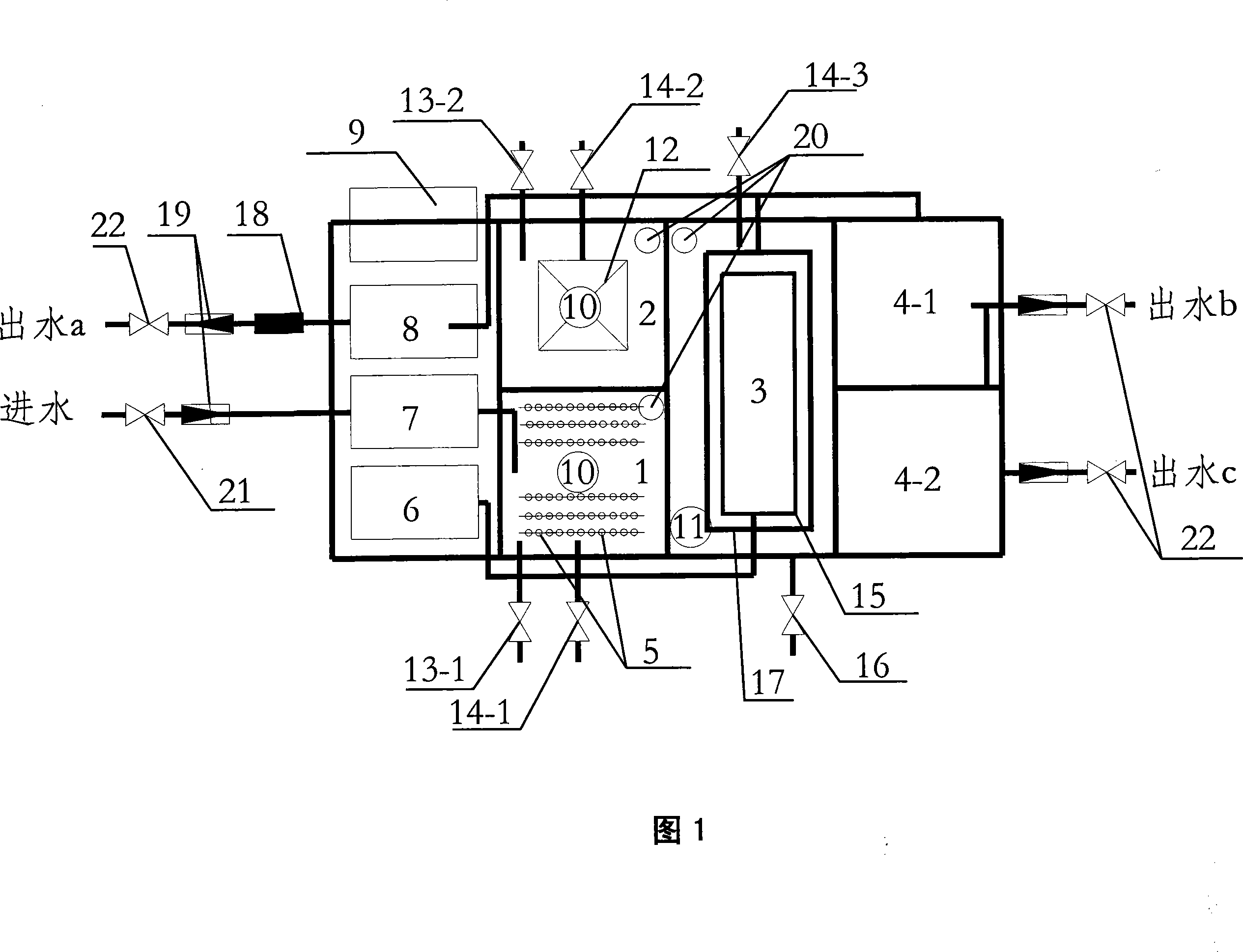

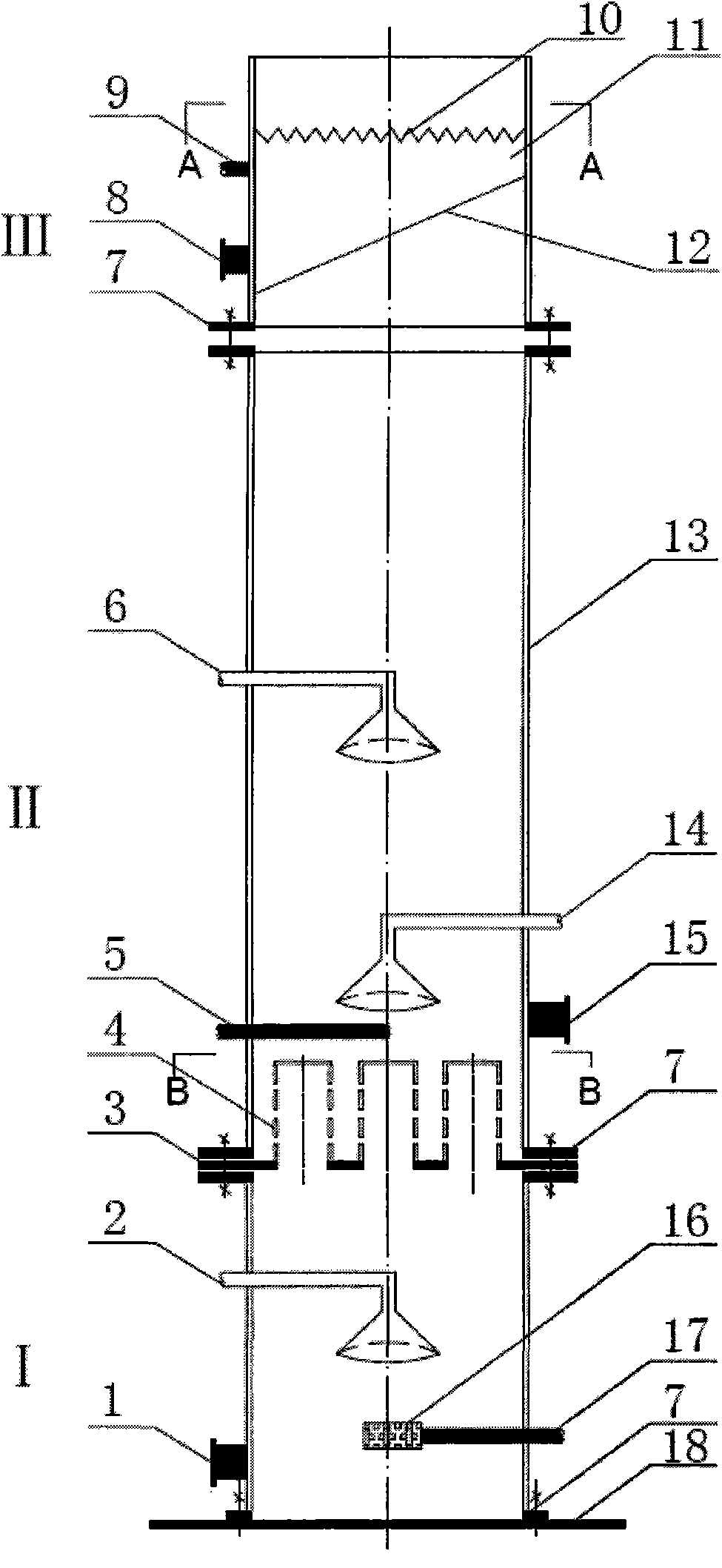

Packaging stage-type film bioreactor device for treating sewage or micro-polluted raw water

InactiveCN101186416ARealize quality water supplyFlexible and simple multi-functional areaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualitySmall footprint

The invention relates to a staged membrane bioreactor device, for treating sewage or micro-polluted source water, with a water container, pertaining to the environmental protection technology field. The device consists of a half-reaction zone, an anaerobic reaction zone, an aeration reaction zone and a pure water zone. The half-reaction is communicated with the bottom of the aeration zone, the bottom of the half-reaction is provided with an empty valve, one side of the half-reaction zone has a water inlet pump, the inside of the half-reaction has an internal ring filled with stuff, and the top of the half-reaction is provided with a stirrer, and the effluent of the half-reaction automatically flows into the anaerobic reaction zone. The top of the anaerobic reaction zone is provided with a stirrer, the bottom thereof is provided with a sludge empty valve, and a sludge empty device is shaped like a horn mouth and positioned in the anaerobic reaction zone, and the top of the anaerobic reaction zone is provided with a drug feeding mouth. The bottom of the aeration reaction zone has an internal return pump, the lower part of the aeration reaction zone is provided with an aeration pipe with an air inlet positioned at one side of the aeration reaction zone, and a fan is connected to the aeration pipe through the air inlet; the top of the aeration reaction zone is provided with an overflow pipe, the bottom of the aeration reaction zone is provided with an empty valve, while the middle is provided with a membrane component. The pure water zone is divided into two units, and the inside of each unit is provided with an effluent valve. The invention has the advantages of good effluent quality, multi purposes, small land occupancy, flexible and convenient using method, and is applied to the treatment of domestic sewage and micro-polluted source water, and can widen and facilitate the application of membrane bioreactor water treatment and water resource reutilization technique.

Owner:TONGJI UNIV

Production process of copper-silver alloy profile

The invention relates to a production process of a copper-silver alloy profile. The production process comprises the following steps that (1) high-purity cathode copper and pure silver are used as raw materials, the high-purity cathode copper and the pure silver are molten in a melting device after being preheated and dried, and a copper rod is upwards pulled through a traction unit; (2) a copper-silver alloy profile blank is prepared through a continuous extrusion unit; (3) drawing is carried out; and (4) slitting is carried out. The copper-silver alloy profile produced through the process is high in purity, low in oxygen content and high in conductivity and surface quality, and the process is short in procedure and efficient and saves energy.

Owner:金川文化发展(江苏)有限公司

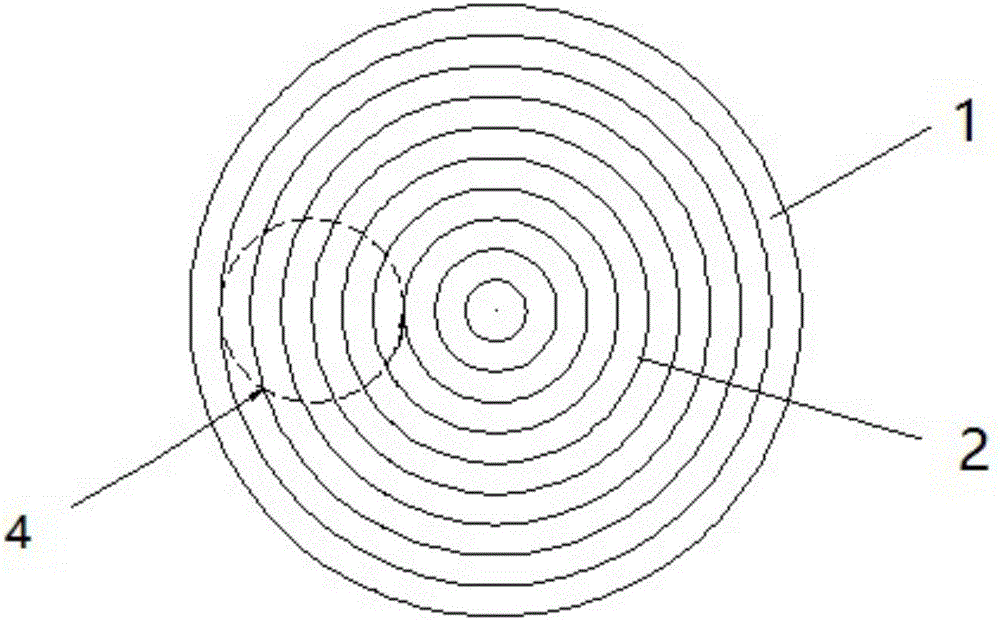

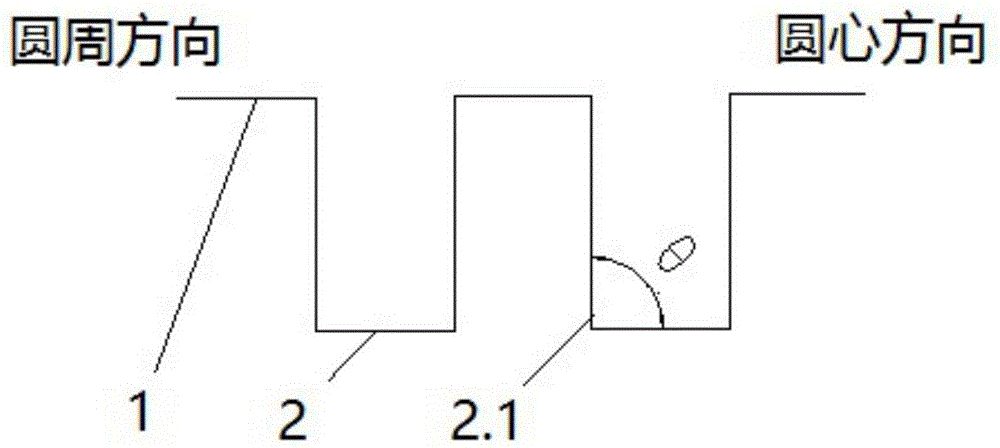

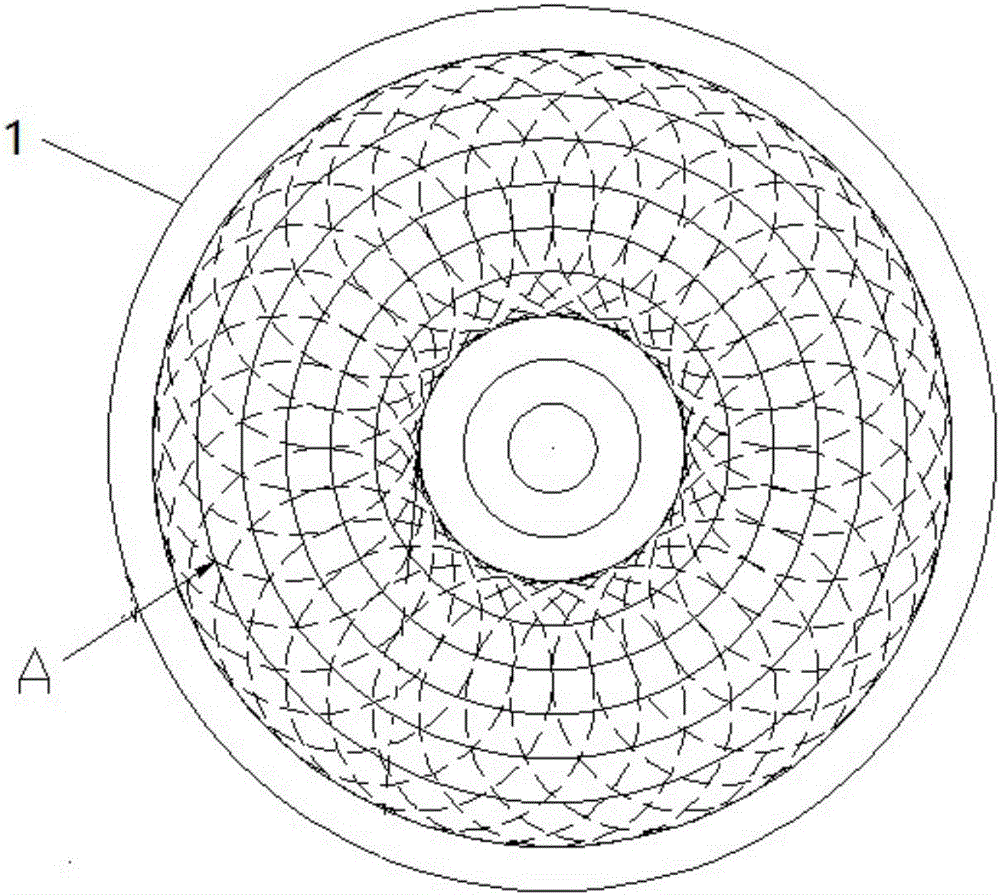

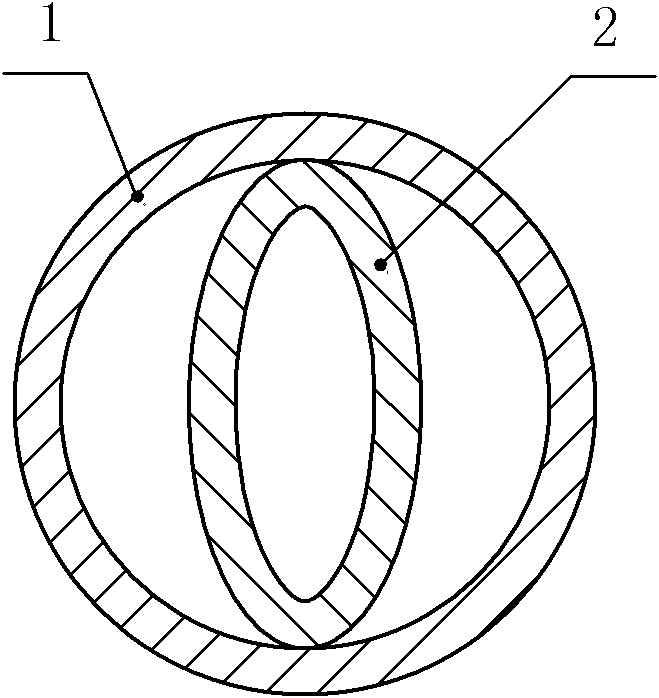

Polishing pad

The invention discloses a polishing pad for solving the problems of nonuniform distribution of polishing liquid and need of further improvement of the polishing speed and the leveling degree in a traditional polishing pad. The polishing pad at least comprises a circular polishing layer; a groove for flowing the polishing liquid is formed in the upper surface of the polishing layer; the groove consists of a peripheral groove and a radial groove; the peripheral groove is a peripheral geometric center symmetry pattern with the circle center of the polishing layer as center; the edges m of the pattern are not fewer than 3; and the radial groove is a straight line or / and a curve scattered from the peripheral direction along the circle center, and has an intersecting point with the peripheral groove. The polishing pad is simple in structure, can enable the polishing liquid to uniformly distribute and flow in a polishing area, keeps uniform concentration of reactants and products in the polishing liquid in the polishing area to the greatest extent, accelerates the polishing speed, and improves the wafer planar degree.

