Chemical and mechanical grinding method

A grinding method and chemical mechanical technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, electrical components, etc., can solve the problems of needing to replace the grinding fluid, lack of versatility, and inconvenient implementation, and achieve low cost , Eliminate surface scratches and increase the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

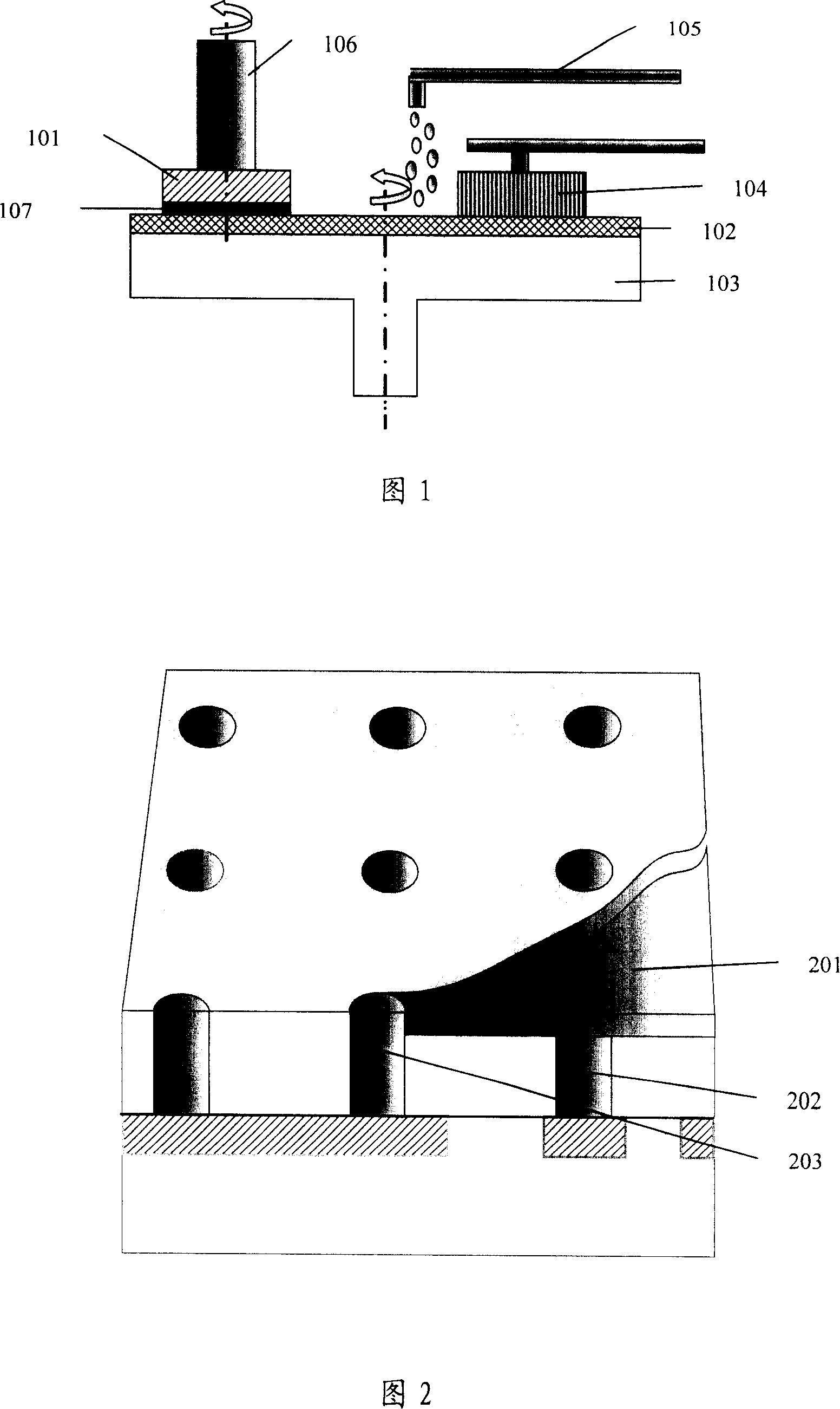

