Flame-retardant AES (acrylonitrile ethylene styrene) material, preparation method for same and application thereof

A technology of antimony-based flame retardant and bromine-based flame retardant, which is applied in the field of modified plastics, can solve problems such as potential safety hazards, and achieve the effects of balanced mechanical properties, balanced fluidity, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

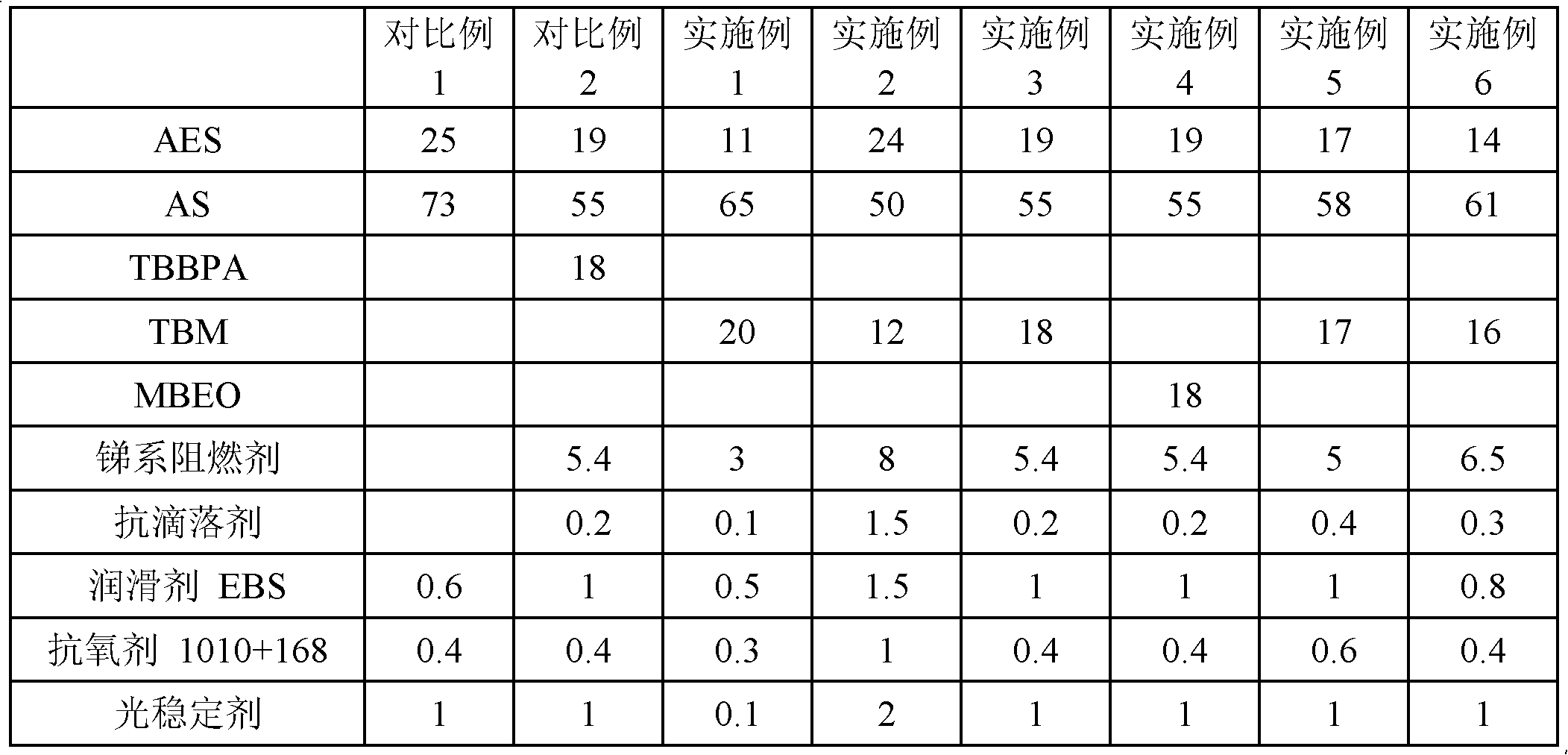

Embodiment 1-6 and comparative example 1-2

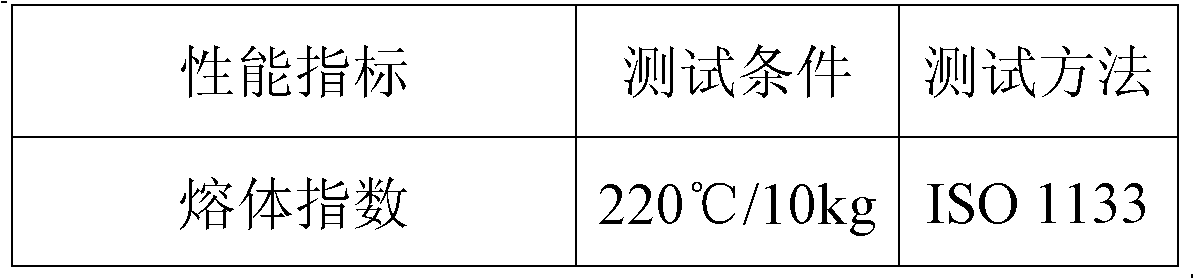

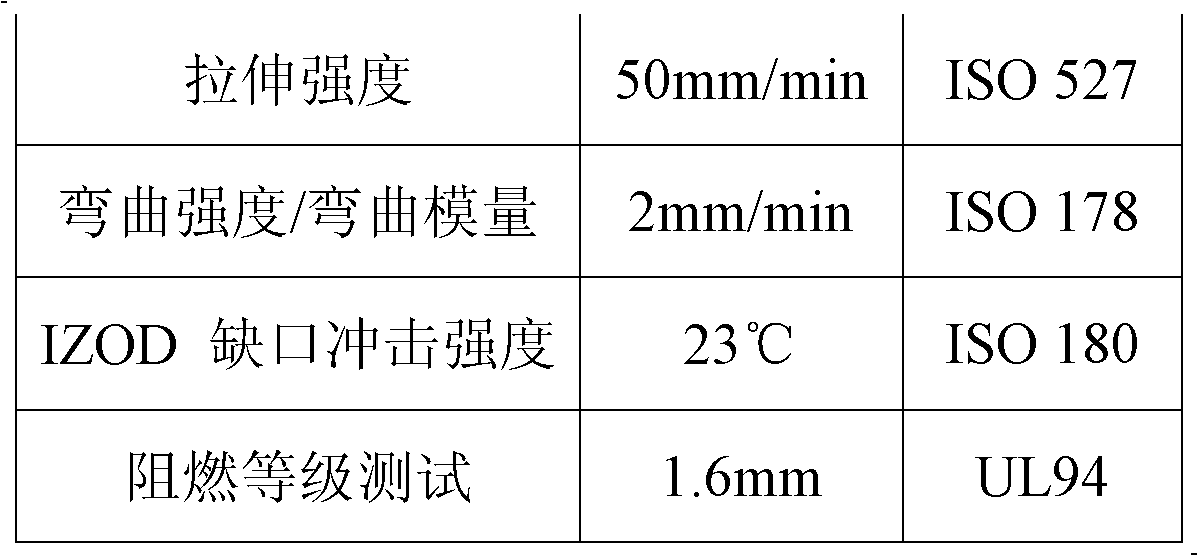

[0055] A preparation method of flame retardant AES material, comprising the steps of:

[0056] (1) Weigh each component according to the proportioning in Table 2.

[0057] (2) Pre-mix AES and AS in a high-speed mixer for 2-5 minutes, and then add brominated flame retardants, antimony-based flame retardants, anti-dripping agents, lubricants, antioxidants and light stabilizers, Mix for another 2-5 minutes to obtain the mixed raw materials;

[0058] (3) Place the mixed raw materials in a twin-screw extruder, and obtain a flame-retardant AES material through melt extrusion, drawing, water cooling, and pelletizing; wherein, the aspect ratio of the twin-screw extruder is 40: 1; The temperature of the screw barrel is set as: the temperature of the first zone is 80°C, the temperature of the second zone is 200°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 210°C, the temperature of the sixth zone is 210°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com