Owner:HUBEI DINGLONG CO LTD

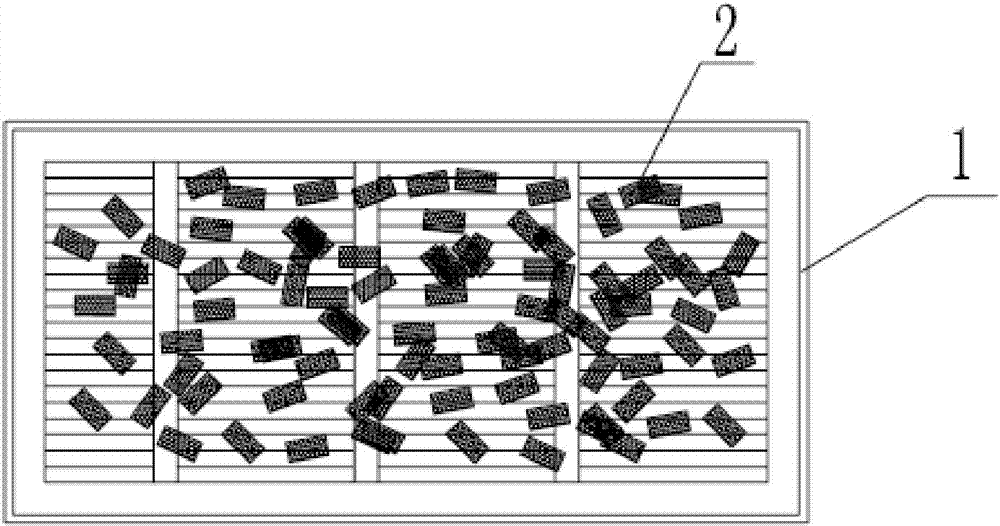

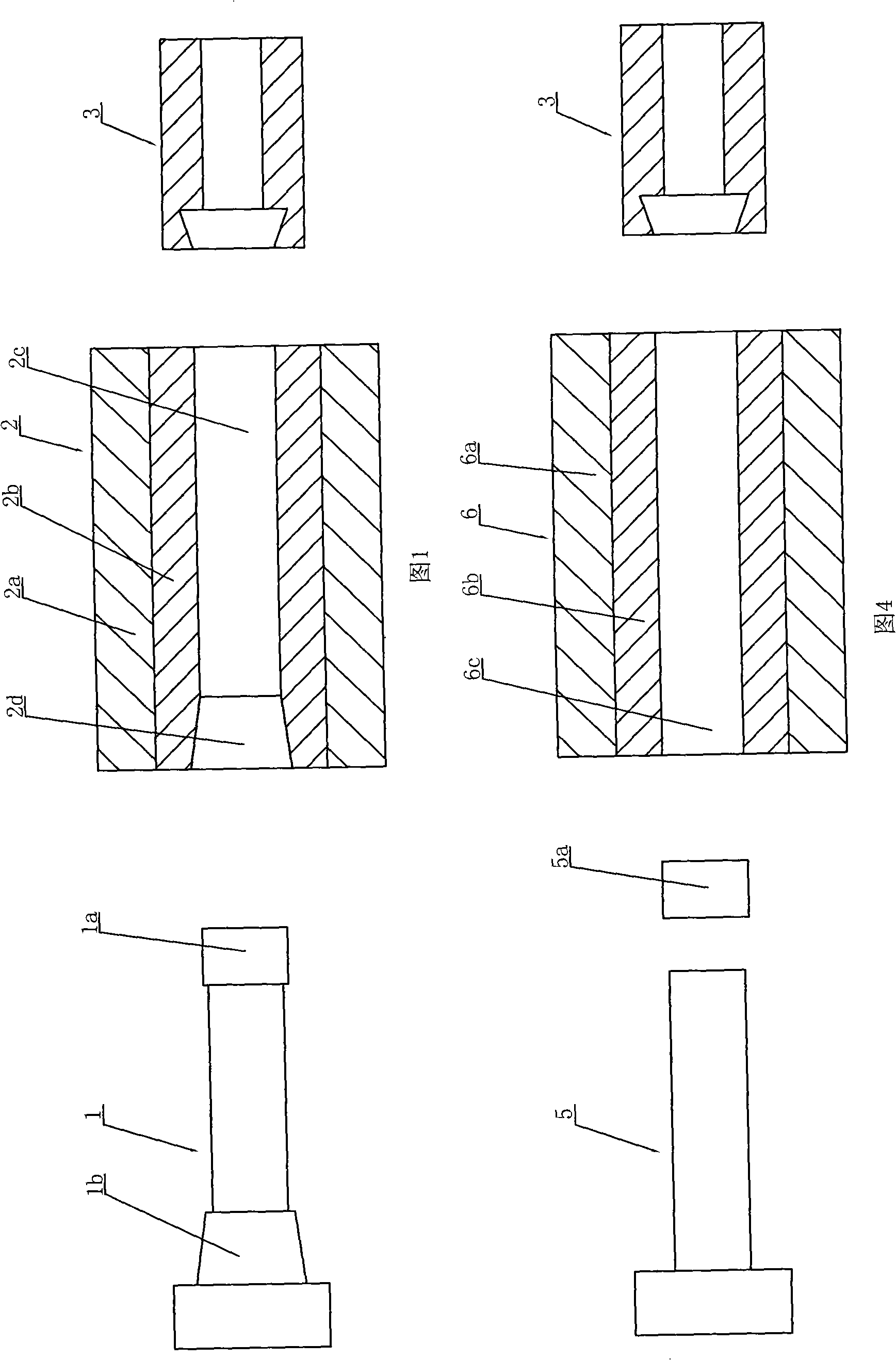

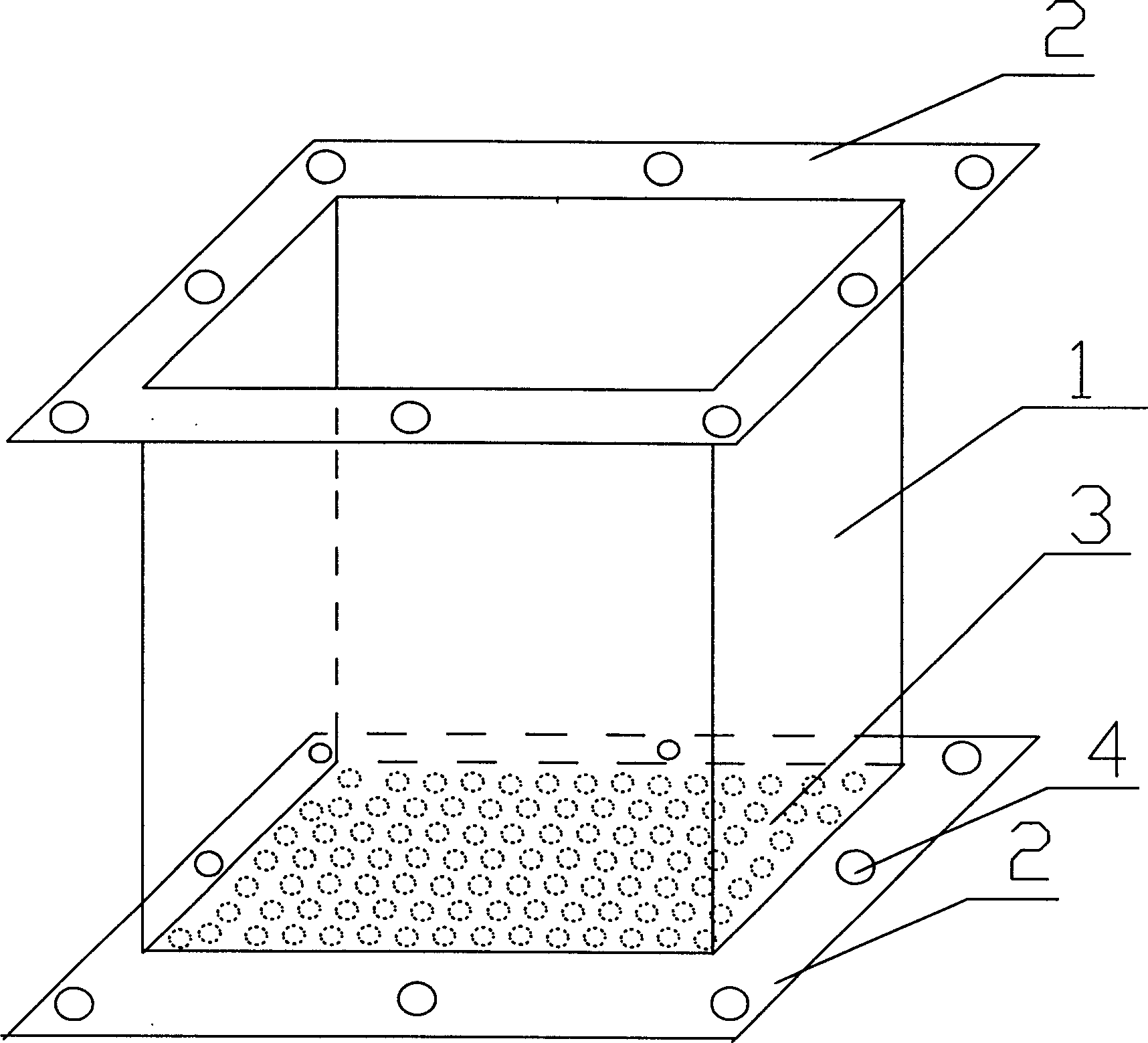

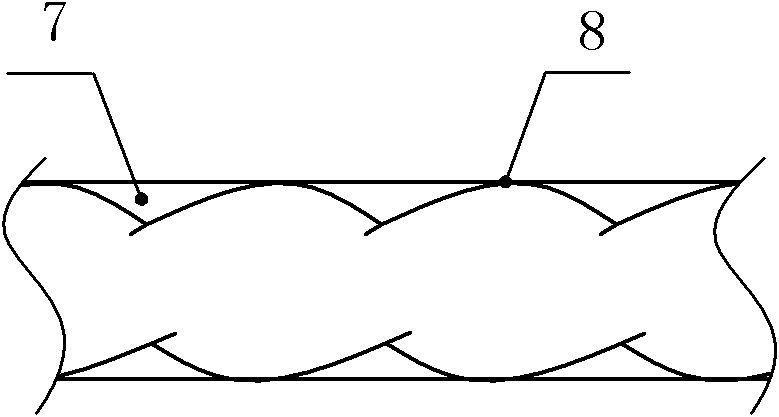

Net cage type biological carrier, immobilized microbiological treatment sewage device and application of immobilized microbiological treatment sewage device

ActiveCN104724817AAvoid short flowPrevent floatingTreatment using aerobic processesTreatment with anaerobic digestion processesHigh concentrationWater flow

The invention discloses a net cage type biological carrier, an immobilized microbiological treatment sewage device and application of the immobilized microbiological treatment sewage device. The net cage type biological carrier comprises a net cage and biological stuffing filled in the net cage, wherein the net cage is in the shape of a rectangle without a top cover, and a hollow-out mesh holes are formed in the side surface and bottom surface of the net cage. The immobilized microbiological treatment sewage device comprises a sewage treatment tank, a perforated mud discharge tube, a perforated aeration tube, a plurality of lower supporting beams and a sealing net, wherein a plurality of the net cage type biological carriers are stacked in the sewage treatment tank and arranged above the lower supporting beams. The net cage type biological carrier disclosed by the invention is large in specific surface area, low in accumulation, caking and blockage possibility, good in gas-water permeability, and convenient to mount and maintain. The immobilized microbiological treatment sewage device is good in gas-water flow state, conductive to bringing mass transfer effect into play, large in biological load amount, good in treatment effect and suitable for high-concentration degradation-resistant sewage treatment and advanced sewage treatment.

Owner:北京三泰正方生物环境科技发展有限公司

Method for preparing magnesium alloy strip blank cogged by flat extruding cylinder

The invention relates to a preparation method for a magnesium alloy sheet strip plate for the cogging of a flat extruding cylinder; the preparation method includes the following steps: the position of the flat extruding cylinder and an extruding rod is adjusted to lead the central line of the extruding rod, the central line of the flat extruding cylinder and the central line of a die for a slab band to be arranged on the same line; an original flat section ingot is uniformly processed for 12 to 24 hours under the temperature of 400 to 420 DEG C after being processed by machine and milled; after being uniformly processed, the flat section ingot of the magnesium alloy is heated to the temperature of 400 to 430 DEG C and heat is preserved; simultaneously, the flat extruding cylinder and the die for the slab band is heated to the temperature of 400 to 430 DEG C and the heat is preserved for 6 hours; the flat section ingot of the magnesium alloy of the steps is fed into a channel of the flat extruding cylinder and enters the die for the slab band to extrude by the channel with a flat hole with the extruding speed of 1.5m / min to 5m / min, thus obtaining the strip plate of the magnesium alloy sheet with a rectangle section. The invention adopts an extruding device with a flat extruding cylinder; the processing method can be used for leading the deformation of magnesium alloy material to be uniform during the extruding process to obtain the magnesium alloy sheet strip plate with excellent anisotropy properties of a tissue.

Owner:CHONGQING UNIV

Functional calcium carbonate and method for producing the same

ActiveCN101456969AIncrease dosageDosage remains the samePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsInterface layerPerformance index

The invention discloses a functionality calcium carbonate and a preparation method thereof. The functionality calcium carbonate is prepared by compound treatment technology of 'wet method + dry method' of superfine coarse whiting, fine calcium carbonate particle, nanometer calcium carbonate and a modification agent. The functionality calcium carbonate of the invention can promote resin plasticization, reduce melt viscosity, improve melt fluidity and melt intensity, make product surface smooth and fine and have the function of processing an addition agent ACR, and meanwhile is provided with the function of strengthening coupling and excellent surface modification effects. Appropriate increasing of padding of the system does not affect each performance index of the product. The functionality calcium carbonate and the preparation method thereof has the advantages of improving dispersivity and compatibility of each component of prescription system, improving plasticity of bonding strength of interface layer, having excellent interface layer performance, realizing the function of annealing strengthening and strengthening.

