Plug flow distillation tray and method for preparing IP (isophorone) through liquid-phase condensation of acetone

A technology of plug flow and rectification tower, which is applied in the preparation of carbon-based compounds, preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of large tray pressure drop, catalyst waste, and large liquid holdup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

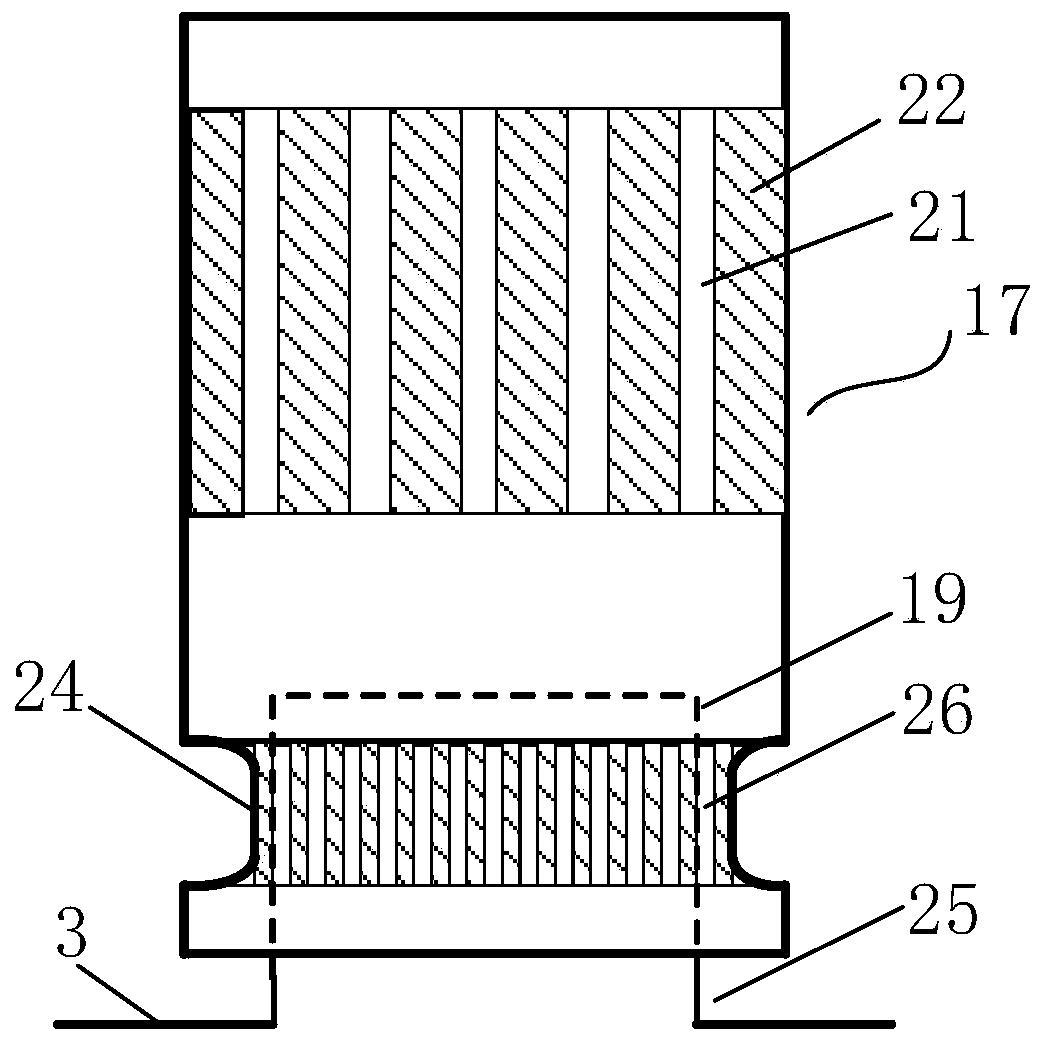

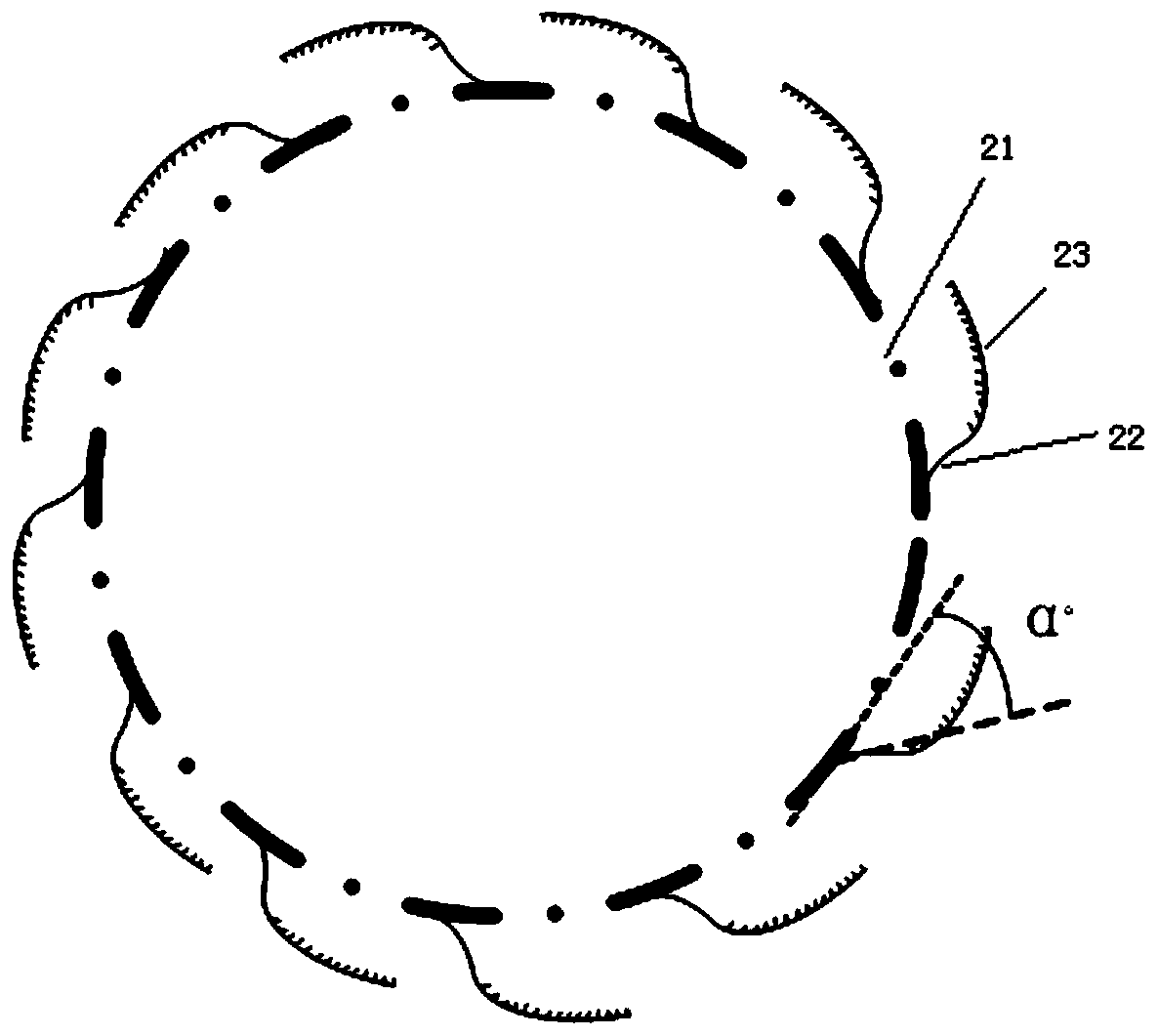

[0133] In this embodiment, the structural diagram of the plug-flow rectification tray can be found in Figure 8 , 6a , 6b.

[0134] The plug-flow rectification tray 1 includes a tray 3 and a plug-flow assembly 48 arranged on the tray 3. The plug-flow assembly 48 includes a graded overflow weir 9, a downcomer plate 16, a light-heavy phase flow splitting element 13, a receiving Liquid pan I6 and flow guiding element 20. The plug-flow rectification tray of the present embodiment is a single overflow, that is, in the rectification tower, a downcomer 5 and a liquid-receiving tray are respectively installed on the trays of each layer of plug-flow rectification trays installed at intervals up and down. Disk I6, that is, a group of plug flow assemblies 48 are installed. The downcomers 5 of the plug flow components 48 of the upper and lower plug flow rectification trays are arranged in a staggered manner, so the liquid receiving pans I6 and 7 in the upper and lower layers are also a...

