Enhanced dephosphorization reactor

A reactor and reaction zone technology, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. High composition requirements, to achieve good solid-liquid separation effect, compact structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

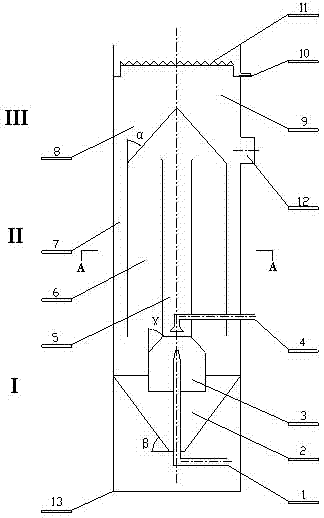

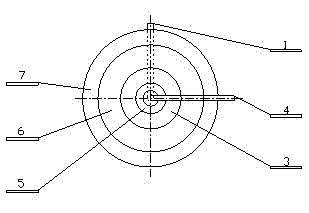

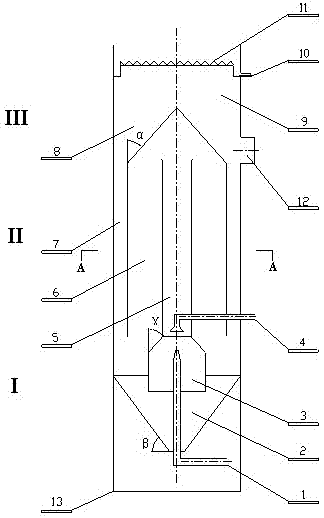

[0012] Such as figure 1 , 2 As shown, the main body of an enhanced phosphorus removal reactor is provided with a water distribution area I, a reaction area II and a precipitation area III in sequence from bottom to top. The upper part is provided with a mixing chamber 3, and the center of the return sludge bucket 2 is provided with a jet water inlet 1, one end of the jet water inlet 1 extends into the upper part of the mixing chamber 3, and the other end of the jet water inlet 1 extends out of the return sludge hopper 2, the reaction zone II is provided with the first reaction zone 5, the second reaction zone 6 and the third reaction zone 7 sequentially from the inside to the outside, and runs through, the bottom of the first reaction zone 5 is provided with a drug feeding tube 4, a mixing chamber 3. It is connected to the lower part of the first reaction zone 5. The sedimentation zone III is provided with a sludge discharge port 12, a sedimentation sludge bucket 8, a sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com