Unleaded back silver paste used for crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of silver electrode solderability, poor solder resistance, high environmental and human hazards, virtual soldering and over-soldering, etc., and achieve outstanding printing performance and uniform printing graphics , Improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

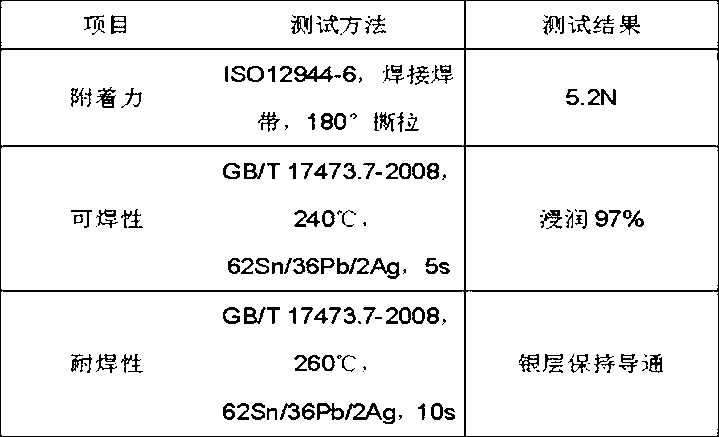

Embodiment 1

[0022] The preparation method of lead-free back silver paste for crystalline silicon solar cells comprises the following steps in sequence: (1) preparing raw materials according to the following components and weight content, 60 parts of silver powder, 29 parts of organic binder and 1 part of inorganic binder; The silver powder has a purity of 99.9% and a flake silver powder with an average particle size of 0.5 μm; the raw material components and weight content of the organic binder are as follows: 40 parts of terpineol, 5 parts of butyl carbitol, butyl carbitol, 5 parts of carbitol acetate, 3 parts of ethyl cellulose, 5 parts of diethyl phthalate and 2 parts of sorbitan stearate; the inorganic binder is lead-free glass powder, and the The raw material composition and weight content of lead glass powder are as follows, Bi 2 o 3 : 30 copies, B 2 o 3 : 5 parts, NaF: 1 part, SiO 2 : 10 parts, ZnO: 5 parts, TiO 2 : 1 part, Al 2 o 3 : 10 copies, P 2 o 5 : 2 servings.

[0...

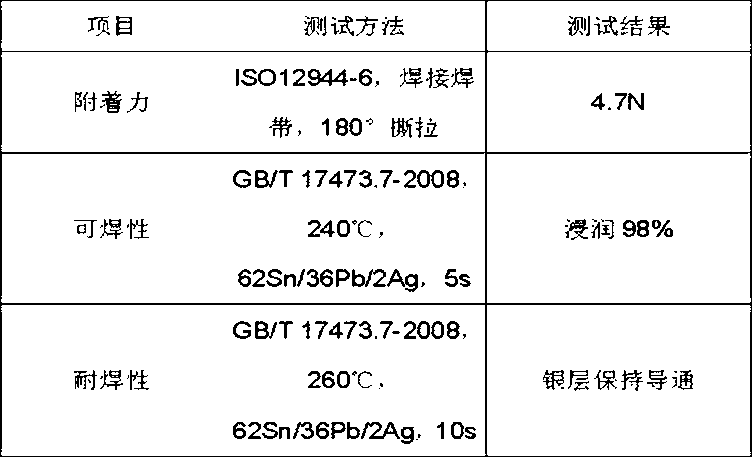

Embodiment 2

[0029] The preparation method of lead-free back silver paste for crystalline silicon solar cells comprises the following steps in sequence: (1) preparing raw materials according to the following components and weight content, 60 parts of silver powder, 35 parts of organic binder and 5 parts of inorganic binder; The silver powder has a purity of 99.95% and a flake silver powder with an average particle size of 2.0 μm; the raw material components and weight content of the organic binder are as follows: 55 parts of terpineol, 8 parts of butyl carbitol, butyl carbitol, 7 parts of carbitol acetate, 7 parts of ethyl cellulose, 10 parts of diethyl phthalate and 2 parts of sorbitan stearate; the inorganic binder is lead-free glass powder, and the The raw material composition and weight content of lead glass powder are as follows, Bi 2 o 3 : 45 copies, B 2 o 3 : 10 parts, NaF: 1.5 parts, SiO 2 : 15 parts, ZnO: 8 parts, TiO 2 : 3 parts, Al 2 o 3 : 15 copies, P 2 o 5 : 2 serving...

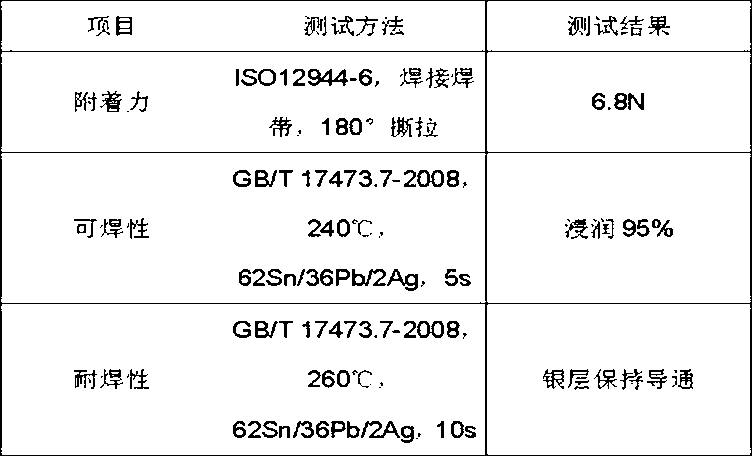

Embodiment 3

[0036] The preparation method of lead-free back silver paste for crystalline silicon solar cells comprises the following steps in sequence: (1) preparing raw materials according to the following components and weight content, 60 parts of silver powder, 42 parts of organic binder and 10 parts of inorganic binder; The silver powder has a purity of 99.99% and a flake silver powder with an average particle size of 4.0 μm; the raw material components and weight content of the organic binder are as follows: 70 parts of terpineol, 10 parts of butyl carbitol, butyl carbitol, 10 parts of carbitol acetate, 10 parts of ethyl cellulose, 15 parts of diethyl phthalate and 2 parts of sorbitan stearate; the inorganic binder is lead-free glass powder, and the The raw material composition and weight content of lead glass powder are as follows, Bi 2 o 3 : 60 copies, B 2 o 3 : 15 parts, NaF: 2 parts, SiO 2 : 20 parts, ZnO: 10 parts, TiO 2 : 5 parts, Al 2 o 3 : 20 copies, P 2 o 5 : 2 serv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com