Owner:NANJING XIEHE CHEM

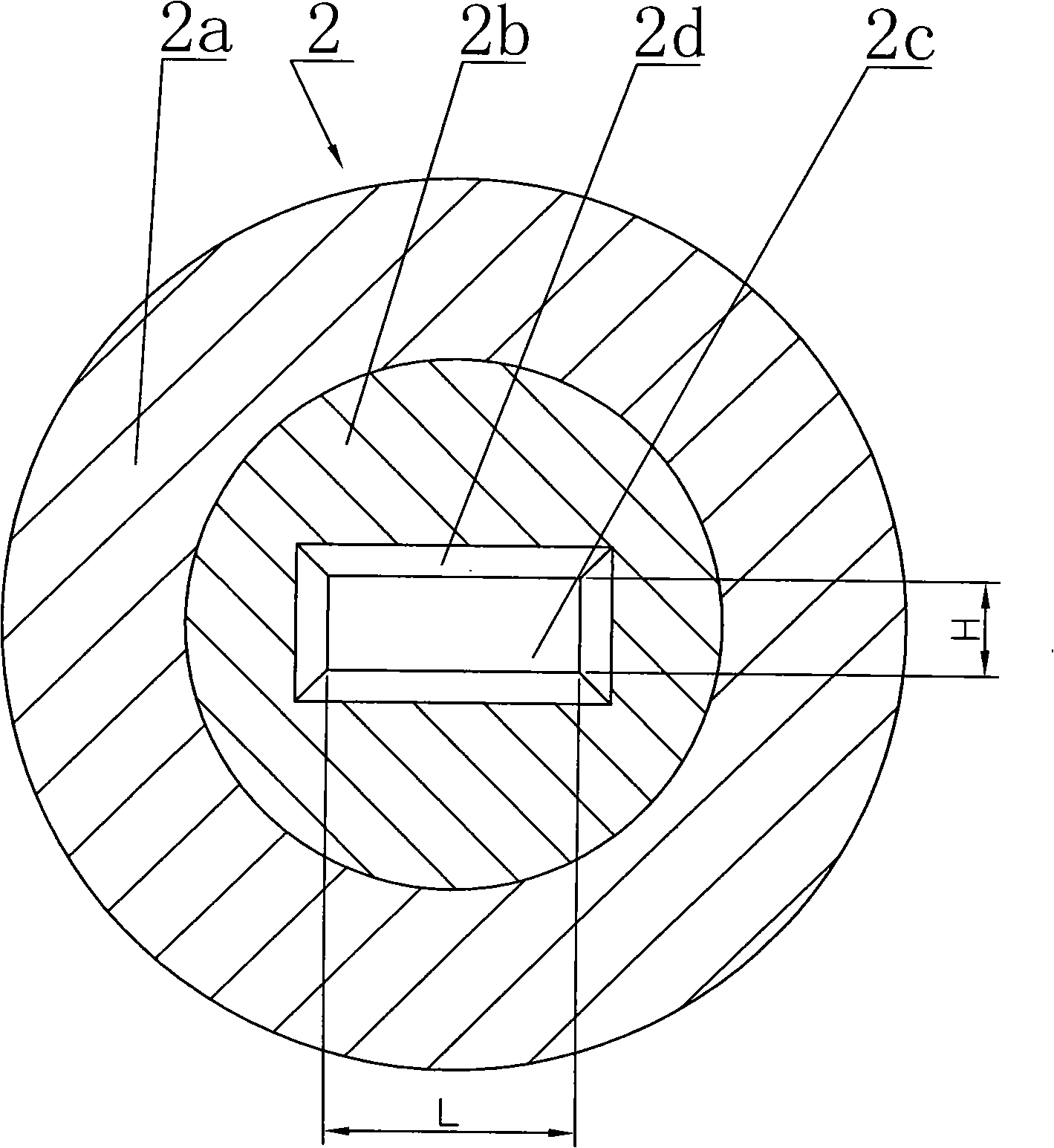

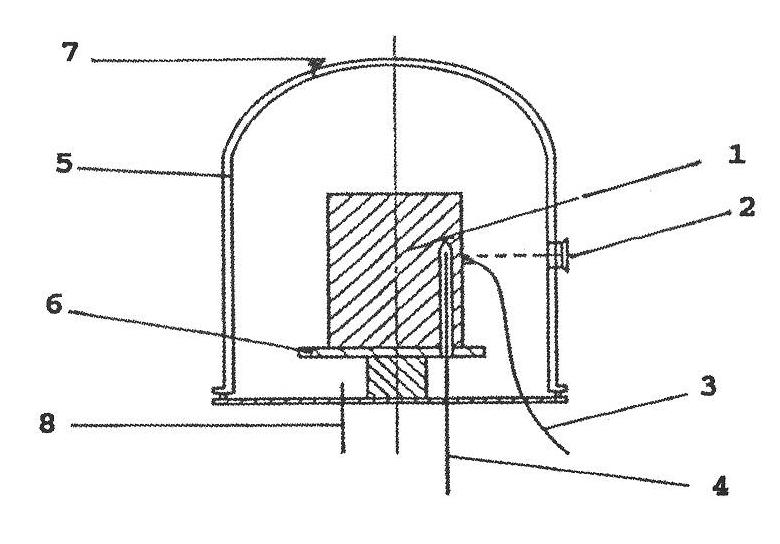

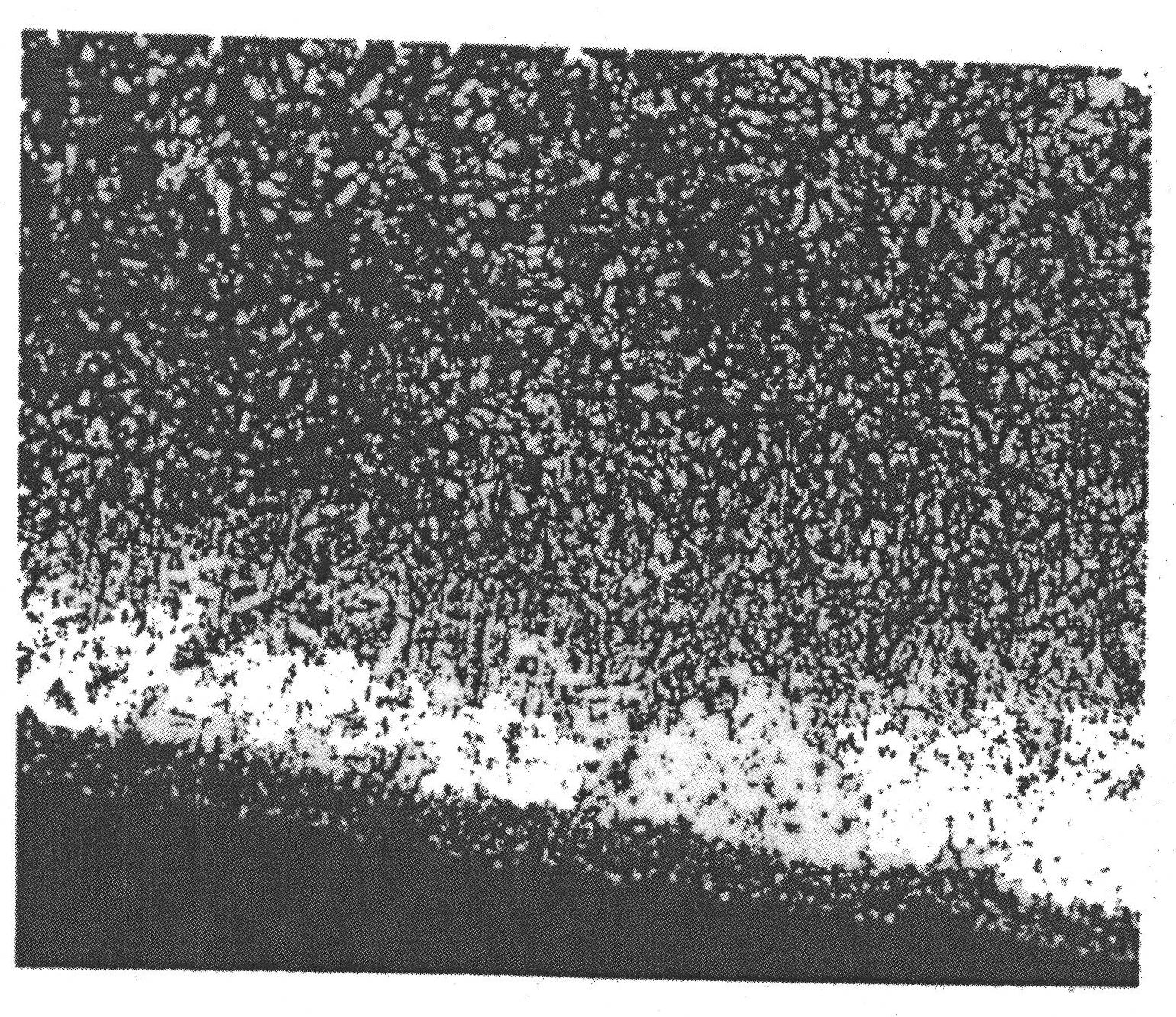

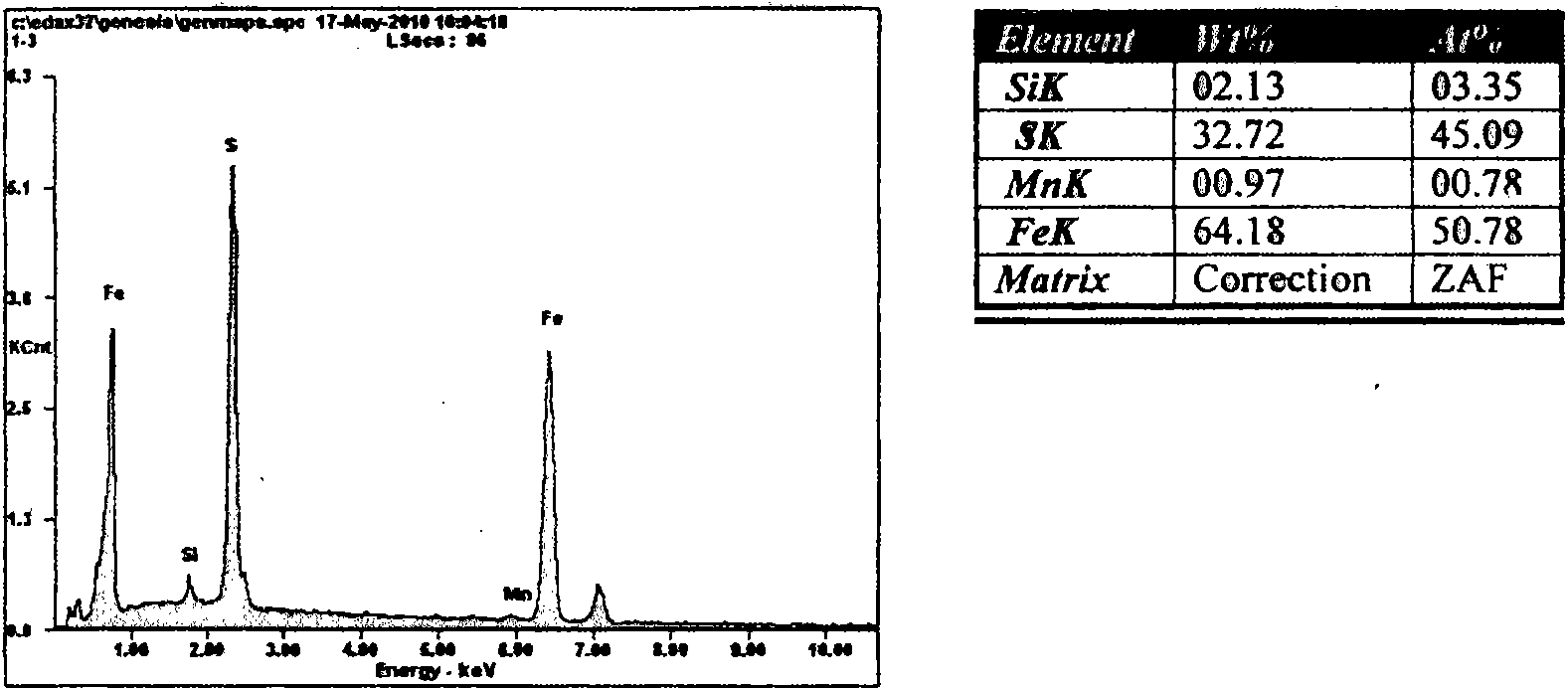

Gas plasma sulfurizing process

InactiveCN101956155AMeet technical quality requirementsEvenly distributedSolid state diffusion coatingWind drivenElectrolysis

The invention discloses a gas plasma sulfurizing process, which belongs to the technical field of surface heat treatment. In the process, a steel workpiece is placed in a sealed sulfurizing furnace with direct-current high voltage and high vacuum, then an appropriate amount of carrier gasses such as hydrogen gas, argon gas, ammonia gas and the like, and hydrogen sulfide are introduced into the furnace to form a sulfurizing atmosphere. Those gases are split into plasma states of nitrogen, hydrogen, argon and sulfur after entering the sulfurizing furnace and dash against the surface of the steel workpiece positioned on a negative plate to ensure that the temperature of the workpiece is raised, wherein sulfur ions infiltrate into the surface of a component to form ferrous sulfide which covers the whole surface of the component to fulfill the aim of sulfurizing. The process has the advantages of no pollution, low cost and high sulfurizing quality, overcomes the defects of serious pollution and high cost of the conventional electrolytic sulfurizing, and also overcomes the defect of low quality of plasma sulfurizing performed by using solid sulfur on the market at present. Through sulfurizing treatment, the mechanical life of a mechanical workpiece can be improved by 2 to 3 times, and the process has obvious economical and social benefits and extensive development prospect when applied to an automobiles, a train, a wind-driven generators, a petroleum machinery and a rolling machine.

Owner:BEIJING TIANMA BEARING CO LTD

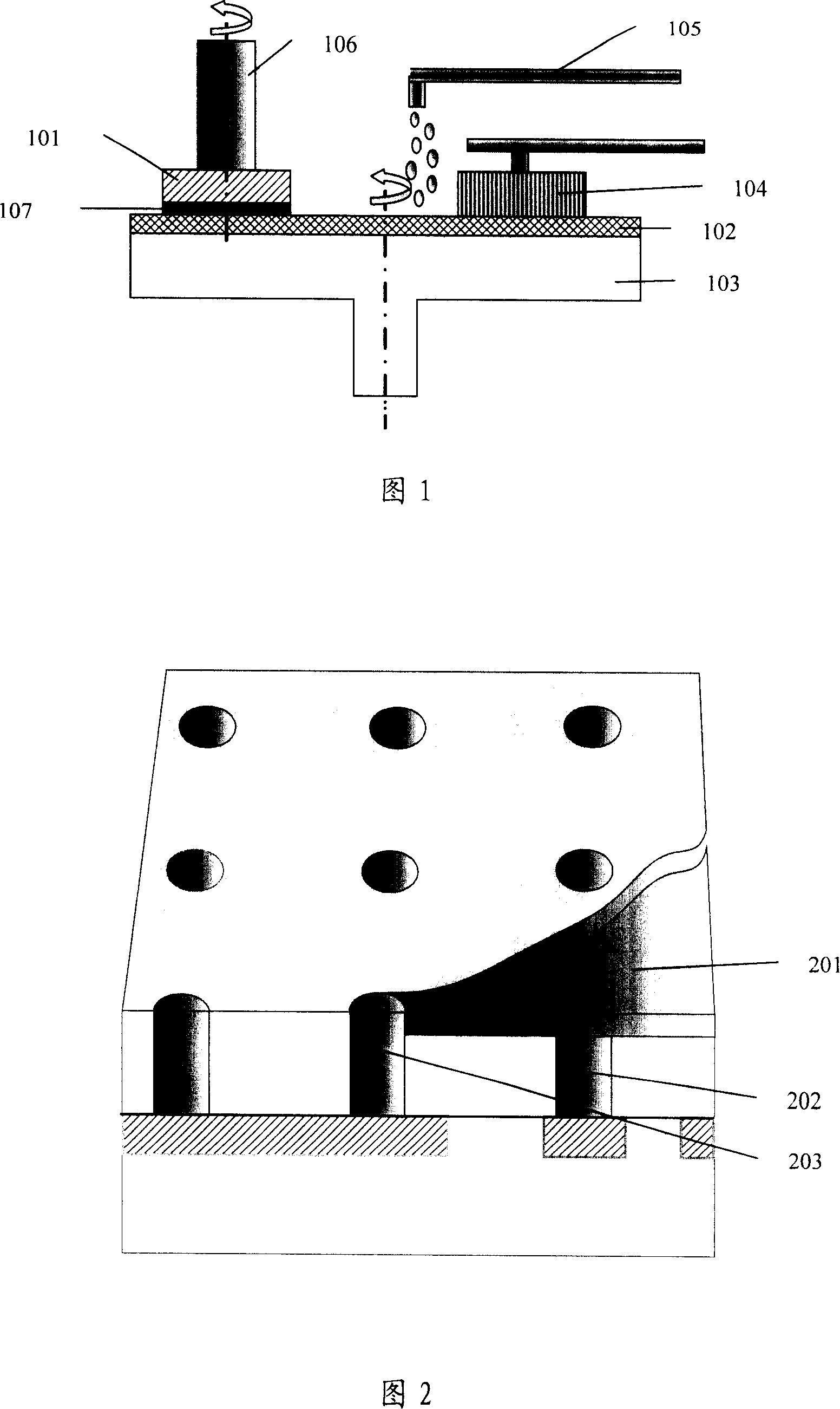

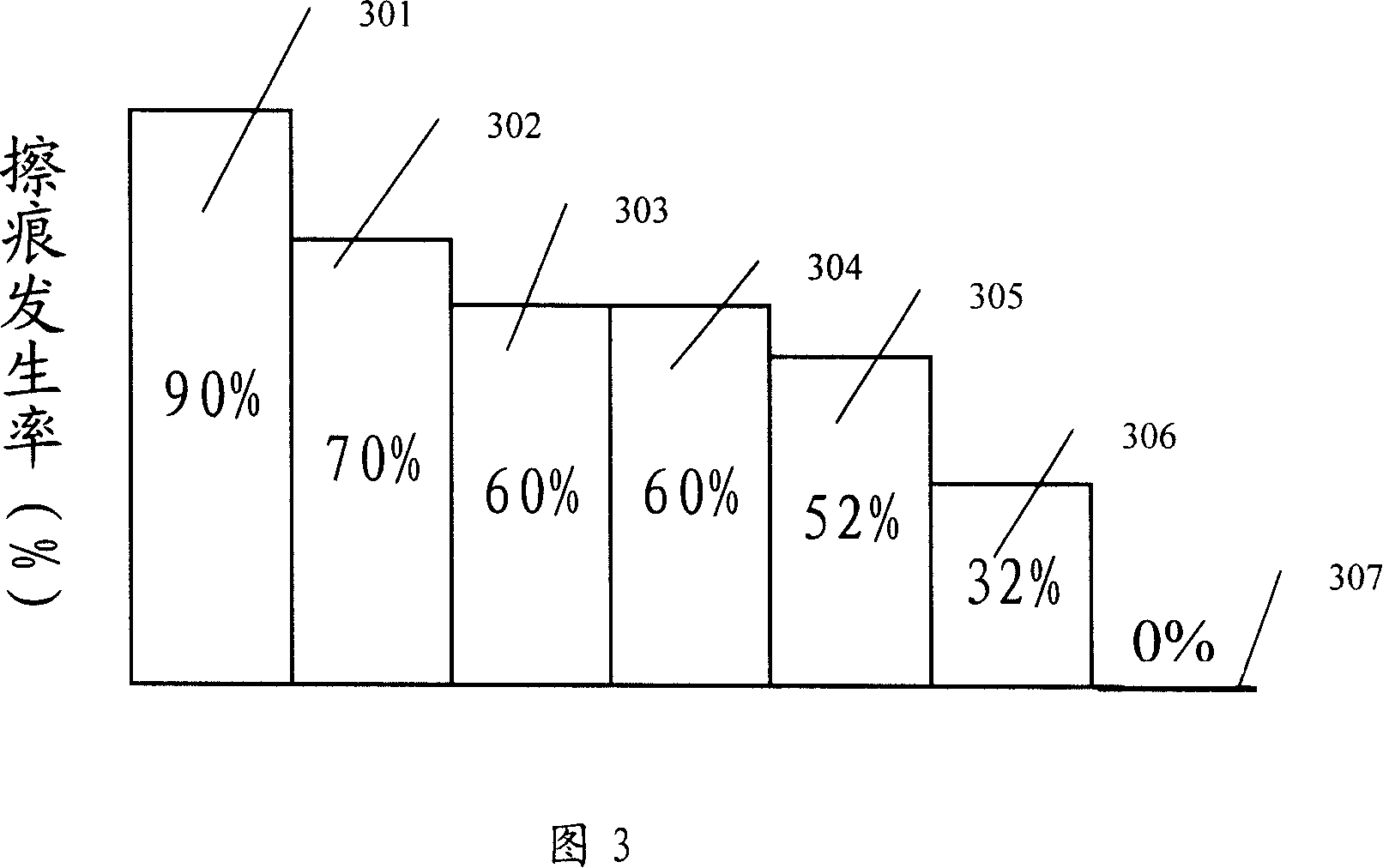

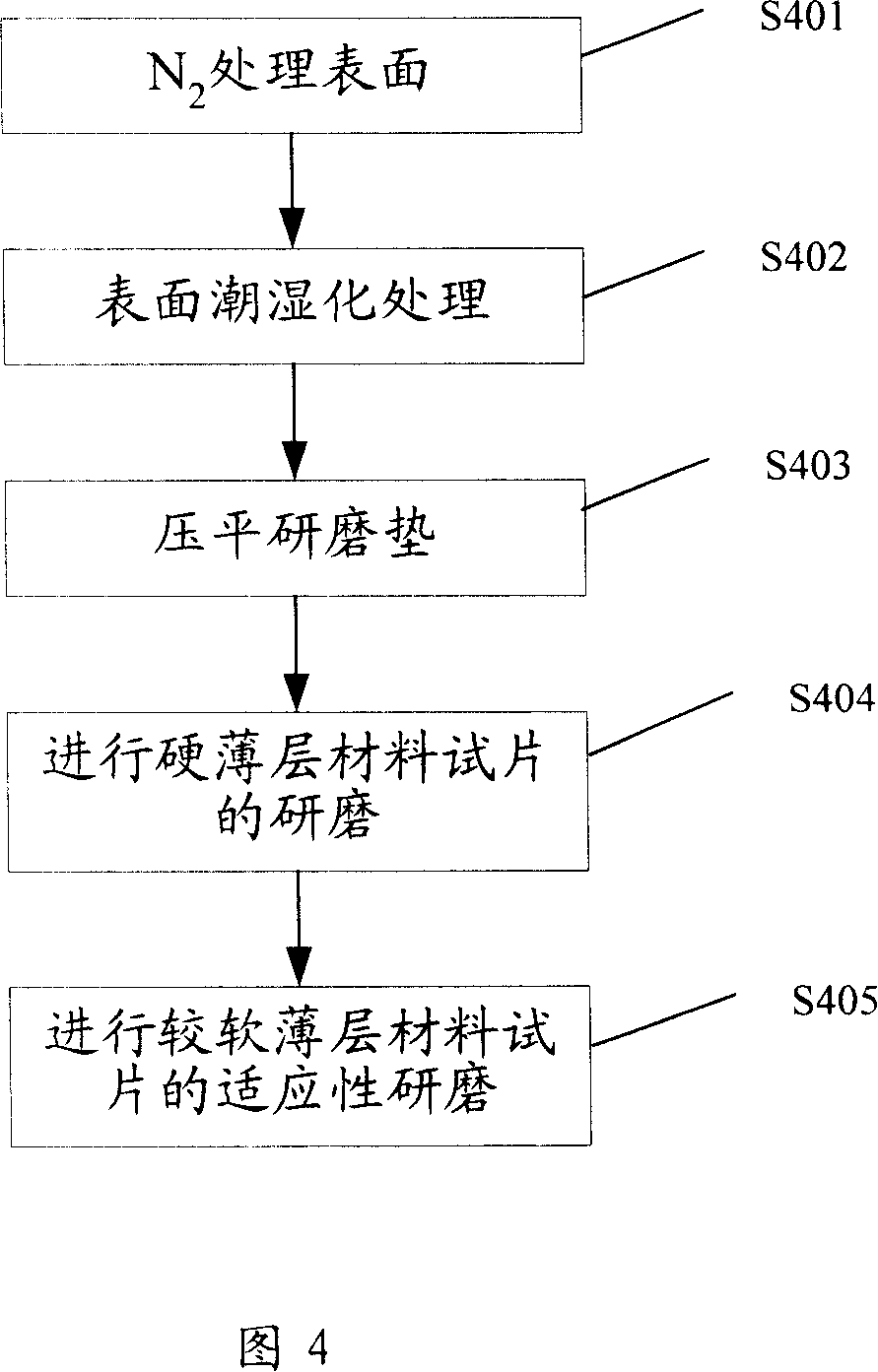

Chemical and mechanical grinding method

ActiveCN101104247AStable working conditionEvenly distributedPolishing machinesSemiconductor/solid-state device manufacturingMetallurgyCompound (substance)

The invention discloses a chemical mechanical grinding method, which reduces or even eliminates scratches produced easily in the chemical mechanical grinding process by processing a grinding pad and improving grinding process. The invention is applicable in various CMP thin materials with characteristics of universality and low cost. On the premise that process difficulty is not increased, the invention improves the rate of the finished products.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

