Method for preparing magnesium alloy strip blank cogged by flat extruding cylinder

A technology of flat extrusion barrel and magnesium alloy plate, which is applied in the direction of metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problem of uneven deformation of magnesium alloy materials, unfavorable slab processing and production, and magnesium alloy microstructure Inhomogeneity and other problems, to achieve the effect of excellent anisotropy performance, uniform deformation, uniform flow and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

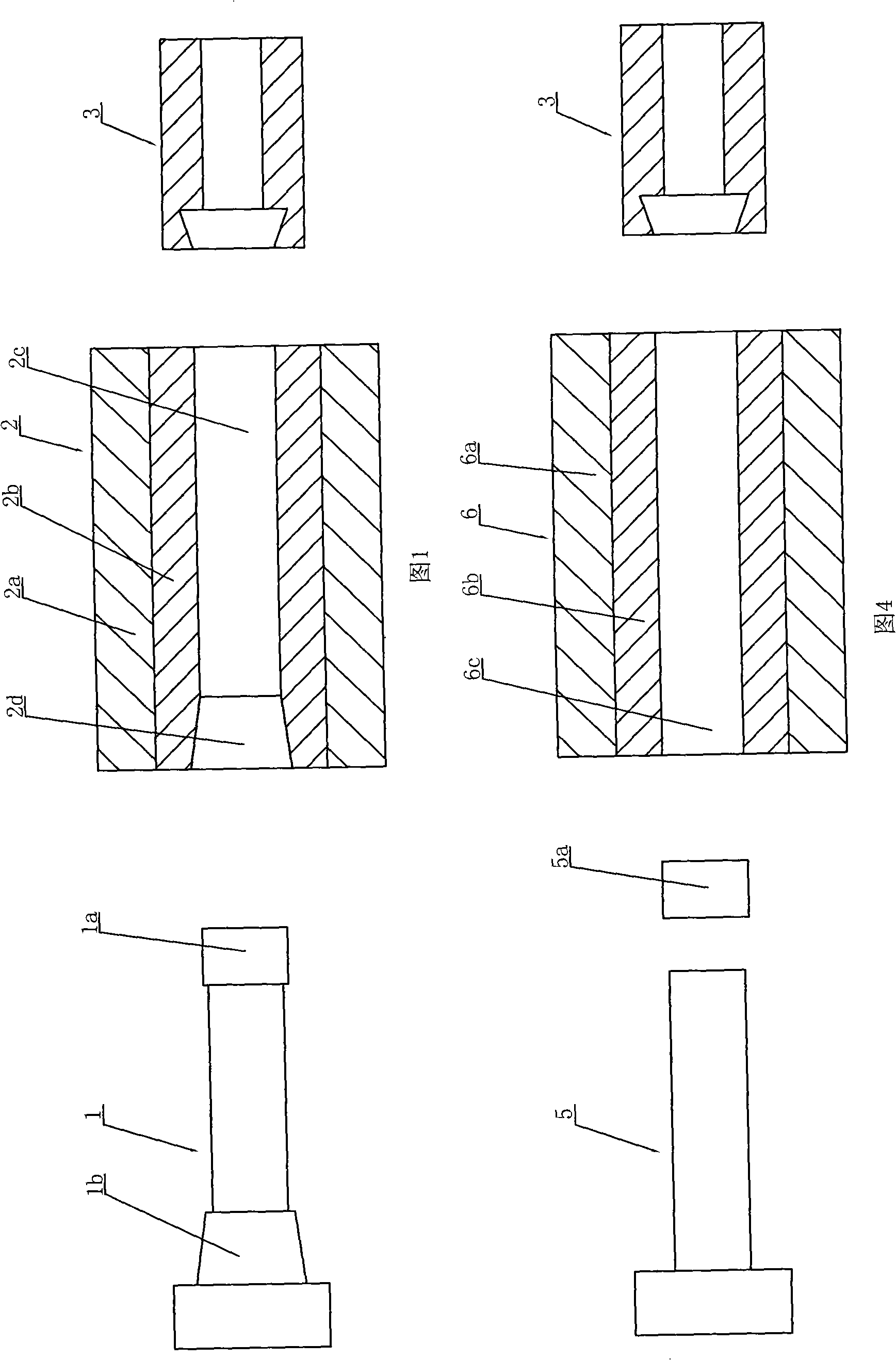

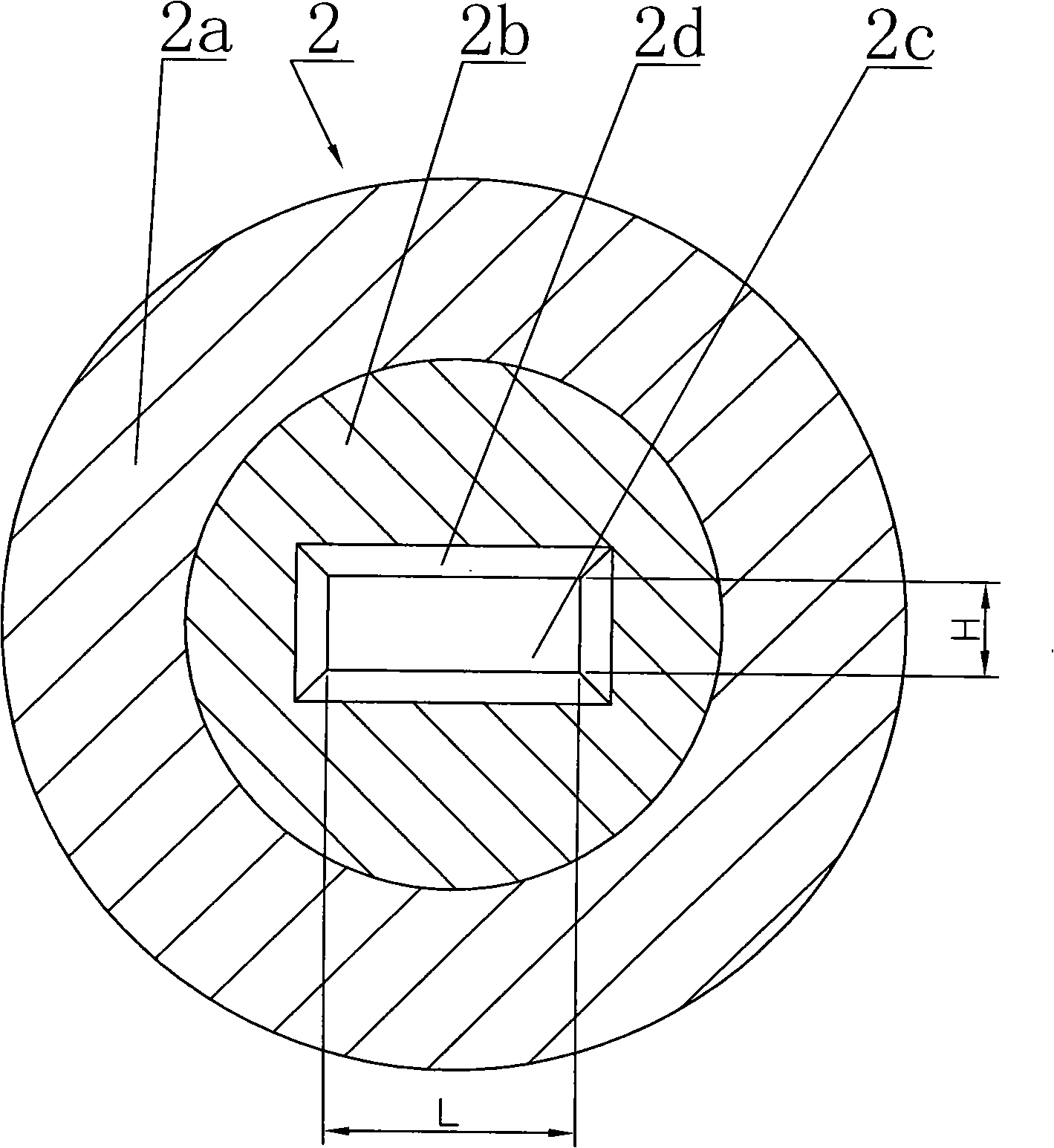

[0039] Centering of the extrusion device: screw the extrusion pad 1a to the extrusion rod 1, adjust the position of the flat extrusion cylinder and the extrusion rod, so that the center line of the extrusion rod 1, the center line of the flat extrusion cylinder and the strip The center line of the mold 3 is on the same straight line. During the extrusion process, the extrusion rod is located in the center of the inner cavity of the flat extrusion cylinder without damaging the inner cavity wall. At the same time, it can prevent the flat ingot from moving around when it moves forward. Ensure uniform deformation of the slab during extrusion.

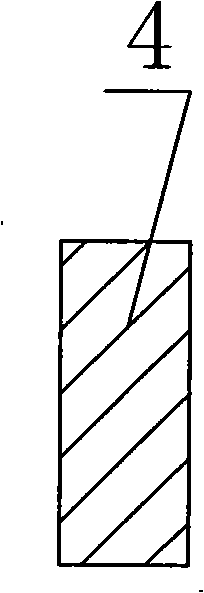

[0040] Processing of magnesium alloy flat ingot: AZ31 magnesium alloy material is used to prepare a magnesium alloy extrusion billet with a length of 100mm, a width of 93mm and a thickness of 55mm through a semi-continuous casting process. After cutting the head and tail of the magnesium alloy extrusion billet, machining obtains a magnesium...

Embodiment 2