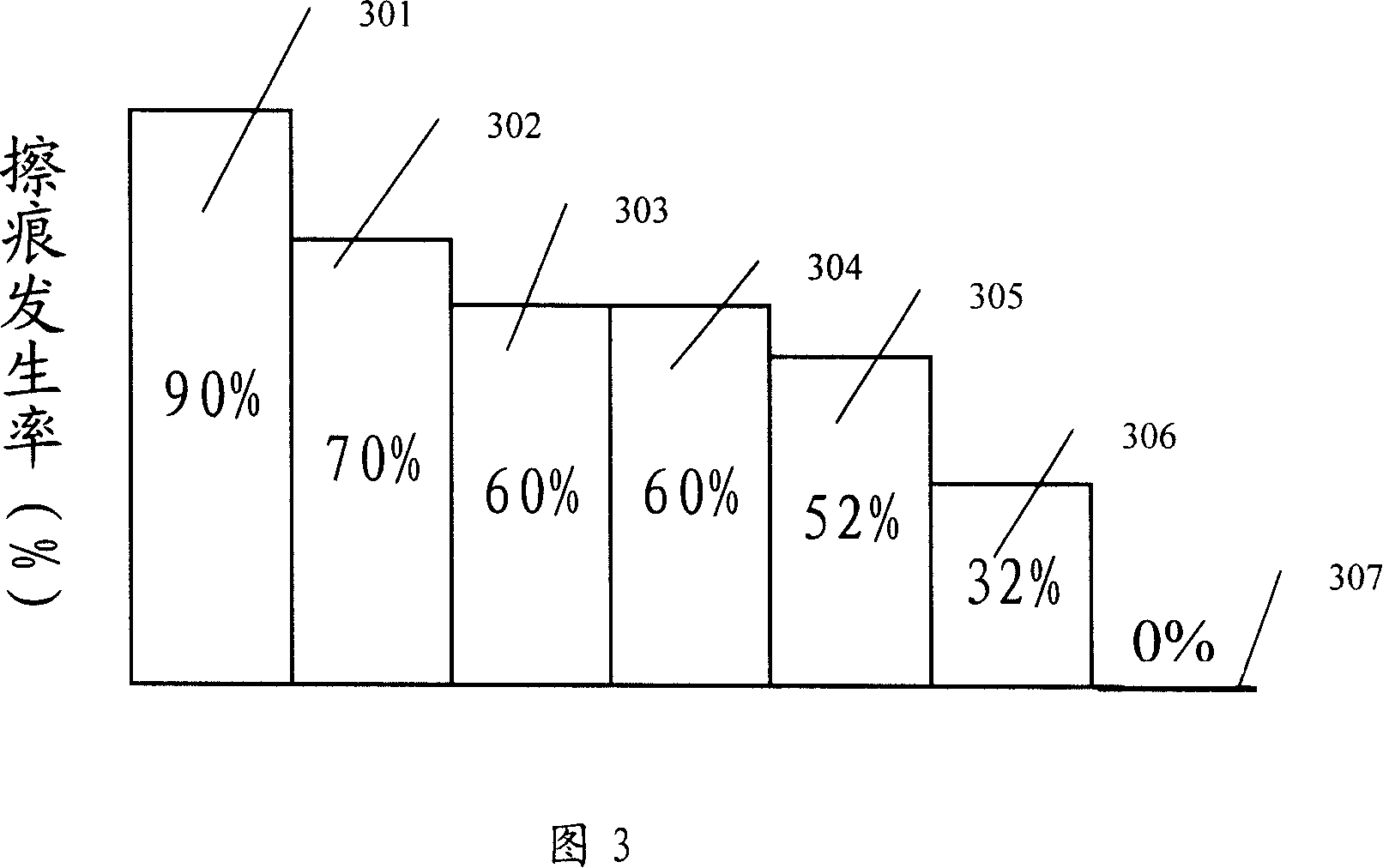

[0054] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

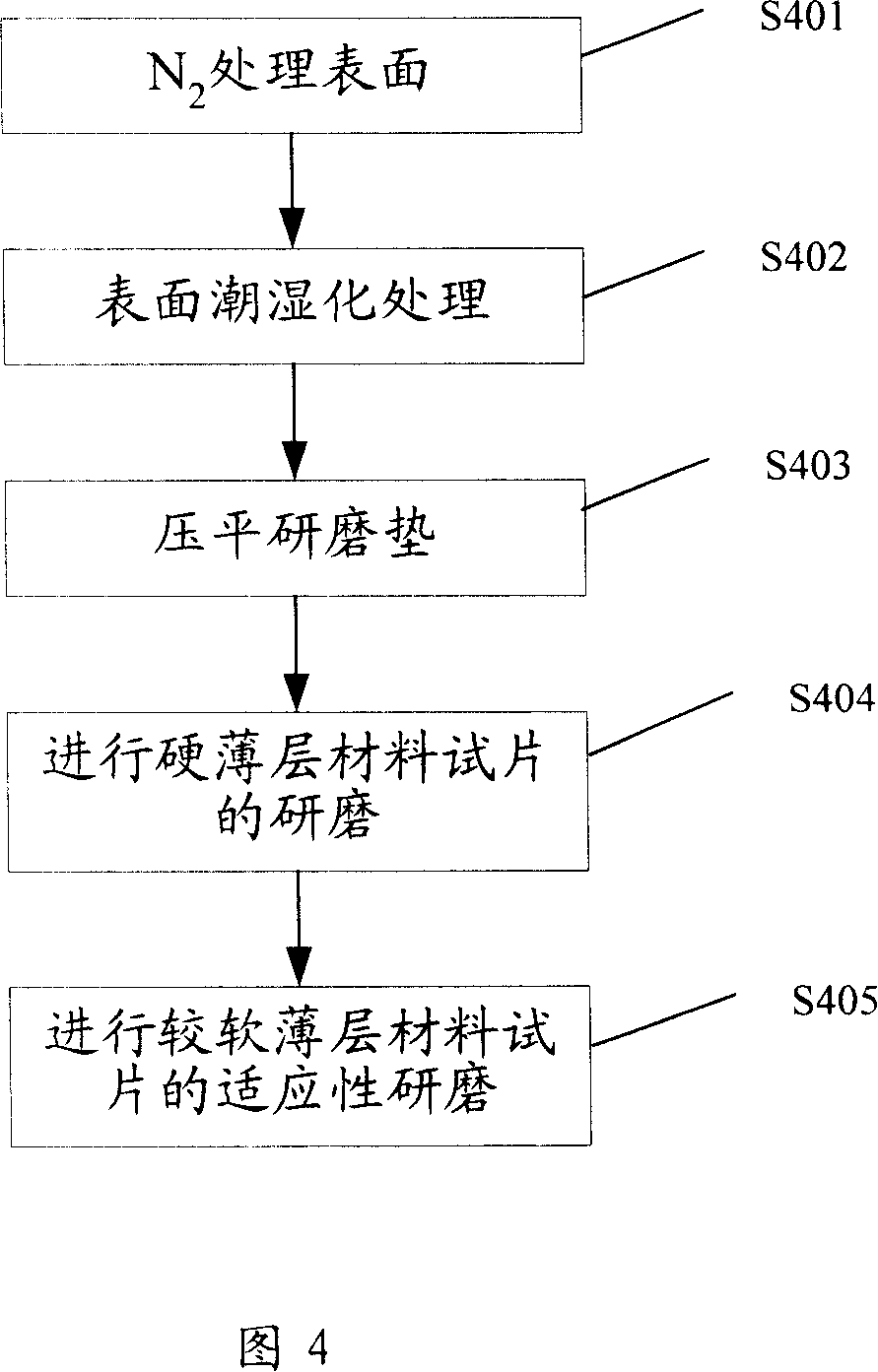

[0055] Chemical mechanical polishing (CMP) technology has been widely used in the field of integrated circuit manufacturing because of its excellent global planarization performance. However, it is found that it tends to form some tiny scratches on the surface of the wafer during the manufacturing process, which may cause an electrical short circuit of the wafer. The chemical mechanical polishing method of the present invention, based on the characteristics of the CMP process, combined with a large number of experimental data, can significantly reduce or even eliminate surface scratches through the improvement of the CMP process conditions, and improve the process quality without increasing the difficulty of the process.

[0056] Gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com