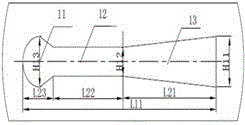

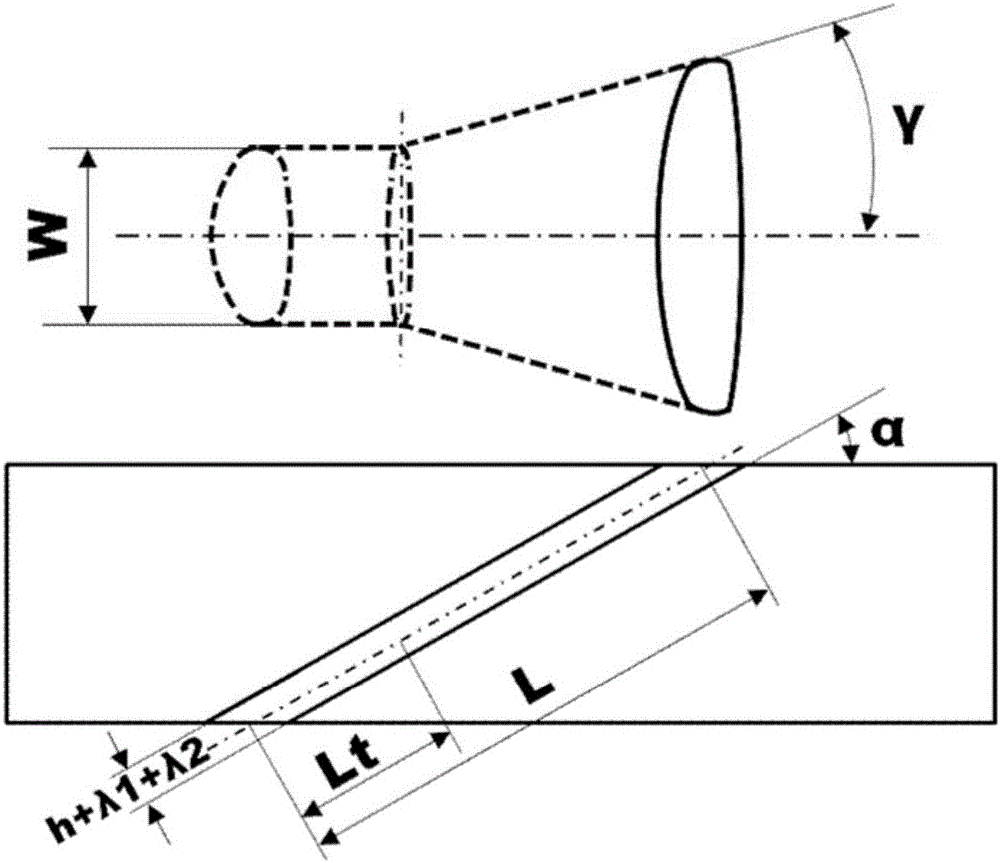

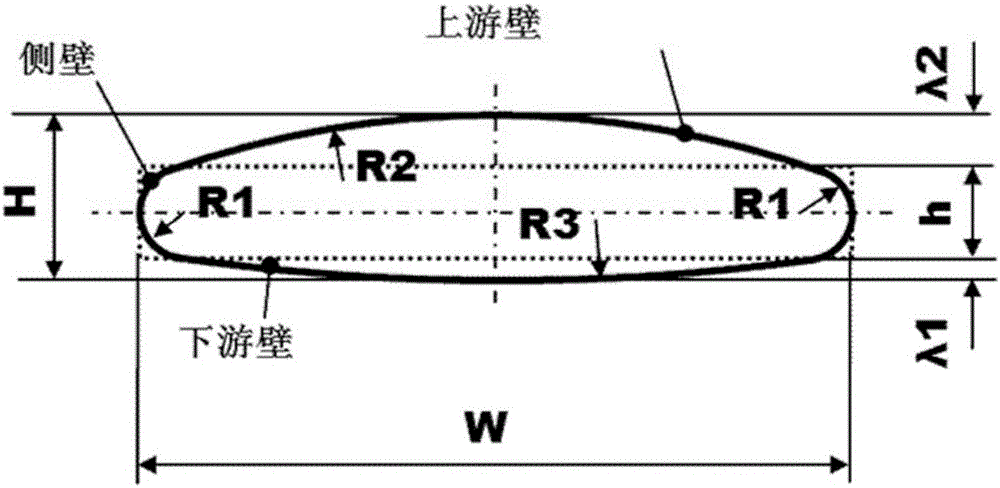

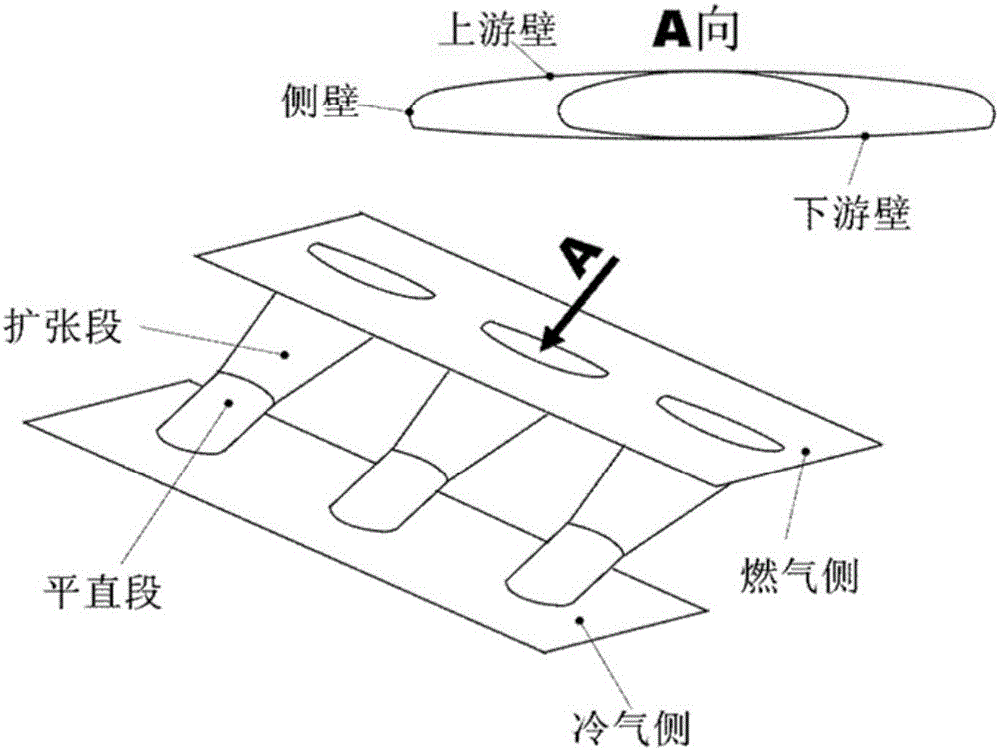

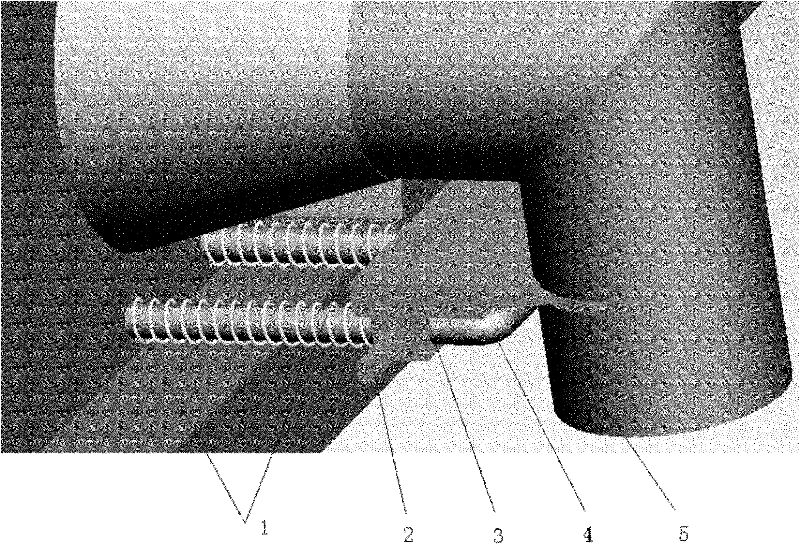

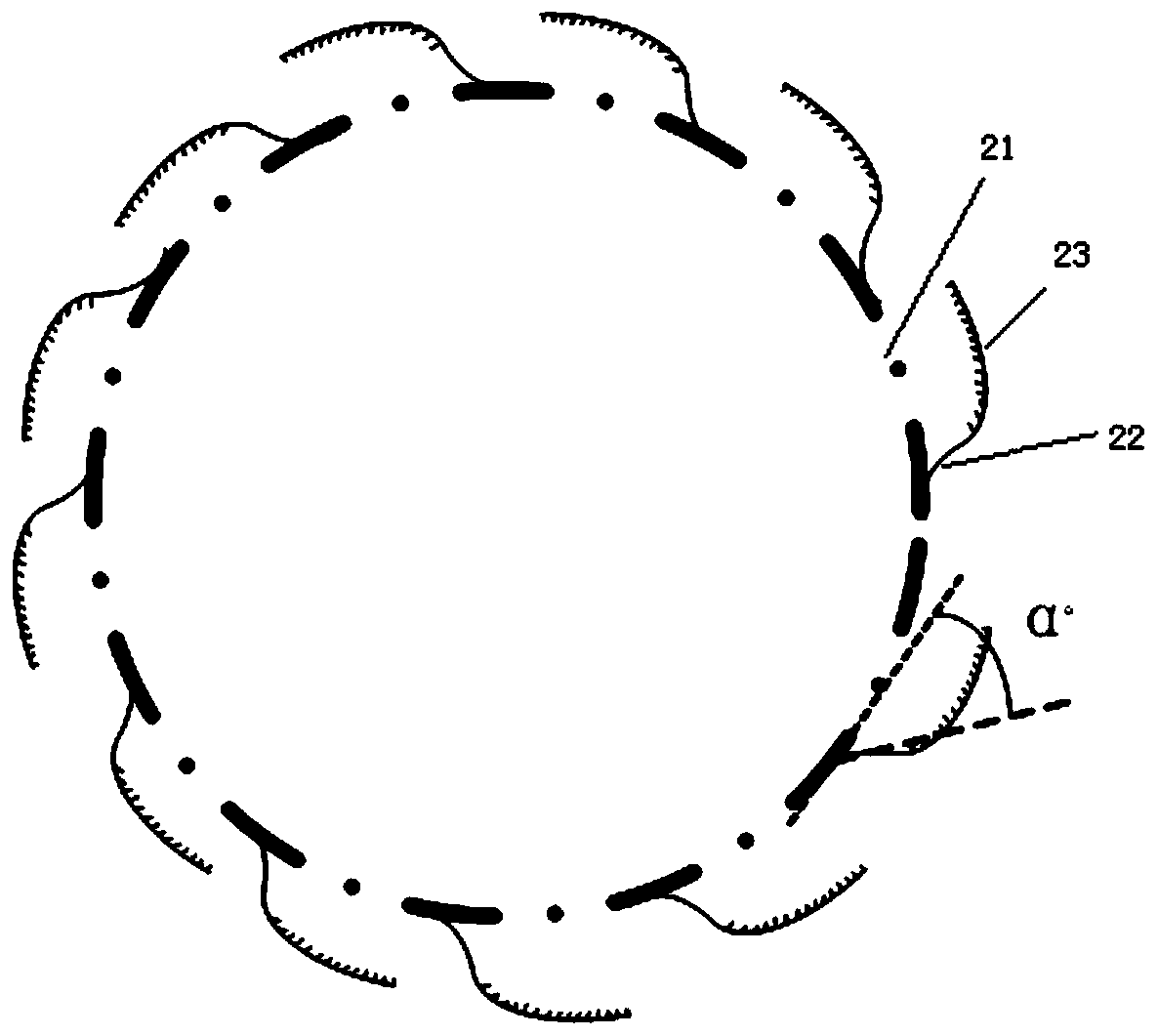

Discrete gas film cooling hole structure

ActiveCN106437866AUniform fluidityUniform coverageEngine fuctionsBlade accessoriesTurbine bladeCooling effect

The invention discloses a discrete gas film cooling hole structure, and relates to gas turbine cooling technologies. Hole patterns are formed with shuttle-like cross sections. Each whole hole is expanded and composed of two sections, the straight section is located on the cooling gas side, and the expanded section is located on the high-temperature gas side. The cross section of each straight section is in a shuttle shape, the shuttle shape is composed of four arc sections which are tangential, and the upstream walls and the downstream walls protrude outwards; and the arcs on the two sides of each straight section expand transversely to form the two side faces of the corresponding expanded section, and the upstream walls and the downstream walls of the expanded sections are outwards-protruding hook faces. The whole gas film cooling hole structure is high in cooling effect, and the gas film cover area is large; controllable inverted-kidney-shaped vortex pairs are generated on the downstream portion, and transverses gas film covering is uniform; speed at a cooling gas outlet is high, and the pneumatic mixing loss is small; and machining is easy, and the structure can be realized through existing gas film hole machining technologies. The gas film hole patterns are used for cooling gas turbine blades and are suitable for pressure surfaces, suction surfaces, upper end wall surfaces and lower end wall surfaces of the turbine blades.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

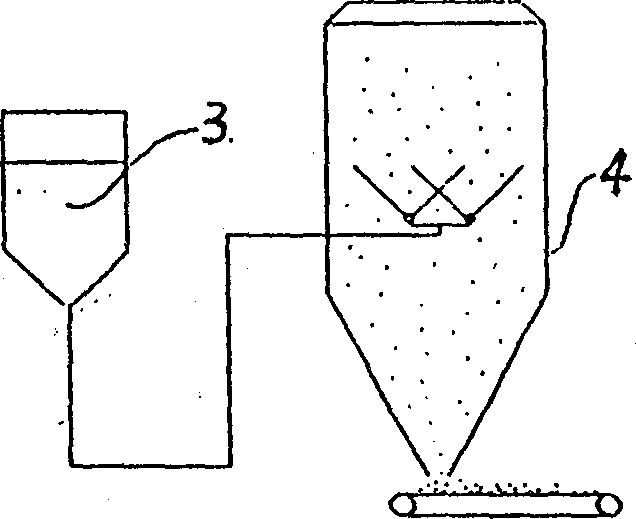

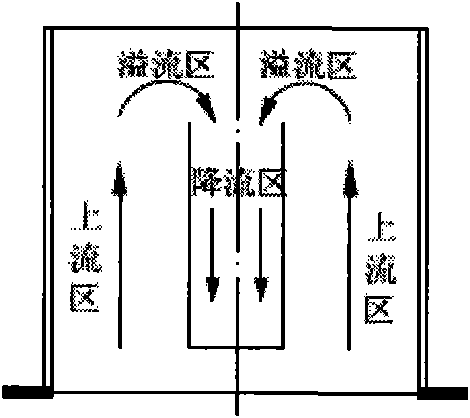

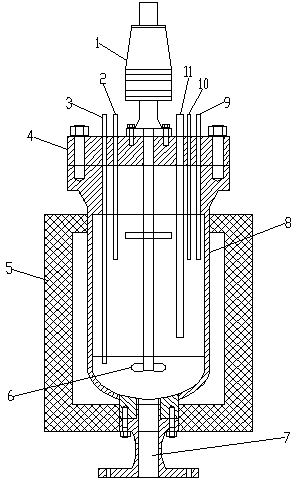

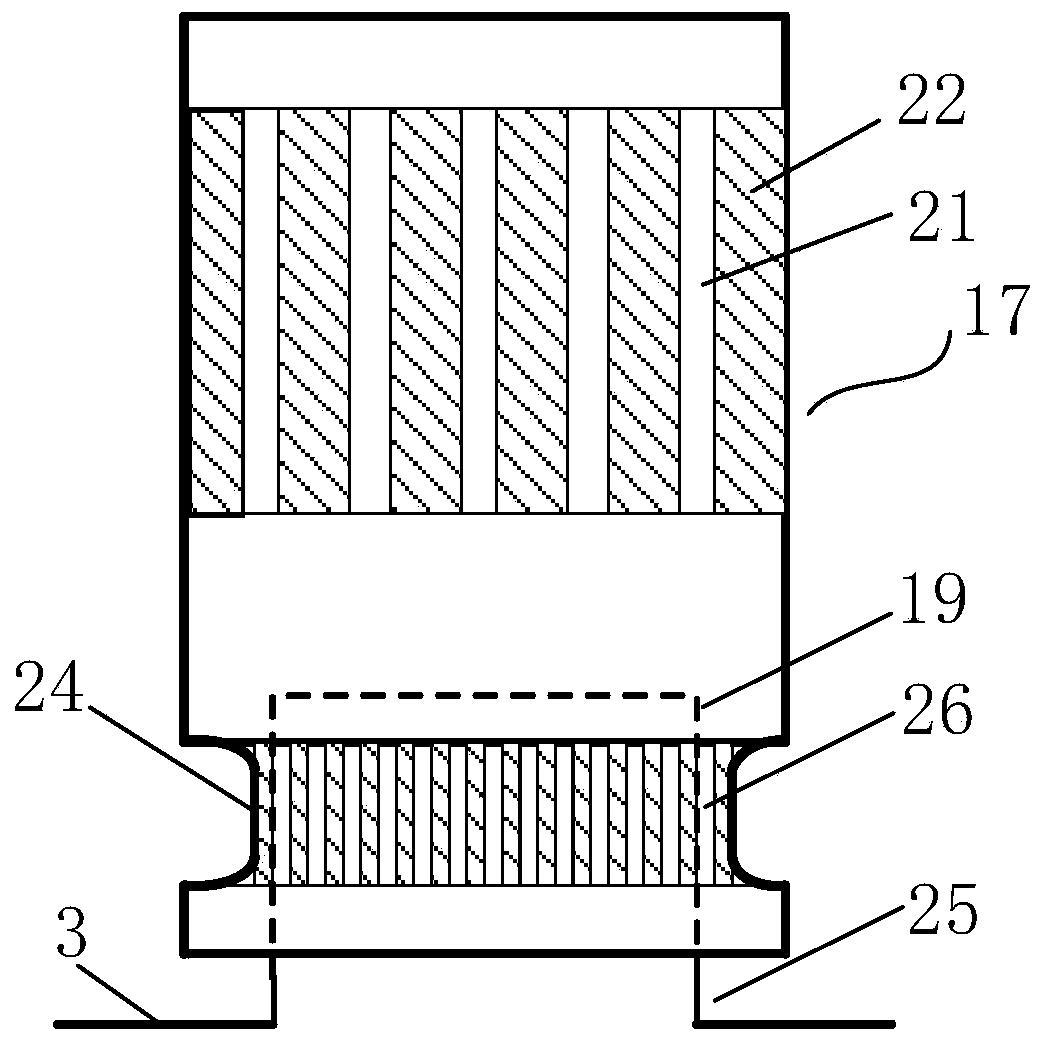

Crystallizing-dephosphorizing reactor

InactiveCN101555057ACompact structureSmall footprintWater/sewage treatmentSalt crystallizationPrecipitation

The invention discloses a crystallizing-dephosphorizing reactor. A water distribution zone, a reaction zone and a sedimentation zone are arranged from bottom to top on a crystallizing-dephosphorizing reactor body, wherein the water distribution zone is provided with a slag discharge pipe, a water inlet pipe, an up-flow column disk type distributor and an aeration device which is formed by the combination of an aeration pipe and an aeration head, the lower part of the reaction zone is provided with a carrier inlet and a drug inlet pipe, the upper part and the lower part at the middle of the reaction zone are provided with a first back flow pipe and a second back flow pipe, the sedimentation zone is provide with a water outlet weir, a water outlet pipe and a discharging opening, the upper part of the water outlet weir is provided with a saw-toothed overflow weir, the lateral side of the water outlet weir is provided with two parallel baffles, and the bottom of the water outlet weir is provided with an inclined board. The crystallizing-dephosphorizing reactor has clear functions; the water distribution zone is provided with the up-flow column disk type distributor which can effectively prevent short-circuiting of fluid; the reaction zone is provided with a carrier which can enhance calcium phosphate salt crystallization; the crystallizing-dephosphorizing reactor adopts a running method of 'continuous feed-intermittent aeration' to prevent the carrier from blocking, and facilitates desorption and recovery of crystals on the carrier; the sedimentation zone is provided with the saw-toothed baffles and the water outlet weir, the water flows out evenly, and the solid-liquid separation is good by providing the inclined board.