Embodiment 2

[0138] This embodiment is basically the same as Embodiment 1, except that the spray hood used in the plug flow rectification tray is a strip-shaped spray hood with a rectangular cross section (or called a rectangular spray hood):

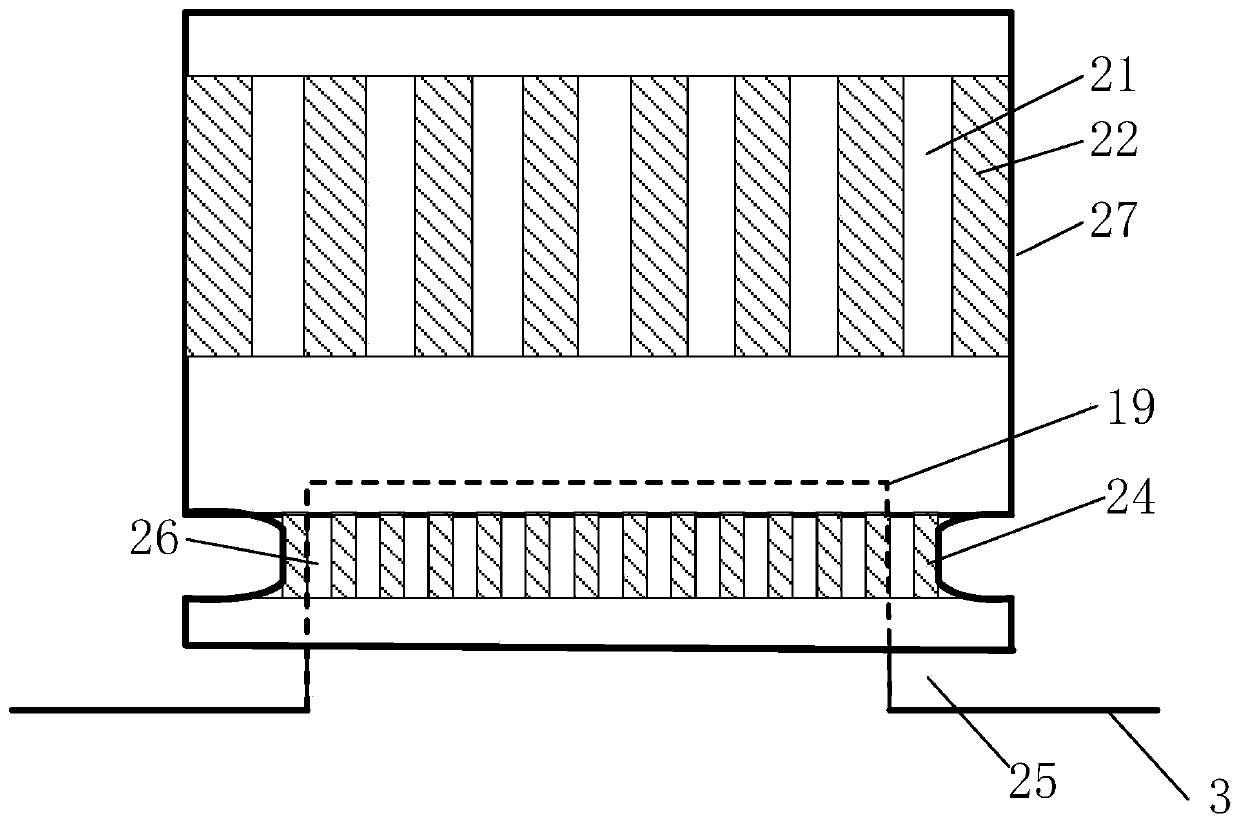

[0139] as attached image 3 and 4 As shown, the strip-shaped spray cover 27 is arranged on the tray 3, and the same structural parts of the strip-shaped spray cover 27 and the cylindrical spray cover 17 of Embodiment 1 will not be repeated here one by one, and can refer to Embodiment 1, below The main difference is explained as follows: the cross-section of the gas riser 19 is a rectangle, and the length and width are 240mm and 20mm respectively. 160mm. The spray cover 27 has a total height of 200mm, and the spray cover 27 is set on the air riser 19, and the overall cross-sectional shape of the spray cover 27 is also rectangular. The spray cover 27 is provided with a necking structure 24 sunken toward the inside of the spray cover at the upper li...

Embodiment 3

[0142] The schematic diagram of the process for preparing isophorone (or IP for short) by liquid phase condensation of acetone is attached Figure 5 As shown, the acetone and NaOH aqueous solution enter the first condensation reactor 30 after being preheated by the preheater 28 and fully mixed by the mixer 29 (this embodiment specifically adopts the SMV type static mixer of Sulzer, Switzerland) (the present embodiment The reactor 30 used is a tubular fixed-bed reactor), the reaction temperature is 210°C, the pressure is 3.5MPa(G), the acetone processing capacity is 600kg / h, the mass ratio of acetone and water is 5:1, and the catalyst is NaOH. The total flow rate of the liquid was taken as the benchmark, and the NaOH mass concentration was 0.1%.

[0143] The acetone conversion rate corresponding to the outlet of the first condensation reactor 30 is 10%, and the reaction liquid (ie, the liquid phase stream) then enters the pressurized reactive distillation tower 31, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com