Direct air-cooling unit system with plate-type evaporative condenser unit adopted

A plate type evaporation and condenser group technology, applied in steam/steam condensers, engine components, machines/engines, etc., can solve the problems of difficult maintenance and high operating costs, and achieve the effect of improving heat exchange efficiency, saving resources and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

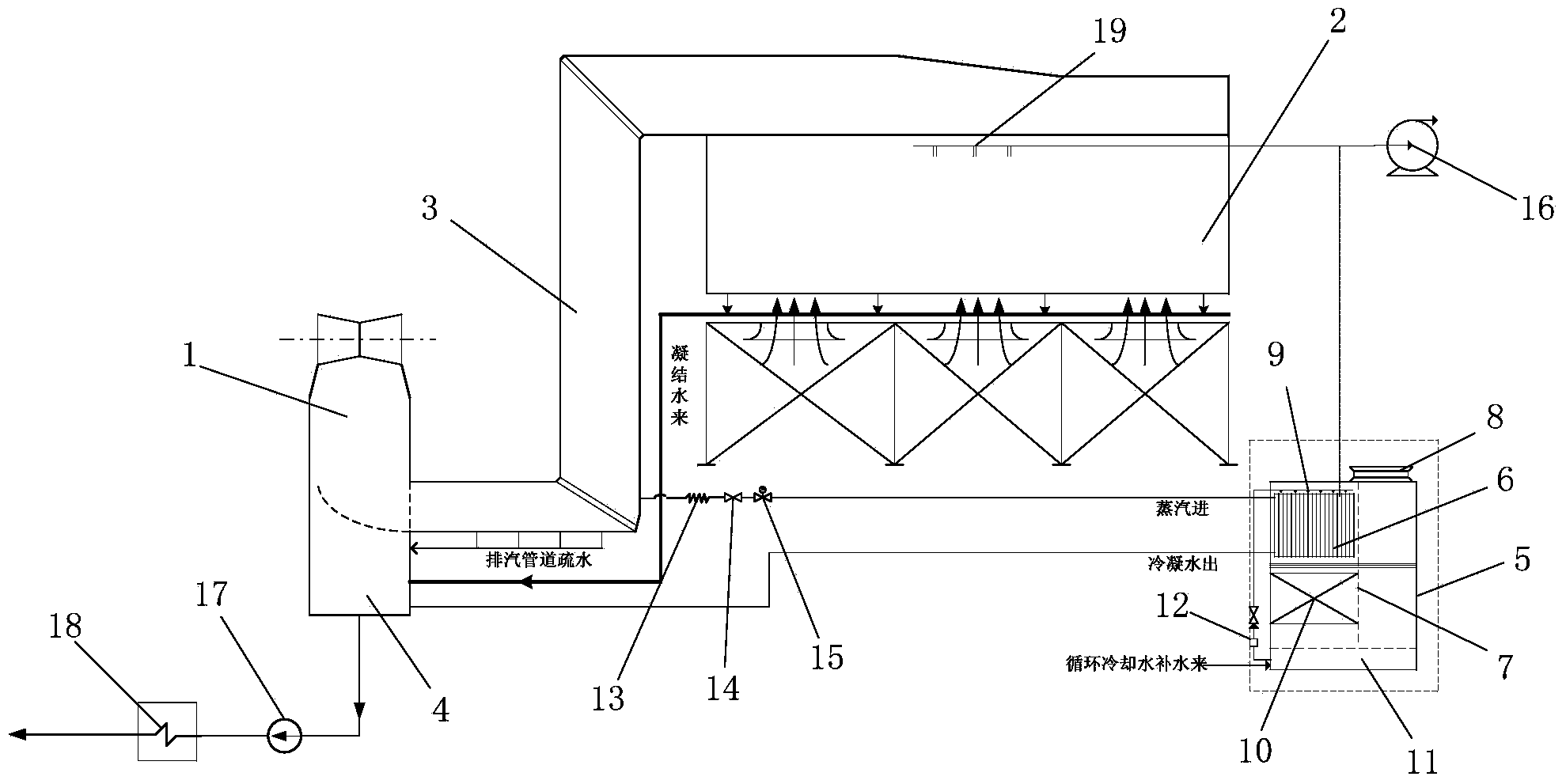

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0032] see figure 1 , the present invention comprises a low-pressure cylinder 1, an air condenser 2 and a plate type evaporative condenser group; the exhaust port of the low-pressure cylinder 1 communicates with the exhaust steam outlet of the steam turbine, and the low-pressure cylinder 1 transports the exhaust steam to the air through the exhaust pipeline 3 The exhaust steam inlet of the condenser 2; the exhaust steam pipe 3 is also connected with the exhaust steam inlet of the plate evaporative condenser through the pipe, and is used to send a part of the exhaust steam discharged from the steam turbine into the plate evaporative condenser group for cooling, and the plate evaporative condensation An expansion joint 13, a manual regulating valve 14, and an electric regulating valve 15 are also provided on the pipe connecting the exhaust steam inlet of the unit and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com