Fluorine free protecting slag for steelmaking and continuous casting and method for manufacturing same

A technology of steelmaking continuous casting and manufacturing method, which is applied in the field of fluorine-free steelmaking and continuous casting mold slag and manufacturing, and can solve the problems of complex structure of processing equipment, troublesome processing, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

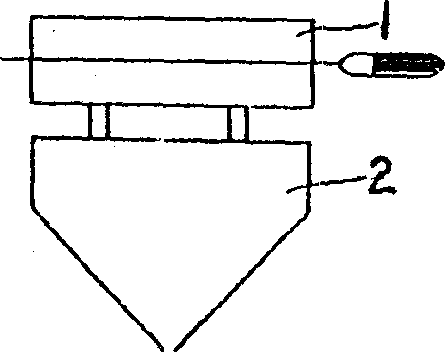

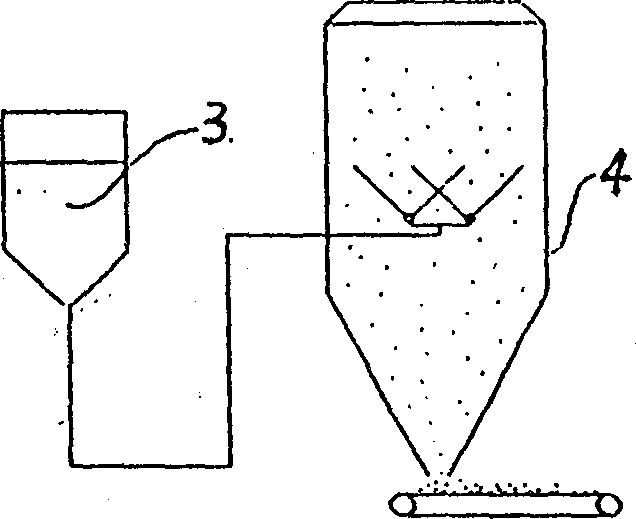

Image

Examples

Embodiment Construction

[0061] Manufacture of fluorine-free mold fluxes for steelmaking and continuous casting. Examples are listed in the following table:

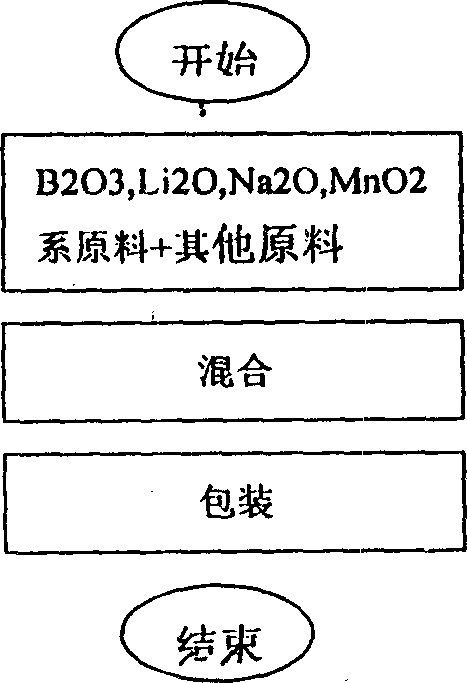

[0062] In the following examples, example 2 is composed of 50% of the fully melted boron liquid slag layer that can replace the role of fluorine, and 7.5% of soda ash is mixed with other raw materials; example 3 is composed of 45% of synthetic silicon calcium that can replace the role of fluorine , Fully melted boron liquid slag layer composition 15%, soda ash 11%, spodumene 2%, lithium carbonate 5%, mixed with other raw materials, passed figure 2 Process manufacturing of granular products for the equipment shown. The remaining example 1, example 4 to example 14 are the same as the above example 2 and example 3, which contain B according to the chemical composition. 2 O 3 Liquid slag layer, containing Li 2 Liquid slag layer of O, containing Na 2 O liquid slag layer and containing MnO 2 The liquid slag layer raw materials, used alone or mixed with o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com