Owner:ZHEJIANG UNIV

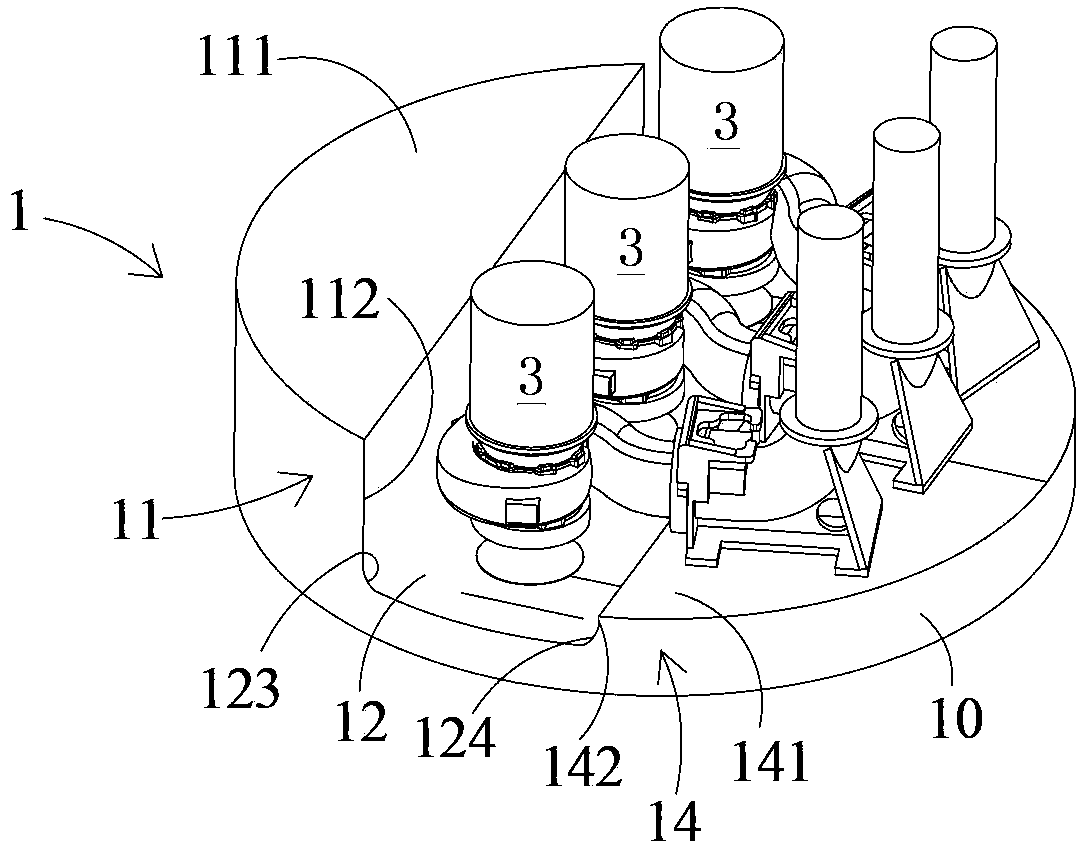

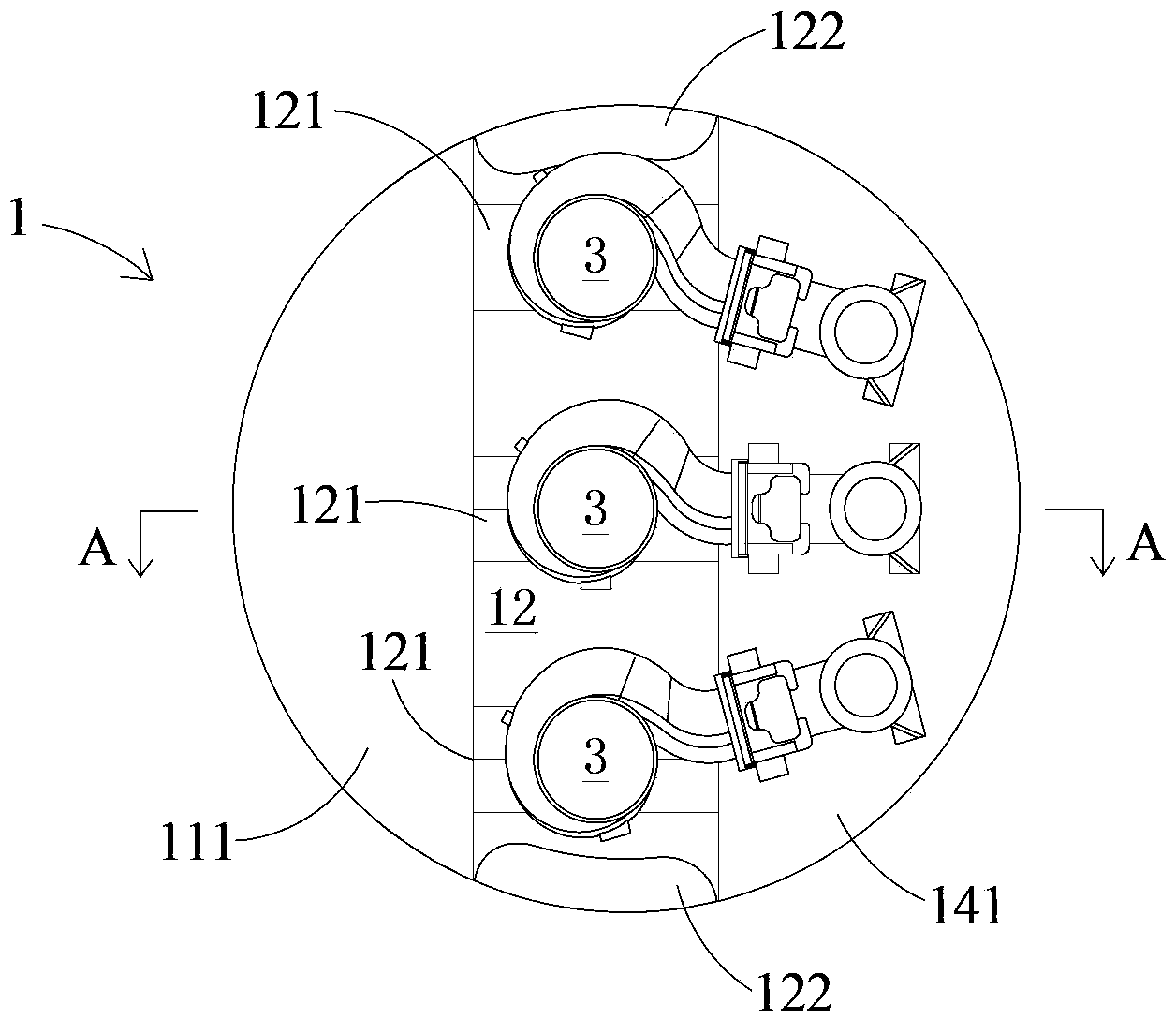

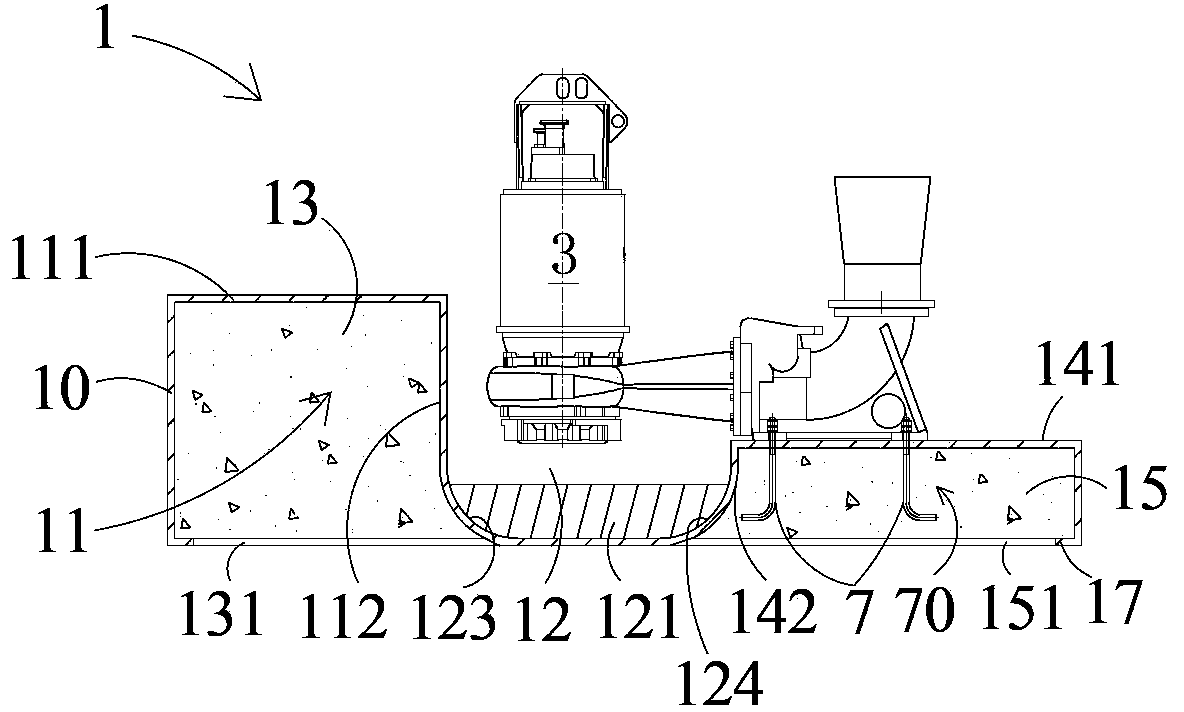

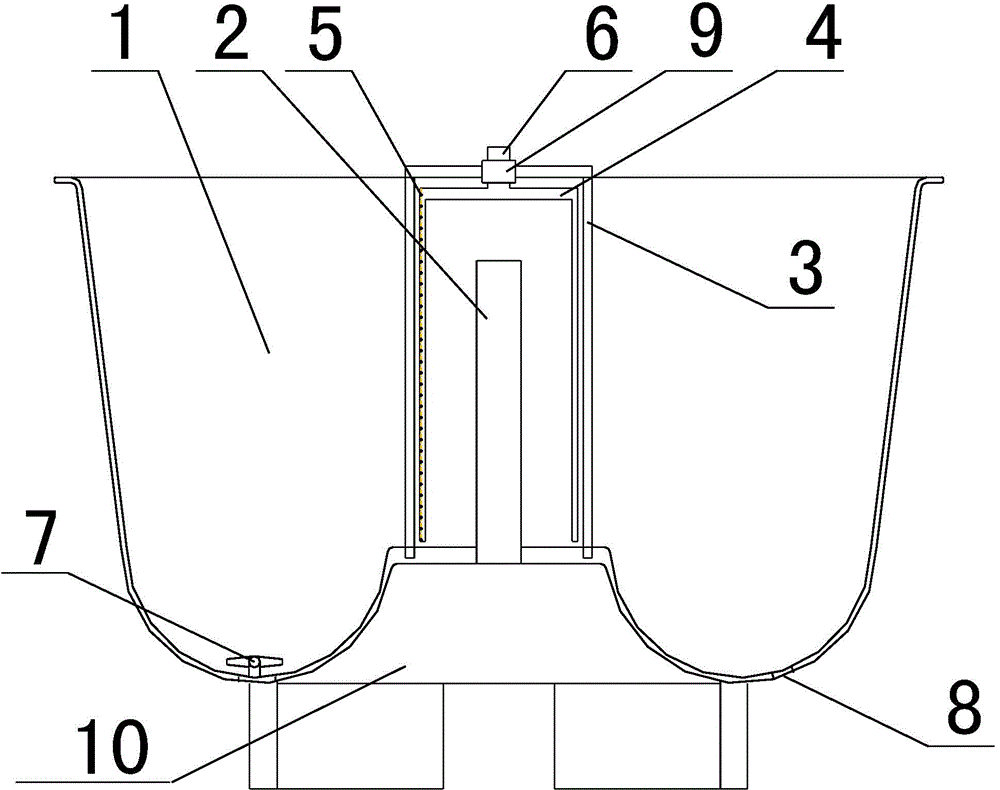

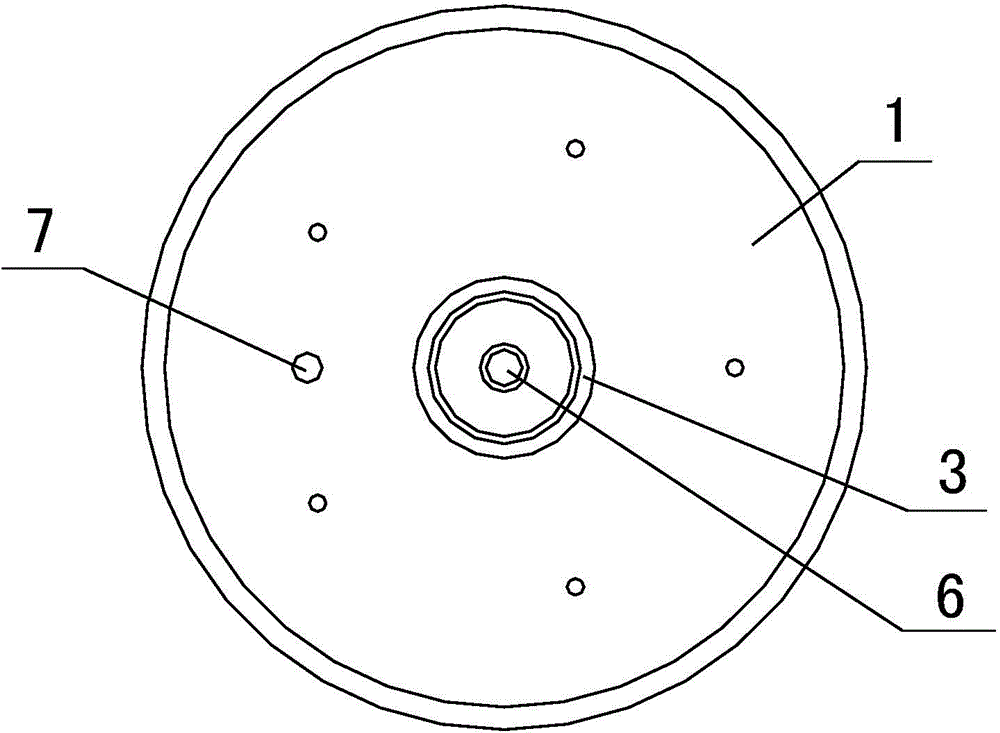

Pump station base, pump station and mounting method for pump station

The invention discloses a pump station base, a pump station and a mounting method for the pump station. The pump station base comprises at least one hollow portion, each hollow portion is provided with at least one pouring portion, and filler can be poured into the hollow portions through the pouring portions. In the site mounting process, concrete is poured into the first hollow portion, the weight of the pump station base is increased, the bearing capacity of the pump station base is enhanced, the pump station can be mounted reliably, the running stability of the pump station is improved, and a large amount of raw material cost is saved. The pump station comprises the pump station base.

Owner:GRUNDFOS HLDG

Nitration denitrification integral type sewage denitrification biomembrane reactor

InactiveCN1962487AFast updatePromote growth and reproductionTreatment with aerobic and anaerobic processesDraining tubeMulti pollutant

The invention discloses a column-shaped denitrifying reactor through integrated nitrated and denitrificated biological film method in the environmental protective technique domain, which comprises the following parts: water collecting system, aerating reacting region, anaerobic region and sediment region, wherein the aerating reacting region is full of suspension fill with aerating pipe on the bottom; the gas inlet and water outlet are opened on the bottom; the gas inlet connects aerating pipe with top opening interconnecting hole; the peole-shaped mud baffle board is set in the sediment region with hole on the top, which connects one end of gas collecting pipe; the other end of gas collecting pipe pierces the water collecting system; the mud drainage valve lies on one side of sediment region under the mud baffle board; the bottom of water collecting system possesses overflow dam with water drainage pipe on one side; the sampling valve is set around aerating reacting region and sediment region.

Owner:TONGJI UNIV

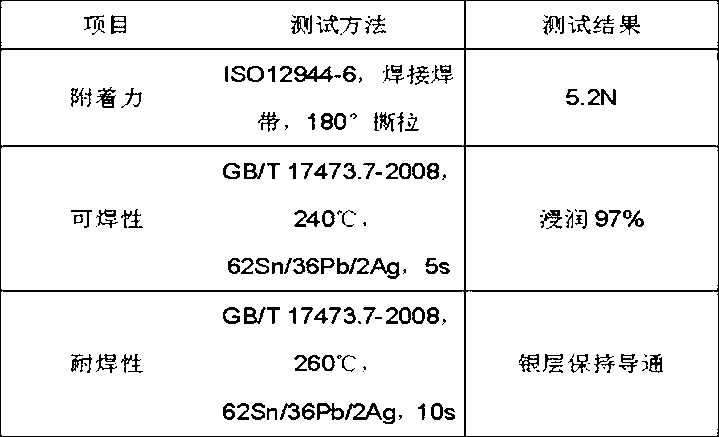

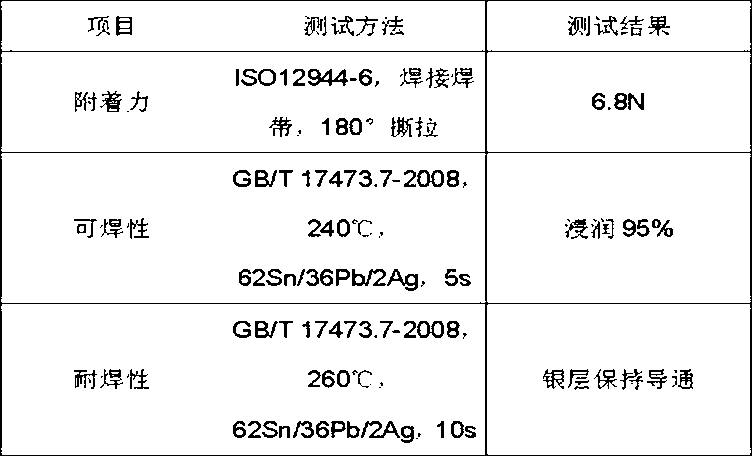

Unleaded back silver paste used for crystalline silicon solar cell and preparation method thereof

ActiveCN103219064ALow shrinkageGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteButyl carbitol

The invention relates to an unleaded back silver paste used for a crystalline silicon solar cell and a preparation method of the unleaded back silver paste used for the crystalline silicon solar cell. Raw materials comprise 60 parts of aluminum powder, 29-42 parts of organic binding agents and 1-10 parts of inorganic binding agents, the organic binding agents comprise 40-70 parts of terpilenol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of diethyl phthalate and 2 parts of sorbitol anhydride stearate, and the inorganic binding agents comprise 30-60 parts of Bi2O3, 5-15 parts of B2O3, 1-2 parts of NaF, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 2 parts of P2O5. After being mixed evenly, the components are rolled until the fineness degree is smaller than or equal to 10 microns, and viscosity is 30-100 Pa.s. The unleaded back silver paste used for the crystalline silicon solar cell is high in adhesive force and good in weldability and welding resistance.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

