Power station air cooling system adopting combined refrigeration with shaft seal steam leakage of steam turbine and continuous blow-down waste heat of boiler as well as method for predicting heat-transfer coefficient of air-cooling condenser

An air-cooled condenser and shaft seal steam leakage technology, which is applied in steam/steam condensers, refrigerators, refrigeration components, etc. The problem of high temperature difference can reduce the amount of ash, maintain cleanliness, reduce condensation temperature and exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below using the drawings and specific embodiments.

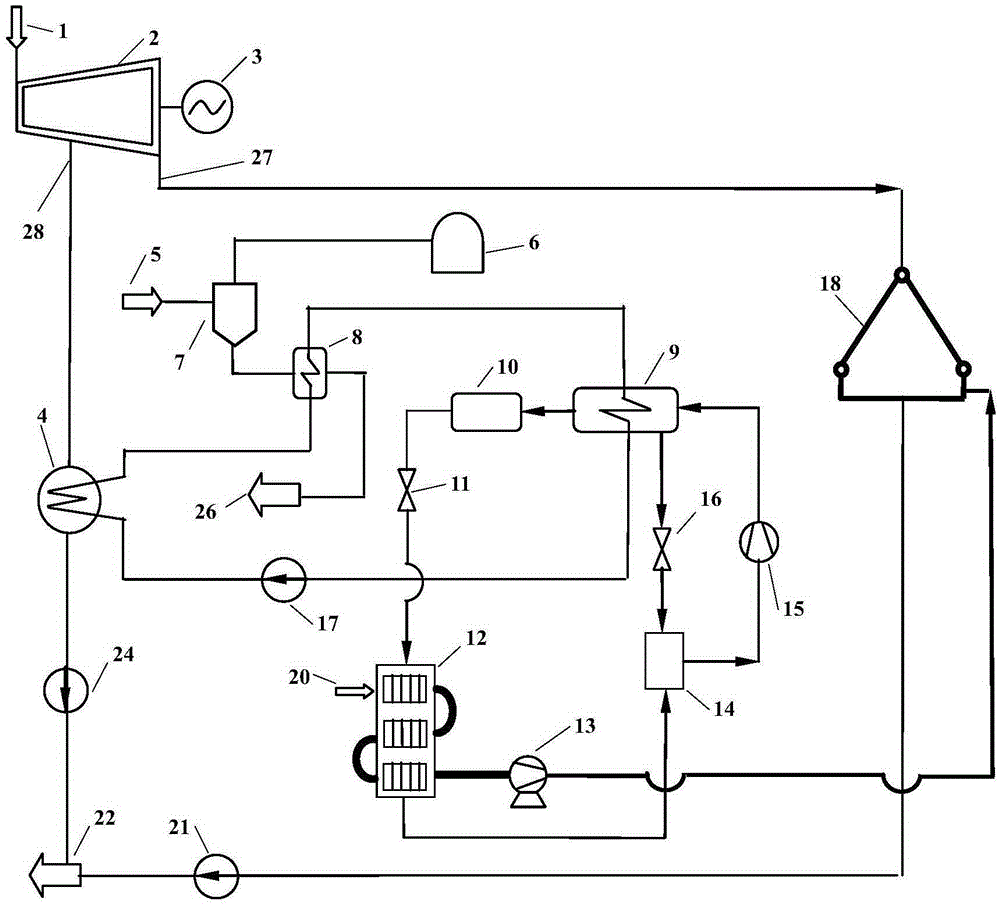

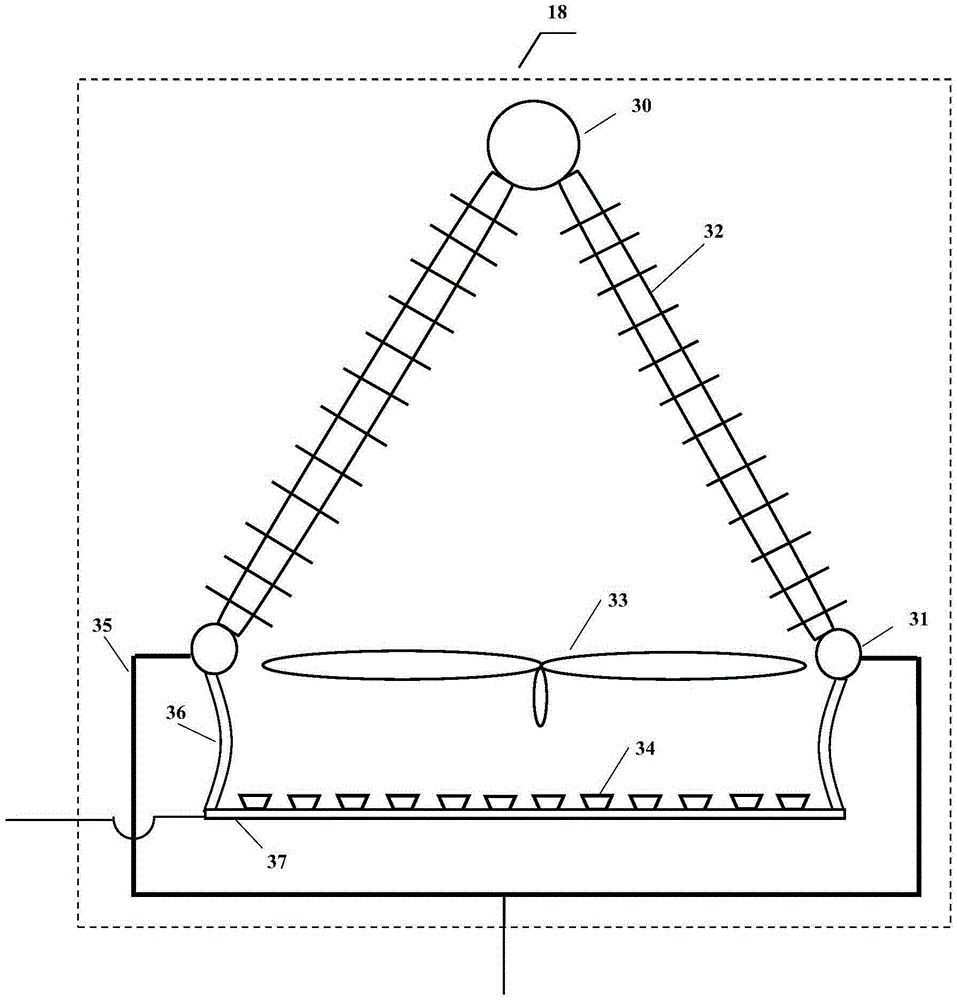

[0032] refer to figure 1 , an embodiment of an air-cooling system for a steam turbine shaft seal combined with steam leakage and boiler continuous sewage waste heat combined refrigeration power station, which is characterized in that: it includes the steam inlet of the steam turbine 2 connected to the steam source 1, the steam turbine 2 is connected to the generator 3, and the steam turbine 2 The exhaust port 27 of the air-cooled condenser 18 communicates with the first input end of the air-cooled condenser 18, and the output end of the air-cooled condenser 18 communicates with the first input end of the boiler makeup water 22 through the condensate pump 21; The input end of the high temperature side of the condenser 4 is connected, and the output end of the high temperature side of the steam leakage condenser 4 is connected with the second input end of the boiler replen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com