[0046] Centering of the extrusion device: screw the extrusion pad 1a to the extrusion rod 1, adjust the position of the flat extrusion cylinder and the extrusion rod, so that the center line of the extrusion rod 1, the center line of the flat extrusion cylinder and the strip The center line of the mold 3 is on the same straight line. During the extrusion process, the extrusion rod is located in the center of the inner cavity of the flat extrusion cylinder without damaging the inner cavity wall. At the same time, it can prevent the flat ingot from moving around when it moves forward. Ensure uniform deformation of the slab during extrusion.

[0047] Processing of magnesium alloy flat ingot: AZ31 magnesium alloy material is used to prepare a magnesium alloy extrusion billet with a length of 100mm, a width of 165mm and a thickness of 90mm by a semi-continuous casting process, and the magnesium alloy extrusion billet is cut head, tail and milled Finally, a magnesium alloy flat ingo...

Embodiment 3

[0053] Centering of the extrusion device: screw the extrusion pad 1a to the extrusion rod 1, adjust the position of the flat extrusion cylinder and the extrusion rod, so that the center line of the extrusion rod 1, the center line of the flat extrusion cylinder and the strip The center line of the mold 3 is on the same straight line. During the extrusion process, the extrusion rod is located in the center of the inner cavity of the flat extrusion cylinder without damaging the inner cavity wall. At the same time, it can prevent the flat ingot from moving around when it moves forward. Ensure uniform deformation of the slab during extrusion.

[0054] Processing of magnesium alloy flat ingot: AZ31 magnesium alloy material is used to prepare a magnesium alloy extrusion billet with a length of 2000mm, a width of 265mm and a thickness of 30mm through a semi-continuous casting process. After cutting the head, tail, and skin milling of the magnesium alloy extrusion billet, a magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com