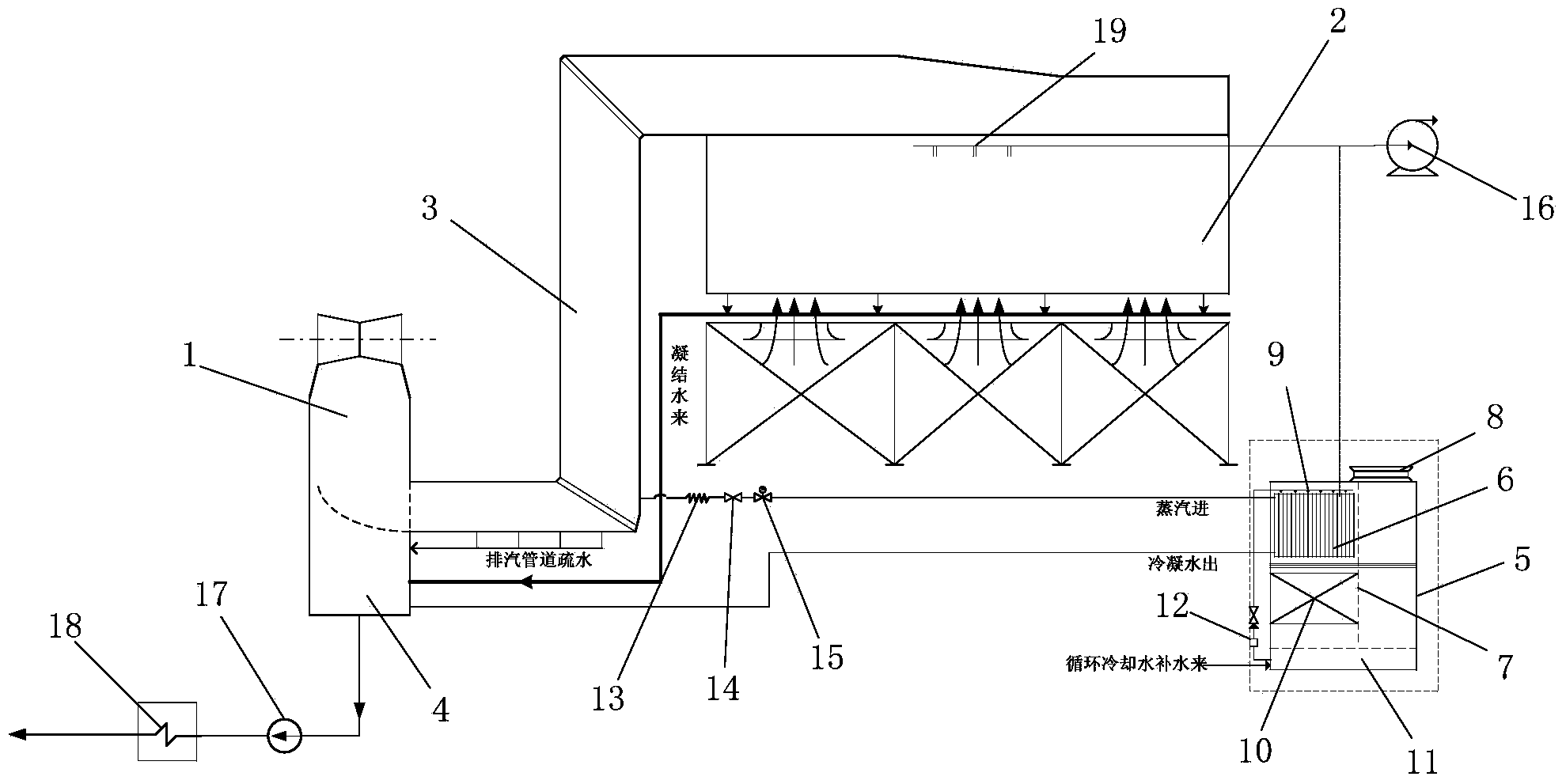

Direct air-cooling unit system with plate-type evaporative condenser unit adopted

ActiveCN103527267AReduce exhaust pressureReduce heat loadSteam/vapor condensersMachines/enginesUnit systemEngineering

The invention discloses a direct air-cooling unit system with a plate-type evaporative condenser unit adopted. The direct air-cooling unit system comprises a low pressure cylinder, an air cooled condenser and the plate-type evaporative condenser unit, wherein an exhaust steam pipe is communicated with a dead steam inlet of the plate-type evaporative condenser unit through a pipeline to send part of dead steam discharged by a turbine to the plate-type evaporative condenser unit to be cooled, and a condensed water outlet of the air cooled condenser and a condensed water outlet of the plate-type evaporative condenser unit are both communicated with a condensed water tank arranged blow the lower pressure cylinder through pipelines. According to the direct air-cooling unit system with the plate-type evaporative condenser unit adopted, steam discharged by the turbine is introduced into the air condense to be condensed through the steal discharging pipeline connected with the lower pressure cylinder, a pipeline communicated with the dead steam inlet of the plate-type evaporative condenser unit is further arranged on the steal discharging pipeline to introduce part of the dead steam discharged by the turbine to the plate-type evaporative condenser unit to be condensed, so that the thermal load entering the air cooled condenser is reduced, and then steam discharging pressure of the turbine is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

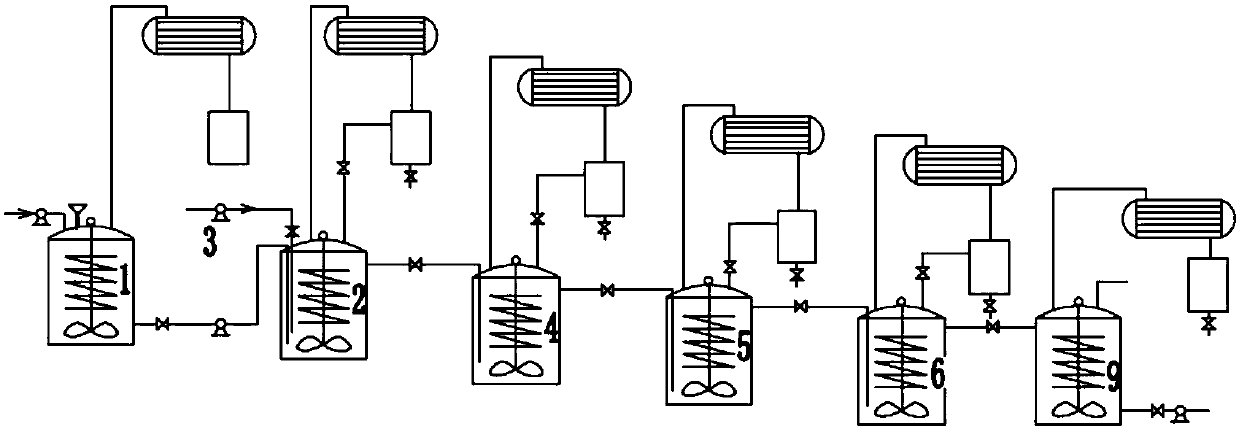

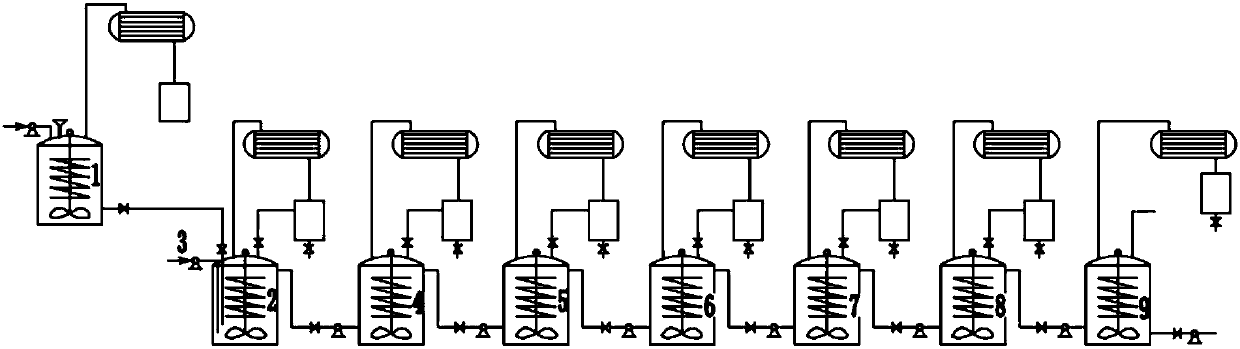

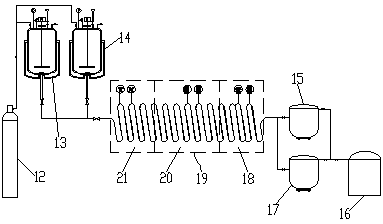

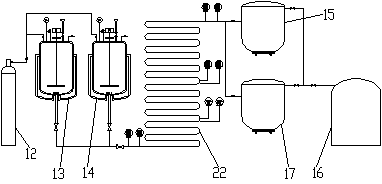

Apparatus and method for continuous production of eco-friendly plasticizer

ActiveCN107935846AImprove continuityIncrease production capacitySequential/parallel process reactionsOrganic compound preparationAlcoholPlasticizer

Disclosed is an apparatus and method for continuous production of an eco-friendly plasticizer. The method comprises: adding materials including solid acid and liquid alcohol to a preheating dehydration kettle, performing stirring and heating till the materials are free of water, and taking the materials out, so that preheating dehydration of materials are achieved; conveying the reaction materialobtained via preheating dehydration from the preheating dehydration kettle to series multiple stages of esterification reaction vessels via a pump or high differential pressure, adding a catalyst to afirst-stage esterification reaction vessel, and performing stirring and heating to carry out a reaction; and with continuous feeding of the reaction material, when the reaction material in one esterification reaction vessel reaches the upper discharging port of the vessel, conveying the reaction material to the next-stage esterification reaction vessel to perform a continuous reaction, regulatingthe flow of the material that enters the esterification reaction vessel, and conveying the material liquid after the reaction is over to a dealcoholization kettle for continuous dealcoholization. Theapparatus is reasonable in layout, simple in operation, high in production efficiency, and stable in operation. The yield per unit time is efficiently increased, and continuous and large-scale massive production of the eco-friendly plasticizer is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Polylactic acid composite material used for three-dimensional printing and preparation method therefor

ActiveCN104845300AAvoid deformationEasy to slideAdditive manufacturing apparatusMetal powder3 dimensional printing

The invention discloses a polylactic acid composite material used for three-dimensional printing. The polylactic acid composite material is characterized by comprising sheet-like micro metal powder, and being prepared from raw materials of the following components in parts by weight: 70-80 parts of polylactic acid, 5-15 parts of sheet-like micro metal powder, 1-2 parts of a surface modifier, 0.5-1 part of a crystallizing agent, 0.2-0.3 part of an antioxidant and 0.2-0.3 part of a processing aid. The sheet-like micro metal powder with flexibility and good thermal capacity is introduced into the polylactic acid, so that the thermal performance of the polylactic acid is changed by utilizing the thermal capacity of the sheet-like micro metal powder, and the polylactic acid is prevented from being quickly cooled to generate deformation. Especially, the sheet-like metal powder has good sliding property and flexibility, so that the flow uniformity and the toughness of the polylactic acid are improved, and the polylactic acid composite material is suitable for manufacturing a high-precision product by three-dimensional printing.

Owner:珠海金骆驼科技有限公司

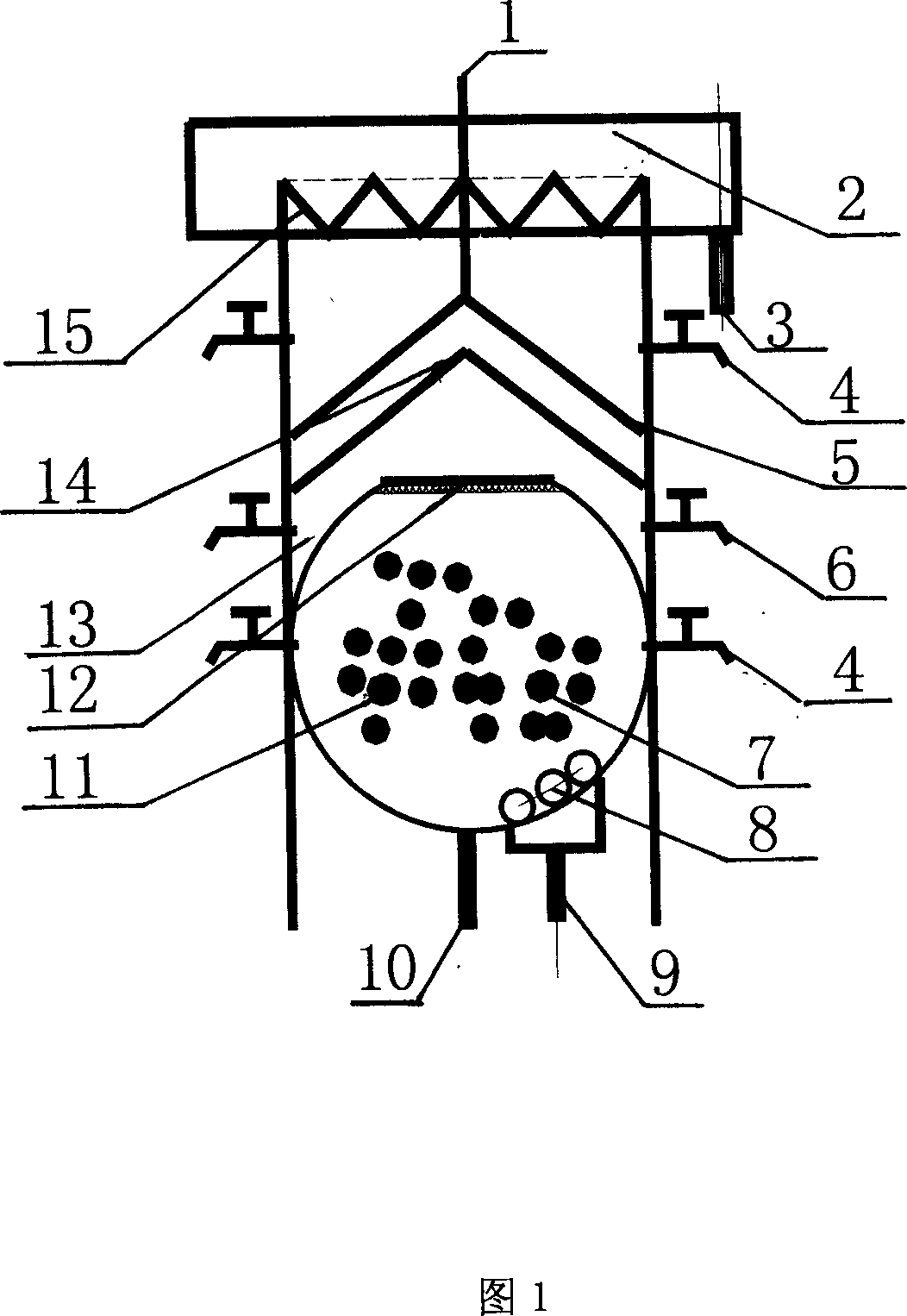

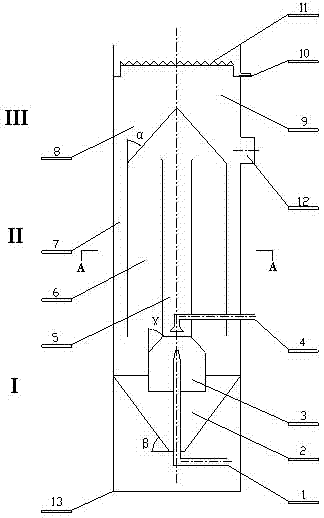

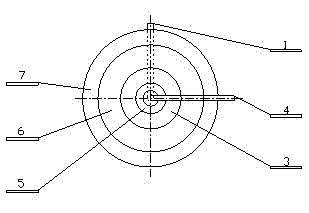

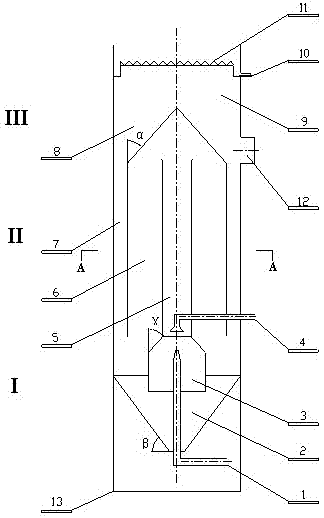

Enhanced dephosphorization reactor

InactiveCN102225799AUniform fluidityImprove the mixing effectWater/sewage treatment by flocculation/precipitationFiltrationSludge

The invention discloses an enhanced dephosphorization reactor. The reactor body comprises, from bottom to top, a water distribution zone, a reaction zone and a precipitation zone in sequence, wherein the lower part of the water distribution zone is equipped with a returned sludge hopper, a mixing chamber is arranged at the upper part of the returned sludge hopper and a jet water inflow device is arranged at the center of the returned sludge hopper; the reaction zone is equipped with, from inside to outside, a first reaction zone, a second reaction zone and a third reaction zone in sequence, and a chemical agent inflow pipe is located at the lower part of the first reaction zone; and the precipitation zone is equipped with, from bottom to top, a sludge discharge port, a precipitated sludge hopper, a sludge precipitation chamber, an overflow weir and a water outlet in sequence, and a saw-toothed overflow mouth is formed at the upper part of the overflow weir. The enhanced dephosphorization reactor combines thawing agglomeration dephosphorization, flocculation dephosphorization and crystallization dephosphorization, realizes the complementation of all functional units, has the advantages of compact structure and small occupation area; in addition, jet water inflow is adopted to enhance the mixing effect of wastewater and chemical agents, promote the reflux of the precipitated sludge for recovery and enhance dephosphorization effect; the solid-liquid separation effect is improved by the synergy of crystalline column layer filtration and inverted triangle sedimentation separation of the precipitation zone; and the precipitated sludge has high phosphorus content.

Owner:ZHEJIANG UNIV

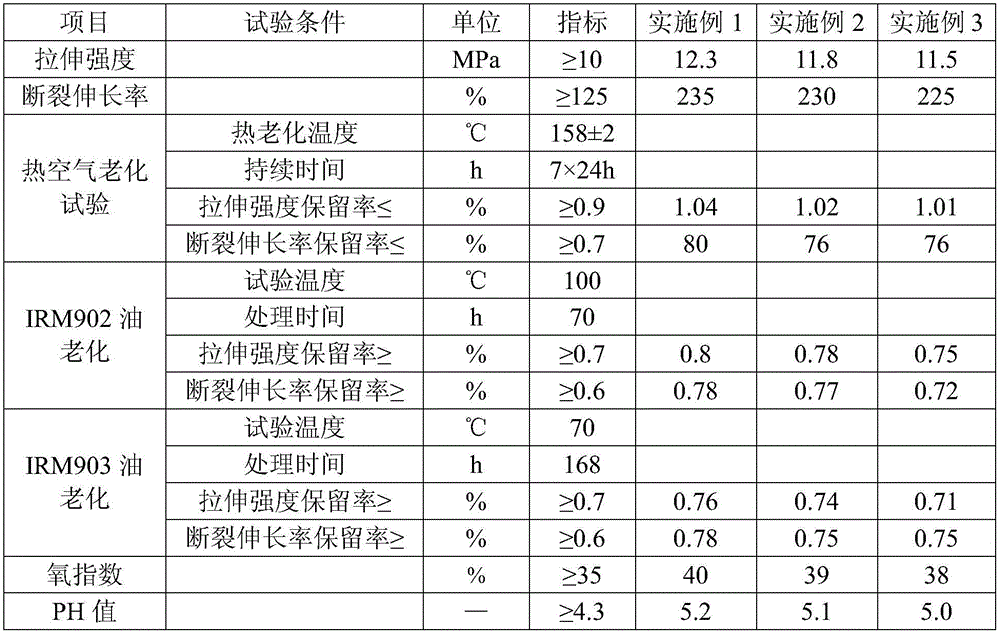

Environmental-protection flame retardant cable material and preparation method thereof

InactiveCN106243479AImprove low temperature performanceImproved low temperature winding performance and low temperature impact performanceRubber insulatorsPlastic/resin/waxes insulatorsCarbon blackAntioxidant

The invention discloses an environmental-protection flame retardant cable material and a preparation method of the environmental-protection flame retardant cable material. The preparation method comprises the following steps: putting EPDM (Ethylene-Propylene-Diene Monomer) rubber and ethylene-vinylacetate rubber into an internal mixer to be mixed, then putting zinc oxide, antioxidants, lubricants, zinc borate and auxiliary crosslinking agents into the internal mixer to be mixed, then putting carbon black pigment, reactive flame retardants, silane coupling agents and processing aids into the internal mixer to be mixed, finally discharging rubber compounds which are uniformly mixed from the internal mixer after the processing aids and peroxide crosslinking agents are put into the internal mixer to be mixed, packaging into triangle bags through an open mill and carrying out fine grinding, and then performing calendaring through a calender to be prepared into slices, thus obtaining the environmental-protection flame retardant cable material. The environmental-protection flame retardant cable material disclosed by the invention has good low-temperature rolling performance and low-temperature impact properties, can effectively lower the production cost of the environmental-protection flame retardant cable material and solve the problem of roll sticking in the EVM mixing process, has good elasticity and flexibility, excellent transparency and surface glossiness and further has good chemical stability, aging resistance and ozone resistant intensity.

