Apparatus and method for continuous production of eco-friendly plasticizer

A plasticizer and environment-friendly technology, which is applied in the field of continuous production of environment-friendly plasticizers, can solve the problems of large fluctuations in product quality, long reaction time, backward technology, etc., and achieve continuous and large-scale mass production and speed up Material transfer speed and reaction speed, the effect of reasonable device layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

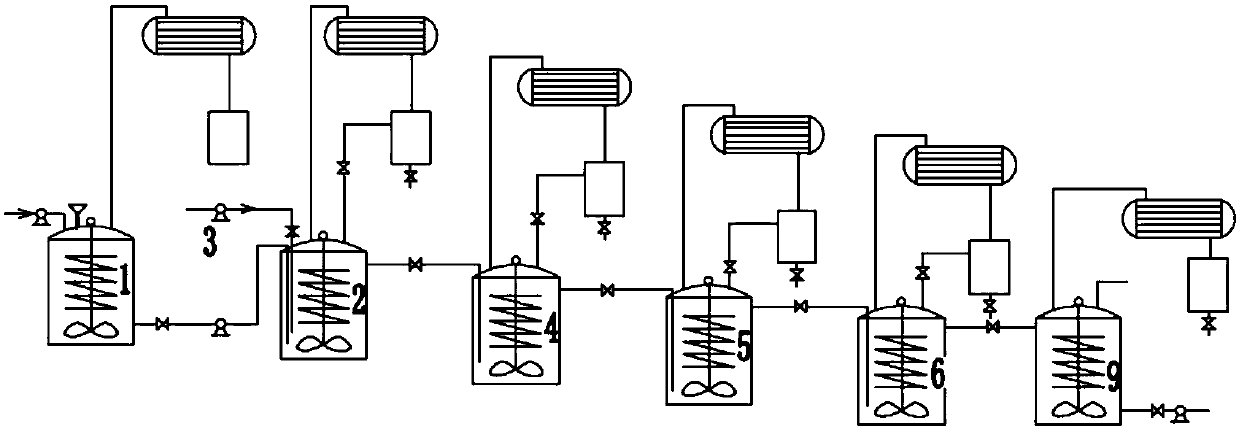

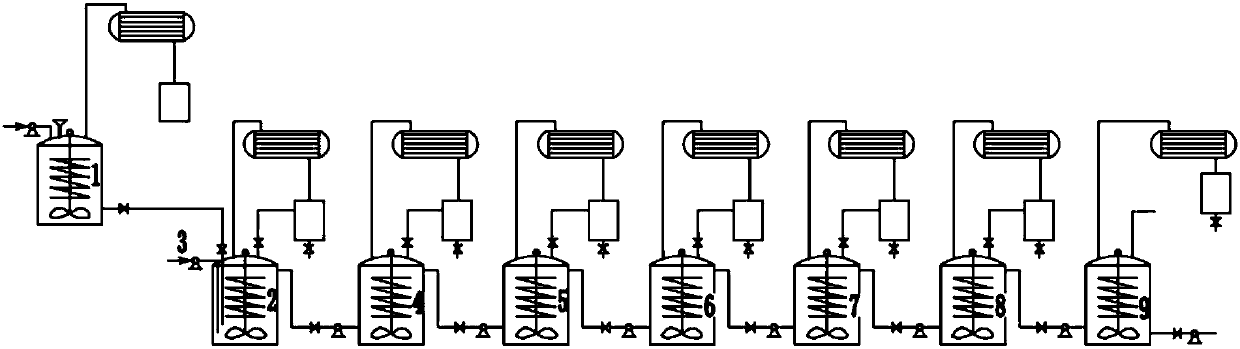

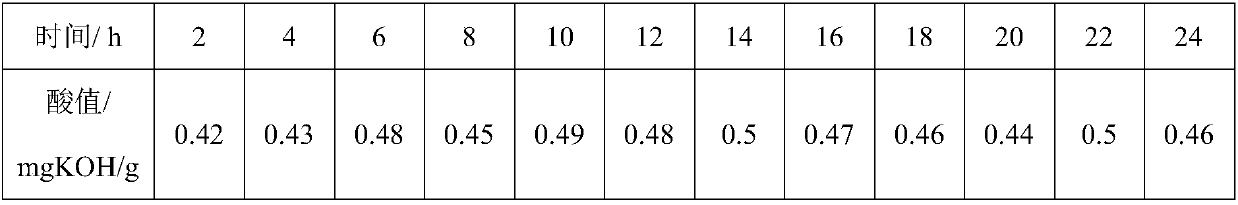

Embodiment 1

[0024] Add the PTA water pool material with a mass ratio of 1:2.8 and 98% isooctyl alcohol into the preheating dehydration kettle, turn on the mechanical stirring and heat transfer oil to raise the temperature, and keep the temperature in the kettle under mechanical stirring not lower than 160°C to realize material preheating. Heat and dehydration treatment; the above-mentioned preheated and dehydrated reaction materials are transported from the preheated dehydration kettle to the No. 1 esterification reaction kettle in the esterification system through a pump (or high head), and the catalyst metering pump on the top of the kettle is turned on. Turn on the mechanical stirring and heat up to react; with the continuous feeding of the reaction materials, when the reaction materials in the No. The reaction continues in the No. 1 esterification reactor. As the reaction progresses, similarly, when the reaction material in the No. 2 esterification reactor reaches the upper outlet of t...

Embodiment 2

[0028] Add the PTA floor material with a mass ratio of 1:2.6 and 98% isooctyl alcohol into the preheating dehydration kettle, turn on the mechanical stirring and heat transfer oil to raise the temperature, and keep the temperature in the kettle under mechanical stirring not lower than 160°C to realize material preheating. Heat and dehydration treatment; the above-mentioned preheated and dehydrated reaction materials are transported from the preheated dehydration kettle to the No. 1 esterification reaction kettle in the esterification system through a pump (or high head), and the catalyst metering pump on the top of the kettle is turned on. Turn on the mechanical stirring and heat up to react; with the continuous feeding of the reaction materials, when the reaction materials in the No. The reaction continues in the No. 1 esterification reactor. As the reaction progresses, similarly, when the reaction material in the No. 2 esterification reactor reaches the upper outlet of the re...

Embodiment 3

[0032] Add the PTA alkali solution with a mass ratio of 1:3.2 and 98% isooctyl alcohol into the preheated dehydration kettle, turn on the mechanical stirring and heat transfer oil to raise the temperature, and keep the temperature in the kettle under the mechanical stirring not lower than 160°C to realize the material Preheating and dehydration treatment; the above-mentioned preheated and dehydrated reaction materials are transported from the preheated dehydration kettle to the No. 1 esterification reaction kettle in the esterification system through a pump (or high head), and the catalyst metering pump on the top of the kettle is turned on , turn on the mechanical stirring and heat up to react; with the continuous feeding of the reaction materials, when the reaction materials in the No. The reaction continues in the No. 2 esterification reactor. As the reaction proceeds, similarly, when the reaction material in the No. 2 esterification reactor reaches the upper outlet of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com