Owner:HENGYANG HENGFEI CABLE CO LTD

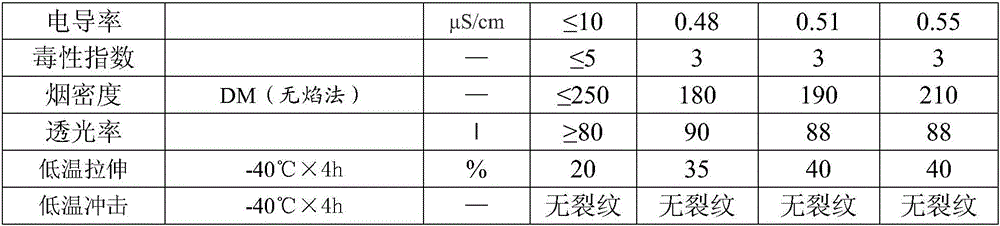

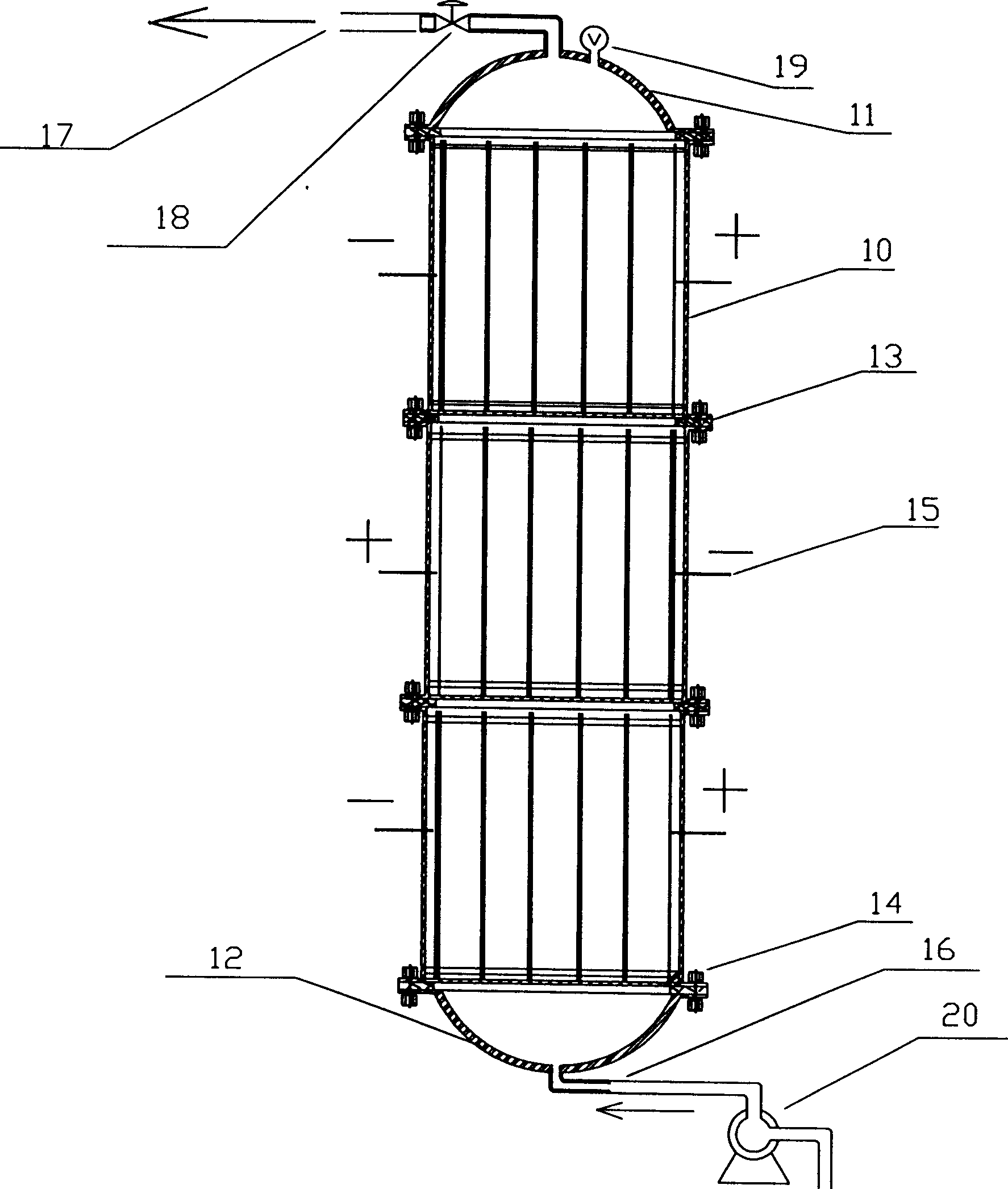

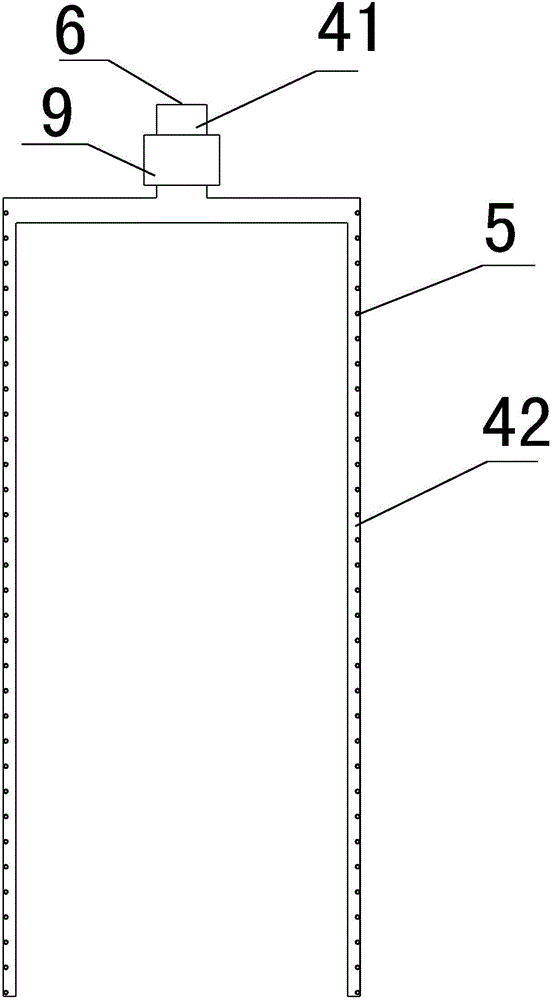

Electrochemical method and device for continuous and fast water treatment

InactiveCN1565984AReduce adverse effectsRealize energy savingWater/sewage treatment by flotationElectrochemical responseCatalytic oxidation

The invention discloses a continuous quick-speed water treatment method by employing a enclosed type electrochemical reactor which comprises at least three identical electrochemical units, wherein the electrochemical reactor is provided with a water intake port and a water outlet port on the bottom and on the top, the water outlet port is connected to a water flow control valve directly, each of the electrochemical unit comprises a square column, an adapting flange, a water distribution board, a plurality of plate electrodes and conductive plates. The electrochemical unit at least comprises a pair of insoluble electrodes, at least a conductive plate unit is arranged between the anode and the cathode. The method realizes ideal effect for removing the surface-active agents in the waste water.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

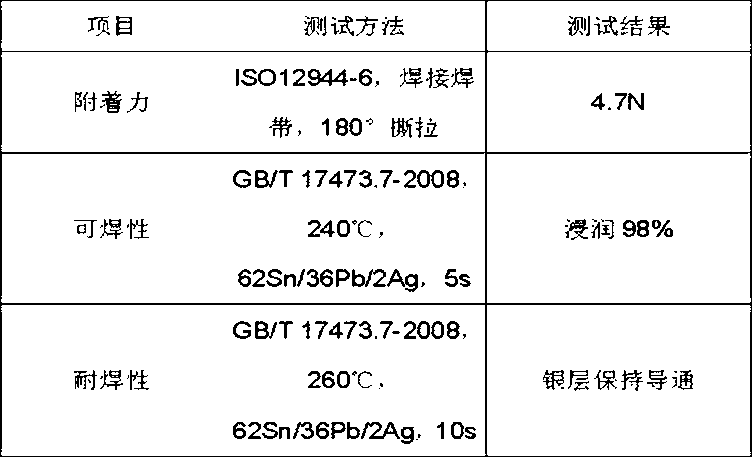

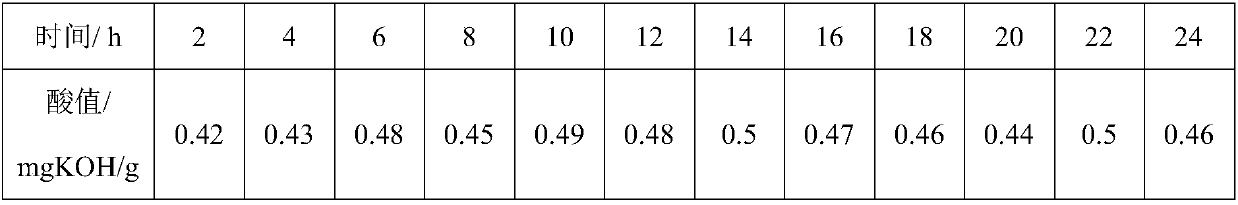

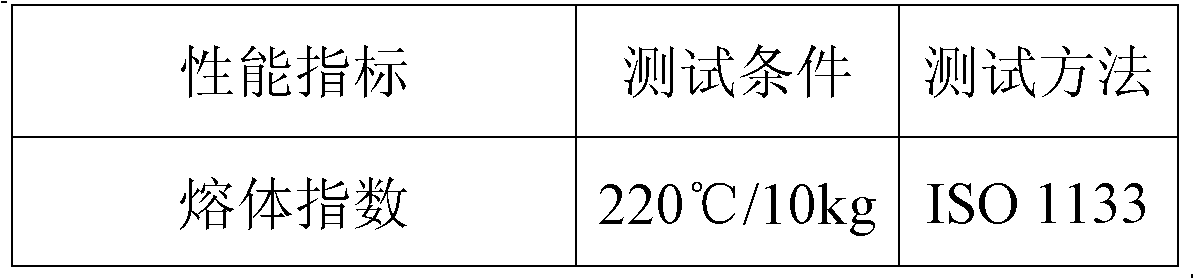

Crystalline silicon solar cell back surface field aluminum paste and preparation method thereof

ActiveCN103208321AUniform fluidityBalanced thixotropyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldWater boil

The invention relates to crystalline silicon solar cell back surface field aluminum paste and a preparation method thereof. The crystalline silicon solar cell back surface field aluminum paste comprises, by weight, 74 parts of aluminum powder, 20-25 parts of organic bonds, 1-4 parts of lead-free glass powder and 0.1-2 parts of additives, wherein the organic bond comprises, by weight, 40-70 parts of terpineol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of dibutyl phthalate and one part of sorbitol anhydride stearate; the lead-free powder comprises, by weight, 30-60 parts of Bi2O3, 5-15 parts of B2O3, 3 parts of BiF3, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 1-3 parts of P2O5; and the additive is spherical copper powder with the purity larger than 99% and the fineness being 20000 meshes. The aluminum powder, the organic bonds, the lead-free glass powder and the additives are evenly mixed and then rolled by a three-roll grinder until the fineness is smaller than or equal to 10 mum and the viscosity is 30-60Pa*s. The crystalline silicon solar cell back surface field aluminum paste is high in photoelectric conversion efficiency and adhesive force, the adhesive force conversion efficiency after high temperature aging declines, and the water-boiling resistance is good.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Annular passage hatching pool with automatic water filter net cover cleaning function

ActiveCN103548741AEasy to installUniform fluidityClimate change adaptationPisciculture and aquariaDraining tubeWater filter

The invention relates to an annular passage hatching pool, and belongs to the field of aquaculture. An annular passage hatching pool with an automatic water filter net cover cleaning function is characterized by comprising an annular passage hatching pool, wherein the middle of the bottom of the annular passage hatching pool is provided with a water outlet, a water discharge pipe is arranged on the water outlet, the height of the water discharge pipe is set according to the height requirement of the annular passage hatching pool, an outer ring of the water discharge pipe is provided with a filter net framework , a filter net is arranged on the filter net framework, a back flushing component is arranged between the filter net framework and the water discharge pipe, and comprises a back flushing pipe arranged in a way of pasting the filter net, one side, corresponding to the filter net, on the back flushing pipe wall is provided with a plurality of small water outlet holes used as back flushing water outlets, a water inlet of the back flushing pipe is formed above the filter net framework, and the bottom of the annular passage hatching pool is also provided with a hatching pool water inlet and a pollution discharge opening. The annular passage hatching pool has the advantages that the installation of the filter net is convenient, in addition, the filter net can be automatically cleaned, and the hatching rate and the survival rate of fries are improved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Reaction system for extraction of heated solvent of coal and reaction method

The invention discloses a reaction system for extraction of a heated solvent of coal and a reaction method. The reaction system comprises a plurality of sets of premixing and stirring devices which are arranged to be in parallel. The outputs of the premixing and stirring devices are communicated with inlets of tubular-type reactors, and transportation of materials is achieved through a pressurized feeding device. The outlets of the tubular-type reactors are communicated with a plurality of sets of post-treatment devices which are arranged to be in parallel and used for separating the material liquid after reaction. The system can stir materials in different phases through the premixing and stirring devices, and achieves uniform contact and flow of the materials in different phases in a reaction pipe. The high efficiency and continuous operation of the system can be ensured. Through alternate operation of the plurality of sets of premixing and stirring devices and post-treatment devices, the continuous operation of operating processes can be achieved. The system has advantages of low requirements to devices, short technological process and low device cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

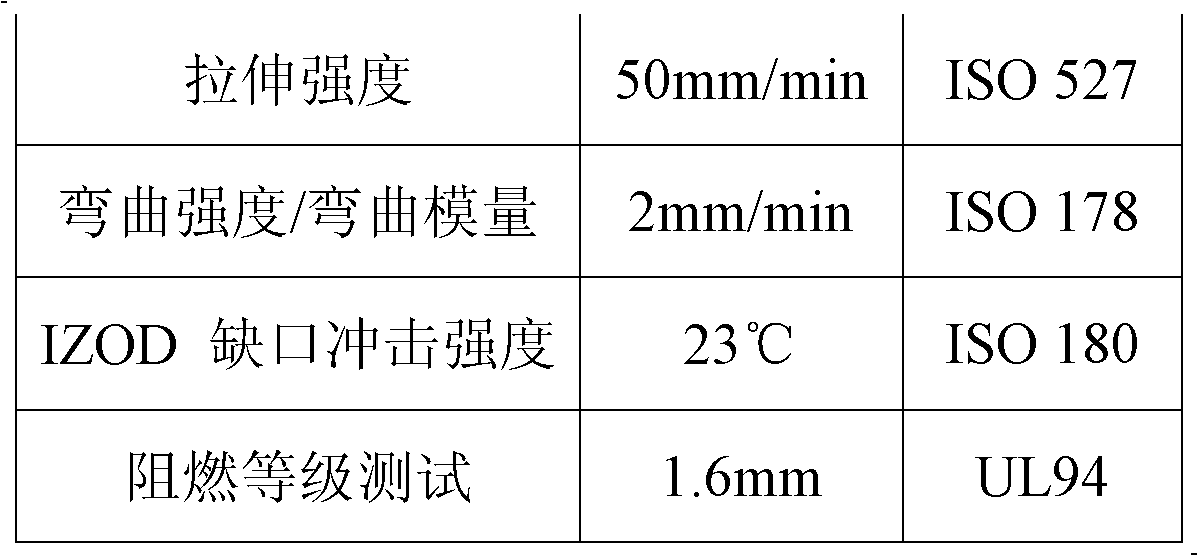

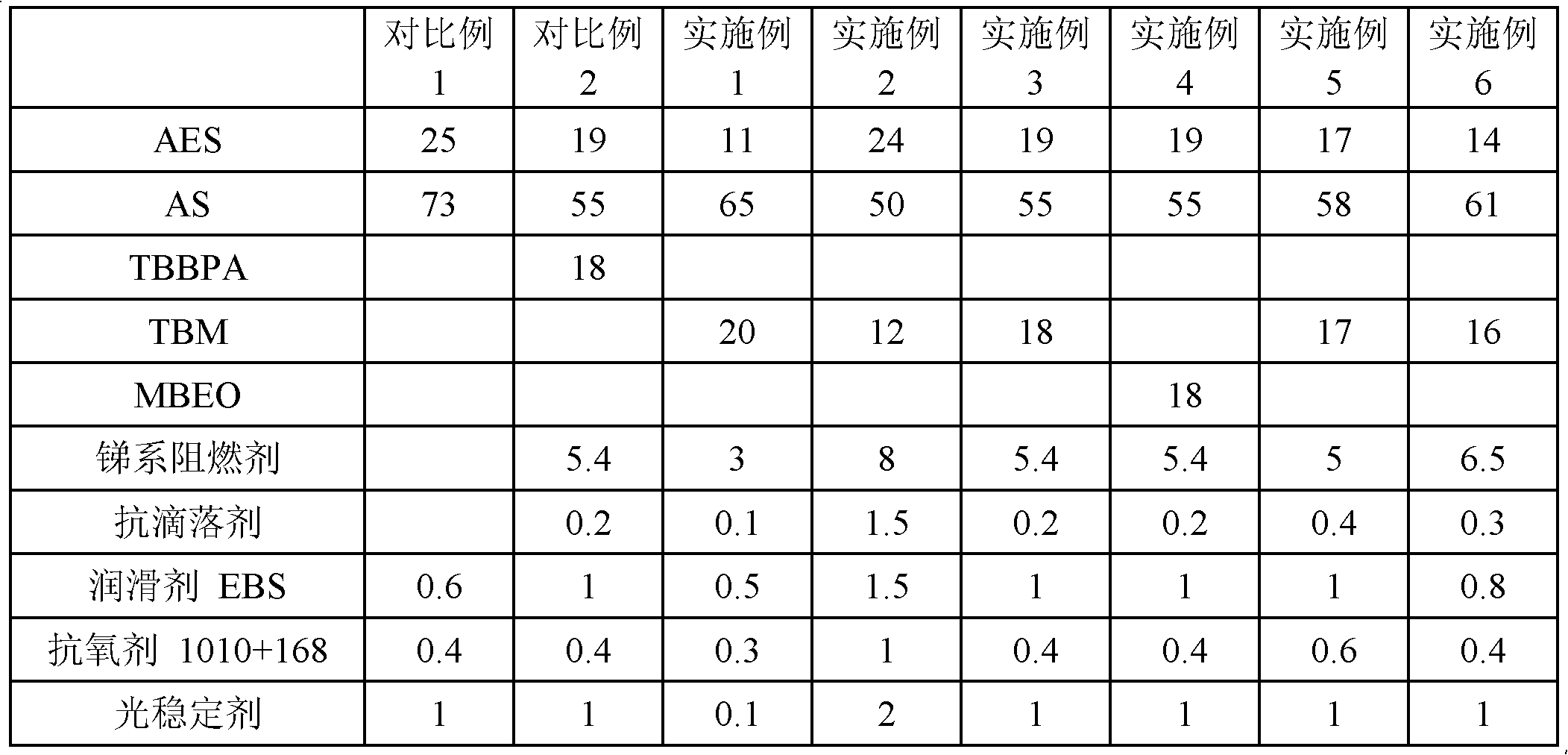

Flame-retardant AES (acrylonitrile ethylene styrene) material, preparation method for same and application thereof

The invention discloses a flame-retardant AES (acrylonitrile ethylene styrene) material, a preparation method for the same and application thereof. The flame-retardant AES material is prepared by 11-24% of AES, 50-65% of AS (acrylonitrile styrene), 12-20% of brominated flame retardant, 3-8% of antimonic flame retardant, 0.1-1.5% of anti-drip agent, 0.5-1.5 of lubricant, 0.3-1% of antioxidant and 0.1-2% of light stabilizer, wherein the brominated flame retardant preferably is tri(tri-bromophenyl) cyanurate and / or tetrabromobisphenol A based epoxy resin. The flame-retardant AES material has good weather fastness, balanced mechanical properties and excellent flame-retardant effect, and application fields of the AES material are widened. The preparation method is high in operability and easy in implementation.

Owner:KINGFA SCI & TECH CO LTD +2

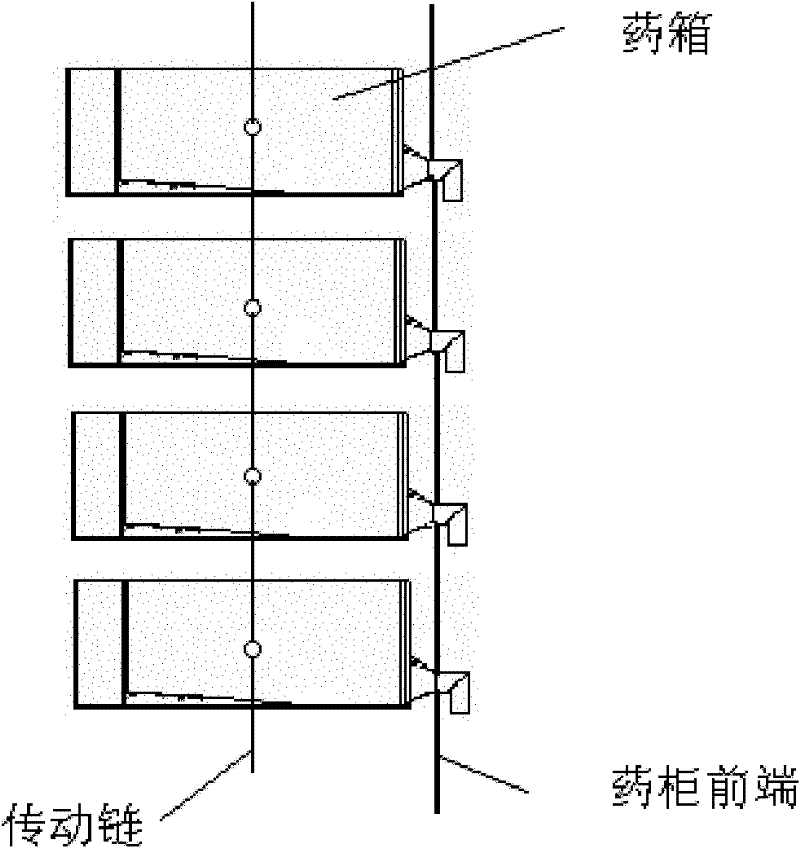

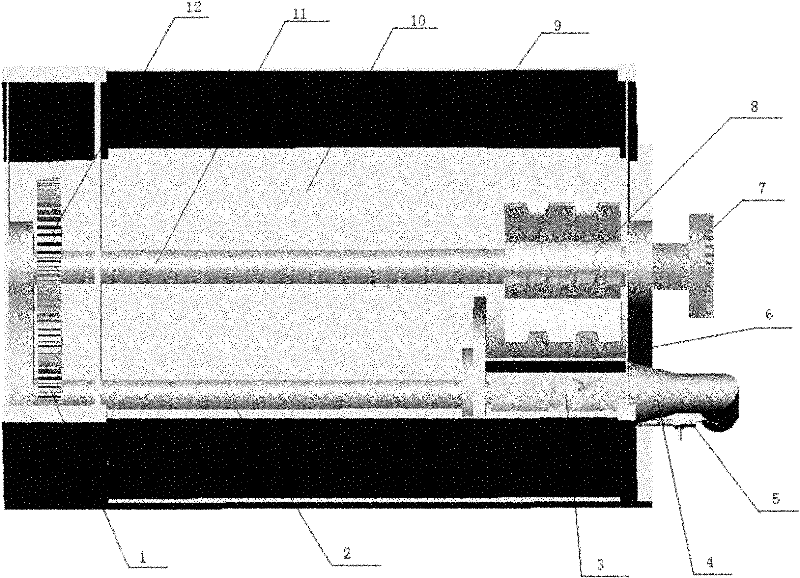

Medicine box mechanism of automatic traditional Chinese medicine discharging machine

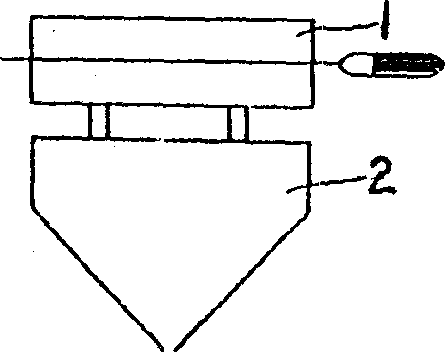

InactiveCN102673899AAdequate doseOvercome the defect of poor liquidityPowdered material dispensingImpellerTraditional medicine

The invention relates to a medicine box mechanism of an automatic traditional Chinese medicine discharging machine. The medicine box mechanism mainly comprises a gear coupling, a medicine box frame, an impeller, an impeller shaft, a large gear, a small gear, a small gear shaft, a medicine discharging screw, a bell mouth, a medicine outlet baffle, bearings and the like. When medicine is taken out, a driving device pushes the medicine outlet baffle open, the impeller shaft rotates and the traditional Chinese medicine particles are discharged from the bell mouth through the screw. When the screw discharges the medicine, a medicine tray below the bell mouth rotates to achieve the goal of equally dividing the medicine. The bottom of the medicine box frame is an inclined surface. A vibrator is arranged on the driving device. According to different shapes and types of traditional Chinese medicine particles, a series of screws with different diameters, thread depths and pitches are designed. The inner diameter of a medicine outlet is designed to be adjustable. Through the design of all mechanisms and the determination of optimum parameters, the defect that the flowability of all kinds of traditional Chinese medicine pieces with different shape and sizes is poor can be overcome, and the goal that the traditional Chinese medicine tablets flow evenly and flow out at the bell mouth is realized.

Owner:SHANGHAI VIEW VALLEY TECH +1

Pure-oxygen pulverized coal entraining combustor

InactiveCN102322633ASpread fastShorten the lengthPulverulent fuel combustion burnersCombustorFlue gas

The invention relates to a pure-oxygen pulverized coal entraining combustor, which comprises a pulverized coal nozzle arranged at the middle part of a combustor block, a pulverized coal feeding flue gas channel, a plurality of circular seam oxygen guns arranged at the circumference of the pulverized coal nozzle, a circular seam oxygen chamber connected to the outer ends of the plurality of circular seam oxygen guns, a central oxygen gun arranged in the pulverized coal flue gas channel and a circular seam oxygen inlet arranged on the central oxygen gun and communicated with the circular seal oxygen chamber. The length of flame of the combustor can be adjusted by adjusting flow adjusting valves on a central oxygen pipeline and a circular seam oxygen pipeline. Pulverized coal-containing flue gas is sprayed out from the pulverized coal flue gas channel, the central oxygen is sprayed out from the central oxygen gun positioned in the center of the pulverized coal flue gas channel, the pulverized coal flue gas and the central oxygen are premixed and burnt to form a stable root flame, therefore the fuel can be saved by 35 percent, the flue gas amount can be reduced by 70 percent, and nitric oxides contained in the flue gas are avoided.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

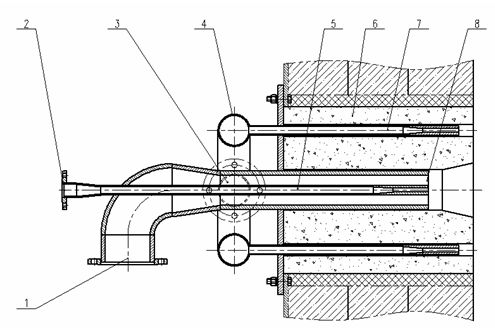

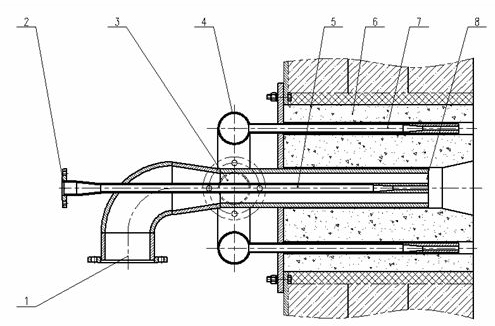

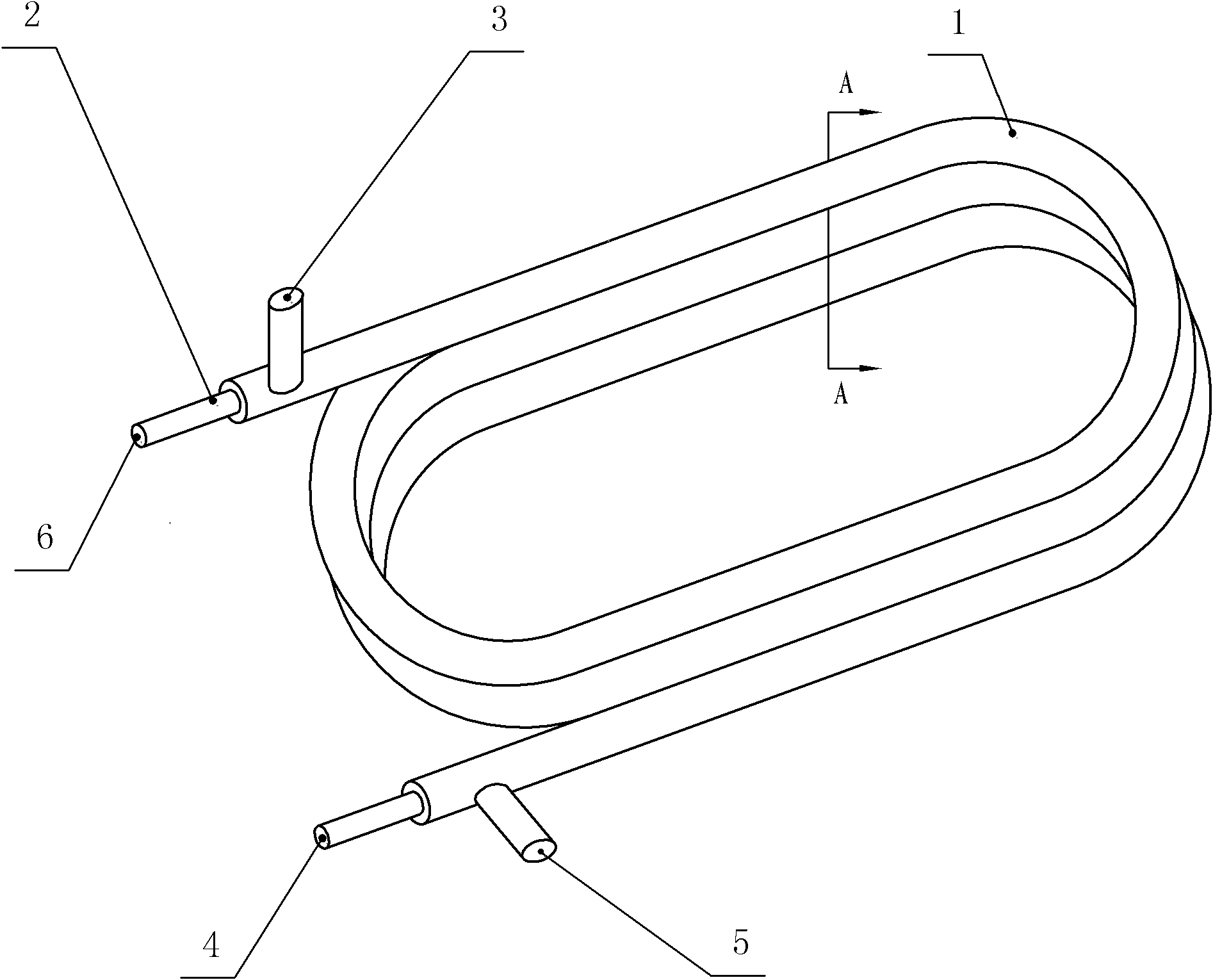

Elliptical continuous twisted tube coaxial heat exchanger

InactiveCN101975520AThe change of the cross-sectional ratio of the runnerUniform temperatureStationary tubular conduit assembliesTubular elementsLongest DiameterEllipse

The invention discloses an elliptical continuous twisted tube coaxial heat exchanger, which is composed of an outer tube and an inner tube arranged in an inlaid manner, wherein the outer tube is a round tube; the inner tube is configured as a single elliptical continuous twisted tube or an approximately elliptical continuous twisted tube, and an outer long shaft of the inner tube is equal to the inner diameter of the outer tube; the ratio of long diameter to short diameter of the inner tube is 1:0.2 to 0.6; the twisting inclination of the inner tube is set as 10 to 60 degrees; the direction of the long short shaft of the inner tube and an included angle of the axis of the inner tube are changed alternatively; an inner tube joint portion and an outer tube joint portion at two ends of the heat exchanger are welded and closed; outer tube walls of the inner tube joint portion and the outer tube joint portion at two ends of the heat exchanger are respectively provided with an inlet and an outlet made of working substance; the inner tube arranged in an inlaid manner and the outer tube are integrally spirally bent in a superposed circular disk shape in order to form the elliptical continuous twisted tube coaxial heat exchanger with the integral shape of spiral runway, spiral mosquito repellent or spring. The elliptical continuous twisted tube coaxial heat exchanger has the advantages of higher heat transfer coefficient, improved compactness, good pressure and vibration resistance as well as dirt resistance, little possibility of deformation and plugging, flexible structure, convenient arrangement, low price and saving expenditure.

Owner:山东双涵石化装备有限公司 +1

Plug flow distillation tray and method for preparing IP (isophorone) through liquid-phase condensation of acetone

ActiveCN110038317AEvenly distributedUniform fluidityOrganic compound preparationChemical industryIsophoroneDistillation

The invention provides a plug flow distillation tray and a method for preparing IP (isophorone) through liquid-phase condensation of acetone. The plug flow distillation tray comprises a tray and a plug flow assembly arranged on the tray, wherein the plug flow assembly comprises a downcomer, a grading overflow weir, a light and heavy phase distributing element, a liquid receiving plate I and a flowguide element; the downcomer is connected with the tray, and the grading overflow weir is arranged at an inlet of the downcomer; the light and heavy phase distributing element is arranged in the downcomer and located below the grading overflow weir; the liquid receiving plate I is connected with the tray and located on the side opposite to the side where the downcomer and the tray are connected;the flow guide element is arranged above the connection position of the liquid receiving plate I and the tray and is provided with multiple flow guide channels. A pressurized reaction distillation tower containing the plug flow distillation tray is applied to perform aftertreatment on an easily foaming IP / alkaline solution system, so that a liquid phase is more uniformly distributed and flow, andthe reaction effect is favorably improved.

Owner:WANHUA CHEM GRP CO LTD +1

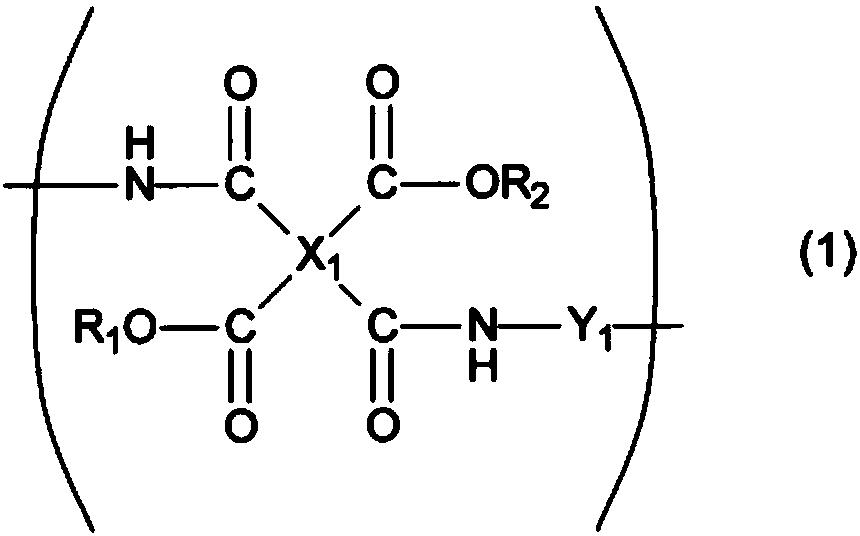

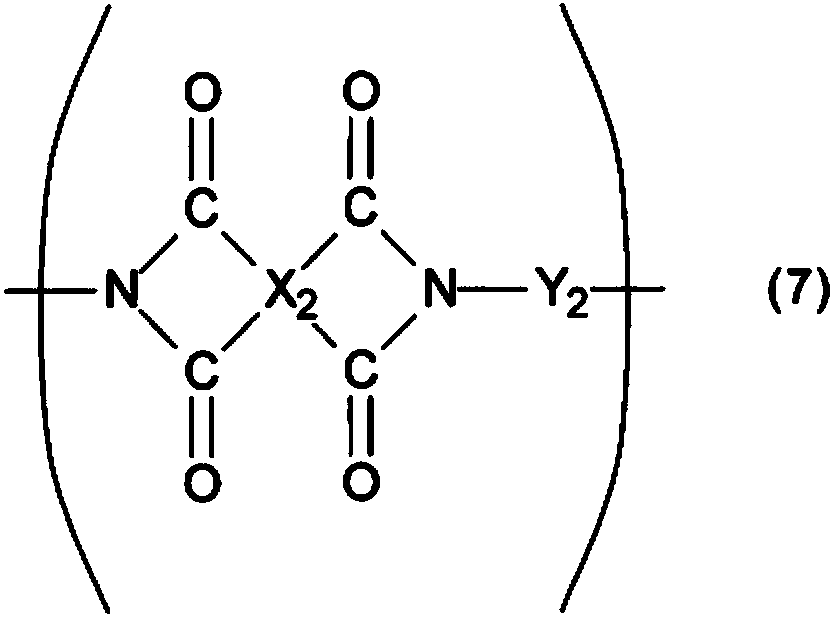

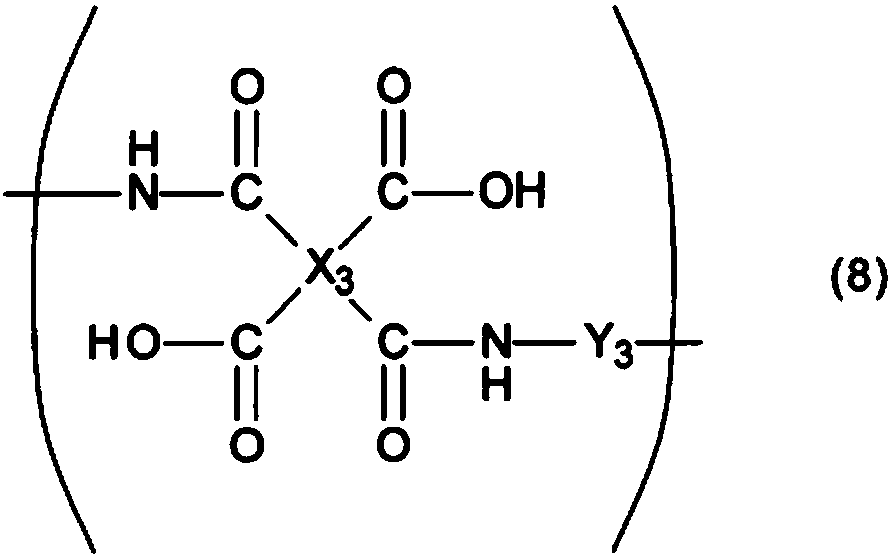

Polyimide precursor composition and polyimide composition

ActiveCN107849352AEasy to produceHigh transparencySemiconductor/solid-state device detailsSynthetic resin layered productsCombinatorial chemistryOptical anisotropy

The present invention pertains to a polyimide precursor composition which comprises a polyimide precursor and fine particles having optical anisotropy and to a polyimide composition which comprises apolyimide and fine particles having optical anisotropy.

Owner:UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com